Page 1

Installation Instructions EWP10

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Water Powered

Back-up Sump

Pump System

Description

The EWP10 is a water powered backup sump pump. It does not replace a

regular pump. This pump is designed

for use with municipal water systems

and is inteded to be used as an

emergency backup to your existing

sump pump.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return

the unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe

the following symbols.

Danger

an imminently hazardous situation

which, if not avoided, will result in

death or serious injury.

Warning

a potentially hazardous situation which,

if not avoided, could result in death or

serious injury.

Caution

a potentially hazardous situation which,

if not avoided, may result in minor or

moderate injury.

Notice

important information, that if not

followed, may cause damage to

equipment.

indicates

indicates

indicates

indicates

General Safety

Information

Do not use to pump flammable

or explosive fluids such as

gasoline, fuel oil, kerosene,

etc. Do not use in a flammable and/or

explosive atmosphere. Pump should only

be used to pump clear water. Fatal injury

and/or property damage could result.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safe keeping.

© 2007 Wayne Water Systems

If the basement has water

or moisture on the floor, do

not walk on wet area until all

power is turned off. If the shutoff box

is in the basement, call an electrician.

Remove pump and either repair or

replace. Failure to follow this warning

could result in fatal electrical shock.

A check

must be used on the primary sump

pump discharge.

This

must only be used to pump clear water.

This pump is not designed to handle

effluent, salt water, brine, laundry

discharge or any other application

which may contain caustic chemicals

and/or foreign materials. Pump damage

may occur if used in these applications

and will void warranty.

valve

pump

Installation

Installation of this unit may take

several hours. Before disabling your

main pump, have ready an appropriate

means of evacuating the sump.

1. Turn power to main pump off.

2. Pump must be installed using 1¼”

or 1½” rigid PVC pipe. Do not use

flexible drain hose.

