Page 1

Self-Priming

Portable Utility Pump

OPERATING INSTRUCTIONS & PARTS MANUAL

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL - DO NOT DISCARD.

Failure to follow these instructions could result in property damage, serious injury or death.

PC4

DESCRIPTION

This self-priming portable utility pump is designed to be used as

a transfer pump for such applications as emptying water heaters,

livestock tanks, etc. Pump can also be used for an intermittent

pressure boost for applications such as washing cars, cleaning

driveways, etc. The motor is air cooled; it is not designed to operate

under water.

NOTE: This pump is not intended for permanent installation or long,

extended periods of continuous operation.

UNPACKING

After unpacking the utility pump, carefully inspect for any damage

that may have occurred during transit. Check for loose, missing or

damaged parts. If you need assistance, call our Customer Service

Department at 1-800-237-0987.

SAFETY GUIDELINES

To help recognize this information, observe the following signal

words/hazard classifications.

Danger indicates an imminently hazardous

situation which, if not avoided, WILL result in

death or serious injury.

Warning indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

Caution indicates a potentially hazardous

situation which, if not avoided, MAY result in

minor or moderate injury.

Notice indicates important information, that if

not followed, may cause damage to equipment.

This is the safety alert symbol. It is used to alert you to potential bodily

injury hazards. Obey all safety messages that follow this symbol to avoid

possible harm.

NOTE: Information that requires special attention.

GENERAL SAFETY INFORMATION

CALIFORNIA PROPOSITION 65

This product or its power cord contains

chemicals, including lead, known to the State of

California to cause cancer and birth defects or other reproductive harm.

Wear gloves when handling this product, and wash hands after handling.

GENERAL SAFETY

Do not submerge motor or allow motor to be

exposed to water. Personal injury and/or death

WILL result.

Do NOT use to pump flammable or explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do NOT use in a flammable

and/or explosive atmosphere. Pump SHOULD only be used to

pump clear water. Personal injury and/or death WILL result.

Risk of electrical shock. ALL wiring must be

performed by a qualified electrician.

Do NOT walk on wet areas until ALL power is turned off.

Failure to follow this warning WILL result in fatal electrical

shock.

1. Read all instructions before operation.

2. Disconnect power and release all pressure within

the system before servicing any component.

3. Drain all liquids from system before servicing.

Secure the discharge line before starting the

pump. An unsecured discharge line MAY whip.

Personal injury and/or property damage COULD result.

4. Periodically inspect pump and system components, checking

for weak and/or worn hoses. Insure all connections are secure.

Motor

Motor

Impeller

Motor Housing

Shaft and Volute

Seal

Maximum Fluid

Temperature

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2016, WAYNE/Scott Fetzer Company.

Single Phase - 115V, 60 Hz, 8,000 RPM

Series Wound (brush type) AC/DC Operation

Thermoplastic

Cast iron

Buna-N

120°F

For parts, product & service information visit www.waynepumps.com

Specications

Horsepower

Inlet/Outlet Openings

Pump Housing

Motor Shaft

Motor Bearings

1/2 HP

3/4 inch NPT

Cast iron

Cold rolled steel

Permanently lubricated

Rolling element bearings

3213 07 -001 6/16

Page 2

Operating Instructions and Parts Manual

GENERAL SAFETY INFORMATION (CONTINUED)

Pump motor is equipped with an automatic

resetting thermal protector and MAY restart

unexpectedly. Protector tripping is an indication of motor overheating

because of operating pump at low heads (low discharge restriction),

excessively high or low voltage, inadequate wiring, excessive surrounding

air temperature, inadequate ventilation, and/or defective motor or pump.

5. Provide a means of pressure relief in the case of an obstructed

discharge line.

6. Protect electrical cord from sharp objects, hot surfaces, oil and

chemicals. Avoid kinking the cord and replace damaged cords

immediately.

INSTALLATION

ALWAYS disconnect power source before attempting to

operate, service, or maintain the pump. NEVER handle a pump

with wet hands or when standing on wet or damp surface or

in water. Fatal electrical shock WILL occur.

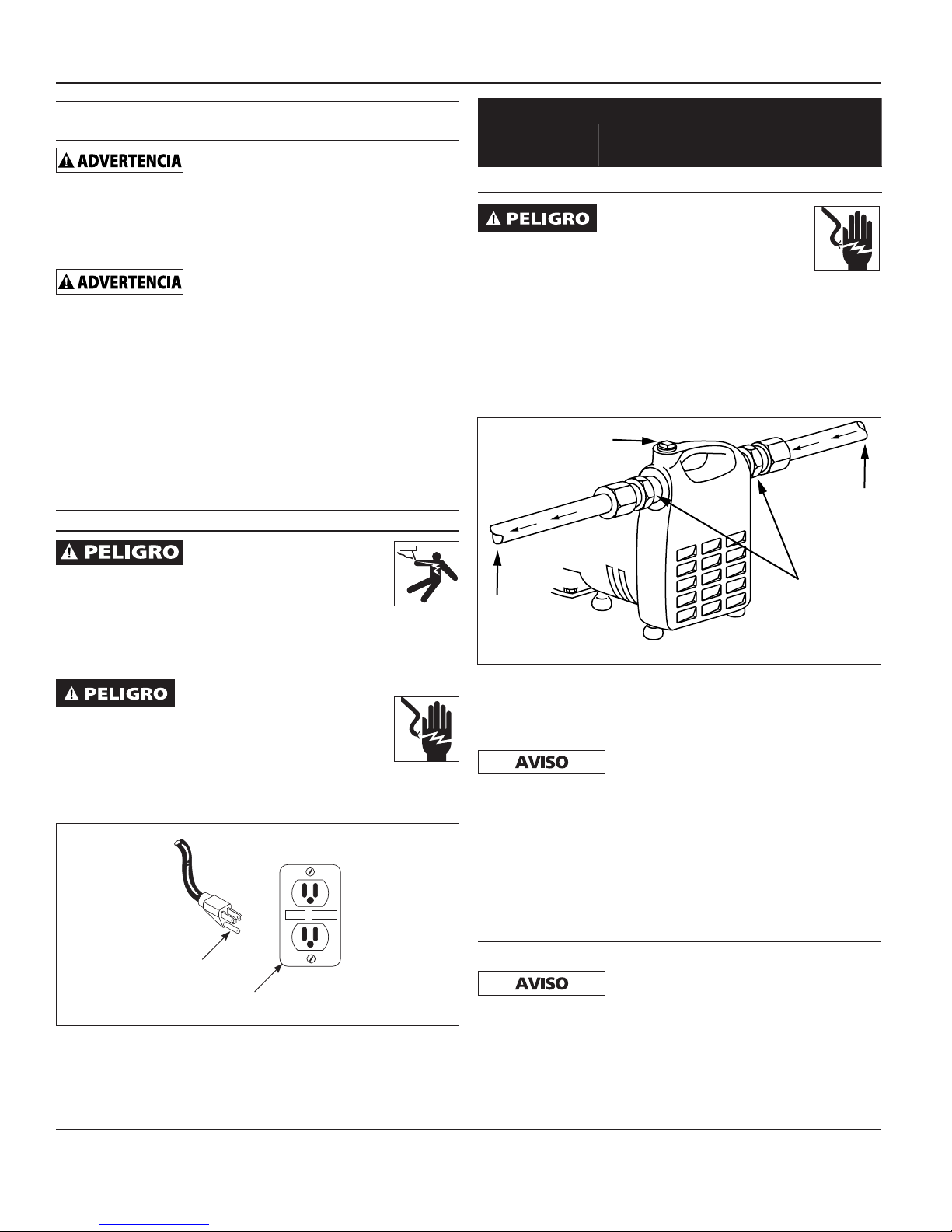

1. A ground fault circuit interrupter (GFCI) is required.

Risk of electrical shock! This pump is supplied with a

grounding conductor and grounding type attachment plug.

