Page 1

EN

WT004139

2008-03-20 V0 Rev.01.0

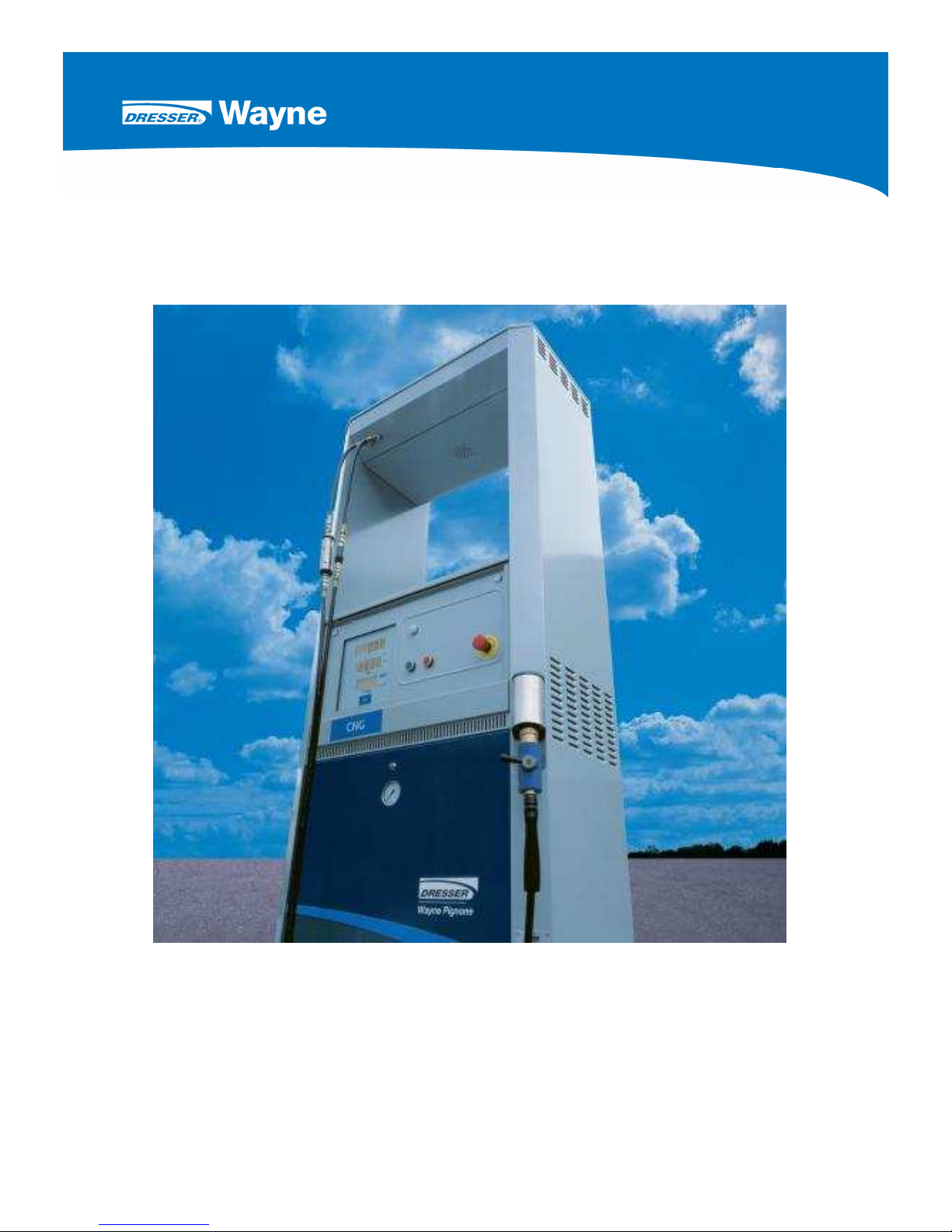

Global Vista CNG

Instruction Manual

Page 2

© Copyright

2008-03-20 V0 Rev.01.0

- 2 - WT004139

Product Liability

The supplier’s product

liability is only valid if no

alterations, additions etc.

have been made to the

equipment without the supplier’s express permission.

Use only genuine parts.

Produktansvar

För att en leverantörs

produktansvar skall gälla får

ändringar, kompletteringar

och liknande ej göras i utrustningen utan leverantörens godkännande.

Originalreservdelar skall

alltid användas

.

Produkthaftung

Damit die Produkthaftung

des Lieferanten ihre

Gültigkeit behält, dürfen

ohne ausdrückliche

Genehmigung des

Lieferanten keine

Änderungen, Ergänzungen

o. Ä. an der Ausrüstung

vorgenommen werden.

Verwenden Sie nur

Originalteile.

Oтветственнoсть

пoставщика

Для сохранения

ответственности нельзя

вводить в оборудование

изменения, дополнения и

т.п. без разрешения

поставщика. Пользуйтесь

только оригинальными

запасными частями,

выпущенным

изготовителем

бензоколонки.

Caution

To prevent damage that

might result in electric shock

or fire, disconnect the main

power prior to any work.

Varning

Gör pumpen/enheten strömlös innan Du gör ingrepp i

den. I annat fall föreligger

risk för skada.

Vorsicht

Um Beschädigungen zu

vermeiden, die zu einem

elektrischen Schlag oder

Feuer führen können,

unterbrechen Sie vor jeder

Arbeit die Stromzufuhr.

Осторожно

Во избежание поражения

электрическим током или

пожара отключайте напряжение питания перед

началом любых работ.

Warning

Never run a leaking pump!

Be careful with the environment and mind the skidding

risk; take care of leaking fuel

immediately.

Varning

Använd aldrig en läckande

pump.

Tänk på miljön och halkrisken, sanera utläckt drivmedel snarast.

Warnung

Lassen Sie nie eine undichte

Zapfsäule laufen! Seien Sie

umweltbewusst und denken

Sie an die Rutschgefahr;

beseitigen Sie austretenden

Kraftstoff umgehend.

Предупреждение

Не пользуйтесь колонкой

при наличии утечки

топлива! Охраняйте

окружающую среду,

помните об опасности

скольжения: в случае

утечки топлива на

дорожное покрытие возле

колонки, примите меры

немедленно.

The contents of this

publication may not be

copied either wholly or

in part without the

consent of Dresser

Wayne AB.

Dresser Wayne AB

reserves the right to

change specifications

contained in the text and

illustrations without

notice.