Pump Installation

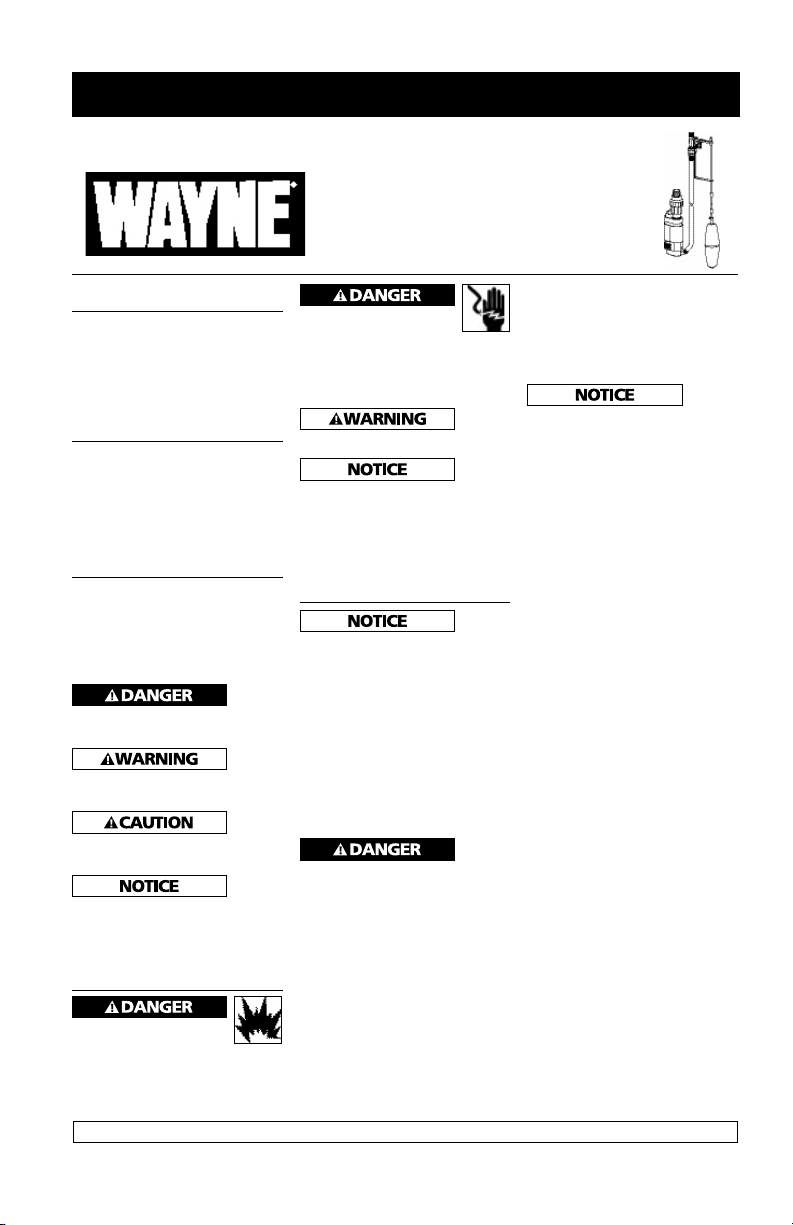

The EWP10 can be installed with a

separate dedicated discharge line

(Figure 1, Method 1) or tied into the

existing sump pump line (Figure 2,

Method 2).

Unplug

existing AC pump. Failure to follow this

warning could result in fatal electrical

shock.

3. Verify that the existing AC pump

is in good working order. If the

AC pump is questionable, it is

recommended that the unit be

replaced.

4. Remove any silt or accumulated

debris from the sump pit and

surrounding area.

5. Locate the EWP10 in an ideal

position in the sump pit. The

ideal position is approximately

2” from the bottom of the sump

pit and located so that it does

not interfere with any part of the

existing sump pump.

For parts, product & service information

visit

www.waynepumps.com

the

6. Method 1 Installation:

(Figure 1) Cut and dry-fit rigid

PVC pipe to the discharge of the

water powered back-up pump.

Cement all fittings and discharge

pipe after all pipe has been cut

and dry-fit together.

The

line installation will vary depending on

individual circumstances. Using sound

plumbing practices, route the discharge

pipe to an exterior wall by the shortest

path. Keep turns to a minimum because

they reduce the flow output of the pump.

The pipe that exits the building structure

should be sealed and sloped downward

so the water will not freeze in the pipe.

