Page 1

Operating Instructions and Parts Manual JSU50

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Jet Pump

Description

These pumps are single stage domestic

water pumps designed for pumping

potable water. Shallow well pumps are

designed for applications where the

water level is less than 25 feet below the

pump. Flammable liquids such as gasoline,

chemicals, or corrosive liquids should never

be used with these pumps.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, call

Customer Service at 1-800-237-0987.

Safety Guidelines

This manual contains information

that is very important to know

and understand. This information

is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS. To

help recognize this information, observe

the following symbols.

Danger indicates an

imminently

hazardous situation which, if NOT

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if NOT

avoided, COULD result in death or serious

injury.

Caution indicates a

potentially

hazardous situation which, if NOT

avoided, MAY result in minor or moderate

injury.

Notice indicates

important

information, that if NOT followed, MAY

cause damage to equipment.

NOTE: Information that requires special

attention.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product

contains chemicals,

including lead, known to the State of

California to cause birth defects and

other reproductive harm. Wash hands

after handling.

1. Read these rules and instructions

carefully. Failure to follow these

instructions COULD cause serious

bodily injury and/or property

damage.

This pump is non-

submersible.

Install indoors only

or in a pump house.

Risk of electrical shock.

Pump only clear water. Do

NOT pump flammable or

explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do NOT

use in a flammable and/or explosive

atmosphere. Personal injury and/or

property damage WILL result.

This pump is

not designed

to handle salt water, brine, laundry

discharge, or any other application

which may contain caustic chemicals

and/or foreign materials. Pump

damage COULD occur if used in these

applications and WILL void warranty.

All wiring must be performed

by a qualified electrician. The

pump must be installed in

compliance with the National Electrical

Code and all local codes.

2. Connect this pump to a grounded

circuit equipped with a ground fault

interrupter device (GFCI).

3. Before installing this product,

have the electrical circuit checked

by an electrician to ensure proper

grounding.

Risk of electric shock! Pump

must be disconnected

from power source before

installing or servicing.

4. Be sure the water source and piping

is clear of sand, dirt, and scale.

Debris will clog pump and void

warranty.

5. Protect pump and piping from

freezing. Failure to protect from

freezing COULD cause severe

damage and will void the warranty.

6. Follow priming instructions. Do NOT

run pump dry.

Installation

Protect pump from the elements by

installing in a basement, garage, tool

shed, or pump house. Install the pump

so the centerline of the pump is as close

as possible to the water level. Keep

installation area clear to provide access

for service and maintenance. Protect

the pump against flooding and excess

moisture.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.waynepumps.com

311405-001 6/11© 2011, WAYNE/Scott Fetzer Company.

Page 2

Operating Instructions and Parts Manual JSU50

Installation (Continued)

Make sure the pump has adequate

ventilation. The surrounding

temperature should not exceed 100˚F

(38˚C) or nuisance tripping of thermal

overload protector on the motor may

occur.

PUMP PIPING INSTALLATION

Use new pipe for best results. Iron,

copper or PVC pipe may be used.

To avoid strain on the pump when

using iron or copper pipe, provide

independent supports for both suction

and discharge piping near the pump.

Minimize use of elbows and fittings

to reduce friction loss. Refer to the

friction loss chart (page 5) for specific

information. Increase diameter of

suction or discharge piping if length is

over 50 feet.

TO

WATER

LINE

TO

WELL

OR

CISTERN

Figure 1 - Pipe Installation

SUCTION PIPING

Install foot valve

or strainer screen

over intake of suction piping.

Never use pipe smaller than 1-1/4”

diameter for suction piping. Keep

suction pipe free of air leaks. For

horizontal runs, lay pipe from the water

source so the upward slope is at least

1/2" per foot. This eliminates trapped

air. The threaded inlet of the pump is

1-1/4" NPT.

Do not install

suction piping near

swimming areas.

www.waynepumps.com

DISCHARGE PIPING (FIGURE 2)

Install a 3/4” pipe cross (sold separately)

in the pump discharge. Plug top of

pipe cross with 3/4” NPT pipe plug (sold

separately). Insert tank tubing into side

opening of pipe cross. Insert pipe into

remaining side opening for connection

to home water supply line.

PIPING TO HOME

WATER SYSTEM

PIPE CROSS

PRIME

PLUG

TANK

TUBING

Figure 2

AIR VOLUME CONTROL

CONNECTION

CONNECTION TO WATER TANK

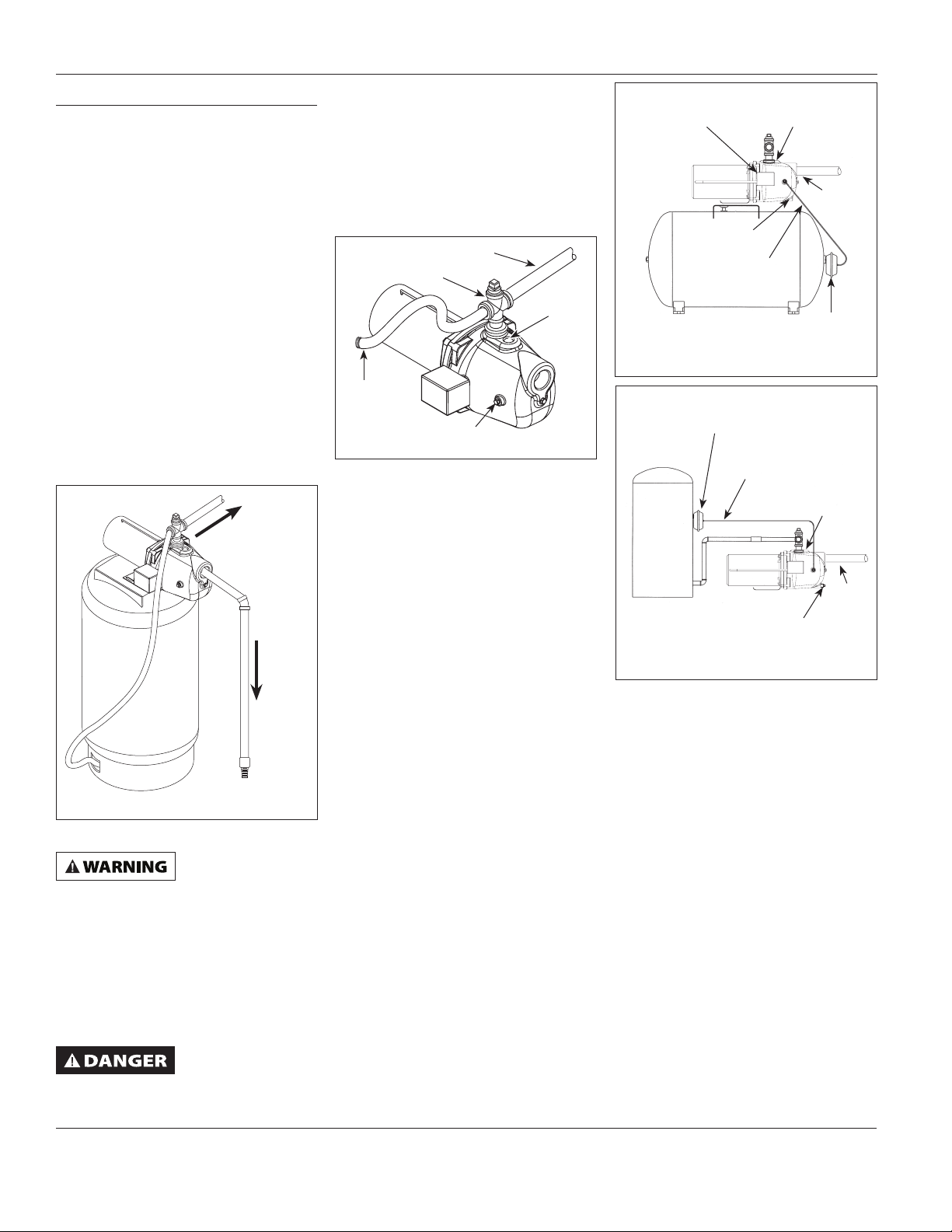

CONVENTIONAL TANK (SEE FIGURES 3

& 4)

A conventional water tank stores

water and pressurized air in the same

compartment. When full, the tank

contains approximately 2/3 water and

1/3 compressed air. This type of tank

requires an air volume control, which

automatically replaces air lost due to

leak or absorption into the water.

1. Shut off power to pump. Disconnect

and lock out power source.

2. Drain the tank. Opening faucet

nearest tank is recommended.

3. Insure tank is secured to the floor or

base.

4. Bolt pump to the floor or the

mounting bracket on tank.

5. Install air volume control on tank.

6. Connect the tube from the air

volume control to the front 1/8"

NPT opening on the side of the

pump. Connections must be tight.

Leaks will cause the pump not to

prime and/or the tank to become

waterlogged.

7. Install a valve and an isolator hose

between the tank and the house

plumbing. This will reduce the noise

level of the pump system and aid in

servicing.

8. Provide a hose bib (faucet) at the

lowest point in the system to drain

the system for service or storage.

PRESSURE

SWITCH

DRAIN FITTING

AIR VOLUME

CONTROL

TUBING

Figure 3 - Shallow Well Pump with

Conventional Horizontal Tank

AIR VOLUME

CONTROL

AIR VOLUME

CONTROL TUBING

Figure 4 - Shallow Well Pump with

Conventional Vertical Tank

PRIME PLUG

INLET

AIR VOLUME

CONTROL

PRIME

PLUG

INLET

DRAIN

FITTING

9. Slope horizontal lines up toward

pump a minimum of 1/4" per foot.

This will prevent trapping air in the

lines.

PRE-CHARGED TANK (SEE FIGURE 5)

A pre-charged water tank stores air

and water in separate compartments,

separated by a flexible bladder. The

barrier prevents the air from being

absorbed into the water. The bladder

design also allows the water to be

acted on by higher pressures for longer

periods than a conventional tank.

Pre-charged tanks have roughly twice

the usable capacity of a conventional

tank with equal volume. The air

pressure in a pre-charged tank must be

checked periodically to insure it is at an

acceptable level (See Maintenance).

1. Shut off power to pump. Disconnect

and lock out power source.

