Page 1

Operating Instructions and Parts Manual PC4, PC4K

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Self-Priming Portable

Utility Pump

Description

This self-priming portable utility pump is

designed to be used as a transfer pump

for such applications as emptying water

heaters, livestock tanks, etc. Pump can

also be used for an intermittent pressure

boost for applications such as washing cars,

cleaning driveways, etc. The motor is air

cooled; it is not designed to operate under

water.

NOTE: This pump is not intended for

permanent installation or long, extended

periods of continuous operation.

Unpacking

After unpacking the utility pump,

carefully inspect for any damage that

may have occurred during transit. Check

for loose, missing or damaged parts. If

you need assistance, call our Customer

Service Department at 1-800-237-0987.

Safety Guidelines

This manual contains information

that is very important to know

and understand. This information

is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS. To

help recognize this information, observe

the following symbols.

Danger indicates an

imminently

hazardous situation which, if NOT

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if NOT

avoided, COULD result in death or serious

injury.

Caution indicates a

potentially

hazardous situation which, if NOT

avoided, MAY result in minor or moderate

injury.

Notice indicates

important

information, that if NOT followed, MAY

cause damage to equipment.

NOTE: Information that requires special

attention.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product

contains chemicals,

including lead, known to the State of

California to cause birth defects and

other reproductive harm. Wash hands

after handling.

GENERAL SAFETY

Do NOT submerge

motor or allow

motor to be exposed to water. Personal

injury and/or death WILL result.

Do NOT use to pump

flammable or explosive

fluids such as gasoline,

fuel oil, kerosene, etc. Do NOT use

in a flammable and/or explosive

atmosphere. Pump SHOULD only be

used to pump clear water. Personal

injury and/or death WILL result.

Risk of electrical

shock. ALL wiring

must be performed by a qualified

electrician.

Do NOT walk on wet areas

until ALL power is turned off.

Failure to follow this warning

WILL result in fatal electrical shock.

1. Read all instructions before

operation.

2. Disconnect power and release all

pressure within the system before

servicing any component.

Specifications

Motor. . . . . . . . . . . . . . . Single Phase - 115V, 60 Hz, 8,000 RPM

Motor. . . . . . . . . .Series Wound (brush type) AC/DC Operation

Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Thermoplastic

Motor Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cast iron

Shaft and Volute Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . .Buna-N

Maximum Fluid Temperature. . . . . . . . . . . . . . . . . . . . . . . 120°F

REMINDER: Keep your dated proof of purchase for warranty purposes!

Horsepower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 HP

Inlet/Outlet Openings. . . . . . . . . . . . . . . . . . . . . . . . . . 3/4” NPT

Pump Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cast iron

Motor Shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . .Cold rolled steel

Motor Bearings . . . . . . . . . . . . . . . . . . .Permanently lubricated

Rolling element bearings

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

321305-001 12/11© 2011, WAYNE/Scott Fetzer Company.

Page 2

Operating Instructions and Parts Manual

General Safety

Information (Continued)

3. Drain all liquids from system before

servicing.

Secure the

discharge line

before starting the pump. An unsecured

discharge line MAY whip. Personal

injury and/or property damage COULD

result.

4. Periodically inspect pump and

system components, checking for

weak and/or worn hoses. Insure all

connections are secure.

Pump motor is

equipped with an

automatic resetting thermal protector

and MAY restart unexpectedly.

Protector tripping is an indication

of motor overheating because of

operating pump at low heads (low

discharge restriction), excessively high

or low voltage, inadequate wiring,

excessive surrounding air temperature,

inadequate ventilation, and/or defective

motor or pump.

5. Provide a means of pressure relief in

the case of an obstructed discharge

line.

6. Protect electrical cord from sharp

objects, hot surfaces, oil and

chemicals. Avoid kinking the

cord and replace damaged cords

immediately.

Installation

ALWAYS disconnect power

source before attempting to

operate, service, or maintain

the pump. NEVER handle a pump with

wet hands or when standing on wet

or damp surface or in water. Fatal

electrical shock WILL occur.

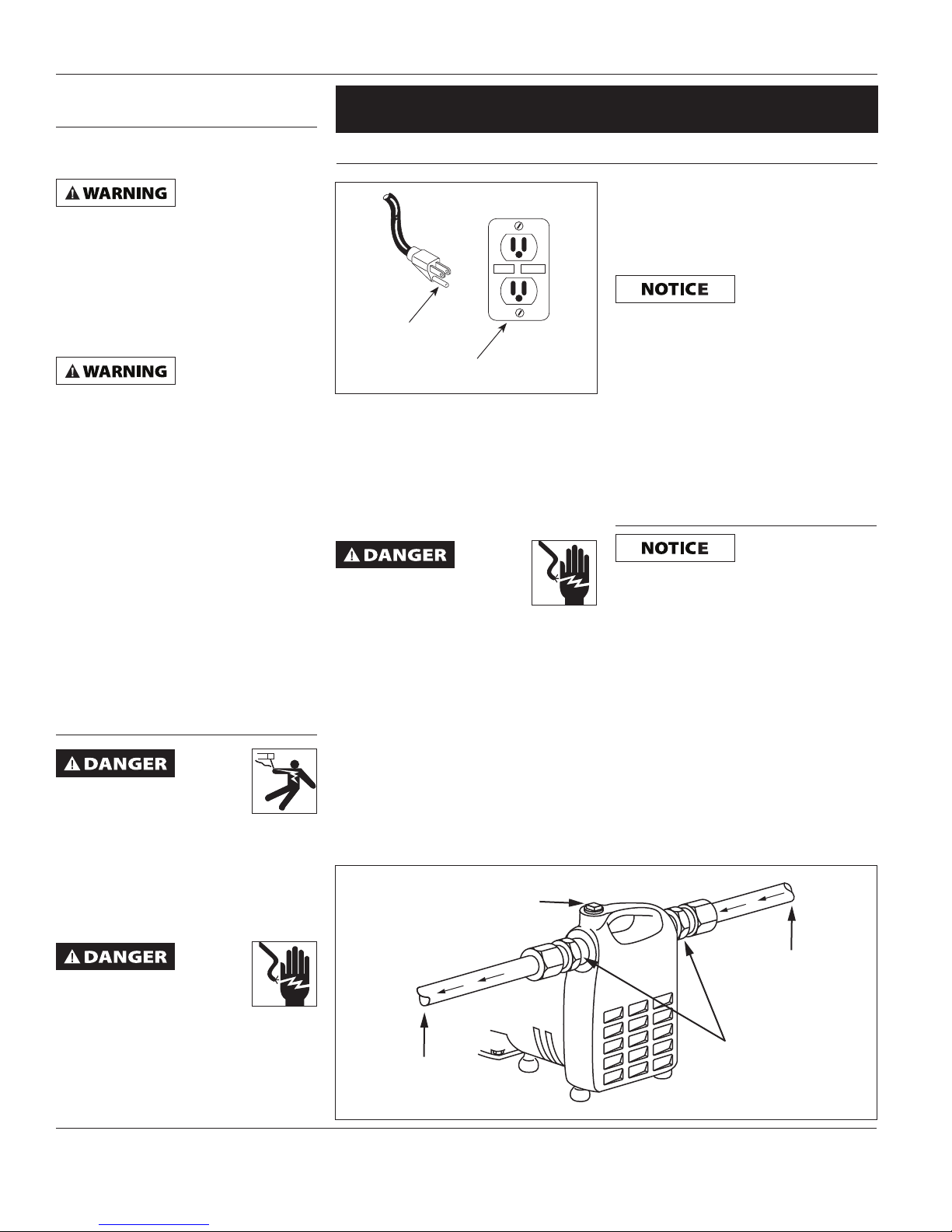

1. A ground fault circuit interrupter

(GFCI) is required.

Extension Cord Length Table

Wire Size #18 #16 #14 #12

Length 25 ft 50 ft 100 ft 150 ft

5. The inlet line may be galvanized

pipe, plastic pipe, or reinforced hose.

Small leaks in suction line greatly

reduce efficiency of pump and may

RESET

TEST

GROUNDING

BLADE

Figure 1

GFCI

RECEPTACLE

2. This pump operates on 115V, 60 Hz

AC, single phase or 115V DC.

