Page 1

Ovation Dispensers

INSTALLATION

OPERATION

Page 2

DANGER

READ THIS MANUAL BEFORE YOU BEGIN

Dispensers have both electricity and a hazardous, flammable and potentially explosive liquid.

Failure to follow the below precautions and the Warning and Caution instructions in this manual

may result in serious injury. Follow all rules, codes and laws that apply to your area and installation.

SAFETY PRECAUTIONS - INSTALLATION AND MAINTENANCE

Always make sure ALL power to the dispenser is turned OFF before you open the dispenser cabinet for maintenance. Physically lock, restrict access to, or tag the circuit breakers you turn off

when servicing the dispenser. Be sure to trip (close) the emergency valve(s) under the dispenser

BEFORE beginning maintenance.

Make sure that you know how to turn OFF power to the dispenser and submersible pumps in an

emergency. Have all leaks or defects repaired immediately.

EQUIPMENT PRECAUTIONS

Be sure to bleed all air from product lines of remote dispensers and prime suction pumps before

dispensing product, otherwise, damage to the equipment may occur. Always use the approved

method for lifting the dispenser. Never lift by the nozzle boot, sheet metal, valance, etc., otherwise equipment damage or personal injury may occur.

HOW TO CONTACT WAYNE

Technical questions related to the installation of the dispenser should be referred to Wayne

Technical Support (1-800-926-3737). Customers needing help with the operation of the dispenser should call the Wayne Help Desk (1-800-289-2963).

INDICATORS AND NOTATIONS

DANGER

WARNING

CAUTION

NOTE:

Danger indicates a hazard or unsafe practice which, if not avoided, will result in severe injury

or possibly death.

Warning indicates a hazard or unsafe practice which, if not avoided, may

injury or possibly death.

Caution indicates a hazard or unsafe practice which, if not avoided, may

Important information to consider, otherwise, improper installation and/or damage to components may occur.

result in severe

result in minor injury.

November 2008 Part No. 920559 Rev H

Page 3

Ovation Series

Dispensers

Installation & Operation

November 2008 Part No. 920559 Rev H

Page 4

November 2008 Part No. 920559 Rev H

Page 5

Table of Contents

Title Page

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Dispensers Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Local, State, and Federal Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Inspect the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Island Construction, Dispenser Anchoring, and Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Emergency Shut-off Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Vapor Return Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Lifting and Installing the Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6.2 Dispenser to Control System Wiring Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6.3 Field Wiring for Dispensers Without a Junction Box. . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.4 Full Service (Stand-Alone) Dispenser Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.5 Multiple Dispenser Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.6 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6.7 Veeder-Root Vapor Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6.8 Non-Dispenser Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Hose and Hose Retractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 Bleeding Product Lines (Remote Dispensers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.9 iMeter or Xflo™ Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 Balance Vapor Recovery System Installation Requirements . . . . . . . . . . . . . . . . . . . . . 16

2.10.1 Dynamic Back Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.10.2 Back Pressure System Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.10.3 Nozzles Approved for Balance System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.11 Wayne Vac Vapor Recovery System Installation Requirements . . . . . . . . . . . . . . . . . . 18

2.11.1 Dispenser Vacuum Decay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11.2 Wayne Pressure/Vacuum Tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Initial Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 IR Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Logical Nozzle/Hose Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5 Setting Unit Prices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.6 Setting Blend Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.7 Setting Fueling Point ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.8 Authorizing the Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.9 Initial Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.10 Disable Stand-alone Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

November 2008 Part No. 920559 Rev H

iii

Page 6

Table of Contents (continued)

Title Page

3.11 Totalizer Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.11.1 Totalizer Readings by Product Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.11.2 Totalizer Volume Readings by Meter Position . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.11.3 Electro-Mechanical Totalizer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.12 Nozzle Boot Switch Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.13 Annunciator Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.14 QCAT Dispensers Self-test and CAT Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.15 iX™ Pay Secure Payment Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.16 Wayne Vac Motor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.17 Audit Report Display Mode (For Weights & Measures Officials/Service Purposes Only) 33

3.18 IDPOS Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.19 iX™ CAT Dispensers Self-test and CAT Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.20 Bill Acceptor (BAC) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 Safety Items You Should Know . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1.1 Portable Tanks and Containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1.2 Health Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.2 How To Get Service On Your Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3 Basic Dispenser Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 Operating the Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5 Restarting After Power Failure or Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6 Cycling Power to Clear Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.7 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.8 Resetting After All Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.9 Stand-alone Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.10 Printer Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.10.1 Changing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.10.2 Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.10 Hazardous Zone Area Classifications for Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1 Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Filter/Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3 Dispenser Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.4 Vapor Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

5.4.1 Wayne Vac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.4.2 Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5 Meter Maintenance Issue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

APPENDIX A1 QCAT SELF-TEST PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

APPENDIX A2 iX CAT SELF-TEST PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

APPENDIX B INSTALLATION DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

APPENDIX C LOCAL AUTHORIZE/STAND-ALONE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 73

APPENDIX D DISPENSER / BACKROOM INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 75

iv

Part No. 920559 Rev H November 2008

Page 7

1 INTRODUCTION

This revision of the manual includes new installation footprint drawings. These drawings show the location

of the conduits for entering the new smaller junction box. The smaller junction box will be standard on production Ovation dispensers in November 2008. This junction box gives the installation personnel more

room to make inlet and conduit connections, and it also allows for bottom entry of conduits coming up outside of the containment box.

1.1 Dispensers Covered

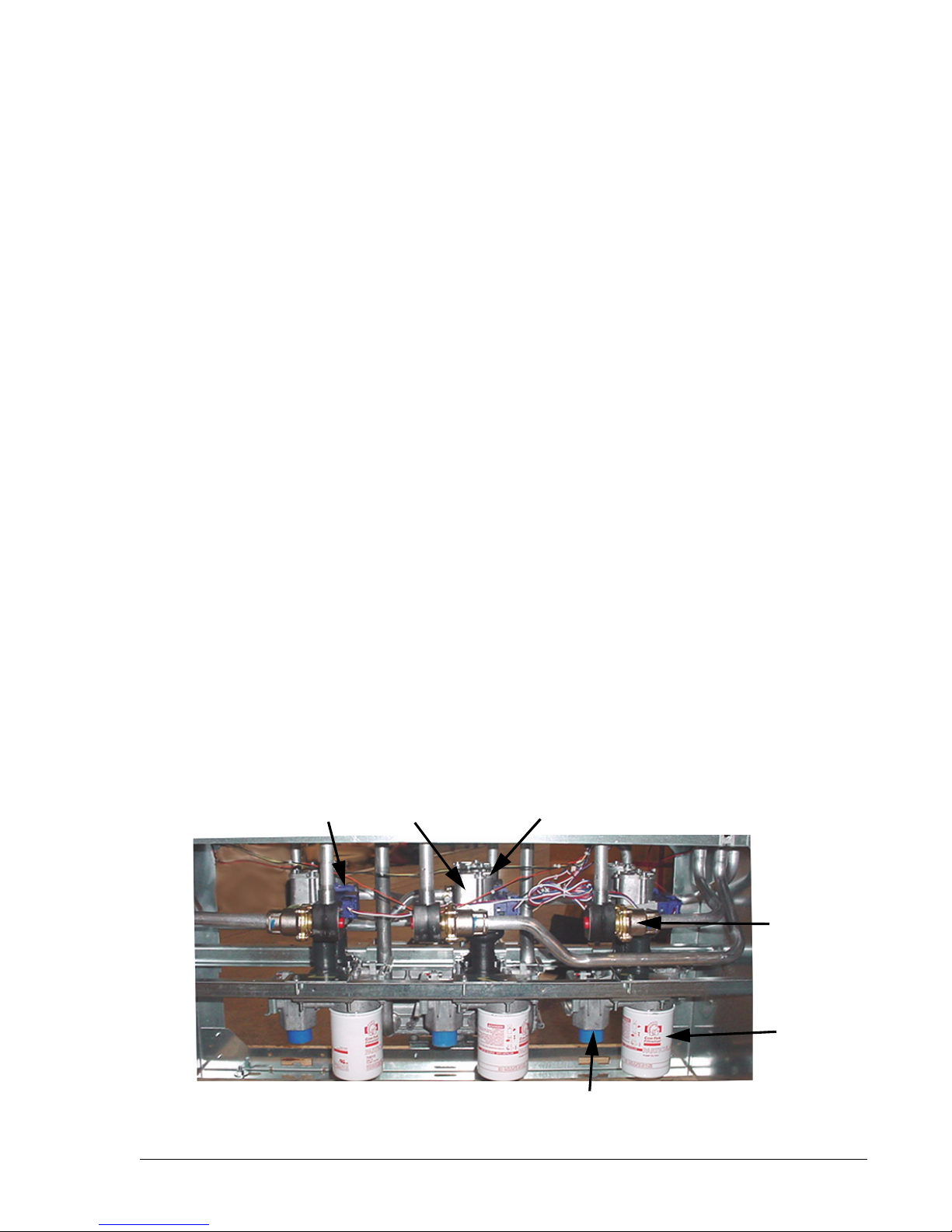

Ovation series dispenser models use the iGEM computer and, either the iMeter assembly with the Wayne

Intelligent Pulser (WIP), or the new Xflo

meter assembly have the letter X in the model number after the second / in the number, for example,

B23/4220D1/JKX/L. There is no difference in the installation and startup of these dispensers, with the only

exception being a one inch change in the location of the field conduit on those models that do not have a

