Page 1

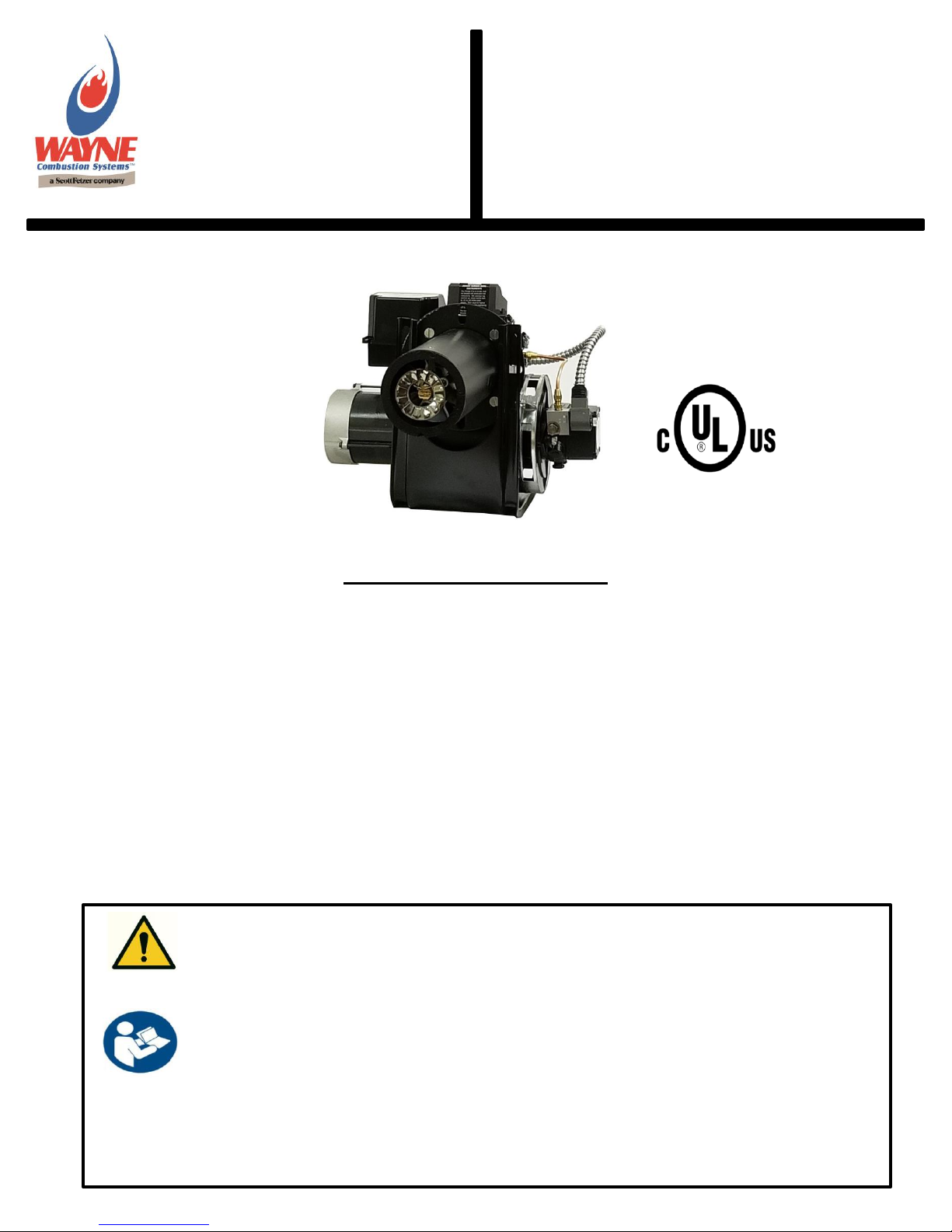

UL File Number: MP-98

SPECIFICATIONS

Firing Capacities:

Model EHA & EHASR

0.75 – 3.00 gal/hr

105,000 – 420,000 Btu/hr Input

Model EH

3.00 – 6.00 gal/hr

420,000 – 840,000 Btu/hr Input

Fuel Pumps

Single Stage Standard

Electrical

Power Supply ……….120 Vac 60Hz, 230 Vac 60 Hz 1 Phase; optional 230 Vac 50 Hz 1 Phase

Motor ………………...3450 rpm, Automatic Reset Overload Protection

Ignition ……………….14,000 V secondary, Continuous Duty or Interrupted Duty

WAYNE COMBUSTION SYSTEMS

801 GLASGOW AVE.

FORT WAYNE, IN 46803

PHONE: (260) 425-9200

(855) WAYNECS

(800) 443-4625

FAX: (260) 424-0904

www.waynecombustion.com

MODEL

EH, EHA &

EHASR

OIL BURNERS

Fuels: Use No.1 or No.2 heating oil (ASTM D-396),

Kerosene, Diesel (ASTM D975-18), JP8

Dimensions (Standard):

Height ……………………….…..…..12 1/2”

Width ……………………….…..……15 1/2”

Depth ………………………….…….. 8 1/4”

Center Line of Tube to Floor ......... 8 1/16”

Mounting:

Rigid Flange, Adjustable Flange, or Pedestal

Mount

READ THIS MANUAL BEFORE USING THIS PRODUCT. FAILURE TO FOLLOW THE

INSTRUCTIONS AND SAFETY PRECAUTIONS IN THIS MANUAL CAN RESULT IN

SERIOUS INJURY OR DEATH. KEEP THIS MANUAL FOR FUTURE REFERENCE.

INSTALLER: LEAVE THIS MANUAL WITH THE END USER.

INSTALLATION OF THE BURNER MUST BE DONE BY A QUALIFIED INSTALLER IN

ACCORDANCE WITH REGULATIONS OF THE NATIONAL FIRE PROTECTION

AGENCY, NFPA NO. 31, AND IN COMPLETE ACCORDANCE WITH ALL LOCAL

CODES AND AUTHORITIES HAVING JURISDICTION.

A QUALIFIED INSTALLER IS THE PERSON WHO IS RESPONSIBLE FOR THE

INSTALLATION AND ADJUSTMENT OF THE EQUIPMENT AND WHO IS LICENSED TO

INSTALL OIL-BURNING EQUIPMENT IN ACCORDANCE WITH ALL CODES AND

ORDINANCES.

Manual 21530 | Revision 10 | Publication Date: 9/14/18

1

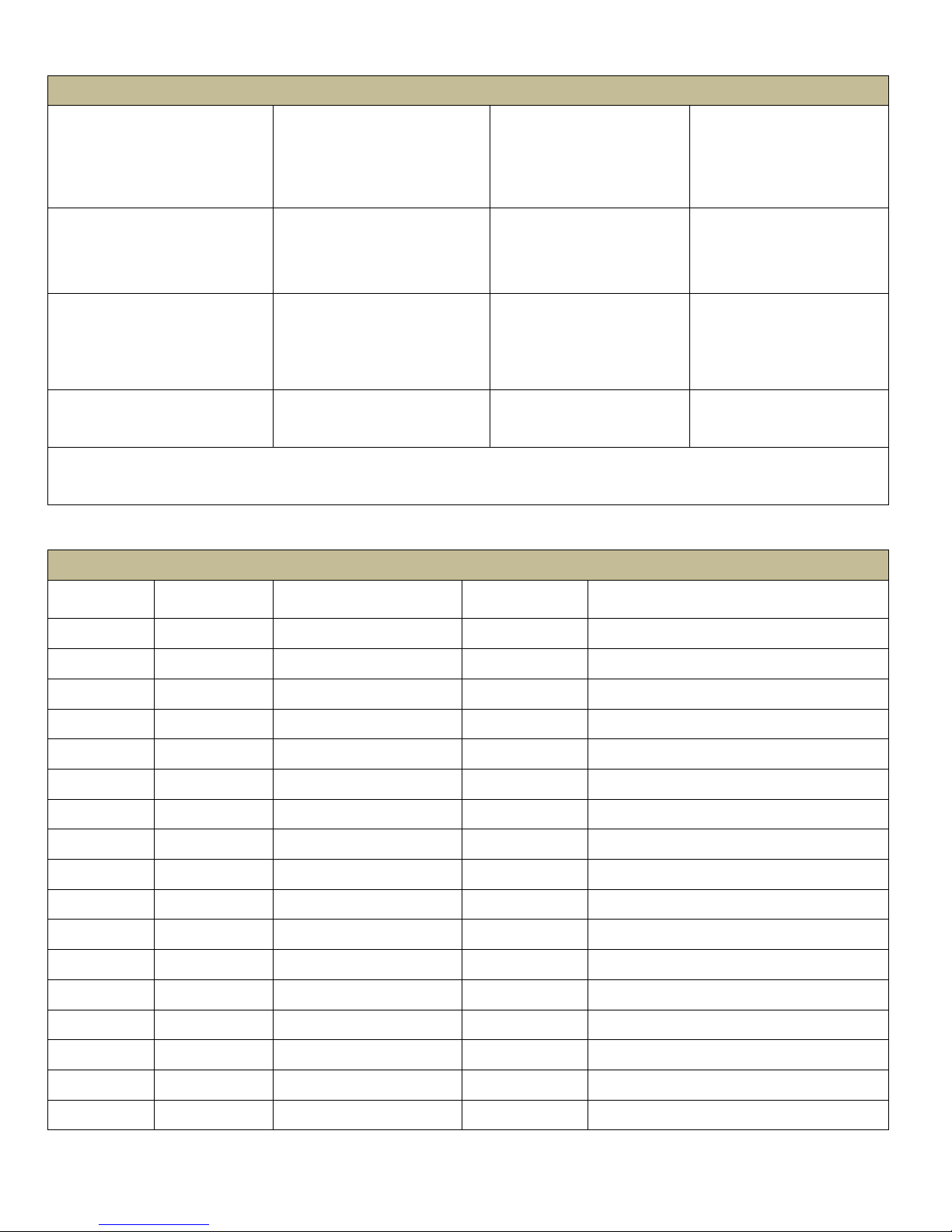

Page 2

INSTALLATION LOG

BURNER MODEL:

SPECIFICATION NUMBER:

FUEL:

Nozzle Size and Pattern:

Pump Fuel Pressure (psi):

CO2 (%):

Smoke Spot:

CO (PPM):

INSTALLER’S NAME:

CONTRACTOR NAME:

CONTRACTOR

ADDRESS:

CONTRACTOR PHONE

NUMBER:

CONTRACTOR LICENSE #:

DATE OF INSTALLATION:

COMMENTS ABOUT INSTALLATION/START UP:

BURNER/APPLIANCE SERVICE LOG

SERVICE

DATE

TECHNICIAN

COMPANY

/ ADDRESS

CONTRACTOR

LICENSE #

WORK PERFORMED

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

/ /

THESE INSTRUCTIONS SHOULD BE AFFIXED TO THE BURNER OR ADJACENT TO THE

HEATING APPLIANCE.