3. Use an extension cord only if

necessary. Follow the Extension Cord

Length Table for proper gage of

3-wire, grounding type extension

cord.

Risk of fatal electrical shock.

NEVER cut off the round

grounding prong. Cutting the

cord or plug WILL void the warranty and

make the pump inoperable.

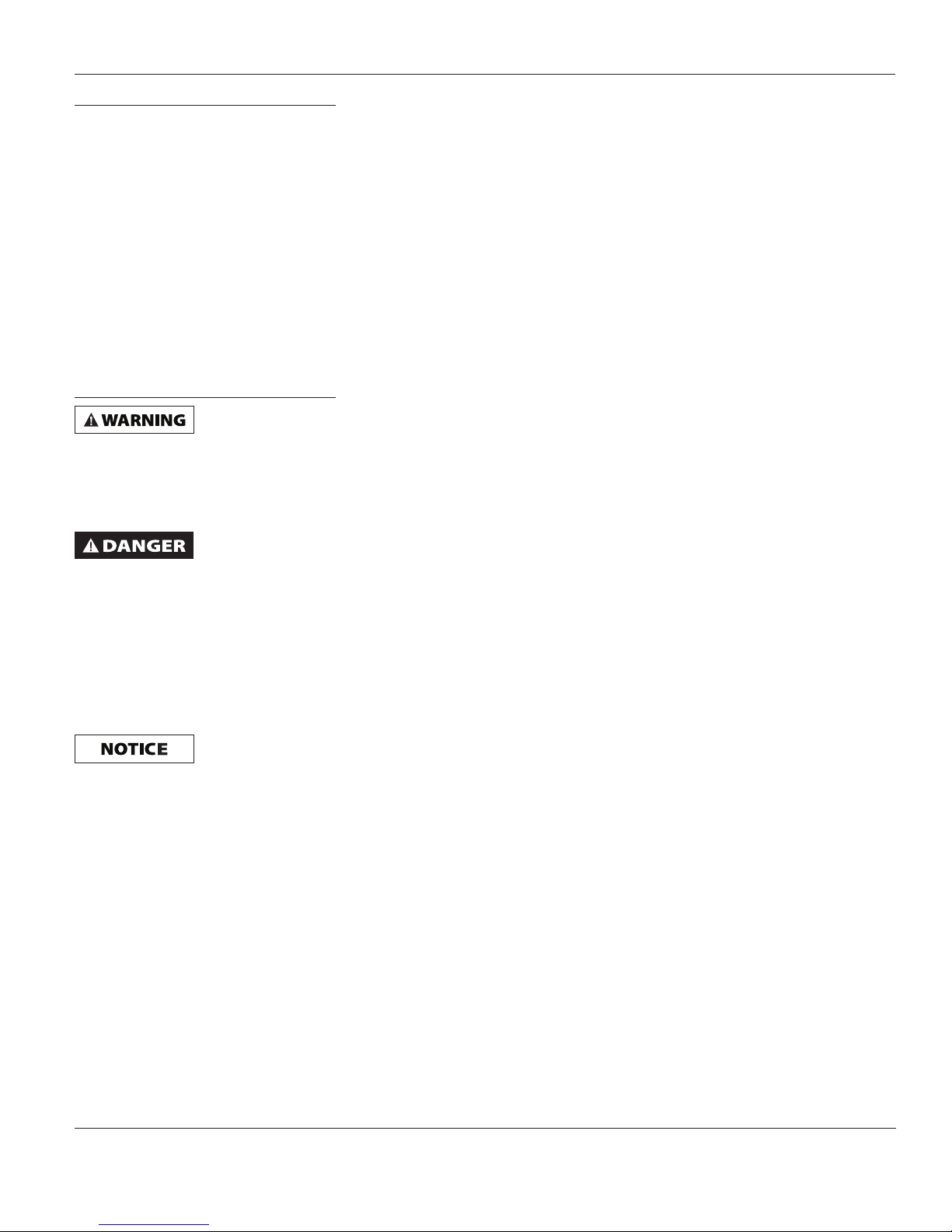

4. Figure 2 shows a typical installation.

Threaded adapters are furnished

for attaching garden hose where

conditions permit its use. In no case

should the pump be more than

15 feet above or away from water

source. Install a foot valve when

suction lift is over 10 feet or when

suction line is over 10 feet long.

prevent priming.

Ordinary garden

hose WILL collapse

under suction pressure and SHOULD

NOT be used for the inlet line, except in

pressure boosting applications.

6. Use a strainer when pumping from a

creek, pond, or source where foreign

objects may be sucked into the

pump. The strainer should prevent

solids from entering the inlet line.

7. A regular garden hose may be used

as a discharge line.

Operation

Pump must be filled

with water before

operation. Running the pump dry WILL

cause damage to the shaft seal.

1. This unit is not waterproof or

weatherproof and is not intended

to be used in showers, saunas, or

other potentially wet locations.

The motor is designed to be used

in a clean, dry location with access

to adequate cooling air. Ambient

temperatures around the motor

should not exceed 104˚F (40˚C).

2. Remove priming plug and fill with

water. Replace plug (plumbers seal

tape should be used on priming plug

to prevent air leaks).

PRIME PLUG

Risk of electrical shock!

This pump is supplied with

a grounding conductor and

grounding type attachment plug. A

grounded receptacle in conformance

with current NEC and local codes must

be used (See Figure 1).

www.waynepumps.com

INLET

HOSE ADAPTERS

OUTLET

Figure 2

2

Page 3

PC4, PC4K

Operation (Continued)

3. Plug power cord into GFCI

protected electrical outlet. The

pump will prime in a few minutes

depending on suction line length.

Use of foot valve on suction line is

recommended.

4. In the case of pressure boosting,

turn water on before starting pump.

This force primes the pump. Then,

plug power cord into GFCI protected

electrical outlet.

5. Unplug cord to turn unit off.

Maintenance

Let pump cool for

at least 20 minutes

before attempting to service. Motor

MAY be extremely hot. Personal injury

MAY result.

1. Pump should be checked periodically

for proper operation.

ALWAYS disconnect

the electrical supply

before attempting to operate, service,

or perform any maintenance. If the

power source is out of sight, lock and

tag in the open (off) position to prevent

unexpected power application. Failure

to do so WILL result in fatal electrical

shock. Only qualified electricians

SHOULD repair this unit. Improper repair

WILL result in fatal electrical shock.

BRUSH REPLACEMENT

Brushes for this

pump SHOULD be

inspected after 100 hours of operation.

Pumps with excess of 100 hours of

operation may stop operating or fail to

start. This could be due to worn brushes

or carbon build-up. The brushes should

be removed and carbon removed.

Worn brushes are not covered under

warranty. Replacement brushes may

be available from WAYNE Pumps. Call

1-800-237-0987 to order.

1) Disconnect electrical cord from

power supply.

2) Remove brush caps with screwdriver.

3) Remove old brush assembly.

4) Insert new brush assembly.

5) Replace brush caps.

For other problems, consult

troubleshooting chart.

ADDITIONAL REPAIRS

To replace bearings, shaft seal, or

gaskets, follow the instructions listed

below.

1. Disconnect electrical cord from

power supply.

2. Relieve pressure in system.

3. Disconnect inlet and outlet lines.

4. Empty water from pump housing.

5. Place pump on bench with motor

end up and remove brushes as

described in BRUSH REPLACEMENT

instructions. If brushes are to be

reused, mark the location from

which each came. Replace brushes

in original orientation upon

completion of repair.

6. Remove the four cap screws holding

motor housing and pump housing

together. Motor housing is now free

and can be removed. Take care not

to lose commutator bearing finger

spring.

7. With a screwdriver, pry the rotorbackhead assembly out of the pump

housing.

8. Remove the impeller by turning

counter clockwise (righthand thread

on shaft).

9. Remove backhead (the bearing is

press fit into the backhead).

10. Place backhead on flat surface with

impeller side down and press out

shaft seal.