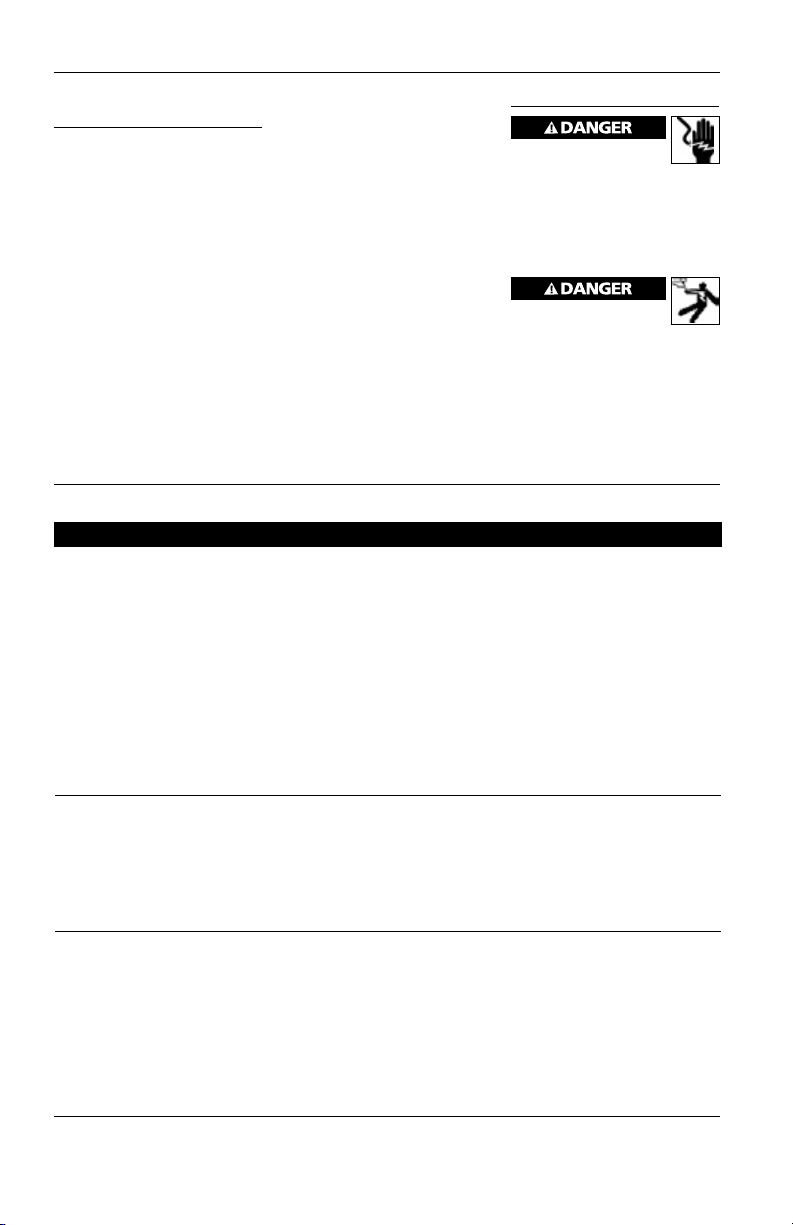

Method 2 Installation:

(Figure 2) Cut the existing main

pump discharge line and cement

a “T” or “Y” fitting. Measure,

cut and dry-fit the pipe required

to connect the EWP10 to the

installed “T” or “Y” fitting.

Cement all fittings and pipe.

7. Shut off the municipal water

supply. Install a rigid water

supply line to the sump area.

Include a shut-off valve in the

supply line. Flush the supply line

of all debris before installing the

automatic valve.

8. Connect the automatic valve

assembly with brass vacuum

breaker to the supply line. Is

should be located about 6” above

the basement floor or sump pit

cover. The supply line needs to be

supported.

9. Attach the hose coupling and

washer to the brass vacuum

breaker of the automatic valve

assembly.

10. Attach the “L” bracket to the

automatic control valve using the

two screws supplied.

11. Install the float rod by threading

the two parts together. Using

the large coupler, secure the rod

connection by threading the top

screw to the top part and the

bottom screw to the bottom part.

12. Install a small coupler and the

float to the float rod by inserting

the float rod through the center

of the float. Insert a small coupler

about ½” above the bottom of

the float rod and tighten the

fastener. Tighten the first small

coupler installed.

discharge

353300-001 7/07

Page 2

Installation Instructions

Installation

(Continued)

13. The float should be set so that

the primary pump starts before

the EWP10. Insert the float rod

through the “L” bracket hole.

Install a rubber grommet onto the

float rod, then insert the float rod

through the automatic control

valve arm and then install the

second rubber grommet on the

top of the float rod.

14. If necessary, adjust the length of

the connecting hose and attach

to the EWP10 pump with the

supplied hose clamp.

15. Turn on the water supply and

check the installation for joint

leaks and proper operation.

Simulate water activating the

water powered backup system

by raising the float to trip the

automatic control valve arm.

Hold the float in the up position

while checking the system for

leaks. Lower the float to turn off

the system and fix any leaks in

the water supply line. Retest if

necessary.

16. Fill the pit with water until the

float trips the automatic control

valve arm. The system will lower

the water level in the pit to the

shut off point of the EWP10.

Verify this on/off level of the

EWP10 is higher than the on level

of the main sump pump.

17. Reconnect power to the main

sump pump. The water level in

the pit should lower to the off

point of the main sump pump.

Test the system again to verify

that the main sump pump and

the EWP10 work together.

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

No Water is pumped

out

Pump does not pump

water to full capacity

Pump does not

shut off

1. Water supply valve closed

2. Automatic valve closed

3. Float does not rise with water

level

4. Suction or ejector clogged

5. Water level below suction in

sump

6. Improper function or missing

check valve in primary pump

discharge

7. Discharge line clogged

8. Pumping height more than

15 ft.