2

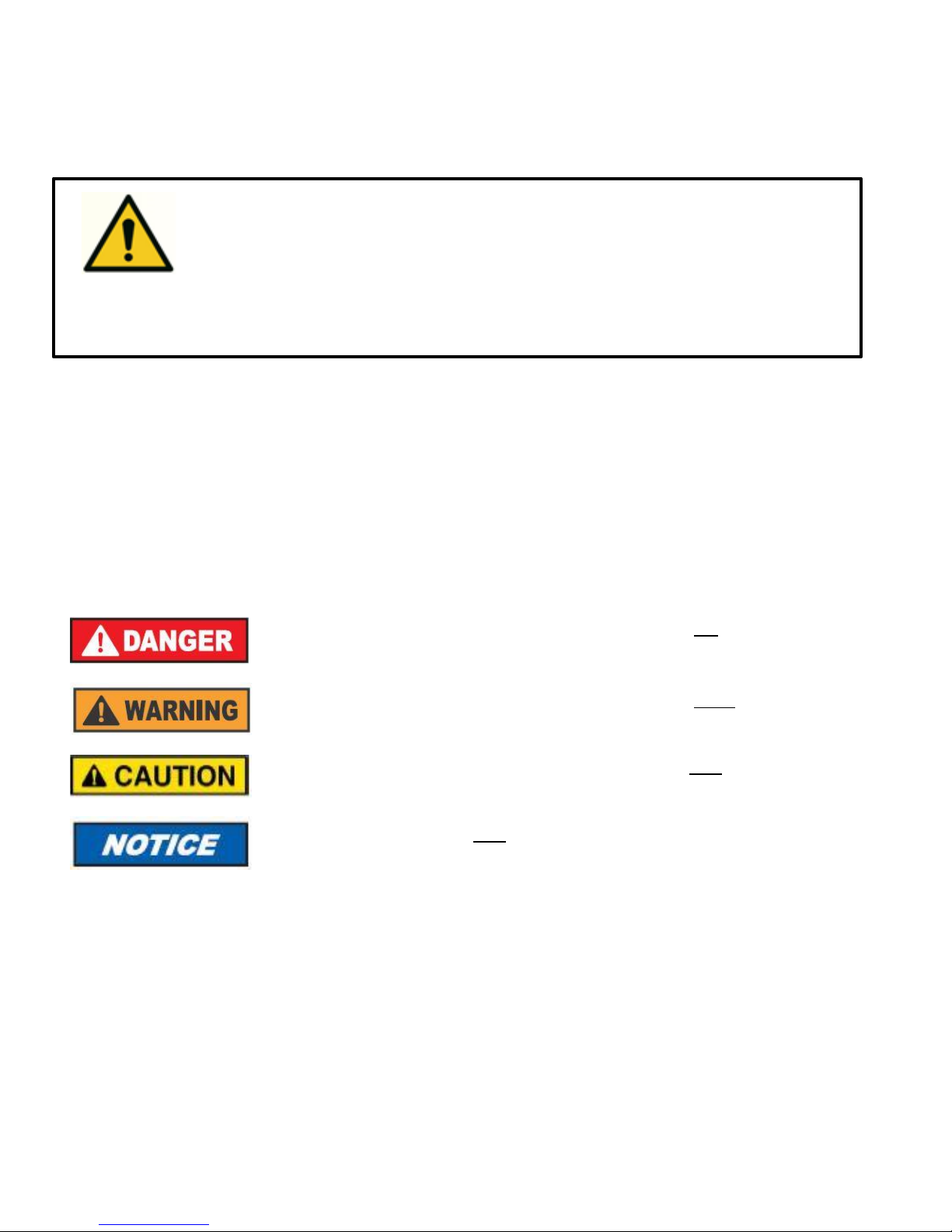

Page 3

Overview of Safety Warning System and Your Responsibilities

Indicates a hazardous situation, which, if not avoided, will result in

death or serious bodily injury.

Indicates a hazardous situation, which, if not avoided, could result in

death or serious bodily injury.

Indicates a hazardous situation, which, if not avoided may result in

minor or moderate bodily injury.

Indicates a situation that may result in equipment-related damage.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. The meaning of this safety alert symbol is as follows: Attention! Become

alert! Your safety may be at risk. The message that appears next to the warning

describes the hazard, which can be either written or pictorially presented. NEVER

remove or tamper with the warning labels, safety devices or guards fitted on the unit.

Wayne Combustion Systems is NOT responsible for any bodily injury and/or property

damage that may result from operation outside of the stated operating conditions for

which this unit was intended.

The safety of you and others depends upon you thoroughly reading and understanding this manual. If you have questions

or do not understand the information presented in this manual, please call Wayne Combustion Systems or see

www.waynecombustion.com.

Hazard Definitions:

3

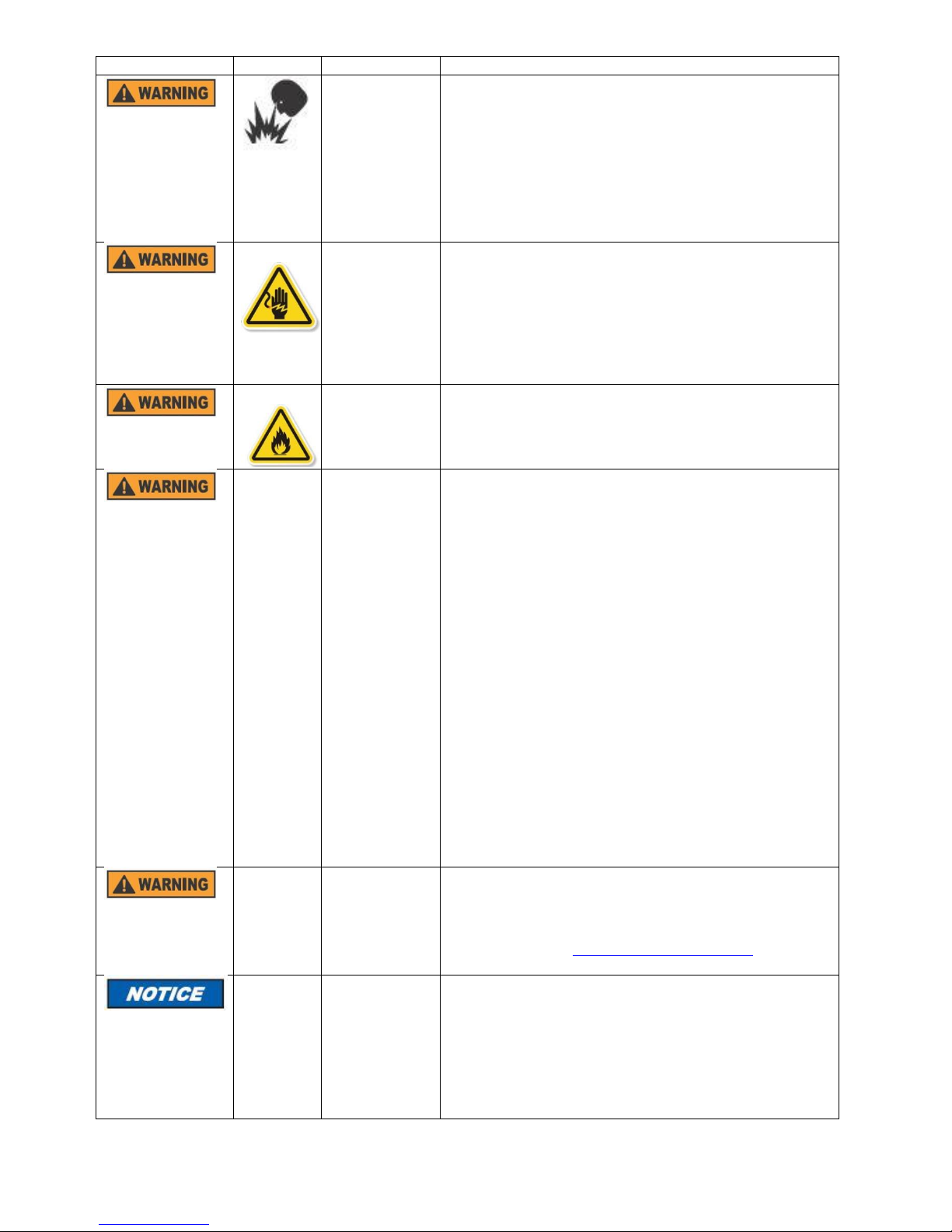

Page 4

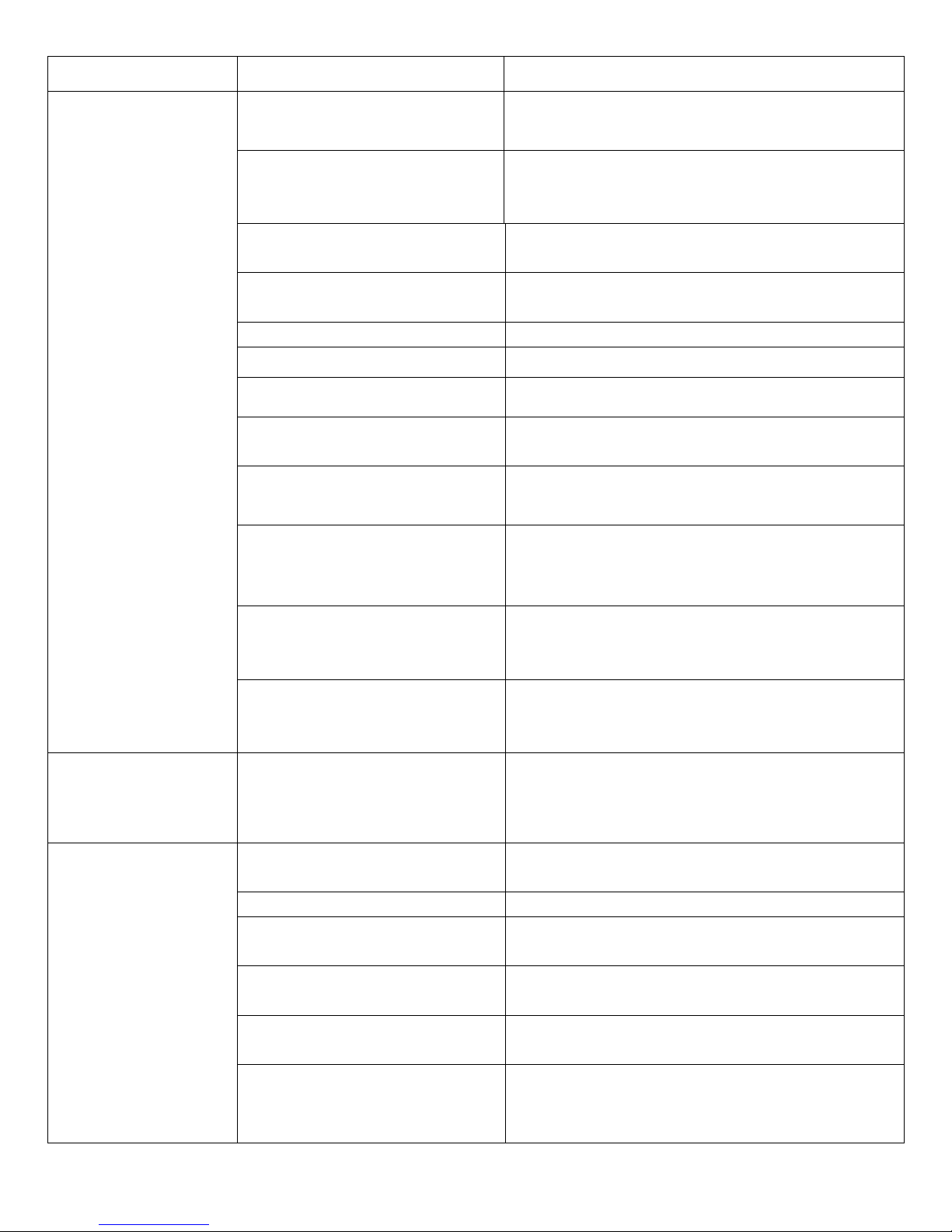

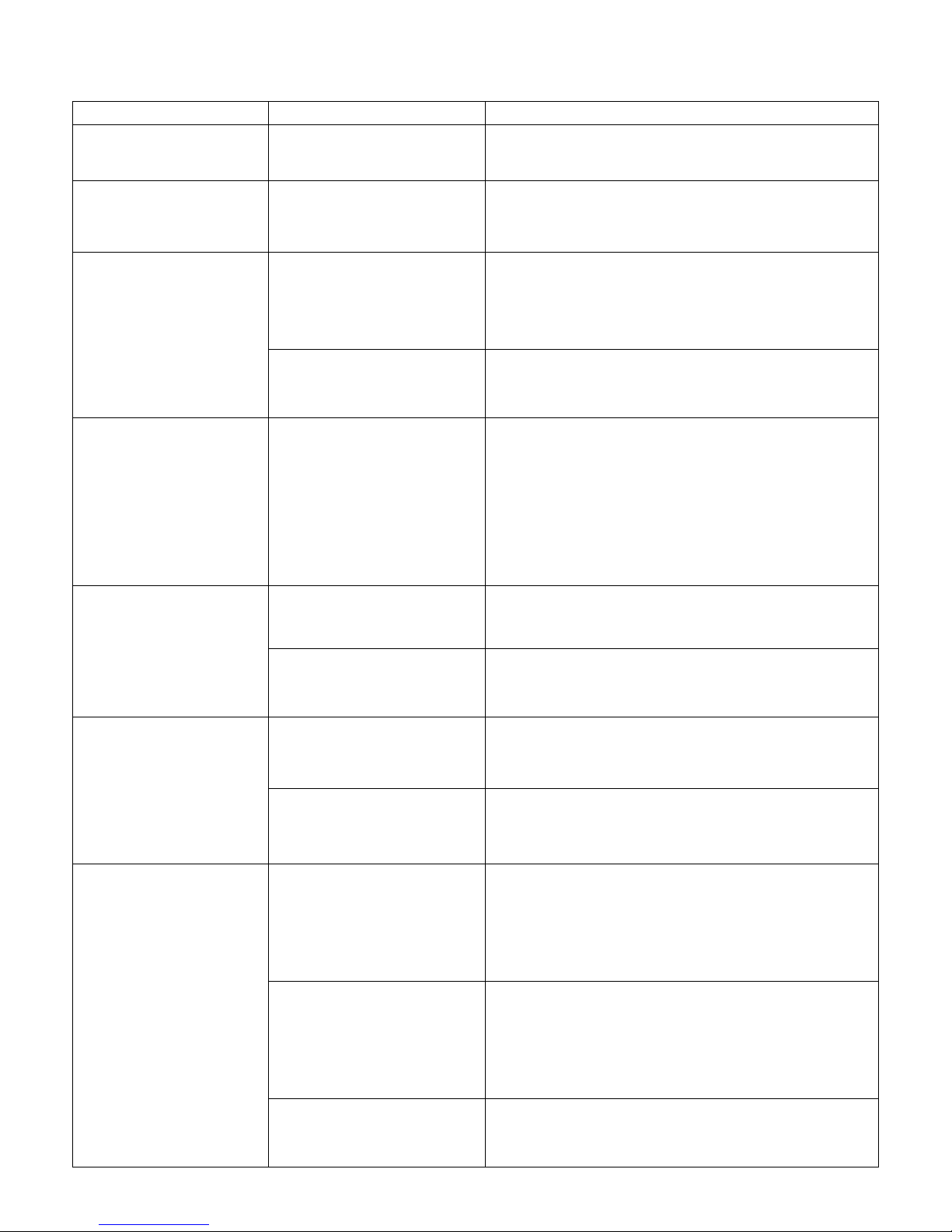

Hazard Level

Pictogram

Type

Hazard Explanation

Fire or

Explosion

Failure to follow safety warnings exactly could result in

serious injury, death or property damage.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

Never attempt to use gasoline as a fuel for this burner,

as it is more combustible and could result in a serious

explosion.

Electric Shock

or Burn

High voltages are present in this equipment. Follow

these rules to avoid electric shock:

Use only a properly grounded circuit. A ground

fault interrupter is recommended.

Do not spray water directly on burner.

Turn off power before servicing.

Read the owner’s manual before using.

Overheating

Should overheating occur:

Shut off the manual oil valve to the appliance.

Do not shut off the control switch to the pump

or blower.

Carbon

Monoxide

Poisoning

Carbon monoxide is a colorless, odorless gas that

can kill. Follow these rules to control carbon

monoxide:

Do not use this burner if in an unvented,

enclosed area. Carbon monoxide may

accumulate.

Check flue gases for carbon monoxide. This

check requires specialized equipment.

Allow only qualified burner service persons to

adjust the burner. Special instruments and

training are required.

Read the burner manual before using.

CARBON MONOXIDE POISONING: Early signs of

carbon monoxide poisoning are similar to the flu with

headaches, dizziness, weakness, nausea, vomiting,

sleepiness, and confusion. If you suspect carbon

monoxide poisoning, get outside to fresh air

immediately, and then call 911. Some people are more

affected by carbon monoxide than others. These

include pregnant women, people with heart or lung

disease or anemia, those under the influence of

alcohol, and those at high altitudes.

Proposition 65

material

This product can expose you to chemicals, including

lead, nickel, carbon monoxide and sulfur dioxide, which

are known to the State of California to cause cancer or

birth defects or other reproductive harm. For more

information, go to www.p65Warnings.ca.gov.

Special

Requirements

When contacting Wayne Combustion Systems for

service information, please have the burner

specification and model number when calling or writing.

Specification number will be located on a 1” X 2”

rectangular sticker on the back of the burner and model

number is on the big square sticker that has the

manufacturer’s logo and contact information. This

sticker will be above the specification label.

4

Page 5

Contents

GENERAL INFORMATION ............................................................................................................................... 6

TROUBLESHOOTING....................................................................................................................................... 7

GENERAL TROUBLESHOOTING GUIDE ..................................................................................................... 7

BURNER DOES NOT LIGHT, HONEYWELL CONTROL REMAINS ON STANDBY .................................... 10

BURNER WILL LIGHT, BUT WILL NOT STAY LIT DURING “CALL FOR HEAT” ........................................ 11

WIRING DIAGRAMS ....................................................................................................................................... 16

SEQUENCE OF OPERATION: BURNERS WITH R7284G AND R8184G CONTROLS .................................. 17

SEQUENCE OF OPERATION: BURNER WITH R7284P CONTROL .............................................................. 18

SEQUENCE OF OPERATION: BURNER WITHOUT CONTROL .................................................................... 19

OPERATIONAL CHECK OF BURNER ............................................................................................................ 19

START SYSTEM ......................................................................................................................................... 19

CHECK SAFETY FEATURES ...................................................................................................................... 19

GENERAL INSTALLATION INFORMATION ................................................................................................... 20

COMBUSTION CHAMBER .......................................................................................................................... 20

FUEL PUMPS .............................................................................................................................................. 20

FUEL LINES ................................................................................................................................................ 20

FUEL TANKS ............................................................................................................................................... 21

ELECTRICAL WIRING OF BURNER ........................................................................................................... 21

CHIMNEY INSTALLATION .......................................................................................................................... 21

DRAFT REGULATORS ............................................................................................................................... 21

AIR SUPPLY FOR COMBUSTION .............................................................................................................. 22

NOZZLE AND AIR CONE SELECTION ....................................................................................................... 22

NOZZLE INSTALLATION ............................................................................................................................ 22

SETTING GUN DEPTH ............................................................................................................................... 27

STARTING PROCEDURE ............................................................................................................................... 30

STARTING BURNER ................................................................................................................................ ... 30

FINAL ADJUSTMENTS ............................................................................................................................... 32

SETTING COMBUSTION EFFICIENCY ...................................................................................................... 32

FINAL CHECKS ........................................................................................................................................... 33

MAINTENANCE .............................................................................................................................................. 33

REFERENCE INFORMATION ......................................................................................................................... 34

REFERENCE FIGURES .............................................................................................................................. 36

OIL PIPE SIZING INFORMATION ............................................................................................................... 37

WARRANTY .................................................................................................................................................... 39

5

Page 6

GENERAL INFORMATION

Read this manual carefully and in it’s entirety prior to performing any maintenance or service on

the burner.

WARRANTY

Wayne Combustion Systems warrants its burner’s specifically to organizations that have purchased it for resale, including

your dealer. If you have a problem with your burner, or its installation, you should contact your dealer for assistance, for a

full description of the warranty see page 39.

MAINTENANCE

Wayne Combustion Systems recommends yearly inspection/service of your oil heating system by a qualified service

agency or individual.

A qualified service agency or individual must be:

Licensed or certified to install and provide technical service to oil heating systems.

Experienced with all applicable codes, standards and ordinances.

Responsible for the correct installation and commission of the equipment.

Skilled in the adjustment of oil burners using combustion test instruments

APPROVALS

This burner complies with ANSI/UL Standard 296 and is for use with No. 1 fuel oil or No. 2 fuel oil and is UL listed for use

with Group I or Group II primary safety controls. The states of Massuchusetts, New York and local approvals are shown

on the burner’s nameplate label. All burners must be installed in accordance with the National Fire Protection Association,

and in complete accordance with all local codes and authorities having jurisdiction. Regulation of these authorities takes

precedence over the general instructions provided in this manual.

MANUAL ORGANIZATION

This manual is organized so that the licensed contractor can troubleshoot the service issue with the burner by working

through the GENERAL TROUBLESHOOTING GUIDE on page 7. The GENERAL TROUBLESHOOTING GUIDE is

organized by the performance issue or “problem” requiring attention. Each problem will list potential root causes that may

result in the problem listed in order from most likely to least likely, and the solution to correct each root cause that may be

affecting burner performance. The solution listed for each root cause will reference supplemental information regarding

normal burner/component operation and service instructions depending on the problem and root-cause. If this is a new

installation see GENERAL INSTALLATION INFORMATION on page 20.

MODEL DIFFERENCES

The EHASR burner utilizes unique air cones and oil gun assemblies to optimize burner performance in its rated firing

range. The air cone is a single piece construction and is fixed to the air tube. The oil gun depth is set in reference to the

fixed air cone The EH and EHA have the flamelock attached to the nozzle adaptor on the oil gun, this allows the burner to

have a variable gun depth setting based on the firing rate needed. An EHA burner is different from a EH because the EHA

uses an oil pump that is rated up to 3 gal/hr, while the EH model will use a larger pump that is rated up to 7 gal/hr to attain

the higher firing rates.

BURNER COMPONENTS

The EHASR, EHA, and EH model burners are constructed with components of varying design. For example, the ignition

device may be an iron core transformer or a solid state igniter. Both devices perform the same function, and they use the

same troubleshooting methodology. There are also two distinct types of motors utilized by these burners. The “Permanent

Split Capacitor” or PSC motors (silver in color) utilize a thermal protection device that automatically resets when the motor

cools down. The “Split-Phase” motors (black jacket) utilize a manual reset thermal protector. Appliance or equipment

manufacturers may specify one type of component over another. Please contact Wayne Combustion Systems for

assistance with replacement component selection.

