Page 1

Engine Driven

Semi-Trash

Pump

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

1

Operating Instructions and Replacement Parts List GPH400 and GPH550

The Wayne pumps are general use

centrifugal water pumps.

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates

a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

1. Know the pump application,

limitations, and potential hazards.

Read these rules and the instructions

carefully. Failure to follow them could

cause serious bodily injury and/or

property damage.

Never run engine in an

enclosed area. Exhaust gases

contain deadly poisonous carbon

monoxide, which has no odor or taste.

320802-001 12/03

Do not use to pump flammable

or explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do not

use in flammable and/or explosive

atmospheres. Pump should only be used

with liquids compatible with pump

component materials. Failure to follow

this warning can result in personal injury

and/or property damage.

2. Observe all safety precautions for the

handling of the fuel.

Do not refuel a hot engine.

Fuel spilled on a hot engine

could result in a fire or explosion. Do not

refuel a running engine.

3. Pump should be located and should

rest on a level solid foundation. Do

not suspend pump by means of the

discharge pipe.

Be sure pump is on

secure footing so it

doesn’t fall over.

4. Do not use torches or apply excessive

heat, fire or flames to this pump as an

explosion may result.

5. Before working on the unit, insulate

the wire from the spark plug,

disconnect the spark plug wire and

mount it on the grounding clip.

Complete pump

and piping system

MUST be protected against below

freezing temperature. Failure to do so

could cause serious damage and voids

the warranty.

6. Do not run pump dry. Water is

required to lubricate the shaft

seal.

7. Pumping chemicals or corrosive

liquids with this pump may shorten

the life of the pump and may be

hazardous to the operator.

8. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean, uncluttered

and properly lighted; replace all

unused tools and equipment.

c. Keep visitors at a safe distance from

the work area.

d. Make workshop child-proof with

padlocks, master switches, and by

removing starter keys.

9. Always use a suction strainer with this

pump to filter large material.

This pump is designed to be selfpriming when installed and operated as

specified below.

1. The pump should be placed as close

as possible to the liquid being

pumped. A pump with 20 foot

suction lift will not remove water as

quickly as a pump with 5 foot

suction lift (Figure 1).

2. Suction hose and fitting must be

airtight.

Description

Safety Guidelines

General Safety

Information

Installation

Figure 1

20 Ft.

Suction Lift

5 Ft.

Suction

Lift

Page 2

Operating Instructions and Replacement Parts List

2

An air leak in the

suction line may

prevent priming of the pump. Use of

thread sealant is recommended.

Suction lines must be reinforced

hose or rigid pipe. Non-reinforced

hose will collapse due to the suction

created by the pump and prevent

pump from operating.

3. A check valve must be used in the

suction line to maintain the selfpriming capability. If no check valve

is used the pump will need to be

primed at the start of each

operation. For best operation, the

check valve should be installed at the

intake of the suction line.(Figure 2).

4. A suction strainer is required to

filter abrasive material.

5. The discharge hose and fitting

should be leak-tight. A leak in the

discharge hose will allow water to

spray around the work site, making

the site hazardous.

6. Keep all pipes and hose lines as

short and straight as possible. Long

lengths and curves in the pipes and

hose lines will reduce the pressure

the pump develops.

7. Fill the engine crankcase with oil.

Refer to the engine operating

manual for the specific grade of oil

and amount required.

8. Fill the engine fuel tank with

gasoline. Refer to the engine

operating manual for specific

gasoline type that is most efficient

for this engine.

