Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Description

The submersible pump is designed for

home sump applications. The unit is

equipped with an 8-ft long, 3-prong

grounding type power cord. Motor is

oil filled and sealed for cooler running

and designed to operate under water.

A float switch is provided for automatic

pump operation. This pump is not

suitable for aquatic life.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return the

unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

General Safety

Information

Do not use to pump

flammable or explosive

fluids such as gasoline, fuel

oil, kerosene, etc. Do not

use in a flammable and/or explosive

atmosphere. Pump should only be used

to pump clear water. Personal injury

and/or property damage could result.

This pump is not

designed to handle

salt water, brine, laundry discharge or

any other application which may

contain caustic chemicals and/or foreign

materials. Pump damage could occur if

used in these application and will void

warranty.

All wiring must be

performed by a

qualified electrician.

If the basement has water

or moisture on the floor,

do not walk on wet area

until all power is turned

Operating Instruction and Parts Manual CDT33, CDT50, SPT33, SPT50, SSPT33 and SSPT50

351002-001 8/05

off. If the shutoff box is in the

basement, call an electrician. Remove

pump and either repair or replace.

Failure to follow this warning could

result in fatal electrical shock.

A backup

system should be

used. Call 1-800-237-0987 for backup

model number.

Installation

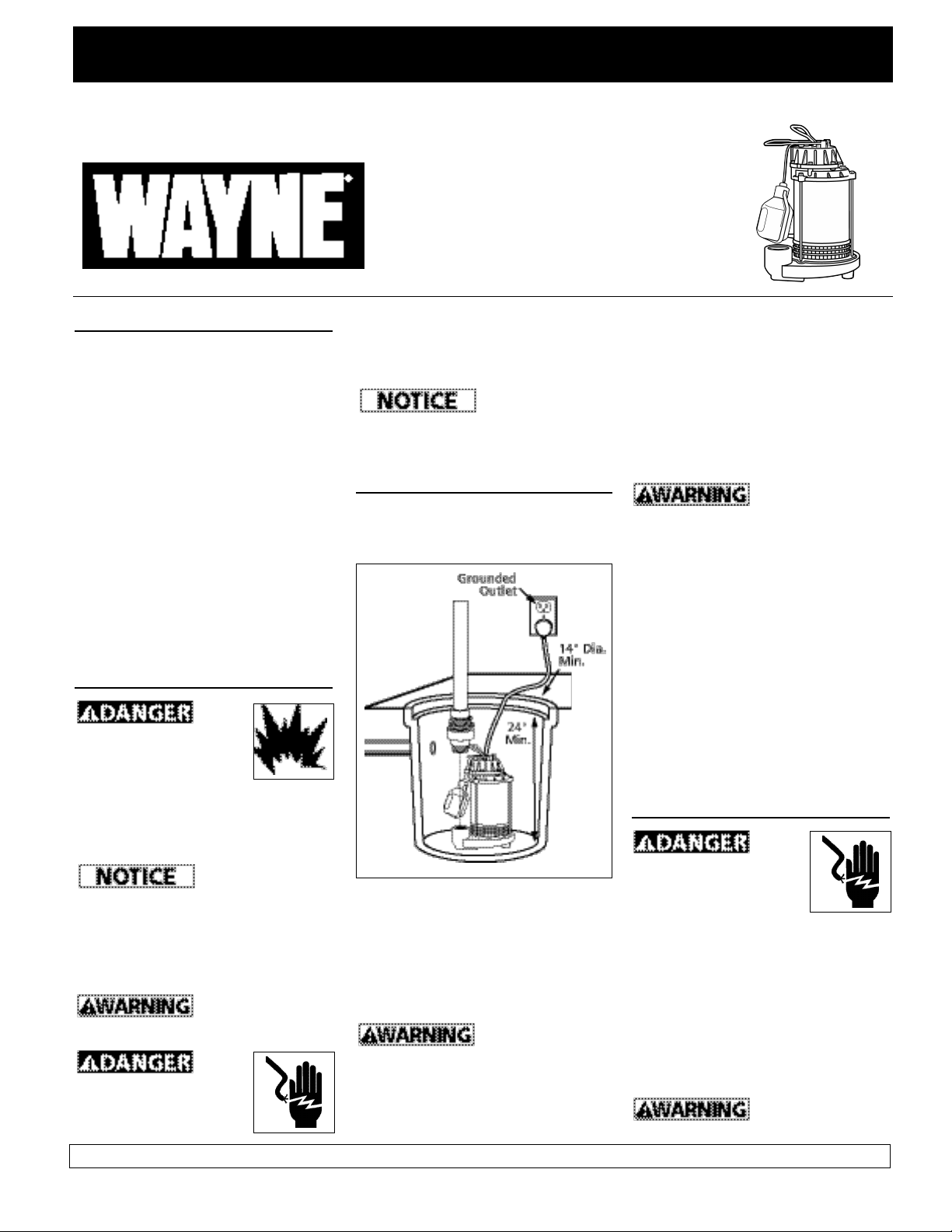

1. Install pump in a sump pit with

minimum size as shown below.

Construct sump pit of tile, concrete,

steel or plastic.

2. The unit should be located and rest

on a solid, level foundation. Do not

place pump directly on clay, earth,

gravel or sandy surface. These

surfaces contain small stones,

gravel, sand, etc. that may clog or

damage the pump and cause pump

failure.

Flood risk. If

flexible discharge

hose is used, make sure pump is

secured in sump pit to prevent

movement. Failure to secure pump

could allow pump movement and

switch interference and prevent pump

from starting or stopping.

3. Thread (optional) check valve

(Wayne No. 66005-WYN)into pump

body carefully to avoid stripping or

cross threading. Do not use pipe

joint sealant.

4. Connect 1-1/4” rigid pipe to rubber

