Page 1

12V Battery

Back-up

Systems

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

Description

The ESP15 and ESP25 are battery operated

back-up sump pump systems. It does not

replace a regular primary pump. It is

designed to provide protection in the event

gasoline, fuel oil, kerosene, etc. Do NOT use in a

flammable and/or explosive atmosphere. Pump

SHOULD only be used to pump clear water.

Personal injury and/or property damage COULD

result.

household electrical power fails. All wiring MUST be

performed by a

are damaged, call our customer service If the

department at 1-800-237-0987. basement

has water or moisture on the Safety

Guidelines floor, do area until all power is turned NOT walk on wet

This manual contains information that is off. If the shutoff box is in the basement, very

important to know and understand. call an electrician. Remove pump and

This information is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

either repair or replace. Failure to follow this

warning COULD result in fatal electrical shock.

observe the following symbols. Do NOT

DANGER indicates expose

an imminently battery to sparks or flames as

hazardous situation which, if NOT avoided, an explosion or fire COULD WILL result in death

or serious injury. result.

WARNING indicates Battery

a potentially acid is

hazardous situation which, if NOT avoided, corrosive. Avoid spilling on COULD result in

death or serious injury. skin or clothing. Eye

protection MUST be worn

CAUTION indicates when handling the battery.

a potentially

hazardous situation which, if NOT avoided,

MAY result in minor or moderate injury.

NOTICE indicates

important

information, that if NOT followed, MAY cause

damage to equipment.

General Safety Information clear water.

This pump is NOT designed

CALIFORNIA PROPOSITION

65 to handle effluent, salt

water, brine,

This product or

its laundry

discharge or any other power cord

contains application which MAY contain

caustic

chemicals known to the State of California to cause

cancer and birth defects or other reproductive

harm. Wash hands after handling.

GENERAL SAFETY

chemicals and/or foreign materials. Pump

damage MAY occur if used in these applications

and WILL void warranty.

Battery Requirements

1. Use only a new fully charged 12 V

© 2011, WAYNE/Scott Fetzer Company.

Operating Instructions and Parts Manual

ESP15, ESP25

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged during

shipment. If the pump or components

qualified electrician. Failure to follow this

warning COULD result in fatal electrical shock.

Page 2

Operating Instructions and Parts Manual

www.waynepumps.com

2

rmation visit www.waynepumps.com

2. Battery sizes that will fit into the battery box are 24C, 24VCM, 27C, 27CM, and 27F.

3. Battery recharge time will be different at each installation. Under normal conditions it will

take two to four days to bring a deep cycle battery back to full charge after it has been

discharged. If electrical power to the house is lost more than once a week, consider keeping

a spare, fully-charged battery to replace an exhausted battery for the back-up sump pump.

Installation – ESP15

Installation of this

unit may take

several hours. Before disabling your main pump, have ready an appropriate means of evacuating the

sump. 1. Turn power to main pump off.

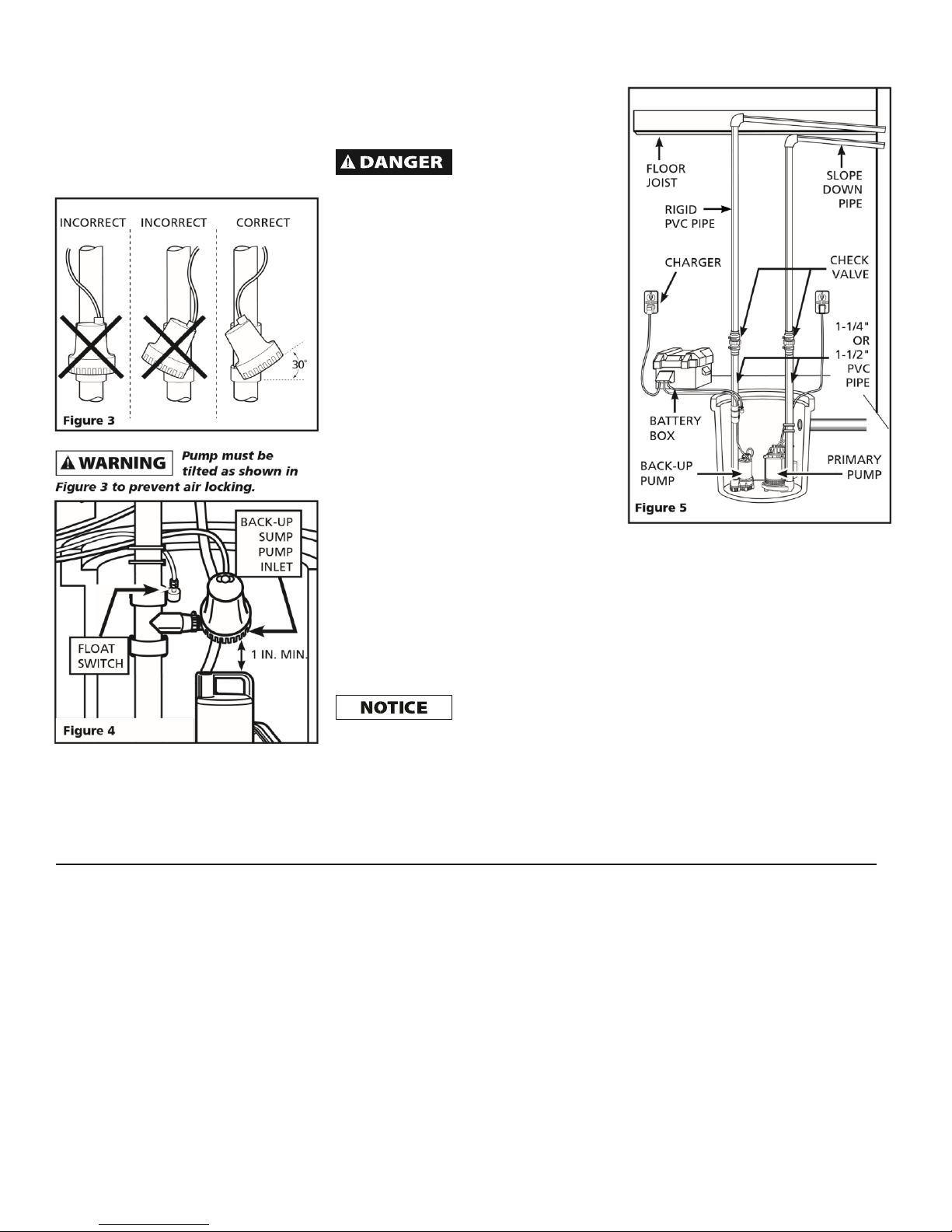

2. Pump must be installed using 1-1/4 in. or 1-1/2 in. rigid PVC piping. A check valve (not

included) must be installed between the ESP’s tee and the main pump (see Figure 1).

LEAVE A 4 IN.

MIN. BETWEEN

BASIN LID

AND

BACK-UP

PUMP

CHECK LEAVE A 1 IN.

VALVE MIN. BETWEEN

BACK-UP AND

PRIMARY PUMP

Figure 1

3. Measure and cut discharge pipe so that back-up pump is a minimum of 1 in. above the main

pump. This will allow main pump to operate normally (see Figure 1).

4. Check the fit of the components

before permanently attaching. Using

354001-001 7/11

Installation - ESP15 (continued)

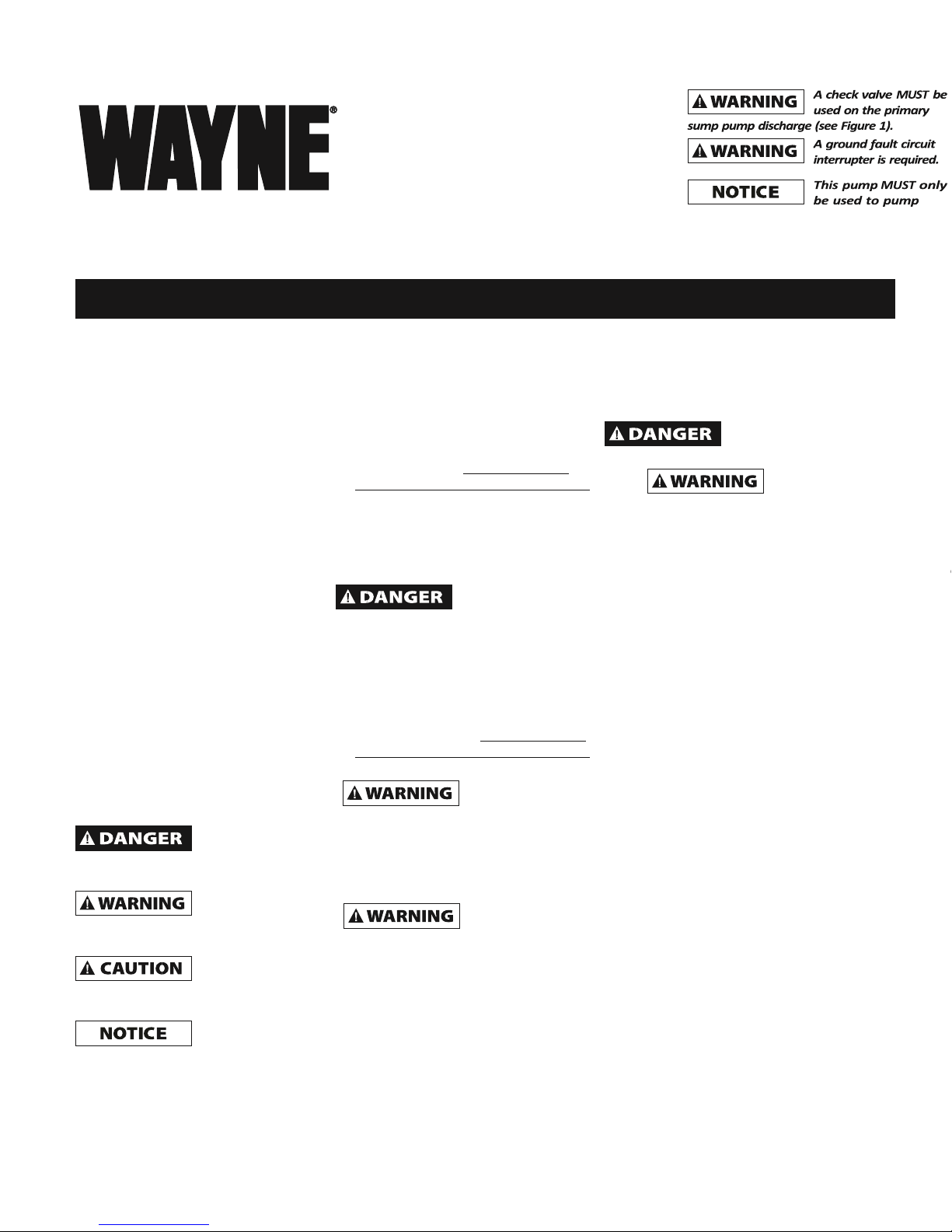

5. Insert flapper valve into tee. Be sure locator

tab is in the notch of the tee fitting (see

Figure 2).

hole, and secure with nut. Make sure

that float switch is above pump base and

that power wires do not interfere with

float switch or pump inlet.