A grounded receptacle in conformance with current NEC and

local codes must be used (See Figure 1).

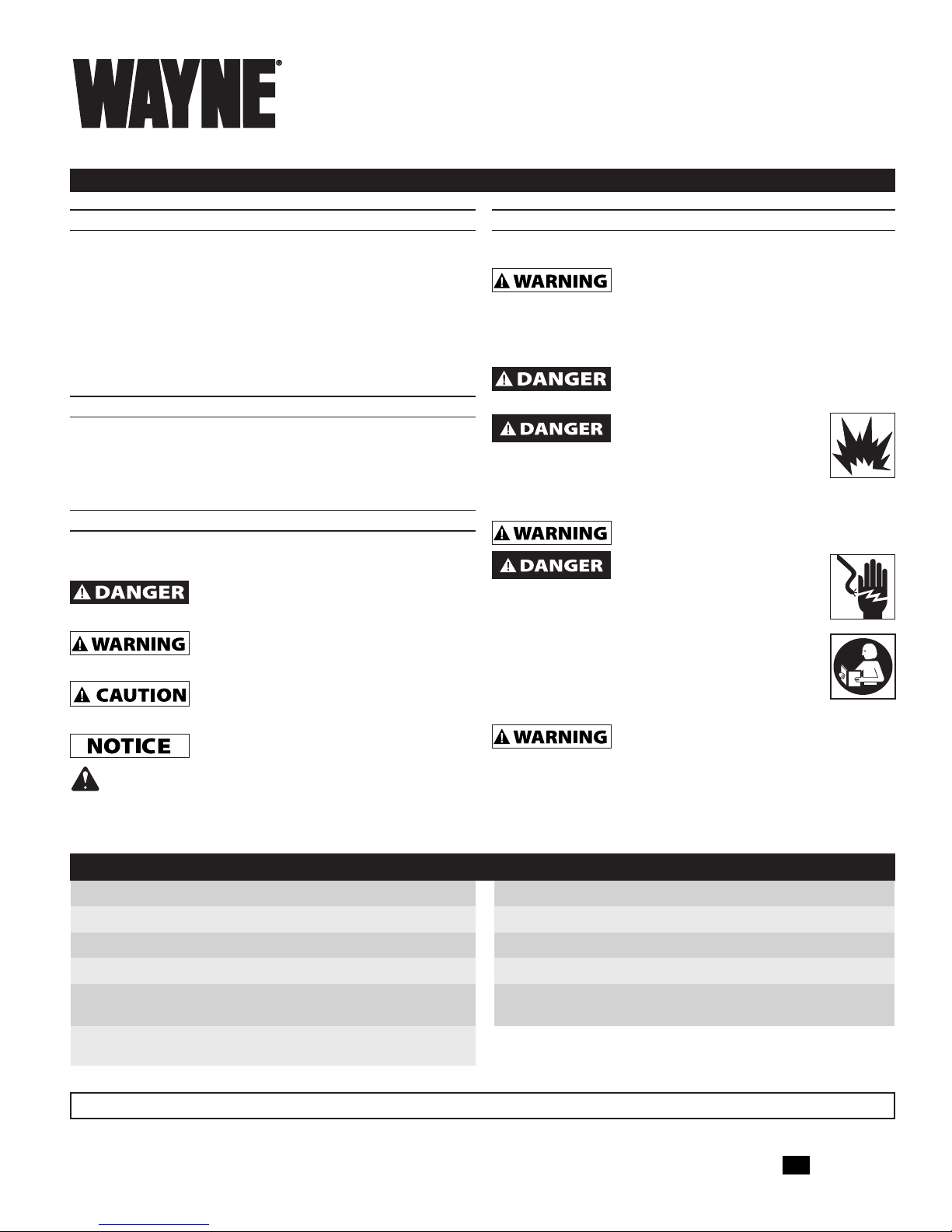

PRIME PLUG

INLET

OUTLET

Figure 2

HOSE

ADAPTERS

4. Figure 2 shows a typical installation. Threaded adapters are

furnished for attaching garden hose where conditions permit its

use. In no case should the pump be more than 15 feet above

or away from water source. Install a foot valve when suction lift

is over 10 feet or when suction line is over 10 feet long.

5. The inlet line may be galvanized pipe, plastic pipe, or reinforced

hose. Small leaks in suction line greatly reduce efficiency of

pump and may prevent priming.

Ordinary garden hose WILL collapse under

suction pressure and SHOULD NOT be used for

the inlet line, except in pressure boosting applications.

6. Use a strainer when pumping from a creek, pond, or source

where foreign objects may be sucked into the pump. The

strainer should prevent solids from entering the inlet line.

7. A regular garden hose may be used as a discharge line.

RESET

TEST

GROUNDING BLADE

Figure 1

GFCI RECEPTACLE

2. This pump operates on 115V, 60 Hz AC, single phase or 115V

DC.

3. Use an extension cord only if necessary. Follow the Extension

Cord Length Table for proper gage of 3-wire, grounding type

extension cord.

Extension Cord Length Table

Wire Size #18 #16 #14 #12

Length 25 ft 50 ft 100 ft 150 ft

Risk of fatal electrical shock. NEVER cut off the round

grounding prong. Cutting the cord or plug WILL void the

warranty and make the pump inoperable.

OPERATION

Pump must be filled with water before

operation. Running the pump dry WILL cause

damage to the shaft seal.

1. This unit is not waterproof or weatherproof and is not

intended to be used in showers, saunas, or other potentially

wet locations. The motor is designed to be used in a clean,

dry location with access to adequate cooling air. Ambient

temperatures around the motor should not exceed 104˚F (40˚C).

2. Remove priming plug and fill with water. Replace plug (plumbers

seal tape should be used on priming plug to prevent air leaks).

3. Plug power cord into GFCI protected electrical outlet. The

pump will prime in a few minutes depending on suction line

length. Use of foot valve on suction line is recommended.

4. In the case of pressure boosting, turn water on before starting

pump. This force primes the pump. Then, plug power cord into

GFCI protected electrical outlet.

5. Unplug cord to turn unit off.

www.waynepumps.com

2

Page 3

MAINTENANCE

Let pump cool for at least 20 minutes before

attempting to service. Motor MAY be extremely

hot. Personal injury MAY result.

1. Pump should be checked periodically for proper operation.

ALWAYS disconnect the electrical supply before

attempting to operate, service, or perform any

maintenance. If the power source is out of sight, lock and tag in the open

(off) position to prevent unexpected power application. Failure to do so

WILL result in fatal electrical shock. Only qualified electricians SHOULD

repair this unit. Improper repair WILL result in fatal electrical shock.

BRUSH REPLACEMENT

Brushes for this pump SHOULD be inspected

after 100 hours of operation.

Pumps with excess of 100 hours of operation may stop operating

or fail to start. This could be due to worn brushes or carbon buildup. The brushes should be removed and carbon removed. Worn

brushes are not covered under warranty. Replacement brushes may

be available from WAYNE Pumps. Call 1-800-237-0987 to order.

