Page 1

Operating Instructions

Operating Instructions AU5ES

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

Limited Warranty

For one year from the date of purchase, Wayne Water Systems (“Wayne”) will repair or replace, at its option, for

the original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination

by Wayne to be defective in materials or workmanship. Please call Wayne (800-237-0987) for instructions or see

your dealer. Be prepared to provide the model number when exercising this warranty. All transportation charges

on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse,

neglect, improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written

instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF

PURCHASE. THIS IS THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or

limitations of incidental or consequential damages, so the above limitations might not apply to you. This limited

warranty gives you specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall

Wayne or its suppliers be liable for any special, consequential, incidental or penal damages including, but not

limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated

equipment, cost of capital, cost of substitute products, facilities, services or replacement power, downtime costs, or

claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim,

you MUST send a copy of the purchase receipt along with the material or correspondence. Please call Wayne

(800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________

INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

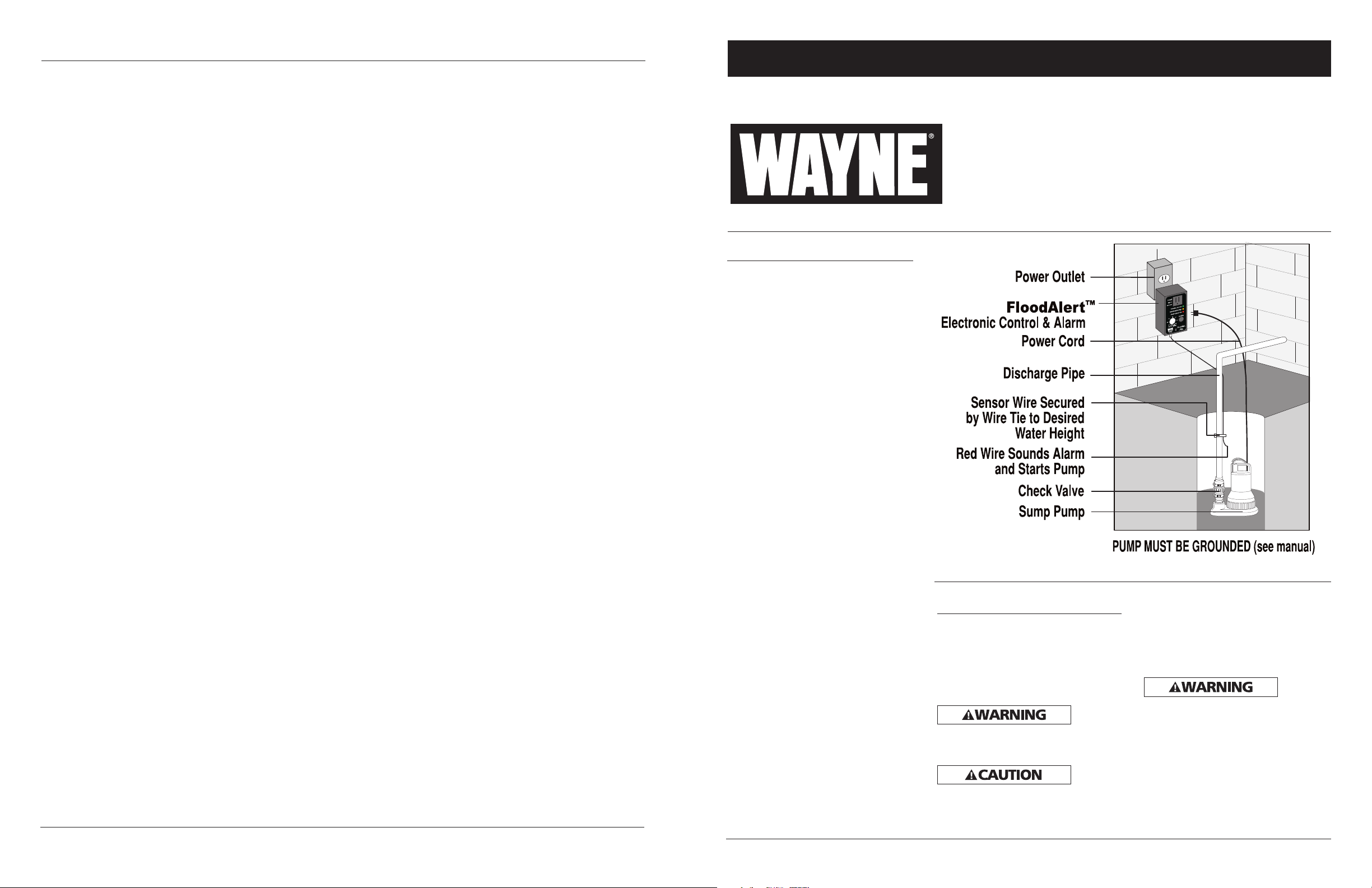

Description

The FloodAlert control uses patented

electronic surface transfer (EST) to

detect the presence of water. Sensing

is not affected by oil, soaps, turbulence

or the waters resistance and is

intrinsically safe.

When water touches the tip of