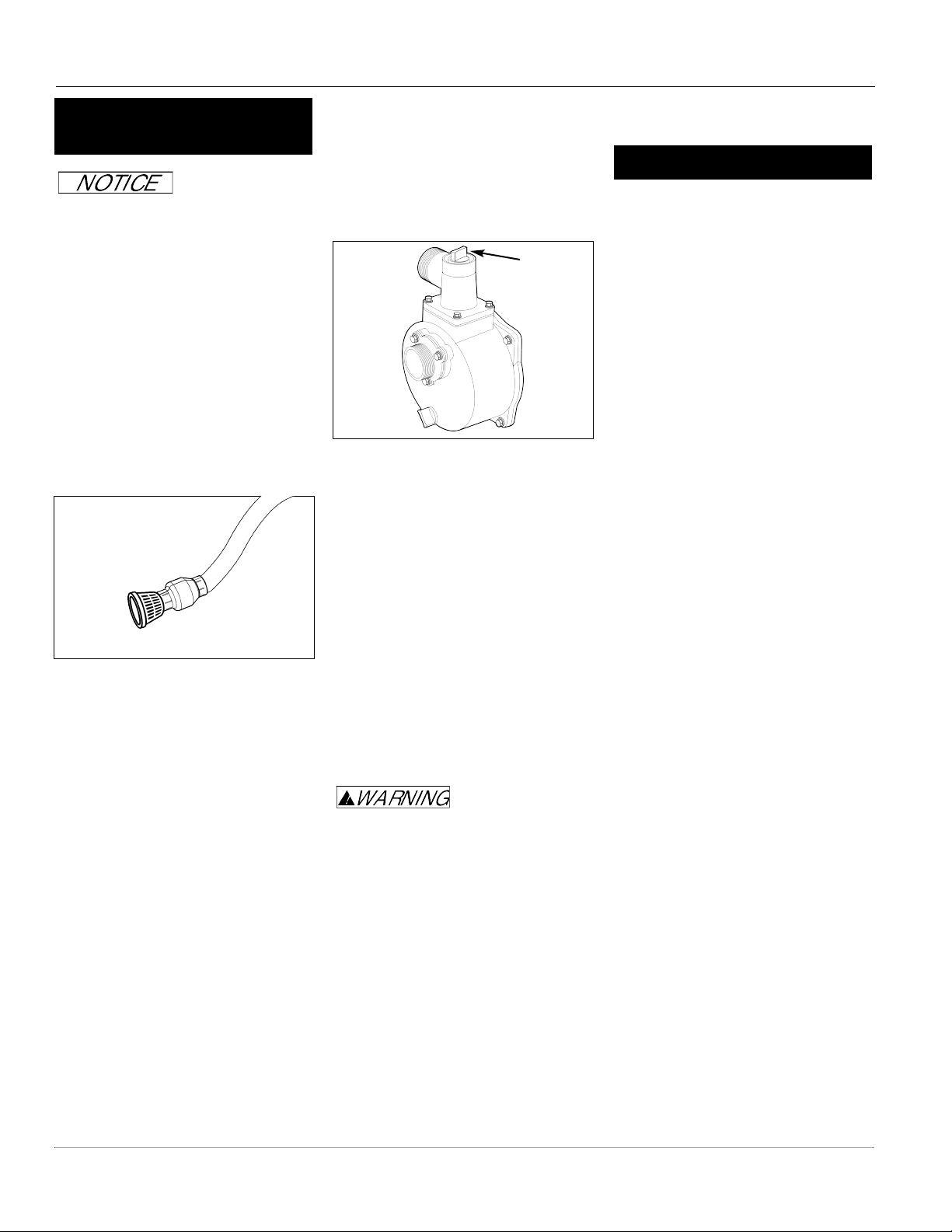

9. Add water to the priming port on

the pump (See Figure 3). Continue

adding water until the water level is

approximately 3 inches from the

top. Install the priming plug. The

water in the pump will create the

suction that primes the pump.

10. Turn fuel valve to ‘ON’ position.

11. Move choke lever to ‘CHOKE’

position.

12. Move throttle lever to ‘START’

position.

13. Pull engine crank until engine starts.

Once engine starts, move choke

lever to ‘RUN’ position.

14. The pump will take several minutes

to prime.

PIPING

Always place the pump as close as

possible to the liquid being pumped.

Keep all pipe and hose lines as short and

straight as possible.

Support pump and

piping when

assembling and after installation. Failure

to do so may cause piping to break, pump

to fail, etc; all of which can result in

property damage and/or personal injury.

All suction connections must be airtight.

If the pump won’t prime, check for leaks

in the suction piping or fittings. If flexible

suction hose is used instead of pipe, use

reinforced hose with a two inch inner

diameter. Non-reinforced flexible hose

may collapse from the vacuum created as

the pump primes.

Always use a strainer at the end of the

suction pipe or hose. Position strainer so

it doesn’t become clogged with stones or

debris. A suction line check valve is

recommended.

Figure 2

Figure 3

Do not use this pump for suction lifts

over twenty-five feet.

Always shut off the engine, allow the

engine to cool, and remove the spark

plug before performing any

maintenance.

During freezing weather, open the drain

port and allow all the water in the pump

to drain. This will prevent damage to the

pump when the water freezes. If the

pump will be stored for a month or

more, drain the water from the pump

and follow the engine manufacturer’s

recommendations for long-term storage.

The Honda engine is equipped with a

low oil shut off sensor. The enigne will

shut down and will not restart if the oil

level becomes low.