1) Disconnect electrical cord from power supply.

2) Remove brush caps with screwdriver.

3) Remove old brush assembly.

4) Replace brushes, make sure springs do not pinch during

assembly. Align/center tabs on the back of the brush spring

with the flats on the brush hlder. REF. fig3.

5) Replace brush caps.

For other problems, consult troubleshooting chart.

PC4

NOTES

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

www.waynepumps.com

3

Page 4

Operating Instructions and Parts Manual

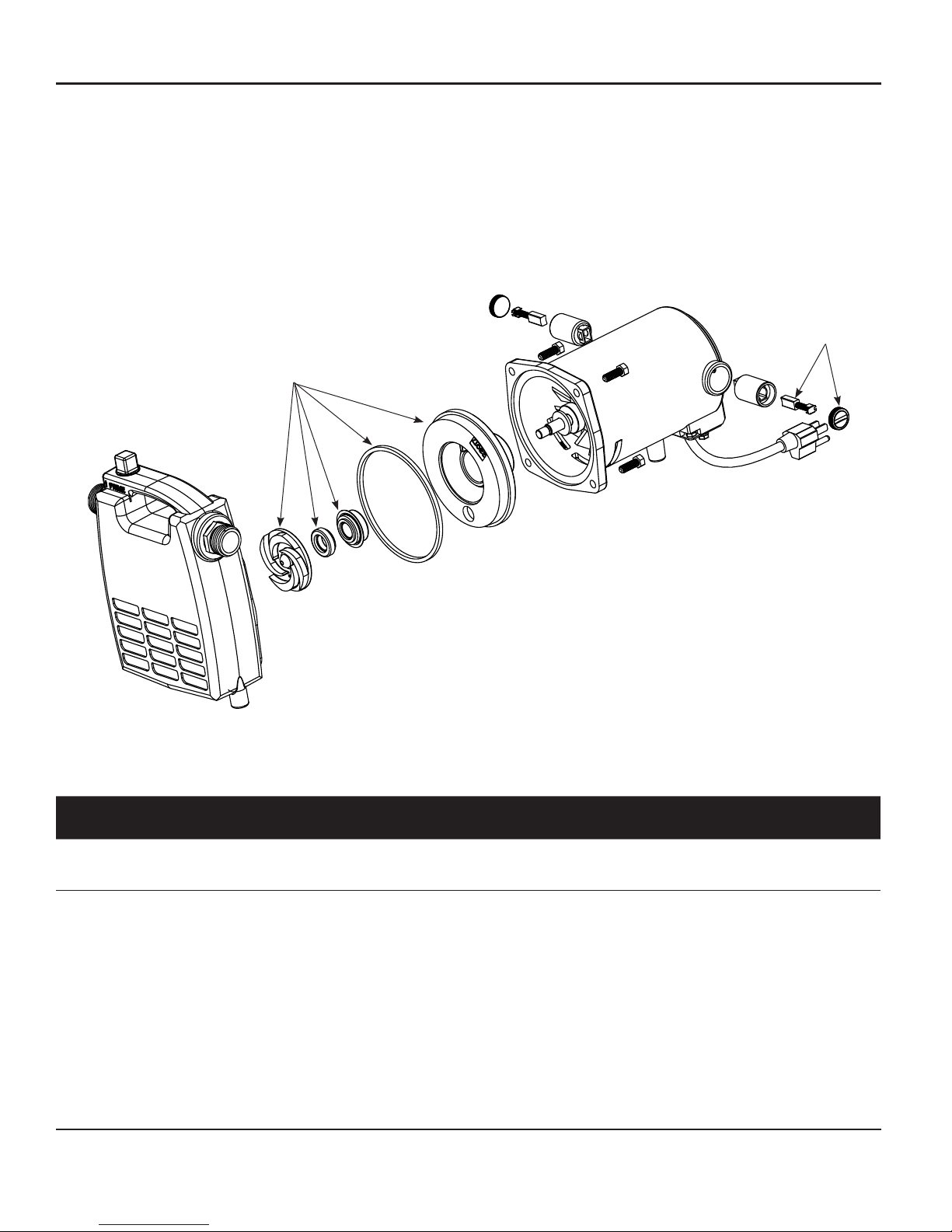

SERVICE PART REPLACEMENT

1. Make sure the pump is unplugged and cooled down before

disassembling the pump.

2. Release any pressure from the pump then disconnect any

hoses or plumbing, and drain the product.