FloodAlert’s sensing wire, a relay closes

turning on your pump. Patent pending

Zcross technology closes the relay

contact at zero volts and opens it at

zero current. This stops relay arcing,

extending relay life, stopping powerline flicker, and making pump startups

smoother.

A settable “Run Timer” allows you to

change the pumping depth without

opening the sump pump pit. This

timer allows any quantity of water to

be pumped out of the sump and can

even pump it completely dry without

running the pump too long.

If the water level does not fall below

the tip of the wire while the pump is

running an alarm sounds indicating

high water pump failure or a clogged

discharge line. Two lights alternately

flash, warning you of a problem before

your basement floods. A standard 9volt battery operates the alarm during

a loss of power at the wall outlet.

The battery maintains the sensor and

alarm for two days without power.

Circuitry maintains the battery voltage

extending its shelf life to 7-years.

Use FloodAlert to convert your manual

pump to automatic or to replace a

defective float switch. FloodAlert

requires a grounded pump plug

or, alternatively, a grounded

connection to the sump. It will not

apply 120-volts to the pump motor

without proper grounding.

Electronic Sump

Pump Control and

Alarm

Figure 1

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe

the following symbols.

Warning

indicates

a potentially hazardous situation

which, if not avoided, COULD result in

death or serious injury.

Caution

indicates

a potentially minor or moderate injury.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make

sure to tighten fittings, bolts, etc.,

before putting unit into service.

Do

not

operate unit if damaged during

shipping, handling or use. Damage may

result in bursting and cause injury or

property damage.

