Page 1

Package: 82293-00B

HOME

Release Date: January, 1997

CYLINK CORPORATION

910 Hermosa Court

Sunnyvale, California 94086, USA

1-408-735-5800

CYLINK LIMITED U.K.

Tel: +44-1256-841919

Fax: +44-1256-24156

CYLINK CORPORATION (Singapore)

Tel: +65-2976-196

Fax: +65-2976-195

CYLINK CORPORATION (New Delhi)

Tel: +91-11-617-6913

Fax: +91-11-617-9529

CYLINK CORPORATION (Bejing)

Tel: +81-10-6467-1905

Fax: +86-10-6467-1906

CYLINK CORPORATION (Pakistan)

Tel: +92-21-5840743

Fax: +92-21-5840727

CYLINK CUSTOMER SUPPORT

1-800-545-6608 (USA - California)

1-800-814-5587 (USA - New Jersey)

1-408-735-5822 (International - California)

1-201-333-3400 (International - New Jersey)

+44-1256-58122 (Cylink Limited - U.K.)

AirLink Pro

T1/E1 Rack Mount

Installer’s Guide

Page 2

COPYRIGHT © 1994 - 1997 Cylink Corporation World Rights Reserved.

Cylink Corporation provides this Manual “as is,” without warranty of any kind, either express or implied,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Cylink Corporation may make improvements and changes to the product described in this Manual at any

time and without any notice. Cylink Corporation assumes no responsibility for its use, nor any infringements

of patents or other rights of third parties that would result.

This Manual could contain technical inaccuracies or typographical errors. Periodic changes are made to the

information contained herein; these changes will be incorporated in new editions of the Manual.

No part of this publication may be stored in a retrieval system, transmitted, or reproduced in any way,

including but not limited to photocopy, photograph, magnetic or other records, without the prior written

permission of Cylink Corporation.

CYLINK is a registered trademark of Cylink Corporation; AirLink is a trademark of Cylink Corporation.

PRODUCT COMPATIBILITY

While every effort has been made to verify operation of this product with many different communications

products and networks, Cylink Corporation makes no claim of compatibility between its products and other

vendors’ equipment. It is assumed that users have thoroughly evaluated this product’s performance in the

communications environment in which it will be used.

SAFETY

The following general safety precautions must be observed during all phases of operation and service of this

product. Failure to comply with these precautions or with specific warnings elsewhere in this Manual willfully

violates standards of design, manufacture, and intended use of the product. Cylink Corporation assumes no

liability for the customer’s failure to comply with these requirements.

This product must be grounded. In the event of a short circuit, grounding reduces the risk of electrical shock

by providing an escape wire for the current.

Do not install or operate this product in the presence of flammable gases or fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

No user maintained or adjustable components are present within this product. The covers should not be

removed by anyone other than authorized Cylink service personnel. The potential for electrical shock exists

within the enclosure at all times unless it is unplugged.

Do not install substitute parts or perform any unauthorized modification to the AirLink Pro T1or E1. Return

the product to Cylink Corporation for service and repair to ensure that safety features are maintained. Prior

to returning any product(s) for repair, contact Cylink at the telephone numbers or address located on the

front of this Manual, and obtain a Return Material Authorization (RMA) number.

Changes or modifications not expressly approved by Cylink Corporation can void the user’s authority to

operate the equipment.

Page 3

LITHIUM BATTERY

The digital module in the AirLink Pro T1/E1 Rack Mount contains a lithium battery molded into the real-time

clock component. The lithium battery is NOT a customer-replaceable part. The lithium battery could explode

if mistreated. Do not attempt to expose the battery by opening the real-time clock component. Do not

attempt to recharge the battery. Do not dispose of the component by fire.

SYSTEM GROUNDING

Direct grounding of the antenna, mast, and tower serves as protection from lightning strikes and static

buildup. A direct electrical connection should be made to a suitable grounding rod at the base of the tower or

mast using at least #10 AWG ground wire, or its equivalent, and non corrosive hardware. For details and

safety standards, consult the appropriate local Electrical Codes or a similar document. Use lightning

arresters in appropriate places.

TOWER CONSTRUCTION

Compliance with local zoning and tower construction regulations is recommended when AirLink Pro T1/E1

Rack Mount systems require a tower. These regulations generally mandate that permits be obtained before

any tower construction begins. Check with local zoning and aviation authorities for more information.

FCC NOTICE TO USERS

The Airlink Pro T1 complies with Part 15 of the FCC rules. Operation is subject to the condition that this

device does not cause harmful interference.