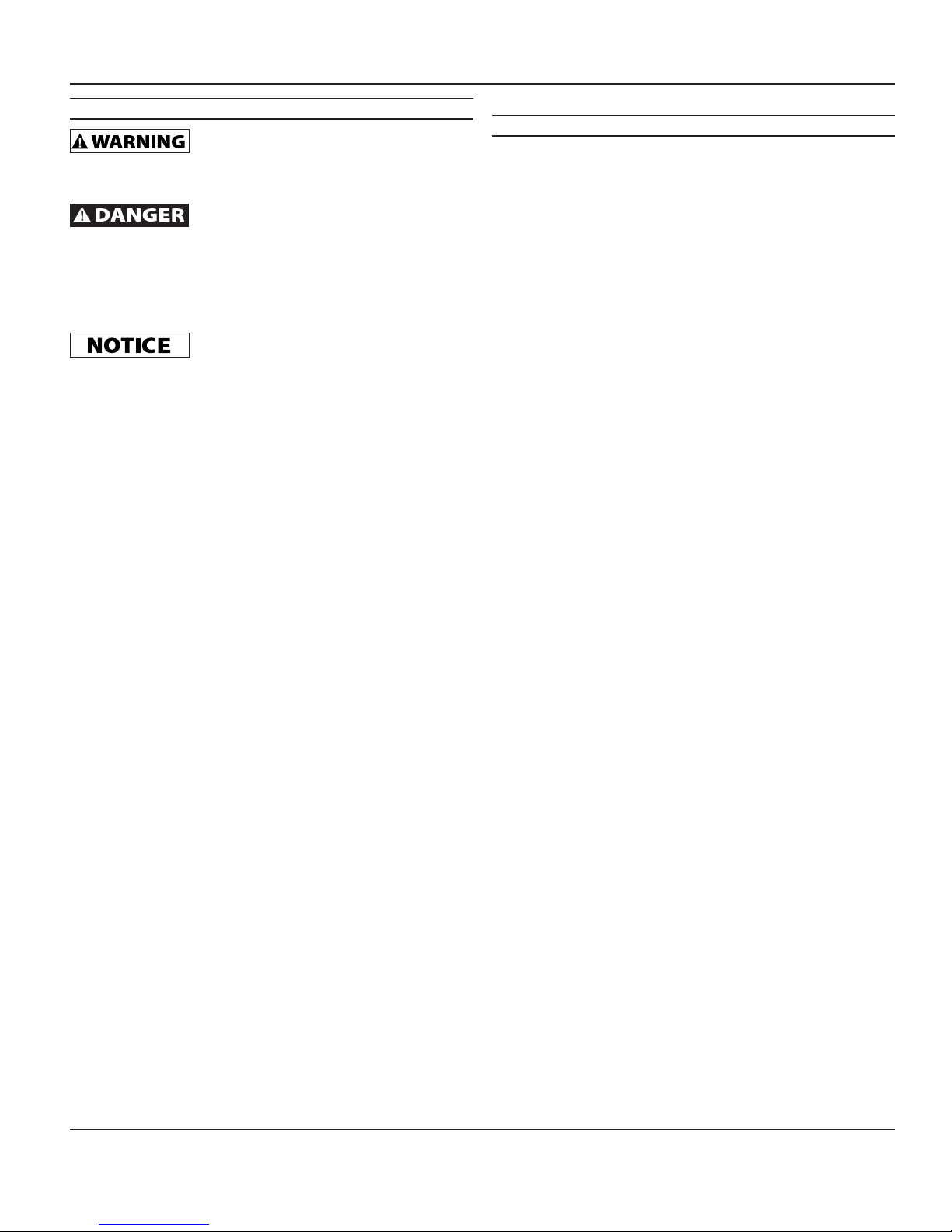

3. Remove brush holder caps and brushes (make note of which

side of the pump the brush was in also the orientation of the

brush as you will want to put them back the same way they

came out.) Ref fig.3. Remove the (4) ¼-20 screws and lock

washers holding the volute to the motor housing. Ref fig.4

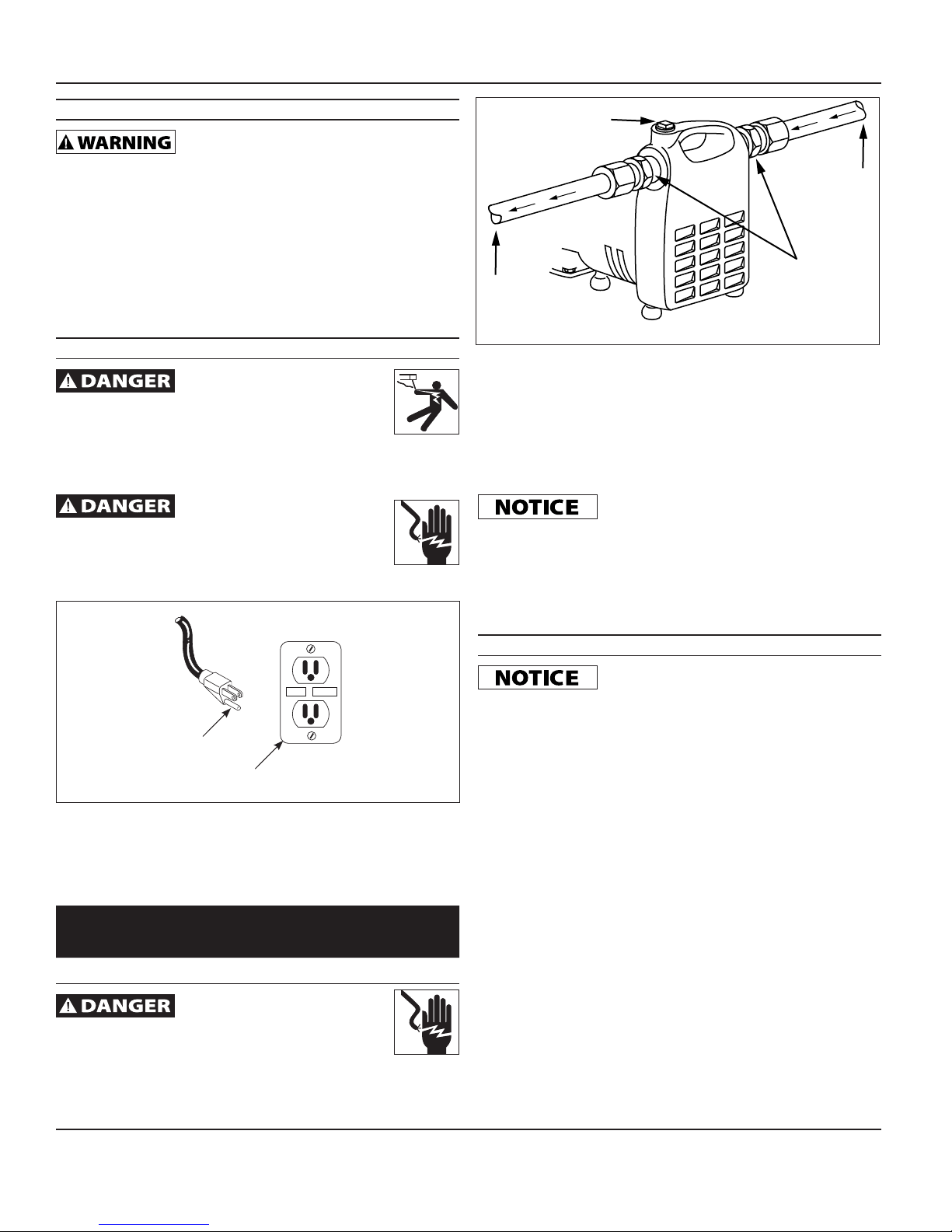

IMPELLER

HEAD SEAL

CERAMIC SEAL

LOOSE

ROTOR ASSEMBLY

THRUST WASHER

BRUSH HOLDER CAP

BRUSH

ALIGN TABS ON BRUSH

WITH FLATS ON BRUSH HOLDER

Figure 3

VOLUTE

GASKET

Figure 4

1/4-20 SCREW

WASHER

PRIMING FEATURE

MOTOR HOUSING

Figure 5

TIGHT

7. Holding the rotor assembly with one hand unscrew the impeller

from the rotor shaft. (Do not use a vise or other such device to

hold the rotor as it may damage the rotor.)

8. Remove both parts of the seal assembly from the back head

and impeller.

9. Push the new head seal (part with the blue metal housing) over

the rotor shaft and into the back head making sure the flange

on the seal seats against the back head and making sure the

black carbon side of the seal is facing away from the back head

towards the impeller.

10. Push the ceramic seal into the impeller pocket making sure the

white ceramic surface faces away from the back of the impeller.

11. Holding the rotor with one hand thread the new impeller onto

the rotor shaft making sure it is tight on the shaft and the white

face of the ceramic seal contacts the black carbon face of the

head seal.

12. Make sure the thrust washer is in the bearing pocket in the

back of the motor housing and guide the rotor assembly back

into the motor housing. Make sure the priming feature on the

back head is on the bottom of the pump, the pump won’t

prime properly if this isn’t in the correct location.

13. Put the new gasket on the motor housing then reattach the

volute to the motor housing using the four ¼-20 screws and

lock washers. Torque the screws to 75 in. lbs.