Maintenance

Installation

(Continued)

Priming

Port

Page 3

3

Operating Instructions and Replacement Parts List

FEET FRICTION LOSS IN 100 FEET OF PLASTIC PIPE

Gallons Per Minute

Pipe

Size 20 25 30 40 50 60 80 100 120

11/

4

5.6 8.5 11.9 20.2 30.5

11/

2

2.6 4.0 5.5 9.4 14.3 19.9 34.2

2 1.2 1.6 2.8 4.2 5.8 9.9 15.0 21.2

21/

2

1.2 1.8 2.5 4.2 6.3 8.8

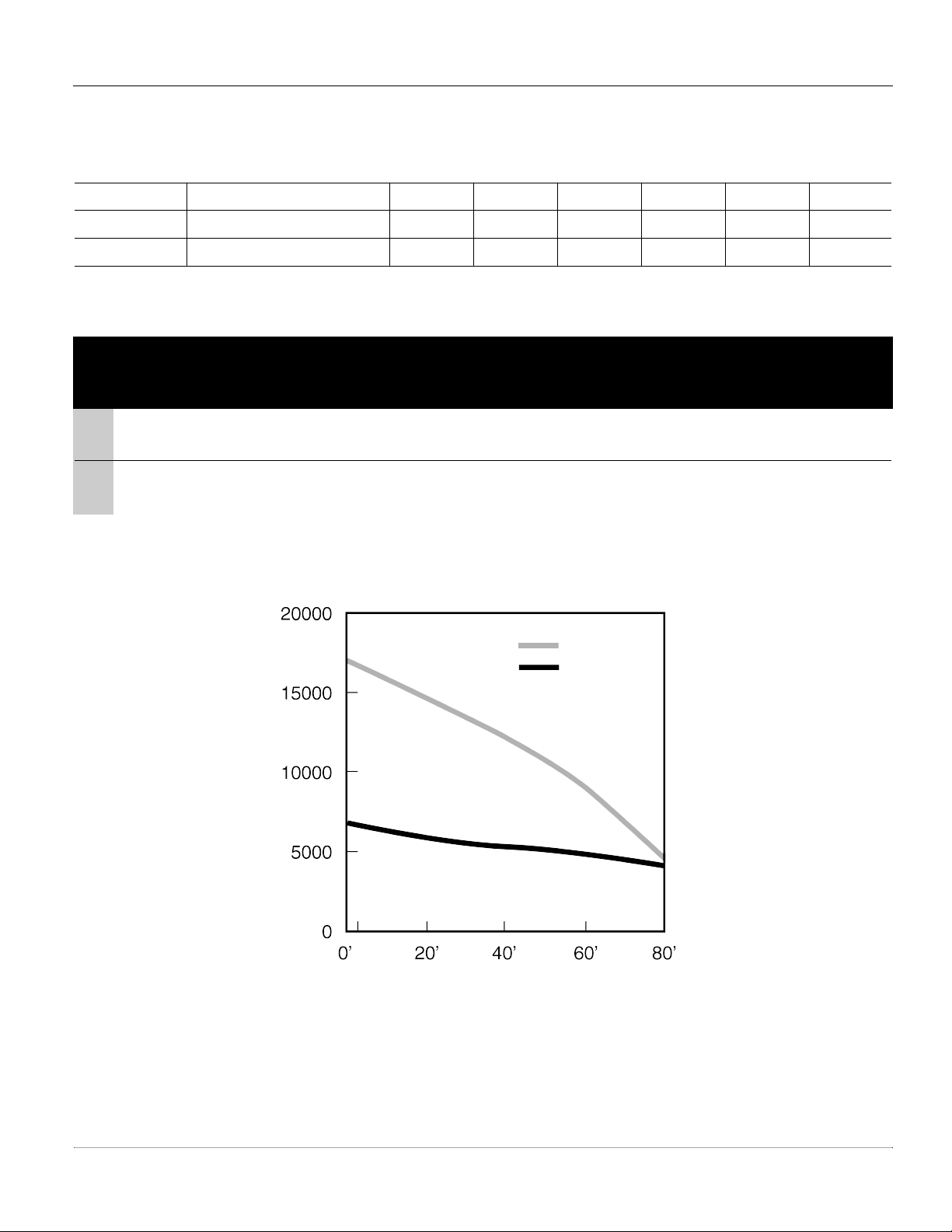

Performance Information

Semi-Trash Pump Performance

Discharge Head

Gallons/Hour

GPH550

GPH400

Gas Performance

GAS PERFORMANCE

Model Discharge Head HP 0’ 20’ 40’ 60’ 80’

