Page 1

MODET

EG-I

WAYI\IE

HOME

EQUIPMEITT

oft

a

Scoflfttef

cornparry

BIIRNER

801 Glasgow Avenue

Fort

Wayne, Indiana 46803

Manual

21255-ml

PUBLICATION

DATE 06-20-88

SPECITICATIONS

FIRING

CAPACITIES

-

Model

EG-l

.50 to 2.75

GALLONS

PER HOUR

70,000 to

350,000 BTU/HR INPUT

FUELS*

.-,

Use No.

I or No. 2 Heating

Oil

(ASTM

D-396) only.

t

*Never

attempt.to use

gasoline

as a fuel for

your

burner, as it is

more

combustible and

could result

in a

senous exploslon.

ELECTRICAL

PowerSupply

.....

1l5V/60H2/lPH

Motor

3450

RPM

N.E.M.A.

Flange, Manual Reset

Overload Protection

Ignition

...,. 10,000V/23MASecondary,

ContinuousDuty-Shielded,

Interrupted

Duty-Shielded

TLansformetr,

or Solid-State

Ignition

System.

50 HERTZ BURNERS AVAILABLE

ON

SPECIAL ORDER

FUEL

UNIT

Sundstrand or Webster

DIMENSIONS

(Standard)

Height

ll%'

width

t3r/r,

Depth

6%'

MOUNTING

Rigid flange,

Adjustable flanqe or Base

mount.

TO

THE HOMEOWNER

Since

1928, Wayne

has supplied

the Homeowners

of the

world

with oil burners. You are obtaining

quality

and

design

unsurpassed with

the engineering

and

product

development.

It

will

provide you

with many

years

of

efficient,

trouble free

operation, if

properly

installed

and serviced. Please read this manual

carefully.

Wayne

warrants its

burners

specifically

to those who have

purchased

it

for resale, includingryor"rr

dealer. If

in

any

case

you

have a

problem

with

your

burner,

or its installation,

you

should

contact

your

dealer for

assistance.

Printed

in

U.S.A.

•

WAYNE HOME EQUIPMENT

[aScoCl~com~

801

Glasgow

Avenue

Fort

Wayne,

Indiana

46803

MODEL

EG-I

OIL

BURNER

Manual

21755-001

PUBLICATION

DATE

06-20-88

Revision

04

•

•

SPECIFICATIONS

FIRING CAPACITIES -

Model

EG-I

.50 to 2.75 GALLONS PER HOUR

70,000

to

350,000 BTUIHR INPUT

FUELS*

Use

No.1

or

NO.2

Heating

Oil (ASTM D-396) only.

*Never

attempttouse

gasolineasa fuel for your

burner,asitismore

combustible

and

could

result

in a

serious

explosion.

ELECTRICAl.

Power

Supply

Il5V 160HZI IPH

Motor 3450 RPM N.E.M.A. Flange, Manual Reset

Overload

Protection

Ignition , ,

1O,000V

123MA

Secondary,

Continuous Duty-Shielded,

Interrupted

Duty-Shielded Transformer,orSolid-State Ignition

System.

50 HERTZ BURNERS AVAILABLE ON SPECIAL ORDER

FUEL UNIT

SundstrandorWebster

DIMENSIONS (Standard)

Height

, , . , , , ,.., . , . . ...11Ye"

Width

,."

,.....

13Ye"

Depth

, .

..

6Ye"

MOUNTING

Rigid flange,

Adjustable

flangeorBase mount.

TO THE HOMEOWNER

Since

1928,

Wayne

has

supplied

the

Homeowners

ofthe world with oil

burners.

You

are

obtaining

quality

and

design

unsurpassed

with

the

engineering

and

product

development.Itwill

provide

you

with

many

years

of

efficient,

trouble

free

operation,ifproperly

installed

and

serviced.

Please

read

this

manual

carefully.

Wayne

warrants

its

burners

specifically to

those

who

have

purchaseditfor

resale,

including

your

dealer.

If

in

any

case

you

haveaproblem

with

your

burner,

or

its installation, you should

contact

your

dealer

for

assistance.

Printed

in U.S.A.

Page 2

APPROVI1LS

The

burner is

U,L.

listed

for use

with Group

I or Group

II

primary

safety controls. State

and local

approvals

are shown on burner

rating

label. AII

burners should be

installed in

accordance

with

the National

Fire

Pro-

tection Association,

and

in complete

accordance

with all local codes and authorities

having

jurisdiction.

Regulations of these

authorities

take

precedence

over

the

general

instructions

provided

in this manual.

GENERAL INTORMATION

HEATING PLANT - Before

installing this burner in a conversion installation,

try to

provide

adequate

space to service the burner

properly

when installing for

easy maintenance.

The

heating

system

should

be

narofirllrr irenoniorl

for defects and cleanliness,

if

proper performance

is to

be obtained,

An oil

bUrner is

only a means of supplying heat for the

firebox and from

there

the heating system

must absorb

and

circulate

the

heat.

The

flue

passages

and heat

absorbingt

surfaces must

be clean

to assure maximum

heat transfer to

the furnace

or boiler. Soot

and fly ash act as

insulators,

retarding

the

transfer of heat. All

doors, openings,

and

cracks should be cemented

air-tight to eliminate air

infiltration

into the heating

plant,

causing heat

Iosses,

Inspect

smoke

pipe

and

chimney

for elimination

of leaks

and obstructions. Be

sure of

adequate

chimney

size and height, Install a mechanical draft adjuster,

if need be,

same size as smoke

pipe (see

column

under

"Draft

Regulators").

