Page 1

Operating Instructions And Parts Manual

Instructions d’Utilisation et Manuel de Pièces

Manual de Instrucciones de Operación y Piezas

CDUCAP Series

2 0- S p

Notes / Notas

Description

The submersible pump is designed for

indoor home sump applications. The

unit is equipped with a 3-prong

grounding type power cord. Motor is

oil filled and sealed for cooler running

and designed to operate under water.

This pump is not suitable for aquatic

life.

This sump pump is provided with

Switch Genius™ Technology to control

the water level. When water is

detected, the pump will start

automatically.

U n p a c k i n g

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return the

unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

I m p o rta nt Safety

I n s t r u c t i o n s

READ AND FOLLOW ALL

I N S T R U C T I O N S .

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols:

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Operating Instruction and Parts Manual CDUCAP Series

352401-001 12/08

Caution indicates

a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

General Safety

I n f o r m a t i o n

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals, including lead,

known to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

S u b m e r s i b l e

Sump Pump

© 2008 Wayne Water Systems

S p e c i f i c a t i o n s

Power supply requirements 120V, 60 hz

M o t o r Single phase, oil filled

Horsepower/Amp Ratings 1 / 3 HP/9.5 A ( C D U C A P 7 2 5 )

1 / 2 HP/10 A ( C D U C A P 8 5 0 )

3/4 HP/10 A ( C D U C A P 9 9 5 )

1 HP/10 A ( C D U C A P 1 0 0 0 )

Liquid temperature range 40°F to 120°F

Circuit requirements 15 amps (min)

D i m e n s i o n s 11-1/2 inch high x 9-3/4 inch base

Cut-in level (factory set) 8 inch

Cut-out level (factory set) Approx. 3inch

C o n s t ru c t i o n

Motor housing Cold rolled steel, Stainless steel (CDUCAP995)

V o l u t e Cast iron

I m p e l l e r Glass reinforced thermoplastic

S h a f t Low carbon steel

S e a l s Buna N

D i s c h a r g e 1-1/2 inch NPT

Motor Cover Glass reinforced thermoplastic

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

For parts, product & service information

visit www.waynepumps.com

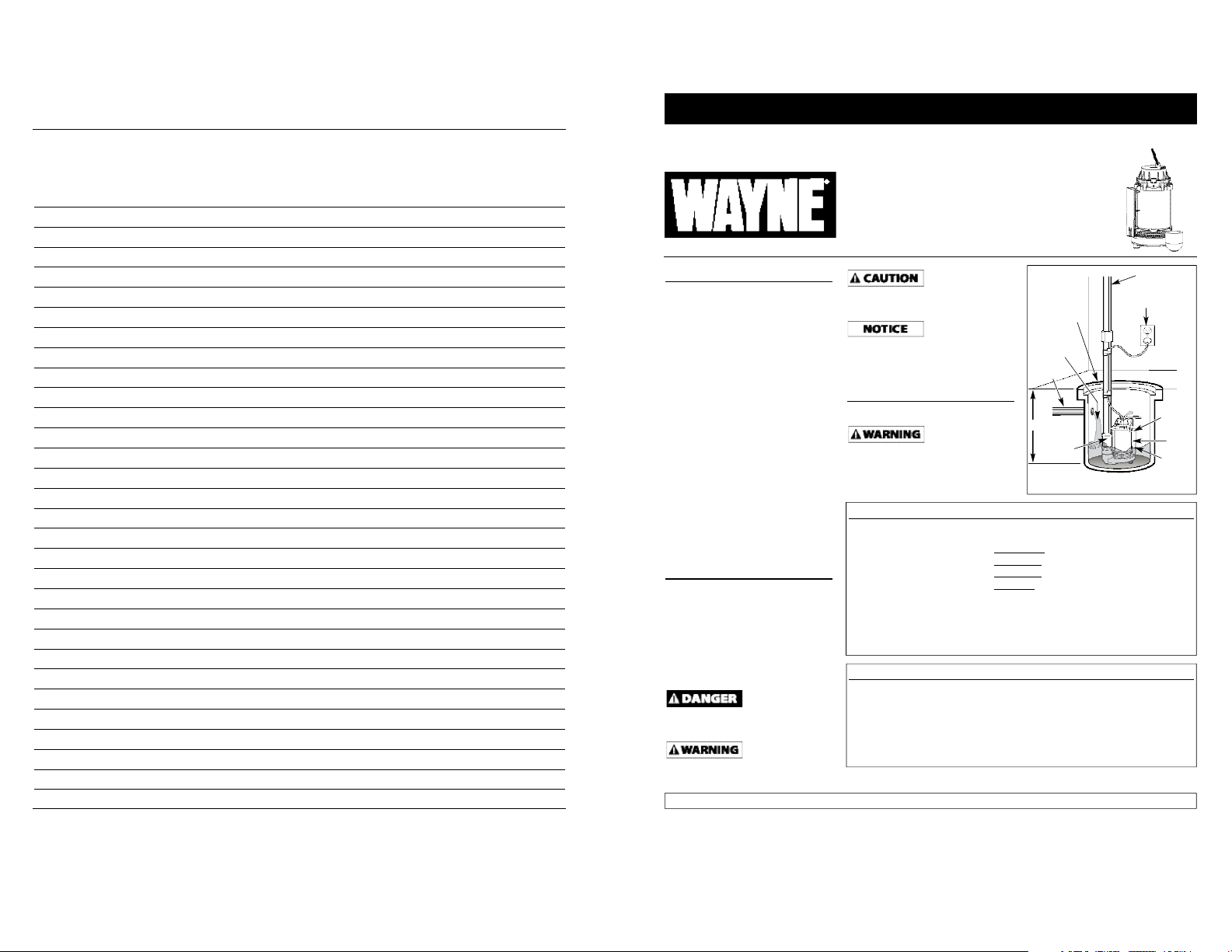

Figure 1 - Typical Installation

Discharge

Pipe

GFCI

Protected

Outlet

On @ 8

inches

Switch

Off @

approx.

3 inches

11 inch

Diameter

Minimum

Incoming

Water

Inlet Pipe

Check

Valve

13 inch min.

Page 2

Garantía Limitada

Durante cinco (5) años a partir de la fecha de compra (Modelos CDUCAP725 y CDUCAP850) y garantía de por

vida (Modelos CDUCAP995 y CDUCAP1000), Wayne Water Systems reparará o reemplazará, según lo decida,

para el comprador original, cualquier pieza o piezas de sus Bombas para cloacas o Bombas de agua

(“Producto”) que después de un examen sea(n) hallada(s) por Wayne Water Systems como defectuosa(s) en su

material o mano de obra. Para recibir información sobre los pasos a seguir, comuníquese directamente con la

compañía Wayne Water Systems (1-800-237-0987, sólo desde EE.UU.), o con el distribuidor autorizado más

cercano a su domicilio. En el momento de reclamar sus derechos bajo esta garantía deberá suministrarnos el

número del modelo. Todos los gastos de flete serán la responsabilidad del comprador.

Esta garantía limitada no cubre los daños debido a accidentes, abusos, uso inadecuado, negligencia,

instalación inadecuada, mantenimiento inadecuado, o funcionamiento sin seguir las instrucciones

suministradas por escrito por la compañía Wayne Water Systems.