boot on check valve. Reverse boot

for 1-1/2” diameter pipe. Tighten

hose clamps.

Support pump and

piping when

assembling and after installation.

Failure to do so could cause piping to

break, pump to fail, etc. which could

result in property damage and/or

personal injury.

5. Protect electrical cord from sharp

object, hot surfaces, oil and

chemicals. Avoid kinking the cord

and replace damaged cords

immediately.

IMPORTANT: Make sure there is

adequate room for tether switch to

swing freely during operation.

6. A sump pit cover must be installed

to prevent debris from clogging or

damaging the pump.

Operation

Always disconnect the

power source before

attempting to install,

service, relocate or

maintain the pump. Never touch sump

pump, pump motor, water or discharge

piping when pump is connected to

electrical power. Never handle a pump

or pump motor with wet hands or when

standing on wet or damp surface or in

water. Fatal electrical shock could

occur.

1. A ground fault circuit interrupter

(GFCI) is required.

Risk of electrical

shock! This pump is

Submersible

Sump Pump

© 2005 Wayne Water Systems

For parts, product & service information

visit www.waynewatersystems.com

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Figure 1

4. Fill sump with water. The pump will

start automatically when the water

has filled the sump to a depth of

approximately 13“. The pump will

stop when the water depth is

approximately 7”. The pump will

recycle thereafter as required.

5. Do not operate the pump unless it is

submerged in water. Dry running

causes pump failure.

6. The motor is equipped with an

automatic reset thermal protector.

7. While the pump is draining the pit,

verify that the discharge piping is

carrying the water to a point several

feet away from the foundation.

8. If pump discharge line is exposed to

freezing temperature, the exposed

line must be pitched to drain.

Trapped water will freeze and

damage the pump.

Maintenance

Always disconnect the

electrical supply before

attempting to install,

service, relocate or

perform any maintenance. If the power

source is out of sight, lock and tag in

supplied with a grounding conductor

and grounding type attachment plug.

Use a grounded receptacle to reduce

the risk of fatal electrical shock.

Never cut off the round grounding

prong. Cutting the cord or plug will

void the warranty and make the pump

inoperable.