GPH400 Gallons/Hour 4.0 6600 5700 5100 4500 3900

GPH550 Gallons/Hour 5.5 16800 14400 12000 9000 4620

Page 4

4

®

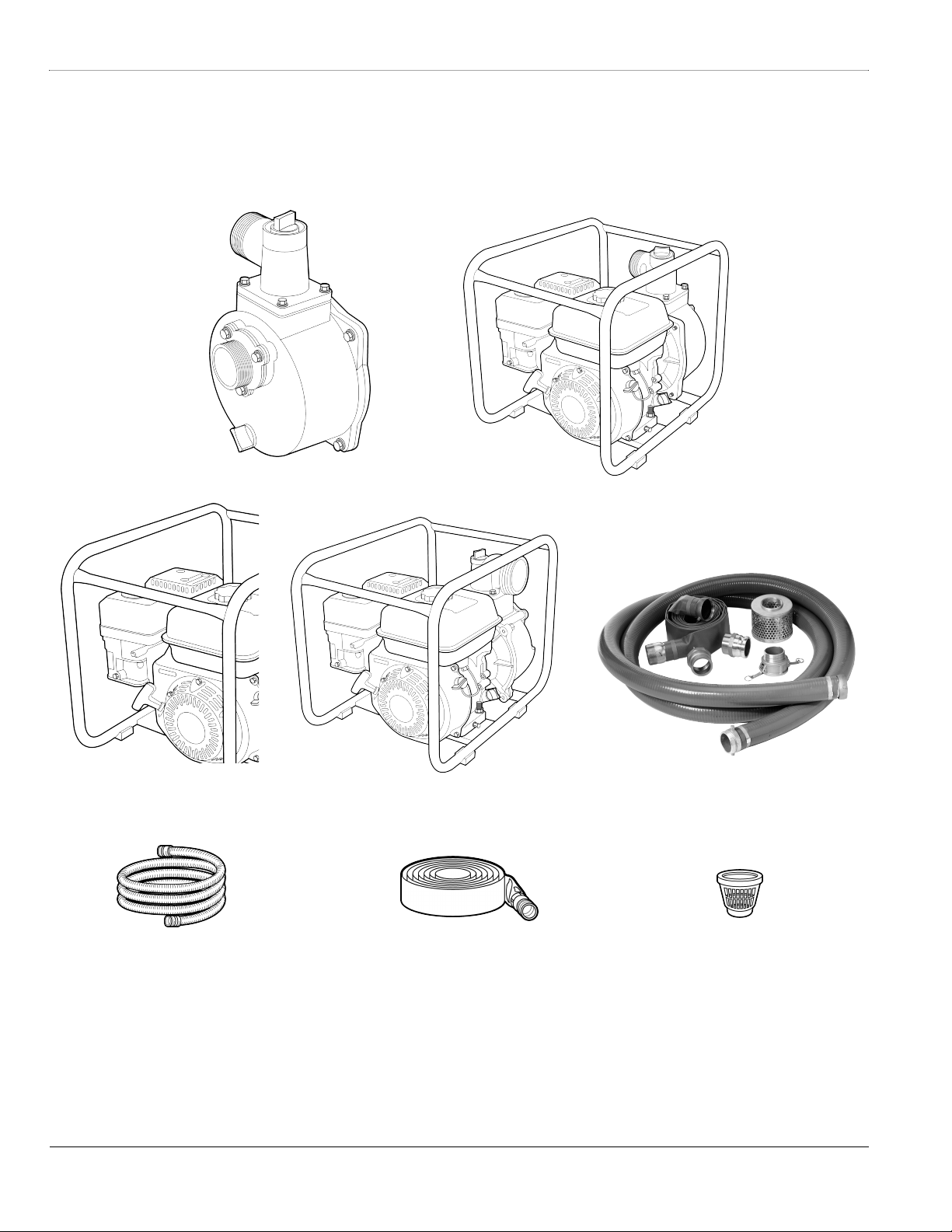

LAY FLAT DISCHARGE HOSE

PART #16511

• Economical

• Lightweight

• Resistant to oils, light chemicals,

abrasion and sunlight

• Will not rot, mildew or absorb

water

Hose couples one end with 2” hose

thread. One 25 ft. hose per carton

SUCTION HOSE

PART #16510-002

• Reinforced to prevent collapse

under suction

Hose coupled both ends with 2” hose

thread. One 20 ft. hose per carton

2” SUCTION STRAINER

PART #66036

• Prevents stones, leaves and other

debris from clogging pump

For Pump Accessories, call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown

Address parts correspondence to:

Wayne Water Systems

100 Production Drive

Harrison, OH 45030

Operating Instructions and Replacement Parts List

400 PUMP

4HP HONDA OHV GPH400

550 PUMP

5.5 HP HONDA OHV GPH550

3” HOSE KIT 62025-WYN1

2” HOSE KIT 62005-WYN1

Page 5

For Replacement Parts, call 1-800-237-0987

5

Operating Instructions and Replacement Parts Manual

Item Part

No. Description GPH400 GPH550 Qty

1 Honda Engine 57813-001 57812-001 1

2 Shaft Seal Kit 66048-WYN1 66047-WYN1 1

3 Suction Flange 42008-001 42007-001 1

4 Flapper Check Valve 37307-001 37306-001 1

5 Discharge Flange Kit 66050-WYN1 66049-WYN1 1

6 Drain/Fill Plug 28444-001 28444-001 2

7 Impeller 41021-001 41020-001 1

8 Wear Plate 72030-001 72031-001 1

9 Volute 72032-001 72033-001 1

10 Volute Seal 19051-001 19052-001 1

*11 Seal Plate (TX2) 72027-001 72029-001 1

*12 Seal Plate (WKT2) 72028-001 72034-001 1

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown

Address parts correspondence to:

Wayne Water Systems

100 Production Drive

Harrison, OH 45030

1

*

2

6

5

4

3

6

7

8

10

9

11, 12

* (TX2) or (WKT2) is noted here. The seal plates are unique to each

number – see items 11 and 12.

Page 6

6

Operating Instructions and Replacement Parts List

Limited Warranty

For three years from date of purchase, Wayne Water Systems (”Wayne Water Systems“) will repair or replace, at its option,

for the original purchaser any part or parts of its Sump Pumps or Water Pumps (”Product“) found upon examination by

Wayne Water Systems to be defective in materials or workmanship. Please call Wayne Water Systems (800-237-0987) for

instructions or see your dealer. Be prepared to provide the model number when exercising this warranty. All transportation

charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Wayne Water Systems’s written

instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR

EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Wayne

Water Systems or its suppliers be liable for any special, consequential, incidental or penal damages including, but not

limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated

equipment, cost of capital, cost of substitute products, facilities, services or replacement power, downtime costs, or claims

of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you

MUST send a COPY of the purchase receipt along with the material or correspondence. Please call Wayne Water Systems

(800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE WATER SYSTEMS. Use this form only to maintain your records.

MODEL NO._____________________ SERIAL NO.___________________________ INSTALLATION DATE ______________________

ATTACH YOUR RECEIPT HERE

Page 7

7

Les pompes Wayne sont des pompes à

l’eau centrifuges d’utilisation générale.

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger

indique

une situation hasardeuse imminente qui

RÉSULTERA en perte de vie ou blessures

graves.

Avertis-

sement

indique une situation hasardeuse

potentielle qui PEUT résulter en perte de

vie ou blessures graves

Attention

indique

une situation hasardeuse potentielle qui

PEUT résulter en blessures.

Avis

indique

de l’information importante pour éviter le

dommage de l’équipement.

1. Se familiariser avec l’application, les

limites et les hasards potentiels de la

pompe. Lire et comprendre toutes

les instructions. Le non-respect de

toutes les instructions ci-après

pourrait mener à un choc électrique

mortel, un incendie, des dommages

à la propriété et/ou de graves

blessures.

Ne faites jamais fonctionner

le moteur dans un endroit

restreint car les gaz d’échappement

contiennent du monoxyde de carbone

mortel, toxique inodore ou sans goût.

Ne pas utiliser pour le pompage

des liquides inflammables ou

explosifs tels que l’essence,

l’huile à chauffage, le kérosène, etc. Ne

pas utiliser dans un atmosphère

inflammable et/ou explosif. Utiliser la

pompe seulement avec les liquides qui

sont compatibles avec les pièces

détachées de la pompe. Manque de

suivre cet avertissement peut résulter en

blessure grave et/ou dégâts matériel.

2. Observer toutes les précautions de

sécurité pour la manipulation du

carburant.

Ne faites pas le plein lorsque

le moteur fonctionne ou

chaud. Tout combustible

échappé sur un moteur chaud peut

provoquer un incendie ou une

explosion.