9. Water pressure less than 40 psi

1. Water supply partially opened

2. Automatic valve partially

opened

3. Suction or ejector partially

clogged

4. Leaky primary pump check

valve

5. Discharge line partially clogged

1. Automatic valve does not shut

off

2. Float is obstructed

1. Open supply valve

2. Check manually the valve operation

3. Check for obstruction of float action

4. Clean pump inlet

5. Adjust the float rod to shut off pump prior to low water

level

6. Install check valve in primary pump discharge

7. Check all discharge lines

8. Reduce pumping elevation to less than 15 ft

9. Run a 3/4” direct line from water supply to reduce friction

loss in pipe

1. Open supply valve

2. Check the valve operation

3. Clean pump inlet

4. Replace check valve in primary pump discharge

5. Check all discharge pipes

1. Check the valve operation

2. Check for obstruction or adjust rubber grommet to proper

off and on position

Operation

Always disconnect the power

source before attempting to

install, service, relocate or

maintain the pump. Never touch sump

pump, pump motor, water or discharge

piping when pump is connected to

electrical power. Never handle a pump

or pump motor with wet hands or when

standing on wet or damp surface or in

water. Fatal electrical shock could occur.

Risk of electrical shock! Use a

GFCI receptacle to reduce the

risk of fatal electrical shock.

Cutting the cord or plug will void

the warranty and make the pump

inoperable.

www.waynepumps.com

2

Page 3

D

Typical Installation with Submersible Pump with a Separate Discharge Pipe

Water Supply

Water-Powered

Backup Sump

Main Sump

Pump

Figure 1

Typcial Installation with Submersible Pump

EWP10

Figure 2

Water Supply

Check valve

Check valve

Water-Powered

Backup Sump

Main Sump

Pump

www.waynepumps.com

3

Page 4

Installation Instructions

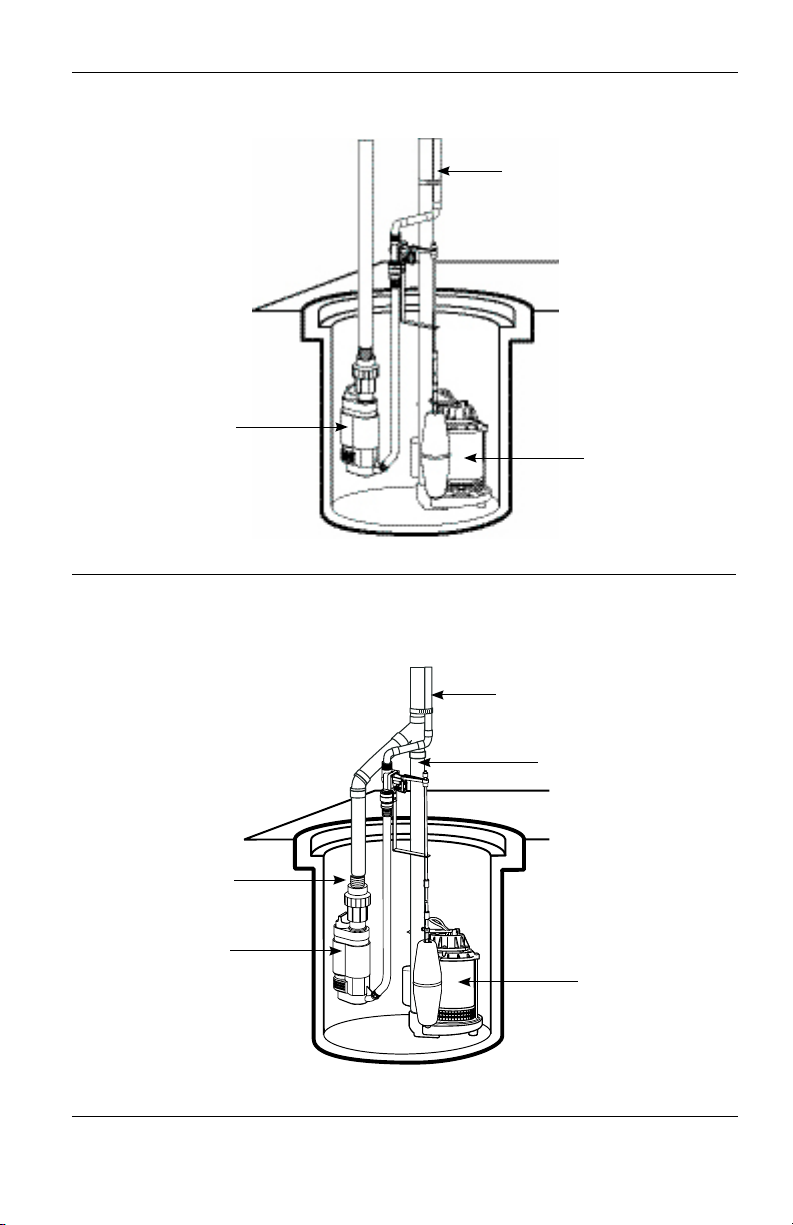

For Replacement Parts, call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part descriptions and number as shown in parts list