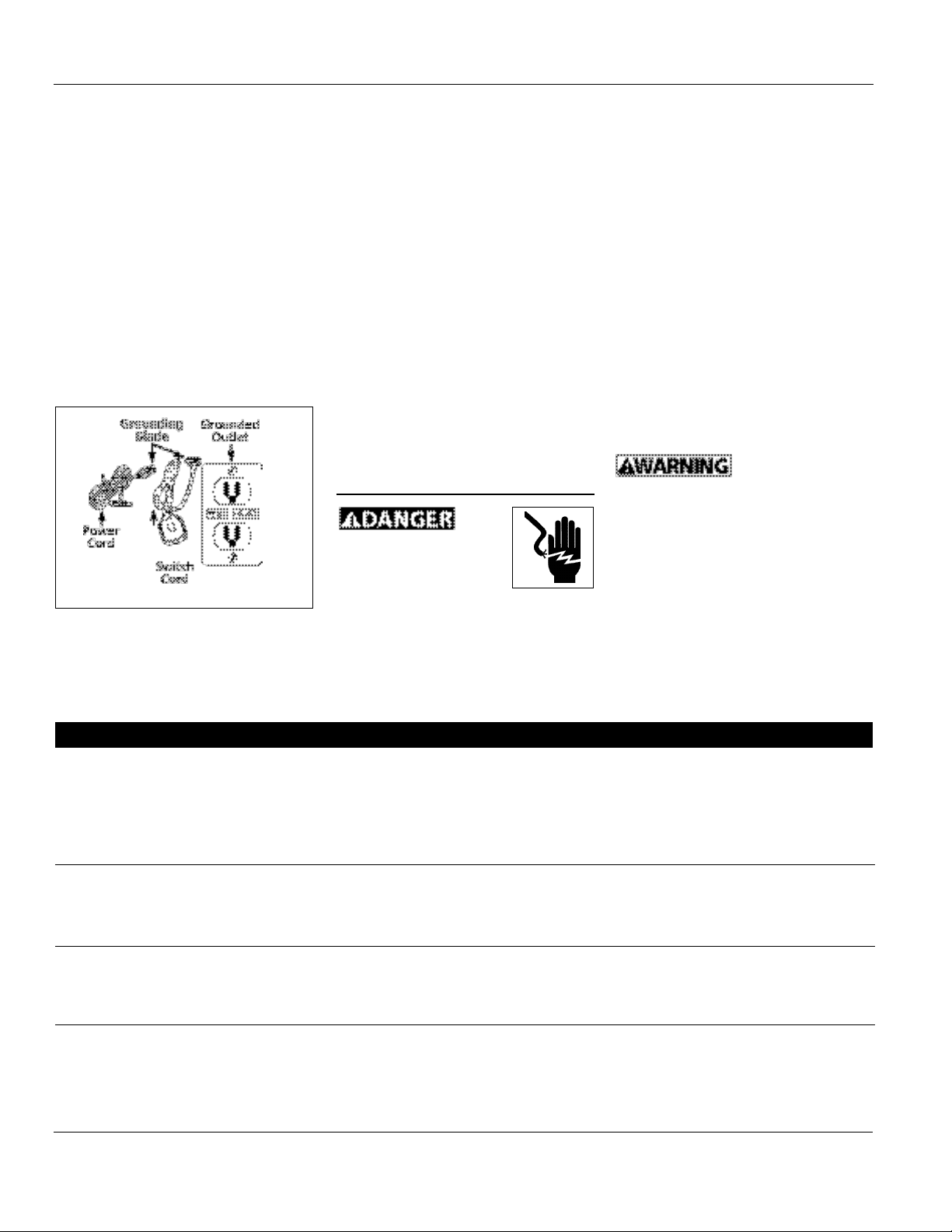

2. This pump is only for use on 120

Volt (single-phase), 60 hz, 15 amp

service and is equipped with a 3conductor cord and 3-prong,

grounding type plug. Insert the

float switch cord plug directly into

a 120 volt outlet.

3. Insert the pump power cord plug

directly into the back of the float

switch cord plug (See Fig. 2).

2

Operating Instructions And Parts Manual

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start

or run

Pump starts and

stops too often

Pump will not shut

off or thermal

protector turns off

Pump operates but

delivers little or no

water

1. Blown fuse

2. Low line voltage

3. Defective motor

4. Defective float switch

5. Impeller

6. Float obstructed

1. Backflow of water from

piping

2. Faulty float switch

1. Defective float switch

2. Obstacle in piping

3. Float obstructed

1. Low line voltage

2. Plugged impeller

1. If blown, replace with proper sized fuse or reset breaker.

2. If voltage is under 108 volts, check wiring size.

3. Replace pump

4. Replace float switch

5. If impeller will not turn, remove housing and remove blockage

6. Make sure float move freely up and down

1. Install or replace check valve (Wayne No. 66005-WYN)

2. Replace float switch

1. Replace float switch

2. Remove pump and clean pump and piping

3. Make sure float moves freely up and down

1. If voltage is under 108 volts, check wiring size.

2. Clean out impeller

the open (off) position to prevent

unexpected power application. Failure

to do so could result in fatal electrical

shock. Only qualified electricians

should repair this unit. Improper repair

could result in fatal electrical shock.