www.waynepumps.com

4

© 2007 Wayne Water Systems

For parts, product & service information

visit www.waynepumps.com

390601-001 6/07

Page 2

Operating Instructions

Model AU5ES

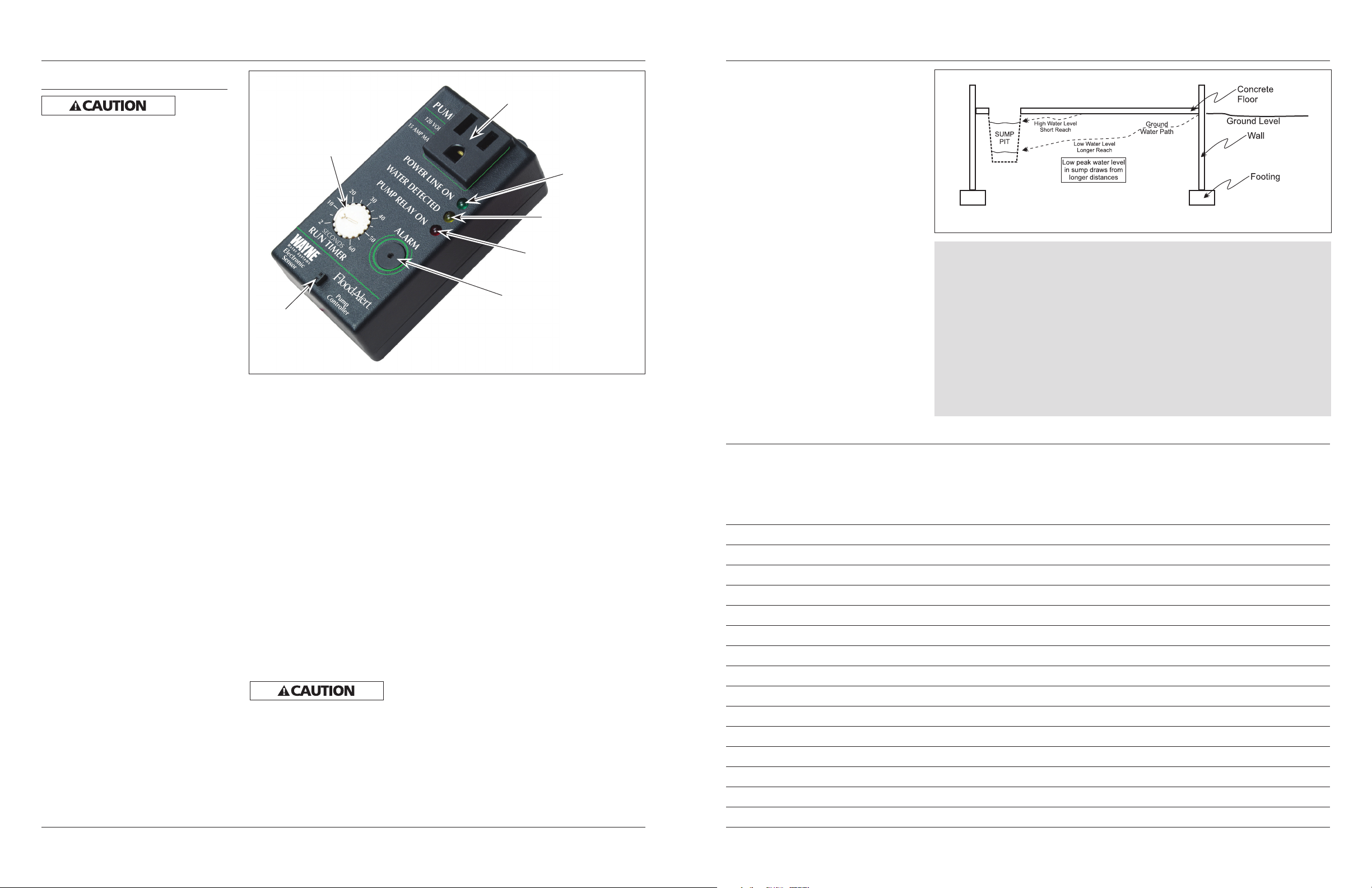

Operation

Before performing any wiring to sump

pump disconnect power to pump.

1) Plug FloodAlert into a 120-volt

grounded wall outlet.

2) Insert the battery jumper (See

Figure 2).

3) Plug grounded pump into FloodAlert outlet.

4) Run the sensor wire to the sump

and fasten using wire ties. Its

tip should be at the level where

you want the pump to begin

operating.

SETTING THE RUN TIMER

The run timer sets the pumping depth

and how much water you prefer to

pump out of the pit. It does not start

timing until the water level drops

below the sensor wire. The moment

the water drops below the sensing

wire the run timer starts limiting

the pumps run time. Initially set the

time to 5-seconds. Test the operation

by filling the sump pit with water

until the sensor wire is below water.