11. Place impeller on flat surface

with vane side down and with

screwdriver and hammer break

ceramic seal ring into several pieces

and remove. Next, remove rubber

seal ring cup from impeller.

12. Remove bearing from armature

shaft (press-fit on shaft). (Impeller

side bearing is the only serviceable

bearing).

13. Inspect the armature commutator

bars. The environment in which

the unit has been operating will

have influence on the condition of

the commutator. Airborne dust an

dirt will accelerate wear. A rough

or scarred appearance may dictate

having commutator reconditioned

before reassembly.

14. To reassemble, install new bearing

on the shaft. Always press against

the inner race to prevent bearing

damage. Make sure bearing is tight

against the shaft shoulders.

15. Press shaft seal into backhead.

When pressing shaft seal into place,

apply force to the cup flange. Avoid

touching the polished seal surface;

oil or scratches on this surface may

cause premature failure of the seal.

16. Press ceramic side of seal into

impeller, ceramic side out. Avoid

touching ceramic with hands as oil

may cause premature failure of the

seal. Wipe oil off both sides of seal

with a soft, lint-free cloth.

17. Reassemble unit in reverse order,

beginning with Step 9.

18. After reassembly check shaft for

free rotation with screwdriver in fan

through air exit openings.

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start or run 1. Blown fuse 1. If blown, replace with proper sized fuse or

reset breaker

2. Low line voltage 2. Contact an electrician

3. Worn brushes 3. Replace brushes

4. Impeller blocked 4. Remove blockage

5. Defective motor 5. Replace pump

Pump will not prime or

retain prime after operating

Flow rate is too low 1. Piping or hose is fouled or damaged 1. Clean or replace

Seal leaks 1. Worn seal 1. Replace seal

Thermal Protector Tripping 1. Damage or misalignment causing

1. Air leak in suction line 1. Repair or replace suction line (use plumbers

tape to install garden hose adpater fittings

and priming plug onto pump body)

2. Impeller blocked 2. Remove blockage

3. Worn seal 3. Replace seal

4. Suction lift too high 4. Lower pump

5. Hose kinked or looped 5. Straighten hose

6. Fittings not tight 6. Tighten fittings

7. Suction hose out of water 7. Submerge suction hose end

8. Clogged inlet 8. Clean inlet

2. Low line voltage 2. Contact an electrician

2. Backhead damaged or cracked 2. Replace backhead

3. Pump head loose on motor 3. Insure proper assembly and no obstruction,

tighten bolts

1. Take to motor repair shop or locate and

rotating parts to bind

2. High surrounding temperature 2. Provide a shaded, well-ventilated area for

3. Low line voltage 3. Contact an electrician

4. Motor housing air-vents blocked 4. Remove air-vent blockage

repair mechanical binding

pump

www.waynepumps.com

4

Page 5

PC4, PC4K

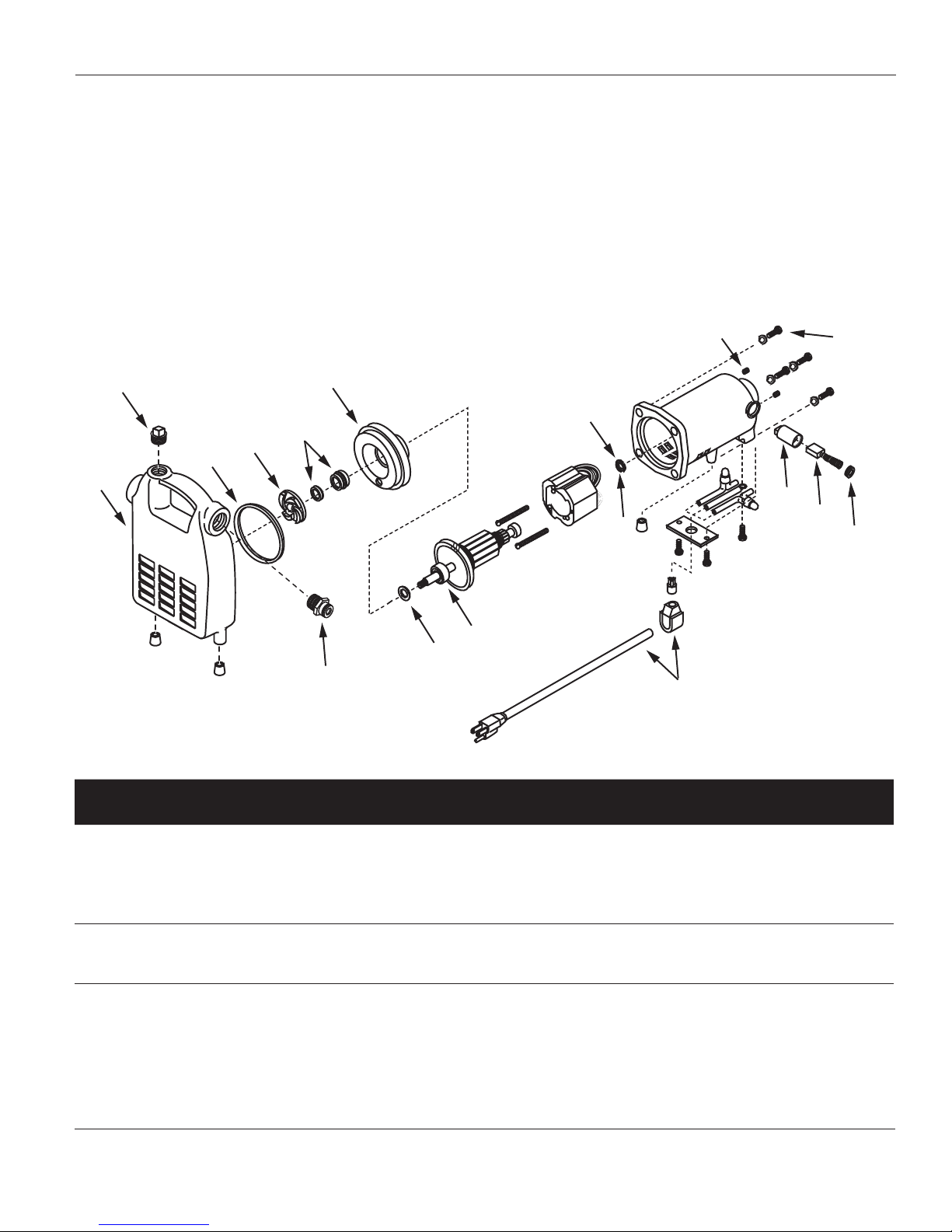

For Replacement Parts or Technical Assistance,

Call 1-800-237-0987

Please provide following information: Address any correspondence to:

- Model number WAYNE Water Systems

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

5, 8

2

3

4,8

8

FINGER SPRING

4,8

4, 7,8

7

2

5

5

5

3

6

Replacement Parts List

Ref.

No.

1 Brush kit 62007-002 1

2 Brush and holder kit 62008-002 1

3 Fittings kit 62009-001 1

4 Impeller and seal kit 62010-001 1

5 Bearing kit 62011-002 1

6 Cord kit 62012-001 1

7 Volute kit 62013-001 1

8 Backhead kit 62026-001 1

Note: Replacement parts are available in kit form only

Description Part Number Qty.

PAR

7

1, 2

1, 2

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual

Limited Warranty

For one year from the date of purchase, WAYNE Water Systems ("WAYNE") will repair or replace, at its option, for the

original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by WAYNE to be

defective in materials or workmanship. Please call WAYNE (800-237-0987) for instructions or see your dealer. Be prepared to

provide the model number when exercising this warranty. All transportation charges on Products or parts submitted for repair

or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with WAYNE's written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE or its

suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call WAYNE (800-237-0987) for return

authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. _____________________ SERIAL NO. ________________________ INSTALLATION DATE _____________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

6

Page 7

Instructions D’utilisation et Manual de Pièces PC4, PC4K

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Pompe à Auto-Amorçage

Portative, Tout Usage

Description

La pompe à auto-amorçage tout usage est

conçue pour être utilisée comme pompe de

transfert pour les applications tels que vider

les chauffe-eau, les réservoirs pour bétail,

etc. La pompe peut aussi être utilisée pour

élever la pression d’une façon intermitente

pour des applications tels que le lavage

d’autos et ne nettoyage d’entrées, etc. Le

moteur est refroidi à l’air, il n’est pas conçu

pour fonctionner sous l’eau.