1. Let the pump cool for a minimum

of two hours before servicing

because the pump contains hot oil

under pressure and the motor is

hot.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required,

see troubleshooting chart.

4. Inlet should be kept clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

5. Pump should be checked monthly

for proper operation.

This pump contains

dielectric oil for

cooling. This oil can be harmful to the

environment. Check the state

environmental laws before disposing

this oil.

www.waynewatersystems.com

Figure 2

3

Operating Instructions And Parts Manual

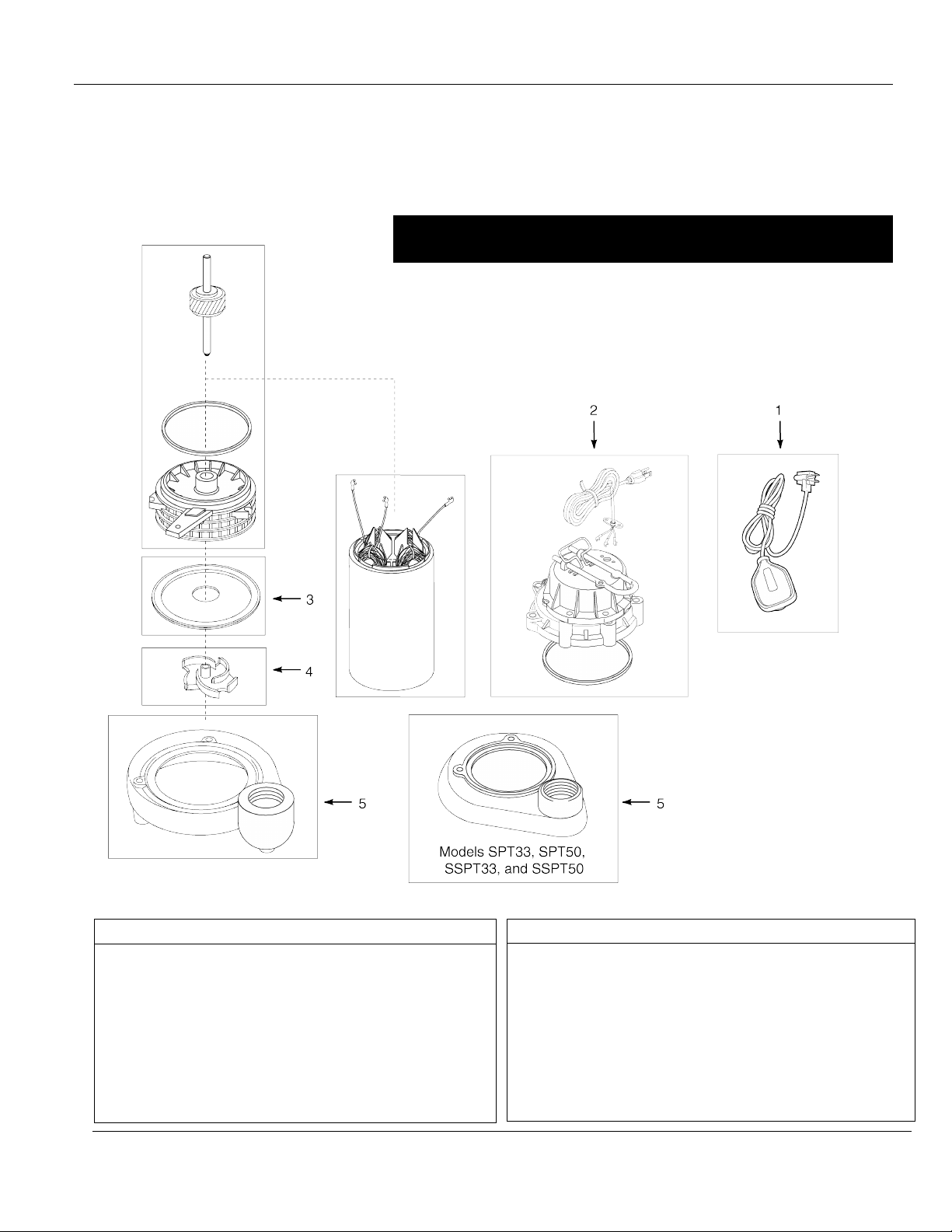

1. Tether Float Switch Kit 60022-001 60022-001

2. Top Cover Kit 60030-001 60030-001

3. Impeller Plate 15958 15958

4. Impeller 60000-001 60000-001

5. Volute 60016-001 60007-001

Part Numbers for Models

Ref. CDT33 SPT33, SPT50

No. Description CDT50 SSPT33, SSPT50

For Replacement Parts, call 1-800-237-0987

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Address parts correspondence to:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030