3

4

2

1

5

Figure 3

Limited Warranty

For two years from the date of purchase, Wayne Water Systems Division (“Wayne”) will repair or replace, at

its option, for the original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found

upon examination by Wayne to be defective in materials or workmanship. Please call Wayne (800-237-0987) for

instructions or see your dealer. Be prepared to provide the model number when exercising this warranty. All

transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse,

neglect, improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written

instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO TWO YEARS FROM THE DATE

OF PURCHASE. THIS IS THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR

CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or

limitations of incidental or consequential damages, so the above limitations might not apply to you. This limited

warranty gives you specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall

Wayne or its suppliers be liable for any special, consequential, incidental or penal damages including, but not

limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities, services or replacement power, downtime

costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty

claim, you MUST send a copy of the purchase receipt along with the material or correspondence. Please call

Wayne (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

Address parts correspondence to:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

Ref.

Description Part

No.

1

Ejector ASM

2

Check Valve

3

Automatic Valve ASM

4

Float Rod

5

Float

Number

60115-001

60116-001

60117-001

60118-001

60119-001

Qty.

1

1

1

1

1

www.waynepumps.com

4

Page 5

Instrucciones para la Instalación EWP10

Sírvase leer y conservar estas instrucciones. Léalas con cuidado antes de intentar armar, instalar, operar o efectuar mantenimiento

al producto descrito. Protéjase a sí mismo y a los demás observando la información de seguridad. El no cumplir con estas

instrucciones podría provocar lesiones personales y/o daños materiales. Conserve estas instrucciones para futura referencia..

Sistema de Bomba de

Sumidero de Respaldo

Accionado por el Agua

Descripción

La EWP10 es una bomba de sumidero

de respaldo accionada por el agua.

No sustituye una bomba normal. Esta

bomba ha sido diseñada para uso con

los sistemas de suministro municipal de

agua y debe usarse como respaldo de su

bomba de sumidero actual en caso de

emergencia.

Desempaque

Inspeccione esta unidad antes de usarla.

Ocasionalmente, los productos son dañados durante el envío. Si la bomba o los

componentes están dañados, devuelva

la unidad al lugar donde la compró

para que le sea reemplazada. Si no lo

hace podría ocasionar lesiones graves o

la muerte.

Medidas de

Seguridad

Este manual contiene información que

es muy importante que se conozca y

comprenda. Esta información se proporciona con fines de SEGURIDAD y para

EVITAR PROBLEMAS CON EL EQUIPO.

Para ayudar a reconocer esta información, observe los siguientes símbolos.

indica una situación inminentemente

peligrosa, que si no se evita, dará como

resultado la muerte o lesiones graves.

Advertencia indica una situación potencialmente peligrosa, que si no se evita,

podría dar como resultado la muerte o

lesiones graves.

Precaución indica una situación potencialmente peligrosa que, si no se evita,

puede dar como resultado lesiones leves

o moderadas.

Aviso indica información importante

que, si no se cumple, puede causar

daños al equipo.

© 2007 Wayne Water Systems

Peligro

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Informaciones

Generales de

Seguridad

Evite bombear fluidos inflamables o explosivos, como

gasolina, fueloil, queroseno,

etc. No la use en atmósfera inflamable

o explosiva. La bomba sólo debe usarse

para bombear agua limpia. De lo contrario podría provocar lesiones mortales

y/o daños a la propiedad.

Si el sótano tiene agua o

humedad en el piso, no camine

sobre el área mojada hasta que

se desconecte la corriente. Si la caja de

desconexión principal está en el sótano,

llame a un electricista. Retire la bomba

y repárela o reemplácela. Si no respeta

esta advertencia puede provocar un

choque eléctrico mortal.

Se debe instalar una válvula de retención en la descarga de la bomba de

sumidero primaria.

Esta bomba sólo debe usarse para

bombear agua limpia. Esta bomba no

está diseñada para bombear aguas

residuales, agua salada, salmuera,

descargas de lavado, ni demás usos que

contengan productos químicos cáusticos

y/o materiales extraños. Si se usa en

dichas aplicaciones, la bomba puede

dañarse y se anula la garantía.