Warning:

If this burner is equipped

with

a relight type control

it shall not be used

on appliances having

brick,

ceramic, or

castable

refractory

liner

for

combustion chamber. Hazard may

occur on flame failure

because

the flame detector may

see the hot

refractory liner

and not respond

to flame outage,

permitting

prolonged

dolirrorrr nf ,"ril hofr'

:d

fnr an Attornnt tn rolinht tho l-rrrrnor

--,Jre

lgnlllon 1S IeIUrnL*

\v lvrryrr(

COMBUSTION

CHAMBER

The

purpose

of a combustion chamber is to maintarn a high

flame temperature, by reflecting

the heat

back

rnto

the flame. A hiqh

temperature

assures

greater

combustion efficrency

and

lower

stack losses.

An insulat-

inq refractory

or a Fiber Fax type chamber can be used with

this burner. It is rmportant to

select

and

install, if

no.6qqiy\r tho anrrggt

srze chamber on a conversion

job

(see

chart). On the

flamelock

conversion

burners

J

|

lrav vvrr

the atomized

oil

burns

just

cff

the

flalnelock. On ail

oil

burners

the atomized

oii must not touch the sides

or

bottom of chamber, or smoke

lvrll

result

To

eliminate the smoke,

excess

arr

will be required, resulting

in

higrh

stack temperature and

lower combustion effrciency. Install

burner so the face of air

cone of burner is set

%

"

behind the inside froirt

wall

of

the charnber

(see

dragranr). Caution

on

rnstalling Flamelock

burners in

stainless steel chambers

shoujd

be taken, because of the higher temperature levels

produced

by high

per-

formance flame retention burners,

The

terrrpelature

may

exceed the

temperature

ratings

of the

stainless

steel

chamber, ancl can result rn chamber

burn outs. When

you

are replacing a standard burner with

a flame

retention burner, take the follor,vrngr

precautiotrs'

(l)

Use

pliable

combustion chamber to

line

the

inside

of

chamber,

(2)

Ad;ust bur;rer

(Se

e

'Final

AdjLrstrrcnts Column)

FIJHXJ

UNIITS AND OII.,

LINN$

Conversion Burners are

provrcied

wrth a srrigle statie

3450

RPM fuel

rrnrts

,vith

the by-pass

plug

removed

f^-..i-^t^

-.;*^

!".^+-

rur Drirvrs

1-,1-c,rrrtdllaii{ttts.

fl ;s is satishcior',''r'here the f,-rt:l

suunly is on the same level,

or

above

burner,

'^^-*:++;--

--^":r"'lovr

oJ"orl

. N:'.c

r exceecj

3 FST

pre-.sure

tn thc srrcr ion

src.e

of fuei unit.

A

pressure

over

B

fJsrlrrrr.rlir9

9r

dvrry 1

PSI

may cause damage tc the

shait seal ancl allo'ur ri to leai.:

oil. When rt

js

necessary to lrft

the oil to the

burner,

a return Ine

shcLrld

bc

r.in

bet'ruecn

fusl unri :ncl

orl suprply.

(lf

Ifl

e>lceeds

j0

feet. a two stage fuel

unit

nrust

be

used wirh : retLrin

-irre.)

lVli:n a t'i.f

iine;s used,

rire b;'

pass

p.ug

nrust be rnstalled. This

is sup-

nliod rlnrrrr

rr:rth

tho

bUrnel-att;;hed

tO

igel U:trt, alCn,,l

".lilh

an rnilrr,ralr3n

plrrnp

data Sheet in a

plaStiC

bag.

When

oil hnes are installed, cc,nlinrrous

iuns of hea','r,

viaii

copper tubri:g

is recommended

Be sure that

ail

connections

are absoiutely alr-trght Check

all connections and

Jornts,

Flared

fittings are recommended,

Do

not

use compression frttings See

pump

data sheet

ior sizing, lift

and length for tubing

recommendations.

Use

an

oil filter of adequate srze

for all rnstallations.

Instali instde the

building bet,,veen the tank shutoff vaive

and

the

burner.

For ease of servrcing, locate the

shutoff

valve and filter near

the burner.

TANKS

AND PtrPING

Local

codes and

regulations must be adhered to

regarding tank and burner

installation.

WIRING

AII

wiring must compiy

with

the

National Electric Code

and

local ordinances.

Refer to dragram

supplied

with

burner or controls,

making sure the burner

and controls are

wired

correctly

and that the Iine

switch is

properly

fused to burner.

A.IR

SUPPLY

FOR

COMBUSTION

Do not install

in

rooms with lnsufficient air to suppoft combustion. Occasionaily it is necessary to

install win-

dows

or cut

holes

in

a door to these

rooms, to obtarn sufficient air and to

prevent

less than atmospheric

air

pressure

in the room. If there

is a lack of combustion air rn the room, the burner flame will be

yellow

and for-

mation

of soot will occur in the heatir-rg

unit. In buildings of conventional frame,

brick

or

stone

construction

without

utility rooms, basement

ivindows,

or stairs

doors, infiltration

is normally

adequate to

provide

air

for

combustion

and

for

operation

of the barometric draft

control. For

installation

in an

enclosed

utility

room

EG-1 - 21755-00l

Rev. 04/06-20-88

PAGE

2

o

o

b~.Y~E\

APPROVALS

The

burner

is U.L.

listed

for

use

with

GroupIor

GroupIIprimary

safety

controls. State

and

local

approvals

are

shownonburner

rating

label.