NO EXISTE OTRA GARANTÍA EXPRESA. LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO AQUELLAS DE

COMERCIALIZACIÓN Y APTITUD PARA UN PROPÓSITO EN PARTICULAR, ESTÁN LIMITADAS A 5 (cinco)

años (MODELOS CDUCAP725 y CDUCAP850) Y GARANTÍA DE POR VIDA (MODELOS CDUCAP995 y

CDUCAP1000) A PARTIR DE LA FECHA DE COMPRA. ESTA ES LA UNICA GARANTIA Y CUALQUIER

PERDIDA O RESPONSABILIDAD CIVIL, SEA DIRECTA O INDIRECTA COMO CONSECUENCIA DE DAÑOS

SON EXCLUIDAS.

Algunos estados no permiten límites en la duración de las garantías, o no permiten que se limiten o excluyan

casos por daños por accidentes o consecuentes, en dichos casos los límites arriba enumerados tal vez no

apliquen para Ud. Esta garantía limitada le otorga a Ud. ciertos derechos que pueden variar de un estado a

otro.

Bajo ninguna circunstyancia, aunque sea debido al incumplimiento del contrato de garantía, culpabilidad (incluyendo negligencia) u otras causas,la compañía Wayne Water Systems o ninguno de sus surtidores serán

responsables legalmente por ningún fallo legal en su contra, incluyendo, pero no limitado apérdida de

ganancias, pérdidas del uso del producto o piezas asociadas con el equipo, pérdidas de capital, gastos para

reemplazar los productos dañados, pérdidas por cierre de fábrica, servicios o pérdida de electricidad, o

demandas persentadas por los clientes del comprador por dichos daños.

Ud. DEBE conservar el recibo como prueba de compra junto con esta garantía. En caso de que necesite

presentar un reclamo de sus derechos bajo esta garantía, Ud DEBERA enviar una copia del recibo de la

tienda junto con el producto o correspondencia. Comuníquese con la compañía Wayne Water Systems (1-800237-0987, sólo desde EE.UU) para recibir autorización e instrucciones de como enviar la mercancía.

NO ENVIE ESTOS DATOS A WAYNE WATER SYSTEMS. Conserve esto sólo como datos.

MODEL NO ____________________

NO. DE SERIE . ____________________

FECHA DE INSTALACION ____________________

GRAPE SU RECIBO DE COMPRA AQUI

3 . Thread check valve (not included)

into pump body carefully to avoid

stripping or cross threading. Do not

use pipe joint sealant.

4 . Connect 1-1/4” (minimum) rigid pipe

to check valve.

Support pump

and piping when

assembling and after installation.

Failure to do so could cause piping to

break, pump to fail, etc. which could

result in property damage and/or

personal injury.

5 . Protect electrical cord from sharp

object, hot surfaces, oil and chemicals.

Avoid kinking the cord and replace

damaged cords immediately.

6. Position Pump switch AWAY from

the inlet so switch is clear from

incoming water (See Figure 1).

7. A sump pit cover must be installed

to prevent debris from clogging or

damaging the pump.

O p e r a t i o n

Always

disconnect the power source

before attempting to install,

service, relocate or maintain

the pump. Never touch sump

pump, pump motor, water or discharge

piping when pump is connected to

electrical power. Never handle a pump

or pump motor with wet hands or when

standing on wet or damp surface or in

water. Fatal electrical shock could occur.

1 . A ground fault circuit interrupter

(GFCI) is required.

Risk of electrical

shock! This pump is

supplied with a grounding conductor

and grounding type attachment plug.

Use a grounded receptacle to reduce

the risk of fatal electrical shock.

Never cut off the round grounding

prong. Cutting the cord or plug will

void the warranty and make the pump

inoperable.

2 . This pump is only for use on 120 Volt

(single-phase), 60 hz, 15 amp service

and is equipped with a 3-conductor

cord and 3-prong, grounding type

plug. Insert the switch cord plug

directly into a 120 volt outlet.

General Safety

I n f o rmation (Cont.)

G E N E R A L

Do not

use to

pump flammable or explosive

fluids such as gasoline, fuel

oil, kerosene, etc. Do not use

in a flammable and/or explosive

atmosphere. Pump should only be used

to pump clear water. Personal injury

and/or property damage could result.

This pump is not

designed to handle

salt water, brine, laundry discharge or

any other application which may

contain caustic chemicals and/or

foreign materials. Pump damage could

occur if used in these applications and

will void warranty.

All wiring must be

performed by a

qualified electrician.

If the

basement

has water or moisture on the

floor, do not walk on wet

area until all power is turned

off. If the shutoff box is in

the basement, call an

electrician. Remove pump and either

repair or replace. Failure to follow this

warning could result in fatal electrical

shock.

A backupsystem

should be used.

Call 1-800-237-0987 for backup model

number.

Installation

1 . Install pump in a sump pit with

minimum size as shown in Figure 1.

Construct sump pit of tile, concrete,

steel or plastic.

2 . The unit should be located and rest

on a solid, level foundation. Do not

place pump directly on clay, earth,

gravel or sandy surface. These

surfaces contain small stones, gravel,

sand, etc. that may clog or damage

the pump and cause pump failure.

Flood risk. If

flexible discharge

hose is used, make sure pump is

secured in sump pit to prevent

movement. Failure to secure pump

could allow pump movement and

switch interference and prevent pump

from starting or stopping.