14. Replace the brushes and caps, make sure to put them back

in the same way they came out. Make sure the springs do not

pinch during assembly and align/center the tabs on the back of

the brush spring with the flats on the brush holder. Ref. fig.3

15. Test thoroughly and check for leaks before use.

4. Remove the volute.

5. Remove the gasket and discard.

6. Remove the rotor assembly from the motor housing. There is

a thrust washer in the bearing pocket at the back of the motor

housing, if the thrust washer falls out make sure it is put back

into the pocket before reassembling. Ref fig.5

www.waynepumps.com

4

Page 5

PC4

TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action

Pump will not start or run 1. Blown fuse 1. If blown, replace with proper sized fuse or reset

2. Low line voltage 2. Contact an electrician

3. Worn brushes 3. Replace brushes

4. Impeller blocked 4. Remove blockage

5. Defective motor 5. Replace pump

Pump will not prime or retain prime after

operating

Flow rate is too low 1. Piping or hose is fouled or damaged 1. Clean or replace

Seal leaks 1. Worn seal 1. Replace seal

Thermal Protector Tripping 1. Damage or misalignment causing rotating

1. Air leak in suction line 1. Repair or replace suction line (use plumbers

2. Impeller blocked 2. Remove blockage

3. Worn seal 3. Replace seal

4. Suction lift too high 4. Lower pump

5. Hose kinked or looped 5. Straighten hose

6. Fittings not tight 6. Tighten fittings

7. Suction hose out of water 7. Submerge suction hose end

8. Clogged inlet 8. Clean inlet

2. Low line voltage 2. Contact an electrician

2. Backhead damaged or cracked 2. Replace backhead

3. Pump head loose on motor 3. Insure proper assembly and no obstruction,

parts to bind

2. High surrounding temperature 2. Provide a shaded, well-ventilated area for pump

3. Low line voltage 3. Contact an electrician

4. Motor housing air-vents blocked 4. Remove air-vent blockage

breaker

tape to install garden hose adpater fittings and

priming plug onto pump body)

tighten bolts

1. Take to motor repair shop or locate and repair

mechanical binding

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual

For Replacement Parts or Technical Assistance,

For Replacement Parts or Technical Assistance,

call 1-800-237-0987

call 1-800-237-0987

Please provide following information:

Please provide following information:

- Model number

- Model number

- Serial number (if any)

- Serial number (if any)

- Part description and number as shown in parts list

- Part description and number as shown in parts list

2

Address parts correspondence to:

Address parts correspondence to:

Wayne Water Systems

Wayne Water Systems

101 Production Drive

101 Production Drive

Harrison, OH 45030 U.S.A.

Harrison, OH 45030 U.S.A.

1

REPLACEMENT PARTS LIST

Ref.

No. Description Part Number Qty.

1

2

Note: Replacement parts are available in kit form only

www.waynepumps.com

Brush kit 62015-WYN1 1

Impeller and seal kit 56671-WYN1 1

6

6

Page 7

PC4

Limited Warranty

For one year from the date of purchase, WAYNE Water Systems (“WAYNE”) will repair or replace, at its option, for the original purchaser any part or

parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by WAYNE to be defective in materials or workmanship. Please call

WAYNE (800-237-0987) for instructions or see your dealer. Be prepared to provide the model number when exercising this warranty. All transportation

charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation,

improper maintenance, or failure to operate in accordance with WAYNE’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE REMEDY

AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of incidental or consequential

damages, so the above limitations might not apply to you. This limited warranty gives you specific legal rights, and you may also have other legal rights

which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE or its suppliers be liable for any

special, consequential, incidental or penal damages including, but not limited to loss of profit or revenues, loss of use of the products or any associated

equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities, services or replacement power, downtime costs, or

claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of the

purchase receipt along with the material or correspondence. Please call WAYNE (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. _____________________ SERIAL NO. ________________________ INSTALLATION DATE _____________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

7

Page 8

Operating Instructions and Parts Manual

NOTES

www.waynepumps.com

8

Page 9

Bomba Portátil de Servicio con

Sistema de Cebado Automático

MANUAL DE INSTRUCCIONES DE FUNCIONAMIENTO Y

EZAS DE REPUESTOI

LEA, ENTIENDA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL. NO LO DESECHE. .

LEA, ENTIENDA Y SIGA TODAS LAS INSTRUCCIONES DE ESTE MANUAL. NO LO DESECHE. .

No seguir estas instrucciones podría provocar daño a la unidad, lesiones graves o la muerte.

No seguir estas instrucciones podría provocar daño a la unidad, lesiones graves o la muerte.

Model #

PC4

DESCRIPCIÓN

Las bombas portátiles de servicio con sistema de cebado automático

están diseñadas para usarse como bombas de desagüe para vaciar

calentadores de agua, tanques para animales, etc. Igualmente, las

bombas se pueden usar de modo intermitente para lavar coches, limpiar

entradas de garajes, etc. El motor se enfría con aire y no está diseñado

para operar bajo agua.

NOTA: Este bomba no está diseñada para una instalación permanente o

para períodos de trabajo continuo largos y extendidos.

PARA DESEMPACAR

Después de desempacar la bomba de uso general, inspecciónela

cuidadosamente para detectar cualquier daño que pueda haber ocurrido

durante el transporte. Verifique que no haya piezas sueltas, dañadas o

faltantes. Si necesita asistencia, llame a nuestro Departamento de Servicio

al Cliente al 1-800-237-0987.

MEDIDAS DE SEGURIDAD

Para ayudar a reconocer esta información, observe las siguientes señales/

clasificaciones de riesgos..

Peligro indica una situación inminentemente

peligrosa, la cual, si no se evita, TENDRÁ como

resultado la muerte o una lesión grave.

Advertencia indica una situación

potencialmente peligrosa, la cual, si no se evita,

PODRÍA resultar en la muerte o una lesión grave.

Ésto le indica que hay una situación que

PODRIA ocasionarle heridas no muy graves.

Aviso indica información importante, que si no

se respeta, puede causar daño al equipo.

Este es el símbolo de alerta de seguridad. Se utiliza para alertarle

sobre los peligros potenciales de lesiones corporales. Obedezca

todos los mensajes de seguridad que siguen a este símbolo para

evitar posibles daños.

NOTA: Información que requiere atención especial.

INFORMACIONES GENERALES DE SEGURIDAD

PROPOSICIÓN 65 DE CALIFORNIA

Este producto o su cable de corriente

contienen químicos, incluido plomo, que son

conocidos por el Estado de California como causantes de cáncer y

defectos de nacimiento u otros daños reproductivos. Use guantes al

manipular este producto y lávese las manos después de manipularlo.

SEGURIDAD GENERAL

NO sumerja el motor ni permita que el motor

esté expuesto al agua. CAUSARÁ lesiones

corporales y/o la muerte.

NO la use para bombear fluidos inflamables o explosivos,

como gasolina, aceite combustible, queroseno, etc. NO la

use en una atmósfera inflamable o explosiva. La bomba sólo

DEBE usarse para bombear agua limpia. CAUSARÁ lesiones corporales

y/o la muerte.

Peligro de electrocutamiento. Un electricista

calificado debe realizar TODO el cableado.

NO camine sobre áreas húmedas sino después de que

TODAS las fuentes de electricidad estén apagadas. El

desobedecer esta advertencia CAUSARÁ un choque

eléctrico mortal.

1. Lea todas las instrucciones antes de comenzar a usar la

bomba.

2. Desconecte el cordón eléctrico y libere toda la

presión del sistema antes de darle servicio a cualquier

componente.

3. Drene todos los líquidos del sistema antes de darle servicio.

Motor Monofásico - 115V, 60 Hz, 8,000 R.P.M. Caballos de Fuerza 1/2 CP

Motor Serie Wound (con escobillas) CA/CD Oricios de Entrada/Salida 19,1 mm (3/4 pulg) NPT

Propela Termoplástico Envoltura de la Bomba Hierro colado

Cubierta del Motor Hierro colado Eje del Motor Acero laminado en frío

Sellos del eje y la

Voluta

Temp. Máx. del

Fluído

RECORDATORIO: ¡Conserve su prueba de compra fechada para la garantía! Adjúntela a este manual o archívela para conservarla de forma segura.

RECORDATORIO: ¡Conserve su prueba de compra fechada para la garantía! Adjúntela a este manual o archívela para conservarla de forma segura.

