Page 1

OWNER INSTALLATION AND

USER MANUAL Series 3000

Models: 3014, 3018, 3018DLX & 3514

Automatic Garage Door Opener

For Sectional Overhead Residential Doors Only

DO NOT USE ON ONE PIECE DOORS

READ THE ENCLOSED INSTRUCTIONS CAREFULLY BEFORE

INSTALLING/OPERATING THIS OPENER! PAY CLOSE ATTENTION TO ALL

WARNING LABELS AND NOTES. THIS MANAUL SHOULD BE ATTACHED IN

CLOSE PROXIMITY TO THE GARAGE DOOR OPENER.

DOOR AND OPENER WILL NOT OPERATE PROPERLY UNTIL INFRARED SAFETY

SENSORS ARE INSTALLED AND PROPERLY ADJUSTED! DO NOT OPERATE DOOR

OPENER UNTIL FULLY INSTALLED, ADJUSTED & INSTRUCTED TO DO SO!

CONTENTS

Important Installation Instructions 2 Infrared Safety Sensor Obstruction Test 25

Features 4 Wireless Keyless Entry Installation 26

Door Tests 5 Opening & Closing Force Adjustment 27

Tools You’ll Need 6 Contact Obstruction Sensing Adjustment 28

Part Identification 7 Mechanical Lock Adjustment 28

Hardware Identification 8 Operational Safety Rules 29

Rail Assembly 9 Operation Of Your Opener 30

Installation Instructions 11 Emergency Release Disconnect 32

Installing Wall Station 13 Maintenance Schedule 33

Installing Infrared Safety Sensors 15 Trouble Shooting 34

Wall Station Code Change & Programming 19 Parts Breakdown - Rail 35

Infrared Safety Sensors Alignment 20 Parts Breakdown - Power Head Assembly

And Accessories

Transmitter’s Code Change & Programming 21 Accessories 37

Travel Adjustment 25 Warranty 39

Obstruction Sensing Test 24 Customer Service Number 40

© Copyright 2003 Wayne-Dalton Corp. Part No: 307532 Rev3 10/15/03

36

Page 2

Read These Important Safety Rules Before Proceeding

This symbol indicates caution and appears throughout this instruction

manual. This garage door opener is designed and tested to offer reasonably safe operation if installation is followed in strict accordance with these

safety instructions. Failure to comply with these instructions may result in

serious personal injury or property damage.

IMPORTANT INSTALLATION INSTRUCTIONS

WARNING: To reduce the risk of severe injury or death:

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

Install only on a properly balanced garage door.

An improperly balanced door could cause severe

injury. Have a qualified service person make repairs to cables, spring assemblies and other

hardware before installing opener.

To reduce the risk of injury to persons, use this

operator only with sectional overhead doors.

Fiberglass, aluminum and steel doors must be reinforced to prevent damage to the door. Check

with your garage door manufacturer for their recommendations.

Remove all ropes and remove or make inoperative

all locks connected to the garage door before installing opener.

Do not use sensitivity adjustments to compensate

for a poorly operating door. This will interfere

with the proper operation of the safety reverse

mechanism and may damage the door.

Locate control button: within sight of door, at a

minimum height of 5 feet, so small children cannot reach it, and away from all moving parts of the

door.

If possible, install door opener 7 feet or more

above floor. Mount the emergency release knob 6

feet above the floor.

AFTER INSTALLATION IS COMPLETE, FASTEN THIS MANUAL NEAR GARAGE DOOR.

PERFORM PERIODIC SAFETY CHECKS, MAINTENANCE AND ADJUSTMENTS, AS RECOMMENDED.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate the receiving antenna. Increase

the separation between the equipment and receiver. Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected. Consult the dealer or an experienced radio/TV technician for help. Warning: Changes or modifications to this unit not expressly approved by Wayne-Dalton Corp. could void the user’s authority to operate the equipment.

FCC Regulatory Information: This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

IC Regulatory Information: This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Do not connect opener to source of power until

instructed to do so.

Installation and wiring must comply with local

building and electrical codes. Connect the power

cord to a properly grounded outlet. Do not remove round ground pin from power cord.

Install entrapment warning label next to control

button in a prominent location, such as the inside

of the garage door, or as instructed in the installation instructions. If label adhesive will not adhere

to the surface, secure the label by additional mechanical means such as staples, nails or screws.

If necessary, use an intermediate mounting surface, such as plywood, cut to the appropriate size.

Install Emergency Release tag to the emergency

red cord.

After installing opener, the door must reverse

when it contacts a 1 inch high solid test object on

the floor.

Open door must not close and closing door must

open if photoelectric system in obstructed by 6”

High object, using test procedure described in

Step 29.

Do not wear rings, watches or loose clothing

when installing or servicing a garage door system. Use a sturdy, non-metallic step ladder.

2

Page 3

Veuillez lire ces règles de sécurité importantes avant de commencer les travaux

Ce symbole vous demande de prendre les précautions voulues. Vous le trouverez d’un bout à

l’autre du présent guide d’installation. Cet ouvre porte de garage a été conçu et essaye pour

vous offrir un fonctionnement sécuritaire dans la mesure ou les directives d’installation sont

respectées conformément a ces mesures de sécurité. Le non respect de ces mesures de

sécurité risqué d’entraîner des blessures corporelles graves et des dommages matériel.

IMPORTANT —NOTICE D’INSTALLATION—

AVERTISSEMENT –POUR REDUIRE LES RISQUES DE BLESSURES MORTELLES

LISEZ CETTE NOTICE ET CONFORMEZ-VOUS AUX

INSTRUCTIONS.

NE POSEZ CET OUVRE-PORTE QUE SUR UNE

PORTE DE GARAGE CORRECTEMENT ÉQUILIBRÉE. UNE PORTE MAL ÉQUILIBRÉE PEUT CAUSER DES BLESSURES GRAVES. CONFIEZ LA REPARATION DES CABLES, DES RESSORTS, ET DE

TOUT AUTRE ÉLÉMENT À UN TECHNICIEN QUALIFIÉ AVANT D’ENTREPRENDRE L’INSTALLATION.

POUR RÉDUIRE LE RISQUE DE BLESSURES CORPORELLES, UTILISER CET OUVRE- PORTE POUR

DES PORTES BASCULANTES SECTIONNELLES

UNIQUEMENT.

LES PORTES EN FIBRE DE VERRE, EN ALUMINUM

ET EN ACIER DOIVENT ETRE RENFORCÉES POUR

EVITER D’ENDOMMAGER LA PORTE. CONSULTEZ

LE FABRICANT DE VOTRE PORTE DE GARAGE

POUR OBTENIR SES RECOMMANDATIONS.

ENLEVEZ LES CORDES ET ENLEVEZ OU NEUTRALISEZ TOUT DISPOSITIF DE VERROUILLAGE SOLIDAIRE DE LA PORTE DE GARAGE AVANT

L’INSTALLATION.

NE VOUS SERVEZ PAS DES RÉGLAGES DE LA

SENSIBILITÉ POUR COMPENSER LE MAUVAIS

FONCTIONNEMENT D’UNE PORTE. CECI POURRAIT FAIRE OBSTACLE AU BON FONCTIONNEMENT DU MÉCANISME DE L’INVERSEUR DE SÉCURITÉ ET POURRAIT ENDOMMAGER LA PORTE.,

DANS LA MESURE DU POSSIBLE, INSTALLEZ

L’OUVRE-PORTE Á AU MOINS 2.14M (7PI) DU SOL.

POSEZ LE DISPOSITIF DE DÉSACCOUPLEMENT

D’URGENCE Á 1.83 M (6 PI) DU SOL.

INSTALLEZ LE BOUTON DE COMMANDE

DROIT QUE L’ON PEUT VOIR DE L’EMBRASURE DE

LA PORTE,

(5 PI) DU SOL –AFIN QUE LES JEUNES ENFANTS

NE PUISSENT PAS L’ATTEINDRE—ET

DES PIECES MOBILES DE LA PORTE.

"Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne causant des règlements

d’équipement. Ľopération est sujette aux deux conditions suivantes: (1) cet dispositif peut ne pas causer l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui peut causer l’opération peu désirée. "

APRÈS L’INSTALLATION, PLACER CE MANUEL À PROXIMITÉ DE LA PORTE DE GARAGE FAIRE RÉ-

GULIÈREMENT LES VÉRIFICATIONS RECOMMANDÉES CONCERNANT LA SÉCURITÉ L’ENTRETIEN

À UNE HAUTEUR MINIMALE DE 1.53 M

Á UN EN-

À L’ENCART

ET LES RÉGLAGES

APPOSEZ L’ÉTIQUETTE DE MISE EN GARDE RELATIVE AU DANGER DE HAPPEMENT À PROXIMITE

DU BOUTON DE COMMANDE ET L’ÉTIQUETTE RE-

LATIVE AU RÉGLAGE DE LA COMMANCE Á UN

EMPLACEMENT EN EVIDENCE—PAR EXEMPLE

SUR LA PAROI INTÉRIEURE DE LA PORTE DE GARAGE OU SELON LES INSTRUCTIONS DE LA NOTICE D’INSTALLATION. APPOSEZ L’ÉTIQUETTE

RELATIVE AU DÉSACCOUPLEMENT D’URGENCE

SUR LE DISPOSITIF OU À PROXIMITE DE CE DERNIER.

NE BRANCHEZ PAS L’OUVRE-PORTE AVANT D’Y

ÊTRE AUTORISÉ PAR LA NOTICE.

UNE FOIS L’OUVRE-PORTE INSTALLÉ, LES SENS

DE LA COURSE DOIT S’INVERSER LORSQUE LA

PORTE ENTRE EN CONTACT AVEC UN OBJET

D’UNE HAUTEUR DE 25.4MM (1 PO) POSE SUR LE

SOL.

L’INSTALLATION ET LE BRANCHEMENT ÉLECTRIQUE DOIVENT ÊTRE CONFORMES AUX CODES

LOCAUX DU BÂTIMENT ET DE L’ÉLECTRICITÉ

RACCORDER LE CORDON D’ALIMENTATION

UNE PRISE ADÉQUATEMENT MISE Á LA TERRE.

NE PAS ENLEVER LA BRANCHE RONDE DE MISE Á

LA TERRE DU CORDON D’ALIMENTATION.

SI LE SYSTÈME PHOTOÉLECTRIQUE EST BLOQUÉ

PAR UN OBJET DE PLUS DE 6 PO X 12 PO, LA

PORTE OUVERTE NE DOIT PAS SE FERMER ET LA

PORTE SE FERMANT DOIT S’OUVRIR. VÉRIFIER

CELA EN UTILISANT LA VÉRIFICATION DÉCRITE

L’ÉTAPE 29.

NE PAS PORTER DES BAGUES, DES MONTRES OU

DES VÊTEMENTS LÂCHES PENDANT

L’INSTALLATION OU LA VERIFICATION TECHNIQUE DU SYSTÈME DE PORTE DE GARAGE. UTILISER UNE ÉCHELLE NON MÉTALLIQUE STABLE.

CONSERVEZ CES INSTRUCTIONS.

Á

Á

3

Page 4

Automatic Garage Door Opener – For Residential Doors Only

FEATURES

1. Open and Close Cycle Control: Allows garage door

to be started and stopped by push button, transmitter or

wall station. The next impulse sends garage door in

opposite direction.

2. Emergency Disconnect: Manual disconnect permit-

ting operation of door during power failure with automatic reconnect when opener is reactivated. See pg

32.

3. Opener light: Automatically turns on when opener is

activated and remains on for 4 minutes for convenience

and safety.

4. Mechanical Door Lock: When properly adjusted,

opener locks door in closed position preventing unwanted entry. See Adj. # 3 pg 28.

5. Obstruction Warning Light: The convenience light

will flash after sensing an obstruction in the down direction and/or if the safety system malfunctions while in

the open position.

6. Motor: Permanently lubricated, thermally protected,

heavy duty motor with automatic reset.

Caution: If your garage has no service entrance door, install optional outside quick release lock. This accessory allows

manual operation of garage door from outside in case of power failure.

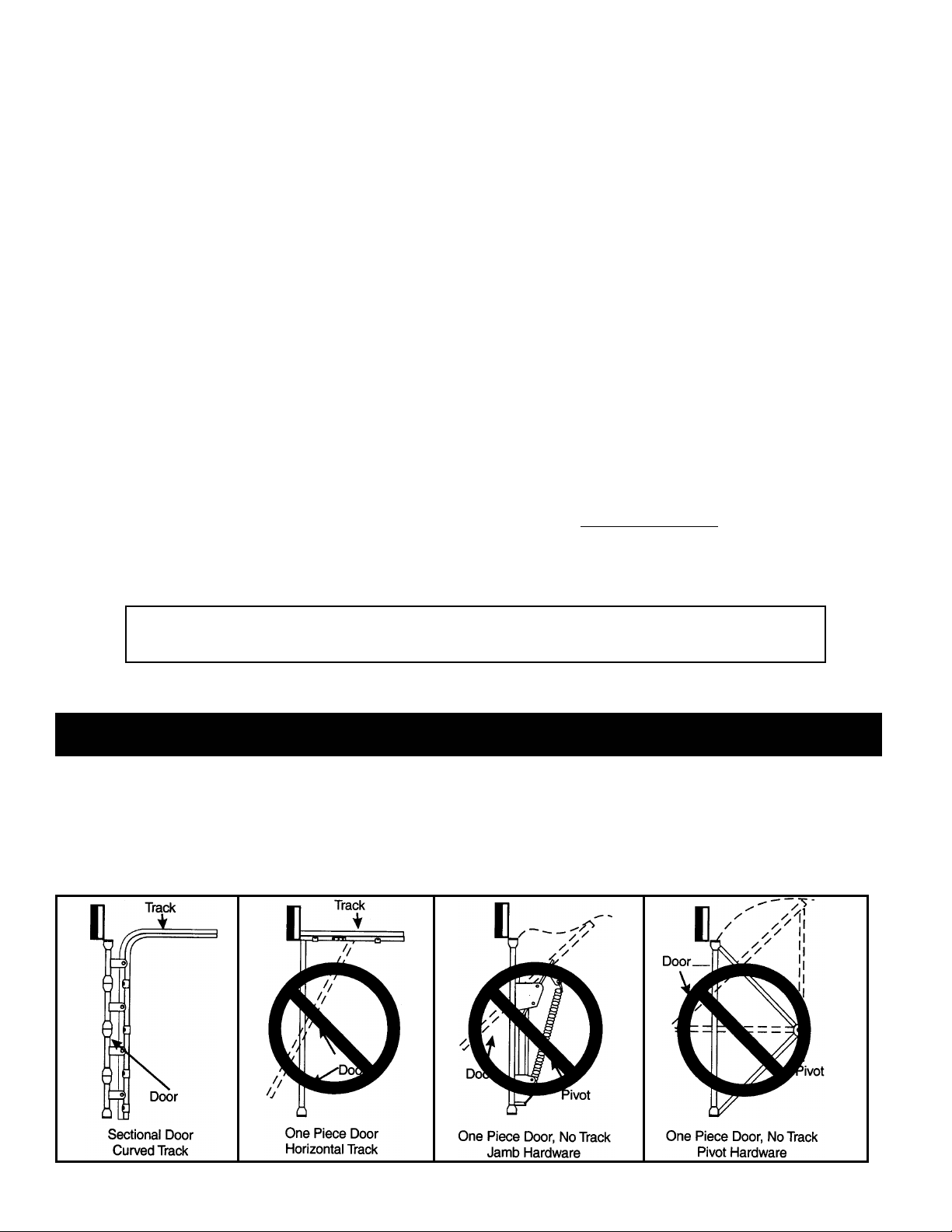

Identify the door referring to illustrations below and verify that the door type is a sectional door with curved track. Do not

install if the door is any type of one piece door.