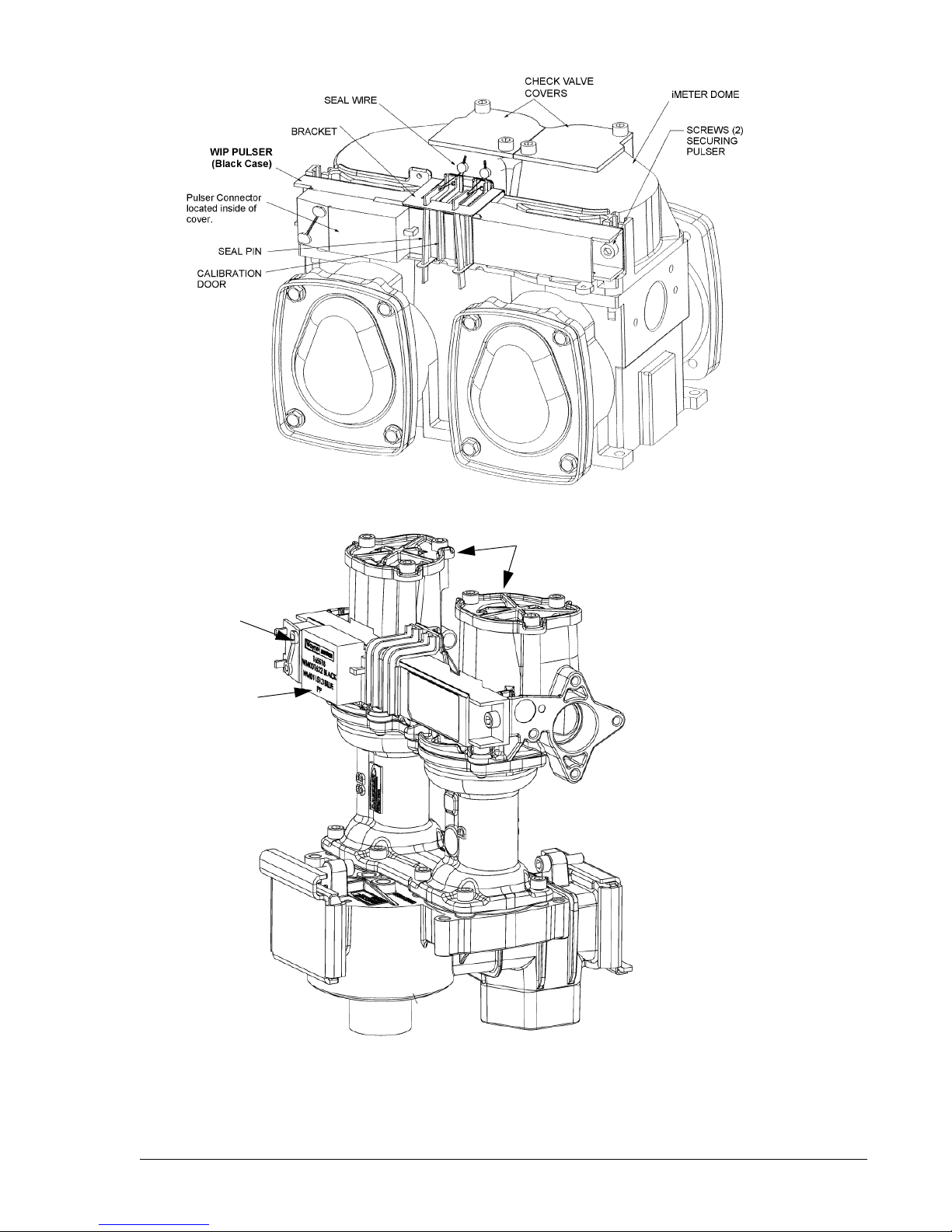

junction box. On those models, the primary conduit location is moved from 1.37 to 2.37 inches off the center line towards the front of the dispenser. Components in a typical Xflo dispenser are shown in Figure 1-1.

E85 Ovation models have the letter E at the very beginning of the model number and use the Xflo meter

assembly. In addition to the noted change above for Xflo models, internal parts such as the Xflo meter, product tubes, and outlet castings, as well as external parts, such as pipes, pipe nipples, hoses, nozzles, breakaways and swivels that come into contact with the Ethanol fuel must be Ethanol compatible; they must be

either nickel-plated or stainless steel. Pipe nipples at the meter inlets need to be made of stainless steel.

Replacement filters should be 1 micron. The recommended filter for Wayne Ethanol dispensers is Cim-Tek's

Bio-Tek, 1 Micron filter. Standard gasoline dispensers commonly use filters rated at 10 microns.

™ meter assembly with the XWIP. Models with the new Xflo

The iGEM computer runs on software that can be downloaded by a laptop. Dispenser models with the Xflo

meter and XWIP use iGEM rev 46 or later pump software; servTerm version 5.4.2 or later is required for

servicing (loading the computer software or dispenser configuration template), however, this is not required

for installation/startup of the dispenser. If it becomes necessary to reload pump software, always use the latest version. Note: The XWIP case is blue and the iMeter WIP case is black; they are not interchangeable.

Computer function settings that are necessary for Ovation dispenser startup and operation, such as prices,

blending ratios, fueling point number, etc., are included in this manual. If additional information on function

settings and statistics is required, refer to the Ovation Dispenser Service manual, part number 920525-002.

Any questions concerning installation and operation of the dispenser that are not covered in this manual

should be referred to Wayne Technical Support (1-800-926-3737).

XWIP

Pulser

Xflo Meter Dome

Check Valves underneath

Cover Plates

Proportional

Valve and Coil

Figure 1-1 Location of Components in Lower Section. MGD, three Xflo Meters, side 2.

November 2008 Part No. 920559 Rev H

Filter

Product Inlet

1

Page 8

1.2 Local, State, and Federal Codes

All tanks (both underground and above ground), piping and fittings, foot valves, leak detectors, corrosion protection devices, wiring, venting systems, etc., must be installed in accordance with the

manufacturer’s instructions and in compliance with local and regional building codes and requirements pertaining to service stations (or other locations where the dispenser may be installed).

These requirements may include references to the National Electrical Code (NFPA 70), Automotive

and Marine Service Station Code (NFPA 30A); Flammable and Combustible Liquids Code (NFPA

30); Code of Federal Regulations, Title 40, Section 280 (40 CFR 280); United States Environmental

Protection Agency (U.S. EPA) Technical Regulations of 9-23-88 and U.S. EPA Financial Responsibility Regulations of 10-26-1988.

Where local requirements do not specify applicable codes, Wayne recommends using the codes

listed above. These codes are comprehensive and detailed, often requiring interpretation to cover

unusual situations, and, therefore, the associated handbooks (where applicable) should also be consulted. (The handbooks are also available from the same sources.)

Due to the variety of locations encountered, further information on installation cannot be dealt with

in this document except as the codes relate directly to the installation of the dispenser. Therefore, it

is strongly recommended that a qualified engineer or contractor familiar with local regulations

and practices be consulted before starting installation.

Sources for various codes are listed on the following page.

2

Part No. 920559 Rev H November 2008

Page 9

Pertinent information and codes are available from the following sources:

Association for Composite Tanks (ACT)

North State Street

Suite 720

Chicago, IL 60602

(301) 355-1307 (for information requests)

Fiberglass Petroleum Tank and Pipe Institute

One SeaGate, Suite 1001

Toledo, OH 43604

(419) 247-5412

National Fire Protection Association (NFPA)

One Batterymarch Park

Quincy, MA 02269-9101

(617) 770-3000

Petroleum Equipment Institute (PEI)

Box 2380

Tulsa, OK 74101

(918) 494-9696

Underwriters Laboratories Inc.

333 Pfingsten Road

Northbrook, IL 60062

(312) 272-8800

United States Environmental Protection Agency

Office of Underground Storage Tanks

401 M St., SW (05-400WF)

Washington, DC 20640

(703) 308-8850 (Underground Storage Tanks)

American Petroleum Institute (API)

1220 L Street, N.W.

Washington, DC 20005

(202) 682-8000

National Assoc. Corrosion Engineers

(NACE)

Box 218340

Houston, TX 77218

(713) 492-0535

National Leak Prevention Association

(NLPA)

685 Fields Ertel Road

Cincinnati, OH 45241

(513) 489-9844 or 1-(800) 543-1838

Steel Tank Institute

P. O. Box 4020

Northbrook, IL 60065

(312) 498-1980

Underwriters Laboratories of Canada

7 Crouse Road

Scarsborough, Ontario, Canada N1R3A9

(416) 757-3611

Western Fire Chiefs Association

5360 South Workman Mill Road

Whittier, CA 90601

(213) 699-0541

U. S. Department of Labor,

Occupational Safety and Health Administration (OSHA)

Washington, DC 20402

• Call OSHA at (202) 523-8148 to determine specific needs; OSHA rules

are covered by Title 29 of the Code of Federal Regulations (29 CFR.)

• Order OSHA publications from:

Government Printing Office (GPO)

Washington, DC 22304

(202) 783-3238

NOTE: Other regulatory codes may apply. Consult your local and regional code requirements to

determine which codes are applicable for your location.

November 2008 Part No. 920559 Rev H

3

Page 10

1.3 SAFETY PRECAUTIONS

NFPA 30A states that:

“When maintenance to Class I dispensing devices becomes necessary and such maintenance may

allow the accidental release or ignition of liquid, the following precautions shall be taken before

such maintenance is begun:

• Only persons knowledgeable in performing the required maintenance shall perform the work.

• All electrical power to the dispensing device and pump serving the dispenser shall be shut off at

the main electrical disconnect panel.

• The emergency shut-off valve at the dispenser, if installed, shall be closed.

• All vehicle traffic and unauthorized persons shall be prevented from coming within 20 ft.(6 m)

of the dispensing device.

WARNING

Electric shock hazard! More than one disconnect switch may be required to de-energize the

dispenser for maintenance and servicing. Use a voltmeter to make sure ALL circuits in the

dispenser are de-energized. Failure to do so may result in serious injury.

1

”

Lockout/Tagout requirements of the U. S. Dept. of Labor, Occupational Safety and Health Administration (OSHA) may also apply. Refer to Title 29, Part 1910 of the Code of Federal Regulations

(29CFR1910), Control of Hazardous Energy Source (Lockout/Tagout).

NOTE: To prevent damage to components located in the hydraulic cabinet, dispenser doors should be

in place during rainy and/or icy weather conditions. Also, check the nozzle boot flipper for

freedom of movement. If ice has formed on the flipper, it should be cleared to prevent

unnecessary damage.

1. Reprinted with permission from NFPA 30A-90, Automotive and Marine Service Station Codes, Copyright

©1990, National Fire Protection Association, Quincy MA 02269. This reprinted material is not the complete

and official position of the National Fire Protection Association on the referenced subject, which is represented only by the standard in its entirety.

4

Part No. 920559 Rev H November 2008

Page 11

2 INSTALLATION

2.1 Inspect the Equipment

Examine the shipment immediately upon arrival to make certain there has been no damage or loss in

transit. Make sure that all the component parts, including keys and optional equipment (if any), are

accounted for. Check and save the Packing Slip, Bill of Lading, Invoice, and all other documents

included in the shipment. Damaged or lost equipment must be reported to the carrier. Any damage or

loss that may occur in transit is not covered under the Wayne/Dresser Warranty.

2.2 Island Construction, Dispenser Anchoring, and Piping

Product lines must avoid the creation of vapor in the lines and deliver a minimum pressure of 25 psi at

the dispenser inlet when all dispensers at the station dispensing the same product are operating.

A concrete foundation must be provided for the dispenser. Do not pour concrete around product lines or

electrical conduit risers.

Anchor bolts must be installed in the island to allow the dispenser to be bolted down in accordance with

NFPA requirements. The base of the dispenser contains six bolt hole slots (5/8 inch by 2 inch) for

anchoring the dispenser to the island. Use of all anchoring locations is re-commended. Position

the anchor bolts in accordance with the dimensions shown on the Installation Instruction drawing for the

dispenser model. These drawings are located in Appendix B.