6

Page 7

TROUBLESHOOTING

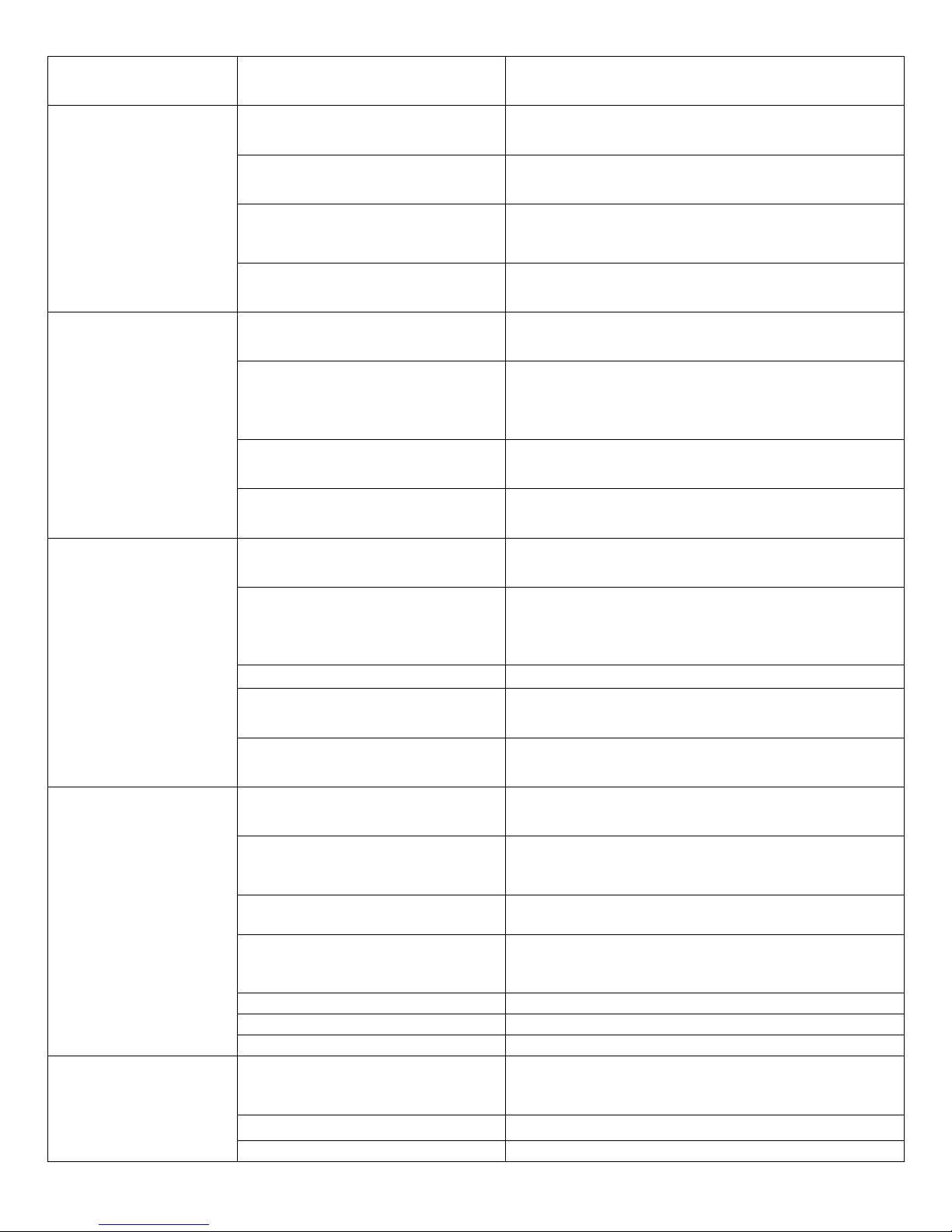

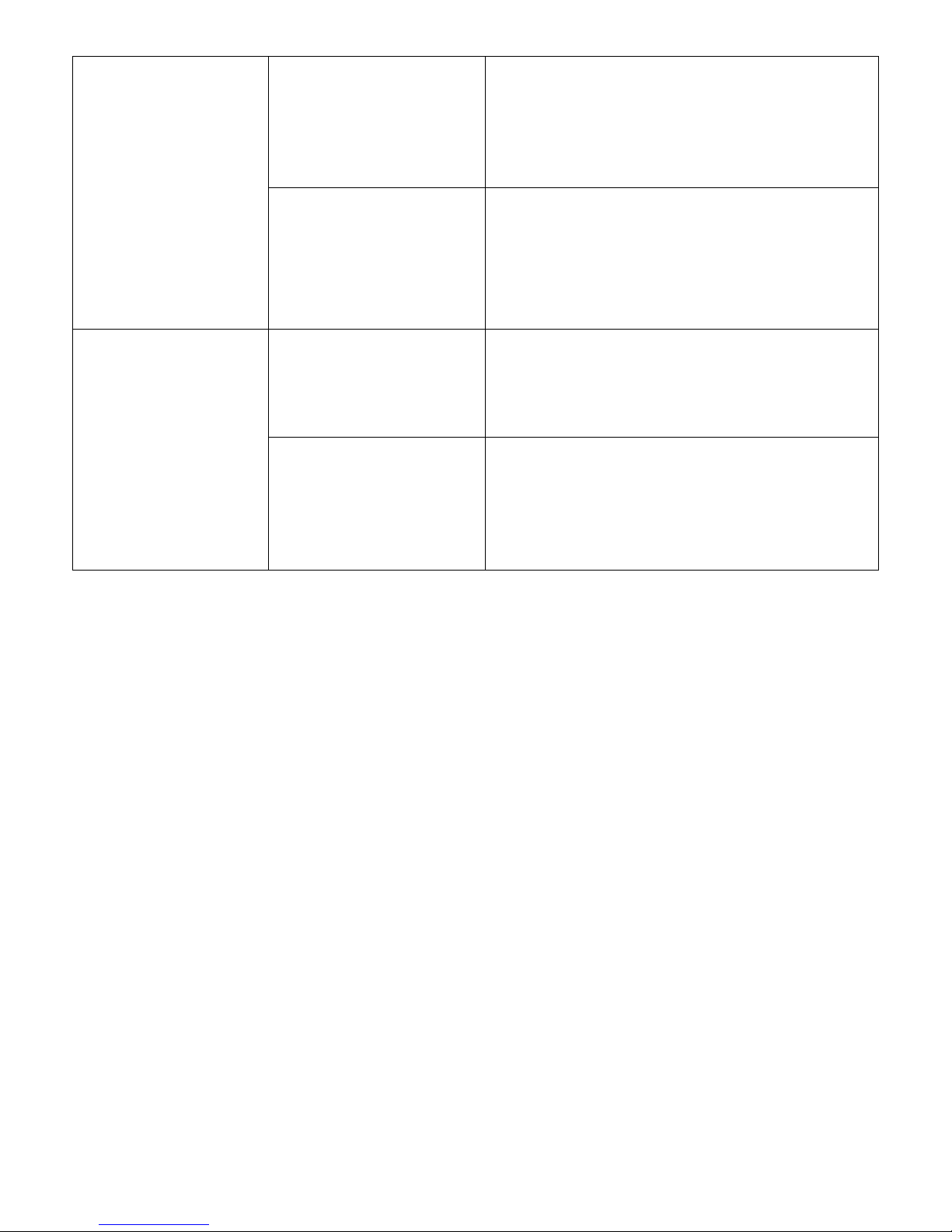

PROBLEM

POSSIBLE CAUSE

SOLUTION

BURNER WILL NOT

LIGHT

Little or no fuel

Fill tank with fuel.

Improper fuel or water in fuel

Drain fuel tank and fill with proper fuel.

Limit switch open

Close limit or thermostat switch, and check limit switch for

proper cycling operation.

Improper electrode spacing, gap to

small

Clean and position electrode tips according to Figure 14 or

Figure 15 on pages 26-27.

Plugged fuel filter

Replace as needed.

Misadjusted burner air bands

Re-adjust air bands for clean burn.

Little or no fuel pressure from fuel pump

Increase fuel pressure to manufacturer's specifications. See

Figure 25 on page 36 for pump features. Check that plastic

coupler (see Figure 1 on page 13, item 10) is not slipping on

pump shaft, replace as needed and/or replace pump.

Before troubleshooting, familiarize yourself with the startup procedures and

sequence of operation. Check the burner, ignitor or transformer, oil primary

control (if equipped), and cad cell (if equipped) for proper operation and condition.

The Honeywell R7284 oil primary control’s reset button is the “i” button, the R7184, R8184 and

Wayne control is the big red button. Pressing the reset button and restarting the burner more

than once with the burner not lighting could cause oil buildup in the firing chamber. This will

cause smoking and possible detonation that could damage the equipment if the burner does light

Preliminary Steps

Check the following common causes of issues:

Wiring connections, fuses, power supply to the burner blower motor, controls, and ignition device.

Limit control is closed.

Thermostat (controller) is calling for heat.

Contacts between ignition device and electrodes.

Electrode gap is properly set at nozzle.

Oil piping to burner and tank is properly sized and is in good condition (see Oil Pipe Sizing Information on

page 37 ).

Oil pump pressure.

Oil nozzle is correctly sized for application.

Check cad cell location and photo eye cleanliness.

GENERAL TROUBLESHOOTING GUIDE

7

Page 8

PROBLEM

POSSIBLE CAUSE

SOLUTION

BURNER WILL NOT

LIGHT

(continued)

Air bubble sucked and trapped in pump

Bleed pump (see page 31 for instructions) and check all fuel

lines for air leaks, replace lines as needed. See Figure 25 on

page 36 for pump features.

Burner motor thermal protector actuated

If tripped, check voltage, connections, and extensions for

cause. Check fuel pump shaft rotation for binding causing

motor to overheat.

Flex-coupling slipping on fuel pump

shaft or burner motor shaft

Replace as needed. See Figure 1 on page 13, Item 10.

Fuel not reaching combustion chamber

Check fuel system for proper flow going through the burner.

Clogged burner nozzle

Replace. See page 22 for instructions.

Low voltage at burner wire leads

Check for proper 120/230 Vac going to the burner

Fuel solenoid malfunction

Replace as needed. See Figure 1 on page 13 for

replacement part.

Faulty burner ignition device

Test ignition device for proper arc between contacts. Replace

as needed. See Figure 1 on page 13 for replacement part.

Disconnected or short in electrical wiring

All wire contacts should be clean and tight. No breaks in wire

insulation, replace as needed. See page 21 for wire size

recommendations.

Oil primary control sees light during

safety check and remains in standby

mode (Applicable only if burner comes

with oil primary control).

Press and hold the reset button for 2 seconds on a Honeywell

control, (push and hold for 3 seconds if it is an older style

Wayne control), observe burner sequence of operations. If

burner remains on standby see Burner does not light,

Honeywell controls remains on standby, on page 10.

Oil gun depth spaced too far ahead

causing electrodes too short to ground

through air cone.

Identify burner model and position oil gun depth according to

Figure 16 and Figure 17. See page 27 for instructions.

Heavy sooting on burner electrodes,

and air cone causing a weak arc

between the electrodes.

Clean as required. Check ceramic for any chips and cracks

that could affect arc between the electrodes, replace as

required. See Table 2 on page 15 for replacement parts.

BURNER WILL LIGHT,

BUT NOT STAY LIT

DURING CALL FOR HEAT

Oil primary control goes into nuisance

lockout (Applicable only if burner comes

with oil primary control).

Press and hold the reset button for 2 seconds on a Honeywell

control, (push and hold for 3 seconds if it is an older style

Wayne control), observe burner sequence of operations. If

burner locks out again see Burner Will Light, But Will Not

Stay Lit During “Call For Heat”, on page 11.

BURNER SMOKES

Improper fuel or water in fuel

Drain tank and replace contaminated fuel.

Improper air adjustment

Re-adjust air bands on burner assembly for clean burn.

Low fuel pressure

Increase fuel pressure to manufacturer's specifications. See

Figure 25 on page 36 for pump features.

Air leaks in fuel lines

Check fuel lines for leaks or air bubbles. Tighten or replace

as needed.

Plugged or dirty burner nozzle

Replace burner nozzle. See page 22 for instructions.

Improper nozzle size installed, nozzle

size too big

Contact appliance manufacturer for proper nozzle size, and

replace. See page 22 for instructions.

8

Page 9

PROBLEM

POSSIBLE CAUSE

SOLUTION

BURNER SMOKES

(continued)

Heavy accumulation of soot on heat

exchanger and burner assembly

Remove burner assembly from heat exchanger. Clean

thoroughly.

Faulty burner nozzle spray pattern

Replace. See page 22 for instructions.

Misaligned or damaged electrode

Realign electrodes according to Figure 14 or Figure 15 on

pages 26-27, and the oil gun depth according to Figure 16 or

Figure 17 on pages 27-28.