Note: The opener has been designed for sectional doors. Do not attempt to install this opener on any style one

piece door. Use of the enclosed opener on a one-piece door may result in serious personal injury of property

damage.

Before Starting Installation Read These Instructions Thoroughly to Familiarize

Yourself with All Aspects of Installation and Adjustment!

Before Starting

7. Safety System: Independent up and down force ad-

justments. When properly adjusted, the safety system

will automatically reverse when obstructed in down direction and return to fully open position. The door will

stop when obstructed in the up direction. See Adj. #2,

pg 28.

8. Infrared Safety Sensors: Wired or wireless infrared

reversing sensors detect an obstruction in door path

and react by reversing door.

9. Multi-Function Wall Station: Wired wall station pro-

vides up/down door motion control and independent

overhead light on/off control. Wireless wall station provides up/down door motion control, independent overhead light on/off control, door down delay, adjustable

“pet position” function, and “pet position” program button.

10. Homelink™ Compatibility: Opener is capable of

“learning” automobile equipped Homelink™ transceivers. Visit: www.homelink.com.

11. Rolling Code Technology: Wireless transmitters and

wall stations use rolling code which prevents would-be

thieves from “grabbing” the transmitter’s digital code.

4

Page 5

Before you begin, complete the following two tests to insure that the door is balanced and working properly. A door that

binds, sticks or is out of balance could cause severe injury. Do not attempt to compensate for an improperly adjusted door

by the installation of an opener. This will interfere with the proper operation of the opener mechanism and/or may damage

the door. Have a qualified service person make any needed adjustments or repairs to cables, spring assemblies and other

hardware before proceeding with installation.

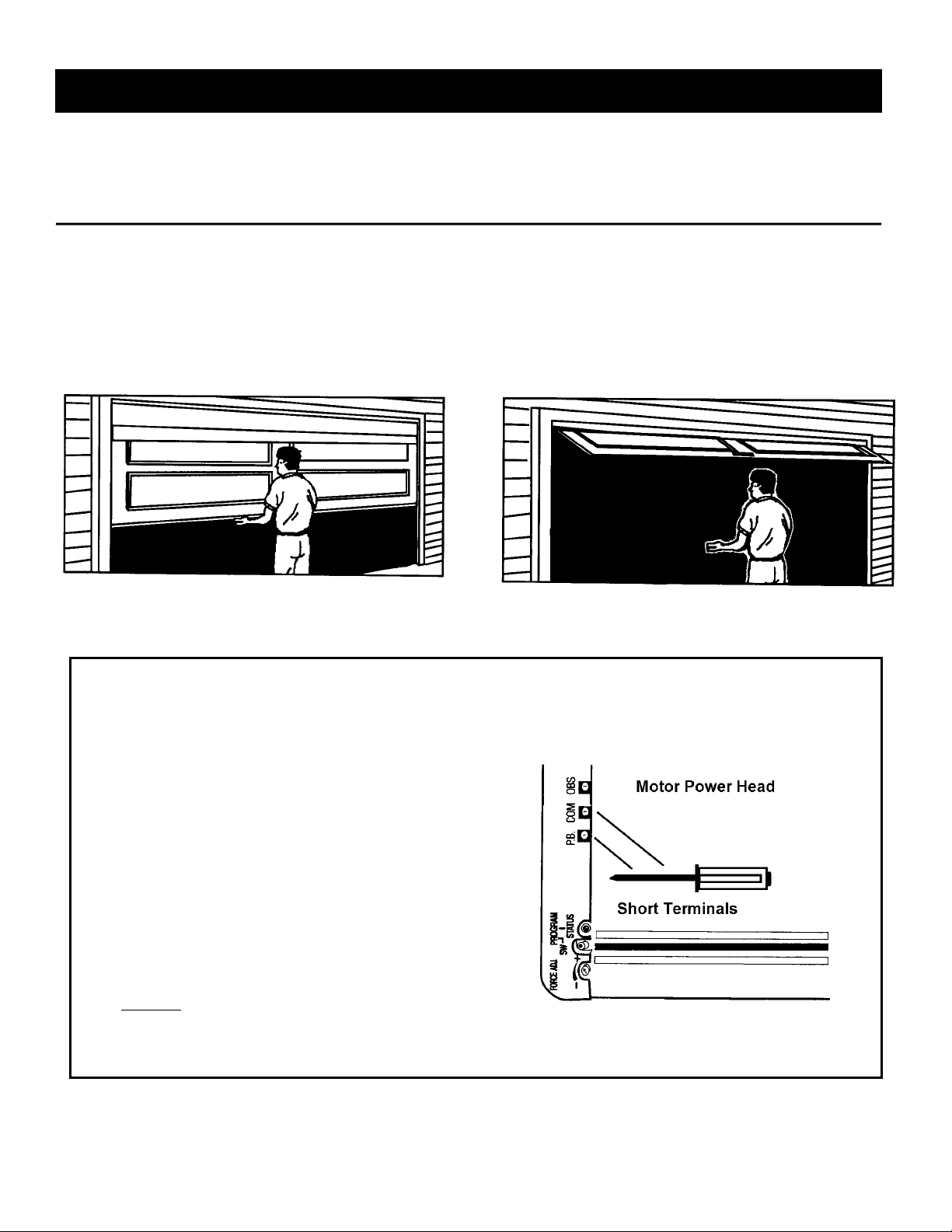

Door Test One

Raise and lower the door and check closely for any

sticking or binding that occurs.

Lift the door approximately half way open, as illustrated.

When releasing the door, it should stay in position. If

spring pressure pulls the door further open or door

weight pulls it further down, your door is not properly

adjusted.

Door Tests Before Starting

Door Test Two

When properly installed, a door should remain clear of

the opening, when allowed to rest at its natural, full open

position.

If “door drift” pulls door back into opening or spring tension is not sufficient to pull door totally clear of opening,

the door is not properly adjusted.

IMPORTANT PRE-ASSEMBLY CHECK

If assembling a motor head unit from a factory sealed box skip this check.

Every Power Head Unit is factory tested and shipped with

the limit switch adjustment in the door CLOSED position.

If the Motor Power Head Unit has been powered up before

assembly, perform the following steps to insure that the

limit switch adjustment is in the door CLOSED position.

Connect Motor Head Unit to a power source and short

across the screw terminals labeled “PB” and “COM” with

a metal screw driver.

Motor should start; run through a full OPEN cycle, and stop.

This will leave Motor Power Head Unit in OPEN position.

To get Motor Power Head Unit back to full CLOSE position,

short and hold

terminals until Motor Power Head Unit stops in the

CLOSED position. Disconnect from power source and

proceed to assembly.

motor terminals again. Continue to short

5

Page 6

Do not plug the power cord into electrical outlet until opener is fully installed and you are instructed to do

so in this manual. Door springs, pulleys, cables and brackets are under extreme tension and can cause

severe injury or fatal injury. Do not attempt to adjust or repair these components yourself, but call a professional door service company.

Do not wear rings, watches or loose clothing when installing or servicing a garage door system. Use a

sturdy, non-metallic step ladder and wear protective gloves and eye protection.

Remove all ropes or cords attached to the garage door, to prevent personal injury due to entanglement.

Disable or remove all locks on the garage door.

Install opener only on a properly balanced garage door. Have qualified service person make any necessary repairs to cables, spring assemblies and other hardware before installing opener.

READ AND FOLLOW ALL INSTALLATION INSTRCTIONS.

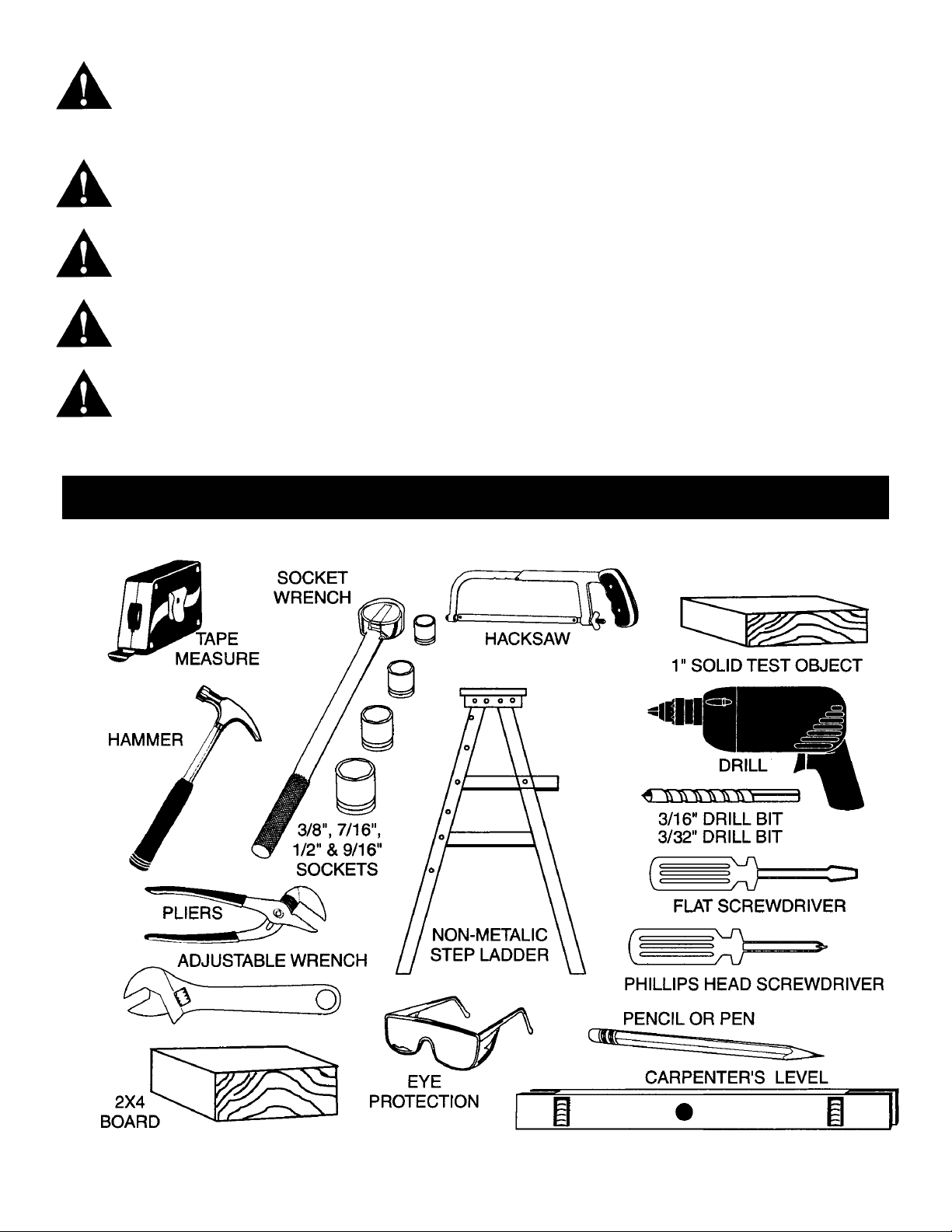

The following tools will be required during different parts of the installation and adjustment procedure.