Installation – ESP25

I

n

s

t

a

l

l

a

t

i

o

n

o

f

t

h

i

s

u

n

i

t

m

a

y

t

a

k

e

several hours. Before disabling your main pump,

have ready an appropriate means of evacuating

the sump. 1. Turn power to main pump off.

Do NOT

use to

deep cycle battery. Electrolyte level PVC cement, glue tee in place. Note must be

checked and maintained the up direction arrow on the tee; the

in accordance with manufacturer’s notch must be to the top or flapper guidelines.

valve will not work (see Figure 2).

pump flammable or explosive

fluids such as

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual

or file it for safekeeping.

6. Slide clamp onto tee.

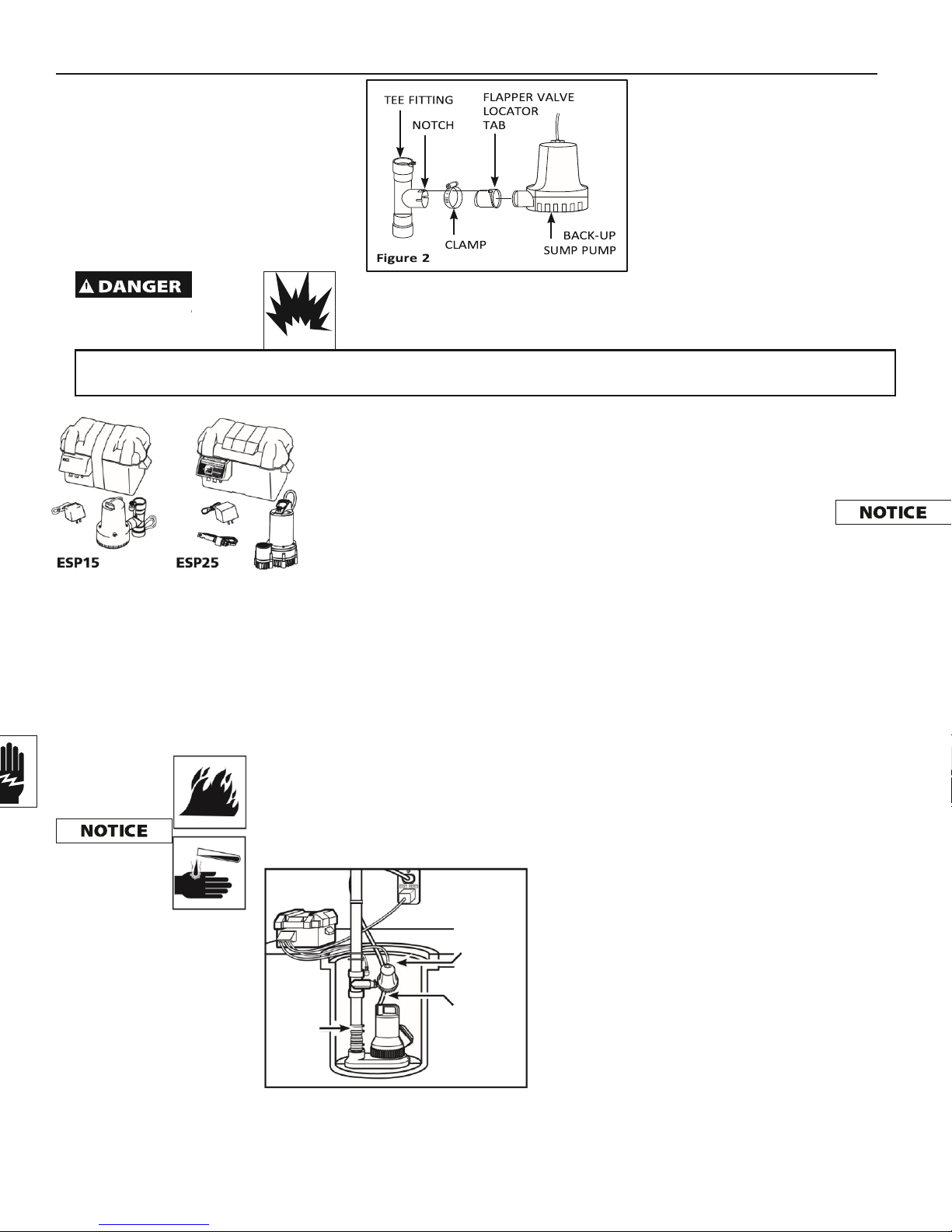

7. Insert pump into flapper valve, tilt pump 30˚.

When tilted, the side with

The ESP25 can be installed as a back-up

system with a separate dedicated discharge

line (Method 1), or tied into an existing sump

pump line (Method 2, Page 3).

Page 3

2. Pump must be installed using 1-1/4” or 1-1/2” rigid PVC piping.

PUMP INSTALLATION

the power cord should be up (see Unplug the existing Figure 3).

Tighten clamp around the AC pump. Failure

to

pump and flapper valve (see Figure 2). follow

this warning could result in fatal electrical shock.

1. Verify that the existing AC pump is in

good working order. If the AC pump is

questionable, it is typically recommended that

the unit be replaced with a 1/3 or 1/2 HP pump.

2. Remove any silt or accumulated

debris from the sump pit and surrounding area.

Method 1 (Preferred)

1. Place the back-up pump on a solid,

level surface in the sump pit. Do not place the

pump on a loose or sandy surface. Small stones

or sand may damage the pump resulting in

potential pump failure.

2. This pump has a 1-1/2 in. NPT

discharge. If a 1-1/4 in. discharge pipe is desired,

an adapter (sold separately) will be necessary.

Smaller diameter piping will reduce pump flow,

rate and performance.

3. Cut a 4 ft. section of 1-1/4 in. or 1-1/2

in. diameter rigid PVC pipe. Cement 1-1/4 in.

pipe to a threaded fitting. Cement 1-1/4 in. pipe

into pipe coupling. Attach 1-1/4 in. pipe section

to the ESP25 discharge adapter.

4. Screw PVC pipe onto pump discharge.

Be careful not to

strip or cross thread

plastic fittings or check valves. Flex hose is not

recommended. Rigid PVC or

8. To install float switch

for standby metal pipe is

required for a permanent pump, first slide bracket

into slot on

installation.

top of tee. Secure bracket with screw

provided. Remove top hex nut from 5. Place the pump with the 4’ section of switch

and slide the cord up and out PVC pipe on a solid, level surface in of the way. Slip cord

through slot in the sump pit on an elevated surface.

bracket, pull threaded stud through

6. Attach a rubber check valve (sold

separately) to the top of the discharge pipe.

This will allow the pump or check valve to

be removed easily for servicing. NOTE:

Check valves can be placed directly in the

pump discharge if desired. However, for

ease of disassembly, it is recommended that

check valves be placed above the sump as

shown in Figure 1, page 1.

The remainder of the discharge pipe

installation will vary depending on

individual circumstances. Using sound

plumbing practices, route the discharge

pipe to an exterior wall by the shortest

path. Keep turns to a minimum because

they reduce flow output of the pump. The

pipe that exits the building structure should

be sloped downward so that water will not

freeze in the pipe.

When installing the separate discharge pipe,

drill through the outside wall with

appropriate drilling equipment. Seal the hole

to prevent water from entering.

Method 2

If a separate, dedicated discharge is not

possible as in Method 1, the ESP25 pump

can be tied in to the primary pump’s

discharge pipe by installing a “Y” connector.

Two check valves will be required.

1. Locate the ESP25 on a solid, level

surface in the sump pit. Do not place

the pump on a loose or sandy surface.

Small stones or sand may damage the

pump resulting in potential pump

failure.

Page 4

Operating Instructions and Parts Manual

www.waynepumps.com

4

Installation - ESP25 (continued)

2. This pump has a 1-1/2 in. NPT

discharge. If a 1-1/4 in. discharge pipe

is desired, an adapter (not included)

will be necessary. Smaller diameter

piping will reduce pump flow, rate and

performance.

3. A check valve will be required in the

discharge line of both the Main AC

pump and the ESP25 pump to prevent

recirculation of water into the sump

pit. System will not function without

two check valves.

4. Cut a 4 ft. section of 1-1/4 in. or 1-1/2

in. diameter rigid PVC pipe. Cement 11/2 in. pipe to a threaded fitting.

Cement 1-1/4 in. pipe into pipe

coupling. Attach 1-1/4 in. pipe section

to the ESP25 discharge adapter.

5. Screw on to pump discharge.

Be

careful not to strip or

cross thread plastic

fittings or check valves. Flex hose is not

recommended. Rigid PVC or metal pipe is

required for a permanent installation.

6. Place the pump with the 4’ section of

PVC pipe on the sump floor or on an

elevated surface if required.

7. Attach a rubber check valve (sold

separately) to the top of the discharge

pipe. This will allow the pump or check

valve to be removed easily for

servicing.

RIGID SLOPE

FLOOR

PVC PIPE DOWN PIPE JOIST "Y"

CONNECTOR

45°

ELBOW

CHECK

CHARGER VALVE

1-1/4"

OR

1-1/2"

PVC

PIPE

BATTERY

BOX

BACK-UP PRIMARY PUMP PUMP

Figure 6

8. Duplicate the discharge piping

arrangement for the primary AC pump if

the existing discharge line has to be

adjusted to accommodate a second pump.

9. Glue a 45º elbow to the short pipe on the

ESP25 pump. Glue a “Y” adapter to the

short pipe on the existing pump, as shown

in illustration for Method 2.

10. Glue a short piece of PVC pipe between

the 45º elbow and the “Y”.

NOTE: Check valves can be placed directly in

the pump discharge if desired. However, for

ease of disassembly, it is recommended that

check valves be placed above the sump as

shown in Figure 2, page 2.

The remainder of the discharge pipe

installation will vary depending on individual

circumstances. Using sound plumbing

practices, route the discharge pipe to an

exterior wall by the shortest distance.

Methods 1 and 2

Install float switch at least 10 in.-12 in. above

bottom of sump pit so that backup unit turns

on only when the water level is higher than

the normal “on” level for primary pump. Use

the wire ties provided to secure the switch to

the discharge pipe. Make sure power wires do

not interfere with float switch, pump inlet, or

main pump operation. Backup pump must not

be allowed to run dry.