2. Drain the tank. Open faucet nearest

the tank.

2

Page 3

Operating Instructions & Parts Manual

JSU50

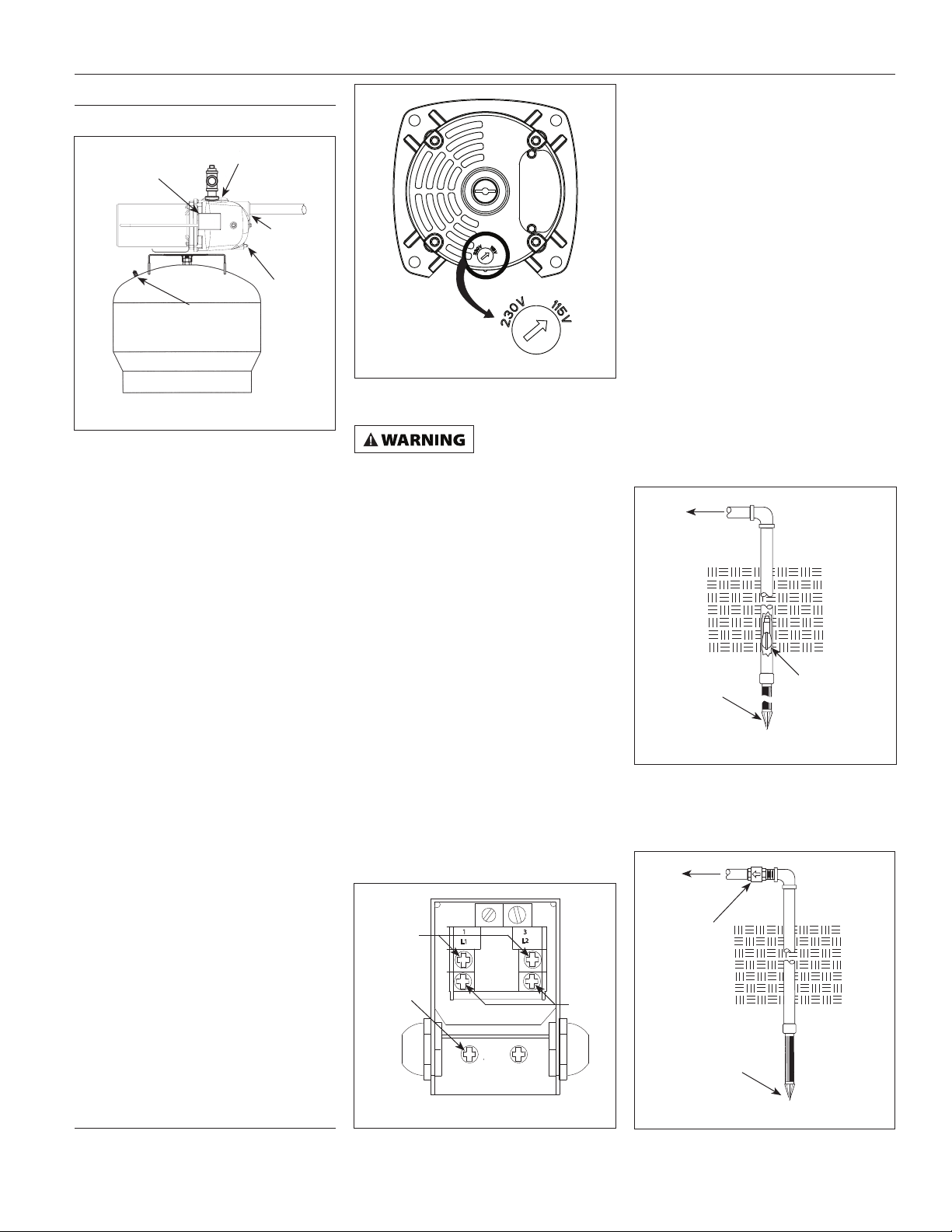

Installation (Continued)

PRESSURE

SWITCH

Air VAlVe

(28-30 PSi)

1/2 HP, 3/4 HP, & 1 HP

Figure 5 - Shallow Well Pump

Precharged Tank

3. Insure tank is secured to the floor or

base.

4. Bolt pump to the floor or the

mounting bracket on tank.

5. Set air pressure in tank to desired

level. An air valve is located on

the side and will accept a standard

fitting from a bicycle pump or air

line.

6. Install a valve and an isolator hose

between the tank and the house

plumbing. This will reduce the noise

level of the pump system and aid in

servicing.

7. Provide a hose bib (faucet) at the

lowest point in the system to drain

the system for service or storage.

8. Slope horizontal lines up toward

pump a minimum of 1/4" per foot.

This will prevent trapping air in the

lines.

ELECTRICAL CONNECTIONS

The voltage of power supply must

match the voltage of the pump. Above

ground well pumps covered in this

manual have dual voltage motors

preset at the factory to 115 volts. The

motors can be converted to 230 volts

by turning the voltage selector to the

desired voltage (See Figure 6). Use a

needle nose pliers to pull the selector

out approximately 1/4”, rotate and then

reinsert in correct position.

Connect the pump to a separate

electrical circuit with a dedicated

circuit breaker. Refer to the electrical

specifications in the Wiring Chart

PRIME PLUG

INLET

DRAIN

FITTING

Figure 6 - Voltage Selector

(on page 5) for recommended circuit

breaker and wire size.

Install and maintain

wiring for this

pump in accordance with the National

Electrical Code and all applicable local

codes.

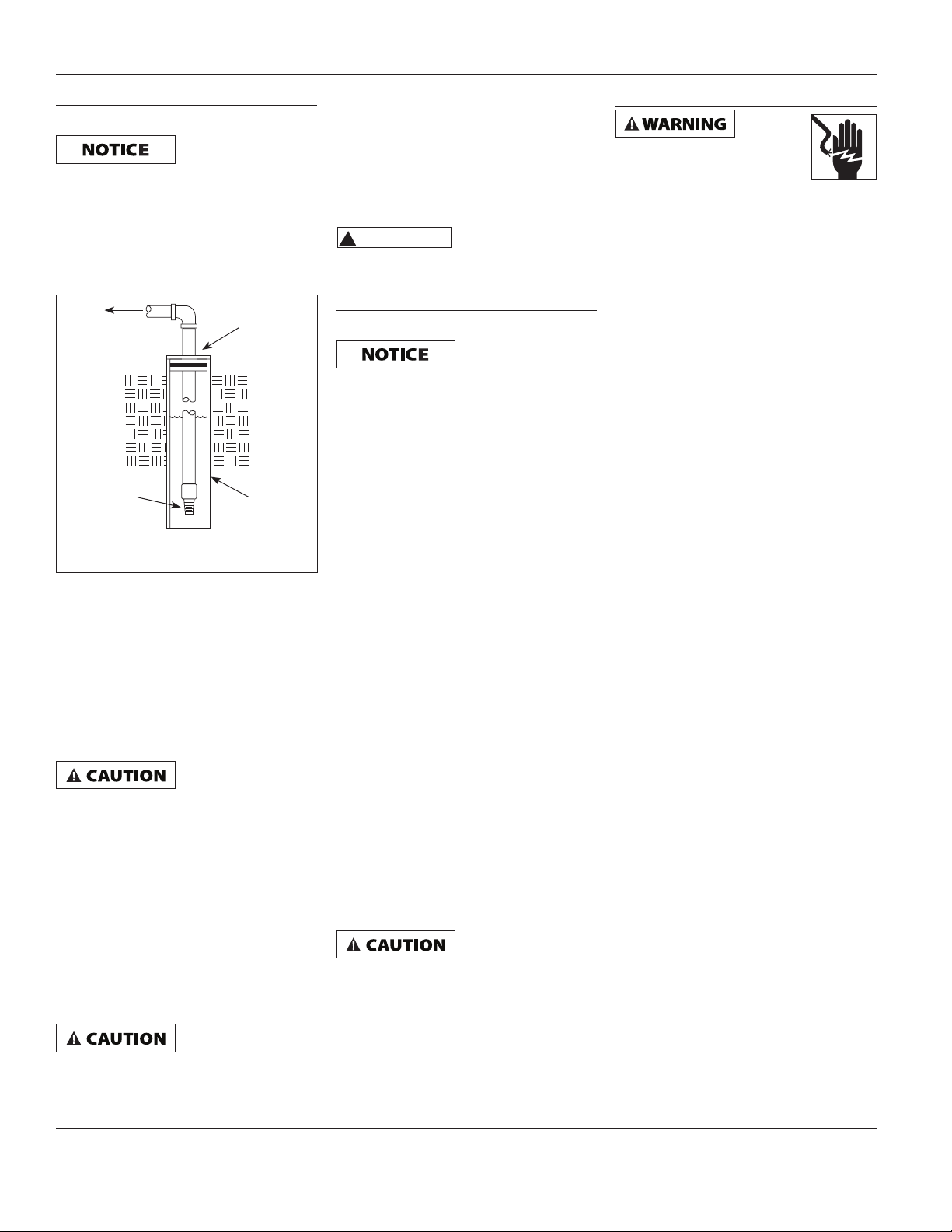

The motor must be grounded by

connecting a copper conductor to the

grounding screw provided within the

wiring compartment in the pressure

switch.

The field wiring compartment for the

jet pump is inside the pressure switch

housing. There is only one proper

ground screw on the unit. The screw is

located under the pressure switch cover,

painted green and is identified as GRD.

The ground connection must be made

to this terminal (Figure 7).

Refer to the wiring diagram located

under the cover of the pressure switch

(Figure 7).

To attach AC power to the pressure

switch, first ensure power has been

disconnected to the circuit. Loosen

the screw holding the cover onto the

pressure switch and remove the cover.

LINE

ATTACH

GROUND

WIRE

HERE

Figure 7 - Electrical Connections

1

L1

3

L2

MOTOR

Loosen unused ground screw and

attach the exposed end of the ground

wire between the screw head and the

pressure switch body, then tighten.

Loosen the top two screws on the

pressure switch and retighten with the

AC power leads captured under the

screw heads. Reattach the pressure

switch cover and tighten the screw.

CONNECTION TO WATER SOURCE

DRIVEN WELL

1. Drive the point several feet below

the water table.