Innehållet i denna publikation får ej helt eller

delvis kopieras utan

medgivande från

Dresser Wayne AB.

Dresser Wayne AB förbehåller sig rätten att

utan särskilt meddelande

ändra specifikationer

givna i text och bild.

Der Inhalt dieses

Handbuches darf ohne

die Erlaubnis von

Dresser Wayne weder

ganz noch teilweise

kopiert werden.

Dresser Wayne behält

sich das Recht vor,

textliche oder bildliche

Inhalte ohne besondere

Mitteilung zu ändern.

Не разрешается

копировать полностью

или частично содержание

настоящей публикации

без разрешения фирмы

Dresser Wayne АВ.

Dresser Wayne АВ

оставляет за собой право

вносить изменения в

спецификации,

содержащиеся в тексте и

иллюстрациях, без

предварительного

уведомления.

Page 3

© Copyright

2008-03-20 V0 Rev.01.0

- 3 - WT004139

Index

General Warnings............................................................................................4

Warnings for fuel station operators...............................................................4

Consulting the manual....................................................................................................................................5

Warnings and safety.......................................................................................................................................5

Protection from pressure-related risks............................................................................................................ 5

Preventing CNG leaks....................................................................................................................................5

Breakaway devices.........................................................................................................................................5

Electrical installation / Preventing electrical shocks ......................................................................................6

Dispenser Identification .................................................................................................................................6

Main technical characteristics ........................................................................................................................ 6

Main technical characteristics ........................................................................................................................ 7

Operating principles....................................................................................................................................... 7

Electrical system ............................................................................................................................................ 7

Typical operating diagram ............................................................................................................................. 8

START-UP........................................................................................................8

Transportation, unpacking and handling internal components.......................................................................8

Installation......................................................................................................................................................9

Initial start-up............................................................................................................................................... 16

Dispensing procedure...................................................................................................................................16

COMPONENTS.............................................................................................17

Hydraulic components.................................................................................................................................. 17

Electrical components..................................................................................................................................17

HYDRAULIC COMPONENTS...................................................................18

Manual ball valve.........................................................................................................................................18

Particulate filter............................................................................................................................................18

Check valve..................................................................................................................................................18

Mass-flow meter...........................................................................................................................................18

Motorized valve ...........................................................................................................................................18

Pressure gauge..............................................................................................................................................18

Delivery hose ...............................................................................................................................................18

Delivery Nozzle ...........................................................................................................................................18

Three-way valve...........................................................................................................................................19

Breakaway Device........................................................................................................................................ 19

ELECTRICAL COMPONENTS.................................................................19

Electronic head.............................................................................................................................................19

Electrical components used in hazardous areas............................................................................................20

MAINTENANCE...........................................................................................20

Relieving pressure from the dispenser..........................................................................................................21

Cleaning.......................................................................................................................................................21

Disassembling / Scrapping the dispenser ..................................................................................................... 21

OPERATIONAL PROCEDURES ON THE ELECTRONIC HEAD......22

Changing prices............................................................................................................................................22

Operational modes of the dispenser .............................................................................................................23

Further information......................................................................................................................................23

ID PLATE.......................................................................................................24

DECLARATION OF CONFORMITY........................................................25

NOTES............................................................................................................26

MARKET & SERVICE ................................................................................27

Page 4

© Copyright

2008-03-20 V0 Rev.01.0

- 4 - WT004139

The descriptions and illustrations in this manual are not binding.

DRESSER reserves the right to make any modifications it considers necessary to make technical improvements

or for any other structural or commercial reason, at any time and without having to update the present

publication. Modifications will not compromise the essential characteristics of the equipment.

General Warnings

• Before using this equipment, read carefully the instructions in this manual in order to effectuate a

correct carry out transportation, start-up and ordinary maintenance.

• Dresser is not responsible for any operations not listed in this manual. In case of breakdown, failure or

malfunction, refer exclusively to the Maintenance Company or Dresser itself.

• Dresser declines responsibility for any damage to things and/or persons due to non-compliance with

safety rules.

• The safety rules in this manual are an integration and not a replacement of the laws in effect in those

countries where this equipment is installed. It is assumed that the station operators have full

knowledge of the safety rules of the country where they operate.

• In case of doubts regarding the proper functioning of the equipment, please refer to the maintenance

company or to Dresser itself to obtain any necessary instructions.

• In case of breakdowns and/or malfunctions of the pump or of its components, refrain from performing

any intervention that may compromise the safety of the equipment. Refer exclusively to the

maintenance company of Dresser itself.

• Periodically check the safety devices in compliance with the instructions of this manual and ensure

they are in perfect condition.

• Dresser will not be held responsible for any tampering performed by the customer, who in this case will

be the only party held liable by the competent authorities.

• For further information on the main components of the equipment (mass flow meter, actuator, board,

etc) and/or original spare parts, see the specific technical documentation given to your technical

assistance/after-sales company.

Warnings for fuel station operators

• The station manager and attendant must carefully read this manual before starting the equipment. We

also recommend keeping this manual throughout the operational life cycle of the equipment, without

adding or modifying anything.

• The customer will be held responsible for any damages due to corrosion, incrustation, pollution,

oxidation, dust, wear-and-tear and gradual deterioration of the product for which conformability limits

have not been set. The customer will also be responsible for any damages related to improper use or

maintenance of the product. Furthermore the customer will also be responsible for any damages

caused by any modifications to the product without prior consent by Dresser, in particular modifications

that are not compliant to what was established in the initial purchase order.

• The use of non-original spare parts by the customer will discharge Dresser from any responsibilities

and from any compensation.

• The GLOBAL VISTA CNG dispenser has the marking guaranteeing that the equipment has been

manufactured in conformity with the applicable EU directives. The dispenser leaves the factory

equipped with the CE declaration of conformity (see the last page of this manual). The CE declaration,

just like this manual, must be kept and shown upon request by the competent authorities, in case of

inspections and/or tests. Any modifications to the product that have not been previously approved by

Dresser will invalidate the declaration of conformity.

Page 5

© Copyright

2008-03-20 V0 Rev.01.0

- 5 - WT004139

Consulting the manual

The GLOBAL VISTA CNG compressed natural gas dispenser is used in areas that are potentially dangerous

and with flammable products.

We recommend scrupulously to follow the precautions and warnings described hereafter. Non-compliance

with the rules listed in this manual could potentially bring serious damages to things or persons.