1 9- S p

2

Operating Instructions And Parts Manual

CDUCAP Series

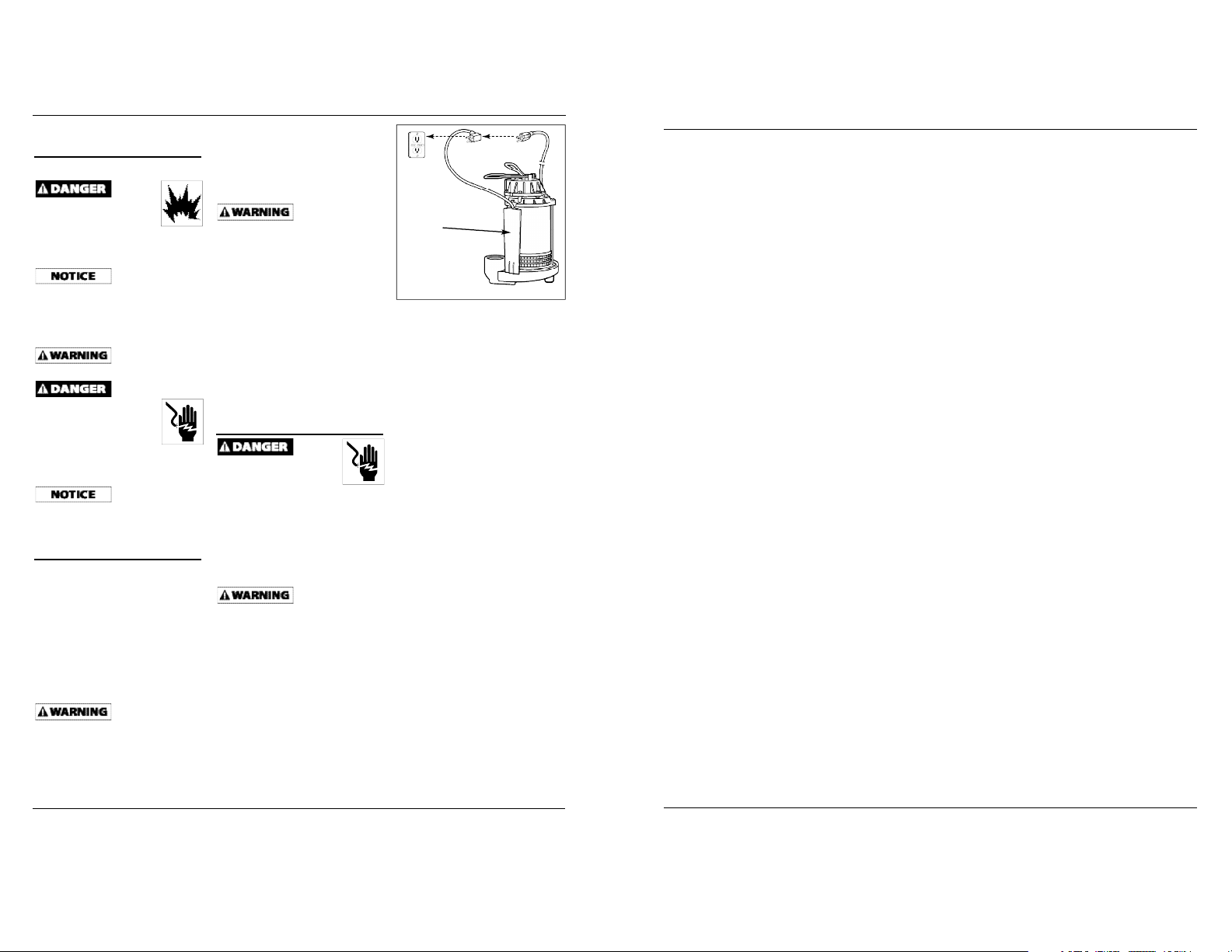

3 . Insert the pump power cord plug

directly into the back of the water

sensor cord plug (Figure 2).

4 . Fill sump with water. The pump will

start automatically when the water is

about 1.5” from the top of the

switch. The pump will recycle

thereafter as required.

• Sump pump will run a minimum of

4 seconds, to a maximum of 16

before stopping.

• Sump pump run time will be

determined by the sump pit size

and water flow rate into the sump

p i t .

• Under flooding conditions, the

sump pump will stop for 1 second,

every 16 seconds, and

automatically turn back on.

5 . Do not operate the pump unless it is

submerged in water. Dry running

causes pump failure.

6 . The motor is equipped with an

automatic reset thermal protector.

7 . While the pump is draining the pit,

verify that the discharge piping is

carrying the water to a point several

feet away from the foundation.

8 . If pump discharge line is exposed to

freezing temperature, the exposed

line must be pitched to drain.

Trapped water will freeze and

damage the pump.

w w w .waynepumps. c o m

Figure 2 – Switch Genius™ Water Sensor

Working surface of

sensor to be kept

free of foreign

material.

Page 3

1 8- S p

Manual de Instrucciones de Operación y Piezas

N o t a s

2 . Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required,

see troubleshooting chart.

3 . Inlet should be kept clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

4 . Pump should be checked monthly

for proper operation. Pump can be

checked for proper operation by

briefly removing pump power cord

from the back of the water sensor

plug and inserting directly into the

M a i n t e n a n c e

Always disconnect

the electrical supply

before attempting to install, service,

relocate or perform any maintenance.

If the power source is out of sight, lock

and tag in the open (off) position to

prevent unexpected power application.

Failure to do so could result in fatal

electrical shock. Only qualified

electricians should repair this unit.

Improper repair could result in fatal

electrical shock.

1 . Let the pump cool for a minimum of

two hours before servicing because

the pump contains hot oil under

pressure and the motor is hot.

3

CDUCAP Series

grounded outlet. In this condition,

the pump will run continuously.

Once pump operation is verified,

replace pump power cord into the

back of the water sensor plug (see

Figure 2).

5 . Wipe water sensor surface regularly

to prevent silt or other coatings

from building up on sensor face

(see Figure 2).

This pump contains

dielectric oil for

cooling. This oil can be harmful to the

environment. Check the state

environmental laws before disposing

this oil.

w w w .waynepumps. c o m

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start or

run

Pump starts and stops

too often

Pump will not shut

off or thermal

protector turns off

Pump operates but

delivers little or no

water

Gurgling sound from

pump at end of cycle

1. Blown fuse

2. Low line voltage

3. Defective motor

4. Impeller

1. Backflow of water from

piping

2. Incoming water is draining

on sensor face

1. Obstacle in piping

2. Low Line Voltage

3. Too many appliances on

circuit

4. Dirty water sensor

5. Incoming water is draining

on sensor face

1. Plugged impeller

2. Check valve installed

backwards

3. Pump airlocked

1. Air injested into pump

2. Time required for

pumping is less than 4

seconds

1. If blown, replace with proper sized fuse or reset breaker

2. If voltage is under 108 volts, check wiring size

3. Replace pump

4. If impeller will not turn, remove housing and remove

blockage

1. Install or replace check valve

2. Position pump switch away from the inlet so switch is clear

from incoming water (see Figure 1)

1. Remove pump and clean pump and piping

2. If voltage is under 108 volts, check wiring size

3. Install pump on dedicated circuit. IMPORTANT: Do not use

extension cord to power pump.

4. Clean sensor face (see Figure 2)

5. Position pump switch away from the inlet so switch is clear

from incoming water (see Figure 1)

1. Clean out impeller

2. Reverse position of check valve

3. Drill 1/8” hole in discharge line between pump and check

valve

1. Wipe off surface of sensor (see Figure 2)

2. Additional run time will not damage pump

Page 4

1 7- S p

CDUCAP Series

Guía de Diagnóstico de Av e r í a s

Problema Posible(s) Causa(s) Acción a Tomar

La bomba no

enciende o no

funciona

La bomba se inicia

y se detiene con

demasiada frecuencia

La bomba no se

apaga o el protector

térmico se dispara

La bomba funciona

pero sale muy poca

agua o nada

La bomba emite un

ruido de borboteo

al final del ciclo

1. Fusible quemado

2. Bajo voltaje

3. Motor defectuoso

4. Impulsor

1. Reflujo de agua desde la

tubería

2. La entrada de agua drena

en la superficie del sensor

1. Obstrucción en la tubería

2. Bajo voltaje

3. Demasiados

electrodomésticos sobre el

circuito eléctrico

4. Sensor de agua sucia

5. La entrada de agua drena

en la superficie del sensor

1. Impulsor atascado

2. Válvula de retención

instalada al revés

3. Aire en la bomba

1. La bomba ha aspirado aire

2. El tiempo requerido para

bombear es menos de

4 segundos

1. Si está quemado, cámbielo por un fusible del tamaño correcto

o reajuste el disyuntor

2. Si el voltaje está por debajo de 108 voltios, verifique el

tamaño del cable

3. Reemplace la bomba

4. Si el impulsor no funciona, retire la caja y quite la obstrucción

1. Instale o cambie la válvula de retención

2. RPosicione la bomba LEJOS de la entrada de agua de manera

que el interruptor no quede cerca de la entrada de agua

(ver Figura 1).

1. Retire la bomba y limpie la bomba y la tubería

2. Si el voltaje está por debajo de 108 voltios, verifique el

tamaño del cable

3. Instale la bomba en un circuito dedicado.

IMPORTANTE: NO use un cordón eléctrico de extensión

para alimentar la bomba.

4. Limpie la superficie del sensor (ver Figura 2)

5. Posicione la bomba lejos de la entrada de agua de manera

que el interruptor no quede cerca de la entrada de agua

(ver Figura 1).