Specifications

Power supply requirements......120V, 60 hz

Motor .........................................Single phase, oil filled

Horsepower................................1/3 HP (CDT33, SPT33, SSPT33)

....................................................1/2 HP (CDT50, SPT50, SSPT50)

Liquid temperature range ........40°F to 120°F

Circuit requirements..................15 amps (min)

Dimensions.................................111/2” high x 93/4” base

Cut-in level (factory set)............13”

Cut-out level (factory set) .........7”

Construction

Motor housing .................Cold rolled steel

Volute ...............................Cast iron (CDT33, CDT50)

..........................................Glass Reinforced Thermoplastic

(SPT33, SPT50, SSPT33, SSPT50)

Impeller ............................Glass reinforced thermoplastic

Shaft .................................Low carbon steel

Seals ..................................Buna N

Discharge..........................11/2” NPT

Motor Cover.....................Glass reinforced thermoplastic

Replacement Parts List

• Only use factory parts to repair

this pump.

www.waynewatersystems.com

Limited Warranty

For one year on models SPT33 and SPT50, for two years on models CDT33 and CDT50, and for 3 years on

models SSPT33 and SSPT50 from the date of purchase, Wayne Water Systems Division ("Wayne") will repair

or re place, at its option, for the original purchaser any part or parts of its Sump Pumps or Water Pumps

(“Product”) found upon examination by Wayne to be defective in materials or work man ship. Please call

Wayne (800-237-0987) for instructions or see your dealer. Be pre pared to provide the model number when

exercising this warranty. All transportation charges on Products or parts submitted for repair or replacement

must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse,

misuse, neglect, improper installation, improper maintenance, or failure to operate in accordance with

Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANT ABIL I TY AND FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO ONE YEAR ON MODELS SPT33

AND SPT50, FOR TWO YEARS ON MODELS CDT33 AND CDT50, AND FOR 3 YEARS ON MODELS SSPT33

AND SSPT50 FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE REM E DY AND ANY LIABILITY

FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAM AG ES OR EXPENSES WHATSOEVER IS

EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or

limitations of incidental or consequential damages, so the above lim i ta tions might not apply to you. This

limited war ran ty gives you specific legal rights, and you may also have other legal rights which vary from

state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall

Wayne or its suppliers be liable for any special, consequential, incidental or penal damages including, but not

limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to

associated equip ment, cost of capital, cost of substitute products, facilities, services or replacement power,

downtime costs, or claims of buyer’s cus tom ers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty

claim, you MUST send a COPY of the purchase receipt along with the material or correspondence. Please call

Wayne (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________

INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

Operating Instructions And Parts Manual

4

www.waynewatersystems.com

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

1 Fr

Description

La pompe immergée est conçue pour

les applications d’assèchement de

maison. Le modèle est équipé d’un

cordon prolongateur type mis à la terre

de 8-pi, 3-broches. Le moteur est rempli

d’huile et scellé pour un

fonctionnement plus efficace et pour le

fonctionnement sous l’eau. Un

interrupteur flotteur est fourni pour le

fonctionnement automatique. Cette

pompe n’est pas convenable aux

animaux aquatiques.

Déballage

Vérifier cette unité avant l’utilisation.

Parfois, un produit peut être

endommagé pendant le transport. Si la

pompe ou d’autres pièces ont subi de

dommages, retourner l’unité à l’endroit

d’achat pour son remplacement. Sinon,

cela pourrait mener à des blessures

graves ou la mort.

Généralités sur la

Sécurité

Ne pas pomper les fluides

explosifs tels que l’essence,

l’huile à chauffage, le

kérosène etc. Ne pas utiliser dans un

atmosphère inflammable et/ou explosif.

La pompe devrait être utilisée pour le

pompage de l’eau claire seulement,

sinon, il y a risque de blessures

personnelles et/ou dégâts matériels.