All

burners

shouldbeinstalledinaccordance

with

the

National

Fire

Pro-

tection

Association,

andincomplete

accordance

with

all

local

codes

and

authorities

having

jurisdiction.

Regulationsofthese

authorities

take

precedence

over

the

general

instructions

provided

in

this

manual.

•

GENERAL INFORMATION

HEATING

PLANT

-

Before

installing

this

burnerina

conversion

installation,

trytoprovide

adequate

spacetoservice

the

burner

properly

when

installing

for

easy

maintenance.

The

heating

system

should

be

carefully

inspected

for

defects

and

cleanliness,ifproper

performance

is to

be

obtained.

An

oil

burner

is

onlyameansofsupplying

heat

for

the

firebox

and

from

there

the

heating

system

must

absorb

and

circulate

the heat.

The

flue

passages

and

heat

absorbing

surfaces

mustbeclean

to assure

maximum

heat

transfer

to

the

furnaceorboiler.

Soot

and

fly ash act as insulators,

retarding

the

transferofheat.

All

doors,

openings,

and

cracks

should

be

cemented

air-tighttoeliminate

air

infiltration

into

the

heating

plant,

causing

heat

losses.

Inspect

smoke

pipe

and

chimney

for

eliminationofleaks

and

obstructions.

Be

sureofadequate

chimney

size

and

height.

Installamechanical

draft

adjuster,

ifneed

be,

same

size as

smoke

pipe

(see

column

under

"Draft

Regulators").

Warning:

If

this

burner

is

equipped

witharelight

type

controlitshall

not

be

used

on

appliances

having

brick,

ceramic,

or

castable

refractory

liner

for

combustion

chamber.

Hazard

may

occur

on

flame

failure

because

the

flame

detector

may

see the hot

refractory

liner

and

not

respondtoflame

outage,

permitting

prolonged

delivery

of

011

before

ignitionISreturned

foranattempttorelight

the

burner.

COMBUSTION CHAMBER

The

purposeofa

combustion

chamber

is to

maintainahigh

flame

temperature,

by

reflecting

the

heat

back

into

the

flame.Ahigh

temperature

assures

greater

combustion

efficiency

and

lower

stack

losses.

An

insulat-

ing

refractory

oraFiber

Fax

type

chamber

canbeused

with

this

burner.

It is

importanttoselect

and

install,

if

necessary,

the

correct

size

chamber

on a

conversion

Job

(see chart).

On

the

flamelock

conversion

burners

the

atomized

oil

burns

just

eff

the

flarnelock

On

all

OJI

burners

the

atomized

oil must

not

touch

the

sides

or

bottomofchamber,

or

smoke

will

result

To

eliminate

the

smoke,

excess

air

will

be

required,

resulting

in

high

stack

temperature

and

lovver

combustion

efficiency.

InstaJl

burnersothe

faceofair

coneofburner

is set

Yi"

behind

the

inside

front

wallofthe

chamber

(see

diagram).

Cautiononinstalling

Flamelock

burners

in

•

stainless

steel

chambers

shouldbetaken,

becauseofthe

higher

temperature

levels

produced

by

high

per-

formance

flame

retention

burners.

The

temperature

may

exceed

the

temperature

ratingsofthe

stainless

steel

chamber,

and

can

result in

chamber

burn

outs.

When

you

are

replacingastandard

burner

withaflame

retention

burner,

take

the

following

precautions

(1) Use

pliable

combustion

chambertoline

the

inside

of

chamber,

(2)

Adjust

burner

(SEe

"Final

Adjustments"

Column)

FUEL UNITS

AND

OIL LINES

Conversion

Burners

are

provided

V'JIth a sir.qle

st2~;e

3450

RPM

fuel units

with

the

by-pass

plug

removed

for

single

pipe

installatil):1s

Ths

is s2tlcofaclory ',vhere the

flk:l

SUl-.)ply

is on the same

level,orabove

burner,

permitting

gravity

flovv 0

1

0)1

Ne':n

exceed

3

F81

preS"lHetothe suctIon

si~e

of

fuel

unit. A

pressure

over

8

PSI

may

cause

damagetothe shaft sea]

and

allow

i:

10

leak

OIl

\NhenItis

necessarytolift

the

oiltothe

burner,areturn

lIne

should

bE-

run bet\rveen

fLl!:?1

Ulllt

and

oil

supply

(If

11ft

exceeds10feet, a

two

stage

fuel

unit

mustbeused

vvith a

return

lll!e)

When

a t,:"o

lineisw,ed,

the

by-pass

plug

mustbeinst3.11ed.

This

is sup-

plied

along

wlth

the

burner

atii?tchedtofuel

U~1It,

along

'Nith an mkJrrl1al10n

plimp

data

sheet

in a

plastic

bag.