Vertical supply risers and electrical conduits must be located per the Installation Instruction for the

appropriate model. Proper height must be maintained to avoid undue stress on the dispenser.

For E85 Ovation models, product piping, pipe nipples, etc., containing Ethanol fuel must be Ethanol

compatible. See the information in Section 1.1 on page 1.

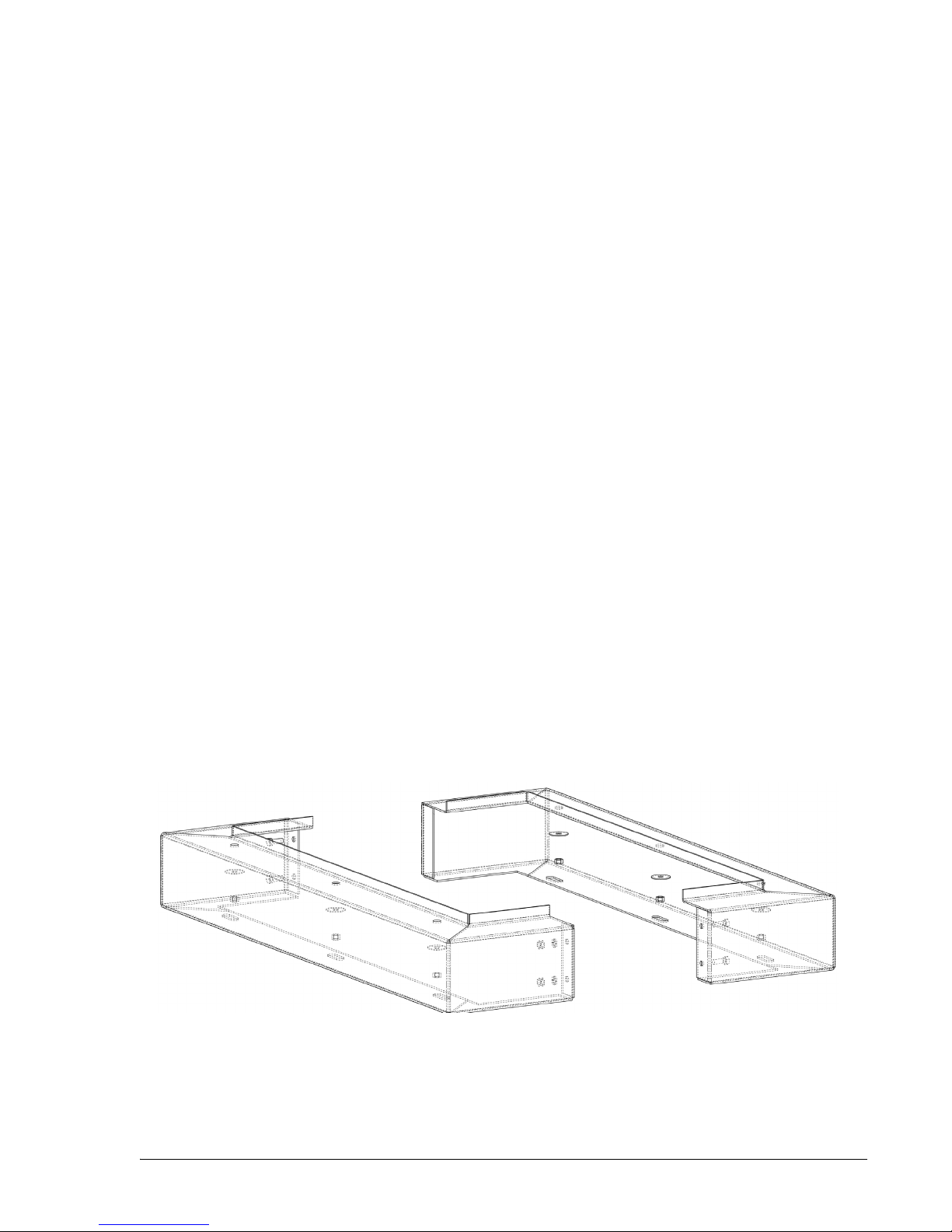

For convenience, a 6” high pedestal is available to install under the dispenser base at locations where

there are no islands. The pedestal, shown in Figure 2-1, can be ordered separately. See the complete

assembly drawing 888813 in Appendix B.

Figure 2-1 Pedestal. See Note under the shear valve drawing on the following page.

November 2008 Part No. 920559 Rev H

5

Page 12

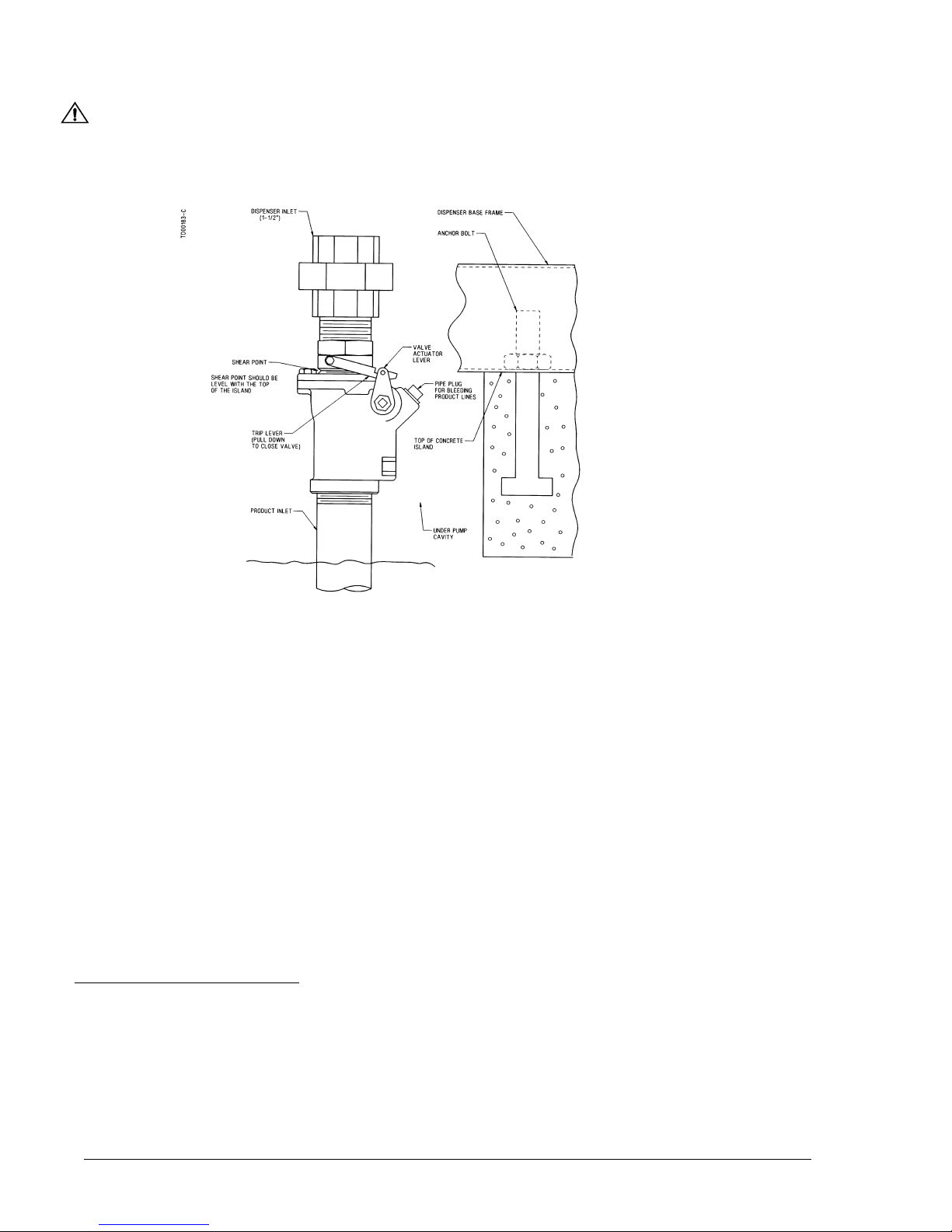

2.3 Emergency Shut-off (Shear) Valves

WARNING

For remote dispensers, a Listed1, rigidly anchored emergency shut-off valve must be installed, in accordance with the manufacturer’s instructions, in each supply line at the base of each dispenser. For a typical emergency valve installation see Figure 2-2. Failure to install the proper emergency shut-off valve will

present a hazardous condition that could result in serious injury.

Figure 2-2 Typical Emergency Valve Installation. The Emergency valve is designed to close the product line due

to shock or fire. The shear section, shown above, functions if the dispenser is knocked out of position.

NOTE: The shear valve must always be at the ground plane. The pedestal shown on the previous page, is considered an extension of the dispenser, not the island.

Note: Wayne does not supply the meter inlet pipe nipple or the union shown above.

2.4 Vapor Return Piping

NFPA 30A Section 4-3-72 states that a vapor return pipe inside the dispenser housing shall have a shear section or flexible connector so that the liquid emergency shut-off valve will function properly. Wayne’s vapor

connections are secured to the chassis allowing for the use of a shear section.

Wayne dispensers provide 1" NPT pipe connections at the base of the dispenser for vapor return connections.

(See the installation foot print for location in Appendix B.) A minimum 1" riser at each dispenser is connected to a minimum 2" return piping to the underground tank. If more than six (6) fueling points are connected, then underground piping must be a minimum of 3". All lines should be sloped at a minimum of 1/8”

per foot (1/4” per foot preferred) from the dispenser to the tank to avoid liquid traps. Note: There is no vapor

recovery for the Ethanol product on E85 Ovation dispensers.

1. “Listed” means published on a list by a nationally recognized testing laboratory (NRTL) which is responsible for product evaluation and is acceptable to the authority having jurisdiction. Underwriters Laboratories, Inc. is one example

of a Nationally Recognized Testing Laboratory. For more information on NRTL’s, see Title 29, Parts 1907 and 1910

of the Code of Federal Regulations, Safety Testing or Certification of Certain Workplace Equipment and Materials.

2. Reprinted with permission from NFPA 30A-90, Automotive and Marine Service Stations Codes, Copyright 1990,

National Fire Protection Association, Quincy MA 02269. This material is not the complete and official position of the

National Fire Protection Association on the referenced subject, which is represented only by the standard in its

entirety.

6

Part No. 920559 Rev H November 2008

Page 13

2.5 Lifting and Installing the Dispenser

Remove the shipping carton from the dispenser and, if the dispenser is equipped with an optional valance, survey the site to determine if it should be installed before or after the dispenser is set on the

island. Wayne recommends installing the valance after the dispenser is installed, if practical, to protect it

from installation damage. See the Valance Module drawing in the back of this manual.