NOTE: A packer-type foot valve can

be installed in the well (Figure 8). This

type of foot valve allows the well pipe

to be filled with water when priming

and makes the inlet pipe much easier to

test for leaks. Follow the manufacturer’s

instructions when installing the packertype foot valve.

TO PUMP

PACKER TYPE

DRIVE POINT

Figure 8 - Packer-Type Foot Valve

FOOT VALVE

As an alternative, an in-line check valve

can be used with a driven well (Figure

9).

TO PUMP

INLINE

CHECK

VALVE

DRIVE POINT

Figure 9 - In-Line Check Valve

www.waynepumps.com

3

Page 4

WARNING

Operating Instructions and Parts Manual

JSU50

Installation (Continued)

Do NOT use both

a check valve and

foot valve in your system. This COULD

significantly reduce the performance of

the pump.

DRILLED WELL

1. Install a foot valve on the first

section of pipe (Figure 10).

TO PUMP

FOOT

VALVE

Figure 10 - Well Seal

2. Lower the pipe into the well.

3. Add pipe until the foot valve is 10

feet below the lowest anticipated

water level.

Leaking joints or couplings will allow

air to leak into the pipe and cause poor

pump operation. Make sure to use pipe

joint compound or plumbers seal tape

on all pipe connections.

Locate foot valve at

least 2 feet from

the bottom of the well so sand or

sediment is NOT drawn into the system.

4. After proper depth is reached, install

a well seal or pitless adapter to

support the pipe.

5. Slope the horizontal pipe upward

toward the pump to eliminate

trapping air.

DUG WELL, CISTERN, LAKE AND SPRING

INSTALLATION

1. Install a foot valve on the inlet pipe

and lower into the water.

Locate foot valve

at least 2 feet

from the bottom of the well so sand or

sediment is NOT drawn into the system.

WELL

SEAL

WELL

CASING

NOTE: When a lake is used for the

water supply, make sure the suction

pipe is deep enough to be submerged

at all times. Slope the pipe upward

toward the pump to eliminate trapping

air. The pipe must be removed during

winter months or protected against

freezing.

Protect the pipe

!

swimmers and boaters.

from damage by

Operation

PRIMING PUMP

Do NOT run pump

dry. Fill with water

before starting motor. Damage to pump

seals WILL result and void warranty.

After pump installation is complete, the

pump must be primed.

1. Remove the priming plug.

2. Fill pump and piping completely full

of water.

3. Replace the priming plug.

4. Open faucet to vent system.

5. Start the motor. Water will be

pumped within a few minutes. If

pump does not deliver water within

5 minutes, shut off motor and return

to step 1.

6. Let the system operate for several

minutes to flush out the pipes.

7. Close the faucet and allow pump

to build pressure in the tank. When

pressure reaches cut-out setting, the

motor will stop.

The system is now operating and will

cycle on demand.

If the pump does not operate after

repeated attempts, check the following:

1. Vertical distance of pump to water

must not exceed 25 feet.

2. Suction piping must be air tight.

3. Be sure valves are open if used in

discharge or suction piping.

NEVER run the

or clogged discharge. The water inside

the pump COULD boil and damage the

pump.

The use of a foot valve is strongly

recommended. This allows the suction

line to be filled during the priming

process, greatly decreasing priming

times.

pump with a closed

Maintenance

Disconnect power supply

and release all pressure from

system before attempting

to install, service, relocate, or perform

any maintenance. Lock the power

disconnect in the open/off position.

Tag the power disconnect to prevent

unexpected application of power.

Serious injury or death COULD result.

Maintain adequate ventilation for the

pump motor. The motor bearings are

permanently lubricated at the factory.

Additional lubrication is not required.

DRAINING PUMP

Drain openings are provided on all

models. To drain the pump:

1. Disconnect power to the pump

2. Remove the drain fitting and

priming plug.

3. Drain all piping to a point below the

frost line.

DRAINING TANK

Conventional tanks can be drained by

opening an outlet at the lowest point

in the system. Remove a plug or the air

volume control to vent the tank.

Pre-charged tanks force virtually all

of the water from the tank when the

system pressure is released. No draining

is necessary.

WATER-LOGGED TANKS

CONVENTIONAL TANKS

When a tank system has an inadequate

ratio of air and water, the pump will

start and stop often and erratically.

1. Disconnect electrical power to

pump.

2. Open the lowest faucet in the

system to release all pressure.

3. Prime the pump.

4. Reconnect power.

As the pump refills the tank, the air

volume control supplies the tank with

the correct air to water ratio. The pump

will then shut off at desired pressure.

If tank water-logs again, examine air

volume control and replace if necessary.

www.waynepumps.com

4

Page 5

Operating Instructions & Parts Manual

JSU50

Maintenance (Continued)

PRE-CHARGED TANKS

If a pre-charged tank becomes water-

logged, the bladder is probably leaking

or broken.

1. Test the tank by depressing the air

valve. The valve will discharge water

if the bladder is broken.

2. If bladder is broken, replace tank.

Once a tank bladder is ruptured, the

tank should be replaced. Repairing

the bladder is not recommended, and

may cause further problems such as:

repeated water-logging, debris in pipes

and clogged discharge in tank.

AIR PRESSURE CHECK FOR PRECHARGED TANKS

Small amounts of air loss is normal

in any tank. To prevent failure and

properly maintain a pre-charged water

tank, check the pressure on a yearly

basis.

1. Disconnect power to pump.

2. Open a faucet nearest the tank and

allow all water to drain from the

tank.

3. Measure the tank pre-charge at the

valve stem using a tire gauge.

4. If necessary, adjust the pre-charge

with an air pump: Precharged

pressure for the this pump is 28-30

psi.

5. Prime the pump.

6. Reconnect power.

7. Close faucet.

RECOMMENDED FUSING & WIRING DATA - 60 HZ MOTORS

Distance in Feet

From Meter to Motor

0 51 101 201

Dual

Element

HP VOLT

115 15 14 12 10 8

1/2

230 10 14 14 14 14

Fuse

250V

to to to to

50 100 200 300

Wire Size

FRICTION LOSS CHART

Feet Friction Loss in 100 Feet of Plastic Pipe

Gallons Per Minute

Pipe Size 20 25 30 40 50 60 80 100 120

1-1⁄4” 5.6 8.5 11.9 20.2 30.5

1-1⁄2” 2.6 4.0 5.5 9.4 14.3 19.9 34.2

2“ 1.2 1.6 2.8 4.2 5.8 9.9 15.0 21.2

2-1⁄2“ 1.2 1.8 2.5 4.2 6.3 8.8

www.waynepumps.com

5

Page 6

Operating Instructions and Parts Manual JSU50

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action(s)

Motor will not run 1. Power off 1. Turn power on or call power company

2. Fuse is blown (Breaker tripped) 2. Replace fuse (Reset breaker)

Motor runs hot and

overload kicks off

Motor hums but

will not run

Motor runs but

little or no water is

delivered.

NOTE: Check prime

before looking

for other causes.

Unscrew priming

plug and see if

water is in priming

hole

Pump starts and

stops too often

3. Wires at pressure switch are

loose, disconnected, or wired

incorrectly

4. Faulty pressure switch 4. Replace switch

5. Motor thermal overload

tripped

1. Pressure switch is wired

incorrectly

2. Voltage is too low 2. Check line voltage. Install heavier wiring if wire size is too

3. Rapid cycling 3. Check pressure switch. Ensure tank is not water-logged

4. High surrounding temperature 4. Provide a shaded, well ventilated area for pump

1. Motor is wired incorrectly 1. Refer to wiring instructions

2. Voltage is too low 2. Check line voltage. Install heavier wiring if wire size is too

3. Obstructed Impeller 3. Disconnect power. Using a flat head screw driver attempt to

4. Voltage selector switch not

properly set.

1. Pump in new installation did

not pick up prime through:

a. Improper priming a. Re-prime according to instructions

b. Air leaks b. Check all connections on suction line

c. Leaking foot valve c. Replace foot valve

2. Pump has lost prime through: 2. Existing installations:

a. air leaks a. Check all connections on suction line and shaft seal

b. water level below suction of

pump

3. Impeller is obstructed 3. Clean impeller

4. Check valve or foot valve is

stuck in closed position

5. Pipes are frozen 5. Thaw pipes. Bury pipe below frost line. Heat pit or pump house

6. Foot valve and/or strainer are

buried in sand or mud

1. Water-logged tank

(Conventional tank)

2. Ruptured diaphragm or

bladder (Pre-charged tank)

3. Air volume control connected

to wrong opening on pump

4. Incorrect tank pre-charge (Precharged tank)

5. Leak in system or house piping 5. Locate and repair leak

6. Foot valve or check valve stuck

open

7. Improperly adjusted pressure

switch

5.

3. Refer to wiring instructions. Check and tighten all wiring Wires

at p

5. Let cool. Overload will automatically reset. Provide a shaded,

well ventilated area for pump

1. Refer to wiring instructions

small (See Wiring Chart, page 5). Check with power company

small (See Wiring Chart, page 5). Check with power company

rotate motor shaft (located under plastic cap at rear of motor).

If shaft does not rotate freely remove obstruction from

impeller.

