Page 1

See Warranty on page 8 for important information about commercial use of this product.

Operating Instructions and Replacement Parts List

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage!

Retain instructions for future reference.

Engine Driven

GPS400

A

N

R

C

U

E

S

S

P

A

R

Need

O

G

R

A

Y

T

I

L

A

U

Assistance?

Q

Call Us First!

1-800-237-0987

M

Centrifugal Pump

Description

The Wayne pumps are general use

centrifugal water pumps. The pump is

equipped with a Viton® seal assembly

that is also compatible with many

agricultural chemicals.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently hazardous

situation which, if not avoided, WILL

result in death or serious injury.

Warning indicates a

potentially hazardous

situation which, if not avoided, COULD

result in death or serious injury.

Caution indicates a

potentially minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm. Wash

hands after handling.

Never run

an enclosed area. Exhaust

gases contain deadly

poisonous carbon monoxide,

which has no odor or taste.

Do not use

to pump

flammable or explosive fluids

such as gasoline, fuel oil,

kerosene, etc. Do not use in

flammable and/or explosive atmospheres.

Pump should only be used with liquids

compatible with pump component materials.

Failure to follow this warning can result in

personal injury and/or property damage.

2. Observe all safety precautions for the

handling of the fuel.

Do not

hot engine. Fuel spilled on a

hot engine could result in a

fire or explosion. Do not

refuel a running engine.

3. Pump should be located and should

rest on a level solid foundation. Do

not suspend pump by means of the

discharge pipe.

Be sure pump is on

doesn’t fall over.

4. Do not use torches or apply excessive

heat, fire or flames to this pump as an

explosion may result.

5. Before working on the unit, insulate

the wire from the spark plug, by

disconnecting the spark plug wire from

the spark plug.

Complete pump and

1. Know the pump application,

limitations, and potential hazards.

Read these rules and the instructions

carefully. Failure to follow them could

cause serious bodily injury and/or

property damage.

MUST be protected against below freezing

temperature. Failure to do so could cause

serious damage and voids the warranty.

6. Do not run pump dry. Water is

required to lubricate the shaft seal.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or fi le it for safekeeping.

engine in

refuel a

secure footing so it

piping system

7. Pumping chemicals or corrosive liquids

with this pump may shorten the life of

the pump and may be hazardous to the

operator.

8. Personal Safety:

a. Wear safety glasses at all times when

working with pumps.

b. Keep work area clean, uncluttered

and properly lighted; replace all

unused tools and equipment.

c. Keep visitors at a safe distance from

the work area.

d. Make workshop child-proof with

padlocks, master switches, and by

removing starter keys.

9. This pump is designed for non-abrasive

fluid transfer; do not use as a trash

pump. Always use a suction strainer with

this pump to filter abrasive material.

Abrasive materials such as sand and

gravel will shorten the life of the pump.

Installation

This pump is designed to be self-priming

when installed and operated as specified

below.