Cette

pompe

n’est pas conçue pour les substances

qui contiennent les produits chimiques

caustiques et/ou les matières étrangères

tels que l’eau salée, la saumure, le

décharge de buanderie. L’utilisation de

ces produits peut endommager la

pompe et annulera la garantie.

Toute installation de fils doit être

effectuée par un électricien qualifié.

Instructions D’Utilisation et Manuel de Pièces CDT33, CDT50, SPT33, SPT50, SSPT33 y SSPT50

351002-001 8/05

Ne pas marcher sur un

plancher de sous-sol trempe

ou humide avant de couper

l’électricité. Si la boîte de branchement

est dans le sous-sol, contacter un

électricien. Enlever la pompe et la

réparer ou remplacer. Manque de suivre

cet avertissement peut résulter en

secousse électrique mortelle.

Un

système

de sauvegarde doit être utilisé.

Composer le 1-800-237-0987 pour le

numéro de modèle du système de

sauvegarde.

Installation

1. Installer la pompe dans une fosse

de taille minumum indiquée cidessous. Construire la fosse de

tuiles, béton, acier ou plastique.

2. Situer le modèle sur une fondation

solide et égale. Ne pas placer la

pompe directement sur une surface

d’argile, terre, gravier ou de sable.

Ces surfaces contiennent des

particules de gravier et de sable

etc., qui peuvent obstruer ou

endommager la pompe et causer la

panne.

Risque

Risque

d’inondation. Si un tuyau de décharge

flexible est utilisé, s’assurer que la pompe

soit fixée dans la fosse afin d’éviter le

movement inattendu. Manque de fixer la

pompe peut résulter en movement de la

pompe et en interférence de

l’interrupteur ce qui peut empêcher le

démarrage ou l’arrêt de la pompe.

3. Fileter le clapet (en option) (Wayne

Nº 66005-WYN) dans le corps de la

pompe avec soin pour éviter le

foirage ou l’abattement. Ne pas

utiliser le mastic de fermeture pour

joints.

4. Brancher le tuyau rigide d’1-1/4 po

au manchon-guêtre en caoutchouc

sur le clapet. Inverser le manchon

pour le tuyau de 1 1/2 po. Serrer les

colliers de serrage.

Il est

nécessaire

de soutenir la pompe et la tuyauterie

pendant l’assemblage et après

l’installation afin d’éviter la rupture du

tuyau ou la panne de la pompe etc, ce

qui peut résulter en dégâts matériels

et/ou en blessures personnelles.

5. Protéger les cordons d’alimentation

des objets pointus, surfaces chaudes,

l’huile et les produits chimiques.

Éviter le tortillement du cordon et

remplacer les cordons endommagés

immédiatement.

IMPORTANT: S’assurer qu’il y ait assez

d’espace afin de permettre le

mouvement libre de l’interrupteur

flotteur pendant le fonctionnement.

6. Il est nécessaire d’installer un

couvercle de fosse afin d’empêcher

l’obstruction ou le dommage à la

pompe par le débris.

Fonctionnement

Toujours débrancher la source

de puissance avant d’essayer

d’installer, de déplacer ou de

Pompe De Puisard

Immergée

© 2005 Wayne Water Systems

Prise de courant

mise à la terre

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Figure 1

procéder à l’entretien de la pompe. Ne

jamais toucher la pompe de puisard, le

moteur de la pompe, l’eau ou la

tuyauterie de décharge lorsque la

pompe est branchée à une source

électrique. Ne jamais manipuler la

pompe avec les mains trempes ni en se

tenant debout sur un plancher trempe

ou humide. Ceci peut résulter en

secousse électrique mortelle.

1. Un interrupteur DDFT est exigé.

Risque

de

secousse électrique! Cette pompe est

fournie d’un fil de terre et une fiche de

prise de poste mise à la terre. Utiliser

une prise de courant mise à la terre

pour réduire le risque de secousse

électrique mortelle.

Ne jamais enlever la broche de terre

ronde. Le coupage du cordon ou de la

fiche annulera la garantie et la pompe

ne fonctionnera pas.

2. Cette pompe a été conçue pour

l’utilisation avec le service 120 V

(monophasé), 60 Hz, 15 A

seulement et est équipée d’un

cordon à 3-conducteurs et d’une

fiche type mise à la terre à 3broches. Brancher le cordon de

l’interrupteur flotteur directement

dans une prise de 120V.