Tools You’ll Need

6

Page 7

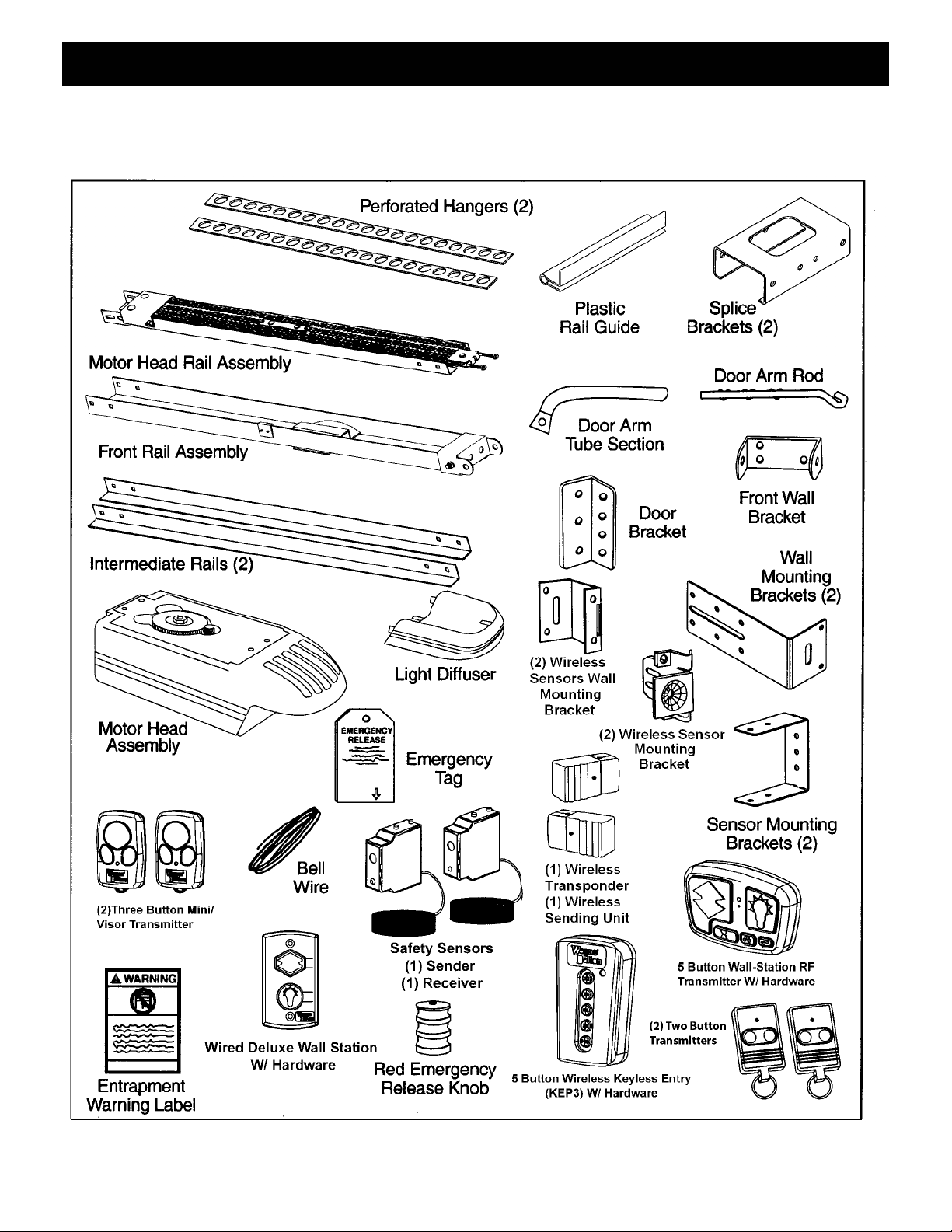

The opener is fully packed in one carton. Unpack and inspect contents carefully for any possible shipping damage or

missing parts. Do not attempt installation if any parts are damaged or missing. NOTE: Depending on opener model,

some parts listed will not be supplied if not necessary.

Part Identification

7

Page 8

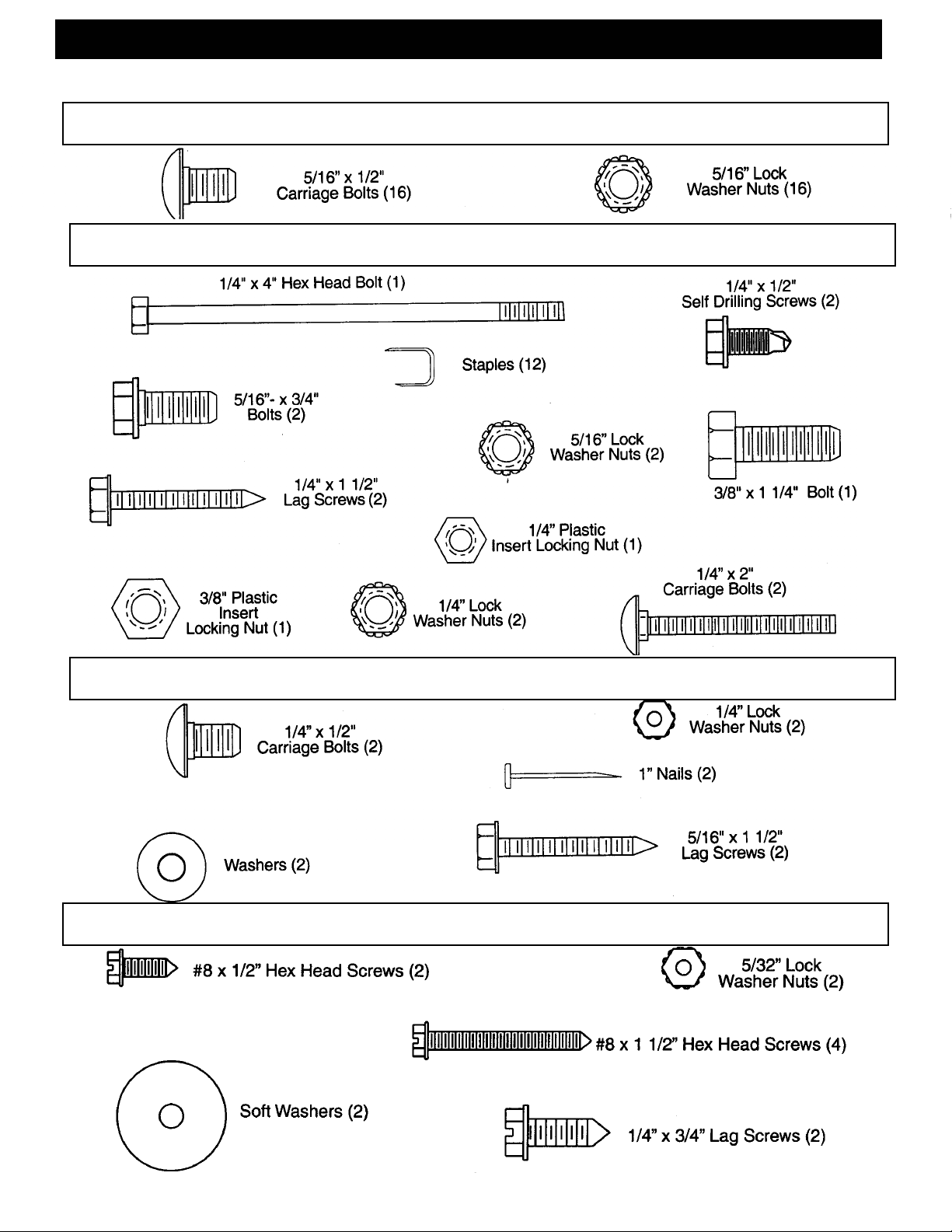

Hardware Identification

For Your reference, all hardware has been illustrated. During assembly and installation, please refer to this page to insure

you are using the proper hardware called for during each step.

Wired Safety Sensor Hardware Bag

Assembly Hardware Bag

Installation Hardware Bag

Wireless Safety Sensor Hardware Bag

8

Page 9

Rail Assembly

WARNING:

DO NOT RUN OPENER UNTIL INSTRUCTED TO DO SO!

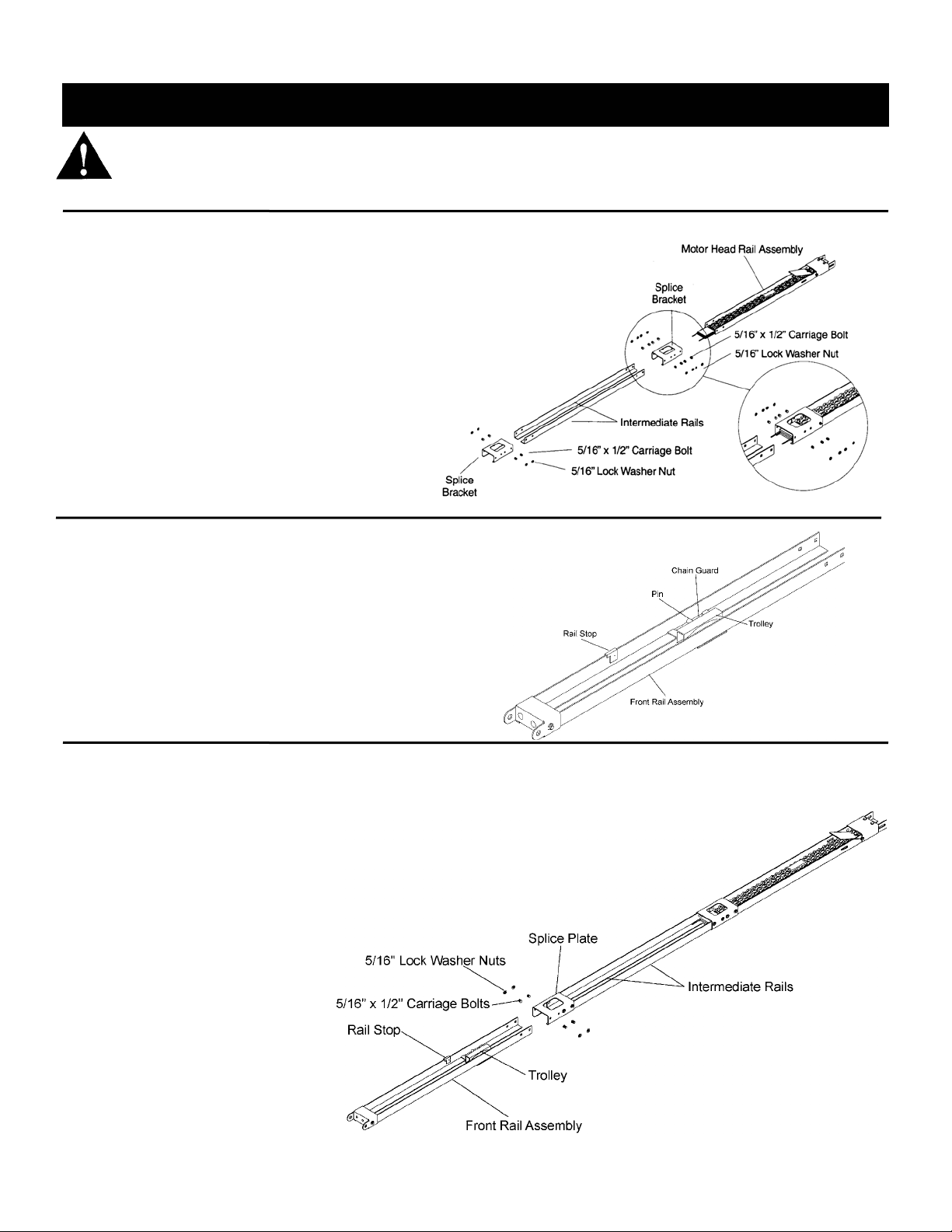

Step One: Rail Assembly

Pre-position parts for assembly. Bolt a splice

bracket to the motor head assembly and bolt the

intermediate rails to the same splice bracket,

using 5/16” x 1/2” carriage bolts and 5/16” lock

washer nuts. The rounded head must be on the

inside of the rails and the nuts outside. Bolt the

other splice bracket to the intermediate rails,

leaving the four holes on the splice bracket open

for the front rail assembly.

NOTE: Keep in mind that the rails will have to

be adjusted later, so only finger tighten the

bolts first. The bolts will have to be tightened

after the rail alignment is achieved.

Step Two: Trolley Alignment

Ensure the rails fit between the upper and lower trolley guides

and the chain guard and pin are oriented as shown in the

illustration.

Step Three: Mounting Front Rail Assembly

Fasten the front rail assembly to the

intermediate rails using the splice

bracket and four 5/16” x 1/2” carriage

bolts and 5/16” lock washer nuts.

9

Page 10

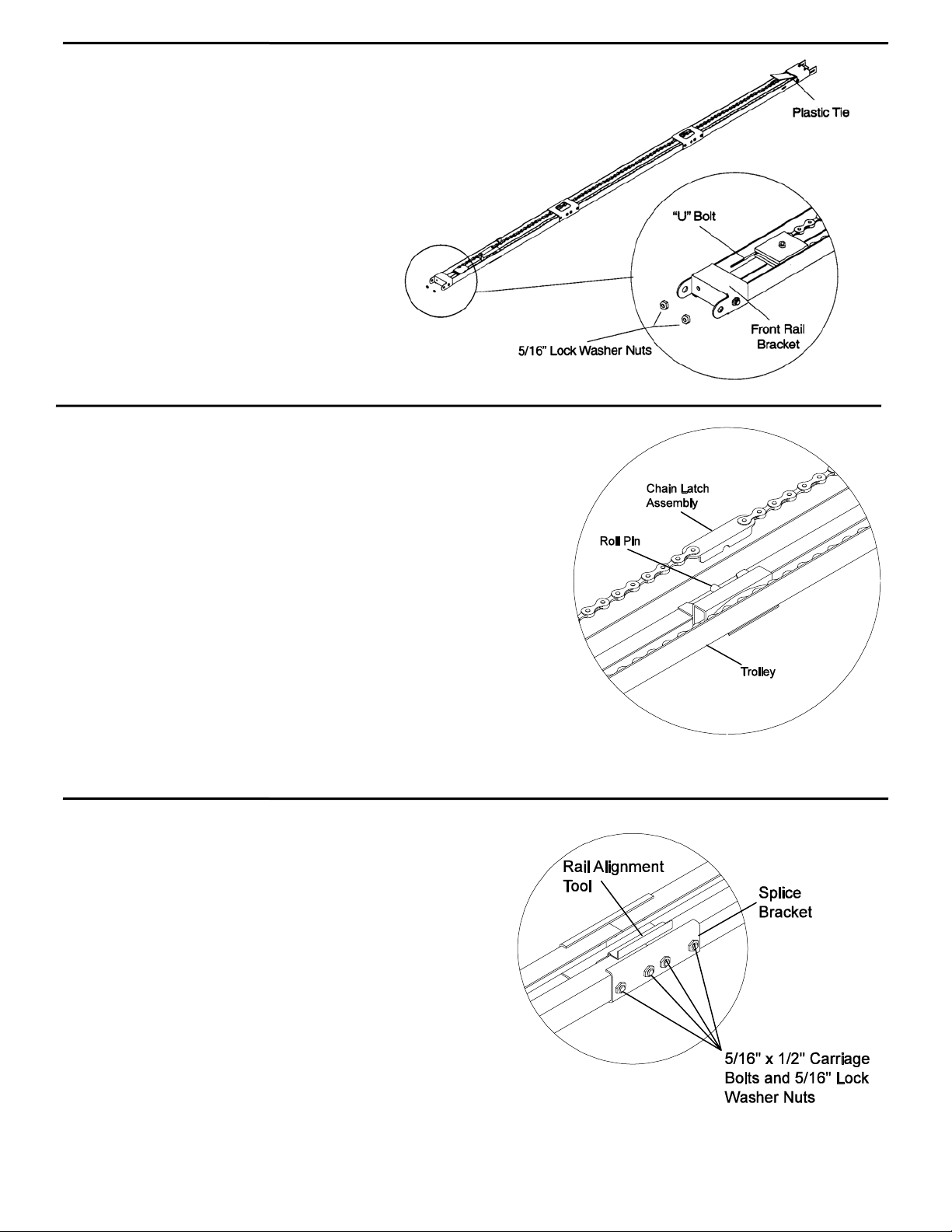

Step Four: Setting The Chain

Pull the chain assembly to the front rail

bracket. Insert the “U” bolt through the holes in

the front rail bracket and fasten with two 5/16”

lock washer nuts. Ensure the chain is on the

sprocket of the Motor Head, and finger tighten

the nuts equally.