Instalación

La instalación de esta unidad puede

llevar varias horas. Antes de desactivar

su bomba principal, tenga disponibles

los medios apropiados para vaciar el

sumidero.

1. Desconecte la energía de la

bomba principal.

2. La bomba debe instalarse usando

tubería de PVC rígido de 31,7 mm

o 38,1 mm. No use tubo flexible

para el drenaje.

Instalación de la bomba

La EWP10 puede instalarse con una

línea de descarga dedicada separada

(Figura 1, Método 1), o conectada a

la tubería de la bomba de sumidero

ya existente (Figura 2, Método 2).

Adjúntela a este manual o archívela en lugar seguro.

Desconecte la bomba de CA existente.

Si no respeta esta advertencia puede

provocar un choque eléctrico mortal.

3. Verifique que la bomba de CA

existente esté en buenas condiciones de funcionamiento. Si la

bomba de CA no se encuentra

en buen estado, recomendamos

reemplazar la unidad.

4. Retire todo sedimento o residuo

acumulado del pozo del sumidero

y los alrededores.

5. Ubique la EWP10 en una posición

ideal en el sumidero. La posición

ideal se encuentra a aproximadamente 50,8 mm del fondo del

pozo del sumidero y ubicada de

manera que no interfiera con ninguna de las piezas de la bomba

existente.

6. Método de instalación 1:

(Figura 1) Corte y pruebe en seco

la tubería rígida de PVC para la

descarga de la bomba de respaldo

accionada por el agua. Pegue con

cemento todas las conexiones y la

tubería de descarga después de

haberlos cortado y probado en

seco juntos.

La instalación de la tubería de descarga

variará dependiendo de las circunstancias

individuales. Dirija la tubería de descarga

hacia una pared exterior, por el camino

más corto, siguiendo las técnicas de

instalación sanitaria más adecuadas.

Mantenga al mínimo los acodamientos

porque reducen la salida de flujo de

la bomba. La tubería que sale de la

estructura de la construcción debe estar

sellada y en declive, para que el agua no

se congele en la tubería.

Método de instalación 2:

(Figura 2) Corte la tubería de

descarga de la bomba existente y

pegue con cemento las conexiones

en “T” o “Y”. Mida, corte y pruebe

en seco la tubería necesaria

para conectar la bomba EWP10

a las conexiones en “T” o “Y”

instaladas. Pegue con cemento

todas las conexiones y la tubería.

7. Cierre el suministro municipal

de agua. Instale una tubería

rígida de suministro al área del

sumidero. Instale una válvula de

cierre en la tubería de suministro.

353300-001 7/07

Page 6

Instrucciones para la Instalación

Instalación

(Continuación)

Libere la tubería de suministro de

todo residuo antes de instalar la

válvula automática.

8. Conecte el conjunto de la válvula

automática con un interruptor de

vacío de bronce a la tubería de

suministro. Debería quedar ubicado

aproximadamente 15 cm (6”) arriba

del piso del sótano o de la cubierta

del pozo del sumidero. La tubería de

suministro debe ser sostenida.

9. Sujete el acople y el empaque de la

manguera al interruptor de vacío

de bronce del conjunto de la válvula

automática.

10. Sujete el soporte en “L” a la válvula

de control automática usando los dos

tornillo que se proporcionan.

11. Instale el vástago del flotador enroscando junto ambas piezas. Con el

acople grande, asegure la conexión

del vástago enroscando el tornillo superior a la pieza superior y el tornillo

inferior a la pieza inferior.

12. Instale un acople pequeño y el

flotador en el vástago del flotador

introduciendo el vástago del flotador

por el centro del flotador. Inserte un

acople pequeño aproximadamente

12,7 mm arriba del fondo del vástago del flotador y apriete el sujetador.

Apriete el primer acople pequeño

instalado.

13. El flotador debe quedar posicionado

de manera que la bomba primaria

se encienda antes de la EWP10.

Inserte el vástago del flotador por

el orificio del soporte en “L”. Instale

un ojal de caucho en el vástago del

flotador, luego inserte el vástago del

flotador por el brazo de la válvula de

control automática y luego instale el

segundo ojal de caucho en la parte

superior del vástago del flotador.