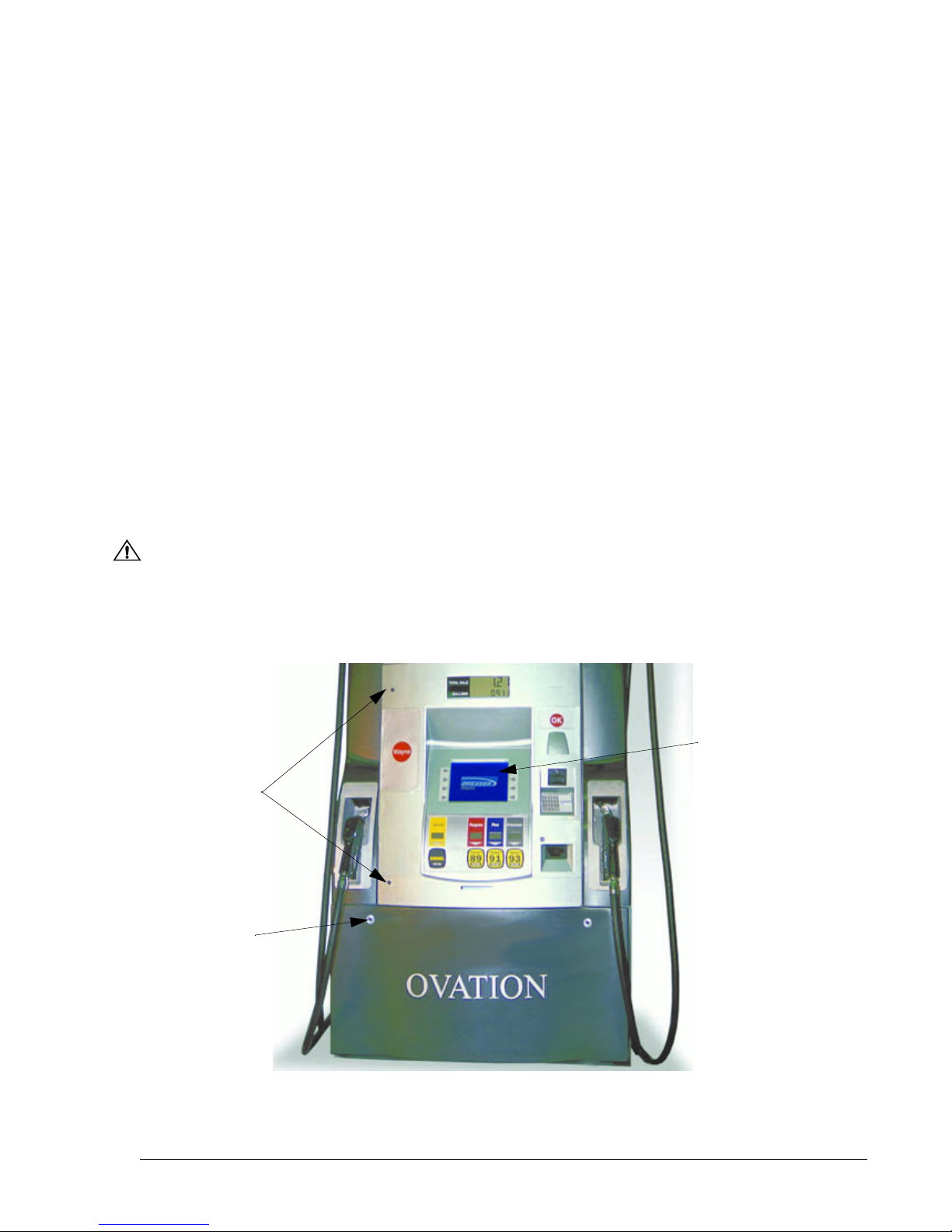

Use door key (p/n 1-202022) to unlock and then remove the lower doors, see Figure 2-3 for location.

Install (2) eye-bolts in the dispenser top castings and lift the dispenser onto the island as per Lifting

Instructions drawing 888514-001 in Appendix B. When handling Ovation dispensers, lift only as per the

Lifting Instructions drawing contained in this manual. Do not lift by the electronic enclosure, nozzle

boot, or any external panels.

Bolt the dispenser into place (Section 2.2), remove the shipping discs from the meter inlets and connect

the product piping per the appropriate Installation Instruction drawing in Appendix B. When installing a

blending dispenser, make sure the Lo and Hi product inlets (and, if applicable, the single product inlet)

are correctly located.

To ensure tight, leak-proof connections when making piping connections, wash all cutting oils off the

threads and use a UL-classified pipe joint sealing compound, rated for use with petroleum-based products.

WARNING

Explosive or flammable vapors may accumulate within the dispenser housing. All piping connections in the final installation must be accurately fitted and all threaded joints tightly made up with a

Listed gasoline-resistant pipe joint compound. Put the compound on male threads only, being

careful not to get excess inside the pipe or fittings. Failure to perform the above will present a hazardous condition that could result in serious injury.

VGA

Screen

Upper Door

Locks

Lower Door

Locks (2)

Option

Figure 2-3 DOOR LOCK LOCATIONS. One door key fits upper and lower door locks.

November 2008 Part No. 920559 Rev H

Optional VGA display screen shown.

7

Page 14

2.6 Electrical Wiring

2.6.1 General

Wayne recommends employing a qualified electrician for all wiring. A hazardous liquid is being handled, so it is

important to ensure that all wiring is in accordance with the National Electrical Code (NFPA 70) as well as all

federal, state and local regulations. Note: U.L. requires that all electrical connections to the dispenser be made

with threaded, rigid conduit and properly sealed conductors. Note: All dispensers and electrical connection

boxes must be grounded per NFPA 70.

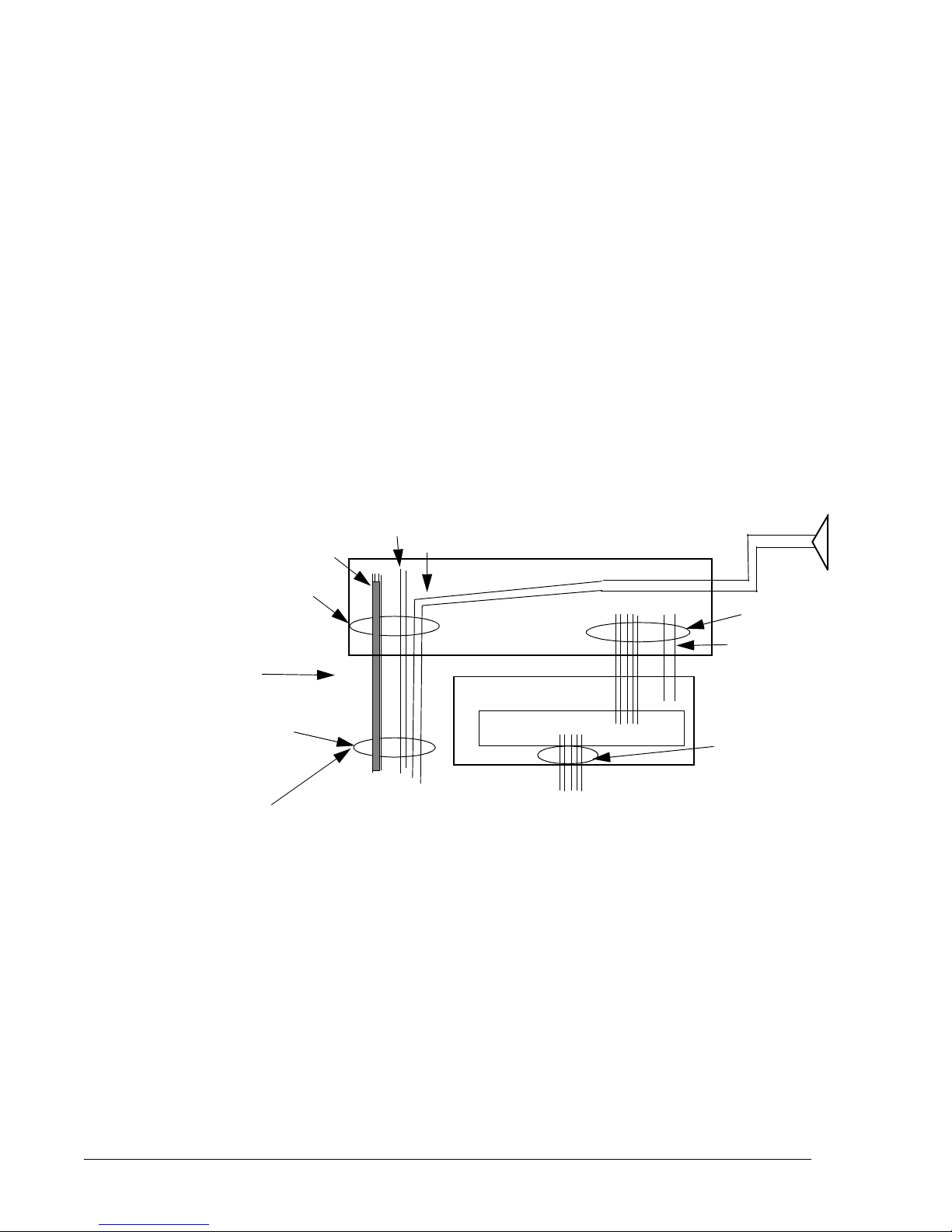

2.6.2 Dispenser to Wayne Control System Interconnection

Dispenser installation wiring diagrams are provided in Appendix B. The system interconnection wiring diagrams

supplied are for reference purposes. Use these diagrams along with the wiring diagrams supplied with the control

system for laying out the system wiring requirements for a new site or when making changes to an existing one.

Two da t a wires to the Data Distribution Cabinet are required for the Wayne control system console operation.

Two da t a wires to the Site Controller Cabinet are required for dispenser card processing CAT operation.

Two da t a wires to the Site Controller Cabinet are required for Wayne TRAC operation.

One ethernet cable (gas and oil resistant) is required for dispensers equipped with the IDPOS or iX CAT option

from the switch in the dispenser to the switch in the building, see Section 2.6.6, Figure 2-5 and Figure 2-6. A UL

AWM Ethernet cable, Category 5 or higher, rated at least 300 V, 60 degrees C with a gasoline and oil resistant

jacket may be used. The conduit in the dispenser must be potted at the end of the installation.

Optional equipment wires, see Section 2.6.6.

NOTE: When data wires are installed, only the two data wires from the Data Distribution Cabinet used for pump control

are to be terminated at the dispenser’s terminal strip. The additional data wires should not be physically

connected to the data terminals on the dispenser’s terminal strip. Instead they should be properly terminated

individually using wire nuts.