NOTE: Do not remove plastic tie from

chain.

Step Five: Setting The Chain Latch Assembly

Attach the chain latch assembly to the roll pin of the trolley as illustrated.

Step Six: Rail Assembly Alignment

Turn the rail assembly upside down and place the plastic rail

alignment tool onto the meeting point of the two rails. Tighten

down the 5/16” lock washer nuts on the side of the splice bracket

with the rail alignment tool in place. Move rail guide alignment

tool to other side and tighten remaining 5/16” lock washer nuts.

Repeat at other splice bracket location. Turn rail right side up.

Remove plastic tie from chain. Ensure the chain remains on the

sprocket at the motor head. Tighten the “U” bolt lock washer nuts

evenly against the front rail so that the chain is approximately

5/8” above the rails.

10

Page 11

INSTALLATION INSTRUCTIONS

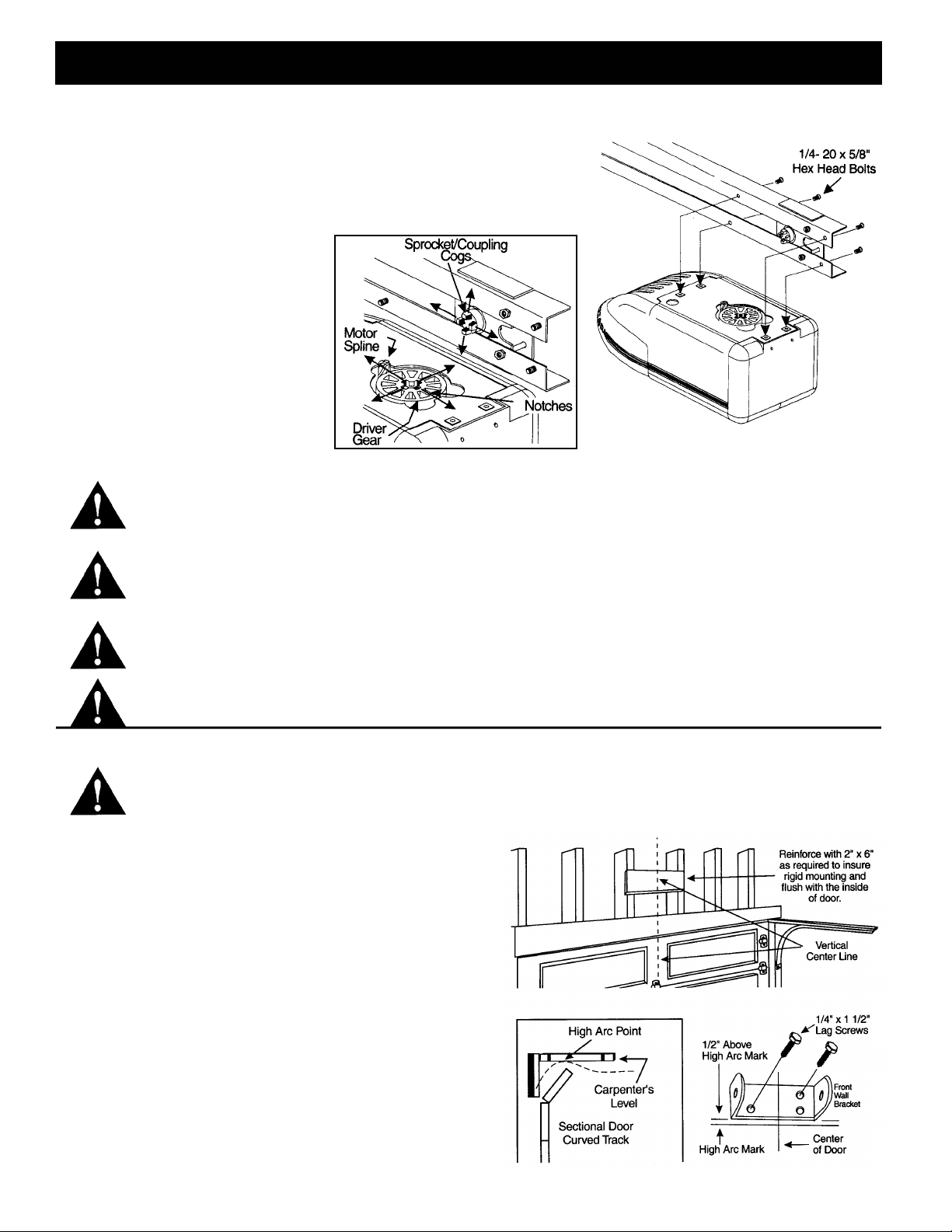

Step 1: Attaching Motor Power Head Unit to Rail

Before assembly, align sprocket/coupling cogs to match notches

of driver gear. Rotate the Motor Spline to position Driver Gear so

that the nearest notch in Driver Gear is directly behind Motor

Spline, as illustrated. Note: Do not rotate more than ½ turn.

Place opposite end of rail on temporary support approximately 6”

in height.

Proceed to attach rail to motor Power

Head Unit making sure that prealignment allows proper engagement

between sprocket/coupling cog and

driver gear notches. Realign as

necessary, making sure to keep any

rotation only to the nearest notch. Using

four (4) supplied 1/4”-20 x 5/8” hex head

bolts, assemble Motor Power Head Unit

to rails with a 3/8” socket. Tighten

securely.

Do not plug the opener power cord into electrical outlet until fully installed and instructed to do so in

this manual. Door springs, pulleys and cables are under extreme tension and can cause severe injury.

Do not attempt to adjust or repair. Call a professional door service company.

Do not wear rings, watches or loose clothing when installing or servicing a garage door system. Use a

sturdy, non-metallic step ladder. Remove all ropes or cords attached to the garage door. Failure to do

so may result in personal injury due to entanglement. Disable all existing locking devices on the garage

door, by securing lock/latch to inside face of door with suitable screw.

Install only on a properly balanced garage door. An improperly balanced door could cause severe

injury. Have a qualified service person make repairs to cables, spring assemblies and other hardware

before installing opener.

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS

Step 2: Positioning and Installing Front Wall Bracket

WARNING: Do not attempt to loosen or remove any portion of door spring system in order to rein-

force header wall or to mount wall bracket. If these are necessary, call a professional garage door service person.

Note: it is recommended that the door opener be installed 7 feet or more above the door.

REINFORCE THE HEADER WALL

Reinforce the header wall (wall above door opening) as

required, to ensure rigid mounting of the front wall bracket.

Locate the vertical center line of the garage door and mark it

on the header above the door and on the top rail of the door.

Raise the door slightly until the top rail reaches the highest

point of travel (see illustration); using a carpenter’s level,

transfer and mark the highest point of travel on the header

wall.

Mount the front wall bracket with its lower edge

approximately 1/2” (room permitting) above the mark showing the highest point of travel centered on the vertical center

line. Mark the two mounting holes and pre-drill with a 3/16”

drill. Mount wall bracket using the lag screws supplied (1/4” x

1-1/2”) to ensure rigid mounting.

11

Page 12

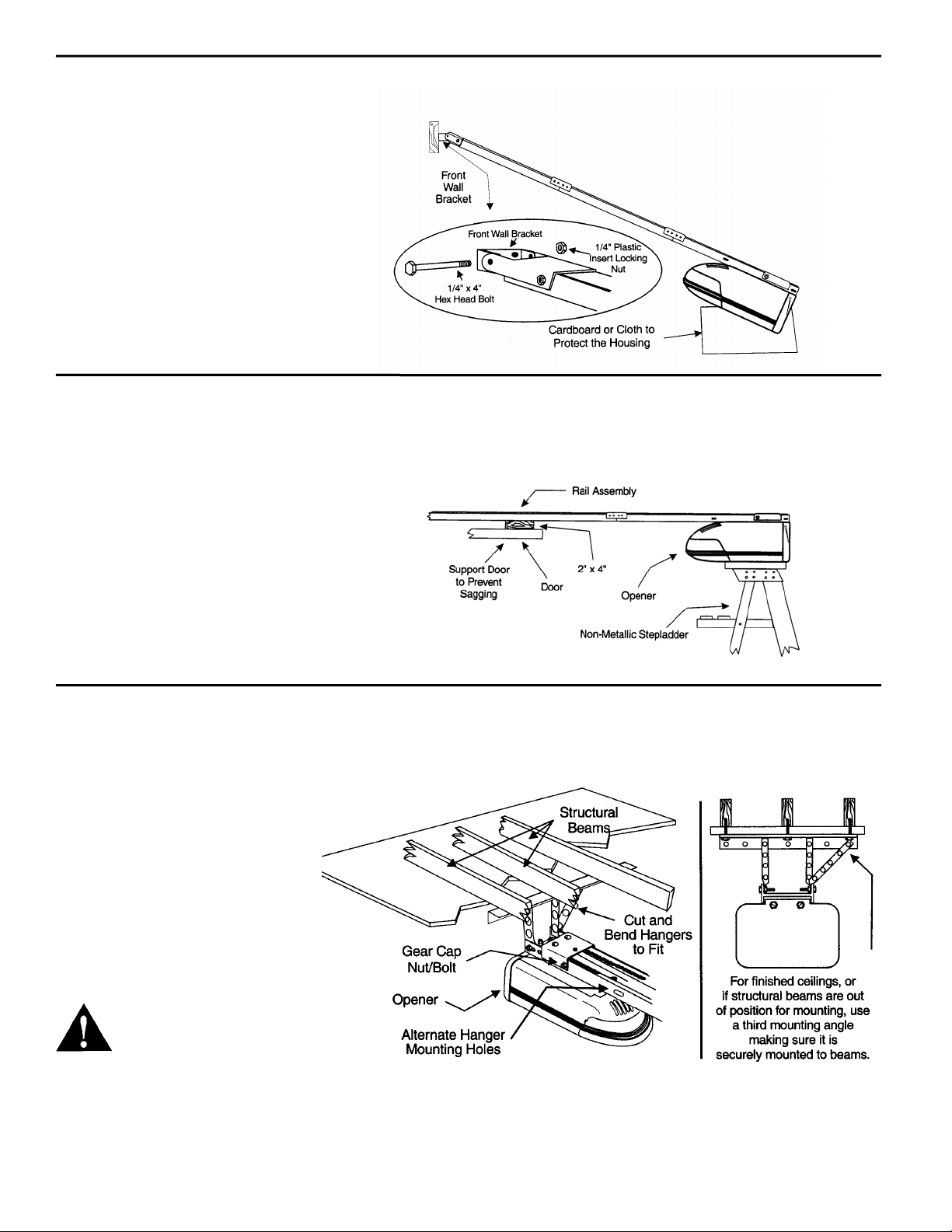

Step 3: Attach Unit to Front Wall Bracket

Raise the front end of the opener and attach

it to the front wall bracket, using the ¼” x 4”

hex head bolt and the supplied ¼” plastic

insert nut. Take care not to over tighten nut;

tighten only until end of bolt is flush with outside of nut.

NOTE: If you have a torsion spring

counter-balance system, it will be

necessary to raise the motor Head

Assembly of the opener and support it

on a step-ladder to attach the front end

of the opener to Wall Bracket.

Step 4: Positioning the Motor End of Operator

CAUTION: To prevent damage to steel, aluminum, fiberglass or glass panel doors do not rest the opener of the

door without using a 2” x 4” at least 12” long.

Raise the motor end of the opener and support it

so you can open the door to its fully open position.

You may need help raising motor end if ladder is

not high enough.

Open the door and place a 2” x 4” piece of wood

along the top section of the garage door. Rest the

double rails on the 2” x 4”, as illustrated.

Support the top section of the door to prevent

sagging.

Step 5: Mounting Motor End of Opener

Align the center of opener tracks with

the center line previously marked on

the top section of the garage door to

ensure rail will be parallel with the direction of door travel.

Use perforated hangers (cut as

needed to adjust length) from ceiling

or beams to hang opener at motor end

(be sure to locate and mount to solid

structural beams, as illustrated).

Pre-drill with 3/16” drill bit and use 1/4”

x 1-1/2” lag screws to ensure a rigid

mount. Attach opener to hangers.

WARNING: Do not use gear cap

bolt or nut for hanger attachment,

this may cause sprocket and

chain misalignment, resulting in

damage or possible injury!

Note: Hanging brackets should be at an angle to provide rigid support. If hangers have no angle or if you use

long hangers, cross brace the hangers to eliminate the possibility of sway during operation of the opener.