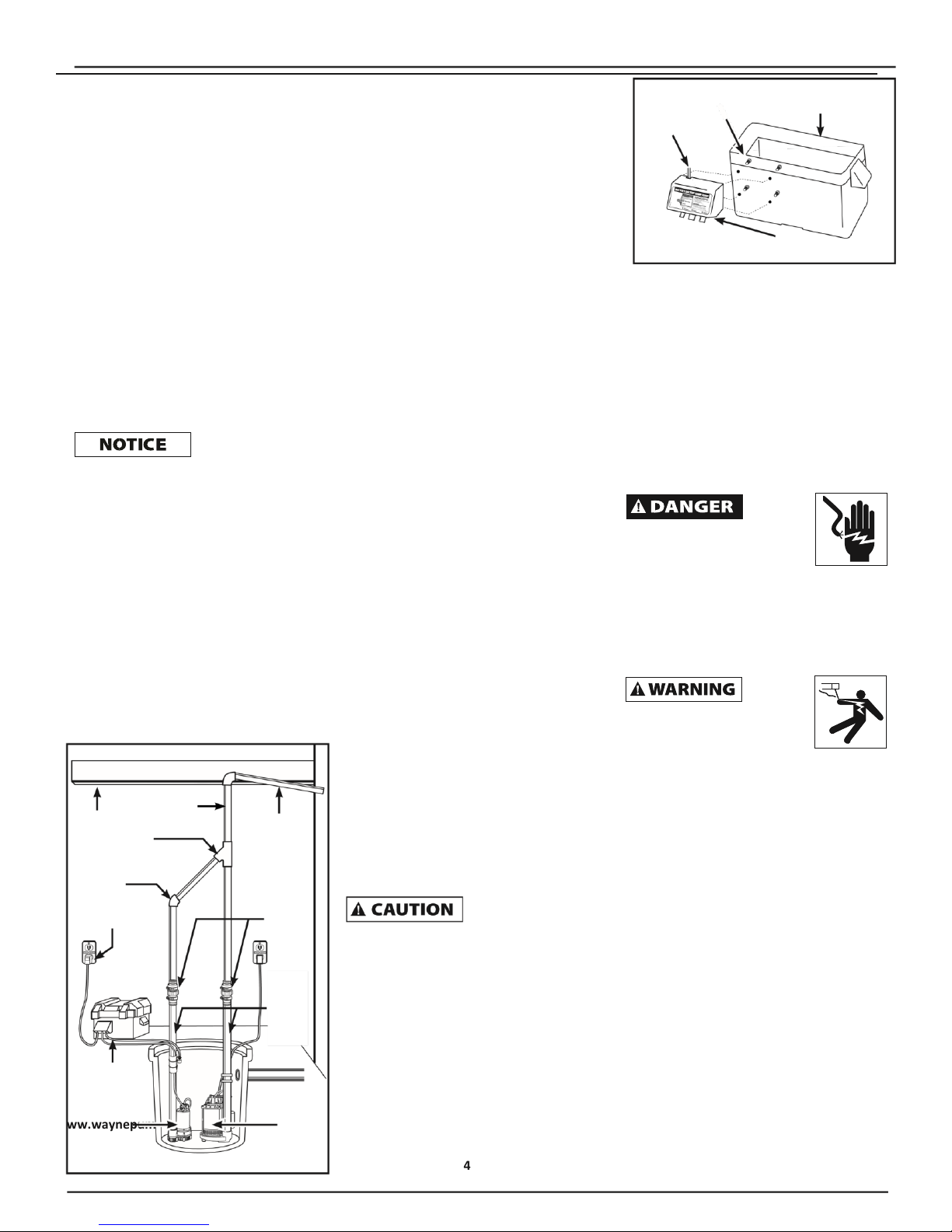

Control Box Installation – ESP15 &

ESP25

1. Attach control box to the side of battery

box as shown in Figure 7. Place battery in

box, attach red cable to positive battery

post and black cable to negative post. Put

lid on box.

If cables are

reversed, damage to

the control box or battery could result, and

warranty will be void.

2. Place battery box within 6 ft. of the sump

and a 115 VAC separately fused outlet. The

outlet must be protected by a ground fault

circuit interrupter (GFCI). The area must

also be clean, dry and well-ventilated.

3. Plug the float switch, pump, and charger

into the control box. (connections are

marked on the control box).

4. Test pump operation by filling the sump

with water while the main pump is

unplugged. If the pump

3

ESP15, ESP25

CONTROL

BATTERY BOX

LEAD BOX SCREW BOTTOM

WIRE

Figure 7 CONTROL BOX

operates properly, plug the charger into

the GFCI protected outlet to begin

charging the battery.

5. Protect electrical cord from sharp objects,

hot surfaces, oil, and chemicals. Avoid

kinking the cord and replace damaged

components immediately.

Operation

ALWAYS

disconnect the power source

before attempting to install,

service, relocate or maintain the

pump. NEVER touch sump pump, pump motor,

water or discharge piping when pump is connected

to electrical power. NEVER handle a pump or pump

motor with wet hands or when standing on wet or

damp surface or in water. Fatal electrical shock

COULD occur.

Risk of

electrical shock! This pump is

supplied with a grounding

conductor and grounding type

attachment plug. Use a grounded receptacle to

reduce the risk of fatal electrical shock. NEVER cut

off the round grounding prong. Cutting the cord or

plug will void the warranty and make the pump

inoperable.

1. With a fully charged battery, test Back-up

Pump operation by filling the sump with

water while the primary pump is

unplugged. If the Back-up Pump operates

properly, plug the charger into the GFCI

protected outlet and the primary pump

into a separate GFCI outlet.

2. After installation, the standby pump will

start when the water level rises above

the depth that the primary pump should

start.

3. The control box has a DC charger

designed to shorten the recharging time

of your battery, and to prevent

overcharging. In addition, the control box

has a time delay which keeps the pump

Page 5

from repeated, short cycles when it shuts

off. This time delay feature will allow the

pump to run 20-25 seconds after the

switch reaches the off position.

www.waynepumps.com

Operation (continued)

4. The control box contains a multicolored

indicator light. When AC power is

present, the light will indicate the

charging state, and not reflect actual

battery voltage, particularly with a

defective battery. In order for the

indicator light to provide an accurate

reading, steps “a” through “d” must be

followed. a. Unplug primary AC pump and

the charger--a power off alert tone will

sound for 30 seconds.

b. Lift and release the float switch to

activate the back-up pump.

c. When the back-up pump stops, read

the test light:

Green: Indicates battery is

charged.

Yellow: Voltage is low,

indicating battery is partially

charged.

Red: Battery is completely

discharged or defective.

d. Plug in charger and main AC pump.

When AC power is out, and when pump

has been running, the light will indicate

battery status.

5. A chirping sound from the control box

will accompany the red light, indicating

that the battery may require attention or

replacement. Voltage is only an indicator

of battery condition and may not reflect

the true condition of the battery. See

Maintenance for instructions on

assessing battery condition.

6. A single 30-second tone will sound when

power to the system is interrupted. The

unit will reset automatically when power

is restored. A 3-second tone will sound

every time the pump starts.

Maintenance

ALWAYS

disconnect the electrical supply

before attempting to install,

service, relocate or perform any

maintenance. If the power source is out of sight,

lock and tag in the open (off) position to prevent

unexpected power application. Failure to do so

could result in fatal electrical shock. Only qualified

electricians should repair this unit. Improper repair

could result in fatal electrical shock.

1. Once a month, check battery condition.

2. Unplug the wall charger.

3. For batteries with top caps that can be

removed, the electrolyte level should be

checked and filled to manufacturer’s

specifications. The charge for each cell

should be checked with a hydrometer. A

specific gravity of 1.265 indicates the

battery is at full charge. If the specific

gravity of any of the cells varies more

than .050, the battery should be

replaced.

NOTE: An inexpensive hydrometer can

be purchased at an automotive parts

dealer.

4. Inspect the terminals and clamps for

corrosion and tightness. Clean and

tighten as required.

5. Unplug the main pump and fill sump

with water until back-up pump turns on.

Repeat process two times to be sure

pump is operating normally.

6. If pump operates normally, plug charger

into wall outlet, turn on main pump. If

pump fails to operate normally, see

Troubleshooting chart and correct

problem. Repeat step 5. BATTERIES

Dangerous hydrogen

gas can be released

from batteries while charging. Sparks can ignite

the gas in an enclosed space. Wear safety

goggles when connecting batteries. Battery

connections should be made in a well-ventilated

area.

Troubleshooting Chart - Back-up Pump

Symptom(s)

Possible Cause(s)

Corrective Action(s)

Pump will not run

1. Connections not secure

2. Low battery

3. Float switch obstruction

4. Defective or blown fuse

1. Check all connections

2. Check battery and replace if low

3. Make sure nothing is interfering with the operation of the switch

4. Check internal fuse located inside the control box. Pull the charger from the wall outlet

and remove. If the fuse is blown, replace it with a 15 amp automotive type fuse

Motor hums but

pump won’t run

1. Defective battery

2. Obstructed impeller

1. Check battery and replace if low or defective

2. Unplug pump and check to see if impeller is free to turn. If impeller is locked, remove the 4

screws on the bottom of the pump to release the housing around the impeller. Remove

the obstruction. Reassemble pump and reconnect

Pump runs but

pumps very little or

no water

1. Check valve missing or improperly

installed

2. Obstruction in discharge pipe

3. Pump not rotated 30˚

4. Pump air locked

5. Discharge pipe length and / or height

exceeds capacity of pump

6. Low or defective battery

1. Check to make sure a check valve is installed and functioning between primary pump

discharge and standby sump pump tee fitting

2. Check for obstruction and clear if necessary

3. Check that pump is rotated 30˚ in tee fitting in ESP15 Installation section, Figure 3, on page

2

4. The impeller housing has a small hole on its side. This hole must be open for the pump to

prime. With the pump unplugged, remove the 4 screws on the bottom of the pump to

release the housing around the impeller. Clean out the hole and replace cover

5. If discharge is too high, a separate line may be required with a lower discharge height

6. Check battery and replace if low or defective

Pump cycles too

frequently

1. Main check valve located between the 1. Install check valve or repair as required

discharge of the primary pump and the back-up sump pump tee fitting or the back-up

sump pump flapper valve not installed or working properly

Page 6

Operating Instructions and Parts Manual

www.waynepumps.com

6

Maintenance (continued)

Working in the

vicinity of lead acid

batteries can be dangerous. Before making

connections or servicing the batteries, read and

follow instructions in all applicable instruction

manuals. To reduce the risk of battery

explosion, follow the instructions in this manual

and those published by the battery

manufacturer, as well as those of any other

equipment used in the surrounding area.

If battery acid

contacts your eye(s),

flush with cold running water for 10 minutes and

seek immediate medical attention. If acid contacts

your skin or clothing, wash immediately with soap

and water.

Never smoke or allow a

spark or

flame in the vicinity of the battery.

