WayCon SX120, SX80, SX50 User Manual

DRAWWIRE SENSOR

Contents:

Introduction – Applications ....2

Options ....3

SX50 up to 1250 mm ....4

SX80 up to 3000 mm ....6

SX120 up to 6000 mm ....8

Analogue output ..10

Digital output ..11

Absolute output ..12

Accessories ..13

Installation – warning notices ..14

Order code ..15

14.06.10

SX120 / SX80 / SX50

Key-Features:

- Ranges 50...6000 mm

- Analogue – Digital – Absolute - Bus

- Linearity up to 0,02 %

- Protection class up to IP67

- High dynamics

- Off-shore sensors

- High EMC-grade

- Customised versions available

- 2 -

INTRODUCTION

WayCon Positionsmesstechnik GmbH is a manufacturer of high quality draw wire position transducers for industrial use. Due to its small overall size, its short assembly time and its possible

customisation, the SX sensor technology is a cost-effective and flexible solution for a wide range of

industrial applications. The dynamics of the draw wire transducer allows a high motion speed and

acceleration of the measuring target. Its rugged design and high quality makes applications in harsh

industrial environments possible. Sensors specifically designed for off-shore use receive a

HARTCOAT surface, which makes them resistant to e. g. sea water. Special instruments are

available with mounting service of encoder on site, as well as customised versions of housing.