NOTE: Cette pompe n’est pas conçue pour

une installation permanente ou pour

des périodes continues de travail long et

prolongé.

Déballage

Après avoir déballé la pompe utilitaire,

l’inspecter attentivement pour tout

signe de dommage susceptible de s'être

produit en transit. Vérifier la présence

de pièces desserrées, manquantes ou

endommagées. Si vous avez besoin

d’aide, appeler le service à la clientèle

au 1-800-237-0987.

Directives de Sécurité

Ce manuel contient de l’information

très importante de connaître et de

savoir qui est fournie pour la SÉCURITÉ

et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

DANGER indique

une situation

hasardeuse imminente qui RESULTERA

en perte de vie ou blessures graves.

AVERTISSEMENT

indique une

situation hasardeuse potentielle

qui PEUT résulter en perte de vie ou

blessures graves.

ATTENTION indique

une situation

hasardeuse potentielle qui PEUT résulter

en blessures.

AVIS indique de

l’information

importante pour ÉVITER le dommage de

l’équipement.

REMARQUE : Informations qui doivent

retenir tout particulièrement votre

attention.

Généralités Sur La

Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales ou

autres problèmes de reproduction. Lavezvous les mains après la manipulation.

RÈGLES DE SÉCURITÉ GÉNÉRALES

NE PAS submerger

le moteur ni le

laisser exposé à l'eau. Danger de

blessures et/ou de mort.

NE PAS pomper les fluides

explosifs tels que l’essence,

l’huile à chauffage, le

kérosène etc. Ne pas utiliser dans un

atmosphère inflammable et/ou explosif.

La pompe DOIT être utilisée seulement

pour pomper de l'eau propre. Danger de

blessures et/ou de mort.

Risque de secousse

électrique. TOUT

le câblage doit être effectué par un

électricien qualifié.

NE PAS marcher dans un

endroit humide avant d’avoir

intégralement coupé le

courant. Le non-respect de cette mise

en garde MÈNERA à un choc électrique

mortel.

1. Lire toutes les instructiions avant de

faire fonctionner le modèle.

2. Débrancher la source de puissance et

dissiper toute la pression du système

Spécifications

Moteur. . . . . . . . . . . . . Monophasé - 115V, 60 Hz, 8,000 tr/min

Moteur. . Moteur En Série (ype balai) Fonctionnement c.a./c.c.

Turbine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Thermoplastique

Carter de Moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fonte

Arbre et Joint de Volute. . . . . . . . . . . . . . . . . . . . . . . . . .Buna-N

Température Max. de Fluide . . . . . . . . . . . . . . . . . . . . . . . . 49ºC

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2011, WAYNE/Scott Fetzer Company. 321305-001 12/11

Puissance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 HP

Ouvertures Arrivée/Sortie. . . . . . . . . . . . . . . . . . . . . 3/4 po NPT

Carter de Pompe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fonte

Arbre du Moteur. . . . . . . . . . . . . . . . . . . . .Acier laminé à froid

Palier du Moteur. . . . . . . . . . . . . . . . . .Graissé en permanance

Roulements de l'élément mobile

7-Fr

Page 8

Instructions D’utilisation et Manual de Pièces

Généralités Sur La

Sécurité (Suite)

avant de procéder à l’entretien de

n’importe quelle pièce détachée.

3. Purger tout le liquide du système

avant de procéder à l’entretien.

Bien fixer la

conduite de

décharge avant de démarrer la pompe.

Toute conduite de décharge mal fixée

PEUT faire l’effet d’un fouet. Des

blessures et/ou des dommages à la

propriété POURRAIENT en résulter.

4. Inspecter la pompe et les pièces

détachées de temps en temps pour

rechercher des tuyaux faibles et usés.

S’assurer que toutes les connexions

soient sûrs.

Le moteur de la

pompe est doté d'un

protecteur thermique à réinitialisation

automatique qui POURRAIT redémarrer

de manière imprévue. Le déclenchement

du protecteur est une indication

de surcharge du moteur causée par

une utilisation de la pompe à faible

hauteur de chute (restriction de faible

décharge), d'une tension excessivement

haute ou basse, d'un câblage inadéquat,

de la température excessive de l'air

ambiant, d'une ventilation inadéquate,

et/ou d'un moteur ou d'une pompe

défectueuse.

5. Fournir un moyen de dissiper la

pression dans le cas d’une ligne de

décharge obstruée.

6. Protéger le cordon d’alimentation

des objets pointus, surfaces chaudes,

d’huile et de produits chimiques.

Ne pas tortiller le cordon et

remplacer les cordons endommagés

immédiatement.

Installation

Tableau De Longueur De Cordons Prolongateurs

Taille de fils #18 #16 #14 #12

Longueur 8 m 15 m 31 m 45 m

conditions permettent son usage.

La pompe ne doit jamais se situer

à plus de 4,6 m (15 pi) au-dessus

ou à distance d'une source d'eau.

TEST

RESET

Installer un clapet de pied lorsque le

montage d'aspiration ou conduite

d'aspiration dépassent 3 m (10 pi) de

long.

BROCHE DE MISE À

LA TERRE

Figure 1

d’une borne de terre. Une prise de courant

qui se conforme aux codes NEC et locaux

doit être utilisée (Voir Figure 1).

PRISE DDFT

2. Cette pompe fonctinne sur un circuit

de 115V, 60 Hz c.a., monophasé ou

115Vc.c.

3. Utiliser un cordon prolongateur

seulement si nécessaire. Consulter

le Tableau de Longueur De Cordon

Prolongateur pour la taille correcte

de cordon prolongateur de type à 3

fils mis à la terre.

5. La conduite d'entrée peut être

constituée de tuyau galvanisé, en

plastique ou renforcé. Les petites

fuites dans la conduite d'aspiration

réduisent grandement l'efficacité

de la pompe et peuvent même

empêcher l'amorçage.

Les boyaux

d'arrosage

courants S'ÉCRASERONT sous la

pression d'aspiration et NE DOIVENT

par conséquent PAS être utilisés dans

le conduit d’entrée excepté pour

augmenter la pression.

6. Utiliser un filtre lorsque vous

pompez de l’eau d’un ruisseau, d’un

étang ou d’une source où des objets

étranges peuvent être aspirés dans

Risque de choc électrique

mortel. NE JAMAIS couper

la broche de terre ronde.

La coupure du cordon ou de la fiche

ANNULERA la garantie et rendrait la

pompe inutilisable.

la pompe. Le filtre devrait empêcher

les solides d’entrer la ligne d’arrivée.

7. Un boyeau d’arrosage ordinaire

peut être utilisé comme ligne de

décharge.

4. La figure 2 démontre une

installation typique. Des adaptateurs

filetés sont fournis pour attacher

un boyeau d’arrosage là où les

TOUJOURS débrancher la

source de courant avant

toute mise en marche,

réparation, ou entretien de la pompe.

NE JAMAIS manipuler de pompe avec

les mains humides ou debout sur une

surface humide ou dans l'eau. Il en

RÉSULTERA un choc électrique mortel.

1. Un interrupteur DDFT est exigé.

Risque de secousse électrique

mortelle! Cette pompe est

fournie d’un fil de terre et

BOUCHON D’AMORÇAGE

SORTIE

Figure 2

ARRIVÉE

ADAPTATEURS DE

TUYAUX

8-Fr

Page 9

PC4, PC4K

Fonctionnement

La pompe doit être

remplie d’eau avant

le fonctionnement. Le fait de faire

tourner la pompe à sec ENDOMMAGERA

le joint d'étanchéité de l'arbre.

1. Ce modèle n’est pas imperméable

ni intempérisé et n’est pas conçu

pour l’utilisation dans les douches,

les saunas, ou autres endroits qui

peuvent être trempes. Le moteur

est conçu pour l’utilisation dans un

endroit propre et sêche qui a accès

à sufisamment d’air refroidissant. La

température ambiante autour du

moteur ne devrait pas dépasser 40ºC

(104ºF).