12

Page 13

Step 6: Mounting Door Bracket

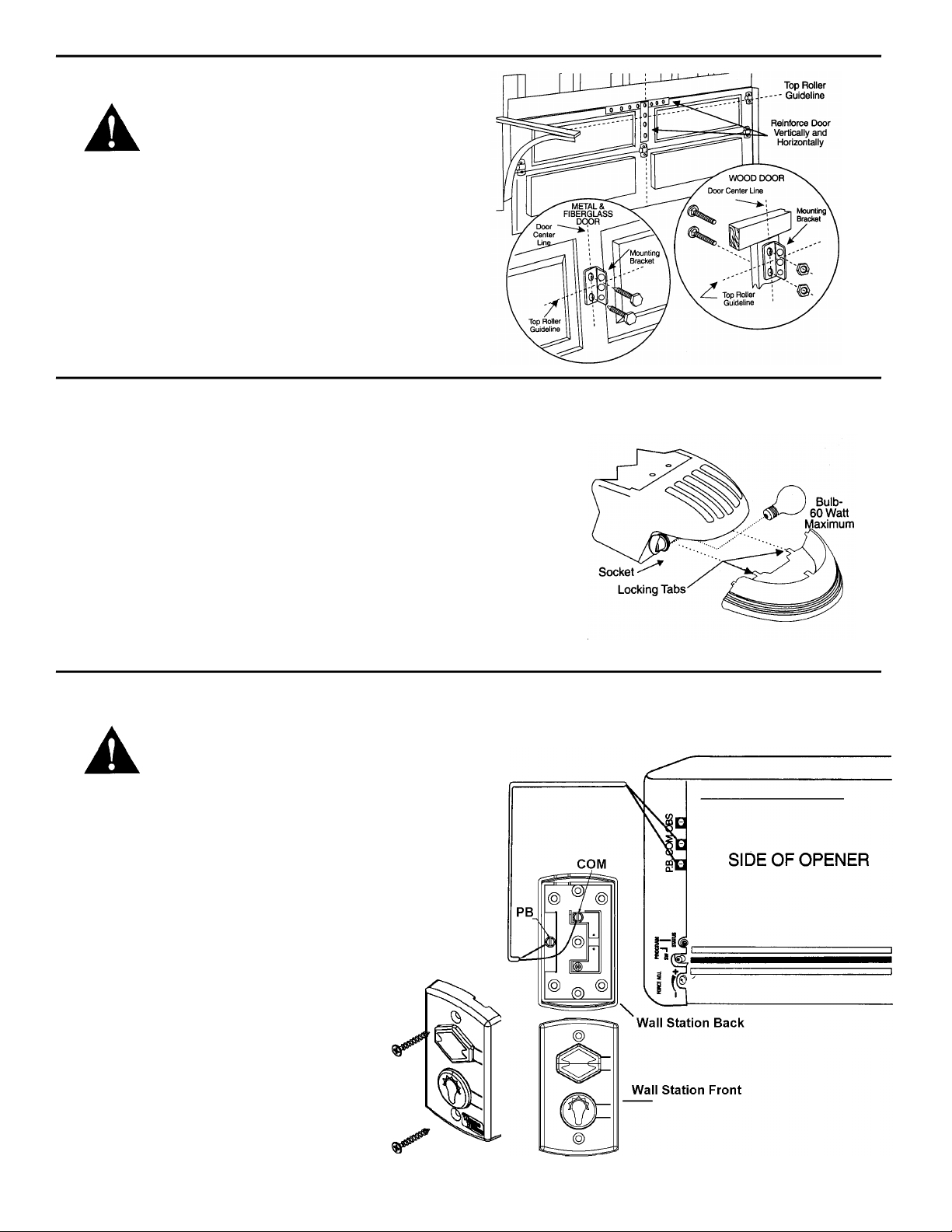

WARNING: Fiberglass, aluminum and

steel doors must be reinforced to prevent

damage to the door. Check with your garage door manufacturer for their recommendations.

Reinforce light weight doors, as illustrated.

For wood doors, mount door bracket, using two 1/4”-20 x

2” carriage bolts and 1/4” nuts supplied, on center line of

door with middle hole in line with top rollers.

For metal doors, mount door bracket, using two 1/4”-20 x

1/2” self drilling screws supplied, on center line of door

with middle hole in line with top rollers.

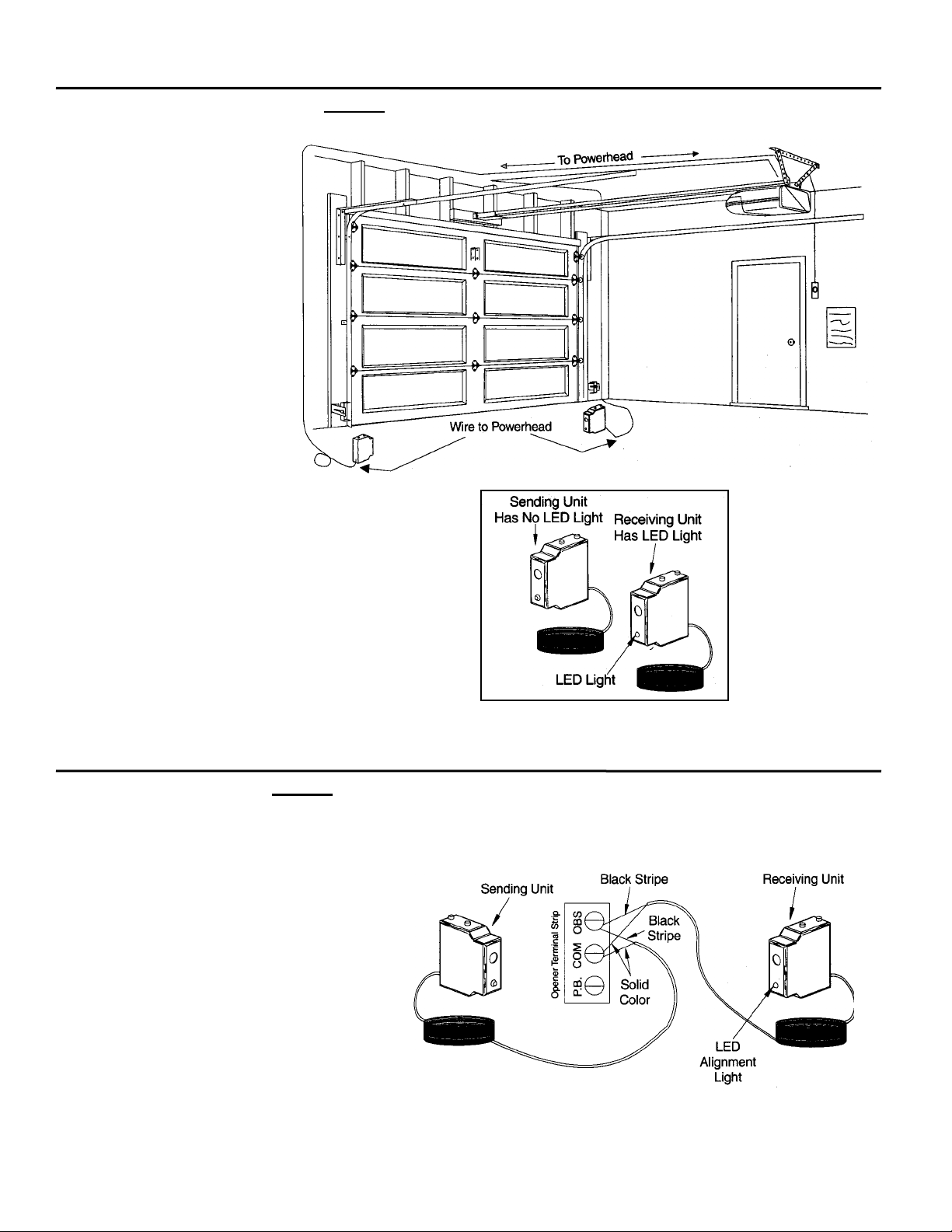

Step 7: Installing Light

Remove diffuser cover by pressing on both sides of the bottom of the

lighting cover at the junction of the housing, releasing the locking tabs,

and pulling forward. Screw a 60 Watt bulb (60 Watt Maximum) into

socket. For maximum bulb life, “rough service” bulbs are recom-

mended. Align top and bottom tabs on cover to Motor Power Head Unit

and push straight on until cover locks into place.

Note: light turns on automatically when door is activated and a 4

minute time delay circuit automatically turns light off, allowing ample time to enter the house. A fully open door with light blinking

indicates an obstruction or problems with external safety sensors

during close travel. See trouble shooting section for further details.

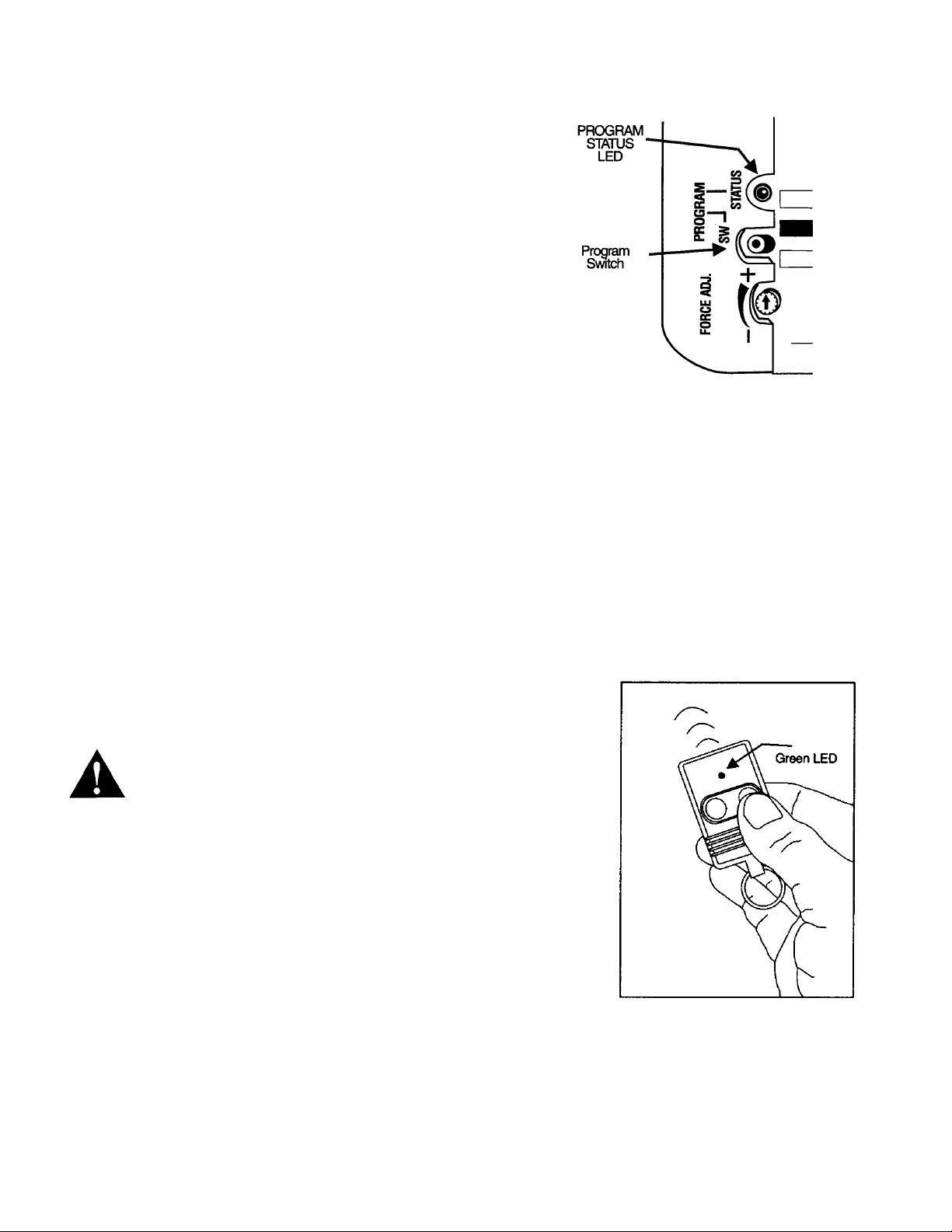

Step 8: Installing Wired Wall Station (if included)

WARNING: Install all wall controls out of the

reach of children and in a location where the

door can be seen before activating. Do not

mount wall controls near or next to garage

door.

Wired Wall Station: Wire the garage door opener wall station

using bell wire (low voltage electrical wire) connected to COM

and P.B. on vertical screw terminal strips, as illustrated.

Locate push button adjacent to service entrance door at a

minimum height of 5 ft., and at least 5 ft. away from garage

door (see illustration in Step 10). Fasten the wall station in a

safe location with the (2) Phillips head screws, making sure

not to over tighten. Pilot drill mounting holes

using a 3/32" bit. Additional wired wall stations

may also be installed in accordance with these

instructions.

CAUTION: Over tightening the screws

could deform plastic.

13

Page 14

Step 9: Installing Deluxe Wireless Wall Station (if included)

WARNING: Install all wall controls out of the reach

of children and in a location where the door can be

seen before activating. Do not mount push buttons

near or next to garage door.

Locate a convenient place to mount wall station. To keep wall station

out of the reach of children, measure at least five feet up from the floor

and secure wall station base into wood wall framing using (2) Phillips

head screws. Pilot drill mounting holes using a 3/32" bit. Use 2 of 3

holes that best align with wood framing.

CAUTION: Over tightening the screws could deform plastic

base and interfere with circuit board snaps.

NOTE: Insert bottom of circuit board behind bottom snap of wall

station base. Pivot circuit board up until board snaps into place.

For best results, press on circuit board between battery terminals.

Insert battery onto circuit board being careful to match (+) positive

battery marking with (+) circuit board marking. Align wall station

cover/button assembly with base. Press cover assembly over base

until cover snaps into place. A uniform seam between the cover and

base indicates a proper installation.

Step 10: Install Entrapment Warning Label

IMPORTANT: Install Entrapment Warning Label

next to wall station in a prominent location

Install Entrapment Warning Label next to Wall Station as

illustrated. If label adhesive will not adhere to the

surface, secure the label by additional mechanical

means such as staples, nails or screws.

14

Page 15

Step 11: Install Wireless Infrared Safety Sensors Wall Mounting Bracket

(If Included)

Select a mounting position 5 inches above the floor to center line of wall bracket.

The EMITTER and TRANSPONDER units must be mounted inside the door

opening to minimize any interference by the sun; however, the sensors must be

mounted against the door track. The brackets may be temporarily mounted to the

wall (or jamb) with a #8 X1/2” screw provided and should be in contact with the

door track. Leave this screw in place after installation is completed to prevent

accidental rotation of beam sensor. It is very important that both wall brackets

be mounted at the same height for proper alignment.