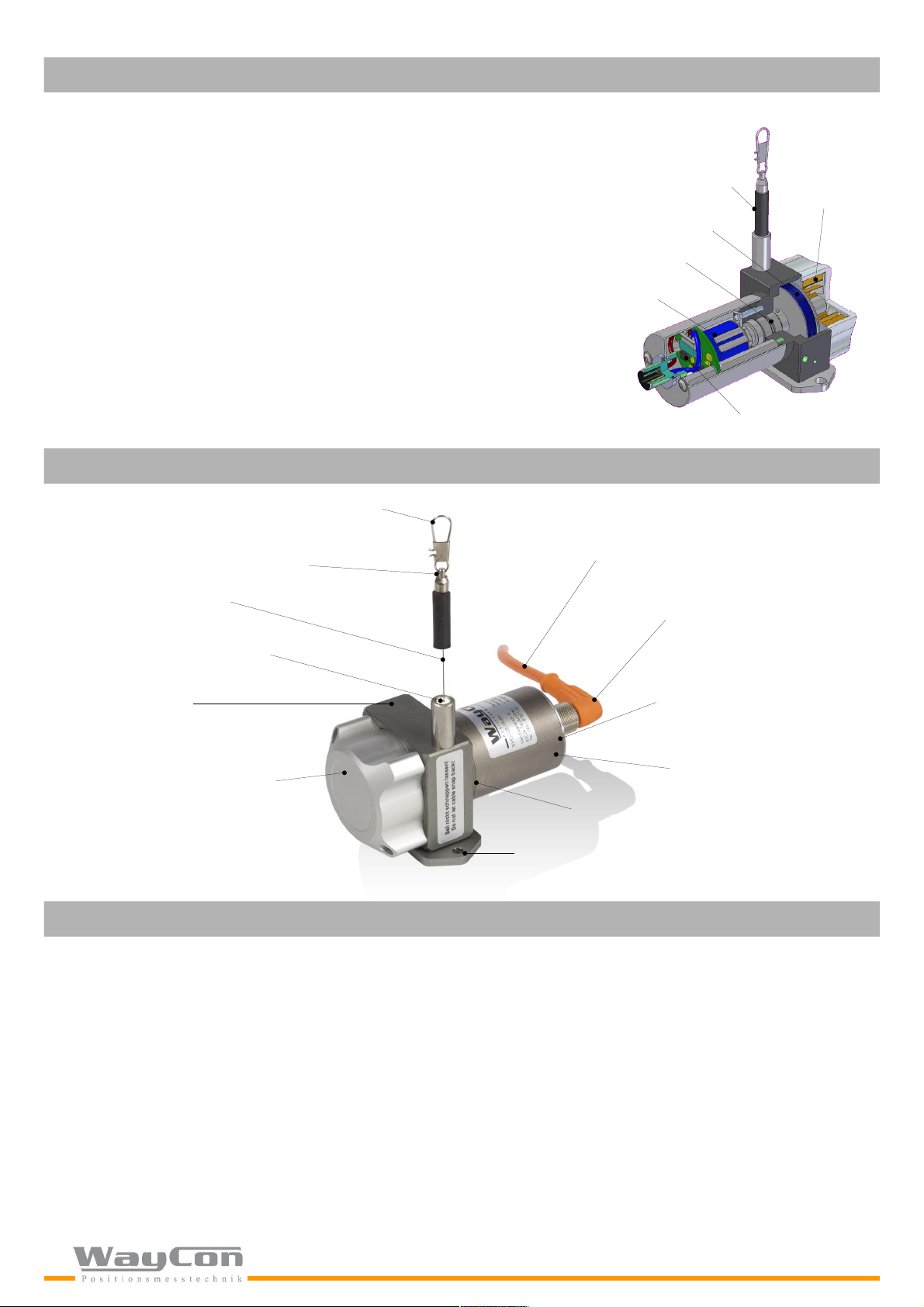

measuring rope

tension spring

rope capstan

Sensor principle:

A constant spring force coils the measuring rope accurately, single-layered on an ultralight rope

capstan, so that its linear motion is converted into rotation. The sensor element (encoder) provides

the output signal required.

OUTLINE

easy rope fixation with rope clip

ball bearing drill protection

measuring rope

(stainless steel)

diamond-polished ceramic bushing

titanium-anodised

aluminium housing

rotating shaft

sensor element

SX50

electronics

flexible sensor cable

M12-connector system or

cable output

waterproof housing

IP65 and IP67

dynamic spring drive

for max. track speed

APPLICATIONS

• lifting tables and platforms

• suspension of vehicles

• positioning of fork-lifts

• level control system

portal frames and gantry cranes

•

medical technology

•

• lifting and rescue technology

• x-y-axis positioning

• pneumatic cylinder

2 ball bearings

allows quick and easy mounting

• hydraulic cylinder and press slit

• injection moulding machine

• crash-tests

• air frame load testing

auto body/ carriage deformation

•

robot application

•

• property management

• linear guides

• pipe displacement

best linearity

- 3 -

OPTIONS

HG

A reinforced spring drive provides a greater rope tension and allows a higher rope acceleration. Please note the different dimensions of the housing and the higher

traction of the rope. This option is only available for the series SX50.

CO

By the use of a special technology all components of the housing and the inner mechanics become HARTCOAT® coated. This coating is a hartanodic oxidation that

protects the sensor from corrosion by aggressive media (e. g. sea water) with a hard ceramics-like layer. The sensor can thus be used off-shore.