4. Set voltage selector switch (Figure 6) to match line voltage.

(See electrical connections page 3)

1. New installation:

b. Lower suction line into water and re-prime. If receding

water level in well exceeds suction lift, a deep well pump is

needed

4. Replace check valve or foot valve

6. Raise foot valve and/or strainer above well bottom

1. Follow instructions in maintenance section (See page 4)

2. Replace tank

3. Move to correct pump opening

4. Add or release air as needed

6. Replace valve

7. Adjust or replace switch

switch

www.waynepumps.com

6

Page 7

Operating Instructions & Parts Manual JSU50

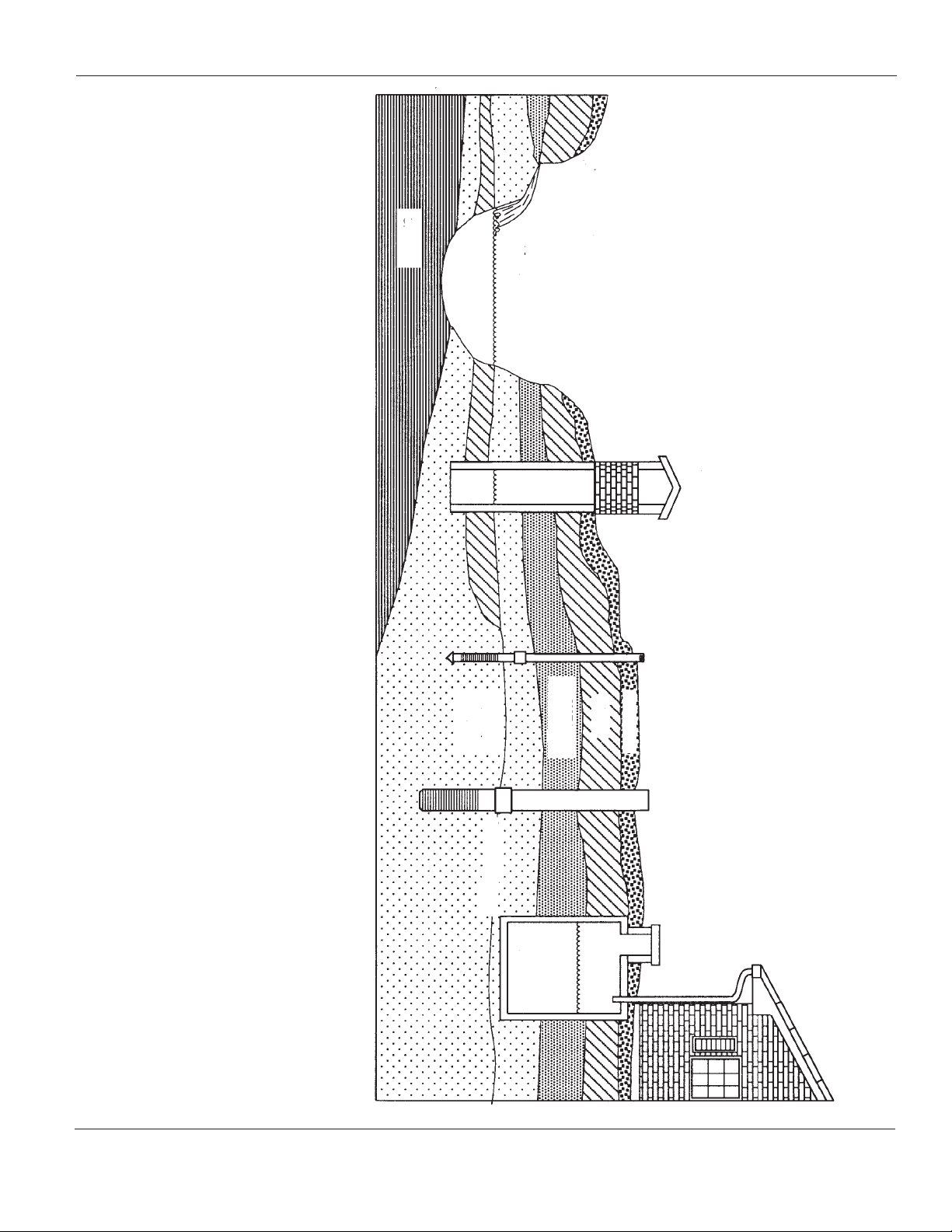

Figure 11 - Water Supplies

(A) SPRING:

A spring that emerges

from the ground.

Occurs when water in

permeable materials is

trapped between

impermeable

material as rock or clay.

(B) LAKE, STREAM or POND:

Surface water, unless treated,

is usually not safe for human

consumption. It may be used

for purposes such as washing

or irrigation.

(C) DUG WELL:

A hole is excavated

several feet in diameter

to a fairly shallow

depth. It is then lined

with brick, stone or

concrete to prevent

cave-in.

SHALE

(A) SPRING

(B) LAKE,

STREAM, POND

(C) DUG WELL

Water Supplies

the ground below

the water table.

The depth is usually

less than 50 feet.

Available

diameters are

1" through 2".

lined with pipe. Depths

range from a few feet

to over 1000 feet.

Common well diameters

are 2", 3", 4" and 6" for

domestic water wells.

water from rooftops.

The water is not fit

for human consumption.

(D) DRIVEN WELL:

Pipe with a pointed

screen is driven into

(E) DRILLED WELL:

A hole bored into the

earth with machinery and

(F) CISTERN:

An underground tank

built to collect rain

BEARING

SAND

WATER

WATER TABLE

PERMEABLE

MATERIAL

CLAY

(D) DRIVEN WELL

TOP SOIL

(E) DRILLED WELL

(F) CISTERN

www.waynepumps.com

7

Page 8

Operating Instructions and Parts Manual

For Replacement Parts, Call 1-800-237-0987

Please provide following information: Address any correspondence to:

- Model number WAYNE Water Systems

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

2

1

3

5

6

7

8, 9

JSU50

12

13

15

4

10

14

NOTE: Only use factory parts to repair this pump.

Ref.

No. Description

1 Motor 32059-001 1

2 Screw 16636-002 4

3 Square ring rubber gasket 17150-001 1

4 Shaft seal assembly 56393 1

5 Impeller 23285-002 1

6 Diffuser 17148-001 1

7 Screw 17165-001 2

8 O-ring 15557 1

Part

No. Qty.

Ref.

No. Description

9 Venturi 17151-002 1

10 Nozzle 15672 1

† 11 3/4” Pipe plug 15921 1

12 Pump housing 41033-001 1

13 Base 23029-001 1

14 Pressure switch 30010-001 1

15 Seal Plate 4372-001 1

† Not Shown

Part

No. Qty.

Limited Warranty

For one year from the date of purchase, WAYNE Water Systems (“WAYNE”) will repair or replace, at its option, for the

original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by WAYNE to be

defective in materials or workmanship. Please call WAYNE (800-237-0987) for instructions or see your dealer. Be prepared to

provide the model number when exercising this warranty. All transportation charges on Products or parts submitted for repair

or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with WAYNE's written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE or its

suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call WAYNE (800-237-0987) for return

authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. _____________________ SERIAL NO. ________________________ INSTALLATION DATE _____________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

8

Page 9

Instructions D’utilisation et Manual de Pièces JSU50

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Pompe À Jet

Description

Ces pompes domestiques à une étage

sont conçues pour le pompage d’eau

potable. Les pompes pour puits de

surface sont fabriquées pour les

applications là où le niveau d’eau

est moins de 7,62 m (25 pi) sous la

pompe. N’utilisez jamais de liquides

inflammables tels que l’essence, les

produits chimiques, ni les liquides

corrosifs avec cette pompe.

Déballage

Vérifiez cette unité avant de

l’utilisation. Parfois, un produit peut

être endommagé pendant le transport.

Si la pompe ou les composants sont

endommagés, contacter le service

clientèle au 1-800-237-0987.

Directives de Sécurité

Ce manuel contient de l’information

très importante de connaître et de

savoir qui est fournie pour la SÉCURITÉ

et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique une

situation

hasardeuse imminente qui RÉSULTERA

en perte de vie ou blessures graves.

Avertissement

indique une

situation hasardeuse potentielle

qui PEUT résulter en perte de vie ou

blessures graves.

Attention indique

une situation

hasardeuse potentielle qui PEUT résulter

en blessures.

Avis indique de

l’information

importante pour ÉVITER le dommage de

l’équipement.

REMARQUE : Information qui exige

une attention spéciale.

Généralités Sur La

Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales ou

autres problèmes de reproduction. Lavezvous les mains après la manipulation.

1. Lire attentivement ces instructions

et directives. Manque de suivre

ces instructions PEUT résulter en

blessures graves et/ou en dégâts

matériels.

Cette pompe n’est

pas submersible.

Installer seulement

à l’intérieur ou

dans une station de pompage. Installer

à l’intérieur seulement

Pomper l’eau claire

seulement. NE PAS pomper

les liquides inflammables

ou explosifs tels que l’essence,

l’huile à chauffage, le kérosène, etc.

NE PAS utiliser dans un atmosphère

inflammable et/ou explosif. Des

blessures et/ou des dommages à la

propriété SERONT causés.

Cette pompe n’est

pas conçue pour

les substances qui contiennent les

produits chimiques caustiques et/

ou les matières étrangères tels que

l’eau salée, la saumure, le décharge de

buanderie. L’utilisation de ces produits

PEUT endommager la pompe et NIERA la

garantie.

Toute installation de fils

doit être effectuée par un

électricien qualifié. La pompe

doit être installée conformément au

code National Electrical Code ainsi

qu’aux codes locaux.

2. Connecter cette pompe à un circuit

mis à la terre équipé d’un appareil

qui protège contre un dérangement

dû à une mise accidentelle à la terre

(DDFT).

3. Avant d’installer ce produit, faire

inspecter le circuit électrique par un

électricien qualifié afin d’assurer la

mise à la terre correcte.

RRisque de choc électrique! La

pompe doit être déconnectée

de la source d’alimentation

avant l’installation ou le service.

4. S’assurer que la source d’eau et la

tuyauterie soient libres de sable,

saleté et dépôts. Le débris peut

obstruer la pompe et annulera la

garantie.

5. Protéger la pompe et la tuyauterie

contre le gel. Manque de protéger

le produit contre le gel PEUT causer

du dommage sérieux et niera la

garantie.

6. Suivre les instruction d’amorçage. NE

PAS faire fonctionner la pompe au

sec.

Installation

Protéger la pompe contre les éléments.

Installer la pompe dans un sous-sol,

un garage, une cabane à outils, ou

un bâtiment pour pompes. Installer la

pompe pour que la ligne centrale de

la pompe soit aussi près que possible

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2011, WAYNE/Scott Fetzer Company. 311405-001 6/11

9-Fr

Page 10

Instructions D’utilisation et Manual de Pièces JSU50

Installation (Suite)

du niveau d’eau. Garder l’endroit

d’installation libre d’obstructions afin

de permettre l’accès à la pompe pour

le service et l’entretien. Protéger la

pompe contre l’inondation et l’humidité

excessive.