© 2016,

© 2016,

WAYNE/Scott Fetzer Company.

WAYNE/Scott Fetzer Company.

Buna-N Cojinetes del Motor Lubricados de por Vida

49ºC (120ºF)

Para obtener información sobre piezas de repuesto, productos y servicio, visite www.waynepumps.com

Especicaciones

Sp-9

Sp-9

Rodamientos de bola

Page 10

Manual de instrucciones de funcionamiento y piezas de repuesto

INFORMACIONES GENERALES DE SEGURIDAD

(CONTINUACION)

Asegure la línea de descarga antes de dar

arranque a la bomba. Si no la asegura, ES

POSIBLE que se sacuda bruscamente y PODRÍAN causarse lesiones

personales y/o daños a la propiedad.

4. Periódicamente inspeccione la bomba y los componentes, chequée

si las mangueras están debilitadas o desgastadas. Cerciórese de

que todas las conecciones estén bien apretadas.

El motor de la bomba está equipado con un

circuito protector térmico de reconfiguración

automática y ES POSIBLE que se reactive repentinamente. La

desconexión del circuito protector indica un recalentamiento del motor

debido a que la bomba está funcionando con presión hidrostática

baja (restricción de descarga baja), voltaje excesivamente alto o bajo,

cableado inadecuado, temperatura excesiva del aire circundante,

ventilación inadecuada y/o motor o bomba defectuosos.

5. Cerciórese de que haya una forma de liberar la presión en caso de

que la línea de descarga se obstruya.

6. Proteja los cordones eléctricos contra objetos afilados, superficies

calientes, aceite y químicos. Evite que el cordón se enrolle y

reemplace los cordones dañados inmediatamente.

INSTALACIÓN

SIEMPRE desconecte la fuente de energía antes de intentar

operar o reparar la bomba, o darle mantenimiento. NUNCA

manipule la bomba con las manos húmedas o cuando se

encuentre sobre una superficie húmeda o mojada, ni dentro del agua.

OCURRIRÁ un choque eléctrico mortal.

1. Necesita usar un cortacircuito automático con conexión a tierra.

¡Peligro de morir electrocutado! Esta bomba tiene un conductor

para conexión a tierra y un enchufe para conexión a tierra. Debe

utilizar un tomacorrientes que cumpla con los códigos vigentes

nacionales (NEC en EE.UU.) y locales (Vea la Figura 1).

2. Esta bomba sólo se debe usar con circuitos de 115 voltios

(monofásicos), 60 Hz CA, ó 115 voltios CD.

RESET

TEST

Tabla de las Longitudes de los Cordones de Extensión

Tamaño del

alambre #18 #16 #14 #12

Longitud 8 m 15 m 31 m 45 m

Riesgo de choque eléctrico mortal. NUNCA corte la clavija

redonda de conexión a tierra. Si corta el cable o el enchufe, SE

ANULARÁ la garantía y hará que la bomba no funcione.

4. La Figura 2 le indica cómo instalar la bomba. Los adpatadores con

roscas se le suministran para que conecte mangueras para jardín

cuando las condiciones lo permitan. En ningún caso la bomba debe

colocarse a más de 4,5 m (15 pies) de distancia o de altura con

respecto a la entrada de agua. Instale una válvula de pie cuando la

altura de succión sea superior a los 3 m (10 pies) o cuando la línea

de succión tenga más de 3 m (10 pies) de largo.

TAPÓN DEL

SISTEMA DE

CEBADO

ENTRADA

SALIDA

Figura 2

ADAPTADORES

DE MANGUERA

5. La línea de entrada puede ser un tubo galvanizado o de plástico, o

una manguera reforzada. Las fugas pequeñas en la línea de succión

reducen en gran medida la eficiencia de la bomba y pueden impedir

el cebado.

Las mangueras de jardín normales

COLAPSARÁN con la presión de succión; por lo

tanto, NO DEBEN usarse para la línea de entrada, con excepción de los

sistemas para aumentar la presión.

6. Use un colador cuando vaya a bombear agua de un riachuelo,

charca o cualquier sitio donde pueda haber basura que podría

obstuir la bomba. El colador debe evitar la entrada de sólidos a la

línea de entrada de la bomba.

7. Puede usar una manguera común para jardines como línea de

descarga.

TERMINAL PARA

CONEXIÓN A TIERRA

Figura 1

TOMACORRIENTES GFCI

(CONECTADO A TIERRA)

3. Use un cordón de extensión sólo cuando sea necesario. Use

cordones de extensión, de tres alambres para conexión a tierra que

sean de la longitud y calibre indicados en la Tabla de cordones de

extensión.

www.waynepumps.com

FUNCIONAMIENTO

Debe llenar la bomba de agua antes de

encenderla. Hacer funcionar la bomba en seco

CAUSARÁ daños en el sello del eje.

1. Esta unidad no es a prueba de agua o a prueba de intemperie y no

está diseñada para usarse en duchas, saunas, ni ningún sitio donde

se pueda mojar. El motor está diseñado para usarse en sitios limpios

y secos donde tenga acceso a aire adecuado para enfriarlo. La

temperatura ambiental alrededor del motor no debe exceder 40˚C

(104˚F).

Sp-10

Page 11

PC4

2. Quítele el tapón al sistema de cebado y llénelo de agua. Vuelva a

colocar el tapón (se debe usar cinta de sellado de plomería en el

tapón de cebado para evitar fugas de aire).

3. Conecte el cordón eléctrico a un tomacorrientes con cortacircuito

automático con conexión a tierra. La bomba completará el proceso

de cebado en pocos minutos, dependiendo de la longitud de la

línea de succión. Le recomendamos que use una válvula de pie en

la línea de succión.

4. En caso de que la vaya a usar para aumentar la presión de agua,

abra la llave de agua antes de encender la bomba. La bomba

se cebará con la presión del agua. Después, conecte el cordón

eléctrico a un tomacorrientes a un tomacorrientes con cortacircuito

automático con conexión a tierra.

5. Desconecte el cordón para apagar la unidad.

MANTENIMIENTO

Debe esperar por lo menos 20 minutos para que

la bomba se enfrie antes de darle servicio. ES

POSIBLE que el motor esté muy caliente. ES POSIBLE causar lesiones

personales.

1. Debe chequear la boomba periódicamente para ver si está

funcionando adecuadamente.

SIEMPRE desconecte el suministro de corriente

antes de intentar operar, efectuar reparaciones

o realizar cualquier tipo de mantenimiento. Si la fuente de energía está

fuera de la vista, bloquéela y etiquétela en la posición abierta (off)

para evitar que se suministre corriente en forma inesperada. Dejar de

hacer esto CAUSARÁ un choque eléctrico mortal. Esta unidad DEBE

ser reparada únicamente por electricistas calificados. La reparación

incorrecta CAUSARÁ un choque eléctrico mortal.

PARA REEMPLAZAR LAS ESCOBILLAS

Las escobillas de esta bomba DEBEN

inspeccionarse después de 100 horas de

funcionamiento.

Después de 100 horas de funcionamiento la bomba podría dejar de

funcionar o no encender. Ésto podría ser debido al desgasto de las

escobillas o a la acumulación de carbón. Debe desmontarle las escobillas

y quitarle los residuos de carbón. Las escobillas no están cubiertas en

la garantía. Para ordenar escobillas de repuesto comuníquese con el

distribuidor de bombas WAYNE más cercano a su domicilio. En EUA

llame al 1-800-323-0620 para ordenarlas.