3. Introduire le cordon d’alimentation

de la pompe directement dans le

dos de la fiche de l’interrupteur

flotteur (Voir Fig. 2).

4. Remplir le puisard d’eau. La pompe

se démarrera automatiquement

quand le puisard est rempli d’eau à

une profondeur d’approx. 13 po. La

pompe s’arrêtera lorsque la

profondeur soit approx. 7 po, ensuite

la pompe fonctionnera au besoin.

5. Ne pas faire fonctionner la pompe

sans l’avoir immergée dans l’eau. Le

fonctionnement au sec causera la

panne de la pompe.

6. Le moteur est équipé d’un

protecteur thermique à rappel

automatique.

7. Pendant que la pompe fonctionne,

vérifier que le tuyau de décharge

transporte l’eau à un endroit

plusieurs pieds de la fondation.

8. Si le tuyau de décharge est exposé à

la congélation, le tuyau doit être

incliné pour purger l’eau. L’eau

prise peut geler et endommager la

pompe.

Entretien

Toujours débrancher la source

d’électricité avant d’essayer

d’installer, de déplacer ou de

2 Fr

Instructions D’Utilisation Et Manuel De Pièces

Guide De Dépannage

Symptôme Cause(s) Possible(s) Mesures Correctives

La pompe ne se

démarre pas et ne

fonctionne pas

La pompe se démarre et

s’arrête trop souvant

La pompe ne s’arrête

pas ou le protecteur

thermique s’arrête

La pompe fonctionne

mais refoule peu ou pas

d’eau

1. Fusible sauté

2. Tension de ligne basse

3. Moteur défectueux

4. Interrupteur flotteur

défectueux

5. Turbine

6. Flotteur obstrué

1. Refoulement d’eau du tuyau

2. Interrupteur flotteur en

panne

1. Interrupteur flotteur

défectueux

2. Obstruction dans la tuyauterie

3. Flotteur obstrué

1. Tension de ligne basse

2. Turbine obstruée

1. Si sauté, le remplacer avec un fusible de taille correcte ou rajuster le

disjoncteur.

2. Si la tension est inférieure à 108 volts, vérifier la taille des fils.

3. Remplacer la pompe

4. Remplacer l’interrupteur flotteur

5. Si la turbine ne tourne pas, enlever le carter et enlever l’obstruction

6. Assurer le movement libre de haut en bas du flotteur

1. Installer ou remplacer le clapet (Nécessaire de clapet Wayne #66005WYN)

2. Remplacer l’interrupteur flotteur

1. Remplacer l’interrupteur flotteur

2. Enlever la pompe et nettoyer la pompe et la tuyauterie

3. Assurer le movement libre de haut en bas du flotteur

1. Si la tension est inférieure à 108 volts, vérifier la taille des fils.

2. Nettoyer la turbine

procéder à l’entretien. Si la source de

puissance est hors vue, verrouiller et

étiquetter dans la position ouverte

(off) pour éviter l’alimentation

inattendu. Manque de suivre ces

directives peut résulter en secousse

électrique mortelle. Seul un électricien

qualifié devrait réparer ce modèle. La

réparation incorrecte peut résulter en

secousse électrique mortelle.

1. Laisser la pompe se refroidir pour

un minimum de deux heures avant

de procéder à l’entretien. La pompe

contient de l’huile chaude sous

pression et le moteur est chaud.

2. Le démontage du moteur avant la

date d’expiration de la garantie

annulera la garantie. Se référer au

guide de dépannage pour la

réparation.

4. Garder l’arrivée propre et libre de

tous matériaux et l’inspecter annuellement. Une arrivée obstruée

peut endommager la pompe.

5. Inspecter la pompe chaque mois

afin d’assurer un fonctionnement

correct.

Cette

pompe

contient l’huile diélectrique pour le

refroidissement ce qui peut nuir à

l’environnement. Consulter les

règlements concernant

l’environnement de votre État/Province

avant la mise au rebut de cette huile.