The timer should be set so that the

pump turns off before the water level

reaches the pump’s inlet. If the water

level reaches the pump’s inlet, it will no

longer pump water. If a pump has an

inlet on the bottom side of the pump

and the water level is low enough to

allow air into the pump, an air-lock

condition may occur. Air-lock happens

when air is trapped in the pump and

can not escape. Air-lock condition can

be avoided if the water level stays

above the pump’s inlet. Adjust set-time

to remove desired amount of water

and to avoid an air-lock condition.

Dial sets the amount of

time the pump needs to

drain water from sump

Battery

Jumper

Figure 2

BATTERY

The jumper on the cover connects the

battery to the circuitry. If the unit loses

power the battery runs the alarm and

sensor. It should be replaced every year

or when a power loss occurs for over

two days.

To replace battery:

Purchase a 9-volt alkaline battery.

Unplug the pump from the unit and

unplug the unit from the wall outlet.

Remove the battery jumper. Remove

the 4-screws holding the cover. Remove

the cover from the base by using a

rocking motion to free the receptacle

from its slide on tabs. Unsnap the

old battery and snap in the new one.

Replace the cover making sure to press

hard on the receptacle to slide it fully

onto its 3-tabs. Replace the 4-screws

holding the cover. Plug the unit into

the wall outlet and the pump into the

unit. Replace the battery jumper.

Do not

plug

unit in with the cover removed. High

voltages are present.

Plug sump pump

into outlet

Power Indicator

Light

Gives indication

that water is in

contact with sensor

Indicates pump

is running

When water is in contact

with sensor for 15 seconds

the alarm will sound and

the “Water Detected” and

“Pump Relay On” LEDs will

flash alternately

WATER SENSING

EST measures the surface area of

liquid contacting two metals. Since the

sump is grounded for safety reasons,

something metal in the sump must be

grounded. This might be the pump

case, the sump itself, or on a plastic

pump, it’s motor shaft. The sensing

wire is the other metal. EST senses the

square inches of contact between the

two metals and their distance. The

purpose is to ignore thin water films

that might coat the surface of a wire

or pipe and only detect the main body

of water. It does not detect resistance

and touching the sensing wire to

ground does not activate it.

OIL FILMS

EST is able to break apart oil films that

might coat its sensing probe. Oil films

float on the surface of water adhering

to the surface of metals preventing

them from making electrical contact

with the water. EST’s tiny fast moving

electronic pulses move non-conductive

liquids away from the probe, busting

them apart if they manage to coat it.

WATER LEVEL

Water seeks its own level but

compacted soil causes it to deviate to

the path of least resistance. As a result

ground water will not rise at a uniform

level across your entire basement.

A sump pump pit must not only be

deep enough, but more importantly

maintain a low enough water level to

insure that the path of least resistance

remains underground and not across

the top of your basement floor. An

empty sump draws more groundwater

from surrounding areas than a full one.

Experience shows this to be roughly a

4:1 ratio; a 1-foot below grade peak

water level draws from only a 4-foot

radius while a 3-foot below grade peak

water level extends this out to 12-feet.

A common error is setting the water

level as high as possible to minimize

pump cycling and later noticing that

water surfaces some distance away.

Zcross technology in FloodAlert allows

you to set the water level as low as

practical without worrying about high

cycle operation.

Notes

Figure 3

RATINGS

Voltage . . . . . . . . . . . . . . . . . . 100-130 VAC

Max. Current . . . . . . . . . . . . . 15-Amps Peak Run Current

Locked Rotor . . . . . . . . . . . . . 40-Amps

Starting Current . . . . . . . . . . . 40-Amps

Battery . . . . . . . . . . . . . . . . . . 9-Volt Alkaline

Alarm . . . . . . . . . . . . . . . . . . . 80db @ 1m Alternating

Run Timer . . . . . . . . . . . . . . . . 2-60 Seconds

Patent . . . . . . . . . . . . . . . . . . . 6,820,483 others pending

www.waynepumps.com

www.waynepumps.com

2

3

Loading...

Loading...