Warnings and safety

Always follow safety precautions in the CNG area of the fuelling station.

Display the following the signs in clearly visible areas:

NO SMOKING

NO OPEN FLAMES

FLAMMABLE PRODUCTS

TRIPPING HAZARD

PERIODICALLY INSPECT THE PROPER FUNCTIONING OF THE EXTINGUISHERS

RISK OF EXPLOSION

ALWAYS USE PROPER PERSONAL PROTECTION

DISCONNECT ALL ELECTRICAL CONNECTIONS BEFORE WORKING ON THE

DISPENSER

VERIFY PROPER FUNCTIONING OF GROUNDING SYSTEM

The positions of these warnings depend on local conditions but they must be visible from the dispenser.

Ensure that all station attendants know how to behave in an emergency situation

Protection from pressure-related risks

The hydraulic circuit of the dispenser works under pressure.

Before performing any maintenance, accurately close the cut-off valve/s located at the base of the dispenser

and release the internal circuit pressure. Pay particular attention in releasing pressure, as, if not performed

properly, some sections of the hydraulic circuit can remain under pressure due to the presence of check

valves and/or motorized valves. To release the dispenser pressure follow the instructions mentioned later on

in the manual.

Preventing CNG leaks

Take all the necessary measures to prevent any gas leaks.

Breakaway devices

In some countries the use of breakaway devices are obligatory by law. We recommend it nonetheless even in

countries where it is not compulsory, in order to guarantee interruption of gas flow in case of an accidental

pull on the hose.

Page 6

© Copyright

2008-03-20 V0 Rev.01.0

- 6 - WT004139

Electrical installation / Preventing electrical shocks

-

Ensure a correct power supply

Never open the CPU when the dispenser is powered.

Never disconnect cables when the dispenser is powered.

Before opening the dispenser for maintenance, always disconnect all power connections.

-

During maintenance, prohibit or restrict access to the switches used to interrupt power supply to

the dispenser.

-

Ensure that the fuelling station has both an electrical line equipped with an automatic breakaway

device as well as a proper grounding system in compliance with all applicable regulations.

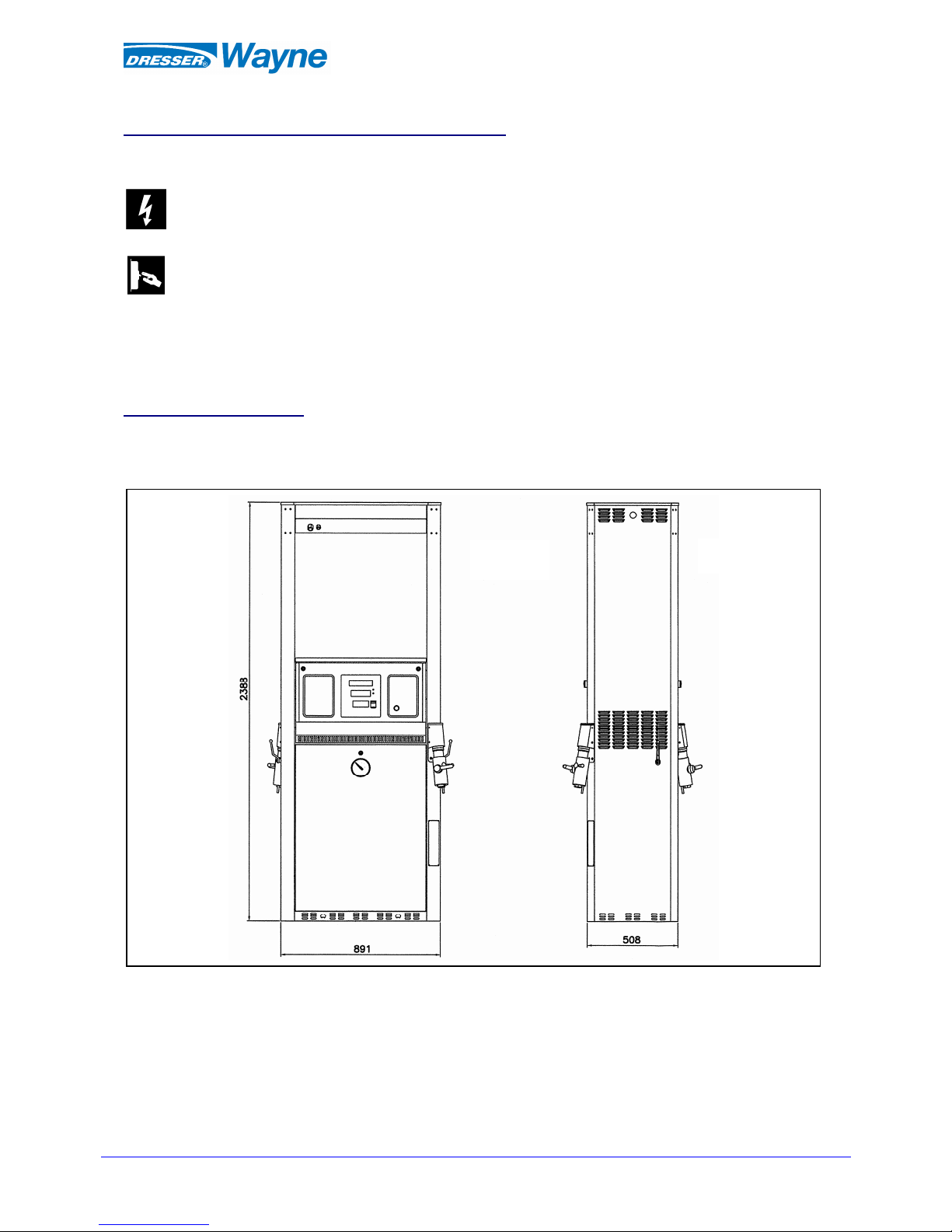

Dispenser Identification

The GLOBAL VISTA CNG dispenser can be manufactured in different versions due mainly to the different

hydraulic configurations.