IN

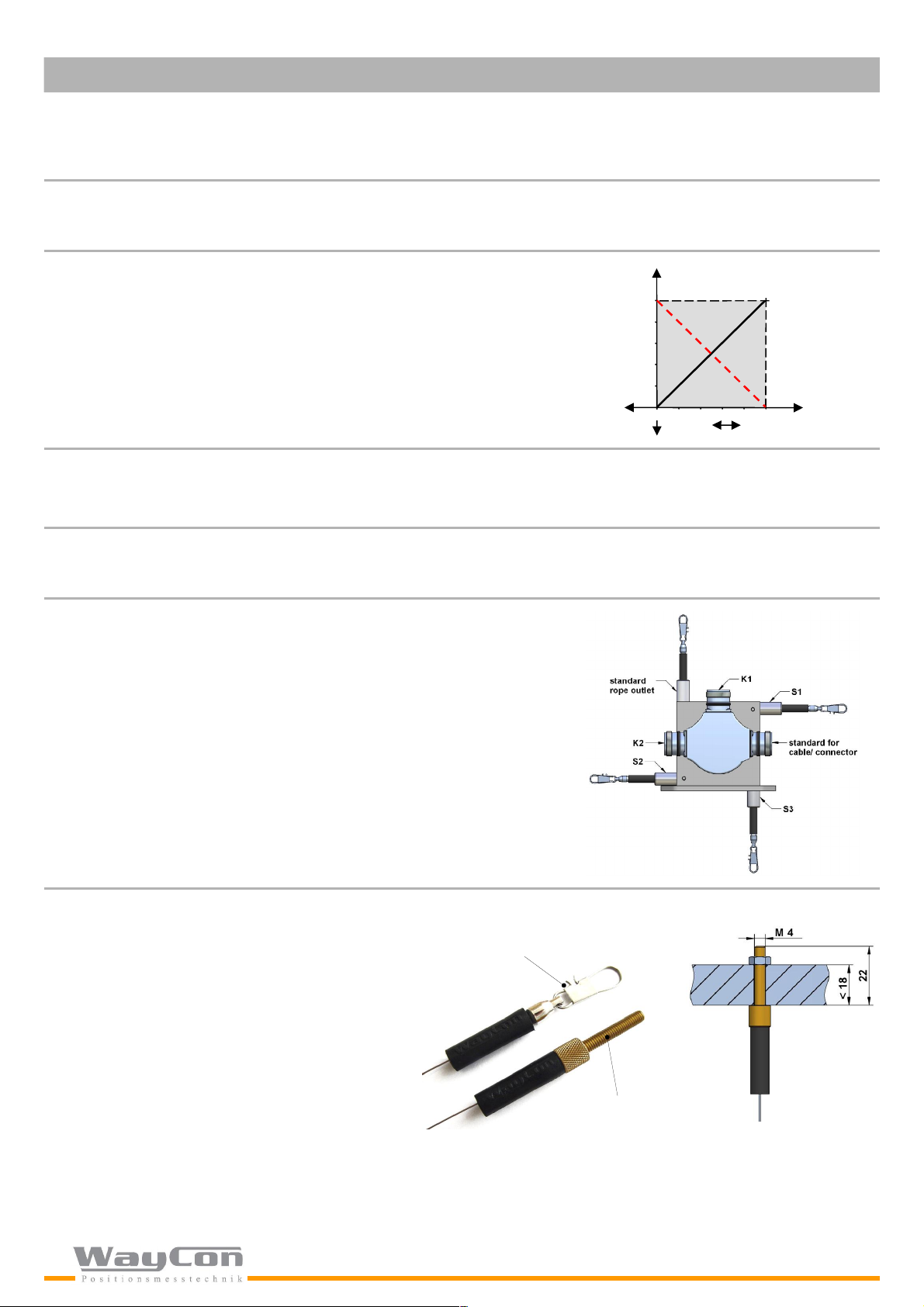

The analogue signal of the sensor is increasing by extracting the rope (standard).

Option IN inverts the signal, i. e. the signal of the sensor declines by extracting the rope.

10V/20mA

0V/4mA

output signal

inverted

standard

0

range

FS

extractretract

L25 / L10 / L05 / L02

Improved linearity on 0,25 %, 0,10 % or 0,05 % of measuring range. Resolution, repeatability and sensibility remain unchanged.

L02: Improved linearity on 0,02 % of measuring range. Resolution, repeatability and sensibility remain unchanged. This option is only available for incremental

sensors.

IP67

Use option IP67, if sensor is fully immersed in water (temporarily). Note that with this option there may occur a light hysteresis in the output signal due to the special

sealing. The max. acceleration is reduced to 60 % of the specified value.

S1 / S2 / S3

Optional rope outlet (see diagram)

S1 rope outlet on up

S2 rope outlet on down

S3 rope outlet at bottom

(S2/ S3 with different mounting plate)

K1 / K2

Optional cable/ connector orientation for sensors with digital output/ encoder (see diagram)

M4 rope fixation

Optional rope fixation with screw thread M4.