ESP15, ESP25

Avoid dropping

metal tools on the battery

posts because they may spark or short-circuit the

system or battery, causing an explosion.

Follow battery manufacturer’s maintenance

procedures and schedules. Be certain that the

area around the batteries is well ventilated.

Before servicing the batteries, blow away

gasses by waving a piece of cardboard near

the batteries.

For Replacement Parts, call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

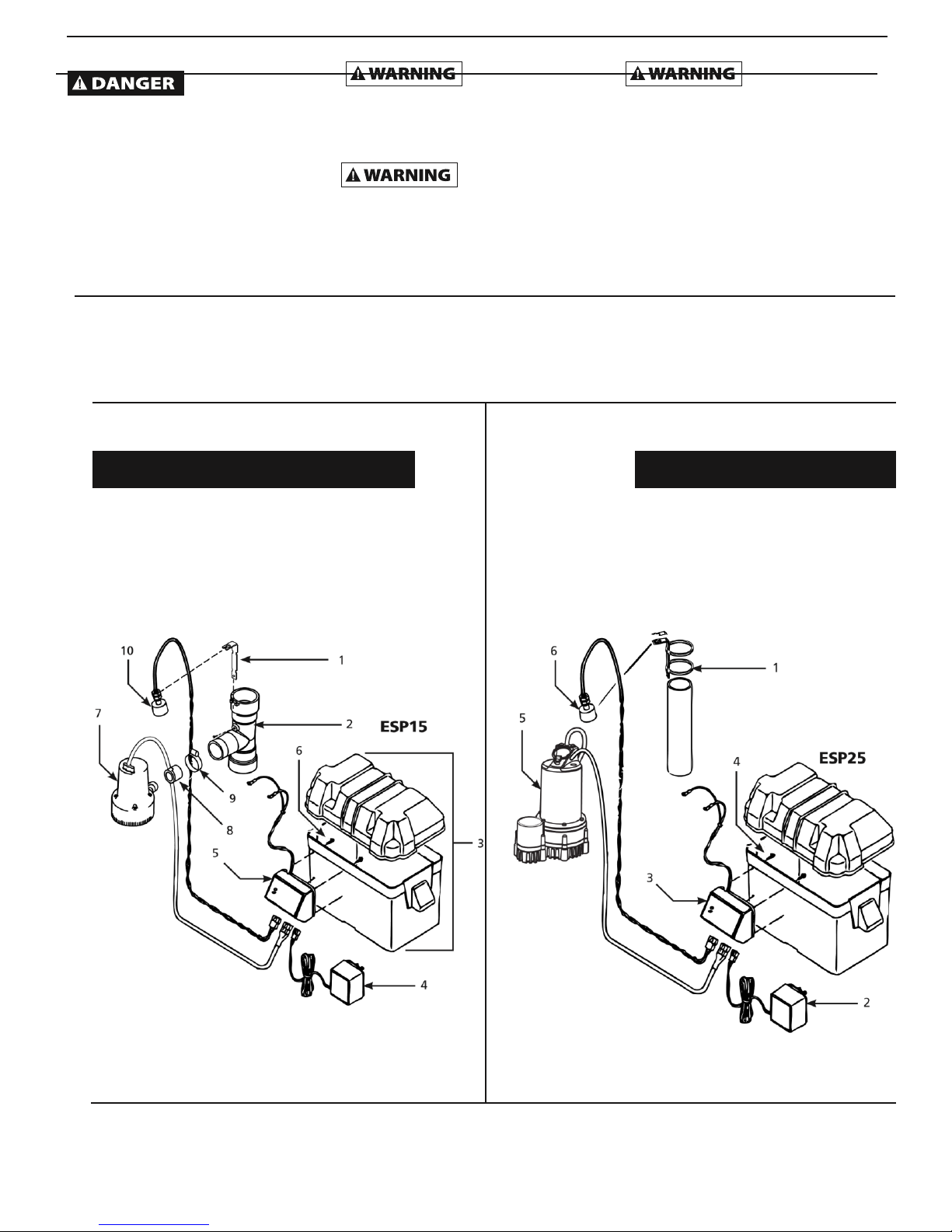

Repair Parts List – ESP15

Repair Parts List – ESP25

Ref.

No. Description Part Number Qty

Ref.

No. Description Part Number Qty

1 Bracket 46049-001 1

2 Tee fitting 17233-002 1

3 Battery box 23217-001 1

4 Charger 17220-004 1

5 Control box 30209-003 1

6 Screw control box 16119-002 4

7 Pump 17218-003 1

8 Flapper valve 17216-001 1 9

Clamp hose 16044-001 1

10 Float switch 30033-001 1

1 Bracket 46049-001 1

2 Charger 30221-001 1

3 Control box 30222-004 1

4 Screw control box 16119-002 4

5 Pump 58324-001 1

6 Float switch 30033-001 1

Page 7

www.waynepumps.com

5

ESP15, ESP25

LIMITED WARRANTY

System ESP15: For one (1) year from the date of purchase, WAYNE Water Systems ("WAYNE") will repair or replace, at its option, for the original

purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by WAYNE to be defective in materials or

workmanship.

System ESP25: For two (2) years from the date of purchase, WAYNE Water Systems ("WAYNE") will repair or replace, at its option, for the original

purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by WAYNE to be defective in materials or

workmanship.

Please call WAYNE (1-800-237-0987) for instructions or see your dealer. Be prepared to provide the model number and the serial number

when exercising this warranty. All transportation charges on Products or parts submitted for repair or replacement must be paid by

purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation,

improper maintenance, or failure to operate in accordance with WAYNE’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE (1) YEAR FROM THE DATE OF PURCHASE ON SYSTEM

ESP15 AND TWO (2) YEARS FROM THE DATE OF PURCHASE ON SYSTEM ESP25. THIS IS THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY

AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of incidental or

consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific legal rights, and you may also

have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE or its suppliers be

liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or revenues, loss of use of the

products or any associated equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities, services or

replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a COPY of the

purchase receipt along with the material or correspondence. Please call WAYNE (1-800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. (PRIMARY PUMP) _______________________ MODEL NO. (BACK-UP PUMP) _______________________ SERIAL NO.

(PRIMARY PUMP) _______________________ SERIAL NO. (BACK-UP PUMP) _______________________ INSTALLATION DATE

__________________ ATTACH YOUR RECEIPT HERE

Page 8

Operating Instructions and Parts Manual

www.waynepumps.com

8

Systèmes de

secours par

batterie de 12V

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner

ou entretenir l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger

d'appliquer ces instructions peut résulter en des blessures corporelles et/ou en des dommages matériels! Conserver ces

instructions pour références ultérieures.

Instructions d'Utilisation et Manual de Pièces

ESP15, ESP25

Description

ESP15 et ESP25 sont des systèmes de pompe

de puisard de secours fonctionnant sur

batterie. La pompe de secours ne remplace

pas la pompe principale. Elle est conçue pour

fournir la protection contre les pannes

d’électricité domestiques.

Déballage

Vérifiez cette unité avant de l’utilisation.

Parfois, un produit peut être endommagé

pendant le transport. Si la pompe ou les

composants sont endommagés, appelez

notre service à la clientèle au 1-800-237-

0987.

Directives De Sécurité

Ce manuel contient de l’information très

importante qui est fournie pour la SÉCURITÉ

et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

DANGER indique

une situation

hasardeuse imminente qui RÉSULTERA en perte

de vie ou blessures graves.

AVERTISSEMENT

indique une situation

hasardeuse potentielle qui PEUT résulter en perte

de vie ou blessures graves.

ATTENTION indique

une situation

hasardeuse potentielle qui PEUT résulter en

blessures.

AVIS indique de

l’information

importante pour éviter le dommage de

l’équipement.

Généralités Sur La Sécurité

PROPOSITION 65 CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques qui, de l’avis de

l’État de Californie, causent le cancer et des

anomalies congénitales ou autres problèmes de

reproduction. Lavezvous les mains après la

manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

utiliser dans un atmosphère inflammable et/ou

explosif. La pompe devrait être utilisée pour le

pompage de l’eau claire seulement, sinon, il y a

risque de blessures personnelles et/ou dégâts

matériels.

Toute installation

des fils DOIT être

effectuée par un électricien qualifié. Manque de

suivre cet avertissement PEUT résulter en secousse

électrique mortelle.

NE

PAS

marcher

sur un plancher de sous-sol

trempe ou humide avant de

couper l’électricité. Si la boîte de branchement est

dans le sous-sol, contacter un électricien. Enlever

la pompe et la réparer ou remplacer. Manque de

suivre cet avertissement peut résulter en secousse

électrique mortelle.

NE PAS

exposer

la pile à des étincelles ou des

flammes. Une explosion ou un feu

PEUT y résulter.

L’acide

de pile

est corrosive. NE PAS le renverser

sur la peau ni sur les vêtements.

La protection oculaire doit être

usure en contrôlant la batterie.

Un clapet DOIT être

utilisé sur le décharge de

la pompe de puisard principale (voir Figure 1).

Un interrupteur pour

protéger contre un

défaut de mise à la terre (DDFT) est exigé.

Cette pompe est

conçue pour le pompage

de l’eau claire SEULEMENT. Cette pompe N’EST

PAS conçue pour les substances qui contiennent

les produits chimiques caustiques et/ou les

matières étrangères tels que l’eau salée, la

saumure, le décharge de buanderie. L’utilisation

de ces produits POURRAT endommager la pompe

et NIERA la garantie.

Exigences de la Batterie de la

Pompe de Secours

doit être vérifié et entretenu selon les

directives du fabricant.

2. La boîte de batterie accomode les

batteries de tailles 24C, 24VCM, 27C,

27CM et 27F.

3. Le temps pour recharger les batteries

varie avec chaque installation. Dans des

conditions normales, la recharge

complète des batteries de décharge

profonde nécessitera entre deux et

quatre jours après qu’elle soit

déchargée. S'il y a une panne de courant

dans la maison plus d'une fois par

semaine, considérez avoir une pile de

rechange, bien chargée pour remplacer

la pile épuisée de la pompe de décharge

de secours.

Installation – ESP15

L’installation de ce

NE PAS

pomper

Utiliser seulement des nouvelles piles de 12 V

complètement chargées à fonctions

décharge profonde. Le niveau

d’électrolyte

de 1 po au dessus de la pompe

principale. Ceci permettra la pompe

principale de fonctionner normalement

(voir Figure 1).

les fluides explosifs tels que

l’essence, l’huile à chauffage, le

kérosène etc. NE PAS

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie! Joignez-la à ce manuel ou

classez-la dans un dossier pour plus de sécurité.

Page 9

modèle pourrait

durer plusieurs heures. Vous devez d’avoir une

méthode alternative fiable disponible pour vider

le puisard après le démontage de la pompe

principale.

1. Couper la puissance à la pompe

principale.