Figure 2-4 shows the location of dispenser components that may need to be accessed during installation. If the

dispenser is not equipped with a junction box in the hydraulic cabinet, field wiring will terminate at the terminal

strip inside the electronic enclosure as shown in Figure 2-5 and the conduit fittings shown will be potted in the

field.

E-M TOTALIZERS

WIP PULSER

CHECK VALVES

(under Valve Plates

in iMeter Dome)

PROPORTIONAL

/

VALVE

VALVE COIL

JUNCTION BOX

PRODUCT INLET

FILETR/STRAINER

CASTING

Figure 2-4 Location of Components in Lower Section (iMeter model shown). Side 1.

See Appendix B for new footprint drawings with the smaller junction box (above) effective in November 2008.

8

Part No. 920559 Rev H November 2008

VAPOR

RECOVERY

OUTLET

Page 15

WARNING

Electric Shock Hazard! No connections (including neutral) may be shared between groups of dispensers.

A separate Control Power Circuit Breaker must be provided for each group. Failure to do so may result in

serious injury.

2.6.3 Field Wiring for Dispensers Without a Junction Box

All field wiring must enter the Electronic Head via potted conduit/conduit fittings. When a dispenser

does not contain a junction box, the conduits must be potted in the field during dispenser installation.

Note: This also applies to the secondary conduit containing the Ethernet cable and the intercom call button/

speaker wires even if the dispenser does have a junction box since these wires do not connect in the junction

box.

1. Install (2) 3/4” field conduits from the UL approved seal-offs at the base of the dispenser to the conduit at

the vapor barrier as identified in Figure 2-5. One conduit will contain, as applicable, the Ethernet cable

and the intercom (call button and speaker) wires (low voltage - Class 2 circuits). The other conduit will

contain the pump power, relay selects, valance lighting and data wires (Power - Class 1 circuits).

Potted conduit for Ethernet and

Intercom Call Button/speaker wires only.

,

Note: With or without j-box,

this conduit now goes directly to the

seal offs under the dispenser to allow

for a straight run of Ethernet cable

from building switch to dispenser switch.

Terminal Block

used when junction box

is not installed.

MGD Wiring Shown.

Potted Fitting contains Pump Power,

Data, Relay Selects, Valance lighting

Note: Main potted fitting contains

intercom speaker wires (Brown pair)

These must run in separate underground

conduit along with the call button wires.

See optional equipment section.

Figure 2-5 Terminal Block Inside Electronic Enclosure. Field wiring connects to this terminal block when

the junction box shown in Figure 2-4 is not installed.

2. Clean conduit threads before connecting.

3. Pull continuous uninterrupted lengths of wires from the station electrical panels and control boxes to the

dispenser electronic head. Allow an extra 18” lengths past the vapor barrier fitting for terminating,

separating, potting and connecting to the terminal block. If installing iX CAT or IDPOS dispensers, allow

an extra 3 ft. of Ethernet cable past the top of the conduit in the vapor barrier.

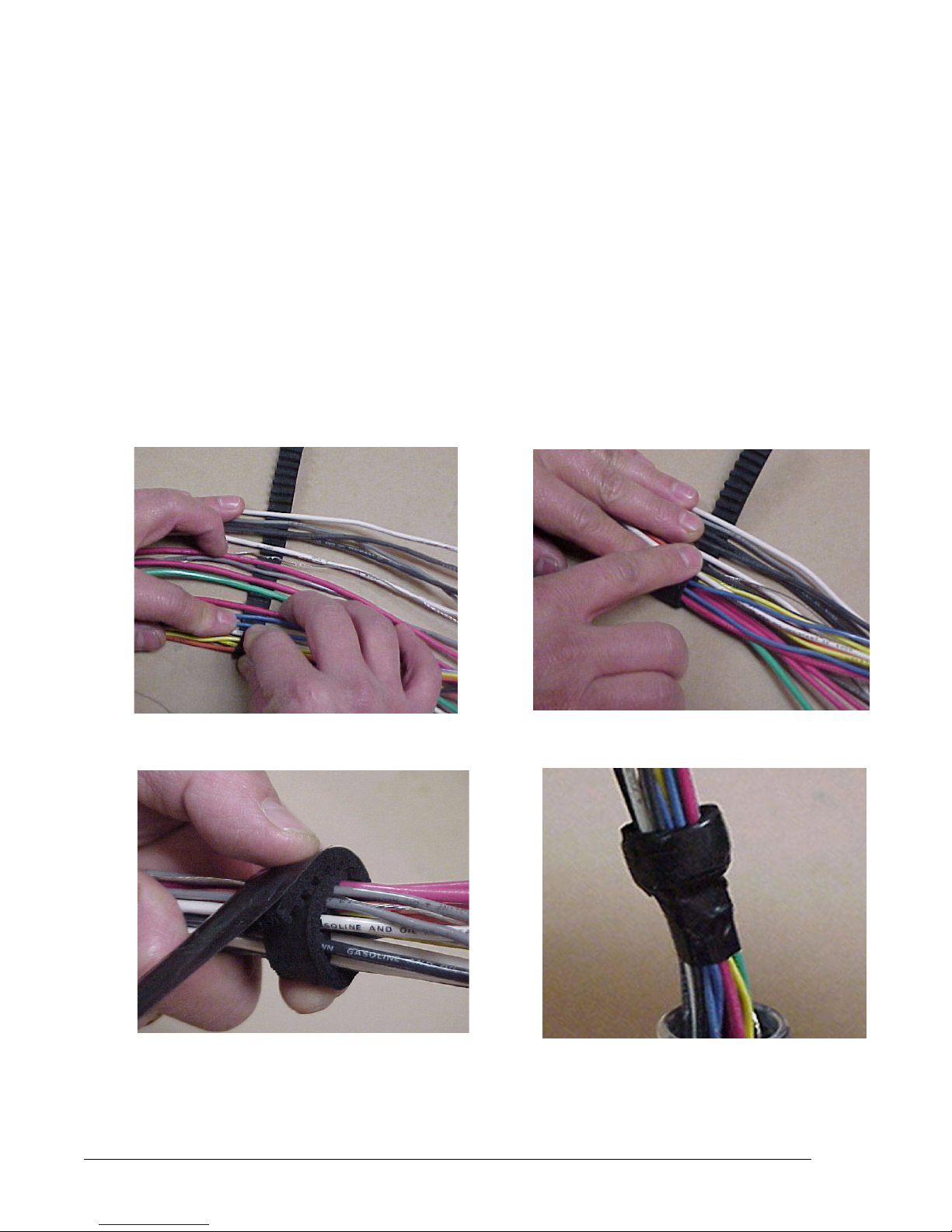

4. From each conduit, separate the wires using 3-201623 Wire Separator Gasket. See Photo 1.

5. Roll separator gasket and wires into a cylinder and secure with electrical tape. Photo 2 and Photo 3.

6. Pull separator gasket and wires back through the conduit fitting (Photo 4) forming a dam in the conduit,

with the top of the separator down in the conduit past the dimple in the conduit.

November 2008 Part No. 920559 Rev H

9

Page 16

2.6 Electrical Wiring, continued

7. Trim wires to appropriate length, terminate ends and connect to the terminal block as per Wiring Diagram

drawing 888445-001 located in the Appendix B of this manual. Note: Field wires are to be connected to

the lower terminals on the block.

8. Prepare the potting compound by pouring 4 oz. Rockite into an eight oz. paper cup.

9. Add 1-1/2 oz. of water.

10. Stir one to two minutes until reaching a consistency similar to pancake batter.

11. Pour mix into fitting and fill to within 1/8” of top of fitting (or top of conduit if the Ethernet conduit).

12. Close the service door.

13. Let fitting set for 12 hours. The wires must not be moved during this time.

Photo 1. Photo 2.

Photo 3. Photo 4.

10

Part No. 920559 Rev H November 2008

Page 17

2.6.4 Full Service (Stand-Alone) Dispenser Wiring

For full service operation, make electrical connections as shown on the Installation Wiring Diagram in

Appendix B. The electrical connections illustrated are typical when additional like model dispensers are

used.

Data wires shown on the wiring diagram are for connecting the dispenser to the Data Distribution Cabinet and the Site Controller Cabinet in a Wayne Control System. These data wires are not required for the

full service (stand-alone) dispenser. However, the six optional data wires and cable, whichever are

applicable, as described in Section 2.6.2, should be run at initial installation if a control system or

optional equipment is being installed or may be installed in the future.

Remote dispensers require a relay to control the submersible pump motor. These relays are available as

an option with the Wayne control system. If the dispenser is not connected to a Wayne control system, a

UL Listed magnetic motor controller assembly, constructed with Potter and Brumfield Relay No.

PRD7AYO (120) or equivalent, shall be used.

A maximum of 12 dispensers (24 fueling points) may be connected to a single PRD7AYO (120) relay;

other relays may have different limitations. All dispensers operating the same pump control relay must

be connected to the same circuit breaker; this may require multiple control relays for a submersible

pump.

Ensure that the submersible pump receives its power from its own separate circuit breaker as illustrated

in the Typical Site Wiring Diagram in Appendix B.

2.6.5 Multiple Dispenser Wiring

A primary requirement in dispenser installation wiring is to provide a means for disconnecting all power

connections, including the neutral, to the dispensers for safe shutdown and servicing of the units. Each

dispenser could be provided with a separate control Power Circuit Breaker. If this is not desirable or

practical, several dispensers can be grouped together and tied to the same Control Power Circuit Breaker

as illustrated in the Typical Site Wiring Diagram in Appendix B. A group of dispensers would then consist of all the dispensers and associated Submersible Pump Control Relay coils supplied by the same

Control Power Circuit Breaker.

When more than one dispenser within the group activates the same submersible pump, the Relay Select

lines may be commoned at the Submersible Pump Control Relay Coil terminal up to a maximum of 12

connections (24 fueling points). Where more than 12 connections activate the same submersible pump,

additional relays should be used and the contacts paralleled as illustrated in the Typical Site Wiring

Diagram.

In larger installations, dispensers can be separated into multiple groups.

November 2008 Part No. 920559 Rev H

11

Page 18

2.6.6 Optional Equipment

Dispensers contain an extra pair of data wires in the junction box for Wayne TRAC as shown in

Figure 2-6 below. These wires are also identified in the installation wiring diagram in Appendix B.

Dispensers with the letter I in the model number will have an intercom call button.

Brown wires are speaker connections. Yellow wires are call button connections see Figure 2-6. Both

circuits are low voltage NEC Class 2 only.

Dispensers with a 3 or 6 in the main body of the model number indicates the dispensers are equipped

with iX CAT board option, VGA or QVGA, respectively. And, dispensers with the letter “L” in the 1st

suffix of the model number indicates iX Secure Keypad. All of these dispensers will require an unin-

terrupted run of Ethernet cable from the switch in the building to the switch in the dispenser electronic head. These dispensers will need a secondary underground conduit for this cable and other

NEC Class 2 wiring as shown below. From the factory, these dispensers will contain a short section of

conduit that can be used for making the connection to the secondary conduit seal off under the dispenser.