Ideal for attachment to through holes or thread holes M4.

rope clip with drill protection

(standard)

optional

M4 rope fixation

- 4 -

SERIES SX50

max. 1250 mm

analogue/ digital

digital-absolute

bus systems

output analogue digital output / digital-absolute / bus systems

potentiometer/ 0...10 V/ 4...20 mA (page 10) A/B-pulse, 90° phase-delayed (page 11-12)

sensor element hybrid potentiometer incremental encoder/ optical code disc

connection M12-connector or cable output connector or cable output

protection class IP65, optional IP67 IP65, optional IP67

humidity max. 90 % relative, not condensating max. 90 % relative, not condensating

life time approx. 2 million full cycles approx. 2 million full cycles

weight approx. 330 g approx. 330 g

housing aluminium, titanium-grey anodised aluminium, titanium-grey anodised

Technical data – analogue output

measurement range [mm] * 50 75 100 125 150 225 250 300 375 500 625 750 1000 1250

linearity [%] 0,50 0,50 0,50 0,50 0,15 0,15 0,15 0,15 0,15 0,15 0,15 0,10 0,10 0,10

linearity optional [%] 0,25 0,25 0,25 0,25 0,10 0,10 0,10 0,10 0,10 0,10 0,10 0,05 0,05 0,05

linearity optional [%] 0,10** 0,10** 0,10** 0,10** - - - - - - - - - -

Technical data – digital output

measurement range [mm] * 500 750 1250

linearity [%] 0,05, independent from measurement range

linearity optional [%] 0,02, independent from measurement range

available resolution [pulses/ mm] 1 4 8 12 16 29 60 ***

Z-pulse-distance [mm] 125

* other measurement ranges on request

** special version with unprotected potentiometer, protection class IP40 (please ask for technical drawing)

*** special version (please ask for technical drawing)

Mechanical data

rope tension velocity acceleration* rope tension HG acceleration HG*

range [mm]

[N] F

min

[N] V

max

[m/s] a

max

[m/s²] F

max

[N] F

min

[N] a

max

max

[m/s²]