The following drawing illustrates the general shape and dimensions of the standard model:

B SIDE

A SIDE

Page 7

© Copyright

2008-03-20 V0 Rev.01.0

- 7 - WT004139

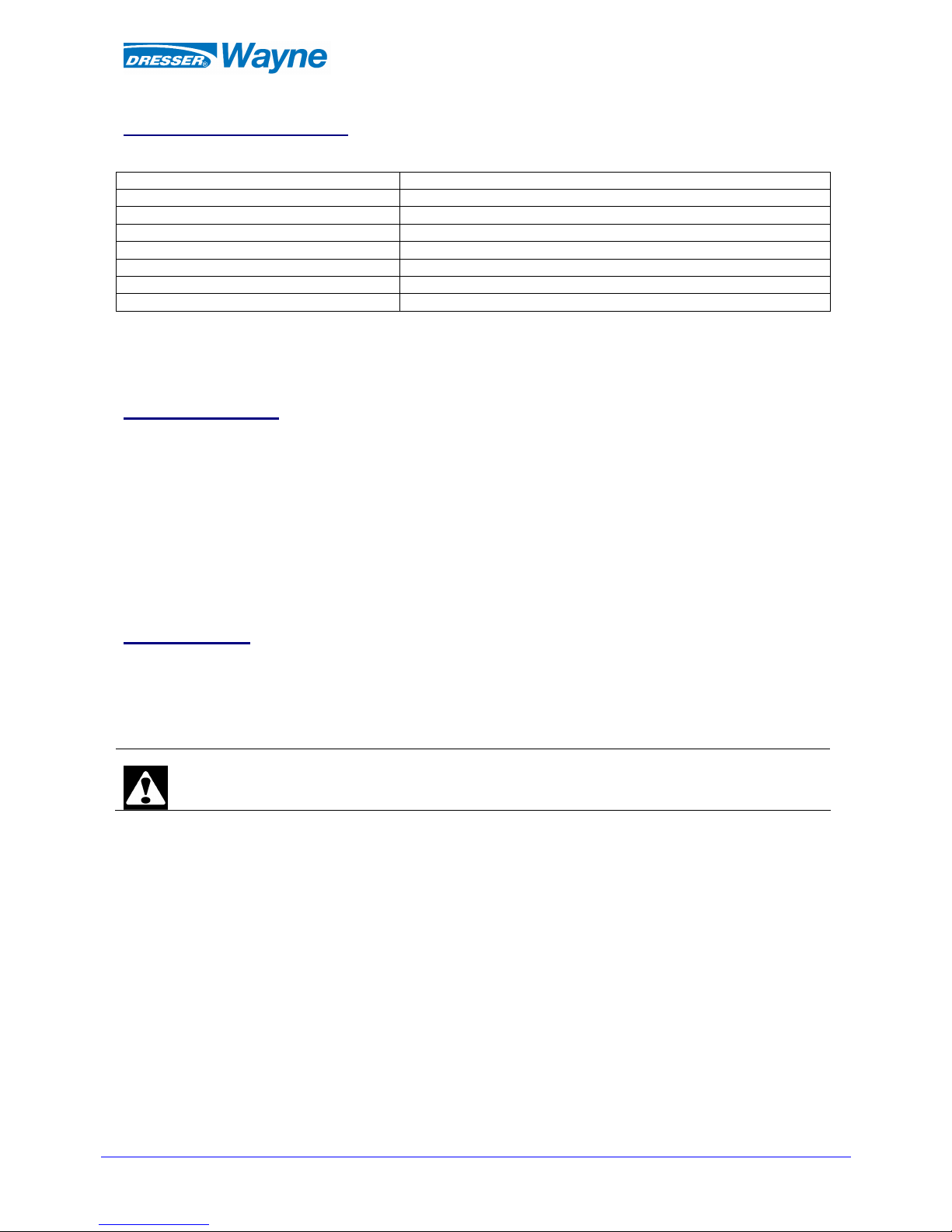

Main technical characteristics

The main technical characteristics of the GLOBAL VISTA CNG dispensers are listed in the following table:

Maximum flow 77 kg/min

Minimum flow 0,06 kg/min

Minimum measurable quantity 5 kg

Measuring accuracy ± 1%

Maximum working pressure 250 bar

Power supply 230 Vac +15 -25% 50-60 Hz

Storage and working temperatures -20°C ÷ +40°C

Approximate weight (with packaging) Min. 200 kg - Max. 300 kg

The function of the CNG dispenser is to fill compressed natural gas into vehicle tanks. Dresser CNG

dispensers can pump both at high flow and standard flow and can therefore fuel all vehicles using CNG, such

as automobiles, vans, buses and trucks.

Operating principles

The compressed natural gas moves from the storage tank or directly from the compression unit, to the CNG

dispenser, and then reaches the vehicle’s tank, passing through the mass-flow meter in the dispenser.

The information given by the mass-flow meter or any other sensors (temperature sensor, pressure sensor,

etc.) are processed by the electronic head, which carries out specific operations based on the values it

receives.

The CNG dispensers can be:

• Single-stage dispensers that control a single valve (first stage level); their hydraulic system

communicates with one storage tank only;

• Multi-level dispensers (cascade system) which control two or three valves (first, second, third

level valves); their hydraulic system communicates with two or three storage tanks with different

pressures.

Electrical system

The electrical system, which allows all of the dispenser’s functions (control, command, lighting, etc.), is in

compliance with the safety regulations and legislations that are relative to the installations in potentially

explosive atmospheres.

Cables and safety switches must be chosen and sized according to applicable EN/CEI norms.

Important!

In order to respect current safety regulations, wiring must be performed exclusively by technicians