NOTE: The field Ethernet cable and Intercom (Call Button and Speaker) wires (NEC Class 2) must be

installed via a separate underground conduit to the dispenser. The intercom/speaker and call button

wires should be terminated with wire nuts in the electronics head.

Call Button

Ethernet Cable for

iX CAT or

(NEC Class 2)

Underground Conduit

for Ethernet cable and

Intercom (call button

and speaker) wires only.

Note: This conduit now goes directly to the seal offs

under the dispenser to allow for a straight run of

Ethernet cable from building switch to dispenser switch.

IDPOS option

Secondary Conduit

in Electronic Head

Y

••

Y

Speaker

Junction Box

Electronic Head

Terminal Strip

BN pair

•

•

BU

OR

_

+

•

•

•

(NEC Class 1)

Underground Conduit

for Pump Power,

and Data,

Valance lighting

and relay select wires.

Speaker

Main Conduit in

Electronic Head

Data Wires for

Wayne TRA C

option

Wire Nut (typical)

Figure 2-6 Ethernet, Intercom Call Button and Speaker Wiring. Ethernet and Intercom (Call Button and

Speaker) wiring must run in a separate underground conduit to the dispenser.

2.6.7 Veeder-Root Vapor Flow Meter

Refer to the installation procedures in the Veeder-Root Manual No. 577013-796 Rev E (page 6, instruction steps 11 and 12) supplied with dispensers equipped with the Veeder-Root option.

2.6.8 Non-Dispenser Equipment

Do not run wiring for any non-dispenser equipment, in the same conduit as the dispenser wiring; this

wiring must be run in a separate conduit.

12

Part No. 920559 Rev H November 2008

Page 19

2.7 Hose and Hose Retractor

Hose assemblies should be U.L. Listed and installed in accordance with the manufacturer’s instructions. To

ensure a proper joint, wash all cutting oil off the threads and use a U.L. classified gasoline-resistant pipe joint

sealing compound. Place the compound on male threads only; be careful not to get any excess compound

inside fittings. Install the fixed end of the hose to the dispenser outlet; secure according to the instructions of

the sealing compound and hose manufacturers. Install the swivel end of the hose or other swivels to the nozzle according to the manufacturer’s instructions.

Exception: Do not use the sealant on balanced or inverted hoses used with vapor recovery.

NFPA code requires a Listed emergency breakaway device, designed to retain liquid on both sides of the

breakaway point, must be installed on each hose dispensing Class I liquids; these devices must be installed

and maintained per the manufacturer’s instructions. Refer to your state and local codes for breakaway device

requirements that apply to your installation.

On E85 Ovation dispensers, all hoses, nozzles, breakaways, etc., containing the Ethanol fuel must be Ethanol

compatible. See the information in Section 1.1 on page 1.

On Wayne vapor recovery dispensers all hoses, nozzles, and breakaways, etc., must be CARB certified.

Hose Retractor: Caution!: On dispensers equipped with the Hose Retractor option, the hose clamp must

be mounted upstream of the breakaway device to avoid damage to the dispenser in the event of a drive-off.

The combined hose, breakaway, and whip maximum lengths are listed below.

Crossover Type

1 Hose per Side

Wayne Vac 14’ 0’’

Non-Vapor 3/4” 10’ 0’’ 10’ 0’’

Non-Vapor 5/8” 14’ 0’’ 14’ 0’’

WARNING

Use only Listed hoses and nozzles. Continuity must be present between the dispenser outlet and nozzle

spout to prevent static discharge while fueling. Continuity must be checked for each outlet/hose assembly to insure that the nozzle is grounded. Failure to do so may result in a hazardous condition that could

cause serious injury.

Loopback Type

1 Hose per Side

Loopback Type

2 Hose per Side

2.8 Bleeding Product Lines (Remote Dispensers)

NOTE: To avoid severe damage to the dispenser, all air and air pockets must be bled from the product trunk

lines before attempting to dispense product.

Step 1 Make sure the power to the appropriate submersible pump is OFF.

Step 2 To bleed air from a trunk line, remove the pipe plug from the safety impact valve on the dispenser

farthest from the storage tank. For pipe plug location see Figure 2-2 earlier in this section.

Step 3 Attach a flexible hose to the pipe plug opening in the safety impact valve. Energize the appropriate

submersible pump and allow the air to bleed out of the trunk line into a test can until product flows

into the test can. De-energize the submersible pump and replace the pipe plug. Repeat the procedure

for each product and each trunk line.

November 2008 Part No. 920559 Rev H

13

Page 20

2.9 iMeter or Xflo™ Meter Calibration Procedure

Sufficient product must be run through each meter to thoroughly flush out all air and completely fill the system

prior to the calibration process.

Each meter assembly contains two meters. The WIP pulser (or XWIP for Xflo meter) contains two sets of sensors, one set for each meter. On the front of the pulser, there are two calibration doors, one for each meter in

the assembly. The door closest to the front of the dispenser controls calibration of the front meter and the other

door controls calibration of the rear meter.

(only one meter at a time can be calibrated).

assure the correct door is opened during the calibration process.

Dispensers have an operation mode setting that establishes the pulser’s calibration mode. This is set at the factory in the dispenser template (Read Only function F16). The imeter and the Xflow meter are calibrated using

the same procedure as shown below.

Verification Accuracy:

1. Dispense some product into the test measure to wet the container and then drain the container thoroughly, 10 seconds or more.

2. Dispense product into test measure until exactly 5 gallons (20 liters) are shown on dispenser display.

See Note 1.

3. Compare reading on site glass of test measure to dispenser display. Volume in test measure should be

within +/- 3 cu. in. (+/- 50 ml). See Note 2.

Only one door may be opened at one time during meter calibration

It is important to verify the product grade for each assembly to

4. If values are out of range, calibrate as described below.

Calibration:

1. Identify calibration door for meter in need of calibration.

2. Remove seal wire and pin to allow access to door.

3. Dispense some product into the test measure to wet the container and then drain the container thoroughly, 10 seconds or more.

4. Open calibration door of meter to be calibrated. (Only one door can be opened at a time during the calibration process).

5. Dispense exactly 5 gallons (20 liters) into the test measure exactly to the “0” mark on the sight glass

(read the bottom of the meniscus).

6. Close the calibration door. (This now redefines the calibration factor in the pulser).

7. Empty the test measure (drain completely, 10 seconds or more) and verify accuracy as described above.

8. Seal calibration door.

Note 1: In the Liter mode, in addition to 20 liters, a 10 liter or 5 liter test measure may be used if required

by the application. However, you should check with your jurisdiction on Weights & Measures tolerance

requirements.

Note 2: For the U.S. and Canada, acceptance tolerance of ±3 cu.in. for a 5 gallon measurement and ± 50

ml for a 20 liter measurement is only required for newly installed, newly placed in service devices for 30

days. After 30 days, the tolerance is increased to ±6 cu.in. for 5 gallons and ±100 ml for 20 liters.

14

Part No. 920559 Rev H November 2008

Page 21

Dispenser

Front

(Side 1)

iMeter

(Side 2)

Meter A

Meter B

(Side 2)

Pulser Connector

located inside of

cover

XWIP

Pulser

(Blue Case)

Check Valve

Covers

Xflo Meter

Meter B

Meter A

Dispenser

Front

(Side 1)

Figure 2-7 Meter Assemblies. The WIP and the XWIP are physically the same size, but have a different

Note:If for any reason the pulser is replaced, be sure the replacement pulser’s tabs snap

into place in the meter slots before tightening the two screws securing the pulser.

November 2008 Part No. 920559 Rev H

colored case because they are not functionally interchangeable.

15

Page 22

2.10 Balance Vapor Recovery System Installation Requirements

2.10.1 Dynamic Back Pressure Testing

At initial installation, balance vapor recovery dispensers should have a dynamic back pressure test

performed at each nozzle to ensure there are no blockages in the vapor recovery system.

The dispenser should be connected to the underground and the hanging hardware (hoses, nozzles,

breakaways, etc.) should be installed.

The following test methods or equivalent methods can be used:

“ST-27 Gasoline Dispenser Facility Back Pressure.” Available from the California Bay Air

Management District via the Internet at http://www.baaqmd.gov/mop/vol4/v4index.htm

“TP201.4” Determination of Dynamic Pressure Performance of Vapor Recovery Systems of

Dispensing Facilities.” Available from the California Air Resources Board.

Maximum allowable dynamic back pressure for an individual dispenser nozzle using either test procedure is listed below:

60 cu. ft. per hr. <

80 cu. ft. per hr. <

0.35 in. of water

0.62 in. of water

Note: Very low numbers for back pressure results may indicate a leak in the system and it should

be checked.

2.10.2 Back Pressure System Check List

Note: Check test equipment for up-to-date calibration stickers. Normal use of rotameters and

pressure gauges necessitates yearly calibration; calibration is also required if this equipment has

been dropped or mishandled.

1. Check test equipment for leaks prior to use. Pressurize with nitrogen supply (plug nozzle end of

the fill pipe). Adjust nitrogen until 50% on pressure gauge is reached. Close off supply. A pressure decay must not be more than 0.2 in. of water in five minutes.

2. If facility has a vapor pod (condensate pot), drain prior to testing.

3. Open dry break poppets.

4. Completely drain hoses and nozzles prior to test. A pulsating needle indicates fluid in the lines.

Re-drain if necessary.

5. The following information should be included on the field data sheet:

• Facility address and ID

• Pump number and grade ID

• Nozzle make and model

• Back pressure in inches of water

• Nitrogen flow rate

16

Part No. 920559 Rev H November 2008

Page 23

2.10 Balance Vapor Recovery System Installation Requirements, continued

6. If back pressure readings are very low (less than .02 @ 20 CFH; 0.18 @ 60 CFH; 0.4 @ 100 CFH):

1. Check test fixture for tight seal at nozzle entry point.

2. Check bellows and face seal for tears.

3. Check vapor piping for leaks.

7. If back pressure readings are high:

1. Check hoses and nozzle bellows are completely drained.

2. Check dry break is open. (If only allowed to have one dry break open during the test, try all.)

3. Check vapor pod.

4. Check vapor impact valve to be open.

5. Check piping under dispenser. Should be a minimum of 1 inch diameter piping and fitting.

6. Check dispenser back pressure, disconnected from the underground and compare to dispenser base line

data.

7. Check hanging hardware separate from dispenser and compare to balance hardware matrix base line

data.