When

oil

lines

are

installed,

cominllous

runsofhea\iY wi'iil

copfjer

tubingISrecommended

Be

sure

that

all

connections

are

absolutely

air-t1gh!.

Check

uJl

connections

and

Joints.

Flared

fittings

are

recommended.

Do

not

use

compression

fittings See

pump

data

sheet for sizing, lIft

and

length

for

tubing

recommendations.

Use

an

oil

filterofadequate

size

for

all installations.

Installlflside

the

building

behveen

the

tank

shutoff

valve

and

the

burner.

For

easeofservicing,

locate

the shutoff

valve

and

filter

near

the

burner.

TANKS

AND

PIPING

Local

codes

and

regulations

mustbeadheredtoregarding

tank

and

burner

installation.

WIRING

All

wiring

must

comply

with

the

National

Electric

Code

and

local

ordinances.

Refertodiagram

supplied

with

burner

or

controls,

making

sure

the

burner

and

controls

are

wired

correctly

and

that the

line

switch

is

properly

fusedtoburner.

AIR

SUPPLY FOR COMBUSTION

Do

not

installinrooms

with

insufficient

airtosupport

combustion.

Occasionally

it is

necessarytoinstall

win-

•

dowsorcut

holesina

door

to these rooms, to

obtain

sufficient

air

andtoprevent

less

than

atmospheric

air

pressureinthe

room.Ifthere

is a

lackofcombustion

air

in the

room,

the

burner

flame

will

be

yellow

and

for-

mationofsoot

will

occur

in the

heating

unit.Inbuildingsofconventional

frame,

brick

or

stone

construction

without

utility

rooms,

basement

windows,orstairs doors,

infiltrationisnormally

adequatetoprovide

air

for

combustion

and

for

operationofthe

barometric

draft

control.

For

installationinan

enclosed

utility

room

EG·'

·21755·001

Rev.

04/06·20·88

PAGE

2

Page 3

without

an outside wall,

a fresh air opening to the

outside with

a free cross sectional

area

of 20 square

inches

nav arnh nrllnn nar

lepl'firing rate is recommended.

For

each

1,000

feet above sea level, increase

the fresh

air

opening by at least four

(4) per

cent. The room

should be

isolated from any

area served

by exhaust fans.

Do

not install

an exhaust fan in this room.

CHIMNEY

Follow

the recommendations

of

the heating

unit manufacturer.

It

must be

properly

designed,

of adequate

size, and

should

be

above

the surrounding objects,

tilelined, with

no obstructions,

and

be in

good

state of

repair. The

smoke

pipe

should

set

flush

with the inside

of tile

and be

cemented

in

place.

All cleanout

doors

should

be sealed.

DRAFT

REGULATORS

The use

of a

draft regulator

is recommended

and should

preferably

be mounted in the smoke

pipe.

Use

a

draft

gauge

to adjust

to

proper

opening. When the burner air

supply and draft is

properly

adjusted,

the com-

bustion

chamber

draft

will

be approximately

.0I

"

to

.02 "WC

and the stack draft

will

be

.02'

to

.04'WC.

The

Iarger

the

installation,

the

greater

the

draft

will be

required

at the stack to obtain

the .0i

"

to

.02'WC

at

the

combustion

chamber.

NOZZLES

Use the

proper

size, type and spray

pattern

nozzle that heater manufacturers

recommend.

In

some

cases

of

upgrading

or

conversion

installations,

the use of 80o Hollow

or Solid

nozzle are

the best to start with.

STARTING

PROCEDURE

STARTING

BURNER

Be

sure main

switch is in

"off"

position,

and be sure

the

thermostat is

substantially above room

temperature,

the

oil tank

is filled, all valves

are open, and

controls set for operation. Adjust air

supply on

burner

by loosening

lockscrew

on outer band, and

open

partially.

Open the

inspection

door and turn

on

switch.

Prime

pump

according

to the

pump

manufacturer's

recommendations and check

pressure.

If safety

lockout

occurs,

reset after

I or 2 minutes. Do not run fuel

unit dry for more than 5

minutes.

When fire

is

established

make a

temporary air adjustment for

clean combustion flame, reduce air supply until flame

tips

appear

slightly

smoky,

then

readjust

so flame tips are

clean iooking.

Leave

inspection door open until

chamber is

dry. When normal

temperatures are reached,

close inspection door and adjust draft regulator.

(See

column under

"Draft

Regulators").

rrNAL

ADIUSTMENTS

At

this

point

a final

adjustment should

be

used

by the use of

a COMBUSTION

TEST KIT. After

operating

l0

minutes to warm up unit,

a smoke tester should

be

used

to take a smoke reading. We are

wanting

no

greater

than

#l

(Shell

Bacarach

scale), less than a

#l

smoke is desired. Some times a new heating unit requires

more

time

than this to burn clean

due to the oil film

on the new heater unit surfaces. Recheck draft and

take a CO,

reading

over

the

fire and in the stack. If a large

differential

between CO, readiners is noted, air leakage

is the

most common

cause

(see

column under

"Heating

Plant").

CO, readings must ali be

taken

ahead of

draft con-

trol. The

CO, measured

in the stack should be at

least

90/of.or oil

rates

1.00

GPH or below, and

be

at

least l0%

for all rates

over

1.00 GPH. Unit should be started and

stopped several times to assure

good

operation. Open

inspection

door,

turn off oil

valve,

and check

out safety

timing

of combustion control. Check operation

of limit

controls

and thermostat.