2. Enlever le bouchon d’amorçage et

remplir avec de l’eau. Remplacer

le bouchon (du ruban d'étanchéité

de plombier doit être utilisé sur le

bouchon de remplissage pour éviter

les fuites d'air).

3. Brancher le cordon d’alimentation

dans une prise de courant protégée

DDFT. La pompe s’ammorçera

dans quelques minutes selon la

longueur de la ligne d’aspiration.

Il est recommandé que vous

utilisez un clapet à pied sur la ligne

d’aspiration.

4. Pour une augmentation de pression,

faire couler l’eau avant de démarrer

la pompe. Ceci ammoce la pompe

avec pression. Ensuite, brancher le

cordon d’alimentation dans une

prise de courant protégée, DDFT.

5. Débrancher le cordon pour mettre le

modèle hors circuit.

Entretien

Permettre que

la pompe se

refroidisse pendant au moins 20

minutes avant de procéder à l’entretien.

Le moteur POURRAIT être extrêmement

chaud. Des blessures PEUVENT en

résulter.

1. Vérifier la pompe de temps en temps

pour un fonctionnement correct.

TOUJOURS

débrancher

l'alimentation électrique avant

toute mise en marche, réparation,

ou entretien. Si la source de courant

n’est pas visible, la verrouiller et

l’identifier en position ouverte (arrêt)

pour éviter toute alimentation de

courant imprévue. Le non-respect de

ces instructions MÈNERA à un choc

électrique mortel. Seuls les électriciens

qualifiés SONT HABILITES à réparer

cet appareil. Une mauvaise réparation

MÈNERA à un choc électrique mortel.

REMPLACEMENT DES BALAIS

Les brosses de cette

pompe DOIVENT

faire l’objet d’une inspection au bout de

100 heures de fonctionnement.

Les pompes qui fonctionnent pour

plus que 100 heures peuvent cesser de

fonctionner ou ne pas se démarrer. Ceci

peut être causé par des balais usés ou

l’accumulation de carbone. Enlever les

balais et nettoyer le carbone des balais.

Les balais usés ne sont pas couverts sous

la garantie. Les balais de rechange sont

disponibles de la division de pompes

WAYNE. Composer 1-800-323-0620 pour

les commander.

1) Débrancher le cordon d’alimentation

de la source de puissance.

2. Enlevver les capots de balais avec un

tournevis

3. Enlever le vieux montage de balai.

4. Introduire le nouveau montage de

balai.

5. Remplacer les capots du balai.

Consulter le guide de dépannage

concernant d’autres problèmes.

RÉPARATIONS ADDITIONNELLES

Pour remplacer les roulements, joint

d'étanchéité de l'arbre, ou joints

d'étanchéité, suivre les instructions

indiquées plus bas.

1. Débrancher le cordon d’alimentation

de la source de puissance.

2. Dissiper la pression du système.

3. Débrancher les lignes d‘arrivée et de

sortie.

4. Purger l’eau du carter de la pompe.

5. Placer la pompe sur un banc avec

le côté du moteur faisant face en

haut et enlever les balais comme

décrit dans lles instructions de

REMPLACEMENT DES BALAIS.

Si vous allez utiliser les balais de

nouveau, inscrire l’endreoit d’où

vous les avez enlevés. Remplacer

les balais dans leur positions

originels lorsque vous complétez la

réparation.

6. Enlever les quatre vis d’assemblage

qui tiennent le carter du moteur et

le carter de la pompe ensembles.

Le carter du moteur est maintenant

libre et peut être enlevé. S’assurer

de ne pas perdre le ressort de doight

du roulement de commutateur

desserré.

7. Avec un tournevis, enlever

le montage de rotor-plaque

d’étanchéité du carter de la pompe.

8. Enlever la turbine en tournant au

sens contraire des aiguilles d’une

montre (filet droit sur l’arbre).

9. Enlever la plaque d’étanchéité

(le palier est fixé dans la plaque

d’étanchéité).

10. Placer la plaque d’étanchéité sur

une surface plate avec le côté de

la turbine faisant face en bas et

pousser le joint d’arbre.

11. Placer la turbine sur une surface

plate avec le côté des ailettes faisant

face en bas et avec un tournevis

et un marteau, casser la bague

d’étanchéité en céramique en

plusieurs morceaux et les enlever.

Ensuite,enlever le godet de la bague

d’étanchéité en caoutchouc de la

turbine.

12. Retirer les roulements de l'arbre

d'induit (ajustage à pression sur

l'arbre). (Le roulement du côté

de l'impulseur constitue le seul

roulement réparable).

13. Inspecter les lames de collecteurs

d’induit. L’environnement dans

lequel le modèle fonctionnait

influencera l’état du commutateur.

La poussière et la saleté dans l’air

accèlera l’usage. Une apparence

rugueuse ou avec cicatrices peut

nécessiter la remise en état du

commutateur avant le remontage.

14. Pour remonter, installer le nouveau

roulement sur l'arbre. Toujours

presser contre la face intérieure

pour éviter d'endommager les

roulements. S'assurer que le

roulement est serré contre les

épaulements d'arbre.

9-Fr

Page 10

Instructions D’utilisation et Manual de Pièces

Entretien (Suite)

15. Appuyer le joint d’arbre dans la

plaque d’étanchéité. Lorsque vous

appuyez sur le joint d’arbre, forcer

le godet de la bride. Ne pas toucher

la surface polie du joint; de l’huile

ou des égratignures sur cette surface

peuvent causer la faillite du joint.

16. Pousser le côté céramique du joint

dans la turbine, le côté céramique

vers l’extérieur. Ne pas toucher le

céramique avec vos mains, l’huile

peut causer la faillite prématurée du

joint. Essuyer l’huile des deux côtés

du joint avec un torchon souple sans

charpie.

17. Remonter le modèle en ordre

contraire de l’étape 9.

Notes

18. Suite au remontage, vérifier que

l’arbre tourne librement avec un

tournevis dans l’évantail à travers les

ouvertures de sortie.

10-Fr

Page 11

Série En Fonte Tout Usage

Guide de Dépannage

Symptôme(s) Cause(s) Possible(s) Mesures Correctives

La pompe ne se démarre pas

et ne fonctionne pas

La pompe ne s’ammorce

pas ou ne conserve pas

l’ammorçage suite au

fonctionnement

Taux de débit trop bas 1. La tuyauterie ou les tubes sont souillis

Fuites dans les joints 1. Joint usé 1. Remplacer le joint

Déclenchement du protecteur

thermique

1. Fusible sauté 1. Si sauté, remplacer avec un fusible de

taille correcte ou enclencher à nouveau le

disjoncteur

2. Tension de ligne basse 2. Communiquer avec un électricien

3. Balais usés 3. Remplacer les balais

4. Turbine obstruée 4. Enlever le blocage

5. Moteur défectueux 5. Remplacer la pompe

1. Fuite d’air dans la ligne d’aspiration 1. Réparer ou remplacer la ligne d’aspiration

(utiliser du ruban d'étanchéité de plombier

pour installer les raccords d'adaptateur et

le bouchon de remplissage sur le corps de

pompe).

2. Turbine obstruée 2. Enlever le blocage

3. Joint usé 3. Remplacer le joint

4. La hauteur d’aspiration trop élevée 4. Baisser la pompe

5. Tuyau en coude ou bouclé 5. Redressir le tuyau

6. Raccords desserrés 6. Serrer les raccords

7. Tuyau d’aspiration hors de l’eau 7. Submerger le bout du tuyau d’aspiration

8. Arrivée obstruée 8. Nettoyer l’arrivée

1. Nettoyer ou remplacer

ou endommagés

2. Tension de ligne basse 2. Communiquer avec un électricien

2. Tête arrière endommagée ou fissurée 2. Remplacer la tête arrière

3. La tête de la pompe desserrée du

moteur

1. Endommagement ou défaut

d'alignement provoquant un grippage

des pièces mobiles

2. Température ambiante élevée 2. Mettre la pompe dans un endroit ombragé

3. Basse tension de ligne 3. Communiquer avec un électricien

4. Évents du boîtier moteur bloqués 4. Retirer le blocage des évents

3. Assurer le montage correct sans

obstructions, serrer les boulons

1. L’emporter dans un atelier de réparation de

moteurs ou localiser et réparer le grippage

mécanique

et bien ventilé

11-Fr

Page 12

Instructions D’utilisation et Manual de Pièces

5, 8

Pour pièces de rechange ou assistance technique,

appeler 1-800-237-0987

S’il vous plaît fournir l’information suivante: Adresser toute correspondance à :

- Numéro de Modèle WAYNE Water Systems

- Numéro de série (si présent) 101 Production Drive

- Description et numéro de la pièce Harrison, OH 45030 U.S.A.