who install CNG dispensers

Page 8

© Copyright

2008-03-20 V0 Rev.01.0

- 8 - WT004139

VENT

GAS INLET

MIDDLE

PRESSURE

LOW

HIGH

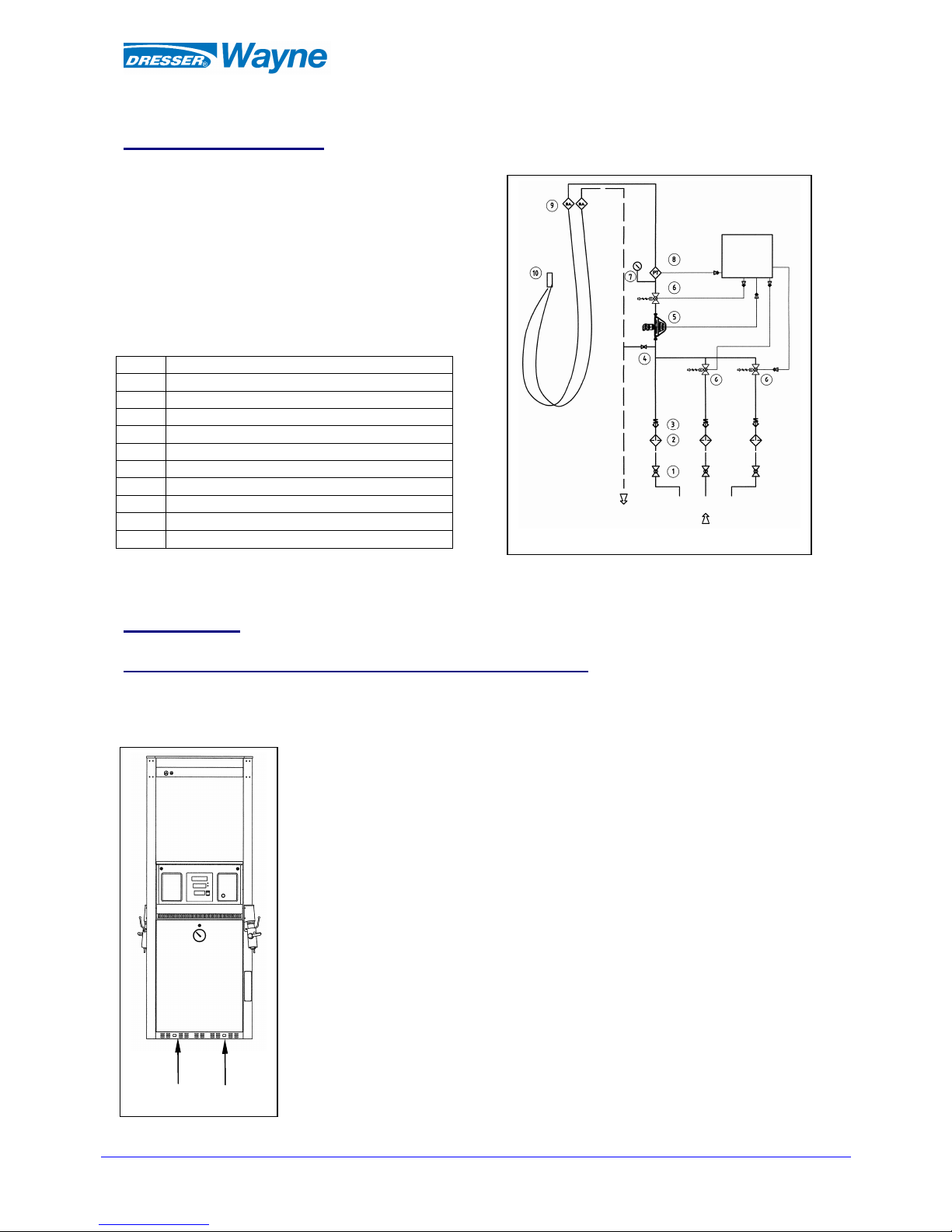

Typical operating diagram

The following diagram illustrates the operating principles of a CNG dispenser with three levels of pressure.

10 Vehicle connection

9 Breakaway device

8 Pressure transmitter

7 Pressure gauge

6 Valve

5 Meter

4 Vent valve

3 Check valve

2 Filter

1 valve (optional)

Pos. Denomination

START-UP

Transportation, unpacking and handling internal components

During transportation the dispenser must be handled with care. Please follow the

instructions on the packaging at all times.

When lifting with forklift trucks lift on the areas indicated with the arrows in this

diagram (areas are about 50 cm one from the other).

Always use the proper methods to lift and transport the dispenser. Non-compliance

with the instructions for moving the dispenser could cause serious damages to

things and people.

Once you have received the dispenser, carefully inspect the equipment to ensure

that it has not been damaged during transportation. Any damaged equipment must

be sent back to the shipper.

While unpacking, make sure not to damage the painted surfaces.

Do not remove the film that protects the dispenser’s lining before it is completely

installed. However, it must be removed immediately after installation to ensure an

easy removal that will not damage painted surfaces. Use proper products (avoid

harmful solvents) to eliminate any glue residues.

Computing

head

Page 9

© Copyright

2008-03-20 V0 Rev.01.0

- 9 - WT004139

To access internal components for installation and ordinary maintenance, use

the proper key supplied with the dispenser to open lower front panels and/or the

head box.

Installation

Before installing the dispenser, it is necessary to ensure that installation is carried out exclusively by qualified

technicians that are fully knowledgeable about both installation procedures as well as about prevailing

applicable regulations.

All equipment must be installed in compliance with the requirements of the applicable regulations.

In many countries there are norms on safety distance that must be carefully followed. It is necessary to

ensure that these norms are respected, starting from the planning project of the system.

In Italy, the connection of the dispenser to the gas adduction line must take place through an excess flow

valve.

Dresser cannot be held responsible for any damages to persons and/or things deriving

from an improper installation of the dispenser.

When installing, it is necessary to pay particular attention to the following aspects.

Electrical system and safety

Install an emergency stopping system (normally composed of an emergency button and one or more safety

switches) that is capable of interrupt the flow to the equipment in case of operating problems. The emergency

stopping system, not included with the dispenser, must comply with national regulations (for example EN

60204-1). The safety device must be placed in the gas station in order that it is easily accessible to

attendants. Following an emergency stop, the emergency button must be reset before returning back power

to the station.

Returning power must not cause an automatically start of the fuelling.

Ensure that all station attendants fully know where the emergency system is located and how it works.

To install the CNG dispenser, perform the following operations:

• open front panels;

• place and fasten the dispenser on the base;

• make hydraulic connections and check the fastening on the dispenser’s connections;

• connect electrical wiring, checking electrical values;

• power the dispenser;

• open the gas inlet valve;

• open the air/instrument valve (6 / 8 bar);

• close front panels;

In order to properly make hydraulic and electrical connections, always refer to the diagrams supplied by

Dresser.

During transportation the dispenser’s hydraulic connections may loosen. Check whether all

the dispenser’s connections are tight. Always verify that the dispenser or, more generally, the

whole system has no gas leaks.