3. La pompe doit se trouver sur une

surface à niveau solide car elle peut

se renverser ou tomber provoquant

de graves blessures. Ne tenez ni ne

suspendez la pompe par un tuyau

de décharge car ce dernier pourrait

casser ou se desserrer.

S’assurer

que la

pompe est sur une base solide pour ne

pas basculer.

4. Ne pas utiliser de chalumeaux ni de

chaleur excessive, feu ou flammes sur

cette pompe car il pourrait y avoir une

explosion.

5. Avant d’utiliser l’appareil, isoler le fil

des bougies, débrancher le fil des

bougies et monter sur une pince de

masse.

Tout le

système

de tuyauterie et de pompe DOIT être

protégé contre les températures de gel.

Le non-respect provoquera de graves

dommages et annulera la garantie..

6. Ne faites pas tourner la pompe

à sec. Il faut de l’eau pour

lubrifier le joint de l’arbre.

7. Pompez des produits chimiques ou

des liquides corrosifs avec cette

pompe peut réduire la vie de la

pompe, être dangereux en

fonctionnant et annulera la

garantie.

8. Sécurité Personnelle:

a. Toujours porter des lunettes de

sécurité si vous travaillez avec les

pompes.

b. Garder l’endroit de travail propre,

non-encombré et bien illuminé.

Ranger tous outils et équipement

après l’usage.

c. Garder les visiteurs à une distance

sûre de l’endroit de travail.

Protéger l’atelier pour les enfants

avec des cadenas, interrupteurs

principals et en enlevant les clefs de

démarrage.

9. Toujours utiliser une crépine

d’aspiration avec cette pompe pour

filtrer de gros matériaux.

Cette pompe est conçue pour s’autoamorcer lorsqu’elle est installée et

utilisé comme suit.

1. Placez la pompe aussi près que

possible du liquide pompé. Une

pompe à soulèvement de succion

de 20 pieds ne pompera pas l’eau

aussi rapidement qu’une à succion

de 5 pieds. (Figure 1)

2. Le flexible de succion et les raccords

doivent être hermétiquement

fermés.

Toute

fuite

d’air dans la conduite de succion peut

empêcher l’amorçage de la pompe. Il

est recommandé d’utiliser un mastic de

joints filetés.

Pompe de

résidus à

moteur Pump

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

Instructions d’Utilisation et Manuel de Pièces de Rechange GPH400 and GPH550

Description

Directives De Sécurité

Généralités sur la

Sécurité

Installation

320802-001 12/03

Page 8

Operating Instructions and Replacement Parts List

8

La conduite de succion ou le tuyau

rigide doit être renforcé pour éviter

qu’il ne s’affaisse à cause de la

succion créée par la pompe.

3. Il faut utiliser une soupape antiretour dans la conduite d’aspiration

pour maintenir la capacité d’autoamorçage. S’il n’y en a pas, il faudra

amorcer la pompe au début de

chaque opération. Pour le meilleur

fonctionnement de la pompe, il

faudrait installer une soupape antiretour à l’entrée de la conduite

d’aspiration. (Figure 2).

4. Il faut une crépine d’aspiration pour

filtrer le matériau abrasif.

5. Le tuyau de décharge et le raccord

doit être étanche. Toute fuite dans

le tuyau de décharge laissera l’eau

gicler autour du site de travail créant

ainsi une situation dangereuse.

6. Gardez tous les tuyaux et flexibles

aussi courts et droits que possible.

Ceci maximisera la performance de

la pompe.

7. Remplir le carter du moteur d’huile.

Se reporter au manuel d’utilisation

du moteur pour connaïtre le type

d’huile et la quantité à utiliser.

8. Remplissez le réservoir d’essence

du moteur d’essence. Reportezvous au manuel de

fonctionnement du moteur pour le

calibre spécifique d’essence et la

quantité requise.

9. Ajoutez de l’eau au port

d’amorçage de la pompe (Figure

3). Continuez à ajouter de l’eau

juaqu’à ce que le niveau soit

d’environ 3 po du dessus. Installez

le bouchon de pompe d’amorçage.

L’eau de la pompe créera une

succion qui amorcera la pompe.

10. Mettez la soupape d’essence à la

position «ON ».

11. Déplacez le levier d’étrangement

à la position «CHOKE ».

12. Déplacez le levier de commande

des gaz à la position « START ».