Check for oil leaks.

Note: All

installations should be

reinspected after

I or 2 weeks

of normal

operation.

rINAL

CHECKS

Be sure

air shutter

and draft control adjustments

are locked, and the controls on heating unit are adjusted

in accordance

with

the heater and Control

Manufacturer's Instruction Sheets.

MAINTENANCE

OILING

MOTOR - By

proper

oiling twice a

year,

the

motor life will be increased; only a few drops

of non-

detergent

type

oil

at

both motor holes are needed.

FILTER

-

The

oil filter cartridge should

be replaced once a

year

so

the fuel oil will

not

become

contami-

nated and

plug

up fuel

pump

and nozzle

of oil burner.

NOZZLE

-

The

nozzle should be changed

at least once each

year

before

the start-up

of the heating

season. Replace

with

proper

nozzle.

COMPONENTS

-

If for any

reason

any of the

burner

parts

have to be

replaced, always use

parts

recom-

mended

by the

manufacturer.

Specify

part

numbers

and description

when

ordering.

(lN

ALL

COM-

MUNICATIONS

STATE

BURNER MODEL AND

SERIAL NUMBERS).

ELECTRODE

SETTINGS

-

This is very important

for reliable

ignition of the

oil;

check these

once a

year

in

accordance

with

the instructions

provided

in

this manual.

FAN

& BLO\IIER HOUSING

-

This must be kept

clean,

free of dirt and

lint; open

transformer to check

fan

blades

from above, Be

sure the

electric

power

is

off on burner

when

the transformer

is

opened up for

this

inspection,

EG-l - 21755-001

Rev.

04/06-20-88

PAGE

3

•

•

•

----------------

..

-----

without an outside wall, a fresh

air

openingtothe outside

with

a free cross sectional

area

of20square

inches

per

each

gallon

per

hour

firing

rate is

recommended.

For

each

1,000

feet

above

sea

level,

increase

the fresh

air

openingbyat least four

(4)

per

cent.

The

room

shouldbeisolated from

any

area

servedbyexhaust fans.

Do

not install an exhaust fan in this

room

.

CHIMNEY

Follow

the

recommendationsofthe

heating

unit

manufacturer.

It must

be

properly

designed,ofadequate

size,

and

should

be

above

the

surrounding

objects,

tile-lined,

with

no obstructions,

andbein

good

state

of

repair.

The

smoke

pipe

should

set flush

with

the

insideoftile

andbecementedinplace.

All

cleanout

doors

should

be

sealed.

DRAFT REGULATORS

The

useofa

draft

regulatorisrecommended

and

should

preferably

be

mounted

in the

smoke

pipe.

Use

a

draft

gauge

to adjust to

proper

opening.

When

the

burner

air

supply

and

draftisproperly

adjusted,

the

com-

bustion

chamber

draft

willbeapproximately

.01" to

.02

"we

and

the stack

draft

will

be

.02" to

.04

"we.

The

larger

the installation, the

greater

the

draft

willberequired

at the

stacktoobtain

the .01" to

.02

"we at

the

combustion

chamber.

NOZZLES

Use the

proper

size,

type

and

spray

pattern

nozzle that

heater

manufacturers

recommend.Insome

cases

of

upgrading

or

conversion

installations, the useof800HolloworSolid nozzle

are

the

best

to start

with.

STARTING PROCEDURE

STARTING BURNER

Be

sure

main

switch

is in

"off"

position,

and

be

sure

the thermostat is

substantially

above

room

temperature,

the

oil

tankisfilled,

all

valves

are

open,

and

controls

set for operation.

Adjust

air

supply

on

burner

by

loosening

lockscrew

on

outer

band,

and

open

partially.

Open

the

inspection

door

and

turn

on

switch.

Prime

pump

according

to the

pump

manufacturer's

recommendations

and

check

pressure.Ifsafety

lockout

occurs,

reset

after1or

2 minutes.

Do

not

run

fuel unit

dry

for

more

than 5 minutes.

When

fire

is

established

makeatemporary

air

adjustment

for

clean

combustion

flame,

reduce

air

supply

until

flame

tips

appear

slightly

smoky,

then

readjust

so

flame

tips

are

clean

looking.

Leave

inspection

door

open

until

chamberisdry.

When

normal

temperatures

are

reached,

close

inspection

door

and

adjust

draft

regulator

.

(See

column

under

"Draft

Regulators").

FINAL ADJUSTMENTS

At

this

point

a final adjustment

shouldbeusedbythe useofa

COMBUSTION

TEST KIT.

After

operating

10

minutestowarmupunit, a

smoke

tester

shouldbeusedtotakeasmoke

reading.

We

are

wantingnogreater

than#1(Shell

Bacarach

scale), less than a#1smokeisdesired.

Some times a

new

heating

unit

requires

more

time

than this to

burn

clean

due

to the

oil

film

on the

new

heater

unit surfaces.

Recheck

draft

and

takeaCO

2

reading

over

the

fire

and

in the stack.Ifa

large

differential

between

CO2readings

is noted,

air

leakage

is the

most

common

cause (see

column

under

"Heating

Plant").