Assurer l’aération suffisante de la

pompe. La température ambiante ne

doit pas dépasser 38˚C. Ceci peut causer

le déclenchement du protecteur de

surcharge thermique sur le moteur.

INSTALLATION DE TUYAUX DE

POMPE

Utiliser des tuyaux nouveaux pour un

meilleur résultat. Utiliser les tuyaux

en fer, cuivre ou CPV. Pour éviter la

tension sur la pompe si vous utilisez

des tuyaux en fer ou en cuivre, fournir

des supports indépendants pour les

tuyaux d’aspiration et de décharge

à proximité de la pompe. Diminuer

l’usage des coudes et des raccordements

afin de réduire la perte par frottement.

Se référer au tableau de perte par

frottement pour plus de renseignements

(Page 13 Fr). Augmenter le diamètre du

tuyau d’aspiration ou de décharge si la

longueur dépasse 15 m.

À LA

TUYAUTERIE

D’EAU

AU

PUITS

OU

RÉSERVOIR À

EAU

Figure 1 - Installation de Tuyaux

TUYAU D’ASPIRATION

Installer un

clapet de pied ou

un tamis de filtre sur l’arrivée du tuyau

d’aspiration.

Ne jamais utiliser un tuyau d’aspiration

avec un diamètre moins de 1-1/4 po.

Garder le tuyau d’aspiration libre

de fuites d’air. Pour l’installation

horizontale, placer le tuyau de la

source d’eau de manière qui permet

que le tuyau s’incline vers le haut à au

moins 1/2 po par pied pour éliminer

l’air emprisonné. L’arrivée filetée de la

pompe est 1-1/4 po NPT.

N’installez pas les

près des endroits de natation.

tuyaux d’aspiration

TUYAU DE DÉCHARGE (FIGURE 2)

Installer une croix de tuyau de 3/4 po

(vendue séparément) dans le décharge

de la pompe. Boucher la partie

supérieure de la croix de tuyau avec un

bouchon mâle de tuyau de 3/4 po NPT

(vendu séparément). Introduire le tuyau

du réservoir dans l’ouverture latérale

de la croix de tuyau. Insérer le tuyau

dans l’ouverture de côté restante pour

une connexion à la ligne d’alimentation

d’eau domestique.

CONDUITE VERS LE SYSTÈME

D’EAU DOMESTIQUE

CROIX DE

TUYAUS

TUYAU AU

RESERVOIR

Figure 2

CONNEXION DU CONTRÔLE

DE VOLUME D’AIR

BOUCHON

D’AMORÇAGE

RACCORDEMENT AU RÉSERVOIR

RÉSERVOIR TRADITIONNEL

(FIGURES 3 & 4)

Un réservoir traditionnel sert à

entreposer l’eau et l’air comprimé dans

le même compartiment. Au plein, le

réservoir contient approximativement

2/3 eau et 1/3 d’air comprimé. Ce type

de réservoir requiert un contrôle de

volume d’air qui remplace l’air perdu

automatiquement lors d’une fuite ou

d’absorption dans l’eau.

1. Couper la puissance à la pompe.

Débrancher et verrouiller la source

d’alimentation.

2. Purger le réservoir. Utiliser le robinet

plus près du réservoir.

3. S’assurer que le réservoir soit fixé

avec sûreté au plancher ou à la base.

4. Boulonner la pompe au plancher

ou sur le support de fixation du

réservoir.

BOUCHON

MANOSTAT

RACCORD DE

VIDANGE

TUYAU DE

CONTRÔLE

DE VOLUME

D’AIR

Figure 3 - Pompe pour Puits de Surface

avec Réservoir Horizontal Traditionnel

CONTRÔLE

DE VOLUME

D’AIR

TUYAU DE CONTRÔLE DE

VOLUME D’AIR

RACCORD

DE VIDANGE

Figure 4 - Pompe pour Puits de Surface

avec Réservoir Vertical Traditionnel

D’AMORÇAGE

ARRIVÉE

CONTRÔLE DE

VOLUME D’AIR

BOUCHON

D’AMORÇAGE

ARRIVÉE

5. Monter un contrôle de volume d’air

sur le réservoir.

6. Connecter le tube du contrôle de

volume d’air à l’ouverture latérale/

avant de 1/8 po NPT sur la pompe.

Les raccordements doivent être

serrés. Les fuites peuvent empêcher

l’amorçage et/ou peut saturer le

réservoir.

7. Installer une soupape et un tuyau

isolateur entre le réservoir et la

plomberie de maison afin de réduire

le niveau de bruit du système et de

faciliter le service.

8. Fournir un robinet de tuyau à

l’endroit le plus bas dans le système

pour vidanger le système pendant le

service ou l’entreposage.

9. Incliner les lignes horizontaux en

haut vers la pompe, un minimum

de 1/4 po par pied afin d’empêcher

d’emprisonner l’air dans les lignes.

10-Fr

Page 11

Instructions D’utilisation et Manual de Pièces JSU50

Installation (Suite)

MANOSTAT

SouPAPe d’Air

(193 À 207 KPA (28-30 PSi))

1/2 HP, 3/4 HP, eT 1 HP

Figure 5 - Pompe pour Puits de

Surface, Réservoir Chargé d’Avance

RÉSERVOIR CHARGÉ D’AVANCE

(FIGURE 5)

Un réservoir d’eau chargé d’avance

contient de l’air et de l’eau dans des

compartiments séparés par une vessie

flexible. La barrière empêche l’absorption d’air dans l’eau. La conception

de vessie permet l’usage d’eau sous

des pressions plus élevées et de temps

prolongé par rapport à un réservoir

traditionnel. Les réservoirs chargés

d’avance ont presque le double de

capacité utilisable par rapport à un

réservoir traditionnel qui comporte

un volume égal. La pression d’air dans

un réservoir chargé d’avance doit être

vérifiée de temps en temps pour assurer

un niveau correct (Se référer à la section

Entretien).

1. Couper la puissance à la pompe.

Débrancher et verrouiller la source

d’alimentation.

2. Purger le réservoir. Ouvrir le robinet

le plus près du réservoir.

3. S’assurer que le réservoir soit fixé au

plancher ou à la base.

4. Boulonner la pompe au plancher

ou au support de fixation sur le

réservoir.

5. Régler la pression d’air dans le

réservoir au niveau désiré. Une

soupape d’air est située sur le côté et

acceptera un raccord standard pour

pompe à vélo ou canalisation d’air.

6. Installer une soupape et un tuyau

isolateur entre le réservoir et la

plomberie de maison pour réduire

BOUCHON

D’AMORÇAGE

ARRIVÉE

RACCORD

DE

VIDANGE

le niveau de bruit du système et de

faciliter le service.

7. Fournir un robinet de tuyau à

l’endroit le plus bas du système

pour vidanger le système pendant le

service ou l’entreposage.

8. Incliner les lignes horizontaux en

haut vers la pompe, un minimum

de 1/4 po par pied afin d’empêcher

d’emprisonner l’air dans les lignes.

CONNEXION ÉLECTRIQUE

La tension de la source d’alimentation

doit correspondre avec la tension de la

pompe. Les pompes de puits de surface,

couvertes dans ce manuel, ont des

moteurs à tension double préréglés en

usine à 115 volts. Les modèles peuvent

être transformés à 230 volts en tournant

le sélecteur de tension à la tension

désirée (Voir la Figure 6). Utiliser des

pinces à long bec et tirer le sélecteur

environ 6,4 mm, tourner, et le fixer dans

la position correcte.

Figure 6 - Sélecteur de Tension

Connecter la pompe à un circuit

électrique unique avec un disjoncteur

unique. Se référer aux descriptions

précises électriques dans le tableau

d’installation de fils pour le circuit et les

tailles de fils recommandés (à la page

13).

Installer et

entretenir les fils

pour cette pompe conformément au

National Electrical Code tous les autres

codes applicables.

Le moteur doit être mis à la terre en

branchant un fil en cuivre à la vis de

terre fournie dans le compartiment

d’installation de fils du manostat.

Le compartiment d’installation de

fils au champ pour le pompe à jet est

dans le carter du manostat. Il existe

seulement une vis de mise à la terre

sur le modèle. La vis est située sous le

couvercle du manostat, est peinturée

verte et est indiquée par les lettres GRD.

La connexion de mise à la terre doit être

à cette borne (Figure 7).

Se référer au schéma d’installation de

fils situé sous le couvercle du manostat

(Aussi sur la Figure 7).

LIGNE

FIXER LE

FIL DE

TERRE

ICI

Figure 7 - Connexions Électriques

1

L1

3

L2

MOTEUR

Pour fixer le c.a. au pressostat, s’assurer

d’abord que le circuit a été mis hors

tension. Desserrer la vis qui maintient le

couvercle sur le pressostat puis retirer le

couvercle.

Desserrer la vis de terre inutilisée et

fixer la partie exposée du fil de terre

entre la tête de vis et le corps du

manostat, puis resserrer.

Desserrer les deux vis supérieures du

manostat et resserrer avec les fils du

courant de c.a saisis sous les têtes de vis.

Replacer le couvercle du manostat et

resserrer la vis.

BRANCHEMENT A LA SOURCE D’EAU

PUITS ENFONCÉ

1. Enfoncer le point plusieurs pieds

sous le niveau hydrostatique.

Remarque: Un clapet de pied

d’étanchéité peut être installé dans le

puits (Figure 8). Ce type de clapet de

pied permet que le tuyau de puits se

remplisse d’eau pendant l’amorçage et

facilite la recherche des fuites. Suivre

les instructions du fabricant pendant

l’installation du clapet de pied.

En option, un clapet en canalisation

peut être utilisé avec les puits enfoncés

(Figure 9).

NE PAS utiliser

de pied dans votre système. Ceci PEUT

diminuer le rendement de la pompe.

de clapet et clapet

11-Fr

Page 12

Instructions D’utilisation et Manual de Pièces JSU50

Installation (Suite)

À LA POMPE

D’ENFONCEMENT

POINT

Figure 8 - Clapet de pied d’étanchéité

À LA

POMPE

CLAPET EN

CANALISATION

POINT

D’ENFONCEMENT

Figure 9 - Clapet En Canalisation

À LA

POMPE

CLAPET

DE PIED

Figure 10 - Joint de Puits

CLAPET DE PIED

D’ÉTANCHÉITÉ

JOINT DE

PUITS

COFFRAGE

DE PUITS

PUITS FORÉ

1. Installer un clapet de pied sur la

première section de tuyau (Figure

10).