1. Limpie el impulsor

2. Invierta la posición de la válvula de retención

3. Taladre un orificio de 1/8" (3 mm) en la tubería de descarga

entre la bomba y la válvula de retención

1. Limpie la superficie del sensor (ver Figura 2).

2. El tiempo de funcionamiento adicional no daña la bomba

4

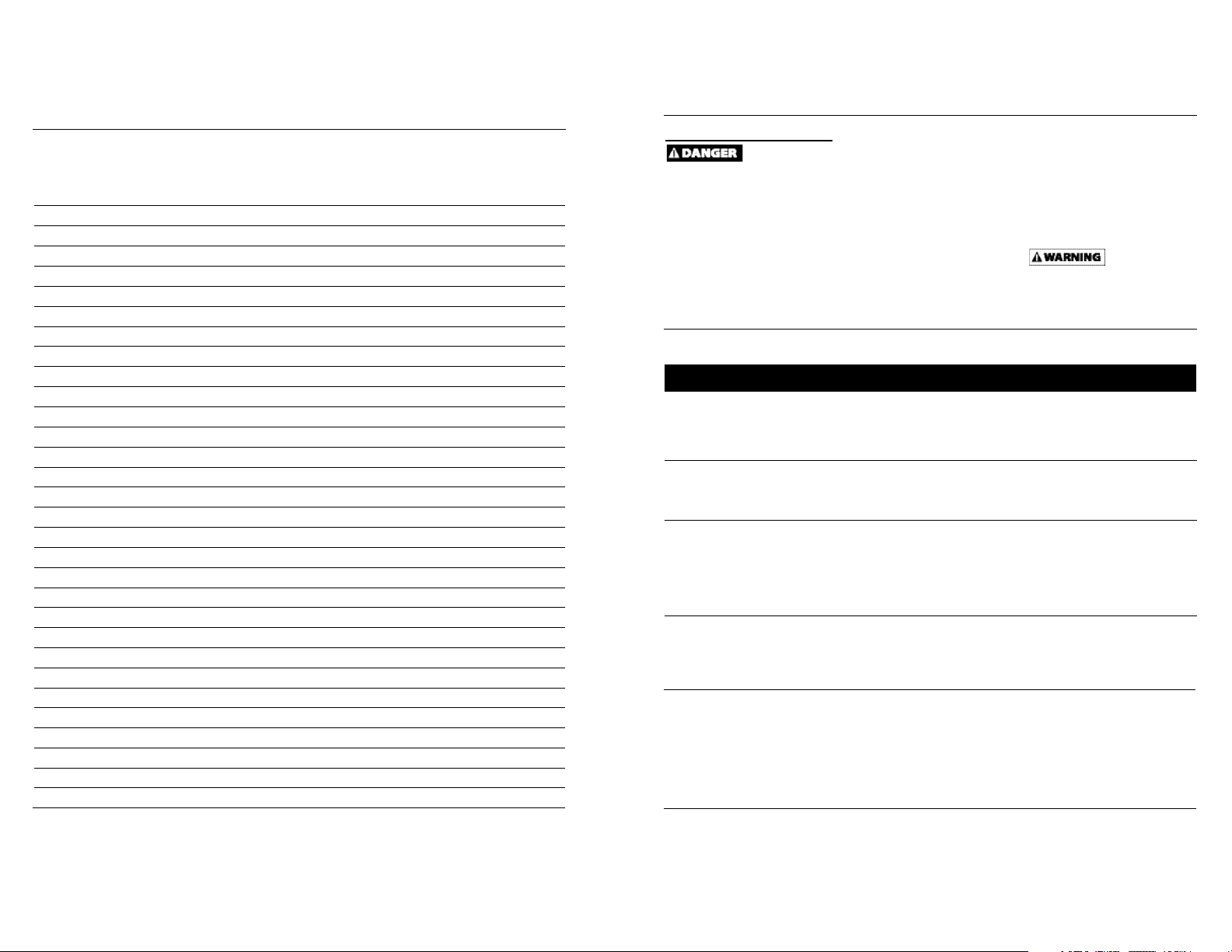

Operating Instructions And Parts Manual

For Replacement Parts, call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

w w w .waynepumps. c o m

1

2

3

4

5

6

7

Replacement Parts List

1 Top cover kit 60030-001

2 Stator —

3 Lower bracket/rotor assembly —

4 Impeller plate 15958

5 Impeller 60001-001

6 Volute 60039-001

7 Switch Genius™ Water Sensor 30037-001

R e f .

N o . D e s c r i p t i o n CDUCAP Series

Page 5

Para Piezas de Repuestos, Llame al 1-800-237-0987

Sírvase proporcionar la suguiente información:

- Número de modelo

- Número de serie (si tiene)

- Descripción y número de repuesto como se muestra en la lista de repuestos

Envíe su solicitud de repuestos a la siguiente dirección:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

1

2

3

4

5

6

7

1 Juego de cubierta superior 60030-001

2 Stator —

3 Ensamble del rotor/abrazadera inferior —

4 Placa del impulsor 15958

5 I m p u l s o r 60001-001

6 Caja espiral 60039-001

7 Sensor de agua Switch Genius™ 30037-001

Lista de Repuestos

No. de

R e f . D e s c r i p c i ó n CDUCAP Series

CDUCAP Series

5

1 6- S p

Manual de Instrucciones de Operación y Piezas

w w w .waynepumps. c o m

N o t e s

Page 6

F u n c i o n a m i e n t o

( C o n t i n u a c i ó n )

• Bajo condiciones de inundación, la

bomba se apaga por 1 segundo

cada 16 segundos y vuelve a

encenderse automáticamente.

5 . No ponga la bomba en

funcionamiento a menos que

e s t é sumergida en agua.

E l funcionamiento en seco causa

daños a la bomba.

6 . El motor está equipado con un

protector térmico de reposición

automática.

7 . Mientras la bomba esté drenando

e l pozo, verifique que la tubería de

descarga esté llevando el agua hacia

un punto bastante alejado de la

c i m e n t a c i ó n .

8 . Si la tubería de descarga de la

bomba queda expuesta a

temperaturas de congelamiento,

l a tubería expuesta debe inclinarse

para que drene. El agua que esté

dentro de la bomba puede

congelarse y dañar la bomba.

M a n t e n i m i e n t o

Siempre

desconecte la

fuente de electricidad antes de intentar

instalar, efectuar un servicio, reubicar o

realizar cualquier tipo de

mantenimiento. Si la fuente de energía

está fuera de la vista, tránquela y

etiquétela en la posición abierta (off)

para evitar que se aplique corriente en

forma inesperada. Si no lo hace puede

provocar un choque eléctrico mortal.

Esta unidad debe ser reparada

únicamente por electricistas calificados.

La reparación incorrecta podría provocar

un choque eléctrico mortal.

1 . Deje que la bomba se enfríe por no

menos de dos horas antes de dar

servicio puesto que la bomba

contiene aceite caliente bajo presión

y el motor está caliente.

2 . Desensamblar el motor antes del

vencimiento de la garantía anulará

la misma. Si se necesitan

reparaciones, vea la tabla de

solución de problemas.

3 . La entrada de agua debe

mantenerse limpia y libre de

cualquier objeto extraño y debe

inspeccionarse anualmente. Si se

atasca la entrada la bomba se daña.