Obstruction in smoke stack

Check for blockage or other foreign objects.

BURNER RUNS

CONTINOUSLY WITHOUT

SATISFYING CALL FOR

HEAT

Improper fuel or water in fuel

Drain fuel tank and fill with proper fuel.

Reduced fuel pressure

Check fuel pump pressure. Check that fuel filter isn’t partially

clogged, replace as necessary. Increase fuel pressure to

manufacturer's specifications. See Figure 25 on page 36 for

pump features. Replace pump if needed.

Soot build-up on heat exchanger.

Clean heat exchanger with soot remover.

Improper burner nozzle installed, nozzle

size too small.

Contact appliance manufacturer for proper nozzle size, and

replace. See page 22 for instructions.

BURNER RUNS BUT

APPLIANCE IS

OVERHEATING

Fuel pump pressure too high

Readjust fuel pressure to appliance manufacturer's specs.

See Figure 25 on page 36 for pump features.

Oil primary control keeps energizing

burner past “call for heat”. (Applicable

only if burner comes with oil primary

control).

Identify control model. Replace Control, and wire accordingly

to Figure 3 or Figure 4 on page 16.

Faulty fuel pump shut-off valve

Replace fuel pump shut-off valve.

Defective high limit switch or

Thermostat

Replace.

Incorrect fuel nozzle size, nozzle size

too big

Contact appliance manufacturer for proper nozzle size, and

replace. See page 22 for instructions.

BURNER MOTOR WILL

NOT RUN

Overload protector activated

Wait 20 minutes for motor to cool down, will restart

automatically.

Faulty oil primary control. (Applicable

only if burner comes with oil primary

control).

Observe burner sequence of operations. Check voltage going

to the burner motor if it does not run during the 15 second

trial for ignition, replace control.

Fuel pump seized

Replace fuel pump. See Figure 1 on page 13 for replacement

parts

Burner fan loose or misaligned

Identify fan part number by measuring O.D of fan then

reference Table 1 on page 14 and position the fan spacing

according to Figure 26 on page 36 and tighten set screw.

Defective control switch

Replace switch.

Loose wire

Check and replace or tighten wiring.

Defective burner motor

Replace motor.

BURNER STAYS ON

WHEN NO CALL FOR

HEAT

Faulty oil primary control. (Applicable

only if burner comes with ignition

control).

Observe burner sequence of operations. Replace control if

necessary

Thermostat defective

Check for proper operation, replace if necessary.

Fuel solenoid defective

Replace fuel solenoid.

9

Page 10

Procedure

Status

Corrective Actions

1. Make sure limit

switches are closed

---------------------

---------------------

2. Check for line voltage

power at primary

Control. 120 vac.

---------------------

Check breaker and investigate appliance wiring

3. Check R7284G or

R8184G indicator light,

(LED Screen if R7284P

control) with burner off,

no call for heat. No

Flame.

R7284G & R8184G indicator

light is pulsing (1/4 sec. ON, 4

sec. OFF), R7284P display

would say “STANDBY”

Sees external light during safety check or

connections are shorted,

4. Shield cad cell from

external light

R7284G & R8184G indicator

light starts pulsing (1/4 sec. ON,

4 sec. OFF), R7284P display

will read “STANDBY”

Energize thermostat to verify that burner goes

through proper sequence of operations.

If burner does not light go to step 5

5. Jumper oil primary T-T

terminals

Burner starts

Trouble in thermostat or limit circuit. Check wiring

connections

Burner does not start

Disconnect line voltage and open thermostat or

limit switch.

If burner does not start, replace primary control.

NOTE: This section refers to Honeywell R7284 and R8184 series controls. The R7284G and

R8184G control use a LED light to display the troubleshooting status, and the R7284P

control comes with a display screen that will output the current operating state of the

burner or any troubleshooting errors that might arise in normal burner operation.

Troubleshooting tables on pages 10-11 are specific to burners that

come equipped with an oil primary control, and these sections only

apply if the general troubleshooting guide tells the licensed

contractor to consult these sections while servicing the burner.

BURNER DOES NOT LIGHT, HONEYWELL CONTROL REMAINS ON STANDBY

10

Page 11

BURNER WILL LIGHT, BUT WILL NOT STAY LIT DURING “CALL FOR HEAT”

Procedure

Status

Corrective Actions

1. Check limit switches

---------------------

---------------------

2. Check for line voltage at

the oil primary control

(120 volts)

---------------------

---------------------

3. Check R7284G or

R8184G indicator light,

(LED Screen if R7284P

control) with burner on,

call for heat.

R7284 or R8184 control is in

lockout. The R7284G &

R8184G control LED flashes for

½ seconds ON, ½ seconds

OFF. The R7284P control reads

“Lockout Mode”

Control is sensing bad flame signal, cad cell or

controller is defective, sees external light or

connections are shorted. Go to step 5.

The R7284P display reads

“Valve on Delay”

Go to step 4.

4. Applications with “valve

on delay”, verify that oil

valve is closed during

the “valve on delay”

period by opening view

port and verifying that

no flame is present

during 15 second “valve

on delay”

R7284P display still reads

“Valve on Delay”

If flame is present, replace valve.

5. Jumper oil primary T-T

terminals

Burner starts, and stays

running.

Trouble is in thermostat or limit circuit.

Burner starts, but doesn’t stay

running.

Disconnect line voltage and open thermostat or

limit switch.

Check all wiring connections

If burner does not stay running, go to step 6

6. Check that nozzle size

is per appliance

manufacturer

recommendation

Burner nozzle incorrect.

Change nozzle and fuel pressure to factory settings

and retest, if burner doesn’t stay lit go to step 7

Burner nozzle correct

Go to step 7

7. Check burner air band

setting is set up per

manufacturer

recommendation

Burner air band setting too low.

Could cause black puff of smoke on ignition if the

fuel-air mixture is too rich.

Use a combustion test kit to measure the CO2 %

and smoke spot in the exhaust.

Adjust air band opening until CO2 % measures

between 10-12 %, and smoke spot is a 1 or less.

If problem persists go to step 8

Burner air band setting too high

Could cause delayed ignition on start-up if the fuel-

air mixture is too lean.

Use a combustion test kit to measure the CO2 %

and smoke spot in the exhaust.

Adjust air band opening until CO2 % measures

between 10-12 %, and smoke spot is a 1 or less.

If problem persists go to step 8

Burner air band set at

manufacturers

recommendations

Go to step 8

11

Page 12

8. Check cad cell sighting

for view of flame.

- Disconnect line

voltage power and

open line switch.

- Unplug cad cell and

clean face with soft

cloth. Check

sighting for view of

flame. Place cad

cell back in socket.

- Reconnect line

voltage and close

line switch.

- Start burner,

Burner locks out.

Go to step 9

Burner keeps running, until “call

for heat” is satisfied.

System is okay.

9. Check Control & Cad

cell.

- Remove cad cell

wires from

connectors on

primary and leave

lead wires open.

- Apply power to

device

- Place jumper

across cad cell

terminals after

burner motor turns

on.

Burner doesn’t run.

Replace primary control.

Burner runs.

Control is okay, replace cad cell.

12

Page 13

Figure 1- Burner Components – Models EHASR, EHA, and EH

13

Page 14

Table 1- EHASR, EHA, and EH Replacement Parts

No.

Description

EHA

EH

EHASR

No.

Description

EHA

EH

EHASR

1

Motor - 1/5 HP,

120V PSC

24003-001

24003-001

12B

2)

Pump – A2VA3006/120V SOL.

101128-009

Motor – 1/5 HP,

120V Cap Start

21569

21569

12B 2)

120V Solenoid

Valve- A2VA3006 pump

100885-001

Motor - 1/4HP,

120V PSC

24005-001

24005-001

24005-001

12B 2)

Pump- A2VA3006/230V SOL.

101128-010

Motor – 1/4 HP,

120V Cap Start

21126

21126

12B 2)

230V Solenoid

Valve- A2VA3006 pump

100885-002

Motor - 1/5 HP,

230V PSC

24006-001

24006-001

13

Cad Cell - Up to

12" Tube

14289-KIT

14289-KIT

14289-KIT

Motor - 1/4HP,

230V PSC

24004-001

24004-001

24004-001

Cad Cell - 12" +

Tubes

13666-KIT

13666-KIT

13666-KIT

2

Motor Cord Cover

13121

13121

13121

14A 3)

Brass Connector

14222

14222

14222

3

Fan - 5 1/4" Outer

Diameter

20288

20288

20288

14B

3), 4)

Brass Connector

90° Elbow

13494

13494

13494

Fan - 5 3/4" Outer

Diameter

20887

20887

20887

15 3)

120V Solenoid

Valve

100610-001

100610-001

100610-001

Fan - 6 1/4" Outer

Diameter

21854

21854

21854

230V Solenoid

Valve

100610-002

100610-002

100610-002

4

Burner Housing Painted

20372

20372

20372

16

Gun Assembly

(See NOTE Below)

5

120V Ignitor-Iron

Core

23101-E

23101-E

23101-E

17

Air Tube

(See NOTE Below)

230V Ignitor-Iron

Core

23103-E

23103-E

23103-E

18A

1)

Cast Iron - 2 3/4"

No Vane

13002

120V Ignitor-Solid

State

101295-SERE

101295-SERE

101295-SERE

18A

1)

Cast Iron - 3" No

Vane

12989

12989

230V Ignitor-Solid

State

101391-SERE

101391-SERE

101391-SERE

18A

1)

Cast Iron - 3 1/4"

No Vane

12990

12990

6

120V Control - 15

second, Honeywell

R7284G

101343-SER

101343-SER

101343-SER

18A

1)

Cast Iron - 3

9/16" No Vane

13003

230V Control - 15

second, Honeywell

R8184G

100490-001

18B

1)

Stainless - SR

#1A

14157

120V Control - 15

second, Honeywell

R7284P

101278-SER

101278-SER

101278-SER

18B

1)

Stainless - SR

#2A

14158

7

Slot Cover Plate

13392

13392

13392

18B

1)

Stainless - SR

#3A

14159

8

Air Band - Inner 8

Slot

2669-002

2669-002

2669-002

18B

1)

Stainless - SR

#4A

14160

9

Air Band - Outer 8

Slot

2668-002

2668-002

2668-002

19

Flange

21426

21426

21426

Air Band - Outer 5

Slot

20310-002

20310-002

20

Gasket

12484

12484

12484

10 4)

Coupling - A/B

Pump

13279

13279

13279

21

Adjustable

Flange

2689-SER

2689-SER

2689-SER

Coupling w/ set

screws – A/B Pump

100838-001

22

Junction Box

21319

21319

21319

11

4)

Oil Line Assembly

14452

14452

14452

Not

Shown

Pedestal

2794-011

2794-011

2794-011

12A 3)

Pump - A2VA-7116

13495

13495

Not

Shown

Tune-Up Kit

31156

31156

31156

12A 3)

Pump - A2YA-7916

14375-SER

NOTE: STATE SPECIFICATION NUMBER, BURNER MODEL, PART DESCRIPTION AND PART NUMBER WHEN ORDERING PARTS

1) Cast Iron Cones - Measure machined ID. Stainless Steel Air Cones - Number/Letter combination stamped into face of outer ring.

2) Item 12B are oil pumps that come with oil solenoid valves already attached, but replacement parts are available for replacing the fuel solenoid.

3) Item 12A are oil pumps that do not come with solenoid valves, solenoid valves are optional for these model. If oil pump comes with a solenoid

valve (item 15), item number 14A must be used. If oil pump does not come with a solenoid valve, brass connector elbow 14B must be used.

4) Part included in 31156 Tune-Up Kit

= Item not available for purchase on that specific burner model

14

Page 15

No.