2. Baisser le tuyau dans le puits.

3. Ajouter des tuyaux jusqu’à ce que le

clapet soit 3 m sous le niveau d’eau

plus bas possible.

Des fuites dans les joints ou

accouplements permettront une fuite

d’air dans le tuyau et résultera en

mauvais fonctionnement de la pompe.

S’assurer d’utiliser de la pâte à joint ou

du ruban adhésif de plombier sur toutes

les connexions de tuyau.

Placer le clapet de

pied au moins 0,61

m du fond du puits pour EMPÊCHER

l’aspiration de sable ou de sédiment

dans le système.

4. Une fois que la profondeur correct

est atteinte, installer un joint de

puits ou adaptateur pour soutenir le

tuyau.

5. Incliner le tuyau horizontal en

haut vers la pompe pour empêcher

d’emprisonner l’air.

INSTALLATION POUR PUITS CREUSÉS,

CITERNES, LACS ET SOURCES

1. Installer un clapet de pied sur le

tuyau d’arrivée et le baisser dans

l’eau.

Placer le clapet de

pied au moins 0,61

m du fond du puits pour EMPÊCHER

l’aspiration de sable ou de sédiment

dans le système.

REMARQUE: Si un lac est la source

d’eau, s’assurer que le tuyau

d’aspiration est assez profond pour

qu’il soit toujours immergé. Incliner le

tuyau en haut vers la pompe pour éviter

d’emprisonner l’air. Enlever le tuyau

pendant l’hiver ou le protéger contre le

gel.

Protéger le tuyau

contre le dommage

causé par les nageurs et les bateaux.

Fonctionnement

AMORÇAGE DE LA POMPE

NE PAS faire

fonctionner la

pompe au sec. Remplir la pompe

d’eau avant le démarrage du moteur,

sinon, les joints de la pompe SERONT

endommagés et la garantie annulée.

Une fois que l’installation de la pompe

est terminée, la pompe doit être

amorcée.

1. Enlever le bouchon d’amorçage.

2. Remplir la pompe et les tuyaux

complètement d’eau.

3. Remplacer le bouchon d’amorçage.

4. Ouvrir le robinet pour aérer le

système.

5. Démarrer le moteur. L’eau sera

pompée dans quelques minutes. Si la

pompe ne pompe pas d’eau pendant

5 minutes, arrêter le moteur et

retourner à l’étape 1.

6. Laisser le système fonctionner

pendant plusieurs minutes afin de

faire la chasse d’eau des tuyaux.

7. Fermer le robinet et permettre que

la pompe augmente la pression dans

le réservoir. Le moteur s’arrêtera

quand la pression atteint le réglage

d’arrêt.

Le système fonctionne et s’actionnera

au besoin.

Si la pompe ne fonctionne pas après

plusieurs essais, vérifier que:

1. La distance verticale de la pompe à

l’eau ne dépasse pas 7,62 m.

2. Le tuyau d’aspiration doit être

étanche.

3. Les soupapes doivent être ouvertes si

utilisées dans les tuyaux de décharge

ou d’aspiration.

NE JAMAIS faire

fonctionner la

pompe avec un décharge fermé ou

obstrué. L’eau dans la pompe peut

bouillir et endommager la pompe.

L’utilisation d’un clapet de pied

est recommandé. Ceci permet le

remplissage de la ligne d’aspiration

pendant l’amorçage et réduit le temps

d’amorçage.

12-Fr

Page 13

Instructions D’utilisation et Manual de Pièces JSU50

Entretien

Débrancher la source

d’alimentation et dissiper

toute la pression du

système avant d’essayer d’installer

de déplacer, ou de procéder au

service ou à l’entretien. Verrouiller

le sectionneur de puissance dans la

position open/off (ouvert/hors circuit).

Etiqueter le sectionneur de puissance

afin d’empêcher une application de

puissance inattendue. Ceci PEUT causer

des blessures graves ou la mort.

Maintenir la ventilation suffisante pour

le moteur de la pompe. Les roulements

de moteur sont lubrifiés en permanence

à l’usine. Le graissage n’est pas requiert.

VIDANGE DU POMPE

Des ouvertures pour la vidange sont

fournies sur tous les modèles. Pour

vidanger la pompe:

1. Mettre la pompe hors tension.

2. Enlever le raccord de vidange et le

bouchon d’amorçage.

3. Purger tous les tuyaux jusqu’à un

point sous le niveau de gelée.

VIDANGE DU RÉSERVOIR

Vidanger les réservoirs traditionnels

en ouvrant un orifice de sortie au

point plus bas du système. Enlever un

bouchon ou le contrôle de volume d’air

pour aérer le réservoir.

Les réservoirs chargés d’avance forcent

toute l’eau du réservoir quand la

pression du système est relâchée. Le

vidange n’est pas nécessaire.

RÉSERVOIRS PLEIN D’EAU

RÉSERVOIRS TRADITIONNELS

Si un système de réservoir a une

proportion insuffisante d’air et d’eau,

la pompe se démarrera et s’arrêtera

souvent et irrégulièrement vant et

irrégulièrement.

1. Couper le courant à la pompe.

2. Ouvrir le robinet le plus bas du

système pour dissiper toute la

pression.

3. Amorcer la pompe.

4. Connecter à nouveau la source

d’énergie électrique.

Quand la pompe remplit le réservoir,

le contrôle de volume d’air fournit au

réservoir la proportion correcte d’air

et d’eau. Ensuite la pompe s’arrête

à la pression désirée. Si le réservoir

se remplit d’eau encore, inspecter le

contrôle de volume d’air et le remplacer

si nécessaire.

RÉSERVOIRS CHARGÉS D’AVANCE

Si un réservoir chargé d’avance devient

plein d’eau, il y a probablement une

fuite ou rupture dans la vessie.

1. Faire l’essai du réservoir en appuyant

sur la soupape d’air. La soupape

déchargera l’eau si la vessie s’est

éclatée.

2. Remplacer le réservoir si la vessie a

éclatée.

Si la vessie de réservoir a éclatée,

le réservoir doit être remplacé. La

réparation de la vessie n’est pas

recommandée, et peut causer d’autres

problèmes tels que le plein d’eau dans

le réservoir, les débris dans les tuyaux et

une décharge obstruée dans le réservoir.

VÉRFIFICATION DE PRESSION D’AIR

POUR LES RÉSERVOIRS CHARGÉS

D’AVANCE

Un peu de perte d’air est normal dans

un réservoir. Pour empêcher la panne et

pour l’entretien correct d’un réservoir

chargé d’avance, vérifier la pression

annuellement.

1. Déconnecter l’énergie à la pompe.

2. Ouvrir le robinet plus près du

réservoir et purger l’eau du réservoir.

3. Mesurer la charge du réservoir à

la tige de soupape en utilisant un

manomètre pour pneus.

4. Si nécessaire, régler la charge

avec une pompe à air: La pression

préchargée pour cette pompe est de

193 à 207 kPa (28 à 30 lb/po²).

5. Amorcer la pompe.

6. Connecter à nouveau l’énergie.

7. Fermer le robinet.

RENCOMMANDATIONS DE FUSIBLES ET DE FILS – MOTEURS DE 60 HZ

Distance en pieds Mètre à Moteur

Fusible à

élément

HP VOLT

115 15 14 12 10 8

1/2

230 10 14 14 14 14

double

250V

0 51 101 201

to to to to

50 100 200 300

Taille de fils

TABLEAU DE PERTES PAR FROTTEMENT

Perte par frottement en 30,5 m de tuyau en plastique

Taille de

Tuyau

75,7 94,6 113,6 151,4 189,3 227,1 302,8 378,5 454,3

Litres par minute

3,2 cm 21,2 32,2 45,1 76,5 115,5

3,8 9,8 15,1 20,8 35,6 54,1 75,3 129,5

5,1 4,5 6,1 10,6 15,9 22,0 37,5 56,8 80,3

6,4 4,5 6,8 9,5 15,9 23,9 33,3

13-Fr

Page 14

Instructions D’utilisation et Manual de Pièces JSU50

Tableau de dépannage

Symptôme Cause(s) Possible(s) Mesures Correctives

Moteur ne

fonctionne

Moteur fonctionne

chaud et le

surcharge se

déclenche.

Moteur ronron mais

ne fonctionne pas

Moteur fonctionne

mais délivre peu ou

pas d’eau

Remarque: Vérifier

l’amorçage avant de

rechercher d’autres

causes. Desserrer le

bouchon d’amorçage

et vérifier qu’il y ait

de l’eau dans le trou

d’amorçage

Pompe s’arrête et

se démarre trop

souvant

1. Source de puissance hors-circuit 1. Mettre en marche ou contacter la compagnie de service

publique

2. Fusible sauté (Disjoncteur

2. Remplacer le fusible (Réenclencher le disjoncteur)

enclenché)

3. Fils au manostat sont desserrés,

déconnectés, ou mal installés

3. Se référer aux instructions d’installation de fils. Vérifier et serrer

tous les fils

Wires at p

4. Manostat défectueux 4. Remplacer le manostat

5. Protecteur thermique du

moteur enclenché

5. Laisser refroidir. Protecteur s’enclenche automatiquement.

Fournir un endroit ombreux, et bien ventilé pour la pompe

1. Fils du manostat mal installés5. 1. Se référer aux instructions d’installation de fils

2. Tension trop basse 2. Vérifier la tension de ligne. Installer des fils de calibre plus élevé

si la taille de fils est trop petite (Voir le tableau d’installation de

fils, page 13 Fr). Consulter la compagnie de service publique

3. Cyclage rapide 3. Vérifier le pressostat. S’assurer que le réservoir ne soit pas plein

d’eau.