CO2readings

must

allbetaken

aheadofdraft

con-

trol

The

CO2measured

in the

stack

shouldbeat least 9% for oil rates

1.00

GPHorbelow,

andbeat

least

10%

for

all

rates

over

1.00

GPH. Unit

shouldbestarted

and

stopped

several

times to assure

good

operation.

Open

inspection

door,

turn

off

oil

valve,

and

check

out safety

timingofcombustion

control

Check

operationoflimit

controls

and

thermostat.

Check

for

oil

leaks. Note:

All

installations

shouldbereinspected

after1or2weeks

of

normal

operation.

FINAL CHECKS

Be

sure

air

shutter

and

draft

control

adjustments

are

locked,

and the

controlsonheating

unit

are

adjusted

in

accordance

with

the

heater

and

Control

Manufacturer's

Instruction

Sheets.

MAINTENANCE

OILING

MOTOR

- By

proper

oiling

twiceayear,

the

motor

life

willbeincreased;

onlyafew

dropsofnon-

detergent

type

oilatboth

motor

holes

are

needed.

FILTER -

The

oil

filter

cartridge

shouldbereplaced

onceayearsothe fuel oil

will

not

become

contami-

nated

and

plug

up

fuel

pump

and

nozzleofoil

burner.

NOZZLE -

The

nozzle should

be

changed

at least

once

each

year

before

the start-upofthe

heating

season.

Replace

with

proper

nozzle.

COMPONENTS

-

If

for

any

reason

anyofthe

burner

parts

havetobe

replaced,

always

use

parts

recom-

mended

by

the

manufacturer.

Specify

part

numbers

and

description

when

ordering.

(IN

ALL

COM-

MUNICATIONS

STATE BURNER

MODEL

AND

SERIAL NUMBERS).

ELECTRODE SETTINGS - This is

very

important

for

reliable

ignitionofthe oil;

check

these

onceayear

in

accordance

with

the instructions

providedinthis

manual

FAN

&BLOWER HOUSING - This must

be

kept

clean,

freeofdirt

and

lint;

open

transformertocheck

fan

blades

from

above.

Be sure the

electric

powerisoffonburner

when

the

transformerisopened

up

for

this

inspection.

EG·1

·21755·001

Rev. 04106-20-88 PAGE 3

Page 4

ATTACHING

AIR

TUBE

COMBINATIONS

TOR

CIIASSIS

PI,AN

ONI,Y

When oil

burner chassis

and air

tube

combination

are

packed

separately,

the

burner

must be assembled

as follows:

l-

Lay

burner

chassis on

its

back

as shown

at right.

Insert

air tube into

burner

chassis

lining up the 3 holes in the chassis with

the

3 holes in the

air tube.

Install the 3 screws

s/s

long and secure.

2- Install

proper

nozzle

into

gun

assembly.

Loosen

and remove the two

screws located on the transformer top

plate

at

the front of

the burner

chassis and swing

open.

Slide drawer assembly

into air

tube

(see

Fig. 2).

3-

Once installed, adjust

grun

assy., either back

or forward to

position

nozzle

from

head, For

correct

positioning (see

Fiq.

3).

Secure the

slide

plate

by

tightening

thumb screw at side of housing.

Attach flared nut of Oil

Line

Assy.,

(Copper

Oil Line) to the end of this adapter

fitting as shown.

Install

arrow decal as shown so

position

of Drawer

Assy. is always known

(see

Fiq. 4).

Recheck for nozzle

centering before burner is installed

(see

Fig, l).

Make

sure

electrode tips ciear retention head.

INSERT

"SE'' SERIES GUN SETTING GAUGE

(AS

SHOWN

EELOW) TO CHECK NOZZLE

POSITION

AND ELECTRONIC SETTING.

Figure

3

ELECTRODE

BURNER AIR TUBE

NOZZLE

FLAMELOCK CONE

"sR" SEFTES

GUN SETTING GAUGE

ALL DIM'S

AS SHOWN UNLESS OTHEFWISE SPECIFIED

'/a

"

t/8"

BURNER

OIL

PIPE

BURNER AIR TUBE

4%

FLAMELOCK

HEAD

NOZZLE FACE TO FACE OF INNER AIR CONE

TRACK

FOR

GUN

ASSEMBLY

AOJUSTMENT BRACKET

Figure

1

t/2"

Figure 2

EG-l - 21755-001

Rev. 0406-20-88

PAGE

6

ATTACHING AIR TUBE COMBINATIONS FOR CHASSIS

PLAN

ONLY

When

oil

burner

chassis

and

air

tube

combination

are

packed

separately,

the

burner

must

be

assembledasfollows:

1-

Lay

burner

chassis on its

back

as shown at right. Insert

air

tube

into

burner

chassis

liningupthe 3 holes in the chassis

with

the 3

holes

in the

air

tube.

Install

the 3

screws%long

and

secure.

2-

Install

proper

nozzle into

gun

assembly. Loosen

and

remove

the

two

screws

located

on the

transformer

top

plate

at the frontofthe

burner

chassis

and

swing

open. Slide

drawer

assembly

into

air

tube

(see Fig.

2).

3-

Once

installed.

adjust

gun

assy.,

either

backorforward

to position nozzle

from

head.

For

correct

positioning

(see Fig.

3).

Secure the

slide

plate

by

tightening

thumb

screwatsideofhousing.