Part Description

EHA

EH

EHASR

1

Nozzle Adaptor

12988-002

12988-002

21913-SER

2

Stamped Stabilizer Support Kit

21923-001

21923-001

21923-001

Cast Stabilizer Support Kit

21408-SER

21408-SER

21408-SER

3

Stem/Insulator Kit

13286

13286

13286

4

Cad Cell Mount

13078

13078

13078 5 Buss Bar Support

13276-002

13276-002

13276-002 6 Cad Cell Wire Tie

100850-001

100850-001

100850-001 7 Oil Pipe Fitting

14295-002

14295-002

14295-002

Figure 2– Oil Gun Assembly Detail View

(Parts not necessarily as shown)

Table 2- Oil Gun Replacement Parts

15

Page 16

WIRING DIAGRAMS

REMOVE JUMPER

TO USE

THERMOSTAT

TERMINALS

REMOVE JUMPER

TO USE

THERMOSTAT

TERMINALS

Figure 3- Wiring Diagram for 120V Honeywell R7284G & 230V Honeywell R8184G Controls

Figure 4- Wiring Diagram for 120V Honeywell R7284P Control

16

Page 17

Do not keep pressing the reset button and restarting the burner more than once with the burner not

lighting this could cause oil buildup in the firing chamber. This will cause smoking and possible detonation that could

damage the equipment if the burner does light.

Figure 5- Wiring Diagram for 120/230V Burners without a control

SEQUENCE OF OPERATION: BURNERS WITH R7284G AND R8184G CONTROLS

BURNER OPERATION

On every call for heat the oil primary control performs an internal safety check which takes five seconds to complete.

During these five seconds, the oil primary control verifies that the cad cell is outputting a “no flame” resistance value. After

the check, the oil primary control will simultaneously energize the burner blower motor, solenoid valve (if equipped), and

ignition device. The control will then enter the 15 second trial for ignition period; once flame is established the oil primary

control will continue to monitor the flame by using the cad cell’s resistance value. The oil primary control allows burner

operation to continue until the thermostat control’s “call for heat” is satisfied. Once the thermostat is satisfied the burner

will be de-energized. If flame is not detected during the trial for ignition, the oil primary control will go into a “lock-out”

condition. If this occurs, proceed to the section titled SAFETY LOCK-OUT TIME.

SAFETY LOCK-OUT TIME

Ignition failure occurs during the first “trial for ignition” period

The cad cell monitors the combustion chamber for flame during the burner’s trial for ignition period. If no flame is detected

the oil primary control will go into a lockout condition. When the oil primary control goes into lockout it will de-energize the

burner, and the control’s LED light will flash ½ sec on, and ½ sec off. Before attempting to start the burner again the

control must be reset. Press and hold the “i” button for three seconds to reset the control. If normal ignition does not occur

see GENERAL TROUBLESHOOTING GUIDE on page 7.

17

Page 18

Intermittent flame failure occurs during a “call for heat”

Do not keep pressing the reset button and restarting the burner more than once with the burner not

lighting this could cause oil buildup in the firing chamber. This will cause smoking and possible detonation that could

damage the equipment if the burner does light.

If the oil primary control stops sensing a flame after the flame has been proven and the trial for ignition timer has expired,

the oil primary control enters a limited recycle mode where it will de-energize the burner for one minute, while the LED

light will flash for 2 seconds on, and 2 seconds off. After one minute the oil primary control resumes the call for heat, and

enters another “trial for ignition” period. If a flame is proven during the trial for ignition, and lost after the trial for ignition

timer expires the control will go into another recycle mode countdown. If no flame is proven during the trial for ignition

period the control will go into a lockout condition. If the control tries three recycle modes where flame is proven, and then

subsequently lost the control will go into a hard lockout condition de-energizing the burner. If normal ignition does not

occur see GENERAL TROUBLESHOOTING GUIDE on page 7.

SEQUENCE OF OPERATION: BURNER WITH R7284P CONTROL

BURNER OPERATION

On every call for heat the oil primary control performs an internal safety check which takes five seconds to complete.

During these five seconds, the oil primary control verifies that the cad cell is outputting a “no flame” resistance value. After

the check, the oil primary control will simultaneously energize the burner blower motor, solenoid valve (if equipped), and

ignition device. The oil primary control will then enter the 15 second trial for ignition period; once flame is established the

oil primary control will continue to monitor the flame by using the cad cell, and it will de-energize the ignitor after 10

seconds. The oil primary control allows burner operation to continue until the thermostat control’s “call for heat” is

satisfied. Once the thermostat is satisfied the burner will be de-energized. If flame is not detected during the trial for

ignition, the oil primary control will go into a “lock-out” condition. If this occurs, proceed to the section titled SAFETY

LOCK-OUT TIME.

SAFETY LOCK-OUT TIME

Ignition failure occurs during the first “trial for ignition” period

The cad cell monitors the combustion chamber for flame during the burner’s trial for ignition period. If no flame is detected

the oil primary control will go into a lockout condition. When the control goes into lockout it will de-energize the burner,

and the control’s screen will display “lockout mode”. Before attempting to start the burner again the control must be reset.

Press and hold the “i” button for three seconds to reset the control. If normal ignition does not occur see GENERAL

TROUBLESHOOTING GUIDE on page 7.

Intermittent flame failure occurs during a “call for heat”

If the oil primary control stops sensing a flame after the flame has been proven and the trial for ignition timer has expired,

the oil primary control enters a limited recycle mode where it will de-energize the burner for one minute while displaying

“recycle” on the display screen. After one minute the oil primary control resumes the call for heat, and enters another “trial

for ignition” period. If a flame is proven during the trial for ignition, and lost after the trial for ignition timer expires the oil

primary control will go into another recycle mode countdown. If no flame is proven during the trial for ignition period the oil

primary control will go into a lockout condition. If the oil primary control tries three recycle modes where flame is proven,

and then subsequently lost the control will go into a hard lockout condition de-energizing the burner. If normal ignition

does not occur see GENERAL TROUBLESHOOTING GUIDE on page 7.

18

Page 19

SEQUENCE OF OPERATION: BURNER WITHOUT CONTROL

Make sure combustion chamber is free of oil or oil vapor before starting system.

BURNER OPERATION

If the burner is controlled by a high voltage limit switch on the incoming power line to the burner, the operation of the

burner is a simple ON/OFF mechanism, where all the burner components will be energized simultaneously to fire the

burner. If any problems arise during ignition or continued operation of the burner see the GENERAL

TROUBLESHOOTING GUIDE on page 7.

OPERATIONAL CHECK OF BURNER

START SYSTEM

Open hand valve in oil supply line.

Make sure system is electrically energized, check circuit breaker, fuses, and close system switch if

provided.

Press and hold the oil primary control i button for two seconds and release (big red button for three

seconds for old Wayne control).

Set thermostat (controller) to “call for heat”.

Burner should light and operate until call for heat is satisfied.

Simulate flame failure

Follow starting procedures to turn on burner.

Close hand valve on supply line, stopping fuel delivery to the burner.

The oil primary control should lockout after control’s trial for ignition timer expires. The burner

blower motor and ignition device should stop, and the solenoid valve should close.

Simulate ignition failure

Close hand valve on supply line, stopping fuel delivery to the burner.

Follow starting procedures to turn on burner.

Oil primary control should lockout after control’s trial for ignition timer expires. The burner blower

motor and igniter should stop, and the solenoid valve should close.

Simulate power failure

With burner running, turn off power supply to the system.

Burner should stop.

Restore power, burner should start.

If system does not operate as described, proceed to GENERAL TROUBLESHOOTING GUIDE on

page 7

CHECK SAFETY FEATURES

19

Page 20

GENERAL INSTALLATION INFORMATION

Never exceed 3 PSI pressure to the suction side of the fuel pump. A pressure over 3 PSI

may cause damage to the shaft seal and allow it to leak oil.

Do not install by-pass plug if running single pipe operation, this will over-pressurize the pump

causing an oil leak at the pump shaft seal.

When installing the burner, be sure to provide adequate space for easy service and maintenance. Prior to installation of

the oil burner, the heating system should be carefully inspected for defects and cleanliness. The flue passages and heat

absorbing surfaces must be clean to ensure maximum heat transfer. Soot acts as an insulator, which retards the transfer

of heat. The combustion chamber, flue gas passages, and all doors and openings must be tightly sealed to eliminate air

infiltration. Excess air cools the flame and thus lowers efficiency. Inspect the flue and chimney for leaks and obstructions.

Be sure the chimney is of adequate size and height. Install a draft regulator the same size as the flue pipe (see paragraph

under DRAFT REGULATORS).

COMBUSTION CHAMBER

The purpose of a combustion chamber is to maintain a high flame temperature by reflecting the heat back into the flame.

A high flame temperature assures greater combustion efficiency and lower stack losses. An insulating refractory or a Fiber

Fax type chamber can be used with this burner. It is important to select and install, the correct nozzle size for a given

combustion chamber size (see Table 4 on page 35). On all oil burners the atomized oil must not touch the sides or bottom

of the combustion chamber or improper combustion will occur leading to smoke and soot build-up. To reduce smoke while

the burner is running, the burner must have an adequate supply of combustion air by having a large enough opening on

the air band assembly. If too much air is utilized it can lead to high gas exhaust temperatures, and lower combustion

efficiency. Install the burner so the face of the air cone on the burner is set a ¼ inch behind the inside front wall of the

chamber (see Figure 20 on page 30).

FUEL PUMPS

Model EHASR, EHA and EH oil burners are provided with single stage 3450 RPM fuel pumps with the by-pass plug

removed for a single pipe installation. This is satisfactory where the fuel supply is on the same level, or above burner,

permitting gravity flow of oil.

When it is necessary to lift the oil to the burner, a return line should be run between the fuel pump and oil tank. (If lift

exceeds 10 feet, a two stage fuel pump must be used with a return line). When a two line installation is made, the by-pass

plug must be installed. This is supplied with the burner attached to fuel pump, along with a pump data sheet in a plastic

bag.

FUEL LINES

When oil lines are continuous runs, heavy wall copper tubing is recommended for the fuel lines. Be sure that all

connections are absolutely air-tight. Check all connections and joints. Flared fittings are recommended. Do not use

compression fittings. Avoid running tubing against the appliance and across ceiling or floor joist; if possible install under

floor. Avoid using fittings in inaccessible locations. If possible, avoid running oil lines overhead. Specific information on

piping, connections, lift capabilities and tank installations is provided in the instruction sheet of the fuel pump

manufacturer, however if the instruction gets damaged or unreadable see oil pipe sizing information under reference

information on page 37. Install an UL certified oil filter of adequate size for all installations.

20

Page 21

FUEL TANKS

Label all wires prior to disconnection when servicing burners. Wiring errors can cause

improper and dangerous operation. Verify proper operation after servicing

If any of the original burner wiring must be replaced, it must be replaced with

#18 AWG 105°C wire or equivalent

Local codes and regulations must be followed regarding tank and burner installation. Check existing tanks for water and

sludge accumulation; clean if necessary. Also clean or replace existing piping.

ELECTRICAL WIRING OF BURNER

The oil burner is shipped completely wired. It is only necessary to supply the line voltage circuit, thermostat and limit

circuit. All wiring must comply with the National Electric Code or the code legally authorized in the locality where the

installation is being made. The burner, when installed must be electrically grounded in accordance with local codes or, in

absence of local codes, with the latest edition of the National Electrical Code, ANSI/NFPA No. 70. Refer to wiring

diagrams Figure 3,Figure 4 and Figure 5 on pages 16 & 17 for reference on wiring, and thermostat connection. If an

external electrical source is utilized, the oil burner, when installed, must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the latest edition of the National Electrical Code, ANSI/NFPA No. 70.