F

50 6,8 6,8 5,6 480 13,2 13,7 660

75 3,9 4,4 5,6 480 7,3 7,9 900

100 3,4 3,4 5,0 360 5,9 6,4 660

125 4,9 5,4 6,3 600 6,9 7,9 900

150 6,8 7,9 5,6 480 13,2 13,7 660

225 3,9 4,6 5,6 480 7,3 8,3 900

250 6,8 7,9 5,6 480 13,2 13,7 660

300 3,2 4,0 5,0 360 5,9 6,7 660

375 4,7 5,4 6,3 600 6,9 7,9 900

500 3,4 4,0 5,0 360 5,9 6,9 660

625 4,4 5,4 6,3 600 6,9 7,9 900

750 3,9 5,4 5,6 480 7,3 9,8 900

1000 3,1 4,0 5,0 360 5,9 7,9 660

1250 4,1 5,4 6,3 600 6,9 8,3 900

* reduced to 60 % with option IP67

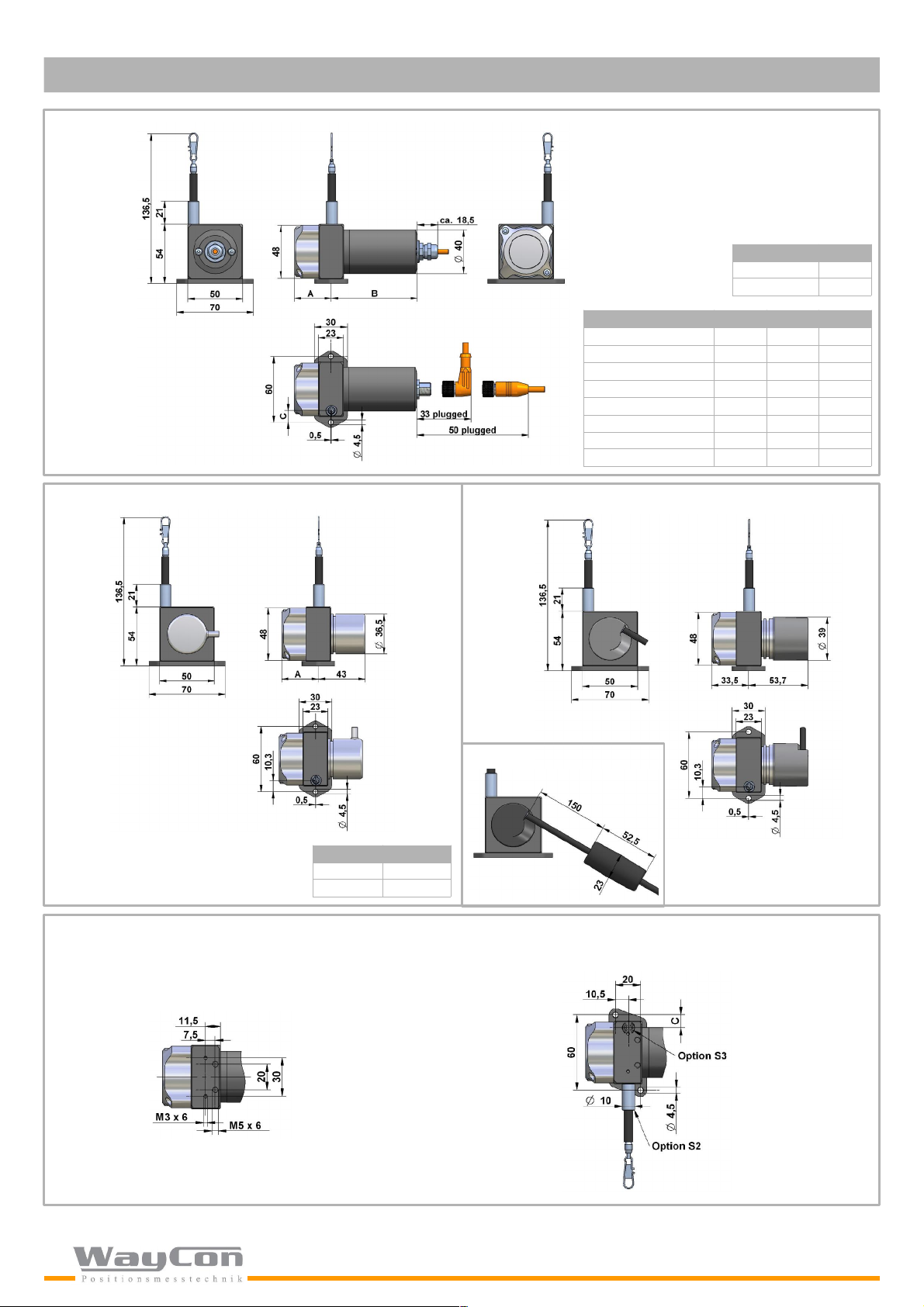

TECHNICAL DRAWING SX50

analogue output

- 5 -

output B

potentiometer 65

10V / 420 A 78,5

range option A C

50 / 150 / 250 mm Standard 26,5 21,3

75 / 225 / 750 mm Standard 26,5 17

100 / 300 / 500 / 1000 mm Standard 26 ,5 12,75

125 / 375 / 625 / 1250 mm Standard 33 ,5 10,3

50 / 150 / 250 mm HG 33,5 21,3

75 / 225 / 750 mm HG 33,5 1 7

100 / 300 / 500 / 1000 mm HG 33,5 12,75

125 / 375 / 625 / 1250 mm HG 46,5 10,3

digital output incremental

option A

Standard 33,5

HG 46,5

mounting

The sensor can be installed by using the mounting plate (see drawing

above).

By disassembling the mounting plate, there are 4 threads (2 x M3, 2 x M5)

in the sensor housing for installing.

digital-absolute: SSI, CAN

detailed view: battery in cable

Sensors with option rope outlet S2 and S3 have a different base

plate.

Loading...

Loading...