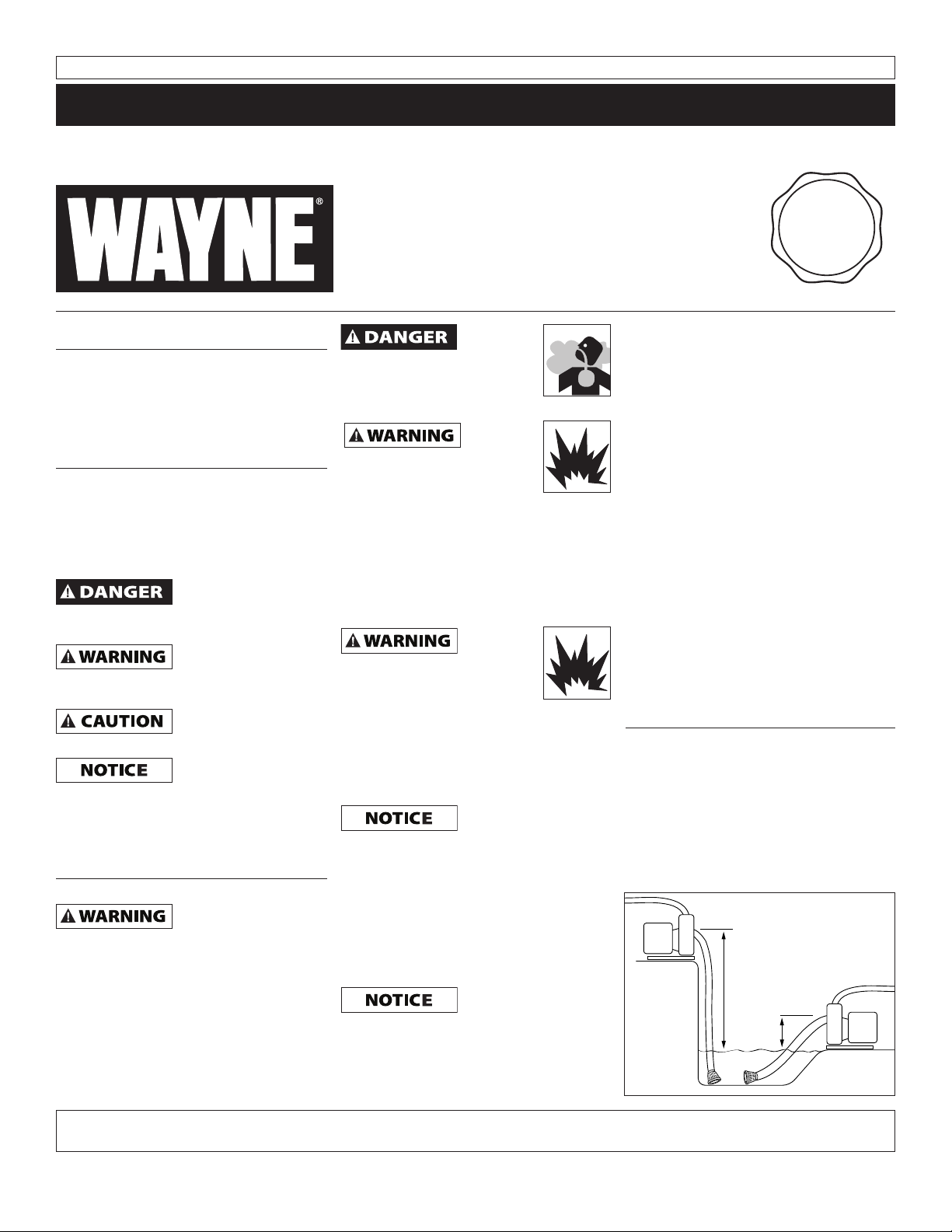

1. The pump should be placed as close as

possible to the water being pumped.

A pump with 20 foot suction lift will

not remove water as quickly as a pump

with 5 foot suction lift (Figure 1).

20 Ft. Suction Lift

5 Ft.

Suction

Lift

Figure 1

© 2010 WAYNE Pumps

For parts, product & service information

visit www.waynepumps.com

320604-001 8/10

Page 2

Operating Instructions and Replacement Parts List

Installation (continued)

2. Suction hose and fitting must be

airtight.

An air leak in the

prevent priming of the pump. Use of

thread sealant is recommended.

suction line may

Suction lines must be reinforced hose

or rigid pipe. Non-reinforced hose will

collapse due to the suction created

by the pump and prevent pump from

operating.

3. A check valve must be used in the

suction line to maintain the selfpriming capability. If no check valve is

used the pump will need to be primed

at the start of each operation. For best

operation, the check valve should be

installed at the intake of the suction

line.(Figure 2).

Check valve

Figure 2

4. A suction strainer is required to filter

abrasive material. Abrasive material,

such as gravel, will destroy the pump

and void the warranty. This pump

is not designed to handle abrasive

materials.

5. The discharge hose and fitting should

be leak-tight. A leak in the discharge

hose will allow water to spray

around the work site, making the site

hazardous.

6. Keep all pipes and hose lines as short

and straight as possible. Long lengths

and curves in the pipes and hose lines

will reduce the pressure the pump

develops.

7. Fill the engine crankcase with oil.

Refer to the engine operating manual

for the specific grade of oil and

amount required.

8. Fill the engine fuel tank with

gasoline. Refer to the engine

operating manual for specific gasoline

type that is most efficient for this

engine.