2. Installer la pompe en utilisant de la

tuyauterie rigide CPV 1-1⁄4 po ou 1-1⁄2

po. Un clapet (Vendu séparément) doit

être installé entre le T du modèle ESP et

la pompe principale (voir Figure 1).

LAISSER UN

ESPACE DE 10 CM

(4 PO.) AU MIN ENTRE

LE COUVERCLE

DE LA CUVE ET

LA POMPE

DE SECOURS

LAISSER UN ESPACE

DE 2,5 CM (1 PO.)

CLAPET AU MINIMUM

ENTRE LA POMPE

DE SECOURS ET LA

POMPE PRINCIPALE

Figure 1

3. Mesurer et couper le tuyau de décharge

afin que la pompe de sauvegarde soit un

minimum

354001-001 7/11

© 2011, WAYNE/Scott Fetzer Company.

7 Fr

Page 10

Instructions d'Utilisation et Manual de Pièces

10 Fr

Installation – ESP15 (suite)

4. Vérifier l’ajustage des pièces avant de les

fixer en permanence. Coller le T en place

avec du ciment CPV. L’encoche doit être

vers le haut, sinon la soupape à clapet ne

fonctionnera pas (Figure 2).

5. Introduire la soupape à clapet dans le T.

S’assurer que la languette indicatrice soit

dans l’encoche du T (voir Figure 2).

6. Glisser le collier sur le T.

7. Introduire la pompe dans la soupape à

clapet, incliner la pompe 30˚, le cordon

d’alimentation devrait être face en haut

(voir Figure 3). Serrer le collier autour de

la pompe et la soupape à clapet (voir

Figure 2).

8. Pour installer l’interrupteur à flotteur

d’une pompe de secours, glisser d’abord

la sangle latérale dans la fente sur le

dessus du T. Fixer avec la vis fournie.

Retirer l’écrou hexagonal supérieur de

l’interrupteur et glisser vers le haut le

long du cordon et de côté. Glissez le

cordon par la fente de la sangle, tirer le

goujon fileté par le trou et fixer avec

l’écrou. S’assurer que l’interrupteur à

flotteur est audessus de la base de la

pompe et que les fils de courant

n’entrave pas le fonctionnement de

l’interrupteur à flotter ou l’entrée de la

pompe.

Installation – ESP25

L’installation de

ce modèle pourrait

durer plusieurs heures. Vous devez d’avoir une

méthode alternative fiable disponible pour vider le

puisard après le démontage de la pompe

principale.

1. Couper la puissance à la pompe

principale.

2. Installer la pompe en utilisant de la

tuyauterie rigide CPV 1-1/4 po ou

1-1/2 po

INSTALLATION DE LA POMPE

Le ESP25 peut être installé comme système de

secours avec une conduite de décharge

distincte (Méthode 1) ou relié à une conduite

de pompe de vidange (Méthode 2, page 11).

Débrancher la pompe de

c.a.

actuelle. Ne pas suivre cet avertissement pourrait

mener à un choc électrique mortel.

1. Vérifier que la pompe de c.a. actuelle soit

en bon état. Si la pompe de c.a. est dans

un état douteux, il est recommandé

normalement de la remplacer avec une

pompe de 1/3 ou de 1/2 HP.

2. Retirer tout débris accumulé ou vase des

environs et du puisard.

MÉTHODE 1 (DE CHOIX)

1. Placer la ESP25 sur une surface solide,

à niveau dans le puisard. Ne pas placer

la pompe sur une surface meuble ou

de sable. De petites pierres ou le sable

peuvent endommager la pompe

menant à une défaillance de pompe

possible.

2. Cette pompe a une décharge de 3,8 cm

(1-1/2 po NPT). Pour utiliser un tuyau

de décharge de 3,2 cm (1-1/4 po NPT),

il faudra installer un adaptateur (Vendu

séparément). Un tuyau d’un plus petit

diamètre réduira l’écoulement, le débit

et la performance de la pompe.

3. Couper une section de 1,2 m (4 pi) de

tuyau rigide de PVC de 3,2 cm (1-1/4

po) ou 3,8 cm (1-1/2 po). Cimenter un

tuyau de 3,8 cm (1-1/2 po) à un

raccord fileté. Cimenter un tuyau de

3,2 cm (1-1/4 po) dans le raccord de

tuyau. Fixer une section de 3,2 cm (1-

1/4 po) de tuyau à l’adaptateur de

décharge ESP25.

4. Visser sur la décharge de PVC de la

pompe.

Attention de ne

pas dénuder ou

fausser le filetage des raccords de plastique ou

les clapets. Un boyau flexible n’est pas

recommandé. Pour une installation

permanente, il faut un tuyau de métal ou de

PVC rigide.

5. Placer la pompe avec la section de 1,2

m (4 pi) de tuyau PVC sur une surface

solide et à niveau dans le puisard sur

une surface élevée.

6. Fixer un clapet de caoutchouc (vendu

séparément) sur le dessus du tuyau de

décharge. Ceci permettra de retirer

facilement la pompe ou le clapet pour

l’entretien ou la réparation NOTE:

Vérifier que les soupapes peuvent être

placées directement dans la décharge

de la pompe s’il y a lieu. Il est toutefois

recommandé pour faciliter le

démontage de placer les clapets au-

dessus du puisard tel qu’illustré dans la

Figure 1, page 13. Le reste de

l’installation de tuyau de décharge

peut varier selon les circonstances

individuelles. Acheminer le tuyau de

décharge vers un mur extérieur en

choisissant le parcours le plus court et

en utilisant de solides pratiques de

Installation – ESP25 (Suite)

plomberie. Réduire les tournants au

minimum car cela réduit l’écoulement de

sortie de la pompe. Le tuyau qui sort de la

structure de l’édifice devrait être en pente

vers le bas pour que l’eau ne gèle pas dans

le tuyau.

En installant le tuyau de décharge distinct,

percer dans le mur extérieur avec

l’équipement de perçage approprié. Sceller

le trou pour éviter que l’eau n’y pénètre.

MÉTHODE 2

Si une décharge séparée et dédiée n’est pas

possible comme dans la méthode 1, la

pompe ESP25 peut être reliée au tuyau de

décharge de la pompe principale en

installant un connecteur en « Y ».. Il faudra

alors deux clapets.

1. Placer la ESP25 sur une surface solide

et à niveau dans le puisard. Ne pas

placer la pompe sur une surface

meuble ou de sable. De petites pierres

ou le sable peuvent endommager la

pompe menant à une défaillance de

pompe possible.

2. Cette pompe a une décharge de 3,8

cm (1-1/2 po NPT). Pour utiliser un

tuyau de décharge de 3,2 cm (1-1/4

po NPT), il faudra installer un

adaptateur (Vendu séparément). Un

tuyau d’un plus petit diamètre réduira

l’écoulement, le débit et la

performance de la pompe.

3. Il faudra un clapet à LA FOIS dans la

conduite de décharge de la pompe

principale c.a. et dans la pompe ESP25

pour éviter la recirculation de l’eau

dans le puisard. Le système ne

fonctionnera pas dans deux clapets.

ESP15, ESP25

Page 11

4. Couper une section de 1,2 m (4 pi) de

tuyau rigide de PVC de 3,2 cm (1-1/4

po) ou 3,8 cm (1-1/2 po). Cimenter un

tuyau de 3,8 cm (1-1/2 po) à un

raccord fileté. Cimenter un tuyau de

3,2 cm (1-1/4 po) dans le raccord de

tuyau. Fixer une section de 3,2 cm (1-

1/4 po) de tuyau à l’adaptateur de

décharge ESP25.

5. Visser sur la décharge de la pompe.

Attention de ne

pas dénuder ou

fausser le filetage des raccords de plastique ou

les clapets. Un boyau flexible n’est pas

recommandé. Pour une installation

permanente, il faut un tuyau de métal ou de

PVC rigide.

6. Placer la pompe avec la section de 1,2

m (4 pi) de tuyau PVC sur le sol du

puisard ou sur une surface élevée, au

besoin.

7. Fixer un clapet de caoutchouc

(vendu séparément) sur le dessus

du tuyau de décharge. Ceci permettra de

retirer facilement la pompe ou le clapet

pour l’entretien ou la réparation.

8. Reproduire la configuration de la

tuyauterie de décharge pour la pompe

principale c.a. si la conduite actuelle

doit être ajustée pour accommoder

une seconde pompe.

9. Coller un coude de 45º au tuyau court

de la pompe ESP25. Coller un raccord

en ‘Y’ au tuyau court sur la pompe

actuelle, tel qu’indiqué dans

l’illustration pour la méthode 2.

10. Coller une petite pièce de tuyau de

PVC entre le coude de 45º et le

raccord en ‘Y’.

NOTE: Vérifier que les soupapes peuvent être

placées directement dans la décharge de la

pompe s’il y a lieu. Il est toutefois

recommandé pour faciliter le démontage de

placer les clapets au-dessus du puisard tel

qu’illustré dans la Figure 5, page 10. Le reste

de l’installation de tuyau de décharge peut

varier selon les circonstances individuelles.

Acheminer le tuyau de décharge vers un mur

extérieur en choisissant le parcours le plus

court et en utilisant de solides pratiques de

plomberie.

MÉTHODES 1 ET 2

Installer l’interrupteur à flotteur à au moins 10

po à 12 po (25 à 31 cm) au-dessus du bas du

puisard pour que l’unité de secours se mette

en marche seulement lorsque le niveau d’eau

est plus élevé

TUYAU RIGIDE

DE PVC

SOLIVE RACCORD PLACER LE

DE EN "Y" TUYAU VERS

PLANCHER LE BAS

COUDE DE

45°

CHARGEUR CLAPET

TUYAU

DE PVC

1-1/4 PO

OU 1-

1/2 PO

BOÎTE DE BATTERIE

POMPE POMPE

DE SECOURS PRINCIPALE

Figure 6

9 Fr

que le niveau normal “on” (MARCHE) pour la

pompe principale. Utiliser les attaches

métalliques fournies pour fixer l’interrupteur

au tuyau de décharge. S'assurer que les fils

d'alimentation n’entravent pas le

fonctionnement de l’interrupteur à flotteur,

l’entrée de la pompe ou la pompe principale.

La pompe de secours ne doit pas fonctionner

à sec.

Installation de la boîte de contrôle –

ESP15 & ESP25

1. Fixer la boîte de contrôle au côté de la

boîte de batterie tel qu’indiqué dans la

Figure 7. Placer la batterie dans la boîte,

brancher le câble rouge à la borne

positive de la pile et le câble noir à la

borne négative. Mettre le couvercle sur

la boîte.

Si les câbles sont

renversés, le

dommage à la boîte de contrôle ou à la pile peut

résulter et niera la garantie.