Attach

flared

nutofOil

Line

Assy.,

(Copper

Oil

Line) to the

endofthis

adapter

fittingasshown.

Install

arrow

decalasshownsopositionofDrawer

Assy. is

always

known

(see Fig.

4).

Recheck

for nozzle

centering

before

burnerisinstalled

(see Fig.

1).

Make

sure

electrode

tips

clear

retention

head.

•

Figure 1

INSERT

"SR"

SERIES GUN SETTING GAUGE

(AS SHOWN BELOW) TO CHECK NOZZLE

POSITION AND ELECTRONIC SETTING.

•

1(2--

II

~

-£1/8

L1

cHB:1~w

~~

-

~~I(B"

FLAMELOCK HEAD

ELECTRODE

FLAMELOCK CONE

"SR"

SERIES

GUN SETTING GAUGE

~

ALL

DIM'S AS SHOWN UNLESS OTHERWISE SPECIFIED

NOZZLE FACE TO FACE

OF

INNER AIR CONE

NOZZLE

TRACK FOR GUN ASSEMBLY

ADJUSTMENT BRACKET

~-+_

GUN ASSEMBLY

ADJUSTMENT BRACKET

BURNER

AIR

TUBE

DECAL--==tr:r-

ELECTRODE SUPPORT

Figure 2

EG·1

. 21755-001

Rev.

04106-20-88

PAGE

6

Page 5

tsURNER

COI\TPONENTS

IVIODEL

EG-l

@-

ST'JTTE

BURT{HR

g{ODEL,

PJIX,IT

DESC;IIPYS.$H

ATTO P,|IA.T

NTMAEER liT}IEN

ORDERING PJT,RTS

4d

-r

@

-\,

v_/

I

I

&,

@

'@

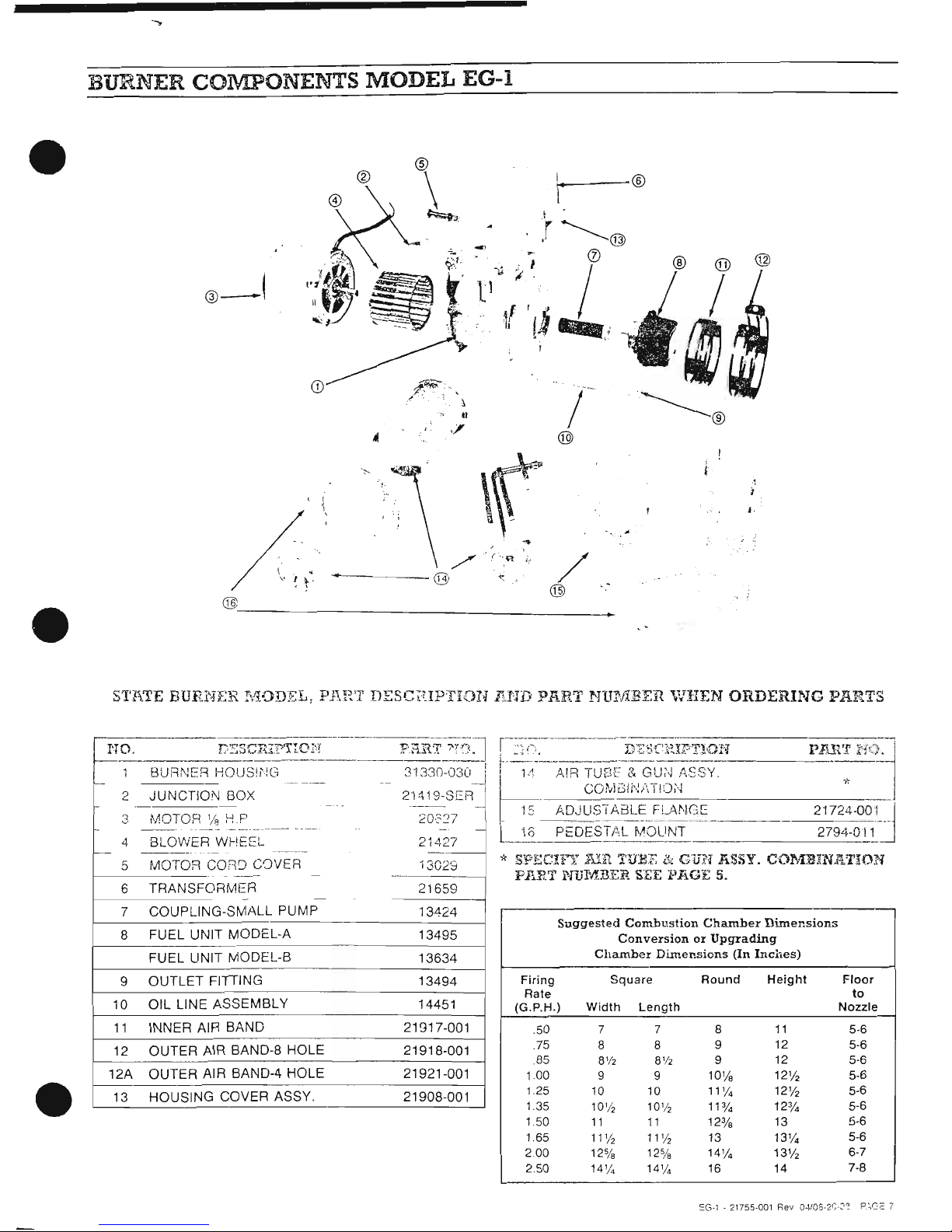

lIO. USSCRIT},TIOII

FSfi,T

-lT'*.