1.) Desconecte el cordón eléctrico del tomacorrientes.

2.) Use un desarmador para quitarle las tapas a las escobillas.

3.) Saque el ensamblaje de las escobillas usadas.

4.) Reemplace los cepillos, asegúrese de que los resortes no queden

mordidos durante el ensamblaje. Alinee/centre las langüetas detrás

del resorte del cepillo con las superficies planas del sujetador del

cepillo. Ref. Fig 3.

5.) Colóquele las tapas de las escobillas.

Si tiene otros problemas, consulte la guía de diagnóstico de averías

NOTAS

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

www.waynepumps.com

Sp-11Sp-11

Page 12

Operating Instructions and Parts Manual

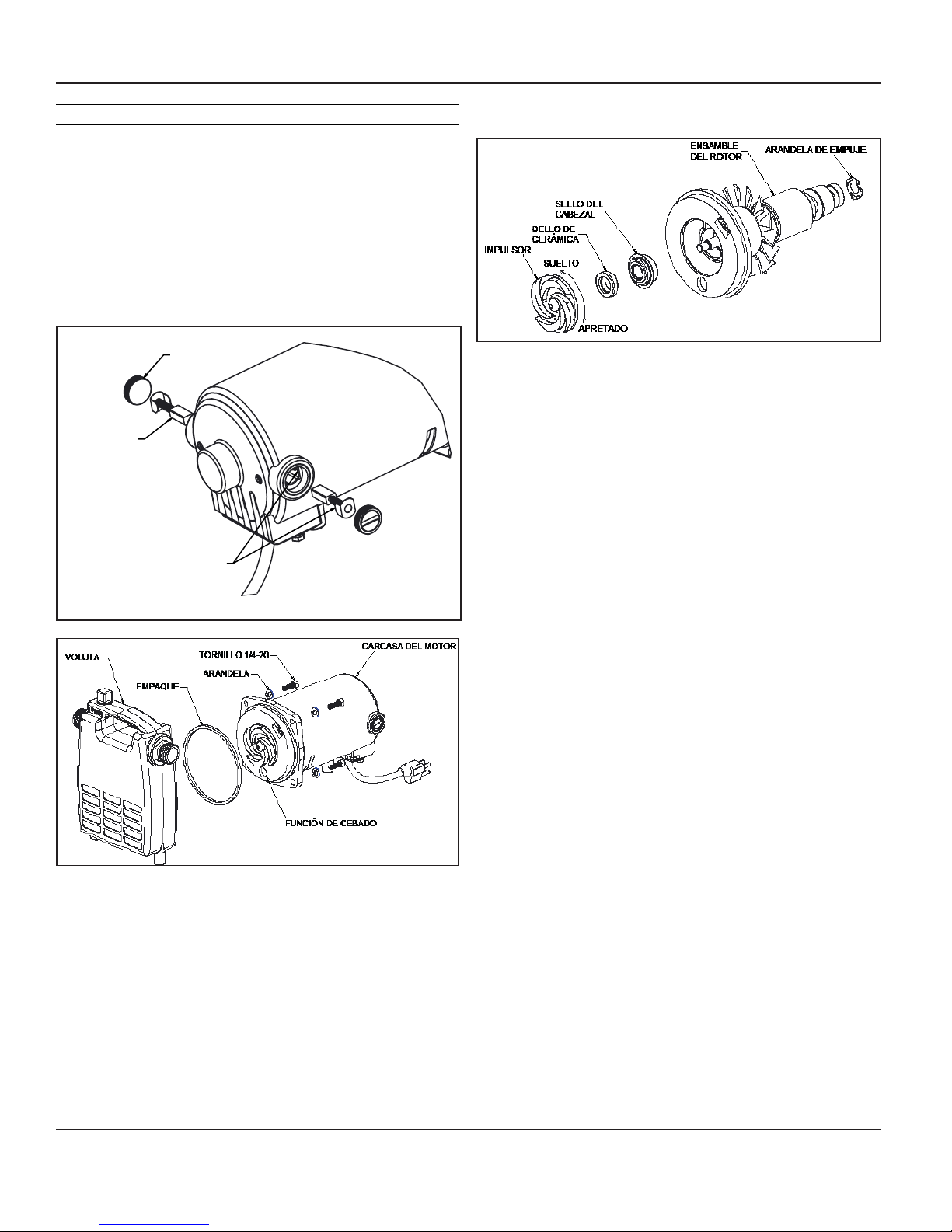

REEMPLAZO DE PIEZAS DE REPUESTO

1. Asegúrese de que la bomba esté desconectada y fría antes de

desarmarla.

2. Libere toda la presión de la bomba y luego desconecte las

mangueras o tuberías, y drene el producto.

3. Retire las tapas de los soportes de las escobillas y las escobillas

(tome nota de qué lado de la bomba estaban las escobillas,

así como la orientación de las mismas, ya que las volverá a

colocar de la misma manera en que las quitó). Consulte la fig.

3. Quite los (4) tornillos ¼-20 y las arandelas de seguridad que

sostienen la voluta a la carcasa del motor. Consulte la fig. 4

TAPA DEL SOPORTE

DE LAS ESCOBILLAS

ESCOBILLAS

ALINEE LAS LENGÜETAS DE LAS

ESCOBILLAS CON LAS ÁREAS PLANAS

DEL SOPORTE DE LAS ESCOBILLAS

Figura 3

Figura 4

4. Quite la voluta.

5. Quite el empaque y deséchelo.

6. Retire el ensamble del rotor de la carcasa del motor. Hay una

arandela de empuje en la cavidad del rodamiento situada en

la parte posterior de la carcasa del motor, si la arandela de

empuje se cae, asegúrese de colocarla de nuevo en la cavidad

antes de volver a armar la bomba. Consulte la fig. 5

Figura 5

7. Sosteniendo el ensamble del rotor con una mano, desenrosque

el impulsor del eje del rotor. (No use un tornillo de banco u otro

dispositivo similar para sostener el rotor, pues puede dañarlo).

8. Quite ambas piezas del ensamble del sello del cabezal trasero y

del impulsor.

9. Empuje el nuevo sello del cabezal (parte con la caja de metal

azul) sobre el eje del rotor y hacia dentro del cabezal trasero,

asegurándose de que la brida del sello se asiente contra el

cabezal trasero y asegurándose de que el lado de carbón

negro del sello esté orientado lejos del cabezal trasero y hacia

el impulsor.

10. Empuje el sello de cerámica hacia dentro de la cavidad del

impulsor, asegurándose de que la superficie de cerámica

blanca esté orientada hacia la parte trasera del impulsor.

11. Sosteniendo el rotor con una mano, enrosque el nuevo

impulsor sobre el eje del rotor, asegurándose de que esté

apretado sobre el eje y la cara blanca del sello de cerámica esté

en contacto con la cara de carbón negro del sello del cabezal.

12. Asegúrese de que la arandela de empuje esté en la cavidad del

rodamiento situada en la parte trasera de la carcasa del motor y

guíe el ensamble del rotor de nuevo hacia dentro de la carcasa

del motor. Asegúrese de que la función de cebado del cabezal

trasero esté en la parte inferior de la bomba; la bomba no se

cebará correctamente si esto no está en el lugar correcto.