4 . Es necesario verificar

mensualmente el funcionamiento

correcto de la bomba. Es posible

verificar que la bomba funcione

correctamente desconectando

brevemente el cordón de

alimentación de la bomba de la

parte de atrás del sensor de agua

y enchufándolo directamente en el

tomacorriente conectado a tierra.

Bajo estas condiciones, la bomba

trabaja en forma continua. Una vez

comprobado el funcionamiento de

la bomba, vuelva a enchufar el

cordón de alimentación de la

bomba en la parte de atrás del

enchufe del sensor de agua

( v e r Figura 2).

5 . Limpie regularmente la superficie

del sensor de agua para impedir

que depósitos de sedimento u otros

materiales se acumulen en la

superficie del sensor (ver Figura 2).

Esta bomba

contiene aceite

dieléctrico para su enfriamiento. Este

aceite puede ser dañino para el medio

ambiente. Verifique las leyes

ambientales de su estado antes de

desechar este aceite.

1 5- S p

CDUCAP Series

Operating Instructions And Parts Manual

6

w w w .waynepumps. c o m

Limited Warranty

For five (5) years (Models CDUCAP725 and CDUCAP850) and lifetime warranty (Models CDUCAP995 and

CDUCAP1000) from the date of purchase, Wayne Water Systems will repair or replace, at its option, for the

original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination

by Wayne Water Systems to be defective in materials or workmanship. Please call Wayne Water Systems (1800-237-0987) for instructions or see your dealer. Be prepared to provide the model number when exercising

this warranty. All transportation charges on Products or parts submitted for repair or replacement must be

paid by purchaser.

This Limited Warranty does NOT cover Products which have been damaged as a result of accident, abuse,

misuse, neglect, improper installation, improper maintenance, or failure to operate in accordance with Wayne

Water Systems’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO FIVE (5) YEARS

(CDUCAP725 and CDUCAP850) AND LIFETIME WARRANTY (MODELS CDUCAP995 and CDUCAP1000)

FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND

ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or

limitations of incidental or consequential damages, so the above limitations might not apply to you. This

limited warranty gives you specific legal rights, and you may also have other legal rights which vary from state

to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall

Wayne Water Systems or its suppliers be liable for any special, consequential, incidental or penal damages

including, but not limited to loss of profit or revenues, loss of use of the products or any associated

equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities, services or

replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty

claim, you MUST send a copy of the purchase receipt along with the material or correspondence. Please call

Wayne Water Systems (1-800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE WATER SYSTEMS. Use this form only to maintain your records.

MODEL NO. ____________________

SERIAL NO. ____________________

INSTALLATION DATE ____________________

ATTACH YOUR RECEIPT HERE

Page 7

I n f o rm a c i o n e s

Generales de

S e g u r i d a d

PROPOSICIÓN 65 DE CALIFORNIA

Este producto o su

cable de corriente

pueden contener químicos, incluido

plomo, que es conocido por el Estado

de California como causante de cáncer y

defectos de nacimiento u otros daños

reproductivos. Lávese las manos

después de manipularlo.

G E N E R A L

Evite

bombear fluidos inflamables

o explosivos, como gasolina,

fueloil, queroseno, etc. No la

use en atmósfera inflamable

o explosiva. La bomba sólo debe usarse

para bombear agua limpia. De lo

contrario podría provocar lesiones

personales y/o daños a la propiedad.

Esta bomba no

está diseñada para

manejar agua salada, salmuera,

descargas de lavado, ni demás usos que

contengan productos químicos cáusticos

y/o materiales extraños. Si se usa en

dichas aplicaciones, la bomba podría

dañarse, anulando la garantía.

Un electricista

calificado debe

realizar todo el cableado.

Si el

s ó t a n o

tiene agua o humedad en el

piso, no camine sobre el área

mojada hasta que se

desconecte la corriente. Sil a

caja de desconexión principal está en el

sótano, llame a un electricista. Retire la

bomba y repárela oreemplácela. Si no

respeta esta advertencia puede provocar

un choque eléctrico mortal.

Es necesario usar

un sistema de

respaldo. Llame al 1-800-237-0987 para

obtener el número del modelo de la

bomba de respaldo.

I n s t a l a c i ó n

1 . Instale la bomba en un pozo de

sumidero con el tamaño mínimo,

como se muestra en la figura 1.

H a g a el pozo de sumidero en loza,

cemento, acero o plástico.

2 . La unidad debe ubicarse y apoyarse

sobre una base sólida y nivelada.

N o coloque la bomba directamente

sobre arcilla, tierra, barro o sobre una

superficie arenosa. Estas superficies

contienen pequeñas piedras, grava,

arena, etc., que pueden obstruir o

dañar la bomba y causar fallas en la

m i s m a .

Riesgo de

inundación. Si se

usa la manguera flexible de descarga,

asegúrese de que la bomba esté

asegurada en el pozo del sumidero para

evitar el movimiento. El no fijar la

bomba puede permitir el movimiento

de la bomba e interferencias del

interruptor, impidiendo que la bomba

arranque o pare.

3 . Enrosque la válvula de retención (no

incluida) en el cuerpo de la bomba,

con cuidado de no dañar la rosca.

N o use sellador para juntas de tuberías.

4 . Conecte el tubo rígido de 31,7 mm

(1-1/4") a la válvula de retención.

Sujete la bomba y

la tubería cuando

la esté ensamblando y después de la

instalación. El no hacerlo podría

provocar que la tubería se rompa, que

la bomba falle, etc., lo que podría dar

como resultado daño a la propiedad y/o

lesiones personales.

5 . Proteja el cable de corriente de

objetos punzantes, superficies

calientes, aceite y productos químicos.

Evite doblar el cable y reemplace los

cables dañados de inmediato.

6. Posicione la bomba LEJOS de la

entrada de agua de manera que el

interruptor no quede cerca de la

entrada de agua (ver Figura 1).

7. Se deberá instalar una tapa para el

pozo del sumidero para evitar que

los desechos obstruyan o dañen la

bomba.

F u n c i o n a m i e n t o

Siempre

desconecte el

suministro de corriente antes de

intentar instalar, efectuar un servicio,

reubicar o realizar el mantenimiento de

la bomba. No toque nunca la bomba de

sumidero, el motor de la bomba, el

agua o el tubo de descarga mientras la

bomba esté conectada al suministro de

corriente. Nunca manipule la bomba o

el motor de la bomba con las manos

húmedas o cuando se encuentre sobre

una superficie húmeda o mojada ni

dentro del agua. Puede presentarse un

choque eléctrico mortal.

1 . Se requiere un interruptor de circuito

de descarga a tierra (GFCI).

¡Riesgo

de

choque eléctrico! Esta bomba

viene con un conductor de

conexión a tierra y un

enchufe de conexión a tierra. Use un

receptáculo con conexión a tierra para

reducir el riesgo de choque eléctrico

mortal.

Nunca corte la clavija redonda de

conexión a tierra. Si corta el cable o el

enchufe se anulará la garantía y hará

que la bomba no funcione.

2 . Esta bomba está diseñada para usarla

sólo con 120 voltios (monofásico),

6 0 Hz, 15 amp. y está equipada con

un cable de 3 conductores y un

enchufe del tipo de conexión a tierra

de tres clavijas. Inserte el enchufe del

cordón del interruptor directamente

en un tomacorriente de 120 voltios.

3 . Enchufe el cordón de alimentación de

la bomba directamente en la parte de

atrás del enchufe del cordón del

sensor de agua (Figura 2).