Page 10

© Copyright

2008-03-20 V0 Rev.01.0

- 10 - WT004139

Page 11

© Copyright

2008-03-20 V0 Rev.01.0

- 11 - WT004139

Page 12

© Copyright

2008-03-20 V0 Rev.01.0

- 12 - WT004139

Page 13

© Copyright

2008-03-20 V0 Rev.01.0

- 13 - WT004139

Page 14

© Copyright

2008-03-20 V0 Rev.01.0

- 14 - WT004139

Page 15

© Copyright

2008-03-20 V0 Rev.01.0

- 15 - WT004139

Page 16

© Copyright

2008-03-20 V0 Rev.01.0

- 16 - WT004139

Initial start-up

Initial start-up is needed to verify whether the dispenser is in perfect operating condition.

Before starting the dispenser, ensure that all installation procedures have been properly carried out (hydraulic

connections, sealing of the fittings, electrical connections, etc.).

Make sure that the junction boxes are properly closed and that all cable glands are accurately fastened.

The junction boxes must not present any signs of openings; any holes not intended for the cables must be

closed with original plugs.

The first start-up of the CNG dispenser must be performed by properly trained personnel. To install the CNG

dispenser, follow the procedure below:

• Switch dispensing selector to the OFF position;

• Power the dispenser complying with the values listed on the corresponding electrical schemes;

• Switch dispensing selector to the ON position;

• Place the hydraulic circuit under pressure and ensure there are no leaks on the hydraulic

connections;

• Switch the dispensing selector to the OFF position;

• Clean the dispenser (minimum delivery of 10 m3 of gas) by dispensing some gas following the

procedure indicated in the following paragraph;

• Check the meter’s calibration by dispensing gas a few times and comparing the measurements

given by the electronic head with those given by a proper sampling instrument (For Example:

precision scale);

Dispensing procedure

To dispense CNG, follow these procedures:

• remove the nozzle from its housing;

• connect the nozzle to the vehicle’s tank or to a test tank (suitable for storing natural gas at the

maximum fuelling pressure);

• bring the three-way valve to the «ON» position (dispensing);

• start dispensing by activating the dispensing selector switch (bring it to the «ON» position);

• the dispenser manages the end of delivery and the stop appears when a pre establish value of

pressure or low flow is reached;

• after stop switch the dispensing selector to the «OFF» position;

• bring the three-way valve to the «VENT» position (no dispensing);

• remove the nozzle from the vehicle’s tank or from the test tank;

• re-insert the nozzle in its housing;

Note 1: the three-way valve can be integrated onto the nozzle or separated.

Note 2: a light signal always indicates the operating status of the dispenser (green= dispenser

ready; red= dispenser fuelling or in error)

Note 3: Pay attention to activate the selector switch only after the three way valve is ON position.

Page 17

© Copyright

2008-03-20 V0 Rev.01.0

- 17 - WT004139

9

10

11

8

12

17

18

19

COMPONENTS

This section briefly describes the main components of a CNG dispenser. The components can be divided into

three groups: external components, hydraulic components and electrical components.

External components

1. Lower front panel

2. Column

3. Nozzle Housing

4. Computing Head Housing

5. Cover

6. Base

7. Id plate

Hydraulic components

8. Manual ball valve

9. Particulate filter

10. Check valve

11. Mass –flow meter

12. Motorized valve

13. Pressure gauge

14. Delivery hose

15. Delivery Nozzle

16. Breakaway Device

Electrical components

17. Electronic head

18. Pressure transmitter

19. Junction box

1

3

2

5

6

7

4

13

14

16

15

Page 18

© Copyright

2008-03-20 V0 Rev.01.0

- 18 - WT004139

HYDRAULIC COMPONENTS

Manual ball valve

The manual ball valve is on the dispenser inlet and prevents the entrance of natural gas in the dispenser itself

during any maintenance operations.

This valve is normally installed on a system when a dispenser is also installed.

Particulate filter

The particle filter is on each inlet line of the dispenser and its function is to separate any solid particles from

the compressed natural gas in order to optimize gas flow and avoid particle deposits in the internal

components.

Check valve

The check valve’s function is to prevent gas flow in the opposite direction of dispensing.

Mass-flow meter

The CNG dispensers are equipped with mass-flow meters that rely on the Coriolis effect. The mass-flow

meter measures the quantity of gas dispensed and communicates with the electronic head.

Coriolis effect: a force apparently due to the speed of rotation of a non-inertial reference system

compared to an inertial reference system; it is equal and opposite to the product of the mass of

particles on which it acts and the relative Coriolis acceleration

For operating characteristics and more information regarding the mass-flow meter, refer to the specific

technical manuals.

Motorized valve

The motorized valve includes a ball valve, a solenoid and a pneumatic actuator.

When the dispensing selector is switched to the ON position (dispensing), the head sends a command to the

solenoid, which activates the inlet of compressed air into the actuator through the inlet door; at this point the

ball valve opens and the gas starts to flow.

The motorized valve returns to its initial position when the head sends the inverse command to the solenoid,

which activates the inlet of compressed air through the outlet door; in this case the ball valve closes and the

flow of the gas stops.

Pressure gauge

The CNG dispenser has a pressure gauge with a scale division from 0 to 400 bar, which allows a constant

monitoring of gas pressure.

Delivery hose

The CNG dispenser’s filling hoses are specifically designed and manufactured to supply natural compressed

gas.

The hoses are wear proof and are high-performance.

There are twin hoses for dispensing and venting.

Standard hoses have an internal diameter of ¼ inch (standard flow) or ½ inch (high flow)

Delivery Nozzle

The CNG dispenser has nozzles capable of satisfying all the requisites of efficiency and safety related to

CNG fuelling.

Generally there are two types of nozzles, for light vehicles (used to fuel automobiles, vans and small trucks)

or nozzles for heavy vehicles (used to fuel buses and trucks). However, there are different nozzles, according

to the characteristics required by different CNG systems (Italy type, NGV1 type, NGV2 type etc).

Page 19

© Copyright

2008-03-20 V0 Rev.01.0

- 19 - WT004139

Three-way valve

The three-way valve is a ball valve which allows gas to flow from the CNG to the vehicle tank.

This valve works according to three different positions:

• OFF position prevents gas flow (no dispensing);

• ON position allows gas flow (dispensing);

• VENT position allows gas to vent from the nozzle;

When the three-way valve is in the vent position, the nozzle can be removed from the CNG vehicle in total

safety.

The three-way valve can be integrated on the connector (standard NGV1 and NGV2).

It is important to place the three-way valve in the vent position before connecting the nozzle to

the tank

Breakaway Device

The CNG dispenser is equipped with breakaway devices capable of immediately interrupting the gas flow if a

vehicle that is being fuelled should move with the nozzle still connected to the tank.