2

4,8

8

RESSORT AU

DOIGT

3

4,8

7

4, 7,8

7

2

1, 2

5

1, 2

5

5

3

6

Liste de pièces de rechange

N°. de

réf.

1 Nécessaire de balai 62007-002 1

2 Trousse de porte-brosses 62008-002 1

3 Nécessaire de raccords 62009-001 1

4 Nécessaire de turbine et de joint 62010-001 1

5 Nécessaire de roulements 62011-002 1

6 Nécessaire de cordon 62012-001 1

7 Nécessaire de volute 62013-001 1

8 Nécessaire plaque joint étanche 62026-001 1

Remarque: Les pièces de rechange sont disponibles en nécessaires seulement.

12-Fr

PAR

Numéro de

piéceDescription Qté.

Page 13

Notes

PC4, PC4K

13-Fr

Page 14

Instructions D’utilisation et Manual de Pièces

Garantie Limitée

Pour un an à compter de la date d’achat, WAYNE Water Systems ("WAYNE") vas réparer ou remplacer, à son option, pour

l’acheteur originel n’importe quelle pièce ou pièces de ces Pompes De Puisard ou Pompes À Eau (“Produit”) déterminées

défectueuses, par WAYNE, en matière ou en fabrication. S’il vous plaît appeler WAYNE (800-237-0987) pour des instructions ou

contacter votre marchand. S’assurer d’avoir, à votre disposition, le numéro du modèle afin d’effectuer cette garantie. Les frais

de transportation des Produits ou pièces soumis pour la réparation ou le remplacement sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation abusive,

mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux

instructions écrit de WAYNE.

IL N’EXISTE AUCUNE AUTRE GARANTIE OU AFFIRMATION. LES GARANTIES EXPRIMÉES, Y COMPRIS CELLES DE

COMMERCIALISABILITÉ ET D’ADAPTION À UNE FONCTION PARTICULIÈRE, SONT LIMITÉES À UN AN À COMPTER DE LA

DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR N’IMPORTE QUEL ET

TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à

l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à

l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni WAYNE ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais pas

limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût

de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre recette d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une copie de la recette d’achat avec

le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler WAYNE (800-237-0987)

pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE _____________________ Nº DE SÉRIE ________________________ DATE D’INSTALLATION _____________________

FIXER VOTRE FACTURE ICI

14-Fr

Page 15

Manual de instrucciones de operación y piezas PC4, PC4K

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto

aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede

ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Bomba Portátil de

Servicio con Sistema de

Cebado Automático

Descripción

Las bombas portátiles de servicio con

sistema de cebado automático están

diseñadas para usarse como bombas de

desagüe para vaciar calentadores de agua,

tanques para animales, etc. Igualmente,

las bombas se pueden usar de modo

intermitente para lavar coches, limpiar

entradas de garajes, etc. El motor se enfría

con aire y no está diseñado para operar

bajo agua.

NOTA: Este bomba no está diseñada

para una instalación permanente o para

períodos de trabajo continuo largos y

extendidos.

Para Desempacar

Después de desempacar la bomba

de uso general, inspecciónela

cuidadosamente para detectar cualquier

daño que pueda haber ocurrido

durante el transporte. Verifique que no

haya piezas sueltas, dañadas o faltantes.

Si necesita asistencia, llame a nuestro

Departamento de Servicio al Cliente al

1-800-237-0987.

Medidas de Seguridad

Este manual contiene informacion

que es muy importante que sepa

y comprenda. Esta informacion se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS.

CON EL EQUIPO. PELIGRO le indica

que hay

una situación inmediata que le

OCASIONARÍA la muerto o heridas de

gravedad.

ADVERTENCIA le

indica que hay una

situación que PODRÍA ocasionarle la

muerte o heridas de gravedad.

PRECAUCION le

indica que hay

una situación que PODRÍA ocasionarle

heridas no muy graves.

AVISO le indica

una información

importante, que de NO seguirla, le

PODRÍA ocasionar daños al equipo.

NOTA: Información que requiere

atención especial.

Informaciones

Generales de Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o su

cordón eléctrico,

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

SEGURIDAD GENERAL

NO sumerja el motor

ni permita que el

motor esté expuesto al agua. CAUSARÁ

lesiones corporales y/o la muerte.

NO la use para bombear

fluidos inflamables o

explosivos, como gasolina,

aceite combustible, queroseno, etc. NO

la use en una atmósfera inflamable o

explosiva. La bomba sólo DEBE usarse

para bombear agua limpia. CAUSARÁ

lesiones corporales y/o la muerte.

Peligro de

electrocutamiento.

Un electricista calificado debe realizar

TODO el cableado.

NO camine sobre áreas

húmedas sino después de

que TODAS las fuentes

de electricidad estén apagadas. El

desobedecer esta advertencia CAUSARÁ

un choque eléctrico mortal.

1. Lea todas las instrucciones antes de

comenzar a usar la bomba.

2. Desconecte el cordón eléctrico y libere

toda la presión del sistema antes de

darle servicio a cualquier componente.

Especificaciones

Motor. . . . . . . . . . . . . . .Monofásico - 115V, 60 Hz, 8,000 R.P.M.

Motor. . . . . . . . . . . . . . . . . Serie Wound (con escobillas) CA/CD

Propela. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Termoplástico

Cubierta del Motor. . . . . . . . . . . . . . . . . . . . . . . . .Hierro colado

Sellos del eje y la Voluta. . . . . . . . . . . . . . . . . . . . . . . . . .Buna-N

Temp. Máx. del Fluído . . . . . . . . . . . . . . . . . . . . . . .49ºC (120ºF)

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2011, WAYNE/Scott Fetzer Company. 321305-001 12/11

Caballos de Fuerza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 CP

Orificios de Entrada/Salida. . . . . . . . . . . . . 19,1 mm (3/4”) NPT

Envoltura de la Bomba. . . . . . . . . . . . . . . . . . . . . Hierro colado

Eje del Motor. . . . . . . . . . . . . . . . . . . . .Acero laminado en frío

Cojinetes del Motor . . . . . . . . . . . . . . . Lubricados de por Vida

Rodamientos de bola

15-Sp

Page 16

Manual de instrucciones de operación y piezas

Informaciones

Generales de Seguridad

(Continuacion)

3. Drene todos los líquidos del sistema

antes de darle servicio.

Asegure la línea de

descarga antes

de dar arranque a la bomba. Si no la

asegura, ES POSIBLE que se sacuda

bruscamente y PODRÍAN causarse

lesiones personales y/o daños a la

propiedad.

4. Periódicamente inspeccione la

bomba y los componentes, chequée

si las mangueras están debilitadas o

desgastadas. Cerciórese de que todas las

conecciones estén bien apretadas.

El motor de la

bomba está

equipado con un circuito protector

térmico de reconfiguración automática

y ES POSIBLE que se reactive

repentinamente. La desconexión

del circuito protector indica un

recalentamiento del motor debido a

que la bomba está funcionando con

presión hidrostática baja (restricción de

descarga baja), voltaje excesivamente

alto o bajo, cableado inadecuado,

temperatura excesiva del aire

circundante, ventilación inadecuada y/o

motor o bomba defectuosos.

5. Cerciórese de que haya una forma de

liberar la presión en caso de que la línea

de descarga se obstruya.

6. Proteja los cordones eléctricos contra

objetos afilados, superficies calientes,

aceite y químicos. Evite que el cordón

se enrolle y reemplace los cordones

dañados inmediatamente.