2. Placer la boîte de pile à moins de 1,83 m

du puisard et d’une prise de courant de

115 Vc.a. (fusible séparé). La prise de

courant doit être protégée d’un

interrupteur qui protège contre un

dérangement dû à une mise accidentelle

à la terre (DDFT). L’endroit doit être

propre, sec et bien aéré.

3. Brancher l’interrupteur flotteur, la

pompe, et le chargeur dans la boîte de

contrôle. (Connexions indiquées sur la

boîte).

4. Faire l’essai de la pompe en remplissant

le puissard d’eau pendant que la pompe

principale est débranchée. Si la pompe

fonctionne correctement, brancher le

chargeur dans la prise de courant DDFT

pour charger la batterie.

5. Protéger le cordon d’alimentation contre

les objets pointus, les surfaces chaudes,

l’huile, et les produits chimiques. Éviter

de tortiller le cordon et remplacer toutes

les pièces endommagées

immédiatement.

VIS DE BOÎTE FOND DE LA

FILS DE DE CONTRÔLE BOÎTE DE PILE

PLOMB

Figure 7 BOÎTE DE CONTRÔLE

Fonctionnement

3.

TOUJOURS débrancher la source

de puissance avant d’essayer

d’installer, de réparer, de déplacer ou de procéder

à l’entretien de la pompe. NE JAMAIS toucher le

pompe de puisard, le moteur de la pompe, l’eau ni

le tuyauterie de décharge lorsque la pompe est

branchée à une source d’alimentation. NE JAMAIS

manipuler une pompe ni un moteur de pompe avec

les mains trempes, ni lorsque vous êtes debouts sur

une 4. surface humide ou trempe ni dans

l’eau, sinon, vous risquez une secousse électrique

mortelle.

Risque

dechoc électrique! Cette pompe

est fournie avec un conducteur de

terre et une fiche de masse.

Utiliser une prise à la terre pour réduire le

risque de choc électrique mortel. NE JAMAIS

couper la broche de terre ronde. Couper le

cordon ou la fiche annulera la garantie et

rendra la pompe inutilisable.

1. Avec une batterie complètement

chargée, tester le fonctionnement de

la pompe de secours en remplissant

le puisard avec de l’eau pendant que

la pompe primaire est débranchée. Si

la pompe de secours fonctionne

correctement, brancher le chargeur

Page 12

Instructions d'Utilisation et Manual de Pièces

12 Fr

dans la prise protégée GFCI et la

pompe principale dans une prise GFCI

séparée.

2. Suite à l’installation, la pompe de

réserve se démarrera lorsque le

niveau d’eau dépasse la profondeur

de démarrage de la pompe

principale. La boîte de contrôle a un

chargeur à impulsions conçu pour

raccourcir le temps nécessaire pour

charger la batterie, et pour éviter de

la surcharger. Aussi, la boîte de

contrôle a un retardateur qui

empêche les cycles courts répétés

lorsqu’il s’arrête. Cette fonction de

surcharge permet à la pompe de

fonctionner 20 à 25 secondes après

que l’interrupteur atteint la position

d’arrêt. La boîte de contrôle a une

lampe indicatrice multicolore. Quand

le courant c.a. est présent, la lampe

indique l’état de charge, mais pas la

tension de batterie actuelle,

particulièrement avec une batterie

défectueuse. Suivre les étapes “a” à

“d” pour une indication précise

a. Débrancher la pompe principale

c.a. et le chargeur - une tonalité

d’avertissement sonnera pendant 30

secondes.

b. Soulever et lâcher l’interrupteur flotteur

pour actionner la pompe de secours de

réserve.

c. Quand la pompe s’arrête de réserve,

vérifier la lampe d’essai:

Vert: Batterie chargée.

Jaune: Tension est basse, batterie

partiellement chargée.

Rouge: Batterie complètement déchargée

ou défectueuse.

d. Brancher le chargeur et la pompe

principale c.a.

Si l’alimentation c.a. est coupée et la

pompe fonctionne, la lampe indicatrice

indiquera l’état de la batterie.

5. Un son de pépiement de la boîte de

contrôle accompagnera la lampe

rouge ce qui indique une batterie qui

requiert l’attention ou le

remplacement. La tension est le seul

indicateur de la condition de la

batterie pourrait indiquer une

condition fausse. Se référer à la

section Entretien pour les instructions

pour évaluer la condition de la

batterie.

6. Une tonalité de 30 secondes sonnera

lorsque l’alimentation au système soit

interrompu. Le modèle se rajustera

automatiquement quand

l’alimentation soit rétablit. Une

tonalité de 3 secondes sonnera

chaque fois que la pompe se démarre.

BATTERIES

Du gaz d'hydrogène

peut être dégagé

des batteries en chargeant. Des étincelles

peuvent enflammer le gaz dans un espace

restreint. Porter des lunettes de sécurité en

connectant les batteries. Les connexions de

batteries doivent se faire dans un endroit bien

ventilé..

Entretien

TOUJOURS débrancher la source d’électricité

avant d’essayer

d’installer, de déplacer ou de

Guide De Dépannage - Pompe de Secours

Symptôme(s)

Cause(s) possible

Action(s) corrective

Pompe ne

fonctionne pas

1. Raccords ne sont pas sûrs

2. Batterie faible

3. Obstruction de l'interrupteur à flotteur

4. Fusible défectueux ou sauté

1. Vérifier tous les raccords

2. Vérifier la batterie et la remplacer si faible

3. S’assurer que rien n‘entrave le fonctionnement de l’interrupteur

4. V érifier le fusible interne dans la boîte de contrôle. Débrancher le chargeur de la prise du

mur et l’enlever. Si le fusible est sauté, le remplacer avec un fusible d’automobile de 15 A

Moteur ronron

mais la pompe ne

fonctionne

pas

1. Batterie défectueuse

2. Impulseur obstrué

1. Vérifier la batterie et la remplacer si faible ou défectueuse

2. Débrancher la pompe et vérifier si la turbine tourne librement. Si la turbine est bloquée,

enlever les 4 vis sur le fond de la pompe pour lâcher le carter autour de la

turbine. Enlever l’obstruction. Remonter la pompe et brancher à nouveau

La pompe

fonctionne mais

refoule peu ou pas

d’eau

1. Clapet manquant ou mal-installé

2. Engorgement dans le tuyau de décharge

3. Pompe pas tournée à 30˚

4. Pompe bloquée à l’air

5. Longueur et/ou hauteur du tuyau de décharge

dépasse la capacité de la pompe

6. Batterie faible ou défectueuse

1. S’assurer que le clapet soit installé et fonctionne entre le décharge de la pompe principale et

le raccord en T de la pompe de puisard de réserve.

2. Vérifier pour un engorgement et l’enlever si nécessaire

3. Vérifier que la pompe est tournée à 30˚ en montage T dans ESP15 Section Installation, Figure

3, à la page 10

4. Le carter de turbine a un petit trou sur le côté. Le trou doit être ouvert pour amorcer la

pompe. Avec la pompe débranchée, enlever les 4 vis sur le fond de la pompe afin de lâcher le

carter autour de la turbine. Nettoyer le trou et remplacer le couvercle

5. Si le décharge est trop haut, une ligne séparée avec une hauteur de décharge plus basse peut

être nécessaire

6. Vérifier la batterie et la remplacer si faible ou défectueuse

Pompe cycle à

maintes reprises

1. Clapet principal entre le décharge de la pompe

principale et le raccord en T de la pompe de

puisard de réserve ou la soupape à clapet de

la pompe de puisard de réserve mal-installé

ou en panne

1. Installer un clapet ou réparer au besoin

ESP15, ESP25

Page 13

Entretien (suite)

procéder à l’entretien. Si la source de puissance est

hors vue, verrouiller et étiquetter dans la position

ouverte (off) pour éviter l’alimentation inattendu.

Manque de suivre ces directives PEUT résulter en

secousse électrique mortelle. Seul un électricien

qualifié DEVRAIT réparer ce modèle. La réparation

incorrecte PEUT résulter en secousse électrique

mortelle.

1. Vérifier la condition de la batterie chaque

mois.

2. Débrancher le chargeur du mur.

3. Vérifier le niveau d’électrolyte et

4.

remplir d’après les recommandations du

fabricant des batteries dont le bouchon

supérieur s’enlève. Vérifier la charge de

chaque cellule avec un hydromètre. Une

densité spécifique de 1.265 indiquerait

que la batterie est complètement chargée.

Si la densité spécifique de n’importe

quelle cellule varie de plus de .050,

remplacer la batterie.

REMARQUE: Un hydromètre peu coûteux

est disponible chez votre marchand de

pièces d’automobile. Inspecter les bornes

et les colliers pour la corrosion et le

serrage.

5.

6.

Nettoyer et serrer au besoin.

Débrancher la pompe principale et

remplir le puisard d’eau jusqu’à ce que

la pompe de sauvegarde se met en

marche. Répéter le procédé deux fois

pour s’assurer que la pompe fonctionne

normalement.

Si la pompe fonctionne normalement,

brancher le chargeur dans la prise du

mur, mettre la pompe principale en

marche. Si la pompe ne fonctionne pas

normalement, voir le guide de

dépannage et corriger le problème.

Répéter l’étape 5.

Pour des pièces de rechange, composer 1-800-237-0987

S’il vous plaìt fournir l’information suivante:

- Numéro de modèle

- Numéro de série (si applicable)

- Description et numéro de pièce d’après la liste de pièces

Correspondance:

WAYNE Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

Liste de Pièces Détachées – ESP15

No. de Réf.

1

2

3

4

5

6

Numéro

Description

de pièce

Qté

Sangle 46049-001 1

Chargeur 30221-001 1

Boîte de contrôle 30222-004 1

Vis - boite de contrôle 16119-002 4

Pompe 58324-001 1

Interrupteur flotteur 30033-001 1

No. de

Réf. Description

Numéro de pièce

Qté

1 Sangle 46049-001 1

2 Raccord en T 17233-002 1

3 Sangle pour batterie 23217-001 1

4 Chargeur 17220-004 1

5 Boîte de contrôle 30209-003 1

6 Vis - boite de contrôle 16119-002 4

7 Pompe 17218-003 1

8 Soupape à clapet 17216-001 1

9 Collier - tuyau 16044-001

1

10 Interrupteur flotteur 30033-001 1

Page 14

Instructions d'Utilisation et Manual de Pièces

14 Fr

11 Fr

ESP15, ESP25

GARANTIE LIMITÉE

Système ESP15: Pendant un (1) an à compter de la date d’achat, WAYNE Water Systems (WAYNE) va réparer ou remplacer, à sa discrétion, pour

l’acheteur original n’importe quelle pièce ou pièces de ces Pompes de Puisard ou Pompes à eau (« Produit ») déterminées défectueuses, par

WAYNE Water Systems, en termes de matériaux ou de fabrication.