This safety device interrupt gas flow and hence prevents damages to persons, the dispenser and the vehicle.

ELECTRICAL COMPONENTS

Electronic head

Description

The CNG dispenser is equipped with a Dresser electronic head which guarantees high performance in

calculating and constantly monitoring all the operations carried out by the dispenser.

The head, designed specifically to manage CNG dispensers, performs the following operations:

• management and control of the valves and sensors in the dispenser (meters, transducers, etc);

• calculation and display of fuel-related prices and weights;

• management of devices indicating the status of the dispenser (signal lights);

• interfacing with any POS System;

Operation

After having received the signals/values from the mass-flow meter (or any other sensors) the head performs

the following operations:

• controls the CNG fuelling procedure;

• shows fuelling data on the LCD displays;

The electronic head, used on different types of CNG dispensers, can work in four different modes:

• single level mode;

• multi level mode (cascade system);

The data displayed is:

• total price;

• volume supplied, displayed in «kg» or «m3» according to the chosen configuration;

• unit price;

Page 20

© Copyright

2008-03-20 V0 Rev.01.0

- 20 - WT004139

Configuration parameters

The proper functioning of the head is guaranteed by programming a series of configuration parameters,

divided into two groups:

• accessible parameters;

• non-accessible parameters (protected by a metric seal);

To set these parameters it is necessary to use the four buttons on the display.

The final part of the manual indicates the operating procedures to change prices and define the operating

modes of the dispenser.

For all other functions refer to the specific manual of the head.

Error conditions

During operation, the head performs a constant error diagnostic. Once an error is identified, the head:

• immediately stops fuelling (blocking condition);

• lights a red led;

• shows the error code corresponding to the identified error on the unit price display;

When an error is identified during fuelling, the unit price displays the «bloc» message and the error code is

displayed only after the dispensing selector is turn to OFF.

Electrical components used in hazardous areas

The dispenser can be used in potentially explosive areas due to the presence of gas.

The whole dispenser is marked CE/ATEX as a device of group II, category 3 G even in compliance with

prEN13638.

For safety, the electrical system uses single components (junction boxes, meter, pressure transmitter,

electro-valves, etc.) suitable for group II, category 2 G.

MAINTENANCE

The dispenser leaves the factory only after passing accurate tests (hydraulic and electrical). A correct

installation and use should guarantee proper functioning.

In any case, in order to maintain the dispenser’s optimal conditions in time and guarantee its safety, the

station manager must check the components listed in the table below periodically.

Component Intervention

Pneumatic actuator Periodically replace all gaskets and piston slides; check cylinder wear

Electronics and measuring tube Perform measuring tests during official inspections

Filter Disassemble the filter and clean filtering element or replace it if

damaged

Delivery hose Replace if damaged

Three-way valve Check sealing of gaskets and replace if damaged

Check valve Check sealing

Vent valve Check sealing of gaskets and replace if damaged

Gas inlet valve Check sealing of gaskets and replace if damaged

The operational life of these components depends of different conditions such as, for example, the quality of

the product being dispensed, environmental characteristics, climatic conditions and method of use.

The periodicity of maintenance operations must be established as a consequence.

Maintenance operations must be performed exclusively by qualified technicians, trained for this purpose.

Maintenance operators will have to use all personal safety protection (proper shoes, gloves and glasses, etc).

Maintenance operators must be knowledgeable of all measures to adopt in order to prevent any explosive

reaction in the presence of gas (for example, avoid naked flames, sparks, and electrostatic discharge).

Page 21

© Copyright

2008-03-20 V0 Rev.01.0

- 21 - WT004139

Relieving pressure from the dispenser

Before intervening on any hydraulic component, it is necessary to completely discharge pressure from the

gas system in the dispenser as follows:

• close the cut-off valve (ball valve at dispenser inlet);

• open ball valve on the actuator with the manual command on the solenoid valve;

• open the vent valve to discharge gas from the dispenser ensuring that all gas completely leaves

the system;

• at this point it is possible to operate on the hydraulic system ;

• after the intervention, close the vent valve and the ball valve on the actuator and open the ball

valve on the dispenser inlet;

Always remember to disconnect the power supply before operating on the components of the

CNG dispenser.

Cleaning

To clean the dispenser, do not use abrasive detergents or products petrol/petroleum-based products.

Instead, use water with non-aggressive detergents and soft cloths. Adopt all necessary precautions to avoid

any water entering the dispenser.

Before entering the head box, carefully dry any traces of cleaning water. In case of bad weather, make sure

no rain enters the head box. Always remove any snow or ice from the dispenser

.

Disassembling / Scrapping the dispenser

For any reason before disassembling the dispenser, make sure it is completely emptied of any gas. For

transportation, observe all applicable laws. For scrapping, keep with local legislation.

To avoid the risk of electrical shock and/or fire, disconnect all electrical power before

disassembling the dispenser.

Page 22

© Copyright

2008-03-20 V0 Rev.01.0

- 22 - WT004139

OPERATIONAL PROCEDURES ON THE ELECTRONIC HEAD

The GLOBAL VISTA CNG dispenser is equipped with an OTP-ELT electronic head that manages all fuelling

operations and allows the programming of a series of functions.

The display screen, that is the interface between head and user, visualizes the data; the different information

appears on the price, volume and unit price displays.

Changing prices

To change the prices values, press the P0, P1, P2 e P3 programming

buttons on the side of the display.

Press the P1 button to enter in the price change mode.

The price display will show some hyphens, while the volume display will show the pre-established unit price

(for example: 1,235)

------ -----0

1.235 1.235

For example, pressing P0 once and P1 twice, the display will appear as follows:

-----2

1.235

Pressing P0 again, another digit is added on the display and it can be increased or decreased by pressing P1

or P2 respectively.

----20

1.235

The same applies when setting the next digits.

If the new price is set the data can be saved pressing the P3 button. At this point, the volume and price

displays show the data from the last fuelling, while the unit price display shows the new price set.

Using buttons P0, P1 or P2, set new

unit price.

Pressing P0, a zero will appear on the

price display. This value 0 can be

increased with P1 and decreased with

P2

Always use clean and dry hands.

During these operations pay attention to not remove the W&M

seals.

Page 23

© Copyright

2008-03-20 V0 Rev.01.0

- 23 - WT004139

Operational modes of the dispenser

The head can be connected to host equipment for fuelling management.