13. Coloque el nuevo empaque en la carcasa del motor, luego

vuelva a sujetar la voluta a la carcasa del motor usando los

cuatro tornillos ¼-20 y las arandelas de seguridad. Apriete los

tornillos a un torque de 75 pulg. lb.

14. Vuelva a colocar las escobillas y tapas, asegúrese de colocarlas

de nuevo de la misma manera en que las quitó. Asegúrese

de que los resortes no pellizquen algo durante el ensamble y

alinee/centre las lengüetas en la parte trasera del resorte de las

escobillas con las áreas planas en el soporte de las escobillas.

Consulte la fig. 3

15. Pruebe por completo y verifique que no haya fugas antes de

usarla.

www.waynepumps.com

Sp-12

Page 13

TABLA DE IDENTIFICACIÓN DE PROBLEMAS

Síntoma Causa(s) Posible(s) Medida Correctiva

La bomba no se

enciende ni funciona

La bomba no se ceba o

lo pierde después de

funcionar

El flujo es muy bajo 1. Las tuberías o mangueras están obstruídas

Los sellos tienen fugas 1. El sello está desgastado 1. Reemplace el sello

Desconexión del circuito protector térmico 1. Daño o desalineación que hace que las

1. Un fusible quemado 1. Si está quemado, reemplácelo con un fusible

adecuado o active el cortacircuito

2. El voltaje es muy bajo 2. Póngase en contacto con un electricista

3. Las escobillas están desgastadas 3. Reemplace las escobillas

4. La propela está obstruída 4. Quítele lo que la está obstruyendo

5. El motor está dañado 5. Reemplace la bomba

1. Hay fuga de aire en la línea de succión 1. Repare o reemplace la línea de succión (use

cinta de plomería para instalar en el cuerpo de la

bomba los adaptadores de la manguera de jardín

y el tapón de cebado)

2. La propela está obstruída 2. Quítele lo que la está obstruyendo

3. El sello está desgastado 3. Reemplace el sello

4. El nivel de succión es muy alto 4. Coloque la bomba en un sitio más bajo

5. La manguera está enrollada 5. Enderece la manguera

6. Las conexiones están flojas 6. Apriete las conexiones

7. La manguera de succión no tiene agua 7. Sumerja el extremo de la manguera de succión

8. El orificio de entrada está obstruído 8. Limpie el orificio de la entrada

o dañadas

2. El voltaje es muy bajo 2. Póngase en contacto con un electricista

2. Cabezal dañado o partido 2. Cambie el cabezal

3. La bomba está mal conectada al motor 3. Cerciórese de que esté bien conectada y que no

piezas giratorias se atasquen

2. Temperatura circundante alta 2. Proporcione un área con sombra y bien ventilada

3. Bajo voltaje de la línea 3. Póngase en contacto con un electricista

4. Agujeros de ventilación de la caja del motor

bloqueados

1. Límpielas o reemplácelas

esté obstruída, apriete los pernos

1. Lleve el motor al taller de reparaciones o ubique

y repare el atascamiento mecánico

para la bomba

4. Quite el bloqueo de los agujeros de ventilación

Sp-13

Sp-13

www.waynepumps.com

Page 14

Manual de instrucciones de funcionamiento y piezas de repuesto

Para Ordenar Repuestos o Asistencia Técnica, Sírvase Llamar al

Para Ordenar Repuestos o Asistencia Técnica, Sírvase Llamar al

Distribuidor Más Cercano a Su Domicilio

Distribuidor Más Cercano a Su Domicilio

Sirvase darnos la siguiente información: Dirija toda la correspondencia a:

- Número del modelo Wayne Water Systems

- Código impreso 101 Production Drive

- Descripción y número del repuesto según la lista de repuestos Harrison, OH 45030 U.S.A.

2

1

LISTA DE PARTES DE REPARACIÓN

No. de

Ref. Descripción Número de Parte Ctd.

1

2

Nota: Los repuestos sólo están disponibles en juegos

www.waynepumps.com

Juego de escobillas 62015-WYN1 1

Juego de propela y sellos 56671-WYN1 1

Sp-14

Sp-14

Page 15

NOTES

PC4

www.waynepumps.com

Sp-15

Page 16

PC4

Manual de instrucciones de funcionamiento y piezas de repuesto

Garantie Limitée

Durante un año a partir de la fecha de compra, WAYNE Water Systems (“WAYNE”) reparará o reemplazará, según lo consideren

adecuadon, cualquier pieza de esta bomba para sumideros (“Producto”) que el comprador original envie a reparación y los empleados o

representantes autorizados de WAYNE determinen que están defectuosos debido a problemas de materiales o manufactura. Para recibir

información sobre los pasos a seguir, comuníquese directamente con la compañía WAYNE (800-237-0987, sólo desde EUA), o con el

distribuidor autorizado más cercano a su domicilio. En el momento de reclamar sus derechos bajo esta garantía deberá suministrarnos

el número del modelo. Todos los gastos de flete serán la responsabilidad del comprador.

Esta garantía limitada no cubre los daños debido a accidentes, abusos, uso inadecuado, negligencia, instalación inadecuada,

mantenimiento inadecuado, o funcionamiento sin seguir las instrucciones suministradas por escrito por la compañía WAYNE.

NO HAY NINGUNA OTRA GARANTIA EXPRESA O IMPLISITA. INCLUYENDO AQUELLAS SOBRE VENTA O USOS

ESPECIFICOS, Y LAS GARANTIAS ESTAN LIMITADAS A UN AÑO A PARTIR DE LA FECHA DE COMPRA. ESTA ES LA UNICA

GARANTIA Y CUALQUIER PERDIDA O RESPONSABILIDAD CIVIL, SEA DIRECTA O INDIRECTA COMO CONSECUENCIA DE

DAÑOS SON EXCLUIDAS.

Algunos estados no permiten límites en la duración de las garantías, o no permiten que se limiten o excluyan casos por daños por

accidentes o consecuentes, en dichos casos los límites arriba enumerados tal vez no apliquen para Ud. Esta garantía limitada le otorga

a Ud. ciertos derechos que pueden variar de un estado a otro.

Bajo ninguna circunstyancia, aunque sea debido al incumplimiento del contrato de garantía, culpabilidad (incluyendo negligencia) u otras

causas,la compañía WAYNE o ninguno de sus surtidores serán responsables legalmente por ningún fallo legal en su contra, incluyendo,

pero no limitado apérdida de ganancias, pérdidas del uso del producto o piezas asociadas con el equipo, pérdidas de capital, gastos

para reemplazar los productos dañados, pérdidas por cierre de fábrica, servicios o pérdida de electricidad, o demandas persentadas por

los clientes del comprador por dichos daños.

Ud. DEBE conservar el recibo como prueba de compra junto con esta garantía. En caso de que necesite presentar un reclamo de

sus derechos bajo esta garantía, Ud DEBERA enviar una copia del recibo de la tienda junto con el producto o correspondencia.

Comuníquese con la compañía WAYNE (800-237-0987, sólo desde EUA) para recibir autorización e instrucciones de como enviar la

mercancía.

NO ENVIE ESTA GARANTIA A WAYNE. Use este documento sólo para mantener sus records.

NO. DEL MODELO _____________________ NO. DE SERIE ________________________ FECHA DE INSTALACION __________________

ANEXE SU RECIBO AQUI

www.waynepumps.com

www.waynepumps.com

Sp-16Sp-16Sp-16

Loading...

Loading...