Federal Communications Commission (FCC) Rules on spread spectrum devices, such as the AirLink Pro T1

or E1, require that you be notified of the following:

FCC regulations require that this device be professionally installed by a person knowledgeable in electronics

and trained in the correct installation of this device.

All interface cables must be shielded.

Operation of this device is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference that may cause undesired operation.

Changes or modifications not expressly approved by Cylink Corporation can void the user’s authority to

operate the equipment.

Page 4

STATEMENT OF WARRANTY

CYLINK products, except as stated otherwise in an applicable price list, are warranted against defects in

workmanship and material for a period of one (1) year from date of delivery as evidenced by CYLINK’s

packing slip or other transportation receipt.

CYLINK’s sole responsibility under this warranty shall be to either repair or replace, at its option, any

component which fails during the applicable warranty period because of a defect in workmanship and

material, provided PURCHASER has promptly reported same to CYLINK in writing. All replaced Products or

parts shall become Cylink’s property.

CYLINK shall honor the warranty at CYLINK’s repair facility in Sunnyvale, California. It is PURCHASER’s

responsibility to return, at its expense, the allegedly defective Product to CYLINK. PURCHASER must

obtain a Return Materials Authorization (RMA) number and shipping instructions from CYLINK prior to

returning any Product under warranty. Transportation charges for the return of the Product to PURCHASER

shall be paid by CYLINK within the United States. For all other locations, the warranty excludes all costs of

shipping, customs clearance and other related charges. If CYLINK determines that the Product is not

defective within the terms of the warranty, PURCHASER shall pay CYLINK all costs of handling,

transportation and repairs at the then prevailing repair rates.

All the above warranties are contingent upon proper use of the Product. These warranties will not apply (i) if

adjustment, repair or parts replacement is required because of accident, unusual physical, electrical or

electromagnetic stress, negligence of PURCHASER, misuse, failure of electric power environmental

controls, transportation, not maintained in accordance with CYLINK specifications, or abuses other than

ordinary use (ii) if the Product has been modified by PURCHASER or has been repaired or altered outside

CYLINK’s factory, unless CYLINK specifically authorizes such repairs or alterations; (iii) where CYLINK

serial numbers, warranty data or quality assurance decals have been removed or altered.

CYLINK also reserves the right to make product improvements without incurring any obligation or liability to

make the same changes in Products previously manufactured or purchased. In no event shall CYLINK be

liable for any breach of warranty in an amount exceeding the net selling price of any defective Product. No

person, including any dealer, agent or representative of CYLINK is authorized to assume for CYLINK any

other liability on its behalf except as set forth herein. Nonpayment of any invoice rendered within the stated

payment terms automatically cancels any warranty or guarantee stated or implied. If any payment is due

CYLINK for services performed hereunder, it shall be subject to the same payment terms as the original

purchase.

CYLINK HEREBY DISCLAIMS ALL IMPLIED WARRANTIES ON PRODUCTS INCLUDING WITHOUT

LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. The warranties expressly stated herein are the sole obligation or liability on the part of CYLINK

arising out of or in connection with the sale or performance of the products.

Products Manufactured by Others - For products not manufactured by CYLINK the original manufacturer’s

warranty shall be assigned to PURCHASER to the extent permitted and is in lieu of any other warranty,

express or implied. For warranty information on a specific product, a written request should be made to

CYLINK.

IN NO EVENT WILL CYLINK BE LIABLE TO PURCHASER FOR (i) REPROCUREMENT COSTS; (ii) SPECIAL,

INDIRECT OR CONSEQUENTIAL DAMAGES; (iii) ANY DAMAGES WHATSOEVER RESULTING FROM LOSS

OF USE, DATA OR PROFITS ARISING OUT OF OR IN CONNECTION WITH THIS AGREEMENT, OR THE

USE OF PERFORMANCE OF CYLINK PRODUCTS, REGARDLESS OF WHETHER THE CAUSE OF ACTION

IS IN CONTRACT, TORT, INCLUDING NEGLIGENCE, OR ANY OTHER FORM.

No action, whether in contract or tort, including negligence, arising out of or in connection with this

Agreement, may be brought by either party more than eighteen (18) months after the cause of action has

accrued, except that an action for nonpayment may be brought within eighteen (18) months of the date of

last payment.