Système ESP25: Pendant deux (2) ans à compter de la date d’achat, WAYNE Water Systems (WAYNE) va réparer ou remplacer, à sa discrétion,

pour l’acheteur original n’importe quelle pièce ou pièces de ces Pompes de Puisard ou Pompes à eau (« Produit ») déterminées défectueuses,

par WAYNE Water Systems, en termes de matériaux ou de fabrication.

S’il vous plaît appeler WAYNE Water Systems (1-800-237-0987) pour des instructions ou contacter votre marchand. S’assurer d’avoir, à votre

disposition, le numéro du modèle afin d’effectuer cette garantie. Les frais de transportation des Produits ou pièces soumis pour la réparation

ou le remplacement sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation abusive, mauvais usage,

négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux instructions écrit de WAYNE Water Systems.

IL N’Y A AUCUNE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS CELLES DE COMMERCIALISATION OU CONVENABLE À UN

USAGE PARTICULIER, SONT LIMITÉES À UN (1) AN DE KA DATE

D'ACHAT POUR LE SYSTÈME ESP15 ET DEUX (2) ANS DE LA DATE D’ACHAT POUR LE SYSTÈME ESP25. CECI EST LA REMÈDE EXCLUSIVE ET

N’IMPORTE QUELLE RESPONSABILITÉ POUR N’IMPORTE QUEL ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST

EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des dommages fortuits

ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à l’acheteur, des droits légales précis,

et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement, ni WAYNE Water

Systems ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais pas limité à la perte de

profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à l’équipement associé, coût de capital,

coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût de temps que le produit n’est pas en service, ou la

réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre recette d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une COPIE de la recette d’achat avec le matériel ou

correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler WAYNE Water Systems (1-800-237-0987) pour l’autorisation

et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE. Utiliser ce bulletin seulement pour vos archives.

Page 15

Nº DU MODÈLE (POMPE PRINCIPALE) ________________ Nº DU MODÈLE (POMPE DE SECOURS) ________________ Nº DE SÉRIE (POMPE

PRINCIPALE) ________________ Nº DE SÉRIE (POMPE DE SECOURS) ________________ DATE D’INSTALLATION

________________ FIXER VOTRE FACTURE ICI

Page 16

Manual de Instrucciones de Operación y Piezas

16 Sp

Sistemas de

respaldo de batería

de 12V

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o da r

mantenimiento al producto aquí descrito. Protéjase usted mismo y a los demás observando toda la información de

seguridad. ¡El no cumplir con las instrucciones puede ocasionar daños, tanto personales como a la propiedad! Guarde

estas instrucciones para referencia en el futuro.

Manual de Instrucciones de Operación y Piezas

ESP15, ESP25

Descripción

Los sistemas ESP15 y ESP25 son sistemas de

bombas de respaldo para sumideros

operados con batería. No sustituye una

bomba principal normal. Está diseñada para

proporcionar protección en el caso de falla

de energía eléctrica doméstica.

Desempacar

Revise esta unidad antes de usarla. A

veces, el producto puede sufrir daños

durante el transporte. Si la bomba o sus

componentes están dañados,

comuníquese con el departamento de

servicio al cliente: 1-800-237-0987.

Medidas de Seguridad

Este manual contiene información que es

muy importante que sepa y comprenda.

Esta información se la suministramos como

medida de SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Debe

reconocer los siguientes símbolos.

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la muerte o

heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle la muerte o

heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle heridas no

muy graves.

Ésto le indica una

información

importante, que de NO seguirla, le PODRÍA

ocasionar daños al equipo.

Informaciones Generales de

Seguridad

PROPOSICIÓN DE CALIFORNIA 65

Este producto, o su

cordón eléctrico,

PUEDE contener productos químicos conocidos

por el estado de California como causantes de

cáncer y defectos de nacimiento u otros daños

reproductivos. Lave sus manos después de usar.

GENERALES DE SEGURIDAD

NUNCA

use esta

bomba para bombear líquidos

inflamables o explosivos tales como gasolina,

combustibles, kerosene, etc. NO la use donde

haya peligro de explosión. Úsela sólo para drenar

agua. Si NO sigue estas recomendaciones

PODRÍA ocasionarle heridas o daños a su

propiedad.

Todos los trabajos de

electricidad los

debe hacer un electricista calificado. Si NO sigue

estas advertencias PODRÍA electrocutarse.

Si el

piso

del sóta

- NO está húmedo o inundado,

NO entre hasta que haya

desconectado la electricidad. Si la caja de fusibles

está en el sótano, llame a un electricista.

Desconecte la bomba y repárela o reemplácela. Si

NO sigue estas advertencias PODRÍA

electrocutarse.

NO

exponga la batería al contacto de

chispas

o llamas ya que PODRÍA provocar

una

explosión o un incendio.

El ácido

de la

batería es corrosivo. Evite derramarlo sobre la piel

o ropa. Al manipular la batería, DEBE protegerse

los ojos.

DEBE utilizar una

válvula de chequeo

en el orificio de descarga de la bomba principal

para sumideros (vea la Figura 1).

Se requiere un interruptor con

dispositivo para desconexión automática en caso

de fallas.

Esta bomba sólo

DEBE usarse para bombear

aguas limpias. Esta bomba NO está diseñada para

bombear efluentes, agua salada, salmuera, agua

con detergentes o en ningún otro líquido que

contenga químicos causticos y/o residuos y

partículas. Ésto le ocasionaría DAÑOS a la bomba y

CANCELARÍA la garantía.

Requisitos de la batería para la

bomba de respaldo

1. Use sólo baterías nuevas totalmente

cargadas de 12 V y ciclo intenso. Se debe

comprobar el nivel electrolítico y

mantenerlo de conformidad con las

estipulaciones impartidas por el fabricante.

2. Las baterías que caben en el

compartimiento de batería son las

siguientes: 24C, 24VCM, 27C, 27CM y 27F.

3. El tiempo de recarga de la batería será

diferente en cada instalación. Bajo

condiciones normales, demorará de dos a

cuatro días recargar totalmente una

batería de ciclo intenso después de haber

sido descargada. Si la energía eléctrica de

la casa se pierde más de una vez a la

semana, considere tener una batería de

repuesto totalmente cargada para cambiar

la batería agotada de la bomba de

sumidero de respaldo.

Instalación – ESP15

La instalación de esta

bomba PODRÍA tomarle

varias horas. Antes de desconectar temporalmente

la bomba principal, cerciórese de tener un plan

para drenar el sumidero en caso de emergencia.

1. Desconecte la corriente que va a la bomba

principal.

2. La bomba debe instalarse utilizando una

tubería rígida de PVC de 3,2 cm (1-1⁄4”) ó

3,8 cm (1-1⁄2”). Entre la conexión en T de

la ESP y la bomba principal, se debe

instalar una válvula de chequeo (Se vende

por separado) (véase la Figura 1).

DEJE UN MÍNIMO

DE 10 CM (4 PULG.)

ENTRE LA

TAPA DE LA

Page 17

17 Sp

PILETA Y LA

BOMBA DE

RESPALDO

DEJE UN MÍNIMO

VÁLVULA DE 2,5 CM

DE (1 PULG.) ENTRE

RETENCIÓN LA BOMBA DE

RESPALDO Y LA

Figura 1 BOMBA PRINCIPAL

Instalación – ESP15 (Continuación)

3. Mida y corte el tubo de descarga de modo

que la bomba auxiliar esté como mínimo a

2,54cm más arriba que la bomba principal.

Ésto permitirá que la bomba principal

operare nor malmente (vea la Figura 1).

4. Usando pegamento para PVC, pegue la

conexión en T en su lugar. La muesca debe

estar hacia arriba, de lo contrario, la

válvula de charnela no funcionará (Figura

2).

5. Inserte la válvula de charnela en la

conexión en T. Asegúrese de que la

orejuela esté en la muesca en la conexión

en T (véase la Figura 2).

6. Deslice la abrazadera sobre la conexión en

T.

7. Inserte la bomba en la válvula de charnela,

vire la bomba 30˚. Una vez que la haya

virado, el cordón eléctrico debe estar hacia

arriba (vea la Figura 3). Apriete la

abrazadera para asegurar la bomba y la

válvula de charnela (vea la Figura 2).

se muestra en la Figura 3 para evitar que que el

aire permanezca.

8. Para instalar el interruptor de flotador

para la bomba de reserva, primero deslice

la ménsula por la ranura en la parte

superior de la T. Asegure la ménsula con el

tornillo que se proporciona. Retire la

tuerca hexagonal superior del interruptor y

deslice el cable fuera. Deslice el cable a

través de la ranura en la ménsula,

introduzca el pasador roscado en el orificio

y asegúrelo con la tuerca. Asegúrese de

que el interruptor de flotador se encuentre

por encima de la base de la bomba y de

que los cables de corriente no interfieran

con el interruptor de flotador ni la entrada

de la bomba.

Instalación – ESP25

La instalación de esta

bomba PODRÍA

tomarle varias horas. Antes de desconectar

temporalmente la bomba principal, cerciórese de

tener un plan para drenar el sumidero en caso de

emergencia.

1. Desconecte la corriente que va a la bomba

principal.

2. La bomba debe instalarse utilizando una

tubería rígida de PVC de 3,2 cm (1-1/4

pulg.) ó 3,8 cm (1-1/2 pulg.).

INSTALACIÓN DE LA BOMBA

La ESP25 puede instalarse como un

sistema de respaldo con una línea de

descarga dedicada

separada (Método

1), o conjuntamente con una línea de

bombeo de sumidero ya existente

(Método 2, página 19).

Desconecte la bomba de CA existente. Si no

respeta esta advertencia puede provocar un

choque eléctrico mortal.

1. Verifique que la bomba de CA existente

esté funcionando bien. Si el estado de la

bomba de CA es cuestionable,

generalmente se recomienda reemplazar

la unidad con una bomba de 1/3 ó 1/2

HP.

2. Retire todo sedimento o residuo

acumulado del pozo del sumidero y los

alrededores.

MÉTODO 1 (SE PREFIERE)

1. Coloque la ESP25 sobre una superficie

sólida y nivelada en el pozo del sumidero.

No coloque la bomba sobre una superficie

blanda o arenosa. Las piedritas o la arena

pueden dañar la bomba, causando fallas

potenciales de la bomba.

2. Esta bomba tiene una descarga de 1-1/2

pulg. NPT (3,8 cm). Si se desea utilizar

tubería de descarga de 1-1/4 pulg. NPT

(3,2 cm), será necesario instalar un

adaptador (Se vende por separado). Las

tuberías de diámetro más pequeño

reducirán el flujo, la velocidad y el

rendimiento de la bomba.