8. Check outlets, hose, and underground, for suspect blockage problems due to fitting bottomed out or

casting flashing. Flashing is aluminum edges left over when the casting was made. This should be your

last resort to diagnosing high back pressure readings since piping will have to be removed to look

inside the casting for flashing. A large amount of flashing would be required to affect readings.

2.10.3 Nozzles Approved for Balance System

The Ovation nozzle boot hook can be adjusted to accommodate different nozzles. Table 2-1 shows the nozzles

approved for use with a balance system and the hook position for each nozzle. Position 1 is the standard position. The hook is in position 1 in the accompanying photo. To change positions, remove the (4) screws shown,

slide the hook down to the new position, and reinstall the (4) screws to secure the hook to the boot.

Table 2-1 Nozzle and Nozzle Hook Position

NOZZLE HOOK POSITION

Emco Wheaton A4005 3

Emco Wheaton A4015 1

OPW 11VF47 4

Husky V Model 5010 and 5020 3

Husky V(short) Model 5110 and 5210 1

1/4-20

Screws (4)

November 2008 Part No. 920559 Rev H

17

Page 24

2.11 Wayne Vac Vapor Recovery System Installation Requirements

2.11.1 Dispenser Vacuum Decay

At initial installation, Wayne Vac vapor recovery dispensers should have a 27” decay test performed on

each point to ensure there are no vapor leaks in the dispenser/hanging hardware - hose, nozzle, breakaway, etc. This test is used to verify the dispenser/hanging hardware integrity so the vapor assist system

will operate at its peak performance.

The test should be performed with the proper hanging hardware installed on the dispenser and the dispenser disconnected from the underground piping.

Connect the test equipment to the discharge of the vapor piping in the dispenser and apply 27” of water

vacuum to the vapor line. Then close off the vapor line and determine if the closed vapor system can

maintain the 27” of water vacuum.

The system should hold the vacuum for one minute. If it does not, apply 10” of water pressure to the system, soaping all connections to find the leak. Use a light soap solution; a heavy soap solution could mask

leaks. If the system piping is tight, check hanging hardware by bagging the nozzles and doing a vacuum

test again, while looking for the bags to deflate. The Wayne vacuum tester, as discussed below, is also

used to test nozzles for leaks.

2.11.2 Wayne Pressure/Vacuum Tester

The Wayne Pressure/Vacuum Tester, part number 1-921168-KIT, is available from Wayne to perform this

test. The Operation manual, part number 920372 included in the kit, explains the various tests that can

performed using both vacuum and pressure.

Additional information on these tests is contained in the Compliance Testing and Preventative Maintenance manual, part number 917947, supplied with each Wayne Vac equipped dispenser.

18

Part No. 920559 Rev H November 2008

Page 25

3START-UP

3.1 Initial Checkout

Before applying power to the dispenser, double-check the wiring to make sure the wires are correctly routed

and terminated. Turn on the dispenser control power circuit breaker and the submersible pump or suction

pump motor circuit breakers. Make sure the dispenser comes on and all lights work. The dispenser displays

will show some numbers, usually the last sale run during factory test.

The dispenser template, which configures the dispenser, has been loaded in the dispenser and tested at the factory. The dispenser will have the necessary data such as unit prices and blend ratios to allow the dispenser to

operate in stand-alone at installation to purge product lines and test operation. At start-up, the procedures in

this section should be performed in sequential order to ensure proper operation before the dispenser is

switched over to control system operation.

3.2 IR Remote Control

The Infrared Remote (IR) Control shown in Figure 3-1 is similar to a television remote control. It has

16 buttons and, when held close (12-18 inches) to the infrared eye located on the sales display board, is used

to access dispenser functions and statistics. The IR remote, as discussed in the following sections, is used to

set the clock, unit prices, fueling point IDs, blend ratios, and read electronic totalizers.

Figure 3-1 IR Remote Control. Hold remote close to the sales display to set the clock, unit prices,

blend ratios and fueling point ID, read totals, view error codes and other dispenser diagnostic functions.

November 2008 Part No. 920559 Rev H

19

Page 26

3.3 Logical Nozzle/Hose Positions

The physical number of hoses on one side of the dispenser is not the same as the number of electronic hose

positions on that side. Unit prices and blend ratios are set in electronic hose position or logical nozzle order.

B23/3, B23/4 and B23/5 model Blenders each have 2 hoses per side and 3 inlets, but either 3, 4 or 5 grade

selects/logical nozzles as shown in Figures 3-2 A-C. Logical nozzles are assigned positions 1 through 7,

depending on the dispenser model as shown in Table 3-1.

Three product MGD models have one hose per side and three logical nozzles, which are positions: 1, 2, and

3. For these non-blending models, such as the R13/3, these products are shown as the X, Y, Z products in

Tab l e 3-1.

Logical nozzle positions for the Ovation models listed below are also shown in the examples in

Figures 3-2 and 3-3 on the following pages.

Table 3-1 Hose (Logical Nozzle) Positions Defined by Values of N.

Ovation Model

# begins with

B23/5 Two Hose (1+4)

B23/4 Two Hose (1+3)

B23/3 Two Hose (1+2)

B12/5 Single Hose 5 Grade

B12/4 Single Hose 4 Grade

B12/3 Single Hose 3 Grade

B12/2 Single Hose 2 Grade

R13/3 3 Grade

R22/2 2 Grade

Dispenser

Description

Blender

Blender

Blender

Blender

Blender

Blender

Blender

Non-Blender

Non-Blender

N=7 N=6 N=5 N=4 N=3 N=2 N=1

Lo

Feedstock

Lo

Feedstock

Lo

Feedstock

Lo

Feedstock

Lo

Feedstock

Lo

Feedstock

Lo

Feedstock

Lo-BL Mid-BL Hi-BL Hi

Lo-BL Hi-BL Hi

Lo-BL Hi-BL Hi

Feedstock

BL Hi

Feedstock

Hi

Feedstock

Feedstock

Feedstock

BL Hi

Feedstock

Hi

Feedstock

ZYX

Single

Grade

Single

Grade

Single

Grade

Y X

R11/1 1 Grade

Non-Blender

Model number designations are defined as follows:

B23/5 model, B = Blender, 2 = two hoses per side, 3 = three inlets, 5 = five grade selects.

R13/3 model, R = Regular piped non-blender, 1 = one hose per side, 3 = three inlets, 3 = three grade selects.

20

Part No. 920559 Rev H November 2008

X

Page 27

position

1

positions

6,5,4,3

positions

7,3

Model B23/5220D1 Model B12/2220D3

positions

7,6,5,4

position

1

positions

6,5,4

Model B23/4220D1 Model B12/4220D3

position

1

positions

6,4

positions

7,5,3

Model B23/3220D1 Model B12/3220D3

Figure 3-2 Blending Models.

21

November 2008 Part No. 920559 Rev H

Page 28

position

1

position

1

Model R11/1220D1 Model R22/2220D1

positions

1,2,3

position

2

22

Part No. 920559 Rev H November 2008

Model R13/3220D1

Figure 3-3 Non-blending Models.

Page 29

3.4 Setting the Clock

The time and date is set in function F02 Clock Configuration. The sub-functions F02.00 is the time

HH.MM, F02.01 is the date MM.DD and F02.02 is the year YY.YY.

1. Press ENTER

PA S S 1 (enter password)

2. Press ENTER

PA S S 2 (enter password)

3. Press ENTER. The unit price display will show F— (indicating it needs a function number to proceed)

4. Press 02 to access F02

5. Press ENTER. The unit price display will show F02 (indicating the function has been accessed)

6. Press ENTER to access the sub-functions of F02. The unit price display will show 2.00

3.5 Setting Unit Prices

The procedure below is used to set the dispenser unit prices when operating in stand alone mode or when

communication with the POS system is disabled. When communication with the POS system is enabled,

the system will not allow unit price setting at the dispenser.

The pump computer recognizes code stored in memory that defines a dispenser model and assigns logical

nozzle numbers to the hose positions as discussed in the previous sections. To set unit prices on side 1 and

side 2, functions F03 and F04 are accessed using the remote control interface. Credit prices on side 1 are

set using sub-functions F03.0N while cash prices are set using sub-functions F03.1N, where N is the logical nozzle number. Active values of N are given in Table 3-1. For side 2, the corresponding sub-functions

are F04.0N and F04.1N, respectively.

To set the unit price, the correct sub-function is accessed, the unit price is changed to its new value and the

data is saved. To access the desired sub-function, perform the following steps using the remote control.

Bold type denotes remote control function; italicized type denotes dispenser response.

Accessing the Unit Price Sub-function for Side 1.

1. Press ENTER

PA S S 1 (enter password)

2. Press ENTER

PA S S 2 (enter password)

3. Press ENTER. The unit price display will show F— (indicating it needs a function number to proceed)

4. Press 03 to access F03

5. Press ENTER. The unit price display will show F03 (indicating the function has been accessed)

6. Press ENTER to access the sub-functions of F03. The unit price display will show 3.01

At this point, pressing of NEXT will advance the sub-function to the next sub-function, incrementing the

value of N by (.01). For example, to access F3.02, press NEXT. The unit price display will show 3.02,

press NEXT. The desired sub-function depends on the dispenser type. Table 3-1 shows the values of N

that define the desired sub-functions for the dispenser models shown. Once the desired sub-function is

accessed, the price display will

show “– – – – – –“ and the volume display will show the current value of the unit price. The following procedure must then be followed to set the unit price.

November 2008 Part No. 920559 Rev H

23

Page 30

3.5 Setting Unit Prices, continued

Changing the Value of the Unit Price

Type in the new unit price with at least three digits for three money display digits to be shown after the

decimal point. For example, to set the new unit price to $1.50, type in 1500. Type in 1509 for $1.509

unit price.

1. Press # key. The volume display will show the unit price with the correct number of digits after the

decimal point. Again, for the example above, the volume display will show 1.500.

2. Press NEXT to input the next unit price, and repeat steps 1 and 2. Continue until all the unit prices

are input. Note that while inputting the unit prices, the unit price display continues to show the

sub-function and not the unit price itself.

Save the New Unit Prices as follows:

1. Press ENTER. The price display will show “– – – – – –“, the volume display will be blank and

the unit price display will show the last sub-function accessed.

2. Press 00 (to access F00)

3. Press ENTER. The unit price should now display F00, the price display will show “– – – – – –“

and the volume display will be blank.

4. Press ENTER and the volume display will show a 1.

5. Press UP twice to change the value in the volume display from 1 to 3

6. Press ENTER. The volume display should show a 3.

7. Press ENTER. CHANGE STORED should appear on the display momentarily. The display

should return to normal in a few seconds. When it does, the unit price displays should show the

new prices. If they do not show the desired unit prices, access the appropriate sub-function to

make sure that the unit price data is correct.