13. Tirez le vilebrequin du moteur

jusqu’à ce qu’il démarre. Lorsqu’il

a démarré, déplacez le levier

d’étranglement à la position «

RUN ».

14. La pompe peut prendre quelques

minutes à s’amorcer.

TUYAUTERIE

Placez la pompe aussi près que

possible du liquide pompé. Gardez

tous les tuyaux et flexibles aussi courts

et droits que possible.

Supportez la pompe et la tuyauterie en

assemblant et après l’installation sinon

les tuyaux peuvent casser ou la pompe

ne pas fonctionner menant à des

dommages à la propriété et/ou des

blessures personnelles et cela pourra

annuler la garantie.

Toutes les connexions d’aspiration

doivent être hermétiques. Si la pompe

ne s’amorce pas, vérifier s’il y a des fuites

dans les raccords ou les tuyaux

d’aspiration. Si le tuyau flexible

d’aspiration est utilisé au lieu d’un tuyau

rigide, utiliser un tuyau renforcé de deux

pouces de diamètre intérieur. Les tuyaux

flexibles non-renforcés peuvent

s’effondrer à cause du vide créé lors de

l’amorçage de la pompe.

Toujours utiliser une crépine à

l’extrémité du tuyau ou du tuyau flexible

d’aspiration. La placer pour qu’elle ne se

bloque pas de pierres ou de débris. Il est

recommandé d’utiliser une soupape antiretour sur cette conduite.

Ne pas utiliser la pompe pour une

aspiration de plus de vingt-cinq pieds.

Coupez toujours le moteur, laissez-le

refroidir et retirez les bougies avant

tout entretien. Durant les temps de

gel, ouvrez l’orifice de drainage et

laissez toute l’eau sortir de la pompe.

Ceci empêchera les dommages à la

pompe lorsque l’eau gèle.

Si la pompe doit être rangée pendant

de longues périodes de temps,

vidangez l’eau de la pompe et suivez

les recommandations du fabricant du

moteur pour le rangement à long

terme.

Le moteur Honda est doté d’un

détecteur de basse pression d’huile. Le

moteur s’arrête et ne démarre pas si le

niveau d’huile est trop bas.

Figure 1

soulèvement de succion

de 20 pi - 6 m

soulèvement de

souccion de

5 pi - 1,5 m

Figure 2

Figure 3

Entretien

Installation

(Suite)

Orifice

d’amorçage

Page 9

3 FR

PERTE DE POMPE A CAUSE DE 100 PIEDS DU TUYAU DE PLASTIQUE

Diamètre Gal/minute

du Tuyau 20 25 30 40 50 60 80 100 120

11/

4

5.6 8.5 11.9 20.2 30.5

11/

2

2.6 4.0 5.5 9.4 14.3 19.9 34.2

2 1.2 1.6 2.8 4.2 5.8 9.9 15.0 21.2

21/

2

1.2 1.8 2.5 4.2 6.3 8.8

Information sur la performance

Performance de la pompe à résidus

Tête de décharge

Gallons/Heure

GPH550

GPH400

PERFORMANCE DU GAZ

PERFORMANCE DU GAZ

Modèle Tête de décharge HP 0’ 20’ 40’ 60’ 80’

GPH400 Gallons/Heure 4.0 6600 5700 5100 4500 3900

GPH550 Gallons/Heure 5.5 16800 14400 12000 9000 4620

Instructions d’Utilisation et Manuel de Pièces de Rechange

Page 10

TUYAU DE DÉCHARGE À DÉPOSER À

PLAT

PIÈCE NO 16511

• Économique

• Léger

• Résistant aux huiles, produits

chimiques légers, abrasion et rayons

du soleil

• Ne pourrit pas, ne moisit pas et

n’absorbe pas l’eau

Tuyau couplé à une extrémité avec un

filet de tuyau de 2 po. Un tuyau de 25

pieds par carton

TUYAU D’ASPIRATION

PIÈCE NO16510-002

• Renforcé pour éviter

l’effondrement sous l’aspiration

Tuyau couplé aux deux extrémités d’un

filet de tuyau de 2 po. Un tuyau de 20

pieds par carton

CRÉPINE D’ASPIRATION DE 2 PO

PIECE NO66036

• Empêche les pierres, feuilles et

autres débris de bloquer la pompe.

Pour les accessoires de pompe, appele 1-800-237-0987

S’il vous plaît fournir l’information suivante:

- Numéro de modèle

- Numéro de série (si applicable)

- Description et numéro de la pièce

Correspondance:

Wayne Home Equipment

100 Production Drive

Harrison, OH 45030 U.S.A.