Instalación

SIEMPRE desconecte la fuente

de energía antes de intentar

operar o reparar la bomba, o

darle mantenimiento. NUNCA manipule

la bomba con las manos húmedas

o cuando se encuentre sobre una

superficie húmeda o mojada, ni dentro

del agua. OCURRIRÁ un choque eléctrico

mortal.

1. Necesita usar un cortacircuito

automático con conexión a tierra.

Tabla de las Longitudes de los Cordones de Extensión

Tamaño del alambre #18 #16 #14 #12

Longitud 8 m 15 m 31 m 45 m

condiciones lo permitan. En ningún

caso la bomba debe colocarse a más

de 4,5 m (15 pies) de distancia o

de altura con respecto a la entrada

TEST

RESET

de agua. Instale una válvula de pie

cuando la altura de succión sea

superior a los 3 m (10 pies) o cuando

la línea de succión tenga más de 3 m

TERMINAL PARA

CONEXIÓN A TIERRA

Figura 1

enchufe para conexión a tierra. Debe

utilizar un tomacorrientes que cumpla con

los códigos vigentes nacionales (NEC en

EE.UU.) y locales (Vea la Figura 1).

TOMACORRIENTES GFCI

(CONECTADO A TIERRA)

2. Esta bomba sólo se debe usar

con circuitos de 115 voltios

(monofásicos), 60 Hz CA, ó 115

voltios CD.

3. Use un cordón de extensión sólo

cuando sea necesario. Use cordones

de extensión, de tres alambres para

conexión a tierra que sean de la

longitud y calibre indicados en la

Tabla de cordones de extensión.

(10 pies) de largo.

5. La línea de entrada puede ser un

tubo galvanizado o de plástico, o

una manguera reforzada. Las fugas

pequeñas en la línea de succión

reducen en gran medida la eficiencia

de la bomba y pueden impedir el

cebado.

Las mangueras de

jardín normales

COLAPSARÁN con la presión de succión;

por lo tanto, NO DEBEN usarse para la

línea de entrada, con excepción de los

sistemas para aumentar la presión.

6. Use un colador cuando vaya a

bombear agua de un riachuelo,

charca o cualquier sitio donde pueda

haber basura que podría obstuir

la bomba. El colador debe evitar

Riesgo de choque eléctrico

mortal. NUNCA corte la clavija

redonda de conexión a tierra.

Si corta el cable o el enchufe, SE ANULARÁ

la garantía y hará que la bomba no

funcione.

la entrada de sólidos a la línea de

entrada de la bomba.

7. Puede usar una manguera común

para jardines como línea de

descarga.

4. La Figura 2 le indica cómo instalar la

bomba. Los adpatadores con roscas

se le suministran para que conecte

mangueras para jardín cuando las

TAPÓN DEL SISTEMA DE

CEBADO

ENTRADA

¡Peligro de morir

electrocutado! Esta bomba

tiene un conductor para

conexión a tierra y un

Figura 2

SALIDA

ADAPTADORES DE

MANGUERA

16-Sp

Page 17

PC4, PC4K

Funcionamiento

Debe llenar la

bomba de agua

antes de encenderla. Hacer funcionar la

bomba en seco CAUSARÁ daños en el

sello del eje.

1. Esta unidad no es a prueba de agua

o a prueba de intemperie y no está

diseñada para usarse en duchas,

saunas, ni ningún sitio donde se

pueda mojar. El motor está diseñado

para usarse en sitios limpios y secos

donde tenga acceso a aire adecuado

para enfriarlo. La temperatura

ambiental alrededor del motor no

debe exceder 40˚C (104˚F).

2. Quítele el tapón al sistema de

cebado y llénelo de agua. Vuelva a

colocar el tapón (se debe usar cinta

de sellado de plomería en el tapón

de cebado para evitar fugas de aire).

3. Conecte el cordón eléctrico a un

tomacorrientes con cortacircuito

automático con conexión a tierra.

La bomba completará el proceso

de cebado en pocos minutos,

dependiendo de la longitud de la

línea de succión. Le recomendamos

que use una válvula de pie en la

línea de succión.

4. En caso de que la vaya a usar para

aumentar la presión de agua, abra

la llave de agua antes de encender

la bomba. La bomba se cebará

con la presión del agua. Después,

conecte el cordón eléctrico a un

tomacorrientes a un tomacorrientes

con cortacircuito automático con

conexión a tierra.

5. Desconecte el cordón para apagar la

unidad.

Mantenimiento

Debe esperar por lo

menos 20 minutos

para que la bomba se enfrie antes de

darle servicio. ES POSIBLE que el motor

esté muy caliente. ES POSIBLE causar

lesiones personales.

1. Debe chequear la boomba

periódicamente para ver si está

funcionando adecuadamente.

SIEMPRE

desconecte el

suministro de corriente antes de

intentar operar, efectuar reparaciones

o realizar cualquier tipo de

mantenimiento. Si la fuente de energía

está fuera de la vista, bloquéela y

etiquétela en la posición abierta (off)

para evitar que se suministre corriente

en forma inesperada. Dejar de hacer

esto CAUSARÁ un choque eléctrico

mortal. Esta unidad DEBE ser reparada

únicamente por electricistas calificados.

La reparación incorrecta CAUSARÁ un

choque eléctrico mortal.

PARA REEMPLAZAR LAS ESCOBILLAS

Las escobillas de

esta bomba DEBEN

inspeccionarse después de 100 horas de

funcionamiento.

Después de 100 horas de

funcionamiento la bomba podría dejar

de funcionar o no encender. Ésto podría

ser debido al desgasto de las escobillas

o a la acumulación de carbón. Debe

desmontarle las escobillas y quitarle

los residuos de carbón. Las escobillas

no están cubiertas en la garantía.

Para ordenar escobillas de repuesto

comuníquese con el distribuidor de

bombas WAYNE más cercano a su

domicilio. En EUA llame al 1-800-3230620 para ordenarlas.

1. Desconecte el cordón eléctrico del

tomacorrientes.

2. Use un desarmador para quitarle las

tapas a las escobillas.

3. Saque el ensamblaje de las escobillas

usadas.

4. Colóquele las escobillas nuevas.

5. Colóquele las tapas de las escobillas.

Si tiene otros problemas, consulte la

guía de diagnóstico de averías

REPARACIONES ADICIONALES

Para reemplazar los rodamientos,

el sello del eje, o las juntas, siga

las instrucciones que se incluyen a

continuación.

1. Desconecte el cordón eléctrico del

tomacorrientes.

2. Libere la presión del sistema.

3. Desconecte las líneas de entrada y de

salida.

4. Vacíe el agua en la envoltura de la

bomba.

5. Coloque la bomba sobre una mesa

con el motor hacia arriba y quítele

las escobillas tal cómo se le indica en

la sección “como reemplazar las

escobillas”. Si va a usar las mismas

escobillas, marque de donde sacó

cada una. Al terminar de hacer las

reparaciones, coloque las escobillas

en su posición original.

6. Quítele los cuatro tornillos que

unen la envoltura del motor a

la de la bomba. La envoltura del

motor estará libre y podrá sacarla.

Cerciórese de que no se extravie el

resorte de los cojinetes.

7. Use un desarmador para sacar la

tapa posterior de la envoltura de la

bomba.

8. Para sacar la propela gírela en

sentido contrario al de las agujhas

del reloj (roscas derechas del eje).

9. Saque la tapa posterior (el cojinete

está calzado a presión a la tapa

posterior).

10. Coloque la tapa posterior sobre una

superficie plana con la propela hacia

abajo y aplíquele presión al sello del

eje para sacarlo.

11. Coloque la propela sobre una

superficie plana con la aleta hacia

abajo y con un desarmador y un

martillo rompa el sello de cerámica

en varios pedazos para sacarlo.

Después, sáquele a la propela el

anillo del sello de goma.

12. Retire el rodamiento del eje del

inducido (colocado a presión en el

eje). (El rodamiento del lado del

impulsor es el único rodamiento que

puede ser reparado por el usuario).