14. Si fuese necesario, ajuste el largo de

la manguera de conexión y sujétela a

la bomba EWP10 con la abrazadera

para manguera que se proporciona.

15. Abra el suministro de agua y

verifique que la instalación no tenga

pérdidas y trabaje correctamente.

Simule el encendido por agua del

sistema de respaldo de la bomba

accionada por agua levantando el

flotador hasta accionar el brazo de

la válvula de control automática.

Sostenga el flotador en la posición

superior mientras verifica que el

sistema no presente pérdidas. Baje

el flotador para apagar el sistema y

repare cualquier pérdida en la tubería de suministro de agua. Vuelva a

verificar si fuera necesario.

16. Llene el pozo con agua hasta que el

flotador accione el brazo de la válvula de control automática. El sistema

reducirá el nivel de agua del pozo

hasta el punto en que la bomba

EWP10 se apaga. Verifique que este

nivel de encendido/apagado de la

EWP10 quede más arriba del nivel de

encendido de la bomba de sumidero

principal.

17. Vuelva a conectar la energía a

la bomba de sumidero principal.

El nivel de agua en el pozo debería

bajar hasta en punto en que la bomba de sumidero principal se apaga.

Verifique nuevamente el sistema

para comprobar que la bomba de sumidero principal y la EWP10 trabajen

en conjunto.

Funcionamiento

Siempre desconecte el suministro de corriente antes de

intentar instalar, efectuar un

servicio, reubicar o realizar el mantenimiento de la bomba. No toque nunca

la bomba de sumidero, el motor de la

bomba, el agua o el tubo de descarga

mientras la bomba esté conectada al

suministro de corriente. Nunca manipule la bomba o el motor de la bomba

con las manos húmedas o cuando se

encuentre sobre una superficie húmeda

o mojada ni dentro del agua. Hay riesgo

de choque eléctrico mortal.

¡Riesgo de choque eléctrico!

Use un tomacorriente GFCI con

conexión a tierra para reducir

el riesgo de choque eléctrico mortal.

Si corta el cable o el enchufe se anulará

la garantía y hará que la bomba no

funcione.

Guía de Diagnóstico de Averías

Problema Posible(s) Causa(s) Acción a tomar

El agua no es

bombeada hacia fuera

La bomba no bombea

agua a su máxima

capacidad

La bomba no se apaga 1. La válvula automática no se apaga

1. Válvula de suministro de agua

cerrada

2. Válvula automática cerrada

3. El flotador no sube con el nivel de

agua

4. Succión o eyector atascados

5. Nivel de agua por debajo de la

succión en el pozo

6. Funcionamiento incorrecto o

ausencia de válvula de retención

en la descarga de la bomba primaria

7. Tubería de descarga atascada

8. Altura de bombeo mayor que 4,6 m

9. Presión de agua menor que 40 psi

1. Suministro de agua abierto

parcialmente

2. Válvula automática abierta

parcialmente

3. Succión o eyector parcialmente

atascados

4. Pérdidas en la válvula de retención

de la bomba primaria

5. Tubería de descarga parcialmente

atascada

2. Flotador obstruido

1. Abra la válvula de suministro

2. Verifique manualmente el funcionamiento de la válvula

3. Busque impedimentos al funcionamiento del flotador

4. Limpie la entrada de la bomba

5. Ajuste el vástago del flotador para que la bomba se apague antes

que el nivel de agua llegue al mínimo

6. Instale la válvula de retención en la descarga de la bomba

primaria

7. Verifique todas las tuberías de descarga

8. Reduzca la altura de bombeo a menos de 4,6 m

9. Instale una tubería directa de 19,1 mm del suministro de agua

para reducir la pérdida por fricción en la tubería

1. Abra la válvula de suministro

2. Verifique el funcionamiento de la válvula

3. Limpie la entrada de la bomba

4. Reempalce la válvula de retención en la descarga de la bomba

primaria

5. Verifique todas las tuberías de descarga

1. Verifique el funcionamiento de la válvula

2. Verifique por obstrucciones o ajuste el ojal de caucho en la

correcta posición de apagado y encendido

6 Sp

Page 7

D

EWP10

Instalación típica con bomba sumergible y con tubería de descarga separada

Suministro de agua

Bomba de Sumidero

de Respaldo

Accionada por Agua

Figura 1

Bomba de

sumidero principal

Instalación típica con bomba sumergible

Válvula de retención

Bomba de Sumidero

de Respaldo

Accionada por Agua

Figura 2

Suministro de agua

Válvula de retención

Bomba de

sumidero principal

7 Sp

Page 8

Instrucciones para la Instalación

Para Piezas de Repuestos, Llame al 1-800-237-0987

Sírvase proporcionar la suguiente información:

-Número de modelo

-Número de serie (si tiene)

-Descripción y número de repuesto como se muestra

en la lista de repuestos

3

4

2

1

5

Figura 3

Garantía Limitada

Durante un año a partir de la fecha de compra, Wayne Water Systems (“Wayne”) reparará o reemplazará para

el comprador original, según lo que decida, cualquier pieza o piezas de su Juego para estanque, Bombas de

resumideros, Bombas de agua (“Producto”) que después de un examen Wayne encuentre que tenían defectos

en su material o mano de obra. Sírvase llamar a la compañía Wayne (800-237-0987, desde EUA) para recibir

instrucciones al respecto o comuníquese con el distribuidor más cercano a su domicilio. Para hacer reclamos bajo

esta garantía deberá suministrarnos el número del modelo y el número de serie del producto. El comprador será

responsable de pagar todos los gastos de flete para enviar las piezas o el Producto para que sean reparados o

reemplazados.

Esta Garantía Limitada no cubre los daños que sufra el Producto debido a accidentes, abusos, usos inadecuados,

negligencia, instalación incorrecta, mantenimiento inadecuado o haberse utilizado sin seguir las instrucciones

escritas suministradas por la compañía Wayne.

NO EXISTEN OTRAS GARANTIAS EXPRESAS. LAS GARANTIAS IMPLICITAS INCLUYENDO GARANTIAS EN

RELACION AL MERCADEO O USOS ESPECIFICOS ESTAN LIMITADAS A UN AÑO A PARTIR DE LA FECHA

DE COMPRA. ESTA ES LA UNICA GARANTIA DISPONIBLE Y TODAS LAS REPONSABILIDADES CIVILES,

DIRECTAS O INDIRECTAS, O GASTOS POR DAÑOS INDIRECTOS O CONSECUENTES QUEDAN EXCLUIDOS.

Algunos estados no permiten que se establezcan límites en la duración de las garantías implicitas o no permiten

que se excluyan ni se establezcan límites en los daños por incidentes o consecuencias, por lo tanto los límites

antes mencionados podrían ser no válidos. Esta Garantía Limitada le otorga derechos legales especificos, y usted

también puede tener otros derechos que varian de un Estado a otro.

En ningún caso, bien sea por ruptura del contrato de la garantía, responsabilidad civil (incluyendo negligencia)

u otra causa, Wayne o sus distribuidores serán responsables pon daños especiales, consecuentes ni circunstanciales ni penales, incluyendo, pero no limitados a la pérdida de ganancias, pérdida de uso del producto o equipos

asociados, daños a equipos asociados, costos de capitales, costos para substituir productos, costos para substituir

o reemplazar servicios, costos por pérdida de productividad, o reclamos de clientes del comprador por dichos

daños.

DEBE conservar el recibo de compra con esta garantía. En caso de que necesite hacer un reclamo bajo esta

garantía, DEBERA enviarnos una copia del recibo junto con el material o correspondencia. Sírvase comunicarse con la compañía Wayne (800-237-0987, en EUA) para recibir autorización e instrucciones para enviar el

producto.

NO ENVIE ESTA GARANTIA A WAYNE. Use este documento sólo para mantener sus records.

NO. DEL MODELO _____________________ NO. DE SERIE ________________________ FECHA DE INSTALACION

__________________

ANEXE SU RECIBO AQUI

Envíe su solicitud de repuestos a la siguiente direccion:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

No. de

Descripción

Ref.

1

Eyector ASM

2

Válvula de retención

3

Válvula ASM automática

4

Vástago del flotador

5

Flotador

No.

Repuesto

60115-001

60116-001

60117-001

60118-001

60119-001

Ctd.

1

1

1

1

1

8 Sp

Loading...

Loading...