For line voltage wiring to the burner use solid copper conductor wire not lighter than #14 AWG. If a fused disconnect is

used, it should be fused for a minimum of 20 amps.

If the oil burner comes equipped with an oil primary control, the burner will be shipped with a jumper wire on the

thermostat (T-T) terminals. The jumper needs to be removed for remote thermostat control and the thermostat needs to

be connected per wiring diagrams. A T-T terminal is an open/close switch for the oil primary control and no voltage should

be connected to it. For boilers it may be necessary to leave the T-T terminal jumped as the aquastat may be providing the

voltage to the burner and controlling when voltage is sent to the burner. The burner is controlled by the appliance. Once

wiring is complete between burner and appliance, verify that the appliance is controlling the burner’s on/off operation.

When connecting the burner to the line voltage electrical supply, utilize the knockout provided on the burner’s junction

box.

CHIMNEY INSTALLATION

Follow the recommendations of the appliance manufacturer. A chimney shall be capable of producing a draft as

recommended by the appliance manufacturer. It must be properly designed, of adequate size, be above the surrounding

objects, tile-lined, with no obstructions, and be in a good state of repair. The smoke pipe should sit flush with the inside of

the tile and be cemented in place. All cleanout doors should be sealed. A draft inducer may be used to overcome

inadequate draft conditions. If a draft inducer is used, provisions must be made to ensure the burner does not operate if

the draft inducer fails.

DRAFT REGULATORS

A draft regulator shall be provided unless otherwise specified by the appliance manufacturer. The draft regulator shall be

installed in accordance with local codes and regulations or in the absence of local codes, with ANSI NFPA31. Refer to

appliance manufacturer’s instructions for recommended over fire and stack draft.

21

Page 22

AIR SUPPLY FOR COMBUSTION

Arrow

Decal

Slot

cover

A burner shall not be installed in an area where normal air circulation or infiltration is limited and it restricts the amount of

air necessary for proper combustion and venting. When the heating appliance is installed in a confined space, two

permanent air openings shall be provided; one near the top of the enclosure and one near the bottom. Each opening shall

have a free area of no less than one square inch per 1000 Btu/hr (140 square inch per gal/hr) of the total input rating of all

the appliances in the space. When the house is of unusually tight construction, has a kitchen ventilating system, exhaust

fans, clothes dryer or vented fireplaces, it is recommended that combustion air be supplied through two permanent

openings. The openings should connect directly, or by means of ducts, with outdoors or to such spaces (attic or crawl)

that are exposed to the outdoors. For additional information, refer to ANSI standard NFPA31.

NOZZLE AND AIR CONE SELECTION

The EHASR, EHA, and EH oil burners typically fire well with a solid or semi-solid nozzle with a spray angle of 80, 70, or

60 degrees. In most upgrading or conversion installations, the use of an 80 degree solid nozzle is a good starting point.

Always use the proper nozzle size, spray cone type and spray angle the appliance manufacturer recommends. Should

this information not be available, your own good judgment will prevail. Under no circumstances attempt to fire the EHA or

EHASR oil burners under their 0.75 gal/hr minimum input rating or over their 3.00 gal/hr maximum input rating. Under no

circumstances attempt to fire the EH oil burner under its 3.00 gal/hr minimum input rating or over its 6.00 gal/hr maximum

input ratings.

NOZZLE INSTALLATION

In order to install or change the nozzle, the oil gun assembly needs to be removed from the burner. The EHASR, EHA,

and EH burners has an arrow decal that lines up with the leading edge of the oil gun slot cover plate. This will help with reinstalling the oil gun in the proper position once the nozzle has been installed. See Figure 6 for part identification.

plate

Figure 6– EH/ EHASR Side View of Oil Gun Slot Plate Cover

1. Locate the slot plate cover, loosen the brass oil assembly nut with a 7/16 inch wrench at the connection with the brass

fitting on the solenoid valve, but do not remove all the way. (Figure 7 on page 23).

Note-For pumps with combination solenoid valves disconnect the oil line from the brass elbow fitting installed in the

nozzle port of the pump.

22

Page 23

Figure 7 EH/EHASR Oil Line Assembly Fitting

2. Loosen and disconnect the brass nut of the copper oil line assembly from the oil gun assembly fitting and rotate the oil

line out of the way (Figure 8).

Figure 8 EH/EHASR Oil Line Removal

23

Page 24

3. Next loosen the ignition device mounting plate clip screw by using a flat head screwdriver, move the hold down clip off

Hold

down

clip

Motor

Flange

Hold

down

clip

of the mounting plate, this will allow the igniter device assembly to swing open to the left. For now leave the plate in

the closed position (Figure 9).

Figure 9 EH/EHASR Ignitor mounting plate screw removal

4. Using a 9/16 inch wrench loosen and remove the oil gun assembly locknut (Figure 10).

Figure 10 EH/EHASR Oil Gun Lock Nut Removal

24

Page 25

5. Now grasp the rear of the oil gun assembly where the oil line fitting adapter exits through the housing and pull the oil

gun to the right out of the housing slot and the slot plate cover (Figure 11).

Figure 11 EH/EHASR Oil Gun Removal

6. While rotating the oil line fitting adapter up at a 45 degree angle, gently lift, but do not force, the entire gun assembly

out of the housing opening (Figure 12).

Figure 12 EH/EHASR Oil Gun Removal (Continued)

25

Page 26

7. Thread the nozzle into the nozzle adaptor finger tight, then tighten the nozzle securely with a 5/8” wrench, while using

DO NOT touch the new nozzle’s filter or touch the face of the nozzle. Oil from

your fingers on either surface can adversely affect nozzle performance

Stamp

a 3/4" backing wrench to hold the nozzle adapter. Do not over tighten. There is a brass stamp that reads “TOP” on the

nozzle adapter that should be orientated up (Figure 13).

Figure 13 EH/EHASR Oil Gun Nozzle Installation (Flamelock and electrodes removed for

clarity).

8. Identify which burner model you have, then measure and verify that the electrode spacing is per Figure 14 or Figure

15 on page 27, if not correct to factory settings.

Figure 14–EH Electrode Positions, Factory settings

26

Page 27

FLAMELOCK

Figure 15–EHASR Electrode Positions, Factory settings

9. At this time position the gun assembly back into the housing in reverse sequence that gun assembly was removed in,

while taking care not to disrupt the electrode spacing.

Note: Re-measure electrodes gap after installing gun assembly in burner to verify that the position has not shifted

SETTING GUN DEPTH

For the oil burner to function properly the distance between the nozzle and the air cone needs to be maintained as shown

in Figure 16 & Figure 17 on page 28.

(For EHA and EH Burners Only)

Suggested startup setting: EHA Flamelock flush with cast iron cone face. EH Flamelock 1/8” ahead of cast iron

cone face for 3.00 to 4.50 gal/hr or ¼” ahead for 5.00 to 6.00 gal/hr

Figure 16- EHA and EH Gun Depth Settings

27

Page 28

Close the ignition transformer and assure there is a positive spring contact with the brass

buss bars. Take care not to pinch the ignition transformer lead wires between the housing and cover plate. Reinstall

the igniter plate hold down clip and tighten the 5/16-18 hex slotted screw securely.

Arrow

Decal

5/16 inch

Hex slotted screw

3/8-24

Hex lock nut

Figure 17– EHASR Gun Depth Settings

1. Identify which E burner model you have and set the gun depth accordingly.

2. To position the gun assembly forward or backwards, loosen the gun assembly 3/8-24 hex lock nut with a 9/16

inch wrench and the 5/16 inch hex slotted slot cover screw as shown in Figure 18.

Figure 18– Oil Gun Depth Adjustment

3. Once in the required position per Figure 16 and Figure 17, retighten the hex lock nut and slot cover screw,

move and align arrow decal with slot plate cover.

28

Page 29

BURNER INSTALLATION

The EHASR, EHA, and EH oil burners were designed for furnaces, boilers, water heaters and a wide variety of

commercial applications ranging from pressure washers & asphalt trucks The burner is supplied as a completely

assembled unit. This burner should be installed into your appliance with the appliance manufacturer’s recommendations;

if no recommendations are available it is up to the expertise of the installer.

NOTE: The burner must be installed in such a manner that all controls will be readily accessible for inspection, cleaning,

adjustment, and repairs.

INSTALLATION OF MOUNTING FLANGE

Position the mounting flange on the furnace wall, adjusting orientation as necessary until the bolt pattern of the appliance

allows the flange to sit flush. (See Figure 19 for flange dimensions.)

Note the orientation of the flange and remove it so that the flange gasket may be placed between the appliance wall and

flange. Tighten the flange to the furnace wall.

Insert the burner tube into the flange and position it per Figure 20 on page 30. Tighten the flange onto the burner tube.

Figure 19– Adjustable Mounting Flange Dimensions

29

Page 30

Air Band

Adjustment

Screw

Figure 20– Combustion Chamber Installation Recommendations

Note: The air tube length (DIM. A) is the distance from the front of the air tube retainer flange to the air tube cutoff where

the air cone mounts in the tube. Note adjustable flange width.

STARTING PROCEDURE

STARTING BURNER

Be sure that the electrical breaker to the appliance is in the “OFF” position, set the thermostat to a temperature

substantially above room temperature, and ensure the oil tank is filled, all valves are open, and controls set for operation.

Adjust air supply on burner by loosening screw on interlocking air bands, and open the air band until black smoke is

eliminated on start-up (see Figure 21).

Figure 21– Air Band Adjustment Screw Location

30

Page 31

Open the ignition device mounting plate and turn on the electrical breaker.

Bleeder Valve

Next, bleed the pump by following steps 1-3 before starting the burner. See Figure 22 for the location of the bleeder valve

on the pump.

Figure 22– Fuel Pump Bleeder Valve Location

Note: If the pump is set up in two pipe operation with the by-pass plug installed, bleeding the pump is not necessary.

1. Slide a 1/8” Vinyl hose on the bleeder valve as shown in Figure 23 and route the hose into a small container

Figure 23– Bleeder hose location

31

Page 32

2. With the burner running, use a 3/8 inch wrench to open the bleeder valve about one-half turn (Figure 24). Allow oil

Do not run fuel unit dry for more than five minutes or damage to the pump may result.

All new installations should be re-inspected after one or two weeks of normal operation.

to drain into the container until a steady, clear bubble free oil stream is noticed. Close the bleeder plug.

Figure 24– Bleeder valve adjustment

Note: If safety lockout occurs during burner operation, reset after one or two minutes.

3. Close the ignition device mounting plate, and tighten the hold down clip screw

FINAL ADJUSTMENTS

At this point a final adjustment should be made by the use of a COMBUSTION TEST KIT. After operating for ten minutes

to warm up the appliance, a smoke tester should be used to take a smoke reading. Smoke test should read no greater

than #1 (Shell Bacharach scale), and less than a #1 smoke is desired. At times, a new heating unit requires more time

than this to burn clean due to the oil film on the new heater unit surfaces. Recheck draft and take a CO2 reading over the

fire and in the stack. If a large differential between CO2 readings is noted, air leakage is the most common cause. CO2

readings must be taken ahead of draft control, if used. The CO2 measured in the stack should be at least 10-12% for oil

rates 1.00 gal/hr or below, and at least above 10% for oil rates over 1.00 gal/hr Units should be started and stopped

several times to assure good operation. Open ignition device mounting plate, unplug solenoid valve lead, and check the

oil primary control (if equipped) for normal operation see SEQUENCE OF OPERATION: BURNERS WITH R7284G

AND R8184G CONTROLS on pages 17-18. Check operation of limit controls and thermostat. Check for oil leaks.

SETTING COMBUSTION EFFICIENCY

1. Fire burner, adjust interlocking air bands until smoke from the exhaust changes from black to clear and see

through.