3. Corte una sección de 4 pi. de 3,18 cm (1-

1/4 pulg.) o de 3,81 cm (1-1/2 pulg.) de

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2011, WAYNE/Scott Fetzer Company. 354001-001 7/11

Page 18

Manual de Instrucciones de Operación y Piezas

18 Sp

diámetro de un tubo de PVC rígido. Pegue

el tubo de 3,18 cm (1-1/4 pulg.) con

cemento a un accesorio de conexión

roscada. Pegue el tubo de 3,18 cm (1-1/4

pulg.) con cemento al acoplador de

tuberías. Adjunte la sección de 3,81 cm (11/4 pulg.) de la tubería al adaptador de

descarga del ESP25.

4. Atornille a la descarga de PVC de la

bomba.

Tenga cuidado de no

pelar ni cruzar

las conexiones plásticas roscadas ni las válvulas de

retención. No se recomienda usar mangueras

flexibles. Para una instalación permanente, se

requieren tuberías de PVC rígido o de metal.

5. Coloque la bomba con la sección de tubo

de PVC de 4’ sobre una superficie sólida y

nivelada en el pozo del sumidero, en una

superficie elevada.

Instalación – ESP25 (Continuación)

6. Adjunte una válvula de retención de

goma (que se vende por separado) al

extremo superior de la tubería de

descarga. Esto permitirá que la bomba

o la válvula de retención se retiren con

facilidad para repararlas.

NOTA: Las válvulas de retención pueden

colocarse directamente en la descarga de la

bomba si lo desea. Sin embargo, para

desarmar más fácilmente, se recomienda

que las válvulas de retención se coloquen

por encima del sumidero, como se muestra

en la Figura 1, página 17.

El resto de la instalación de la tubería de

descarga variará dependiendo de las

circunstancias individuales. Dirija la tubería

de descarga hacia una pared exterior, por

el camino más corto, siguiendo las técnicas

de instalación sanitaria más adecuadas.

Mantenga al mínimo los acodamientos

porque reducen la salida de flujo de la

bomba. La tubería que sale de la estructura

de la construcción debe estar en declive,

para que el agua no se congele en la

tubería. Cuando instale la tubería de

descarga separada, perfore a través de la

pared exterior con el equipo de perforación

adecuado. Selle el agujero para evitar que

entre el agua.

MÉTODO 2

Si no es posible lograr una descarga

separada y dedicada como en el Método 1,

la bomba ESP25 puede conectarse a la

tubería de descarga de la bomba que

funciona con primaria, instalando un

conector "Y". Se requerirán dos válvulas de

retención.

1. Coloque la ESP25 sobre una superficie

sólida y nivelada en el pozo del sumidero.

No coloque la bomba sobre una superficie

blanda o arenosa. Las piedritas o la arena

pueden dañar la bomba, causando fallas

potenciales de la bomba.

2. Esta bomba tiene una descarga de 1-1/2

pulg. NPT (3,8 cm). Si se desea utilizar

tubería de descarga de 1-1/4 pulg. NPT

(3,2 cm), será necesario instalar un

adaptador (Se vende por separado). Las

tuberías de diámetro más pequeño

reducirán el flujo, la velocidad, y el

rendimiento de la bomba.

3. Es necesario colocar una válvula de

retención tanto en la línea de descarga de

la bomba de CA principal como en la de la

bomba ESP25 , para evitar la recirculación

de agua hacia adentro del pozo del

sumidero. El sistema no funcionará sin dos

válvulas de retención.

4. Corte una sección de 4 pi. de 3,2 cm (1-1/4

pulg.) o de 3,81 cm (1-1/2 pulg.) de

diámetro de un tubo de PVC rígido. Pegue

el tubo de 3,8

cm (1-1/2 pulg.) con cemento a un

accesorio de conexión roscada. Pegue el

tubo de 3,2 cm (1-1/4 pulg.) con

cemento al acoplador de tuberías.

Adjunte la sección de 3,2 cm (1-1/4

pulg.) de la tubería al adaptador de

descarga del ESP25.

5. Atornille a la descarga de la bomba.

Tenga cuidado de no

pelar ni cruzar

las conexiones plásticas roscadas ni las válvulas de

retención. No se recomienda usar mangueras

flexibles. Para una instalación permanente, se

requieren tuberías de PVC rígido o de metal.

6. Coloque la bomba con la sección de tubo

de PVC de 4 pi sobre el piso del sumidero o

sobre una superficie elevada, si fuera

necesario.

7. Adjunte una válvula de retención de goma

(que se vende por separado) al extremo

superior de la tubería de descarga. Esto

permitirá que la bomba o la válvula de

retención se retiren con facilidad para

repararlas.

8. Duplique la disposición de la tubería de

descarga para la bomba de CA primaria si

la línea de descarga existente tiene que

ajustarse para contener una segunda

bomba.

9. Pegue un codo de 45º al tubo corto en la

bomba ESP25. Pegue un adaptador en “Y”

al tubo corto en la bomba existente, como

se muestra en la ilustración del Método 2.

10. Pegue un tramo corto de tubo de PVC

entre el codo de 45º y la “Y”.

NOTA: Las válvulas de retención pueden

TUYAU RIGIDE

DE PVC

VIGA DEL CONECTOR DECLIVE DE PISO

"Y" LA TUBERÍA

CODO

DE 45° VÁLVULA DE

RETENCIÓN

CARGADOR

3,18 CM

O

3,81 CM

TUBO

DE PVC

CAJA DE

LA BATERÍA

BOMBA DE

RESPALDO

BOMBA

PRIMARIA

Figura 6

colocarse directamente en la descarga de la

bomba si lo desea. Sin embargo, para

desarmar más fácilmente, se recomienda que

las válvulas de retención se coloquen por

encima del sumidero, como se muestra en la

Figura 5, página 18.

ESP15, ESP25

Page 19

19 Sp

El resto de la instalación de la tubería de

descarga variará dependiendo de las

circunstancias individuales. Dirija la tubería de

descarga hacia una pared exterior, por la

distancia más corta, siguiendo las técnicas de

instalación sanitaria más adecuadas.

MÉTODOS 1 Y 2

Instale el interruptor de flotador al menos 25,4

cm - 30,5 cm por encima del pozo del

sumidero de modo que la unidad de respaldo

se encienda sólo cuando el nivel del agua sea

mayor que el nivel de “encendido” normal de

la bomba principal. Use los amarres de

alambre para asegurar el interruptor a la

tubería de descarga. Asegúrese de que los

cables de energía no interfieran con el

interruptor de flotador, la entrada de la

bomba ni con el funcionamiento de la bomba

principal. No se debe dejar que la bomba de

respaldo funcione en seco.

INSTALACIÓN DE LA CAJA DE

CONTROL – ESP15 Y ESP25

1. Conecte la caja de control a uno de los

lados del compartimiento de la batería

tal como se muestra en la Figura 7.

Coloque la batería en el

compartimiento, conecte el cable rojo

al borne positivo de la batería, y el

cable negro al borne negativo. Ponga la

tapa a la caja.

Si los cables se

conectan al revés,

puede dañarse la caja de control o la batería, y la

garantía será invalidada.

2. Coloque la caja de la batería a unos

1,83 m del sumidero y de un

tomacorrientes de 115 VCA. El

tomacorrientes debe tener un

dispositivo automático contra

cortocircuitos. El área debe estar

limpia, seca, y bien ventilada.

3. Conecte el interruptor/ flotante, la

bomba y el cargador a la caja de

controles (Las conexiones están

indicadas en la caja de controles).

TORNILLO DE LA CAJA FONDO DE LA

DE CONTROLES BATERÍA

TERMINALES

Figura 7 CAJA DE CONTROLES

Installation (Continuación)

4. Cerciórese de que la bomba funcione

adecuadamente. Para hacerlo, desconecte

la bomba principal y llene el sumidero de

agua. Si la bomba funciona

adecuadamente, conecte el cargador al

tomacorrientes con el dispositivo contra

cortocircuitos, para comenzar a cargar la

batería.

5. Proteja el cordón eléctrico contra objetos

afilados, superficies calientes, aceite y

químicos. Evite que el cordón se enrolle y

reemplace las piezas dañadas

inmediatamente.

Funcionamiento

SIEMPRE

desconecte la unidad de la fuente

de energía antes de intentar

instalar, dar servicio, reubicar o darle

mantenimiento a la bomba. NUNCA toque la

bomba para sumideros, el motor de la bomba, el

agua o la tubería de descarga cuando la bomba

esté conectada al tomacorrientes. NUNCA

manipule una bomba o motor de bomba con las

manos mojadas, o estando parado sobre una

superficie mojada o húmeda o sobre el agua.

PUEDE ocurrir un choque eléctrico de consecuencias

fatales.

Hay

riesgo de descarga eléctrica! Use un

tomacorriente con interruptor de circuito de

pérdida a tierra para reducir el riesgo de un

choque eléctrico de consecuencias fatales. El

cortar el cordón o el enchufe invalidará la

garantía y no permitirá que la bomba funcione.

1. Con una batería totalmente cargada,

verifique el funcionamiento de la bomba

de respaldo llenando el sumidero con agua

y manteniendo desconectada la bomba

principal. Si la bomba de respaldo

funciona correctamente, conecte el

cargador en el tomacorriente protegido

GFCI y la bomba principal en otro

tomacorriente GFCI.

2. Después de instalada, la bomba auxiliar

comenzará a funcionar cuando el nivel de

agua suba sobre el nivel en el que la

bomba principal debe comenzar a

funcionar.

3. La caja de control tiene un cargador de

pulsos diseñado para acortar el tiempo de

recarga de su batería y para impedir la

sobrecarga. Además, la caja de control

tiene un retardo de tiempo que, cuando se

desconecta, evita los ciclos cortos y

repetidos de la bomba. Este dispositivo de

retardo de tiempo permitirá que la bomba

funcione por 20 ó 25 segundos después de

que el interruptor/ flotante llegue a la

posición de apagado.

4. La caja de controles contiene una luz

multicolor indicadora. Si se utiliza corriente

alterna, la luz le indicará que se está

cargando la unidad, pero no le indicará

el voltaje de la batería, especialmente

si la batería está dañada. Para que la

luz le indique información correcta

debe seguir los pasos de “a” a “d”.

a. Desconecte la bomba principal y el

cargador- sonará una alarma por 30

segundos para indicarle que están

desconectados.

b. Alce y suelte el interruptor/flotante para

activar la bomba auxiliar.

c. Cuando la bomba de respaldo deje de

operar vea las luces multicolores: Verde:

Le indica que la batería está cargada.

Amarilla: Voltaje es bajo, la batería sólo

está parcialmente cargada.

Roja: La batería está totalmente

descargada o dañada.

d. Conecte la bomba principal y el cargador

al tomacorrientes. Si la corriente

alterna está apagada, mientras la bomba

está funcionando, la luz le indicará la

carga de la batería.