1 _9!l!!Iri?9si,1c,

1l!30!!!l

2 JUNCTION

BOX

21419-SEI1

3

MOTCR

1/s

L

P

2C327

a

_B_!9l.Ell{fitli_

__,

_____}:!ry

5

MO]-OR

COnD

COVER

i3029

6

TFANSFGRMER

21659

7 COUPLING-SMALL

PUMP

13424

8 FUEL UNIT

MODEL-A

13495

FUEL

UNIT

MODEL.B

13634

9 OUTLET

FITTING

13494

10 OIL LINE ASSEMBLY

14451

11 INNEB AIR

BAND

21917-001

12

OUTER

AIR BAND-8 HOLE 21918.001

12A

OUTER AIR

BAND-4 HOLE

21921-001

13

HOUSING

COVER

ASSY. 21908.001

f;7^

-_---D,If.'-"'rilffi

'*

s$',gctr}"Y il,llt TU$E it G'iili

P.ERT

FIIIF/IBSR

SEE iltg,cE

plilt'J

l,ic.

2172,1'OO1

2794-Al1

J[$SY.

CoIwSSil"RTIr)H

R

| " t arn rr rnr- o /

i

r.r

^:n

rL/r,r .r dUi'l

ASSY.

i

r.i nii r

I uLri

(l

uvt\ ,'1.Jt

I COlvlBiii,iillOiJ

L

I

r: ADJLISTABLE

FiAt\tcE

--

I

r6_PEpLSItLU!!Ur_

Suggested

Combustion Chamber Dirnensions

Conversion or Upgrading

Chamber Dirnensions

(In

Inches)

Firing

Square

Bound Height Floor

Rate

to

(G.P.H.)

Width Length Nozzle

.50

7

7

8 11 5-6

.75889',t25-6

.85

81/z BVz

9

12

5-6

1.00

9 9

101/a

121/z

5_6

1 .25

.t

0 1 0

j

11/a

121/z

5_6

1.35

101/z

101/z

113/o

123/a

5_6

1 .S0

1

.1

1 1 123/e 13 5-6

1.65

111/z 111/z 13 131/e 5-6

2.00 12s/s 125/e 141/q 131/z 6-7

2.50 141/q

141/q 16

14 7_8

=G-1

-

21755-001

Fev.

0.1/06-2t-3.c

F.iCE 7

/--

@

:o-----®

®

\

~,,;

®

< I

"

CD

/

®

@-------------------

..

@-

BURNER COlVIPONENTS MODEL EG-l

•

•

STFI.TE

BUR.NER I\10DEL,

PJ\l~T

DESCIUPTION

lU'JD

PllRT

NUMBER

'VHEN

ORDERING

PARTS

•

I I

, J

..,

~

, ,

-

L-.

..

_.-._--

.

---"

------

2

JUNCTION

BOX

2'1419-SER

1----

-

- -

--

.

-

2

MOTOR

1/

8

HP

20'2::'7

--

.

__

._--.--

----

4

BLOWER WHEEL 21427

-

-----

-----

5

MOTOR

CORe>

CaVER

13029

6

TRANSFORMER

21659

7

COUPLING-SMALL PUMP

13<124

8

FUEL UNIT MODEL-A

13495

FUEL UNIT MODEL-S

13634

9

OUTLET

FiniNG

13494

10

OIL LINE ASSEMBLY 14451

11

INNER AIR BAND

21917-001

12

OUTER

AIR BAND-8 HOLE

21918-001

12A

OUTER AIR BAND-4 HOLE 21921-001

13 HOUSING COVER ASSY.

21908-001

r-

jl~:-------D·'S:;C'?XP'T10N

p~{'J

I'j.t)J·

r----·--------

1'1.

AIR

TUEH:

&

GU~'J

(,.SSY.

Cm,iGIi'U\TI<XJ

'*

15

ft,DJUSi

AaL~

__

F!.J\1'!G_~

21724'001_j~

13 PEDESTAL

MOUNT

2794-011

-----_.

*

SPECln:

run

'HIEF.

&:

Gun

liSSY.

C01\flHNAT:!DN

PART

N1J"MRER

SEE

PliGE

5.

Suggested

Combustion

Chamber

Dimensions

ConversionorUpgrading

Chamber

Dimensions

(In

Inches)

Firing

Square

Round

Height

Floor

Rate

to

(G.P.H.)

Width

length

Nozzle

.50 7 7 8

11

5-6

.75

8 8

9

12 5-6

85

8'12 8'12

9

12 5-6

1.00

9

9

10'/8

12%

5-6

1.25

10

10

11'1.

12%

5-6

1.35

10'/2 10'/2

1131.

12

3

/.

5-6

1.50

11 11

12

3

/8

13 5-6

1.65

11

'12

11'/2

13 13'1.

5-6

2.00

12%

12%

14'/.

13%

6-7

2.50

14'1. 14'1.

16

14 7-8

=G-l

·21755-001

Rev

O-lt06-2~-::~

P.~Gc

7

Loading...

Loading...