2. Record CO2 and smoke levels. If CO2 is low, close the air band by a 1/8 inch using a ruler or scale, and repeat

CO2 and smoke test. Continue this adjustment until desired CO2 and smoke levels are obtained. Record stack

temperature.

3. Check lighting with cold and hot chamber.

4. Lock all adjustment screws.

32

Page 33

FINAL CHECKS

Before beginning any maintenance work on the burner, be sure that all oil valves

from the tank are closed and electrical power to the burner is disconnected.

Be sure all screws are locked and the controls on heating unit are adjusted in accordance with the heater and control

manufacturer’s instruction sheets.

Note: O2 % should be over 3 %, and for CO emissions the lower the better but, typical applications for pressure washers

should be under 250 ppm, and under 125 ppm for boilers.

MAINTENANCE

The following routine maintenance operations should be performed on the burner once a year:

- Filter/strainer: The oil filter cartridge should be replaced once a year so the fuel oil will not become contaminated

and plug up fuel pump and nozzle of oil burner.

- Nozzle: The nozzle should be changed at least once a year before the start of the heating season. Replace with

proper nozzle.

- Electrode Settings: This is very important for reliable ignition of the oil; check these once a year in accordance

with the instructions provided in this manual. Replace electrodes if worn excessively or if electrode insulator is oil

soaked or cracked.

- Fan and Blower Housing: This must be kept clean, free of dirt and lint; open transformer to check fan blades

from above. Be sure the electric power is off on burner when the transformer is opened up for this inspection

Components: If replacement of a burner component becomes necessary, always use parts recommended by the

manufacturer. Specify part numbers and description when ordering. (In all communications, state burner model, serial

numbers, and appliance manufacturers and appliance model designation).

33

Page 34

REFERENCE INFORMATION

Net Stack Temperature (°F)

300°

350°

400°

450°

500°

550°

600°

650°

700°

750°

800°

850°

900°

CO2 % Measured from Flue Exhaust

15

87.5

86.5

85.3

84.3

83.3

82.0

81.0

79.8

78.8

77.5

76.3

75.5

74.3

14.5

87.5

86.3

85.0

84.0

83.0

81.8

80.8

79.3

78.5

77.3

76.0

75.0

73.8

14

87.5

86.0

84.8

82.8

82.8

81.5

80.3

79.0

78.0

76.8

75.5

74.5

73.0

13.5

87.0

85.8

84.5

82.5

83.5

81.3

80.0

78.8

77.5

76.3

75.3

74.0

72.3

13

86.8

85.5

84.3

83.3

82.0

80.8

79.5

78.3

77.0

75.8

74.5

73.5

71.8

12.5

86.5

85.3

84.0

83.3

81.5

80.3

79.0

77.8

76.5

75.3

73.8

72.8

71.0

12

86.3

85.0

83.8

82.5

81.5

79.8

78.5

77.3

75.8

74.5

73.0

71.5

70.3

11.5

86.0

84.8

83.5

82.0

80.8

79.3

78.0

76.3

75.3

73.8

72.3

70.8

69.5

11

85.8

84.5

83.0

81.5

80.3

78.8

77.3

75.8

74.5

73.0

7.5

70.0

68.5

10.5

85.5

84.0

82.5

81.0

79.5

78.0

76.5

75.0

73.8

72.0

70.5

69.0

67.5

10

85.0

83.5

82.0

80.5

78.8

77.3

75.8

74.3

72.8

71.0

69.5

68.0

66.3

9.5

84.5

83.0

81.5

79.8

78.0

76.5

75.0

73.3

71.8

70.0

68.3

66.8

65.0 9 84.0

82.3

80.8

79.0

77.3

75.8

74.0

72.3

70.8

68.8

67.0

65.3

63.5

8.5

83.5

81.8

80.0

78.3

76.5

74.8

73.0

71.3

69.3

67.5

65.5

63.8

62.0 8 83.0

81.0

79.3

77.5

75.5

73.8

71.8

70.0

68.0

66.0

64.0

62.0

60.0

7.5

82.3

80.3

78.5

76.5

74.5

72.5

70.5

68.5

66.5

64.3

62.3

60.0

58.0 7 81.5

79.5

77.3

75.3

73.3

71.0

69.0

67.0

64.8

62.5

60.3

57.8

55.5

6.5

80.8

78.5

76.3

74.0

71.8

69.5

67.3

65.0

62.8

60.3

57.8

55.5

53.0 6 79.8

77.2

75.0

72.5

70.0

67.8

65.3

62.8

60.3

57.5

55.5

52.5

50.0

5.5

78.5

76.0

73.5

71.0

68.0

65.5

63.0

60.3

57.5

54.5

51.8

49.0

46.5 5 77.3

74.5

71.8

69.0

65.8

63.0

60.0

57.0

54.0

51.0

48.0

45.5

42.5

4.5

75.5

72.5

69.0

66.3

63.0

60.0

56.8

53.5

50.3

47.0

43.5

40.3

36.8 4 73.3

69.8

66.3

62.8

59.3

55.8

52.0

48.5

45.0

41.3

37.5

33.8

30.0

Table 3- Efficiency Chart for No. 2 Fuel Oil

34

Page 35

Firing

Rate

(gal/hr)

Square Chamber

Diameter

Round

Chamber

Rectangular

Chamber

Rect.

Chamber

Height

Nozzle

Distance

to Floor

0.75 * 10"

8" x 9"

9"

4"

1.00 * 11"

10" x 10"

10"

4 1/2"

1.25 * 12"

11" x 11"

11"

5"

1.35 * 12"

11" x 11"

11"

5"

1.50 * 13"

11" x 12"

12"

5"

1.65 * 14"

12" x 13"

13"

5"

1.75 * 14"

12" x 13"

13"

5"

2.00 * 15"

13" x 14"

13 1/2"

5 1/2"

2.50 * 17"

14" x 16"

14"

5 1/2"

3.00

15 1/2" x 15 1/2"

17 1/2"

13" x 18 1/2"

14"

7"

3.50

17 3/4" x 17 3/4"

20"

15" x 23"

15"

7 1/2"

4.00

19" x 19"

23 1/2"

16" x 22 1/2"

16"

8"

4.50

20" x 20"

*

17" x 23 1/2"

17"

8 1/2"

5.00

23 1/4" x 23 1/4"

*

18" x 25"

18"

9"

6.00

24 x 1/2" x 24 1/2"

*

23" x 28 1/2"

20"

10"

EH Only

EHA & EHASR Only

Table 4– Max Suggested Firing rate for a Given Combustion Chamber Size

*- Chamber size not recommended with given firing rate

35

Page 36

REFERENCE FIGURES

Figure 25- Pump Feature Identification

Figure 26– Blower Wheel Spacing

36

Page 37

OIL PIPE SIZING INFORMATION

Inlet

Tubing

Size

Lift H

(ft.)

Model A Single Stage

Model B Two-Stage

3450 RPM

3450 RPM

3 gal/hr

7 gal/hr

3 gal/hr

7 gal/hr

3/8" O.D.

Copper

Tubing

0

84

71

93

80

2

73

62

85

73

4

63

53

77

66 6 52

44

69

59 8 42

35

60

52

10

31

27

52

45

12

21

18

44

38

14 - -

36

31

16 - -

27

24

18 - - - -

1/2" O.D.

Copper

Tubing

0

100

100

100

100 2 100

100

100

100

4

100

100

100

100

6

100

100

100

100 8 100

100

100

100

10

100

100

100

100

12

83

70

100

100

14

41

35

100

100

16 - -

100

100

18 - -

76

65

L= Max total line length (ft.), H+R

H= Vertical distance in feet from bottom of

tank to centerline of pump, or lift (ft.)

R= Horizontal distance in feet from

tank to centerline of burner pump (ft.)

Q=firing rate capacity of fuel pump (gal/hr)

Figure 27– Fuel line sizing diagram for fuel tank below burner, burner setup in two-pipe

operation

Table 5: Max Allowable Fuel Line Lengths for two pipe operation

NOTE: Max. total line length L=H + R, values were calculated based off a fuel viscosity of 57 SSU. Elbows, valves & filters

will further reduce total line length. It is recommended to avoid 3/8” lines where feasible.

37

Page 38

One Pipe Operation

NOTE: For one-pipe operation (no return line) use the following line length equations

3/8” line: L=(6-.75H)/.0086Q

1/2” line: L=(6-.75H)/.00238Q

NOTE: If tank is above the pump, change the “-“ to a “+”

Sample Calculation for one pipe operation

If the fuel tank is installed below the ground and it is found that the distance from the bottom of the tank to the centerline

of fuel pump is H=7 ft, ½ inch copper tubing is being installed, and the oil pump max flow rate is rated at 3 gal/hr

according to the label, (Q=3 gal/hr), the maximum total line length (L) would be

L=(6-.75*(7))/.00238*(3)

L≈105 ft.

Now to calculate the maximum horizontal distance from the burner pump to the tank (R)

R= L-H,

R=105-7; R=98 ft.

Note: If (6-.75H)=0 or a negative number, based off H≥8 it means that the pump will not be able to pull fuel from the

tank for that given lift (H), either run a return line or use a two-stage pump to overcome this issue.

38

Page 39

4. A burner so repaired will then carry the LIMITED

WARRANTY equal to the unexpired portion of the

original burner LIMITED WARRANTY.

5. If inspection by WAYNE does NOT disclose any

defect covered by this LIMITED WARRANTY, the

burner or burner component(s) will be either

repaired or replaced at the expense of the

customer and WAYNE”S regular charges will

apply.

6. If the original manufacturer of a burner component

offers a warranty greater than either of our

LIMITED WARRANTIES described above, then

this portion will be added to our LIMITED

WARRANTY.

This LIMITED WARRANTY does NOT cover products

which have been damaged as the result of accident,

abuse, misuse, neglect, improper installations,

improper maintenance or failure to operate in

accordance with WAYNE’s written instructions.

These LIMITED WARRANTIES do not extend to

anyone except the first purchaser at retail and only

when the burner is in the original installation site.

IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE

SHALL BE LIMITED TO THE DURATION OF THE

LIMITED EXPRESS WARRANTIES CONTAINED

HEREIN. WAYNE EXPRESSLY DISCLAIMS AND

EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL

OR INCIDENTAL DAMAGES OF ANY NATURE FOR

BREACH OF ANY EXPRESS OR IMPLIED

WARRANTY.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you. Also, some states do not allow the

exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not

apply to you. WAYNE neither assumes or authorizes

any person to assume for WAYNE any other liability or

obligation in connection with the sale of these products.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to

state.

WAYNE COMBUSTION SYSTEMS (“WAYNE”)

warrants to those who purchase its Oil Burner Models

for resale or for incorporation into a product of resale,

that its burner is free from defects in material and

workmanship under normal use and service for thirty-six

(36) months from the date of manufacture. ALL GAS

BURNERS manufactured by “WAYNE” will be similarly

warranted for eighteen(18) months from date of

manufacture except where original manufacture offers a

greater warranty. (Reference #6 below) THESE LIMITED

WARRANTIES DO NOT APPLY UNLESS THE BURNER

COVERED BY IT IS PROPERLY INSTALLED BY A

QUALIFIED, COMPETENT TECHNICIAN, WHO IS

LICENSED WHERE STATE AND/OR LOCAL CODES

PREVAIL, AND WHO IS EXPERIENCED IN MAKING

SUCH INSTALLATIONS, in accordance with NFPA #31

of the national fire protection association and in

accordance with all local, state and national codes.

Any IN-WARRANTY burner component which is

defective in material or workmanship will be either

repaired or replaced as follows:

1. Fuel pumps, motors, transformers, gas valves, and

controls should be returned to an authorized service

station or distributor of WAYNE for determination of

applicability of this LIMITED WARRANTY as to

either repair or replacement, where said service

station or distributor is reasonably available in the