Using the 1/4” x 3/4” lag screw provided, attach the wall mounting bracket to the

wall. In some installations it may be necessary to attach wooden spacers to the

wall to achieve the required clearance. Expansion bolts (not supplied) may be

required to attach brackets to walls constructed of materials other than wood or

gypsum.

Step 12: Install Wireless Infrared Safety Sensor Bracket

Attach the sensor bracket to the wall bracket using the

two #8 x 1-1/2” screws supplied (make sure that the

curved hooks protruding from the bracket are positioned

over and in firm contact with the door track).

Note: This opener is equipped with state-of-the-art

wireless infrared safety sensors which are activated

by door movement. It is extremely important to

position and mount the sensor brackets in firm

contact with the door track so that the sensors are

immediately activated by the door movement.

Step 13: Install Wireless Infrared Safety Sensor

Open hinged cover on infrared safety sensors and remove battery protective paper strip.

Observe proper battery polarity, as illustrated, in battery compartment.

Identify the TRANSPONDER (green LED) and

mount this unit on the right side (from inside the

garage looking to the outside) of the garage door

and the EMITTER (red LED) on the left side. This

same right/left mounting procedure must be

followed on two and three door installations.

Mount the infrared safety sensors to

the sensor bracket keeping the soft

washer between the sensor and sensor bracket and then place the conical

washer, lock washer and hex nut on

the extender bolt, as illustrated.

Keeping the sensors pointing in towards door and aimed at each other,

tighten nut until there is enough friction to hold in place. Do not fully tighten

until the final alignment has been completed.

15

Page 16

Step 14: Install Wired Infrared Safety Sensor Wall Mounting Brackets

Use the following instructions if your opener is

equipped with Wired Infrared Safety Sensors. If

you just installed the Wireless Infrared Safety Sensors go to step 19.

Select a mounting position 5 inches above the floor to

center line of wall bracket. The sending and receiving

units should be mounted inside the door opening to

minimize any interference by the sun. However, the

sensors should be mounted as close to the door track

or inside edge of the door as possible to offer

maximum entrapment protection. It is very important

that both wall brackets be mounted at the same

height for proper alignment.

The brackets may be temporarily mounted to the jamb with a 1” flat

head nail (provided), permanently mount the wall mounting bracket

to both door jambs. In some installations it may be necessary to

attach wooden spacers to the wall to achieve the required

clearance. Expansion bolts (not included) may be required to

attach brackets to walls constructed of materials other than wood

or gypsum.

Step 15: Install Wired Infrared Safety Sensor Wall Mounting Brackets

Attach the “U” brackets to the wall brackets with a

1/4 -20 carriage bolt, washer and hex nut

(provided). Insert the bolt from the inside of the “U”

bracket and hand tighten only at this time.

16

Page 17

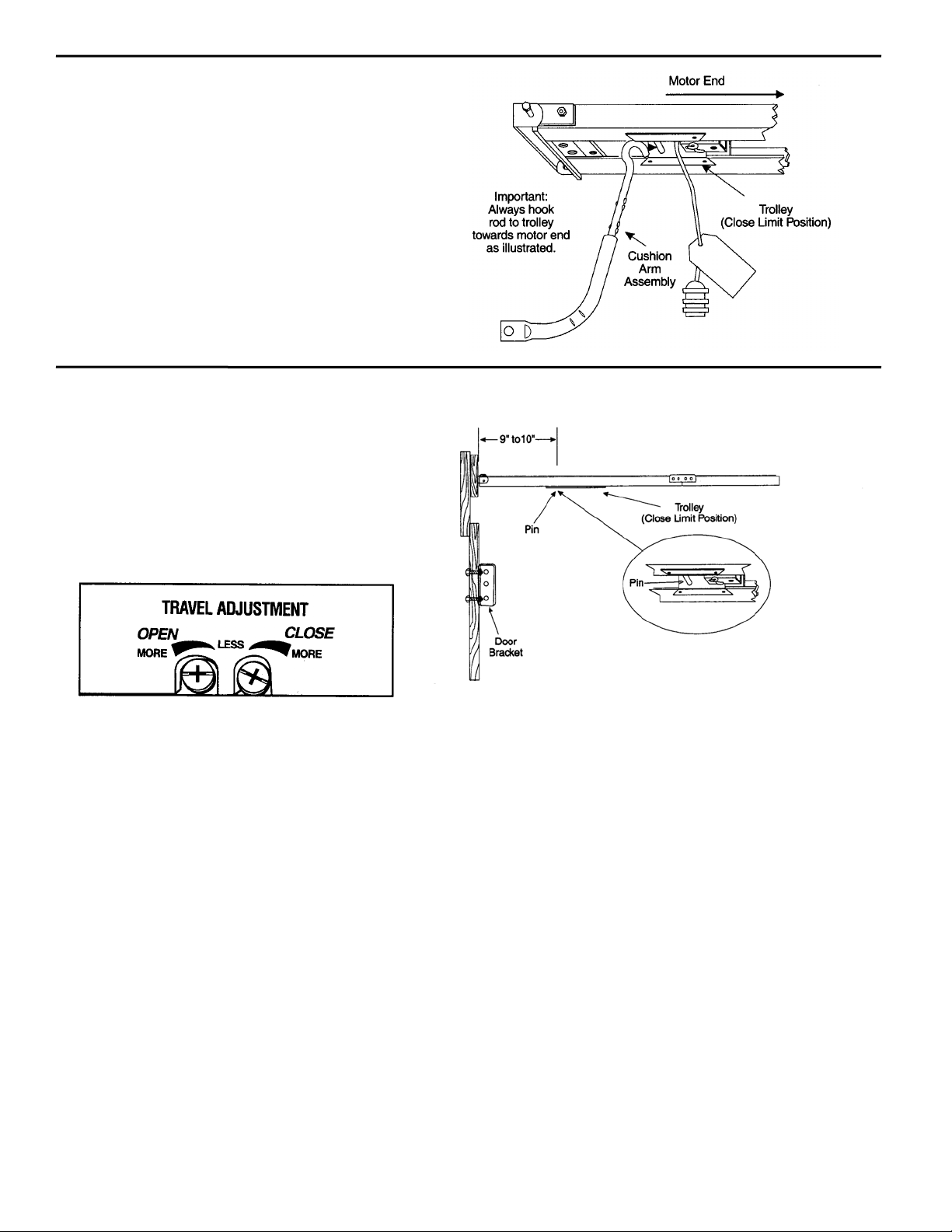

Step 16: Install Wiring for Wired Infrared Safety Sensor

Identify which side of the garage

door opening (if any) the sun is

“likely” to shine on to. Since

sunlight may affect infrared safety

sensors, you should mount the

sending unit on the side of the

door opening exposed to the sun.

Uncoil the wires from the infrared

safety sensors and route the wire

up the garage wall across the

ceiling and down to the back of

the power head, as illustrated.

Tack the wires in place using

staples. Take care to run the wires

in a location where they will not

interfere with the operation of the

door and do not staple through

wire. Be sure to leave about 12” of

excess wire at each end so you

will have enough slack wire to

mount units.

Note: If wires must be lengthened or spliced into prewired installation, use wire nuts or a suitable connector.

Step 17: Connecting Wired Infrared Safety Sensor to Opener

Connect Infrared Safety Sensors to power head

as per diagram. Shorten the wires as necessary

and separate the wire ends. Strip about 1/2" of

insulation off each wire and attach the wires to

the proper terminal screws, then tighten

securely, using a small blade screwdriver.

One wire has marking on it (numbers, black

stripe, etc). Be sure to observe polarity. Apply

tension to external wires to test for secure

connection. Check that the wires are stapled in

place.

17

Page 18

Step 18: Mount Wired Infrared Safety Sensors

Attach the sending and

receiving units to the “U”

brackets by inserting their tabs

into their respective holes.

Step 19: Connecting Electrical Power

To reduce the risk of electrical shock,

connect the power cord only to a

properly grounded 3 prong, 120 volt

outlet.

Do not use an extension cord or change

the plug in any way. At this point, plug in

the opener to an electrical outlet. If the

plug does not fit into the outlet, or you

require permanent wiring, contact a

qualified electrician to install the proper

outlet. As soon as power is applied to

the unit, the light on the opener will blink

once to indicate a successful self-check of the controls.

WARNING: Check your local electrical

codes. If your local code requires permanent wiring, use the specifications called

for and instructions illustrated.

Permanent Wiring Procedure

1. Ensure line cord is disconnected from power source.

2. Cut line cord 1/2” – 1” from strain relief / bushing.

3. Use needle nose pliers to remove strain relief bushing from frame. Squeeze tabs in on underside of bushing and

work bushing out of hole.

4. Pull or strip off remaining section of outer insulation from three conductors of line cord. Pull the three wires into

the operator. Discard remaining line cord.

5. Strip 1/2" of insulation from the black, white, and green wires.

6. Using UL/CSA approved wire nuts for 14-18AWG wire, wire nut black-black, white-white, and green-green (earth)

wires securely.

7. Replace Power Head Unit cover.

DO NOT USE AN ELECTRICAL EXTENSION CORD OF ANY TYPE

18

Page 19

Step 20: Wireless Wall Station Security Code Change and Programming

Note: The following steps describe the process to change the Wireless Wall Station security code and to program

the Wireless Wall Station to the opener.

IMPORTANT: You MUST change the Wireless Wall Station security code prior to programming the device to

the power head unit.

WARNING: During programming the garage door may operate. Keep people and objects clear of the

moving door to prevent door damage or possible personal injury.

Changing Wireless Wall Station Code

1. Press and hold the wall station’s light button for approximately 10

seconds until the wall station’s LED begins to blink rapidly. Release

button (LED will turn off).

2. Press and hold the wall station’s light button again (LED will light) for

approximately 5 seconds until the wall station’s LED begins to blink

rapidly. Release button.

3. LED will blink on and off three times indicating a successful security

code change.

Programming Wireless Wall Station to Power Head Unit

Note: Do not press any button on the wall station until instructed

1. Press the PROGRAM Switch button located on the garage

door power head unit once. The red PROGRAM STATUS

light on the motor power head unit and overhead lamp will

turn on and remain lit for one minute, indicating that it is

ready to learn the wall station.

2. Press the light on/off button on the wall station. The

PROGRAM STATUS light will turn on and off three times

indicating a successful learn.

3. Press the light on/off button on the wall station once more to

confirm operation. The overhead light will toggle from on to

off and from off to on.

At this point you will be able to activate the opener. It will open, but will not close the door. Before unit will close door the

beam sensors must be aligned and programmed (next step).

Battery: If the LED (light) on wall station does not turn on when a button is pressed, repeat “changing wireless

wall station code” operation. If LED fails to light replace battery. To change battery, insert a coin in the coin slot

and twist coin to access battery compartment. Replace battery with a single MN21 or equivalent battery. Snap

case together after replacing.

19

Page 20

Step 21: Alignment of the Wireless Infrared Safety Sensors

Use the following instructions if your opener is equipped with Wireless Infrared Safety Sensors. If your opener is equipped with Wired Infrared Safety Sensors proceed to step 22.

IMPORTANT: This infrared beam sensor sends an invisible beam of light from the emitter unit to the trans-

ponder unit across from the pathway of the door. The door opener will not operate until the safety sensor is programmed to the power head and it is properly aligned. If the invisible beam of light is obstructed, an open door

cannot be closed by the transmitter or a momentary activation of the wall station up/down button. However, the

door may be closed by continuously holding your finger on the wall station up/down button (constant pressure)

until the door travels to a fully closed position.

Note: If two or more door openers are installed in

the same garage, the safety sensor transponder for

the second and/or third doors must be set to a different code to prevent interference with the first

transponder. The code is set by a jumper, located

under the battery, closest to the center of the compartment, as illustrated. The code jumper has three

positions (A-B-C), selected by a moveable jumper,

and has been randomly set at the factory to one of

these positions. If the factory random selection of

the jumper position has resulted in a different code for each transponder, no further changes are necessary. If

not, note the position of the jumper (A, B or C) on the first door transponder and set the second door transponder jumper to one of the other two positions. A third door will use the remaining un-used position. Temporarily remove the batteries from all but the door being worked on and then replace when all jumpers have been set.

The jumper has no polarity and can be applied to the pins in either direction. For more than three doors, call for

technical assistance.

At this point you will be able to activate the opener. It will open, but will not

close the door. Before unit will close door the beam sensors must be aligned

and programmed.

First, the “Align-Normal” switch on the EMITTER (under the protective

cover) must be set to Align. (See illustration). This should cause the

adjacent RED LED indicator light to turn on. Check to see that the

EMITTER is pointed toward the TRANSPONDER and that the hex nut

holding the EMITTER in place is tight enough that the unit will not

move.

Loosen the hex nut on the TRANSPONDER just

enough that you can rotate it up and down and

side to side. Rotating the TRANSPONDER will

cause the GREEN LED on the TRANSPONDER

to blink when aligned. Rotate TRANSPONDER up

and down and side to side to determine best

alignment. We recommend wide rotations to help

determine the closest center point of alignment.

Tighten hex nut on TRANSPONDER and push

and release the PROGRAM Switch button

located on the garage door power head unit

once. The red PROGRAM STATUS light on the

motor power head unit and overhead lamp blinks

showing programming and alignment are

completed. Reset “Align-Normal” switch on the

EMITTER to Normal and snap cover shut. Now,

using the wall control up/down button, activate the

opener and check that it will operate through full

open and close cycles.

20

Page 21

Step 22: Alignment of the Wired Infrared Safety Sensors

Use the following instructions if your opener is equipped with Wired Infrared Safety Sensors.

Otherwise proceed to step 23.

IMPORTANT: This infrared beam sensor sends an invisible beam of light from the sending unit to the receiver

unit across from the pathway of the door. The door opener will not operate until the safety sensor is connected to

the power head and properly aligned. If the invisible beam of light is obstructed, an open door cannot be closed

by the transmitter or a momentary activation of the wall station up/down button. However, the door may be

closed by continuously holding your finger on the wall station up/down button (constant pressure) until the door

travels to a fully closed position.