Instructions d’Utilisation et Manuel de Pièces de Rechange

POMPE 400

HONDA 4 HP OHV GPH400

POMPE 550

HONDA 5.5 HP OHV GPH550

KIT DE TUYAU DE 3 PO 62025-WYN1

KIT DE TUYAU DE 2 PO 62005-WYN

Page 11

Pour pièces de rechange, composer 1-800-237-0987

11

Instructions d’Utilisation et Manuel de Pièces de Rechange

No.

de Réf Description GPH400 GPH550 Qty

1 Moteur Honda 57813-001 57812-001 1

2 Trousse de joint d’étancheité 66048-WYN1 66047-WYN1 1

3 Bride à succion 42008-001 42007-001 1

4 Clapet anti-retour à battant 37307-001 37306-001 1

5 Trousse de bride à décharge 66050-WYN1 66049-WYN1 1

6 Bouchon de vidange/remplissage 28444-001 28444-001 2

7 Rotor 41021-001 41020-001 1

8 Plaque d’usure 72030-001 72031-001 1

9 Volute 72032-001 72033-001 1

10 Étanchéité de volute 19051-001 19052-001 1

*11 Plaque d’étanchéité (TX2) 72027-001 72029-001 1

*12 Plaque d’étanchéité (WKT2) 72028-001 72034-001 1

S’il vous plaît fournir l’information suivante:

- Numéro de modèle

- Numéro de série (si applicable)

- Description et numéro de la pièce

Correspondance:

Wayne Home Equipment

100 Production Drive

Harrison, OH 45030 U.S.A.

1

2

6

5

4

3

6

7

*

8

10

9

11, 12

* (TX2) ou (WKT2) est illustré ici. La plaque d’étanchéité est

particulière pour chaque numéro – voir les réf. 11 et 12.

Page 12

Garantie Limitée

Pendant un an à compter de la date d’achat, Wayne Water Systems ("Wayne") va réparer ou remplacer, à sa discrétion, pour

l’acheteur original toute pièce ou pièces du Kit D’Étang, de ces Pompes De Puisard ou Pompes À Eau ("Produit") déterminées

défectueuses, par Wayne, soit pour les matériaux ou la fabrication. Veuillez appeler Wayne (800-237-0987) pour des

instructions ou contacter votre marchand. S’assurer d’avoir, à sa disposition, le numéro du modèle afin d’effectuer cette

garantie. Les frais de transport des Produits ou pièces soumis pour leur réparation ou leur remplacement sont la responsabilité

de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés suite à un accident, une utilisation abusive, un

mauvais usage, de la négligence, une mauvaise installation, un mauvais entretien, ou une utilisation non conforme aux

instructions écrites de Wayne

IL N’EXISTE AUCUNE AUTRE GARANTIE OU DÉCLARATION. LES GARANTIES EXPRESSES, Y COMPRIS CELLES DE

COMMERCIALISABILITÉ ET D’ADAPTATION À UNE FONCTION PARTICULIÈRE, SONT LIMITÉES À UN AN À COMPTER DE LA

DATE D’ACHAT. CECI EST LE SEUL RECOURS EXCLUSIF ET TOUTE AUTRE RESPONSABILITÉ POUR TOUT AUTRE DOMMAGE

QUELCONQUE INDIRECT OU DÉPENSES QUELCONQUES SONT EXCLUS.

Certaines Provinces n’autorisent pas de limites de durée pour les garanties implicites, ni l’exclusion ni la limite des dommages

fortuits ou indirects. Les limites précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne à l’acheteur, des

droits légaux précis, et vous pouvez avoir d'autres droits légaux qui varient d’une Province ou d’un État à l’autre.

En aucun cas, soit par suite d’une rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni Wayne ni ses fournisseurs ne seront tenus responsables pour aucun dommage spécial, indirect ou pénal, y compris, mais sans

s'y limiter la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou capacité de remplacement,

coût de temps que le produit n’est pas en service, ou réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre reçu d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une copie du reçu d’achat avec le

produit ou la correspondance afin d’effectuer une réclamation sous la garantie. Veuillez appeler Wayne (800-237-0987) pour

l’autorisation et les instructions concernant le renvoi.

.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE _____________________ Nº DE SÉRIE ________________________ DATE D’INSTALLATION _____________________

FIXER VOTRE FACTURE ICI

Instructions d’Utilisation et Manuel de Pièces de Rechange

Loading...

Loading...