Page 5

Table of Contents

Preface .........................................................................................................ix

Who Should Read This Guide................................................................. x

Prerequisite Knowledge .......................................................................... x

Guide Organization ................................................................................ x

Guide Conventions ................................................................................. xi

Typographic Conventions ............................................................... xii

Keyboard Usage..............................................................................xii

Notes, Cautions, and Warnings ....................................................... xii

Customer Support ............................................................................... xiii

Reader Response .................................................................................. xiv

Chapter 1: Product Description................................................................... 1-1

Introduction to the AirLink Pro T1/E1 ................................................... 1-2

Features and Capabilities ................................................................... 1-3

Airlink Pro T1/E1 Antenna..............................................................1-5

ASCII terminal interface.................................................................1-5

Programmed Configuration Parameters .......................................... 1-5

Monitoring and Diagnostic Capabilities ......................................... 1-5

T1/E1 Link Backup Capability ...................................................... 1-6

Alarm Relay Contacts ................................................................... 1-7

Order Wire Interface ..................................................................... 1-7

Fail-Safe Link .............................................................................. 1-7

Block Diagram .............................................................................. 1-7

Chapter 2: Installation and System Administration.................................... 2-1

Overview............................................................................................ 2-2

Unpacking ........................................................................................... 2-2

Remote Connection................................................................................2-3

Identifying Physical Features.............................................................. 2-3

Front Panel.................................................................................... 2-3

Rear Panel..................................................................................... 2-3

Rev. B - 1/97 v

Page 6

Preparing a Place..................................................................................2-4

General Physical and Environmental Characteristics.......................2-5

Lightning Protection........................................................................2-5

Rack Mounting............................................................................... 2-5

Power and Grounding Requirements................................................. 2-5

Setting Up the System.......................................................................... 2-6

Installing the Antenna ................................................................... 2-6

Installing the AirLink Pro T1/E1 Rack Mount.................................. 2-8

Wiring for Burst Synchronization .................................................. 2-20

Checking Operation ........................................................................... 2-21

Initial Unit Configuration ............................................................ 2-21

Aligning the Antenna ................................................................... 2-23

Chapter 3: Configuration ........................................................................... 3-1

Overview ............................................................................................ 3-2

Using the ASCII Terminal Interface ..................................................... 3-2

Terminal Setup Requirements ......................................................... 3-2

Command-Line Interface................................................................ 3-3

Setting Administrative Parameters ............................................... 3-5

Site Name ..................................................................................... 3-5

Date and Time ............................................................................... 3-6

Password ....................................................................................... 3-7

Setting T1/E1 Line Parameters ............................................................. 3-8

Coding .......................................................................................... 3-8

Equalization ................................................................................. 3-9

Setting Link Parameters ..................................................................... 3-10

Application ................................................................................. 3-10

Burst Mode ................................................................................... 3-15

PN Code ....................................................................................... 3-16

RF Power Level ............................................................................ 3-17

Order Wire Type .........................................................................3-17

Interface Type (E1 Only)............................................................... 3-18

vi Rev. B - 1/97

Page 7

Setting Alarm Control Parameters.......................................................3-18

Alarm Reporting .......................................................................... 3-18

Alarm Level ................................................................................. 3-19

1-Hour Errored Seconds Threshold ................................................ 3-20

1-Hour Unavailable Seconds Threshold ........................................ 3-20

24-Hour Errored Seconds Threshold ............................................... 3-21

24-Hour Unavailable Seconds Threshold ...................................... 3-22

Receive (Rx) Power Threshold ...................................................... 3-22

Transmit (Tx) Power Threshold ..................................................... 3-22

Setting Modem Parameters ................................................................. 3-23

Connections and Configuration....................................................... 3-24

Testing the Modem Link ................................................................ 3-25

Functions ...................................................................................... 3-26

RS-232 Modem Port Interface........................................................ 3-30

User Interface Additions ............................................................... 3-32

Getting AirLink Pro T1/E1 Configuration Information .......................... 3-39

Configuration Parameter Settings ................................................. 3-39

Threshold Settings ....................................................................... 3-38

Hardware and Software Revision Levels ...................................... 3-38

Command Keywords and Operands ..................................................... 3-39

Chapter 4: Operations and Maintenance ..................................................... 4-1

Overview ............................................................................................ 4-2

Acquiring Status Information ............................................................... 4-2

Viewing Status Information ........................................................... 4-3

Acquiring Alarm Information ............................................................... 4-5

The Event Queue ............................................................................ 4-6

AirLink Pro T1 Indicators ............................................................... 4-7

Acquiring Performance Information ..................................................... 4-11

Viewing Performance Information ................................................. 4-12