24

Part No. 920559 Rev H November 2008

Page 31

3.6 Setting Blend Ratios

The procedure below is used to set the dispenser blend ratios. When enabled, the POS system verifies and

confirms that its blend ratio data corresponds to the manually set blend ratios. The Wayne POS system will

not allow fuel to be dispensed if these numbers do not match.

The pump computer recognizes code stored in memory that defines a dispenser model and assigns logical

nozzle numbers to the hose positions as explained in Section 3.3. Once this is done, the function F18 is

accessed to set the blend ratios, using the remote control interface. The sub-function F18.1N, where N is the

logical nozzle number, is used to set the blend ratios for side 1 and the sub-function F18.2N is used to set

the blend ratios for side 2. Active values of N are given in Table 3-1.

To set the blend ratio, the correct sub-function is accessed, the blend ratio is changed to its new value and

the data is saved. To access the desired sub-function, the following steps must be performed using the

remote control (Bold type denote remote control function and italicized type represents dispenser response):

NOTE: BLEND RATIOS MUST BE SET FOR SIDE 1 AND AGAIN FOR SIDE 2.

To access the Blend Ratio sub-function:

1. Press ENTER

PASS 1 (enter password)

2. Press ENTER

PA SS 2 (enter password)

3. Press ENTER. The unit price display will show F— (indicating that it needs a function number to proceed)

4. Press 18 to access F18

5. Press ENTER. The unit price display will show F18 (indicating that the function has been accessed)

6. Press ENTER to access the sub-functions of F18. The unit price display will show 18.11 (here N=1)

The volume display will indicate the value of the blend ratio corresponding to logical nozzle #1(N=1). If

there is no data for this logical nozzle, the number “101” will be displayed. This applies to all logical nozzles. To access the blend ratio for the next logical nozzle, press NEXT. The unit price display will show

18.12 and the volume display will show whatever the value of the blend ratio is for logical nozzle #2. Suc-

cessive presses of NEXT will advance the unit price display to 18.17, the last logical nozzle. Pressing

NEXT again will advance the unit price display to 18.21

, The “2” in “18.21” indicates Side 2 and the “1”,

logical nozzle #1. The volume display will show the blend ratio assigned to logical nozzle #1 of Side 2.

Changing the Value of the Blend Ratio

1. When the desired logical nozzle is shown on the unit price display, enter the desired value of the blend

ratio by using UP and DOWN keys on the remote control interface or by typing the # sign followed by

the value of the blend ratio, followed by ENTER. For example, to change the value of the blend ratio

from 101 to 89, press the DOWN button until 89 shows up on the price display, then press ENTER, or

type in #89, ENTER.

2. Continue until all the blend ratios are entered for side 1.

3. Repeat for side 2 and save as follows:

November 2008 Part No. 920559 Rev H

25

Page 32

3.6 Blend Ratio Setting, continued

Saving the New Blend Ratio

1. Press ENTER. The price display will show “– – – – – –“, the volume display will be blank and the unit

price display will show the last sub-function accessed.

2. Press 00 (to access F00)

3. Press ENTER. The unit price should now display F00, the price display will show “– – – – – –“

and the volume display will be blank.

4. Press ENTER and the volume display will show a 1.

5. Press UP twice to change the value in the volume display from 1 to 3.

6. Press ENTER. The volume display should show a 3.

7. Press ENTER. CHANGE STORED should appear on the display momentarily. The display should

return to normal in a few seconds. When it does, the unit price displays should show the new prices. If

they do not show the desired unit prices, access the appropriate sub-function to make sure that the unit

price data is correct.

For reference, the following is a 50% blend ratio setting for a single hose blender, Ovation model B12/3 xxxx,

as listed in Table 3-1. Any unused position has to be set to 101 not 0.

Side 1 Side 2

18.11 = 101 18.21 = 101

18.12 = 101 18.22 = 101

18.13 = 100 Super (Hi Feedstock) 18.23 = 100

18.14 = 101 18.24 = 101

18.15 = 50 Plus (Blend BL) 18.25 = 50

18.16 = 101 18.26 = 101

18.17 = 0 Regular(Lo Feedstock) 18.27 = 0

Typically, stations sell the low and high grades at zero and 100 percent ratios and may sell the middle grade

at 35 percent or some other intermediate value between 0 and 100. On the above model, the technician

would need to change only sub-functions 18.15 and 18.25 to the intermediate value.

As a reminder, always get the blend ratios from the station owner to avoid any confusion over which values

to use.

26

Part No. 920559 Rev H November 2008

Page 33

3.7 Setting the Fueling Point ID

The procedure below is used to set the pump fueling point address. The pump FPID should be input and

saved before control is transferred to the POS system.

Functions F05 and F06 are accessed to set the FPID on Side 1 and Side 2, respectively. To set the FPID, the

desired FPID must be input and saved.

Accessing the FPID Function.

1. Press ENTER

PASS 1 (enter password)

2. Press ENTER

PASS 2 (enter password)

3. Press ENTER. The unit price display will show F— (indicating that it needs a function number to proceed)

4. Press 05 to access F05

5. Press ENTER. The unit price display will show F05 indicating the function has been accessed and the

volume display will show the current FPID or a “0” when no FPID has been assigned to that dispenser

side.

6. Input the desired FPID by using the UP and DOWN keys on the remote control interface followed by

ENTER, or by typing the # sign followed by the valve of the FPID followed by ENTER.

7. Repeat the procedure for Side 2.

Saving the New FPID

1. Press ENTER. The price display will show “– – – – – –“, the volume display will be blank and the unit

price display will show the last sub-function accessed.

2. Press 00 (to access F00)

3. Press ENTER. The unit price should now display F00, the price display will show “– – – – – –“and the

volume display will be blank.

4. Press ENTER and the volume display will show a 1.

5. Press UP twice to change the value in the volume display from 1 to 3.

6. Press ENTER

7. The volume display should show a 3.

8. Press ENTER. CHANGE STORED should appear on the display momentarily. The display should return

to normal in a few seconds. When it does, the unit price displays should show the new prices. If they do

not show the desired unit prices, access the appropriate sub-function to make sure that the unit price data

is correct.

8. Repeat the procedure for Side 2.

Note: For models equipped with IDPOS, see configration in Section 4.

November 2008 Part No. 920559 Rev H

27

Page 34

3.8 Authorizing the dispenser

The dispenser must be authorized before it will dispense product.

The dispenser filling mode is set in programming function F01. In stand-alone mode (not connected to a

control system), the dispenser is always authorized, unless the dispenser is equipped with the (optional)

Authorize keyswitch on the bezel. This momentary contact keyswitch can be used for one time

authorizations.

When connected to a control system, the system programming determines authorization.

NOTE: At Startup, the local Authorize switch jumper should be removed as explained in Section 3.10.

3.9 Initial Delivery

To dispense product from a newly installed dispenser, make sure unit prices and blend ratios are set (as previously described) and proceed as follows:

1. Authorize the dispenser.

2. Remove the nozzle, start the reset sequence and observe the reset cycle; make sure all sales display and

unit price display elements operate.

3. Check that when reset is started, the correct submersible pump motor is activated, and at the end of the

display reset (approximately three seconds) the solenoid valve(s) opens (listen for the audible click of

the valve(s).

NOTE: Make sure the product lines are properly bled before dispensing any product through a

remote dispenser. Make sure suction pumps are primed before dispensing any product

through a suction pump.

4. After verifying air is bled properly from each trunk line, slowly dispense product through each dispenser until free of air. Dispense enough product through each hose of each dispenser to ensure the dispenser and the lines are free of air, before checking the meters.

5. For dispensers equipped with Wayne Vac, verify that the correct vacuum pump motor is running when

dispensing product. Verify by checking that air is being drawn through the vapor return hole(s) in each

nozzle spout. Also, see Testing Procedures manual, p/n 917947.

3.10 Disable Stand-alone Operation

Once the dispenser is switched over to the POS control system, standalone operation should not be

required. As an extra security measure, the jumper that enables stand-alone operation should be removed.

The jumper is located on the unit price display board as shown in Appendix C of this manual.

1. Access dispenser Filling Mode function F01 and set sub-function to 1.01 for serial mode.

2. Open the service door.

3. See Appendix C for location of the Local Authorize jumper (J7) on the Unit Price Display board.

4. Remove the J7 jumper.

5. Close and lock service door.

28

Part No. 920559 Rev H November 2008

Page 35

3.11 Electronic Totalizer Readings

3.11.1 Totalizer Readings by Hose (Product) Position

Each fueling point of the dispenser maintains electronic totalizers for both money and volume. Dispensers equipped for Cash/Credit operation also keep separate cash and credit totalizers by grade. Rather than

mechanical totalizers, each position has an electro-mechanical totalizer for each feedstock. See Figure 24 for EMT locations.

Electronic totals are stored in statistical functions that are accessed using the IR remote control. The

totals for Side 1 are stored in statistical function S01 and those for Side 2 are stored in statistical function

S02. The associated sub-functions take the format TN, where T is the type of totals defined below and

nozzle postion N depends on the dispenser model as defined in Table 3-1.

T= totals type: 1=Volume

2=Total Money

3=Credit

4=Cash

5=Serial Filling Mode Count

6=Stand Alone Mode Filling Count

For example, volume totals by hose position for Side 1 are accessed by examining the contents of statistical function S01.1N while money totals are obtained by accessing S01.2N, where N is the hose position

number. For Side 2, the corresponding functions for these variables are S02.1N and S02.2N, respectively.

To read the electronic totalizers, perform the following steps using the IR remote. Bold type denote

remote control function; italicized type represents dispenser response:

Accessing the Totalizer Sub-function.

1. Press ENTER

PA S S 1 (enter password)

2. Press ENTER

PA S S 2 (enter password)

3. Press ENTER. The unit price display will show F

4. Press either UP or DOWN to enter the statistics viewing mode. The unit price display will show S—

(indicating a number needs to be selected)

5. Press 01 to access S01

6. Press ENTER. The unit price display will show S01 indicating the function has been accessed.

7. Press ENTER to access the sub-functions of S01. The unit price display will show 1.11 and the sales

display shows the side 1, volume for nozzle position 1.

Consecutive presses of NEXT will advance to the next sub-function, incrementing the value of N by

(.01). For example, pressing NEXT advances the statistical function to S01.12 and the unit price display

will show 1.12. The least significant six (6) digits of the data value appear on the volume display, while

higher order non-zero digits of the data value, if present, appear on the money display.

November 2008 Part No. 920559 Rev H

29

Page 36

3.11.2 Totalizer Volume Readings by Meter Position

Meter volume totals are stored in statistical functions that are accessed using the remote control interface. The totals for Side 1 are stored in function S05 and those for Side 2 are stored in function S06. The

value of the meter totals are stored in the sub-functions that take the format .M0, where M is the meter