Operational modes can be set with the P001 parameter.

Values are 0 e 1.

0 = manual mode

1 = automatic mode

Warning, if the dispenser is connected to the Host, it will shift into automatic mode even if it is set

to manual.

Further information

For further information regarding programming, operation and the meaning of certain error codes displayed

by the electronic head, refer to the related manual.

Page 24

© Copyright

2008-03-20 V0 Rev.01.0

- 24 - WT004139

ID PLATE

The GLOBAL VISTA CNG ID plate lists the following information

1 Serial number

2 Year of construction

3 Type of product

4 Space for directions

5 II 3 G (group II surface, category 3, potentially explosive atmosphere due to presence of gas, vapors or

fog)

6 CE marking (in compliance with EMC and ATEX)

7 Epsilon-X marking (in compliance with the ATEX directive)

8 Name and address of the manufacturer

3

1

2

ID PLATE

4

5

6

7

8

Page 25

© Copyright

2008-03-20 V0 Rev.01.0

- 25 - WT004139

DECLARATION OF CONFORMITY

Page 26

© Copyright

2008-03-20 V0 Rev.01.0

- 26 - WT004139

NOTES

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Page 27

© Copyright

2008-03-20 V0 Rev.01.0

- 27 - WT004139

MARKET & SERVICE

To obtain name and address of the closest authorized maintenance company, please contact:

DRESSER WAYNE

DRESSER Italia S.r.l.

Via Roma 32 - 23018 TALAMONA (SO)

Tel. 0342 608111 - Fax 0342 608299

Page 28

Headquarters

3814 Jarrett Way

Austin, TX 78728

Phone: +1 512.388.8311

Fax: +1 512.388.8302

www.wayne.com

Wayne Sweden

Limhamnsvägen 109

Box 30049

SE-200 61 Malmö

Sweden

Phone: +46 40 360500

Fax: +46 40150381

www.wayne.se

Wayne Brazil

Estrada do Timbo

126-Bonsucesso

Rio de Janeiro, Brazil

Phone: +55-21-2598-7711

Fax: +55-21-2598-7860

Wayne China

1221 Dong Lu Road

Pudong, Shanghai

200135

China

Phone: +8 21-5899-3976

Fax: +8 21-5899-0974

More than a century of experience

Über 100 Jahre Erfahrung

Mer än 100 års erfarenhet

Более, чем столетний опыт работы

Wayne Dresser develops,

manufactures and markets

complete operative systems for

fuel handling at service stations.

Everything from development

and design to efficient production and assembly of components is pursued under one

roof.

Wayne Dresser entwickelt,

produziert und vermarktet

komplette funktionierende

Systeme für die Abgabe von

Kraftstoffen an Tankstellen..

Von der Entwicklung über das

Design bis zur Herstellung und

Installation liefern wir alles aus

einer Hand.

Wayne Dresser utvecklar, tillverkar och marknadsför kompletta operativa system för drivmedelshantering på servicestationer. Under ett och samma tak

ryms allt från utveckling och

konstruktion till rationell tillverkning och sammansättning av

komponenter.

Wayne Dresser разрабатывает,

производит и продает

совершенные оперативные

системы для торговли топлива

на станциях обслуживания.

Все начиная от разработок и

конструкции до эффективного

производства и сборки

компонентов происходит в

пределах одного предприятия.

Wayne Dresser’s

operations comprise four

interdependent functions:

Die Niederlassungen von

Wayne Dresser umfassen vier

ineinander greifende Bereiche:

Verksamheten omfattar fyra

samverkande delar:

Действия Wayne Dresser

включают четыре

взаимосвязанных

направления:

• Equipment such as petrol

pumps, payment terminals, pointof-sale terminals and service

station operative systems.

• Software for recording and

for internal communication at the

station, as well as between the

station and the oil company,

banks and credit institutes.

• Project design with overall

responsibility to the customer.

• Field service, technical

support and supply of spare parts.

• Ausrüstungen wie

Zapfsäulen, Zahlterminals,

Kassenterminals und

Tankstellensysteme

• Software für Registrierung

und Kommunikation auf der

Tankstelle u. zwischen Station

und Mineralölfirma sowie Banken

und Kreditinstituten.

• Projektgestaltung mit

umfassender Verantwortlichkeit

dem Kunden gegenüber.

• Service, technische Unter-

stützung und Lieferung von

Ersatzteilen.

• Utrustning som

bensinpumpar, betalterminaler,

butiksterminaler och stationsdatorer.

• Programvara för registrering

och kommunikation internt på

stationen samt mellan stationen

och oljebolaget, banker och

kreditinstitut.

• Projektering med totalansvar

gentemot uppdragsgivaren.

• Service på fältet, teknisk

support och reservdelsförsörjning.

• Оборудование, например,

топливораздаточные колонки,

платежные терминалы,

терминалы точек продажи и

системы управления АЗС.

• Программное обеспечение

для регистрации и для

внутренней связи на АЗС, а

также между АЗС и нефтяной

компанией, банками и

институциями кредитов.

• Проектирование с полной

ответственностью к клиенту.

• Обслуживание на местах,

техническая поддержка и

поставка запасных частей.

Wayne Dresser makes it easier

for the motorist to fill up and

make his motoring purchases,

while effectively meeting the

needs of the service station

owner for operating supervision

and for conforming to the

demands of the authorities for

measurement accuracy,

minimising pollution and

ensuring safety.

Wayne Dresser erleichtert dem

Fahrer die Betankung und

damit verbundene Einkäufe,

unterstützt gleichzeitig den

Stationär bei der

übersichtlichen Führung seines

Betriebes unter

Berücksichtigung der

behördlichen Vorschriften

hinsichtlich Messgenauigkeit,

Umwelt- und

Sicherheitsauflagen.

Wayne Dresser gör det lättare

för bilisten att tanka och handla.

Samtidigt tillgodoses stationsägarens krav på en effektiv

driftskontroll och myndighetskraven på mätnoggrannhet,

miljövänlighet och

driftssäkerhet.

Wayne Dresser упрощает

процесс заправки и

приобретения покупок при

эффективном согласовании

потребностей владельца АЗС

для оперативного управления

и для соблюдения требований

государственных и

метрологических служб, а

также уменьшения

загрязнения окружающей

среды и обеспечения

безопасности.

Loading...

Loading...