4. Température ambiante élevée 4. Fournir un endroit ombreux, et bien ventilé pour la pompe

1. Installation de fils du moteur

1. Se référer aux instructions d’installation de fils

incorrect

2. Tension trop basse 2. Vérifier la tension de ligne. Installer du fil de calibre plus élevé

si la taille de fils est trop petite (Voir le tableau d’installation de

fils, page 13 Fr). Vérifier avec la compagnie de service publique

3. Impulseur obstrué 3. Desconecte la corriente. Con un destornillador plano intente

rotar el eje del motor (ubicado bajo la tapa plástica en la parte

posterior del motor). Si el eje no rota libremente, quite la

obstrucción del impulsor.

4. Sélecteur de tension mal réglé 4. Fije el interruptor selector de voltaje (Figura 6) para que

coincida con el voltaje de línea. (Consulte las conexiones

eléctricas en la página 11)

1. Nouvelle pompe ne s’amorce

1. Nouvelle installation:

pas à cause de:

a. l’amorçage incorrect a. Amorcer de nouveau selon les instructions

b. fuites d’air b. Vérifier les branchements sur la ligne d’aspiration

c. fuites au clapet de pied c. Remplacer le clapet de pied

2. Pompe perd l’amorçage à cause

2. Installation présente:

de:

a. fuites d’air a. Vérifier les branchements sur la ligne d’aspiration et le joint

d’arbre

b. niveau d’eau sous l’aspiration

de la pompe

b. Baisser la ligne d’aspiration dans l’eau et amorcer de

nouveau. Si le niveau d’eau dans le puits dépase la hauteur

d’aspiration, une pompe à puits profonde est nécessaire

3. L'impulseur est obstrué 3. Nettoyer la turbine

4. Clapet ou clapet de pied pris

4. Remplacer le clapet ou le clapet de pied

dans la position fermée

5. Tuyaux gelés 5. Dégeler les tuyaux. Enterrer les tuyaux sous le niveau de gel.

Chauffer le trou ou la cabane de la pompe

6. Clapet de pied et/ou tamis

enfouis dans le sable ou la boue

1. Réservoir plein d’eau (réservoir

6. Élever le clapet de pied et/ou le tamis par dessus le fond du

puits

1. Respecter les directives dans la section entretien (à la page 13)

traditionnel)

2. Diaphragme ou vessie rupturé

2. Remplacer le réservoir

(Réservoir chargé d’avance)

3. Contrôle de volume d’air

3. Déplacer à l’orifice correcte

branché au mauvais orifice de la

pompe

4. Charge du réservoir incorrect

4. Ajouter ou dissiper l’air au besoin

(Réservoir chargé d’avance)

5. Fuite dans le système ou dans la

5. Situer et réparer la fuite

tuyauterie de maison

6. Clapet de pied ou clapet pris

6. Remplacer la soupape

dans la position ouverte

7. Manostat mal réglé 7. Régler ou remplacer le manostat

14-Fr

Page 15

Instructions D’utilisation et Manual de Pièces JSU50

Figure 11 - Sources d'Eau

quand l’eau dans les

matériaux perméables

est pris entre les

matériaux imperméables

tels que la roche ou

l’argile.

généralement impropre à

la consommation humaine

sans traitement. Cette eau

peut être utilisée pour le

lavage ou l’irrigation.

plusieurs centimètres

de diamètre à une

distance peu profonde.

Le trou est cuvelé de

briques, pierres ou

béton pour empêcher

que le trou s’effonde.

(A) SOURCE D’EAU:

Eau qui sort de la terre

SCHISTEUSE

ARGILE

(B) LAC, RUISSEAU, ÉTANG:

L’eau de surface est

(C) PUITS CREUSÉ:

Un trou est creusé

(B) LAC,

RUISSEAU, ÉTANG

(A) SOURCE D'EAU

(C) PUITS CREUSÉ

Un tuyau avec un

tamis pointu est

enfoncé dans la terre

sous le niveau

hydrostatique. La

profondeur est

généralement moins

de 15 m. Les diamètres

disponibles sont

2,5 cm à 5,1 cm.

Un trou foré dans la

terre avec une machine

et cuvelé d’un tuyau.

La gamme de profondeurs

est de plusieurs centimètres

à 305 m. Les diamètres de

puits ordinaires sont

5,1 cm (2"), 7,6 cm (3"),

10,2 cm (4") et 15,2 cm (6")

pour les puits domestiques.

Un réservoir souterrain

fabriqué pour la

collection de pluie des

toits. Cette eau est

impropre à la

consommation humaine.

(D) PUITS ENFONCÉ:

(E) PUITS FORÉ:

(F) RÉSERVOIR À EAU:

AQUIFORE

SABLE

HYDROSTATIQUE

NIVEAU

PERMÉABLE

MATÉRIEL

ARGILE

(D) PUITS ENFONCÉ

COUCH

ARABLE

(E) PUITS FORÉ

(F) RÉSERVOIR

À EAU

15-Fr

Page 16

Instructions D’utilisation et Manual de Pièces JSU50

Pour des Pièces de Rechange, composer 1-800-237-0987

S’il vous plaît fournir l’information suivante: Adresser toute correspondance à :

- Numéro de Modèle WAYNE Water Systems

- Numéro de série (si présent) 101 Production Drive

- Description et numéro de la pièce Harrison, OH 45030 U.S.A.

1

2

3

5

6

7

8, 9

12

13

15

4

10

14

NOTE: Utiliser seulement des pieces de l’usine pour reparer la pompe

No.

de

Réf.

Description No. de

1 Moteur 32059-001 1

2 Vis 16636-002 4

3 Joint de caoutchouc à anneau

carré

4 Assemblage de boîte

d'étanchéité

5 Rotor 23285-002 1

6 Diffuseur 17148-001 1

7 Vis 17165-001 2

8 Joint torique 15557 1

pièce Qté.

17150-001 1

56393 1

No.

de

Réf.

Description No. de

pièce Qté.

9 Venturi 17151-002 1

10 Buse 15672 1

† 11 Bouchon de tuyau 3/4 po 15921 1

12 Boîtier de pompe 41033-001 1

13 Base 23029-001 1

14 Manostat 30010-001 1

15 Plaque de joints 4372-001 1

† Pas indiqué

Garantie Limitée

Pour un an à compter de la date d’achat, WAYNE Water Systems (“WAYNE”) vas réparer ou remplacer, à son option, pour

l’acheteur originel n’importe quelle pièce ou pièces de ces Pompes De Puisard ou Pompes À Eau (“Produit”) déterminées

défectueuses, par WAYNE, en matière ou en fabrication. S’il vous plaît appeler WAYNE (800-237-0987) pour des instructions ou

contacter votre marchand. S’assurer d’avoir, à votre disposition, le numéro du modèle afin d’effectuer cette garantie. Les frais

de transportation des Produits ou pièces soumis pour la réparation ou le remplacement sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation abusive,

mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux

instructions écrit de WAYNE.

IL N’EXISTE AUCUNE AUTRE GARANTIE OU AFFIRMATION. LES GARANTIES EXPRIMÉES, Y COMPRIS CELLES DE

COMMERCIALISABILITÉ ET D’ADAPTION À UNE FONCTION PARTICULIÈRE, SONT LIMITÉES À UN AN À COMPTER DE

LA DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR N’IMPORTE QUEL

ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à

l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à

l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni WAYNE ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais pas

limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût

de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre recette d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une copie de la recette d’achat avec

le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler WAYNE (800-237-0987)

pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE _____________________ Nº DE SÉRIE ________________________ DATE D’INSTALLATION _____________________

FIXER VOTRE FACTURE ICI

16-Fr

Page 17

Manual de instrucciones de operación y piezas JSU50

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto

aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede

ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Bomba Eyectora

Descripción

Estas bombas son bombas de agua

de una etapa para uso doméstico,

diseñadas para bombear agua potable.

Las bombas para pozos de poca

profundidad están diseñadas para

aplicaciones en las que el nivel de agua

no exceda los 7,62 m (25 pies) debajo de

la bomba. Nunca use con estas bombas

fluidos inflamables, tales como gasolina,

químicos o corrosivos.

Para Desempacar

Revise esta unidad antes de usarla. A

veces, el producto puede sufrir daños

durante el transporte. Si la bomba o

sus componentes están dañados, llame

a Servicio al cliente, por el 1-800-237-

0987.

Medidas de Seguridad

Este manual contiene informacion

que es muy importante que sepa

y comprenda. Esta informacion se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una

información

importante, que de NO SEGUIRLA, le

PODRÍA ocasionar daños al equipo.

NOTA: Información que requiere

atención especial.

Informaciones

Generales de Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o su

cordón eléctrico,

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

1. Sírvase leer cuidadosamente todas

estas normas e instrucciones. El

no cumplir con estas instrucciones

PODRÍA provocar lesiones personales

y/o daños materiales.

Esta bomba no es

sumergible.

Instale únicamente

en interiores o

dentro de una construcción especial

para la bomba de agua. Existe riesgo de

un choque eléctrico.

Bombee sólo agua limpia,

NUNCA fluidos inflamables

o explosivos, tales como

gasolina, petróleo combustible,

kerosene, etc. NO la use en atmósferas

inflamables y/o explosivas. PROVOCARÁ

lesiones y/o daños a la propiedad.

Esta bomba

no ha sido diseñada

para controlar agua salada, salmuera,

descargas de lavandería o cualquier

otra aplicación que pueda contener

sustancias químicas cáusticas y/o

materias extrañas. PODRÍA producirse

daño en la bomba si se usa en estas

aplicaciones, INVALIDANDO la garantía.

Un electricista calificado

deberá realizar todo el

cableado. La bomba se debe

instalar de acuerdo al Código

Nacional de Electricidad y a todos los

códigos locales.

2. Conecte esta bomba a un circuito de

conexión a tierra equipado con un

interruptor de circuito de pérdida a

tierra (GFCI).

3. Antes de instalar este producto,

haga que un electricista verifique el

circuito eléctrico a fin de asegurar

una adecuada conexión a tierra.

¡Riesgo de choque eléctrico!

Desconecte siempre la fuente

de energía antes de instalar

la bomba o darle servicio.

4. Asegúrese de que la fuente de agua

y la tubería estén libres de arena,

suciedad y óxido. Los residuos

atorarán la bomba e invalidarán la

garantía.