4 . Llene el sumidero con agua. L a b o m b a

se enciende automáticamente

cuando el agua es cerca de 1,5" 3,81

cm (1.5”) desde el extremo superior

del interruptor. L a bomba se reciclará

a partir de ese momento, cada vez que

sea necesario.

• La bomba de sumidero trabaja por

un mínimo de 4 segundos, hasta un

máximo de 16 antes de apagarse.

• El tiempo de funcionamiento de la

bomba de sumidero es

determinado por el tamaño del

pozo del sumidero y el flujo de

agua en el pozo de sumidero.

1 4- S p

Manual de Instrucciones de Operación y Piezas

Figura 2 – Sensor de agua Switch

Genius™

La superficie de

trabajo del sensor

debe mantenerse

libre de material

extraño.

D e s c r i p t i o n

La pompe immergée est conçue pour les

applications de puisard intérieur

résidentiel. L’appareil est doté d’un

cordon d’alimentation mis à la terre, à

3 broches. Le moteur est rempli d’huile

et scellé pour un fonctionnement plus

frais et il et conçu pour fonctionner

sous l’eau. Cette pompe n’est pas

conçue pour la vie aquatique.

Cette pompe de puisard est fournie

avec la technologie Switch Genius™

pour contrôler le niveau d’eau.

Lorsque de l’eau est détectée,

la pompe démarre automatiquement.

D é b a l l a g e

Vérifiez cette unité avant de

l’utilisation. Parfois, un produit peut

être endommagé pendant le transport.

Si la pompe ou d’autres pièces ont subi

de dommages, renvoyez l’unité à la

place d’achat pour son remplacement.

Si vous ne faites pas ça, vous risquez

des blessures graves ou la perte de vie.

I m p o r t a n t e s

i n s t r uctions de s é c u r i t é

LIRE ET SUIVRE TOUTES LES

I N S T R U C T I O N S

D i r ectives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger indique

une situation

hasardeuse imminente qui résultera en

perte de vie ou blessures graves.

Avertissement

indique une

situation hasardeuse potentielle qui

peut résulter en perte de vie ou

blessures graves.

Instructions d’Utilisation et Manuel de Pièces

CDUCAP Série

352401-001 12/08

Attention indique

une situation

hasardeuse potentielle qui peut

résulter en blessures.

Avis indique de

l ’ i n f o r m a t i o n

importante pour éviter le dommage de

l ’ é q u i p e m e n t .

Généralités sur la

S é c u r i t é

POSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques, y

compris du plomb, relevés par l'État de

Californie comme cause de cancer,

d'anomalies congénitales ou d'autres

problèmes reproductifs. Lavez-vous les

mains après toute manipulation.

© 2008 Wayne Water Systems

S p é c i f i c a t i o n s

Exigences d’alimentation de courant 120 V, 60 Hz

Moteur Monophasé, rempli d’huile

Valeurs en ampères/horsepower 1/3 HP/9,5 A (CDUCAP725)

1/2 HP/10 A (CDUCAP850)

3/4 HP/10 A (CDUCAP995)

1 HP/10 A (CDUCAP1000)

Plage de température liquide 4,4 à 48,9 °C (40 à 120 °F)

Exigences du circuit 15 ampères (min)

Dimensions : 29 cm de haut x 24,7 cm de base

(11 1/2 x 9 3/4 po)

Niveau de coupe (réglé en usine) 20 cm (8 po)

Niveau de découpe (réglé en usine) environ

7,6 cm (3 po)

C o n s t ru c t i o n

Boîtier de moteur Acier laminé à froid,

acier inoxydable (CDUCAP995)

Volute Fonte

Impulseur Thermoplastique renforcé de verre

Arbre Acier à faible teneur en carbone

Garnitures Buna N

Décharge 1 1/2 po (6,3 mm) NPT

Couvercle du moteur Thermosplastique renforcé de verre

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

7- F r

Figure 1 - Typical Installation

Discharge

Pipe

GFCI

Protected

Outlet

On @ 8

inches

Switch

Off @

approx.

3 inches

11 inch

Diameter

Minimum

Incoming

Water

Inlet Pipe

Check

Valve

13 inch min.

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à

l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a

risque de blessure et/ou dégâts matériels! Conserver ces instructions comme référence.

Pompe De Puisard

Immergée

Page 8

D e s c r i p c i ó n

La bomba sumergible está diseñada

para aplicaciones de sumidero

domésticas al interior. L a unidad está

equipada con un cordón eléctrico con

enchufe de tres clavijas y conexión a

tierra. Elmotor se entrega lleno de

aceite y sellado permitiendo un

funcionamiento a menor temperatura

y está diseñado para trabajar debajo

d e l agua. Esta bomba es nociva para

l a vida acuática.

Esta bomba trae la tecnología Switch

Genius™ para el control del nivel de

agua. La bomba se enciende

automáticamente cuando se detecta

la presencia de agua.

D e s e m p a c a r

Revise esta unidad antes de usarla. A

veces, el producto puede sufrir daños

durante el transporte. Si la bomba u

otras piezas se han dañado, devuelva la

unidad al lugar donde ha sido

comprada para que la sustituyan. De

no hacer eso, se pueden producir serios

daños o la muerte.

I n s t r u c c i o n e s

d e s e g u r i d a d

i m p o rt a n t e s

LEA Y SIGA TODAS LAS

I N S T R U C C I O N E S .

Medidas de Seguridad

Este manual contiene información que

es muy importante conocer y

comprender. Esta información se

proporciona con fines de SEGURIDAD y

para EVITAR PROBLEMAS CON EL

EQUIPO. Para ayudarlo a reconocer

esta información, observe los siguientes

s í m b o l o s :

Manual de Instrucciones de Operación y Piezas CDUCAP Series

352401-001 12/08

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica que

hay una situación

que PODRIA ocasionarle la muerte o

heridas de gravedad.

Ésto le indica que

hay una situación

que PODRIA ocasionarle heridas no

muy graves.

Ésto le indica

una información

importante, que de no seguirla, le

podría ocasionar daños al equipo.

Bomba

Sumergible para

Sumideros

© 2008 Wayne Water Systems

E s p e c i f i c a c i o n e s

Requisitos de suministro de energía 120 V, 60 hz

Motor Monofásico, lleno de aceite

Clasificación de Caballos de 1/3 HP/9.5 A (CDUCAP725)

fuerza/Amp 1/2 HP/10 A (CDUCAP850)

3/4 HP/10A (CDUCAP995)

1 HP/10 A (CDUCAP1000)

Rango de temp. del líquido 40ºF a 120ºF (4ºC a 49ºC)

Requisitos del circuito 15 A (mín)

Dimensiones 29 cm de alto por 24,9 cm de base

(11-1/2 inch x 9-3/4 inch)

Nivel de activación (ajuste de fábrica) 20 cm (8 inches)

Nivel de corte (ajuste de fábrica) Aprox. 7,5 cm (3 inches)

C o n s t ru c c i ó n

Caja del motor Acero laminado, acero inoxidable (CDUCAP995)

Caja espiral Hierro fundido

Impulsor Termoplástico reforzado con vidrio

Eje Acero bajo en carbono

Sellos Buna N

Descarga 1-1/2" (3,8 cm) NPT

Cubierta del motor Termoplástico reforzado con vidrio

Sírvase leer y conservar estas instrucciones. Léalas con cuidado antes de intentar armar, instalar, operar o efectuar

mantenimiento al producto descrito. Protéjase a sí mismo y a los demás observando la información de seguridad. El no cumplir

con estas instrucciones podría provocar lesiones personales y/o daños materiales. Conserve estas instrucciones para futura

referencia.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

1 3- S p

Figura 1 – Instalación típica

Tubería de

descarga

T o m a c o r r i e n t e

protegido por

interruptor de circuito

de descarga a tierra

( G F C I )

A c t i v a c i ó n

a 8 "

( 2 0 c m )

Interruptor

Apagado

a aprox.