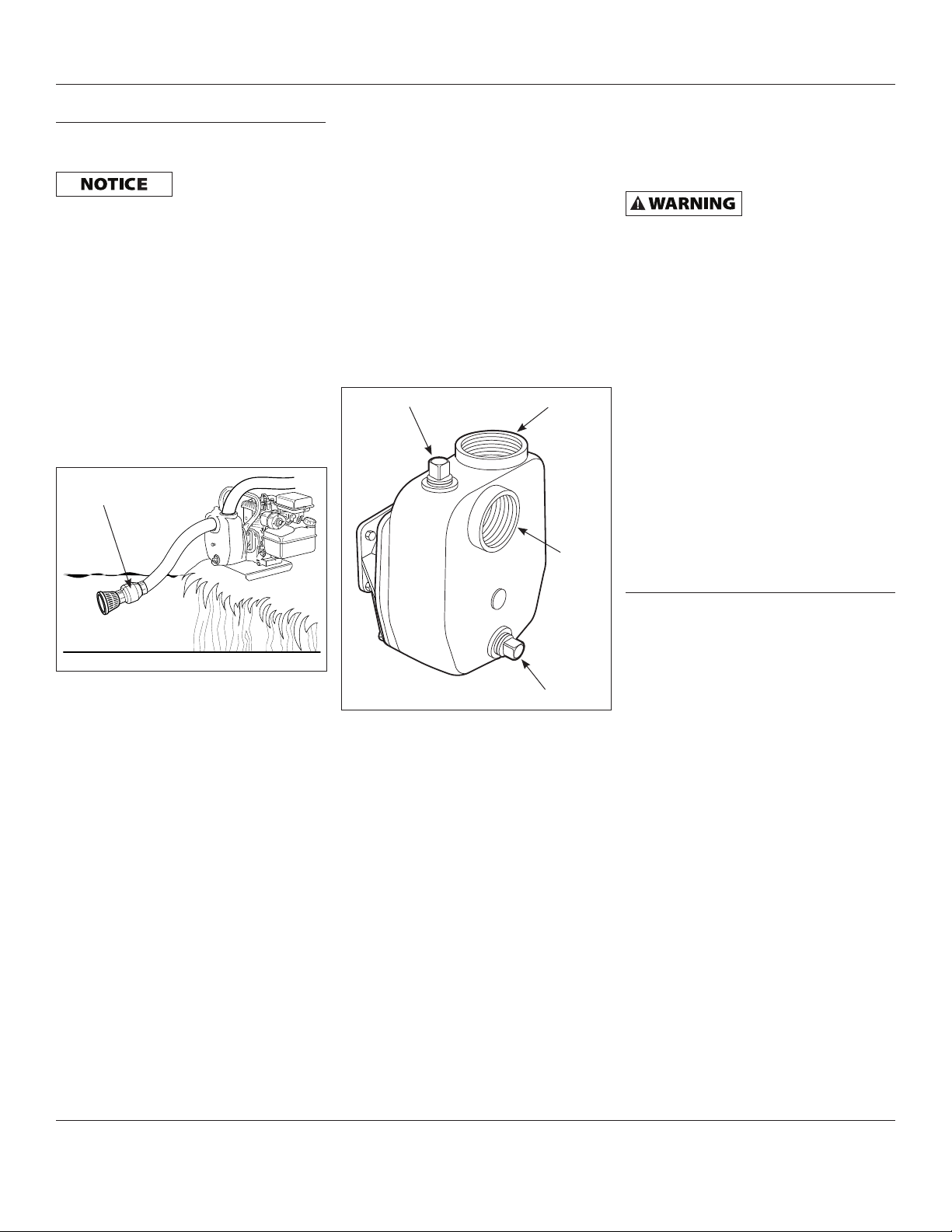

9. Add water to the priming port on

the pump (See Figure 3). Continue

adding water until the water level is

approximately 3 inches from the top.

Install the priming plug. The water in

the pump will create the suction that

primes the pump.

Priming port

Figure 3

Discharge

Suction

Drain port

10. Turn fuel valve to ‘ON’ position

11. Move choke level to ‘CHOKE’ position.

12. Move the engine switch to ‘ON’

position.

13. Pull engine crank until engine starts.

Once engine starts, move choke lever

to ‘RUN’ position.

14. The pump will take several minutes to

prime.

PIPING

Always place the pump as close as possible

to the water being pumped. Keep all pipe

and hose lines as short and straight as

possible.

Support pump and

piping when

assembling and after installation. Failure

to do so may cause piping to break, pump

to fail, etc; all of which can result in

property damage and/or personal injury.

All suction connections must be airtight.