Prise de courant mis

à la terre

Cordon

d’alimentation

Cordon

d’interrupteur

Broche de terre

3 Fr

Instructions D’Utilisation Et Manuel De Pièces

1. Néc. d’interrupteur flotteur 60022-001 60022-001

2. Néc. de couvercle supérieur 60030-001 60030-001

3. Plaque de Turbine 15958 15958

4. Turbine 60000-001 60000-001

5. Volute 60016-001 60007-001

Numéro de Pièces pour Modèles

Nº de CDT33 SPT33, SPT50

Réf. Description CDT50 SSPT33, SSPT50

Pour Les Pièces De Rechange, composer 1-800-237-0987

S’il vous plaît fournir l’information suivante:

-Numéro du Modèle

-Numéro de Série (si présent)

-Description et numéro de la pièce

Correspondance:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030

Spécifications

Exigences d’alimentation ................120V, 60 Hz

Moteur..............................................Monophasé, rempli d’huile

Puissance...........................................1/3 HP (CDT33, SPT33, SSPT33)

...........................................................1/2 HP (CDT50, SPT50, SSPT50)

Gamme de température liquide .....40°F à 120°F

Exigences de circuit..........................15 A (min)

Dimensions .......................................111/2 po H x 93/4 po base

Niveau de démarrage (réglé à l’usine)..13 po

Niveau d’arrêt (réglé à l’usine) .......7 po

Fabrication

Carter de moteur .............Acier laminé à froid

Volute ...............................Fonte (CDT33, CDT50)

..........................................Thermoplastique renforcé

de verre

(SPT33, SPT50, SSPT33, SSPT50)

Turbine .............................Thermoplastique renforcé

de verre

Arbre.................................Acier cémentation

Joints.................................Buna N

Décharge ..........................11/2po NPT

Couvercle de moteur.......Thermoplastique renforcé

de verre

Liste De Pièces De Rechange

Utiliser seulement les pièces de

l’usine pour la réparation de cette

pompe.

Garantie Limitée

Pendant un an pour les modèles SPT33 et SPT50, pendant deux ans pour les modèles CDT33 et CDT50 et

pendant trois ans pour les modèles SSPT33 et SSPT50 à compter de la date d’achat, Wayne Water Systems

Division (« Wayne ») réparera ou remplacera, à sa discrétion, pour l’acheteur original toute pièce ou pièces de

ces Pompes à l'eau ou à épuisement (« Produit ») déterminées défectueuses, suite à un examen par Wayne,

en termes de matériaux ou de fabrication. S’il vous plaît appeler Wayne (800-237-0987) pour des instructions

ou contacter votre marchand. S’assurer d’avoir, à votre disposition, le numéro du modèle afin d’effectuer cette

garantie. Les frais de transportation des Produits ou pièces soumis pour la réparation ou le remplacement sont

la responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont endommagés en résultat d’un accident, utilisation

abusive, mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation

conformément aux instructions écrit de Wayne.

IL N’EXISTE AUCUNE AUTRE GARANTIE OU AFFIRMATION. LES GARANTIES IMPLICITES, Y COMPRIS

CELLES QUI INDIQUENT SI LE PRODUIT EST VENDABLE OU CONVENABLE À UN USAGE PARTICULIER,

SONT LIMITÉES À UN AN POUR LES MODÈLES STP33 ET SPT50, À DEUX ANS POUR LES MODÈLES

CDT33 ET CDT50, ET À 3 ANS POUR LES MODÈLES SSPT33 ET SSPT50 À COMPTER DE LA DATE

D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR N’IMPORTE

QUEL ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la

limitation des dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer.

Cette garantie limitée donne, à l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales

qui sont variable d’une Province ou d’un État à l’autre.

En aucun cas, soit par suite d’une rupture de contrat de garantie, acte dommageable (y compris la négligence)

ou autrement, ni Wayne ni ses fournisseurs ne seront responsables pour aucun dommage spécial, incidentel ou

pénal, y compris, mais pas limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe

quel équipement associé, dommage à l’équipement associé, coût de capital, coût de produits remplaçants,

aménagements, services ou abilité de remplaçement, coût de temps que le produit n’est pas en service, ou la

réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre reçu d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une COPIE du reçu

d’achat avec le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît

contacter Wayne (800-237-0987) pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, CE BULLETIN À WAYNE PAR LA POSTE. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE__________________________ Nº DE SÉRIE________________________________

DATE D’INSTALLATION_____________________________________________

FIXER VOTRE REÇU ICI

Instructions D’Utilisation Et Manuel De Pièces

Loading...

Loading...