3" (7,5 cm)

Diámetro mín.

de 11 pulg.

(27,5 cm)

Agua en

e n t r a d a

T u b e r í a

d e e n t r a d a

Válvula de

retención

M í n .

4 6 cm

(1 3 " )

Généralités sur la

Sécurité (Suite)

G É N É R A L

Ne pas

pomper de fluides

inflammables ou explosifs tels

que l’essence, le mazout, le

kérosène, etc. Ne pas utiliser dans un

milieu inflammable et /ou explosif.

L a pompe ne doit être utilisée que pour

pomper de l’eau fraîche. Sinon il pourrait

y avoir des blessures personnelles et/ou

des dommages à la propriété.

Cette pompe n’est

pas conçue pour

traiter l’eau salée, la saumure, la décharge

de lessive ou toute autre application qui

pourrait contenir des produits chimiques

caustiques et/ou des matières étrangères.

Si la pompe est utilisée pour ces

applications, elle pourrait être

endommagée et cela annulera la garantie.

Tout le câblage doit

être effectué par

un électricien qualifié.

Si le

s o u s - s o l

a de l’eau ou de l’humidité

sur le plancher, ne pas

marcher aux endroits

mouillés avant que le courant ne soit

coupé. Si la boîte d’arrêt est dans le

sous-sol, appeler un électricien. Retirer

la pompe et la nettoyer ou la remplacer.

Ne pas suivre cet avertissement pourrait

mener à un choc électrique mortel.

Il faut utiliser

un système de

secours. Appeler le 1-800-237-0987 pour

le numéro de modèle de l’appareil de

secours.

Installation

1 . Installer la pompe dans un puisard

d’une taille minimale tel qu’indiqué

sous la figure 1. Construire le puisard

de carreaux, béton, acier ou plastique.

2 . L’appareil doit être installé et reposer

sur une base solide et à niveau.

N e pas placer la pompe directement

sur de l’argile, de la terre, du gravier

ou sur une surface sablonneuse.

C e s surfaces contiennent de petites

pierres, du gravier, du sable, etc. qui

peuvent bloquer ou endommager la

pompe menant à une défaillance de

pompe possible.

Risque

d’inondation. Si

l’on utilise un tuyau de décharge

flexible, s’assurer que la pompe est bien

fixée dans un puisard pour éviter tout

déplacement. Ne pas fixer la pompe en

place pourrait mener àson déplacement

et à l’interférence del’interrupteur et

ainsi empêcher le démarrage et l’arrêt

de la pompe.

3 . Enfiler le clapet (pas compris) dans le

corps de la pompe avec soin pour

éviter de dénuder ou de fausser le

filetage. Ne pas utiliser de mastic de

j o i n t o i e m e n t .

4 . Connecter un tuyau rigide de 3,2 cm

(1 1/4 po) (minimum) au clapet.

Supporter la

pompe et la

tuyauterie en assemblant et après

l’installation. Ne pas suivre ces

directives pourrait mener à des bris de

tuyaux, à la défaillance de la pompe

etc. qui pourrait ensuite mener à des

dommages à la propriété et/ou à des

blessures.

5 . Protéger le cordon électrique des

objets tranchants, des surfaces

chaudes, de l’huile et des produits

chimiques. Éviter le tortillement du

cordon et remplacer immédiatement

les cordons endommagés.

6. Placer l’interrupteur de la pompe

LOIN de l’entrée pour que

l’interrupteur soit loin de l’entrée

d’eau (voir la figure 1).

7 . Il faut installer un couvercle de puisard

pour éviter que les débris ne bloquent

ou n’endommagent la pompe.

F o n c t i o n n e m e n t

Danger indique

Toujours débrancher

le cordon d’alimentation avant

d’essayer d’installer, de réparer, de

déplacer ou de faire l’entretien de la

pompe. Ne jamais toucher la pompe de

puisard, le moteur de pompe, la

tuyauterie d’eau ou de décharge

lorsque la pompe est branchée au

courant. Ne jamais manipuler de pompe

ou de moteur de pompe avec les mains

humides ou debout dans l’eau ou sur

une surface humide. On pourrait avoir

un choc électrique mortel.

1 . Il faut installer un disjoncteur de fuite

à la terre.

Risque

dechoc

électrique ! Cette pompe est

fournie avec un conducteur

de terre et une fiche de

masse. Utiliser une prise à la terre pour

réduire le risque de choc électrique

mortel.

Ne jamais couper la broche de terre

ronde. Couper le cordon ou la fiche

annulera la garantie et rendra la pompe

inutilisable.

2 . Cette pompe ne doit être utilisée

qu’avec 120 volts (monophase),

6 0 Hz, 15 ampères et est dotée d’un

cordon à 3 conducteurs et 3 broches

et à fiche de masse. Insérer la fiche du

cordon de l’interrupteur dans une

prise de 120 volts.

3 . Insérer la fiche du cordon de la

pompe directement à l’arrière de la

fiche du cordon à capteur d’eau

(figure 2).

4 . Remplir le puisard d’eau. La pompe

se mettra en marche

automatiquement lorsque l’eau est à

environ 3,8 cm (1,5 po) du dessus de

l’interrupteur. La pompe reprendra

son cycle ensuite au besoin.

• La pompe de puisard fonctionnera

pendant au moins 4 secondes à un

maximum de 16 secondes avant de

s ’ a r r ê t e r .

• Le temps de fonctionnement de la

pompe de puisard sera déterminé

par la taille du puisard et le rythme

d’écoulement d’eau dans le

p u i s a r d .

• Pendant les inondations, la p o m p e

s’arrêtera pendant 1 s e c o n d e ,

toutes les 16 secondes et se

remettra en marche

a u t o m a t i q u e m e n t .

5 . Ne pas faire fonctionner la pompe

à moins qu’elle ne soit submergée

dans l’eau. Tourner à sec mène à une

défaillance de pompe.

6 . Ce moteur est doté d’un protecteur

thermique à réinitialisation

automatique.

8- F r

Instructions d’Utilisation et Manuel de Pièces

Figure 2 - Capteur d’eau Switch Genius™

La surface de

travail du capteur

doit rester libre de

toute matière

étrangère.

Page 9

Instructions d’Utilisation et Manuel de Pièces

CDUCAP Série

1 2- F r

Garantie Limitée

Pendant cinq (5) ans (modèles CDUCAP725 et CDUCAP850) et sous une garantie à vie (modèles CDUCAP995 et

CDUCAP1000) à compter de la date d’achat, Wayne Water Systems va réparer ou remplacer, à sa discrétion,

pour l’acheteur original n’importe quelle pièce ou pièces de ces Pompes de Puisard ou Pompes à eau (« Produit

») déterminées défectueuses, par Wayne Water Systems, en termes de matériaux ou de fabrication. S’il vous

plaît appeler Wayne Water Systems (1-800-237-0987) pour des instructions ou contacter votre marchand.