13. Inspeccione las barras conmutadoras

de la armadura. La condición de

éstas dependerá de donde haya

utilizado la bomba. El polvo en

el aire acelerará su desgasto.

Si lucen estar dañadas, deberá

reacondicionar el comutador antes

de reensamblarlo.

14. Para volver a armarlo, instale el

rodamiento nuevo en el eje. Siempre

haga presión contra el aro de

rodamiento interior para evitar que

se dañe el rodamiento. Asegúrese

de que el rodamiento esté ajustado

contra las pestañas del eje.

15. Aplíquele presión al sello del eje

para conectarlo a la tapa posterior.

Para colocarlos aplíquele la presión

a la lengüeta. Evite tocar la

superficie pulida del sello; si esta

superficie se contamina con aceite

o se raya el sello podría dañarse

prematuramente.

17-Sp

Page 18

Manual de instrucciones de operación y piezas

Mantenimiento

(Continuacion)

16. Presione el lado de cerámica del

sello contra la propela, con el lado

de cerámica hacia afuera. Evite tocar

la cerámica con las manos ya que los

residuos de aceite podrían dañar el

sello prematuramente. Limpie los

residuos de aceite de ambos lados

del sello con un trapo suave y sin

hilachas.

17. Para reemsamblar la unidad siga los

pasos anteriores en orden contrario,

comenzando con el paso 9.

18. Después de reensamblar la unidad

introduzca un desarmador por el

orificio de entrada de aire para

verificar que las aletas puedan rotar

libremente.

Tabla de Identificación de Problemas

Síntoma(s) Causa(s) Posible(s) Medida Correctiva(s)

La bomba no se

enciende ni funciona

La bomba no se ceba o

lo pierde después de

funcionar

El flujo es muy bajo 1. Las tuberías o mangueras están

Los sellos tienen fugas 1. El sello está desgastado 1. Reemplace el sello

Desconexión del circuito

protector térmico

1. Un fusible quemado 1. Si está quemado, reemplácelo con un fusible

adecuado o active el cortacircuito

2. El voltaje es muy bajo 2. Póngase en contacto con un electricista

3. Las escobillas están desgastadas 3. Reemplace las escobillas

4. La propela está obstruída 4. Quítele lo que la está obstruyendo

5. El motor está dañado 5. Reemplace la bomba

1. Hay fuga de aire en la línea de succión 1. Repare o reemplace la línea de succión

(use cinta de plomería para instalar en el

cuerpo de la bomba los adaptadores de la

manguera de jardín y el tapón de cebado)

2. La propela está obstruída 2. Quítele lo que la está obstruyendo

3. El sello está desgastado 3. Reemplace el sello

4. El nivel de succión es muy alto 4. Coloque la bomba en un sitio más bajo

5. La manguera está enrollada 5. Enderece la manguera

6. Las conexiones están flojas 6. Apriete las conexiones

7. La manguera de succión no tiene agua 7. Sumerja el extremo de la manguera de

succión

8. El orificio de entrada está obstruído 8. Limpie el orificio de la entrada

1. Límpielas o reemplácelas

obstruídas o dañadas

2. El voltaje es muy bajo 2. Póngase en contacto con un electricista

2. Cabezal dañado o partido 2. Cambie el cabezal

3. La bomba está mal conectada al motor 3. Cerciórese de que esté bien conectada y que

no esté obstruída, apriete los pernos

1. Daño o desalineación que hace que las

piezas giratorias se atasquen

2. Temperatura circundante alta 2. Proporcione un área con sombra y bien

3. Bajo voltaje de la línea 3. Póngase en contacto con un electricista

4. Agujeros de ventilación de la caja del

motor bloqueados

1. Lleve el motor al taller de reparaciones o

ubique y repare el atascamiento mecánico

ventilada para la bomba

4. Quite el bloqueo de los agujeros de

ventilación

18-Sp

Page 19

PC4, PC4K

5, 8

Para Ordenar Repuestos o Asistencia Técnica, Sírvase

Llamar al Distribuidor Más Cercano a Su Domicilio

Sirvase darnos la siguiente información: Dirija toda la correspondencia a:

- Número del modelo WAYNE Water Systems

- Código impreso 101 Production Drive

- Descripción y número del repuesto según la lista Harrison, OH 45030 U.S.A.

de repuestos

2

3

4,8

4, 7,8

7

8

RESORTE DE

RETENCIÓN

4,8

2

5

5

5

3

6

7

1, 2

1, 2

Lista de Partes de Reparación

No. de

Ref. DescripciónDescripción Ctd.

1 Juego de escobillas 62007-002 1

2 Juego de soportes y escobillas 62008-002 1

3 Juego de conectores 62009-001 1

4 Juego de propela y sellos 62010-001 1

5 Juego de cojinetes 62011-002 1

6 Juego de piezas del cordón 62012-001 1

7 Juego de piezas de la voluta 62013-001 1

8 Juego de placa del sello 62026-001 1

Nota: Los repuestos sólo están disponibles en juegos

19-Sp

Page 20

Manual de instrucciones de operación y piezas

Garantía Limitada

Durante un año a partir de la fecha de compra, WAYNE Water Systems ("WAYNE") reparará o reemplazará, según lo

consideren adecuadon, cualquier pieza de esta bomba para sumideros (“Producto”) que el comprador original envie a

reparación y los empleados o representantes autorizados de WAYNE determinen que están defectuosos debido a problemas

de materiales o manufactura. Para recibir información sobre los pasos a seguir, comuníquese directamente con la compañía

WAYNE (800-237-0987, sólo desde EUA), o con el distribuidor autorizado más cercano a su domicilio. En el momento de

reclamar sus derechos bajo esta garantía deberá suministrarnos el número del modelo. Todos los gastos de flete serán la

responsabilidad del comprador.

Esta garantía limitada no cubre los daños debido a accidentes, abusos, uso inadecuado, negligencia, instalación inadecuada,

mantenimiento inadecuado, o funcionamiento sin seguir las instrucciones suministradas por escrito por la compañía WAYNE.

NO HAY NINGUNA OTRA GARANTIA EXPRESA O IMPLISITA. INCLUYENDO AQUELLAS SOBRE VENTA O USOS

ESPECIFICOS, Y LAS GARANTIAS ESTAN LIMITADAS A UN AÑO A PARTIR DE LA FECHA DE COMPRA. ESTA ES

LA UNICA GARANTIA Y CUALQUIER PERDIDA O RESPONSABILIDAD CIVIL, SEA DIRECTA O INDIRECTA COMO

CONSECUENCIA DE DAÑOS SON EXCLUIDAS.

Algunos estados no permiten límites en la duración de las garantías, o no permiten que se limiten o excluyan casos por daños

por accidentes o consecuentes, en dichos casos los límites arriba enumerados tal vez no apliquen para Ud. Esta garantía

limitada le otorga a Ud. ciertos derechos que pueden variar de un estado a otro.

Bajo ninguna circunstyancia, aunque sea debido al incumplimiento del contrato de garantía, culpabilidad (incluyendo

negligencia) u otras causas,la compañía WAYNE o ninguno de sus surtidores serán responsables legalmente por ningún fallo

legal en su contra, incluyendo, pero no limitado apérdida de ganancias, pérdidas del uso del producto o piezas asociadas

con el equipo, pérdidas de capital, gastos para reemplazar los productos dañados, pérdidas por cierre de fábrica, servicios o

pérdida de electricidad, o demandas persentadas por los clientes del comprador por dichos daños.

Ud. DEBE conservar el recibo como prueba de compra junto con esta garantía. En caso de que necesite presentar un

reclamo de sus derechos bajo esta garantía, Ud DEBERA enviar una copia del recibo de la tienda junto con el producto

o correspondencia. Comuníquese con la compañía WAYNE (800-237-0987, sólo desde EUA) para recibir autorización e

instrucciones de como enviar la mercancía.

NO ENVIE ESTA GARANTIA A WAYNE. Use este documento sólo para mantener sus records.

NO. DEL MODELO _____________________ NO. DE SERIE ________________________ FECHA DE INSTALACION __________________

ANEXE SU RECIBO AQUI

20-Sp

Loading...

Loading...