5. Proteja la bomba y la tubería del

frío excesivo. El no protegerla del

frío PODRÍA causar un daño grave e

invalidaría la garantía.

6. Siga las instrucciones principales. NO

haga funcionar la bomba al seco.

Instalación

Proteja la bomba del medio ambiente

instalándola en un sótano, garaje,

depósito de herramientas o caja de

bombas. Instale la bomba de tal manera

que el eje de la misma esté lo más cerca

posible al nivel de agua. Mantenga

despejada el área de instalación a fin

de brindar servicio y mantenimiento.

Proteja la bomba de inundaciones y

humedad excesiva.

Asegúrese de que la bomba tenga una

ventilación adecuada. La temperatura

ambiental no debe exceder los 38˚C

puesto que podría ocasionar daños en el

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2011, WAYNE/Scott Fetzer Company. 311405-001 6/11

17-Sp

Page 18

Manual de instrucciones de operación y piezas JSU50

Instalación (Continúa)

accionador del protector de sobrecarga

térmico del motor.

INSTALACIÓN DE LA TUBERÍA DE LA

BOMB

Para mejores resultados use una tubería

nueva. Puede usarse tuberías de hierro,

cobre o PVC. Para evitar que la bomba

se deforme cuando utilice una tubería

de hierro o cobre, proporciónele

soporte independiente a la tubería de

succión y desagüe cerca de la bomba.

Reduzca al mínimo el uso de tubos

acodados y accesorios a fin de disminuir

la pérdida por rozamiento. Remítase

al cuadro de pérdida por rozamiento

para información específica (pg. 21 Sp).

Aumente el diámetro de la tubería de

succión o desagüe si es que la longitud

excede los 5,25 m (50 pies).

AL NIVEL

DE

AGUA

AL

POZO

O A LA

CISTERNA

Figura 1 - Instalación de la tubería

TUBERÍAS DE SUCCIÓN

Instale la válvula

de pie o el filtro

sobre la toma de las tuberías de succión.

Nunca utilice tuberías de diámetro

menor a 3,2 cm (1-1⁄4 “) para las

tuberías de succión. Asegúrese de que

la tubería de succión no tenga fugas de

aire. Para funcionamientos horizontales,

tienda la tubería desde el suministro de

agua para que la inclinación superior

sea de por lo menos fi pulg. por pie.

Esto evita que el aire quede atrapado.

La entrada roscada de la bomba mide

3,2 cm (1-1⁄4“) NPT.

No instale tuberías

áreas de natación.

de succión cerca de

TUBERÍAS DE DESCARGA (FIGURA 2)

Instale un conector en cruz de 19,1 mm

(3/4”) (no incluido con la unidad) en el

orificio de salida de la bomba. Cierre el

orificio de la parte superior del conector

con un tapón de 19,1 mm (3/4”) NPT

(no incluido con la unidad). Conecte la

tubería del tanque al orificio lateral del

conector en cruz. Inserte la tubería en la

abertura del lado restante para conectar

a la línea de suministro de agua en el

hogar.

TUBERÍAS CONECTADAS AL

SISTEMA DE AGUA DEL HOGAR

T DOBLE PARA

TUBERÍA

TAPÓN

DE

CEBADO

TUYAU DE

TANQUE

Figura 2

CONEXIÓN DE CONTROL

DE VOLUMEN DEL AIRE

CONEXIÓN AL TANQUE DE AGUA

TANQUE CONVENCIONAL (FIGURAS 3

& 4)

Un tanque de agua convencional

almacena agua y aire comprimido en

el mismo compartimiento. Cuando

el tanque está lleno, éste contiene

aproximadamente 2/3 de agua y 1/3 de

aire comprimido. Este tipo de tanque

requiere de un control de volumen de

aire debido a las fugas o absorciones en

el agua.

1. Desactive la energía eléctrica para

bombear. Desconecte y bloquee la

fuente de energía eléctrica.

2. Drene el tanque. Se recomienda la

llave de salida más cerca al tanque.

3. Cerciórese de que el tanque esté

seguro en el piso o la base.

4. Atornille la bomba en el piso o en el

soporte de montaje sobre el tanque.

5. Instale el control de volumen de aire

en el tanque.

6. Conecte el tubo del control de

volumen de aire a la salida frontal de

3,2 mm (1/8“ NPT) al costado de la

bomba. Las conexiones deben estar

bien ajustadas. Las fugas harán que

INTERRUPTOR

DE PRESIÓN

ADAPTADOR DE

DRENAJE

TUBERÍA DEL

CONTROL DE

VOLUMEN DE

AIRE

Figura 3 - Bomba de pozo de poca

profundidad con tanque horizontal

convencional

CONTROL DE

VOLUMEN DE AIRE

TUBERÍA DEL

CONTROL DE

VOLUMEN DE AIRE

ADAPTADOR

DE DRENAJE

Figura 4 - Bomba de pozo de poca

profundidad con tanque vertical

convencional

TAPÓN DE

CEBADO

ENTRADA

CONTROL DE

VOLUMEN DE AIRE

TAPÓN

DE

CEBADO

ENTRADA

la bomba no se cebe y/o el tanque se

inunde.

7. Instale una válvula y una manguera

aisladora entre el tanque y las

cañerías domésticas. Esto reducirá

el nivel de ruido del sistema

de la bomba y ayudará en el

mantenimiento.

8. Coloque un grifo de manguera

(llave) en el punto más bajo del

sistema para drenarlo a fin de darle

mantenimiento o almacenarlo.

9. Incline las líneas horizontales hacia

arriba con dirección a la bomba a

un mínimo de 6,4 mm (1/4”) por pie.

Esto evitará que se atrape aire en las

líneas.

TANQUE PRE-CARGADO (FIGURA 5)

Un tanque de agua pre-cargado

almacena aire y agua en

compartimientos distintos, separados

por una bolsa flexible. Esta barrera evita

18-Sp

Page 19

Manual de instrucciones de operación y piezas JSU50

Instalación (Continúa)

INTERRUPTOR

DE PRESIÓN

VálVulA de Aire

(1,9 A 2,1 BAr (28-30 PSi)) 1/2

HP, 3/4 HP, Y 1 HP

Figura 5 - Bomba de pozo de poca

profundidad con tanque pre-cargado

que se absorba aire en el agua. Este

diseño de bolsa también permite que se

ejerzan presiones mayores sobre el agua

durante periodos más prolongados que

en un tanque convencional. Los tanques

pre-cargados poseen aproximadamente

el doble de capacidad utilizable que la

que tiene un tanque convencional de

igual volumen. La presión de aire en

un tanque pre-cargado debe verificarse

periódicamente para cerciorarse de

que esté a un nivel aceptable (Vea

Mantenimiento).

1. Apague la energía eléctrica para

bombear. Desconecte y bloquee la

fuente de energía eléctrica.

2. Drene el tanque. Se recomienda la

llave de salida más cerca al tanque.

3. Cerciórese de que el tanque esté

seguro en el piso o la base.

4. Atornille la bomba al piso o en el

soporte de montaje sobre el tanque.

5. Ajuste la presión de aire al nivel

deseado. Una válvula de aire se

encuentra al costado y aceptará una

conexión estándar de una bomba de

bicicleta o línea de aire.

6. Instale una válvula y una manguera

aisladora entre el tanque y las

cañerías domésticas. Esto reducirá

el nivel de ruido del sistema

de la bomba y ayudará en el

mantenimiento.

7. Coloque un grifo de manguera

(llave) en el punto más bajo del

sistema para drenarlo a fin de darle

mantenimiento o almacenarlo.

TAPÓN DE

CEBADO

ENTRADA

ADAPTADOR

DE DRENAJE

8. Incline las líneas horizontales hacia

arriba con dirección a la bomba a

un mínimo de 6,4mm (1/4”) por pie.

Esto evitará que se atrape aire en las

líneas.

CONEXIÓNES ELÉCTRICAS

El voltaje de la fuente de suministro

eléctrico debe ser similar al de la bomba.

Las bombas para pozo de instalación

sobre superficie, referidas en este

manual, tienen motores de doble voltaje

preconfigurados en la fábrica a 115

voltios. Para conectarlas a circuitos de

230 voltios simplemente gire la perilla

al voltaje deseado (Vea la Figura 6). Use

una pinza (alicate) de punta afilada

para halar la perilla aproximadamente

un 6,4 mm (1/4”), gírela y colóquela en

su posición correcta.

Figura 6 - Perilla para Seleccionar el

Voltaje

Conecte la bomba a un circuito eléctrico

por separado con un interruptor de

circuito automático dedicado. Remítase

a las especificaciones eléctricas en la

Tabla de Conexiones para el interruptor

de circuito automático y el tamaño del

cable (en la página 21).

Instale y mantenga

las conexiones

de esta bomba de acuerdo al Código

Nacional de Electricidad y demás

códigos locales aplicables.

El motor debe estar conectado a tierra

mediante la conexión de un conductor

de cobre al tornillo de conexión a tierra

provisto en el comportamiento de

cables en el interruptor de presión.

El compartimiento de cables para

tendido de la bomba de eyector se

encuentra dentro de la cubierta del

interruptor de presión. La unidad sólo

tiene un tornillo para conexión a tierra.

Este tornillo está ubicado debajo de la

tapa del presostato, está pintado de

verde e identificado como GRD. Deberá

realizarse la conexión a tierra de este

terminal (Figura 7).

CONEXIÓN

CONECTE

AQUÍ EL

CABLE DE

CONEXIÓN

A TIERRA

Figura 7 - Conexiones eléctricas

1

L1

3

L2

MOTOR

Vea el diagrama de cableado debajo de

la cubierta del interruptor de presión.

Para conectar la corriente CA al

interruptor de presión, asegúrese

primero de que la corriente haya sido

desconectada del circuito. Afloje el

tornillo que sostiene la cubierta sobre

el interruptor de presión y retire la

cubierta.

Afloje el tornillo de conexión a tierra

no usado y conecte el extremo expuesto

del cable de conexión a tierra entre

la cabeza del tornillo y el cuerpo del

interruptor de presión, luego apriételo.

Afloje los dos tornillos superiores del

interruptor de presión y vuélvalos a

apretar con los conductores de energía