S’assurer d’avoir, à votre disposition, le numéro du modèle afin d’effectuer cette garantie. Les frais de

transportation des Produits ou pièces soumis pour la réparation ou le remplacement sont la responsabilité de

l ’ a c h e t e u r .

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident,

utilisation abusive, mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque

d’utilisation conformément aux instructions écrit de Wayne Water Systems.

IL N’Y A AUCUNE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y INCLUS CELLES DE

QUALITÉ MARCHANDE ET CONVENABLE À UN USAGE PARTICULIER, SONT LIMITÉES À CINQ (5) ANS

( M O D È L E S CDUCAP725 et CDUCAP850) ET À VIE (MODÈLES CDUCAP995 et CDUCAP1000) À COMPTER

DE LA DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR

N’IMPORTE QUEL ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la

limitation des dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer.

Cette garantie limitée donne, à l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales

qui sont variable d’une Province ou d’un État à l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou

autrement, ni Wayne Water Systems ou ses fournisseurs seront responsables pour aucune dommage spéciale,

incidentel ou pénal, y compris, mais pas limité à la perte de profits ou recettes, la perte d’usage des produits ou

n’importe quel équipement associé, dommage à l’équipement associé, coût de capital, coût de produits remplaçants,

aménagements, services ou abilité de remplaçement, coût de temps que le produit n’est pas en service, ou la

réclamation des clients de l’acheteur pour ces dommages.

Vous D E V E Z garder votre recette d’achat avec ce bulletin. Il est N É C E S S A I R E d’envoyer une C O P I E de la

recette d’achat avec le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous

plaît appeler Wayne Water Systems (1-800-237-0987) pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À WAYNE WATER SYSTEMS. Utiliser ce bulletin

seulement pour vos archives.

Nº DU MODÈLE ____________________

Nº DE SÉRIE ____________________

DATE D’INSTALLATION ____________________

FIXER VOTRE FACTURE ICI

F o n c t i o n n e m e n t

( S u i t e )

7 . Tandis que la pompe draine le

puisard, vérifier que le tuyau de

décharge transporte l’eau vers un

point à plusieurs pieds ou mètres de

distance de la fondation.

8 . Si la conduite de décharge est

exposée au gel, il faut incliner la

conduite exposée pour la drainer.

L’eau emprisonnée gèlera et

endommagera la pompe.

E n t r e t i e n

Toujours couper

le courant avant

d’essayer d’installer, de réparer, de

déplacer ou de faire tout entretien.

Si la source de courant est loin de la

vue, verrouiller et étiqueter en

position ouverte (arrêt) pour éviter

toute application de courant imprévue.

Ne pas suivre ces instructions pourrait

mener à un choc électrique mortel.

Seulement des électriciens qualifiés

devraient réparer cet appareil.

Une mauvaise réparation pourrait

mener à des chocs électriques mortels.

1 . Laisser la pompe refroidir pendant

au moins deux heures avant tout

entretien ou réparation parce que

l a pompe contient de l’huile chaude

sous pression et le moteur est

c h a u d .

2 . Démonter le moteur avant

l’expiration de la garantie annulera

la garantie. S’il faut des réparations,

consulter le tableau de dépannage.

3 . L’entrée doit rester propre et libre

de tous objets étrangers et être

inspectée chaque année. Une entrée

bloquée endommagera la pompe.

4 . La pompe doit être vérifiée chaque

mois pour assurer son bon

fonctionnement. La pompe se

vérifie pour assurer son bon

fonctionnement en retirant

brièvement le cordon de la pompe

de l’arrière de la fiche du capteur

d’eau et en l’insérant directement

dans la prise mise à la terre.

D a n s cet état, la pompe

fonctionnera continuellement.

Lorsque le fonctionnement de la

pompe est vérifié, replacer le

cordon de la pompe à l’arrière

d e l a fiche du capteur d’eau

( v o i r l a figure 2).

5 . Essuyer régulièrement la surface du

capteur d’eau pour éviter que de la

vase ou autres revêtements

s’accumuler sur le capteur

( v o i r l a figure 2).

Cette pompe

contient de l’huile

diélectrique pour son refroidissement.

Cette huile peut être dangereuse pour

l’environnement. Vérifier les lois

environnementales de l’état avant de

jeter cette huile.

9- F r

CDUCAP Série

Guide De Dépannage

Symptôme Cause(s) Possible(s) Mesure Correctives

Pompe ne démarre

pas ou ne fonctionne

pas

Pompe démarre et

s’arrête trop souvent

Pompe ne s’arrête

pas ou le protecteur

thermique s’éteint

Pompe fonctionne

mais livre peu ou

aucune eau

Son de gargouillis de

la pompe à la fin du

cycle

1. Fusible grillé

2. Basse tension

3. Moteur défectueux

4. Impulseur

1. Retour d’eau de tuyauterie

2. Entrée d’eau draine sur

la face du capteur

1. Obstacle dans la

tuyauterie

2. Basse tension

3. Trop d’appareils sur le

circuit

4. Capteur d’eau sale

5. Entrée d’eau draine sur la

face du capteur

1. Impulseur bloqué

2. Clapet installé à l’envers

3. Poche d’air dans la pompe

1. Air injecté dans la pompe

2. Le temps requis pour

pomper est de moins de

4 secondes

1. Si grillé, remplacer avec un fusible de bonne taille ou

réinitialiser le disjoncteur

2. Si la tension est inférieure à 108 volts, vérifier la taille du

câblage

3. Remplacer la pompe

4. Si l’impulseur ne tourne pas, retirer le boîtier et retirer

le blocage

1. Installer ou remplacer le clapet.

2. Placer l’interrupteur de la pompe loin de l’entrée pour que

l’interrupteur soit loin de l’entrée d’eau (voir la figure 1).

1. Retirer la pompe et la nettoyer ainsi que la tuyauterie.

2. Si la tension est inférieure à 108 volts, vérifier la taille du

câblage

3. Installer la pompe sur un circuit réservé. IMPORTANT : Ne pas

utiliser de rallonges pour alimenter la pompe.

4. Nettoyer la face du capteur (voir la figure 2)

5. Placer l’interrupteur de la pompe loin de l’entrée pour que

l’interrupteur soit loin de l’entrée d’eau (voir la figure 1).

1. Nettoyer l’impulseur

2. Inverser la position du clapet.

3. Percer un trou de 3,1 mm (1/8 po) dans la conduite

de décharge entre la pompe et le clapet

1. Essuyer la surface du capteur (voir figure 2)

2. Un temps de fonctionnement supplémentaire

n’endommagera pas la pompe

Page 10

1 1- F r

N o t e s

1 0- F r

Instructions d’Utilisation et Manuel de Pièces

CDUCAP Série

Pour des Pièces de Rechange, composer 1-800-237-0987

S’il vous plaìt fournir l’information suivante:

- Numéro de modèle

- Numéro de série (si applicable)

- Description et numéro de pièce d’après la liste de pièces

C o r r e s p o n d a n c e :

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

1

2

3

4

5

6

7

1 Néc. de couvercle supérieur 60030-001

2 Stator —

3 Support inférieur/Assem. de Rotor —

4 Plaque de turbine 15958

5 T u r b i n e 60001-001

6 Volute 60039-001

7 Capteur d’eau Switch Genius™ 30037-001

Liste de Pièces de Rechange

No. de

R é f . D e s c r i p t i o n CDUCAP Séries

Loading...

Loading...