At this point you will be able to activate the opener; it

will open, but will not close the door unless the beam

is aligned. The beam sensors must be aligned by

moving the sending and receiving units in or out (see

Figure 1) until the alignment light on the receiving unit

comes on. The 1/4"-20 carriage bolt can be loosened

to move the unit in or out, as required. If you have

difficulty aligning beams, check that both brackets are

mounted at the same height (see Step 14 & 15) and

remount if necessary. Additional minor adjustments

can be made by lightly bending the mounting brackets

(see Figure 2).

Once the alignment light comes on, tighten all bolts

and mounting screws.

Finish securing all wire making sure not to break or

open any of the conductors. Loop and secure any

extra wire.

Now, using the wall station up/down button, activate

the opener and check that it will operate through full

open and close cycles.

Step 23: Three Button Transmitter Security Code Change and Programming

Note: The following steps describe the process to change the Transmitter security code and to program the

Transmitter to the opener.

IMPORTANT: You MUST change the Transmitter security code prior to programming the device to the power

head unit.

WARNING: During programming the garage door may operate. Keep people and objects clear of the

moving door to prevent door damage or possible personal injury.

Changing the Transmitter Code

1. Press and hold the Transmitter’s large button for approximately 10

seconds until Transmitter’s LED begins to blink rapidly. Release

button (LED will turn off).

2. Press and hold the Transmitter’s large button again (LED will light) for

approximately 5 seconds until the Transmitter’s LED begins to blink

rapidly. Release button.

3. LED will blink on and off three times indicating a successful security

code change.

4. You must now re-program this transmitter to the motor head unit.

See “Programming Transmitter to Motor Head Unit” below.

21

Page 22

Programming Transmitter to Power Head Unit

Note: Do not press any button on the Transmitter until instructed.

1. Press the PROGRAM Switch button located on the garage door

power head unit once. The red PROGRAM STATUS light on the

motor power head unit and overhead lamp will turn on and

remain lit for one minute, indicating that it is ready to learn the

Transmitter.

2. Press the button on the Transmitter you wish to use to operate

the door. (NOTE: For the 2 button transmitter this must be

the same button that was used in “Changing the

Transmitter Code” )The PROGRAM STATUS light on the

power head will turn on and off three times indicating a

successful learn.

3. Press the same button on the Transmitter once more to confirm

operation. The opener will turn on and move the door.

At this point you will be able to activate the opener.

Battery: If the LED (light) on Transmitter does not turn on when a button

is pressed, repeat “changing the transmitter code”

operation. If LED fails to light replace battery. To change battery, insert

a coin in the coin slot and twist coin to access battery compartment.

Some transmitters use two CR2016 or equivalent batteries while others

use a single MN21 or equivalent battery. Snap case together after

replacing.

Step 23a: Two Button Transmitter Security Code Change and Programming

Available only for 303/372 MHz combo models.

Note: The following steps describe the process to change the Transmitter security code and to program the

Transmitter.

IMPORTANT: You MUST change the Transmitter security code prior

to programming the device to the power head unit.

WARNING: During programming the garage door may

operate. Keep people and objects clear of the moving door

to prevent door damage or possible personal injury.

Changing the Transmitter Code

1. Press and hold the button on the transmitter that you want to change

(left button or right button). The GREEN LED (light) will flash once

and then turn off.

2. Continue to hold the button until the GREEN LED begins to flash

(approx. 10 seconds).

3. When the GREEN LED flashes, immediately release the button and

then immediately press and hold the same button again. The

GREEN LED will now come on steady.

4. Continue to hold the button until the GREEN LED begins to flash

(approx. 5 seconds).

5. When the GREEN LED flashes, immediately release the button.

6. The code for this button has now been changed to a new randomly generated code. Do not press the button

again until instructed in “Programming Transmitter to Motor Head Power Unit”.

7. You must now re-program this transmitter to the motor head unit. See “Programming Transmitter to Motor Head

Unit” above.

Note: After the transmitter is programmed, see “Programming Transmitter to Power Head Unit” above. After

completing “Programming Transmitter to Power Head Unit” proceed to step 24.

22

Page 23

Step 24: Connecting Cushion Arm to Trolley

Activate opener to bring trolley to factory pre-set close

limit (See illustration).

Cushion arm assembly consists of the door arm tube

section and door arm rod, which are packed

separately. To assemble, screw the door arm rod into

the door arm tube in a clockwise direction

approximately ten turns.

Connect cushion arm assembly into trolley with open

end of rod hook facing motor.

Attach warning tag and red pull knob to red release

cord connected to trolley.

Step 25: Setting Trolley Close Position

Activate opener to confirm trolley close position is 9”

to 10” between the inside face of the door and the

solid cushion arm rod. If adjustment of the trolley

position is necessary, use the CLOSE TRAVEL ADJUSTMENT knob located on the bottom of the motor

power head unit. A 1/4 turn equals approximately 1”

of trolley movement; turn clockwise to move forward;

counterclockwise to move back.

23

Page 24

Step 26: Connecting Door Arm to Door

Door Mounted Bracket

Visually align cushion arm connecting hole with middle

hole of door bracket by rotating tube section in appropriate

direction.

Release trolley (cushion arm attached) with manual

release cord and pull trolley a few inches toward motor.

Now rotate cushion arm tube section 2 turns

counterclockwise to provide a cushion when door is closed

or encounters an obstruction. Align connecting hole in

cushion arm to middle hole in door

bracket; insert 3/8” dia. bolt and

tighten locking nut, allowing for free

pivoting of arm.

Note: Do not over tighten locking

nut, as this will cause binding

between cushion arm and door

bracket.

WARNING: Failure to secure door

arm to door bracket with locking nut can cause door arm to become disengaged from

the trolley and fall, resulting in possible damage or personal injury.

Step 27: Setting Door Close Travel Plus “Contact Obstruction Sensing” Test

With wall control up/down button, activate door to

full open position; reactivate to close position. The

door should stop on the floor with the cushion arm

and the bottom door seal slightly compressed. If the

door reverses off the floor, turn close travel knob 1/4

turn “less”. If door is not completely closed, turn

travel knob 1/4 turn “more”. Repeat if necessary.

IMPORTANT! Test “Contact Obstruction Sensing Feature”

IMPORTANT: After installing opener, the door must reverse when it contacts a 1 inch high object on the floor.

Activate the door to the full, open

position and place a 1” (25mm) solid

test obstacle on the floor under the

garage door. Activate the door to the

closed position. The door should

reverse upon contact with the 1”

obstacle.

If door stops on the 1” obstacle, adjust

the close travel knob 1/4 turn “more”

until door reverses upon contact with

obstacle. Repeat if necessary.

When the door reverses, remove the test object and run the full cycle of open and close of the door. Door should not

reverse when it comes to the fully closed position.

Note: If opener fails to pass this test, repeat Step 27. Also see Adjustment #2, page 28, (Contact Obstruction

Sensing Adjustment).

24

Page 25

Step 28: Setting Door Opening

Travel

Do not use adjustments to compensate for a poorly

balanced door. This will interfere with the proper

operation of the travel adjustments and may damage

door.

The door opener is assembled with the open travel

adjustment preset for a typical door, but all doors should be

adjusted to stop as close as possible to the door’s “natural”

fully open, resting position.

To determine the door’s “natural” fully open, resting position, disconnect door from opener using the Emergency Release

Disconnect (see page 32, HOW TO OPERATE YOUR DOOR MANUALLY) and manually raise door to its “natural” fully

open, resting position. Use this location for your open limit setting. To determine if door needs adjustment, activate the

opener to bring door to fully open position.

NOTE: If door does not open fully and opener light flashes (make sure the bulb is installed and operating) check

for an obstruction or see Adjustment #1, page 27 (Adjusting Opening Force).

To adjust for a non-standard door or to precisely set the open position: Using the wall station, operate the door and stop it

in mid-travel position; using a flathead screwdriver turn the OPEN travel adjuster for more (counter-clockwise) or less

(clockwise) travel. A 1/4 turn equals approximately 1” of trolley movement.

NOTE: Confirm that the door has stopped in the UP position as a result

of the Upper Limit Switch and not because the Trolley has hit the open

Stop Bolt, which is mounted in the Rail near the power head. The

correct condition can be verified by observing that the openers

Convenience Light does not flash

stop. The faulty condition may also be confirmed visually by checking

to see if the Trolley is resting against the stop bolt.

To confirm final OPEN travel adjustment, activate the opener to bring door to

fully open position. The opener light should not

after the fully open door comes to a

be flashing.

Step 29: Infrared Safety Sensor Obstruction Test

Test Procedure

Starting with the door in the fully open

position, place a 6” High object on the floor

progressively one foot from the left side of

the door; center of door and one foot from

the right side of door (as illustrated). In each

position, activation of the opener with the

wall station should cause the door to move

approximately one foot, stop and then

reverse to fully open position. The same 6”

High object when placed on the floor should

also cause a closing door to reverse.

If the door does not respond properly to these tests, the Infrared Safety Sensors must be adjusted (refer to step 21 or 22

depending on type of sensors used). Repeat this test procedure. If the door opener still will not respond properly and fails

this test, the door may cause severe injury or death. Have a qualified service person make repairs.

25

Page 26

Step 30: Programming Wireless Keyless Entry (If Included)

NOTE: To facilitate installation, program the Keyless Entry station to the opener before mounting to wall.

WARNING: During programming the garage door may operate. Keep people and objects clear of

1. Press the PROGRAM Switch button located on the garage door power

2. Press the desired five digit PIN (PERSONAL IDENTIFICATION

3. Wait five seconds and press any button on the keyless entry. The

A single Wireless Keyless Entry device may be programmed to operate multiple garage door openers. To program

additional openers, repeat programming steps using a different five digit PIN for each additional opener

the moving door to prevent door damage or possible personal injury.

NOTE: Before programming ensure garage door is in the

“down” position.

head unit once. The red PROGRAM STATUS light on the motor

power head unit and overhead lamp will turn on and remain lit for one

minute, indicating that it is ready to learn the Keyless Entry.

NUMBER), Example 1-2-3-4-5. The PROGRAM STATUS light will turn

on and off three times indicating a successful learn.

door will move to the up position.

NOTE: If an error is made entering codes, simply press and hold

both the “7/8” and “9/0” buttons for two seconds. The Keyless

Entry will reset. Repeat programming procedure again.

Step 31: Installing Wireless Keyless Entry (If Included)

WARNING: Install all wall controls out of the reach of children and in a

location where the door can be seen before activating.

CAUTION: The keypad should be mounted a minimum of 5 feet from the floor to keep it out

of the reach of small children.

Locate a convenient place to mount the Wireless Keyless Entry. Choose a convenient location

that does not interfere with the normal opening and closing of the door. To keep keyless entry out

of the reach of children, measure and mark a spot at least five feet up from the floor. Use the

drilling template located on Page 38 to determine hole positions. Drill 5/64” pilot holes 3/4" deep at

each screw location.

Snap open the Wireless Keyless Entry case with a coin.

Secure keyless entry base into wood wall framing using the

two screws provided. Snap the front case half with the base. Remove paper backing from instruction label and apply to a clean surface inside garage.

NOTE: Two screws are included for mounting to wood structures.

Ensure proper hardware is used for mounting to other materials.

Battery Replacement: Under normal operating conditions, the batteries should be changed once every 12 months.

Dispose used batteries properly. To change batteries, snap open case with a coin and remove old batteries. Insert two

CR2032 or equivalent coin cell batteries and snap case together.

26

Page 27

A

DJUSTMENTS

Adjustment # 1 Opening and Closing Force

This garage door opener is built with a safety system that allows the door to reverse in the close direction and stop in the

open direction. This must be adjusted so your opener does not use excessive force in the down direction or react to the

weight of the door during upward travel.

CLOSING FORCE ADJUSTMENT

To help determine that the closing door force is not excessive, grasp the door handle or bottom edge during downward

travel. The opener should REVERSE

To adjust the closing force follow one of the two methods listed below.

to this force. NOTE: Do not stand under door during this test.

Method A (manual)

1. Turn the FORCE ADJ. (see illustration) counter clockwise to decrease

force and repeat reversal test until door reacts properly.

Method B (computer assisted)

1. Operate the door to the fully open

2. Turn the FORCE ADJ. (see illustration) counter clockwise to the minimal

force setting.

3. Press the PROGRAM SWITCH button two

button on the Wireless Wall Station (if included) until the LED turns on

solid (5 sec.). The STATUS LED and the overhead lamp will flash on

and off at a slow rate.

4. Operate the door to the fully closed

5. Turn the FORCE ADJ. clockwise until the STATUS LED flickers or just

turns off.

6. Press the PROGRAM SWITCH once to confirm setting.

position.

times or the PROGRAM

position.

OPENING FORCE ADJUSTMENT

To determine that the opening force is not excessive, grasp the door handle or bottom edge during upward travel. If the

opener does not stop or is hard to hold, decrease the open force setting. The opener should STOP

excessive force.

To change the opening force follow the procedure listed below.

1. Operate the door to the fully closed

2. Press the PROGRAM SWITCH button three

off. The blink rate which corresponds to the force setting will consist of 1 to 5 fast blinks followed with a long

pause between blink sets.

3. The first time an attempt is made to increase the force, the setting will begin at the lightest setting (1 blink).

4. To increase the force, press and release the door up/down button on any control (The STATUS LED will remain

lit during button press).

5. Continue to press and release the door button until the desired force setting is achieved.

6. Press the PROGRAM SWITCH once to confirm setting.

position.

times. The STATUS LED and the overhead lamp will flash on and

without using

27

Page 28

Adjustment # 2 Contact Obstruction Sensing (Closing Direction)

The opener is designed to automatically reverse the door during closing travel whenever it comes in contact with an object

up to the last 1 inch of travel above the floor. An object on the floor with a height less than 1” will cause the door to stop.

(Test according to instructions on Step 27.)

If opener reverses properly with a 1” high solid test object laid flat on garage floor (Step 27) and stops without the solid

test object in the fully closed position, proceed to Adjustment # 3.

When door comes in contact with a 1” high solid test object laid flat on garage floor and stops instead of reversing, reset

the door close limits according to instruction in Step 27, adjusting until door reverses upon contact with the 1” high solid

test object.

If door reverses when it comes in contact with the floor, reset the door close limits according to instruction in Step 27.