If the pump won’t prime, check for leaks

in the suction piping or fittings. If flexible

suction hose is used instead of pipe, use

reinforced hose with a two inch inner

diameter. Non-reinforced flexible hose may

collapse from the vacuum created as the

pump primes.

Always use a strainer at the end of the

suction pipe or hose. Position strainer so

it doesn’t become clogged with stones

or debris. A suction line check valve is

recommended.

Do not use this pump for suction lifts over

twenty-five feet.

Maintenance

Always shut off the engine, allow the

engine to cool, and remove the spark plug

before performing any maintenance.

During freezing weather, open the drain

port and allow all the water in the pump

to drain. This will prevent damage to the

pump when the water freezes. If the pump

will be stored for a month or more, drain

the water from the pump and follow the

engine manufacturer’s recommendations

for long-term storage.

www.waynepumps.com

2

Page 3

Performance Information

y

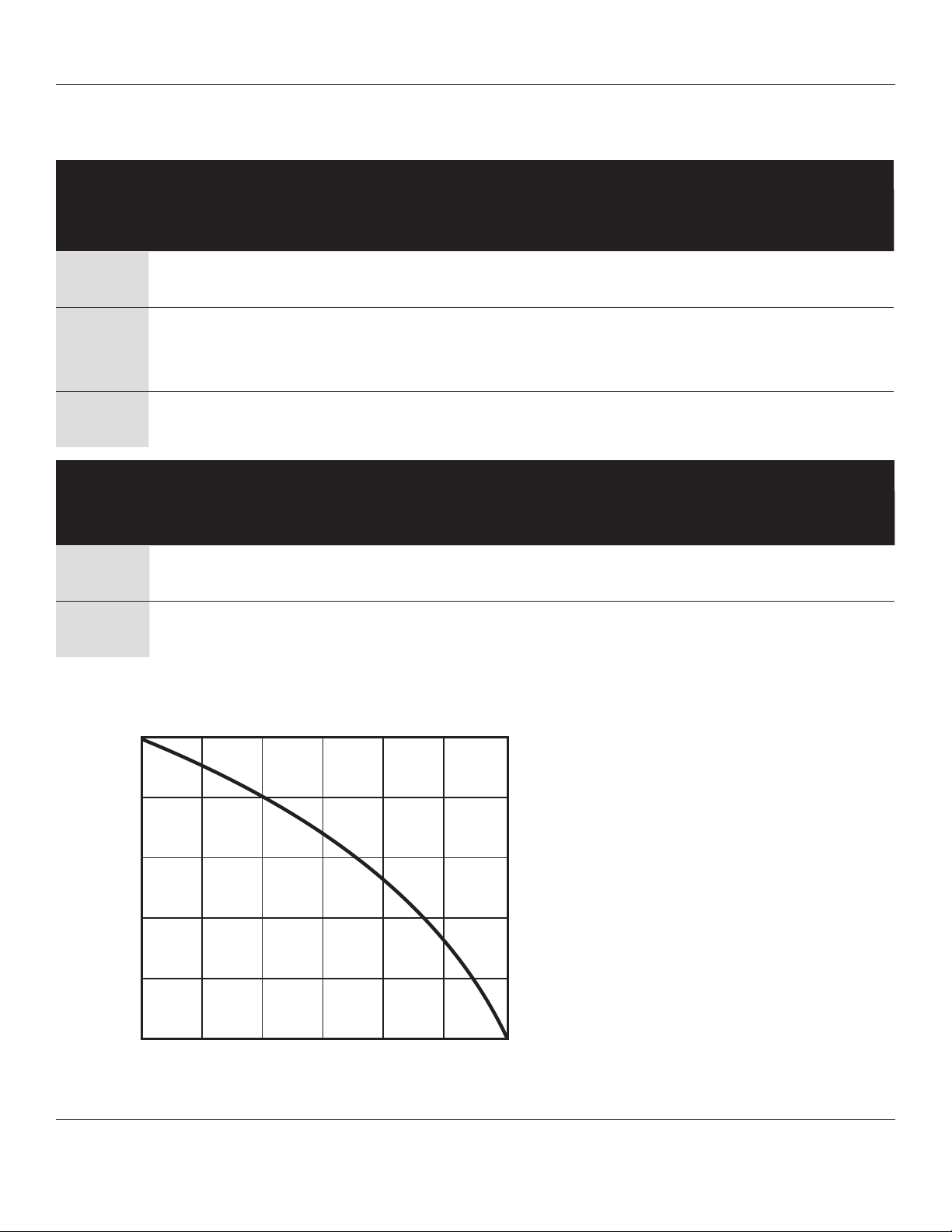

2” Cast Iron Pump Performance

CAPACITIES IN GALLONS PER HOUR

Discharge

Head Feet

20 6600 6420 6180 6000 5640 5220

30 6180 6000 5640 5220 4800 4380

40 5640 5220 4800 4380 4080 3660

50 4800 4380 4080 3660 3300 2820

60 4080 3660 3300 2820 2400 1800

70 3300 2820 2400 1800 1260 720

80 2400 1800 1260 720 0 0

0 5 10 15 20 25

FEET FRICTION LOSS IN 100 FEET OF PLASTIC PIPE

Dynamic Suction Lift - Feet

GPS400

Pipe

Size

1 1/

4

1 1/

2

2 1.2 1.6 2.8 4.2 5.8 9.9 15.0 21.2

2 1/

2

20 25 30 40 50 60 80 100 120

5.6 8.5 11.9 20.2 30.5

2.6 4.0 5.5 9.4 14.3 19.9 34.2

Gallons Per Minute

1.2 1.8 2.5 4.2 6.3 8.8

PERFORMANCE CURVE

100

80

60

40

20

Total Dynamic Head - FEET

0

1200 2400 3600 4800 6000 7200

Capacit

- GPH

www.waynepumps.com

3

Page 4

Operating Instructions and Replacement Parts List

For Pump Accessories, call 1-800-237-0987

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown

SUCTION HOSE

PART #16510-002

• Reinforced to prevent collapse under

suction

Hose coupled both ends with 2” hose

thread. One 20 ft. hose per carton

LAY FLAT DISCHARGE HOSE

PART #16511

• Economical

• Lightweight

• Resistant to oils, light chemicals,

abrasion and sunlight

• Will not rot, mildew or absorb water

Hose couples one end with 2” hose

thread. One 25 ft. hose per carton

Address parts correspondence to:

WAYNE Pumps

101 Production Drive

Harrison, OH 45030

2” SUCTION STRAINER

PART #66036

• Prevents stones, leaves and other

debris from clogging pump

www.waynepumps.com

4

Page 5

For Replacement Parts or Technical Assistance,

call 1-800-237-0987

GPS400

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown

8

13

4

Address parts correspondence to:

WAYNE Pumps

101 Production Drive

Harrison, OH 45030

1

10

2

5

3

3a

6

9

11

7

Item No. Description Part Number Qty

1 Engine 57800-001 1

2 Volute Bracket 56724-001 1

3 & 3a Impeller kit with shims 66057-WYN1 1

4 Screw 17046-001 1

5 Key 16997-001 1

®

6 Shaft seal kit (VITON

7 Volute 56723-001 1

8 Pipe plug, 3/4 NPT 15921 2

9 Volute gasket 15556-002 1

10 Cap screw, 5/16 - 18 x 1 12701 5

11 Cap screw, 5/16 - 24 x 7/8 16209 4

12 Lock washer, split 5/16 (not shown) 15916 4

13 Handle 56722-001 1

14 Base 11007-001 1

) 56712 1

14

www.waynepumps.com

5

Page 6

Operating Instructions and Replacement Parts List

Notes

www.waynepumps.com

6

Page 7

Maintenance / Service Record

Date Maintenance Performed Replacement Components Required

GPS400

www.waynepumps.com

7

Page 8

Operating Instructions and Replacement Parts List

GPS400

Limited Warranty

For one year from date of purchase, WAYNE Water Systems (”WAYNE Pumps“) will repair or replace, at its option, for the

original purchaser any part or parts of its Sump Pumps or Water Pumps (”Product“) found upon examination by WAYNE

Pumps to be defective in materials or workmanship. Please call WAYNE Pumps (800-237-0987) for instructions or see your

dealer. Be prepared to provide the model number when exercising this warranty. All transportation charges on Products or

parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with WAYNE Pumps' written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall WAYNE Pumps

or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit

or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a COPY of the purchase receipt along with the material or correspondence. Please call WAYNE Pumps (800-237-0987) for

return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE PUMPS. Use this form only to maintain your records.

MODEL NO._____________________ SERIAL NO.___________________________ INSTALLATION DATE ______________________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

8

Loading...

Loading...