Adjustment # 3 Positive Mechanical Door Lock

The garage door opener is designed with an

automatic mechanical locking system. This lock

secures the door in the fully closed position.

To adjust, activate the door opener and allow the

door to go to its fully closed position. Loosen the

two screws on the rail stop and move it behind the

chain latch assembly with a gap of 3/4” between

“stop” and “latch”. Retighten screws.

28

Page 29

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of severe injury or death:

Before you proceed, please thoroughly read the safety rules on page 2 and the following operating instructions. Operate

only when opener is properly adjusted and the door is visible and unobstructed.

READ AND FOLLOW ALL INSTRUCTIONS.

Always keep moving door in sight and away

from people and objects, until it is completely

closed. NO ONE SHOULD CROSS THE PATH

OF A MOVING DOOR.

Never let children operate or play with door

controls. Keep remote control away from children.

NEVER GO UNDER A STOPPED, PARTIALLY

OPEN DOOR.

KEEP GARAGE DOORS PROPERLY BALANCED. See owner’s manual. An improperly

balanced door could cause severe injury or

death. Have a qualified service person make

repairs to cables, spring assemblies and other

If possible, use the emergency release only

when the door is closed. Use caution when

using this release with the door open. Weak

or broken springs may cause the door to fall

rapidly, causing serious injury or death.

Test door opener monthly. The garage door

MUST reverse on contact with a 1 inch high

solid test object on the floor. If adjusting either the force or the limit of travel, retest the

door opener. Failure to adjust the opener

properly may cause severe injury of death.

Test door opener monthly. Open door must

not close and closing door must open if Infrared Safety System is obstructed by 6” High

object, using test procedure described in Step

29.

hardware.

SAVE THESE INSTRUCTIONS.

AVERTISSEMENT—POUR RÉDUIRE LES RISQUES DE BLESSURES MORTELLES

Avant de commencer, veuillez lire attentivement les règles de sécurité, page 3 et les instructions suivanres. Faire fonctionner uniquement lorsque l’ouvre-porte est correctement réglé et que la port est visible et sans obstacle.

LISEZ CETTE NOTICE ET CONFORMEZ-VOUS

AUX INSTRUCTIONS.

NE LAISSEZ JAMAIS LES ENFANTS MANOEUVRER LES COMMANDES DE LA PORTE. NE

LAISSEZ PAS LA TÉLÉCOMMANDE À PORTÉE

DES ENFANTS.

SURVEILLEZ LA COURSE DE LA PORTE JUSQU'Á CE QUE CETTE DERNIÈRE SOIT COMPLETEMENT FERMÉE EN VEILLANT A TENIR Á

L’ÉCART TOUTE PERSONNE ET TOUT OBJET

AVOISINANT. IL NE FAUT JAMAIS PASSER EN

DESSOUS D’UNE PORTE EN MOUVEMENT.

VÉRIFIEZ LE FONCTIONNEMENT DE L’OUVRE

PORTE UNE FOIS PAR MOIS. LE SENS DE LA

COURSE DOIT S’INVERSER LORSQUE LA

PORTE ENTRE EN CONTACT AVEC UN OBJET

D’UNE HAUTEUR DE 1 PO POSÉ SUR LE SOL

VÉRIFIEZ Á NOUVEAU L’OUVRE-PORTE

APRES TOUT RÉGLAGE DE LA FORCE DE DÉCLENCHEMENT OU DU SEUIL DE FIN DE

COURSE. UN REGLAGE INCORRECT DE

L’OUVRE-PORTE PEUT CAUSER DES BLESSURES MORTELLES.

IMPORTANT—MESURES DE SÉCURITÉ

DANS LA MESURE DU POSSIBLE, NE DÉCLENCHEZ LE DISPOSITIF DE DÉSACCOUPLEMENT

QUE LORSQUE LA PORTE EST FERMÉE. USEZ DE

PRUDENCE SI VOUS DÉCLENCHEZ LE DISPOSITIF

LORSQUE LA PORTE EST OUVERTE ; UN RESSORT AFFAIBLI OU CASSÉ PEUT ENTRAÎNER UNE

DESCENTE BRUTALE DE LA PORTE ET CAUSER

DES BLESSURES MORTELLES.

ASSUREZ-VOUS QUE LA PORTE DE GARAGE EST

CORRECTEMENT ÉQUILIBRÉE. UNE PORTE MAL

ÉQUILIBRÉE PEUT CAUSER DES BLESSURES

GRAVES. CONFINEZ LA RÉPARATION DES CÂBLES, DES RESSORTS, ET DE TOUT AUTRE ÉLÉMENT Á UN TECHNICIEN QUALIFIÉ.

VÉRIFIER L’OUVRE-PORTE UNE FOIS PAR MOIS. SI

LES SYSTÈME PHOTOÉLECTRIQUE EST BLOQUÉ

PAR UN OBJET DE PLUS DE 6 PO X 12 PO, LA

PORTE OUVERTE NE DOIT PAS SE FERMER ET LA

PORTE SE FERMANT DOIT S’OUVRIR. VÉRIFIER

CELA EN UTILISANT LA VÉRIFICATION DÉCRITE Á

L’ÉTAPE 29.

CONSERVEZ CES INSTRUCTIONS

29

Page 30

r

Operation of Your Opene

HOW TO ACTIVATE THE OPENER

WARNING: Never let children operate or play with

door controls. Keep remote control away from children.

Use any of the following devices:

1. The Remote Control Transmitter; momentary push of the button and the door will start to move.

2. The Wall Station Up/Down button; push momentarily the button until the door starts to move. Constant push of the

button, until door is closed is required if light flashes (indicating a Safety Sensor obstruction).

3. The Wireless Keyless Entry System; (see below)

4. The Outside Key Switch (see manufacturer’s instructions for use of this device).

HOW THE DOOR MOVES WHEN THE OPENER IS ACTIVATED

WARNING: Always keep moving door in sight and away from people and objects, until it is com-

pletely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

1. If open, the door will close. If closed, the door will open.

2. If closing, the door will stop. Next activation will open.

3. If opening, the door will stop. Next activation will close.

4. If an obstruction is contacted or the beam is interrupted while closing, the door will reverse and the light will flash.

5. If an obstruction is encountered while opening, the door will stop and the light will flash. The next activation will

close the door.

6. The Infrared Safety Sensor uses an invisible beam which, when broken by an obstruction, causes a closing door

to reverse, prevents an open door from closing and causes the light to flash.

7. If door stops travel for 1 second at midpoint during close and then continues to close, it indicates that the batteries

in the Wireless Infrared Safety Sensors are weak and need replacement.

HOW THE LIGHT WORKS AND WHAT IT MEANS WHEN IT FLASHES

1. Overhead light automatically turns on when opener is activated and remains on for 4 minutes for convenience and

safety.

2. The light will flash after coming upon an obstruction in the up or down direction to warn you of a problem. It will

continue flashing for 4 minutes, and then shut off.

If the light begins to flash and the door moves a short distance and then reverses from a wall station button,

transmitter or keyless entry, the external safety sensor device is activated or defective. To temporarily override

and close door, activate wall station up/down button, keeping button depressed; opener will begin in down direction. The button must remain depressed until cycle is completed. If the button is release before cycle is completed, the door will reverse and come to full up position. Problems in the safety system should be inspected by

a professional garage door installer.

HOW TO OPERATE THE WIRELESS KEYLESS ENTRY (if Included)

1. Enter the 5-digit PIN number assigned to the door. Door will move. Unit remains active for 25 seconds. Pressing

any key will stop the door if opening and stop or reverse the door if closing. NOTE: If an error is made entering

codes, simply press and hold both the “7/8” and “9/0” buttons for two seconds. The Keyless Entry will

reset.

children.

WARNING: Never let children operate or play with door controls. Keep remote control away from

30

Page 31

HOW TO OPERATE THE WIRELESS WALL STATION (If Included)

WARNING: Never let children operate or play with door

controls. Keep remote control away from children.

The Wireless Wall Station Provides the Following Features:

1. Momentarily pressing the UP/DOWN button activates the door.

An open door will close and a closed door will open.

2. Momentarily pressing the LIGHT button will toggle the overhead

light on and off. The light will remain on until it is turned off by

another LIGHT button press or the door is activated. The

overhead light turns on automatically with door activation and

will turn off automatically after a 4 minute delay.

3. Momentarily pressing the Timer button activates a 10 second

exit delay. The overhead light will flash on and off for 10

seconds. After the 10 second delay the door will close. The exit

delay feature works only when the door is in the up position.

4. Pressing the PET LOCK button opens a closed door to a preset position between eight and thirty inches above

the floor, allowing pets to enter and exit the garage without the door being fully open. The door must be fully

closed to activate the pet open feature. Pressing the PET LOCK button while the door is in the pet position will

cause the door to close. Pressing the UP/DOWN button while the door is in the pet position will cause the door to

open. NOTE: a door in the pet position is not locked and should not be used as a secured door position.

5. The wall station PROGRAM button has several functions.

a. It can be used to set a custom pet position. (see below)

b. It can be used to set the opener’s closing force (See Adjustment #1 Page 27).

To set a custom pet position, start with the door in the closed position.

1. Operate the door then stop it at the desired height. If desired height is not achieved, the door must be

returned to the closed position.

2. Press the wall station PROGRAM button until the LED turns on solid (5 sec.), or the opener power head

PROGRAM SWITCH button two times. The STATUS light on the power head unit and the overhead light

will flash on and off at a normal rate.

3. Press the PET POSITION button. The STATUS light on the power head and the overhead light will flash

on and off three times indicating successful programming.

OPENER POWER HEAD CONTROLS

The PROGRAM SWITCH located in the opener power head has several

functions.

1. Pressing the PROGRAM SWITCH button once, will make the

STATUS light and overhead lamp turn on solid. This mode allows

programming of Transmitters, Wireless Keyless Entry, and Wireless

Wall Stations (see pages 19, 21, and 26).

2. Pressing the PROGRAM SWITCH button two times will make the

STATUS light and overhead lamp blink on and off. This mode allows

programming of a custom pet position (see above).

3. Pressing the PROGRAM SWITCH button three times will make the

STATUS light and overhead lamp blink on and off with a long pause at

each blink cycle. This mode allows programming of the opening force

(see page 27).

4. Pressing and holding the PROGRAM SWITCH button for 10 seconds

will erase all transmitters from memory. The STATUS light and overhead light will flash 3 times indicating a successful erase operation.

31

Page 32

HOW TO OPERATE THE DOOR MANUALLY – Emergency Release Disconnect

WARNING: The door should be fully closed if possible, weak or broken springs could allow an open

door to fall rapidly. Property damage or serious personal injury could result. Do not use the manual release knob to pull the door open or closed. Do not stand near or in the path of door when using the

emergency release disconnect.

The opener is equipped with an emergency release

recessed trolley-type disconnect system, enabling

manual operation of the garage door during power

failure.

The trolley is disconnected from the chain by pulling

down on the red release knob, allowing the garage

door to be operated manually.

The trolley will automatically reconnect when power is

restored and door is activated.

If emergency release is used, close door before

operating opener.

NOTE: Outside keylock emergency releases are

an available accessory and are recommended for

garages without a service entrance.

Programming a HomeLink™ Equipped Automobile to the Power Head Unit

WARNING: During programming the garage door may operate. Keep people and objects clear of the

moving door to prevent door damage or possible personal injury.

NOTE: Use the instructions included with your vehicle FIRST

vehicle then follow the instructions listed below.

Make sure you use a hand held transmitter which is already programmed to the Power head (see step 23), to perform the

procedure listed below.

1. Press and hold the two outside buttons on the HomeLink™ unit until the light begins to flash rapidly (approx. 20

sec.). Release both buttons. (Do not perform this step to train additional hand-held transmitters).

Note: This operation erases all previously trained transmitters. Additional transmitters must be programmed using steps 2-5 below.

2. Hold the hand held transmitter about 1” to 3” away from the HomeLink™ unit keeping the both units indicator

lights in view.

3. Press and hold the hand held transmitter large center button. The transmitter’s red indicator will turn on. After 10

seconds the red indicator will blink rapidly. After 5 more seconds the red indicator will come on steady. Do not

release the button.

4. While still holding the Wayne-Dalton transmitter button (red indicator on steady), immediately press and hold the

desired HomeLink™ button. Keep pressing the buttons until step 5 has been completed.

5. The HomeLink™ indicator light will be blinking during the training operation. When the HomeLink™ indicator light

flashes rapidly or turns off (approx. 5 to 60 seconds), both buttons may be released. The HomeLink™ light

flashing rapidly or turning off indicates successful programming of the new frequency signal.

Now that HomeLink™ has learned the hand held transmitter code you must program HomeLink™ to the Power Head

Unit.

1. Press the PROGRAM Switch button located on the garage door Power Head Unit once. The red

PROGRAM STATUS light on the motor Power Head Unit and overhead lamp will turn on and

remain lit for one minute, indicating that it is ready to learn the Transmitter.

2. Now press the HomeLink™ button used in Step 4 above for 1 to 3 seconds. The PROGRAM

STATUS light on the power head will turn on and off three times indicating a successful learn.

3. Press the HomeLink™ button once more to operate the door. The opener will turn on and move the

door.

. If the Power Head Unit does not activate with the

32

Page 33

MAINTENANCE OF YOUR OPENER SYSTEM

Test door opener monthly. The garage door MUST reverse on contact with a 1 inch high solid test object on the floor. If adjusting either the force or the limit of travel, retest the door opener. Failure to adjust the opener properly may cause severe injury of death.

KEEP GARAGE DOORS PROPERLY BALANCED. See owner’s manual. An improperly balanced door

could cause severe injury or death. Have a qualified service person make repairs to cables, spring assemblies and other hardware.

Once a Month:

1. Manually operate door, if unbalanced or binding, call a professional garage door service person.

2. Check to be sure door opens and closes fully. Adjust Limits and/or Force, (see pages 23, 24 and 27).

3. Perform safety reverse tests (Step 27 and 29). Make any necessary adjustments.

Twice a Year:

Check chain tension. If chain rests on bottom of rail, adjust tension by turning the two chain adjusting nuts at the end

of the rails (opposite the power head end) clockwise. Make sure to adjust both nuts equal amounts and until chain is