Resetting Performance Counters ..................................................... 4-13

Rev. B - 1/97 vii

Page 8

Diagnostic Tools..................................................................................4-13

Radio QRSS Testing ..................................................................... 4-13

Loopback Tests ............................................................................. 4-15

Rack Mount Unit Working with Ruggedized Unit ................................4-22

Features of Various Units ..............................................................4-23

Appendix A: Messages .............................................................................. A-1

General Information ........................................................................... A-2

Fault Messages ................................................................................... A-3

Alarm Messages ................................................................................. A-3

Advisory Messages ............................................................................. A-4

Status Messages .................................................................................. A-5

Appendix B: Specifications ........................................................................ B-1

General Specifications ......................................................................... B-2

Interface Specifications ....................................................................... B-2

T1 DSX-1 Interface ........................................................................ B-2

E1 Interface General Specifications......................................................B-3

Output Specifications....................................................................B-4

Input Specifications......................................................................B-4

Radio Interface ................................................................................... B-5

Signal-to-Pin Assignments ........................................................... B-11

Terminal and Modem Adapter Cables..................................................B-11

Terminal Configuration ..................................................................... B-16

Configuration Defaults ...................................................................... B-19

Appendix C: Commands ............................................................................. C-1

Appendix D: Glossary ............................................................................... D-1

Index ................................................................................................... Index-1

viii Rev. B - 1/97

Page 9

List of Figures

Figure Page Number

Figure 1-1 AirLink Pro T1/E1 Rack Mount Unit .................................1-2

Figure 1-2 Typical AirLink Pro T1/E1 Rack Mount

Operating Environment....................................................1-4

Figure 1-3 A Point-to-Point Backup Link.......................................... 1-6

Figure 1-4 Block Diagram of the AirLink Pro T1/E1 Rack Mount........1-8

Figure 2-1 AirLink Pro T1/E1 Rack Mount Front Panel........................2-3

Figure 2-2 AirLink Pro T1/E1 Rack Mount Rear Panel....................... 2-3

Figure 2-3 Typical Antenna Mounts...................................................2-7

Figure 2-4 23” Rack Mount..............................................................2-11

Figure 2-5 Alarm Relay Contacts....................................................2-14

Figure 2-6 Terminal Connection to the AirLink Pro

T1/E1 Rack Mount..........................................................2-15

Figure 2-7 Modem Connection to the AirLink Pro

T1/E1 Rack Mount..........................................................2-16

Figure 2-8 Two-Wire Order Wire Connection...................................2-16

Figure 2-9 Four-Wire Order Wire Connection..................................2-17

Figure 2-10 ELPAC Power Supply....................................................2-18

Figure 2-11 FORTRON Power Supply ..............................................2-19

Figure 2-12 Burst Sync Wiring ..........................................................2-20

Figure 2-13 Test Point Locations .......................................................2-21

Figure 3-1 Point-to-Point Link........................................................2-24

Figure 3-2 Hub Application Different Paths...................................3-12

Figure 3-3 Hub Application Same Paths.........................................3-13

Figure 3-4 AirLink Pro T1/E1 Rack Mount Two Part Repeater Link...3-14

Figure 4-1 Conventional Carrier Failure Response.............................4-7

Figure 4-2 AirLink Pro T1 Carrier Failure Response...........................4-7

Figure 4-3 Front Panel Indicators......................................................4-9

Figure 4-4 Rear Panel Indicators.......................................................4-9

Figure 4-5 AirLink Pro T1/E1 Rack Mount QRSS Test.......................4-14

Figure 4-6 AirLink Pro T1/E1 Rack Mount Loopback Tests................4-16

Rev. B - 1/97

ix

Page 10

Figure 4-7 AirLink Pro T1/E1 Rack Mount in Normal Operation ......4-17

Figure 4-8 AirLink Pro T1/E1 Rack Mount in

Local Loop Test, Near End..............................................4-18

Figure 4-9 AirLink Pro T1/E1 Rack Mount in

Remote Loop Test, Near End...........................................4-19

Figure 4-10 AirLink Pro T1/E1 Rack Mount in

Local Loop Test, Far End................................................4-20

Figure 4-11 AirLink Pro T1/E1 Rack Mount in

Remote Loop Test, Far End..............................................4-20

Figure B-1 Terminal Cable: AirLink Pro T1 Terminal Port

to a DB-25 Terminal Port................................................B-16

Figure B-2 Modem Cable: AirLink Pro T1 Terminal Port

to a DB-25 Modem Port...................................................B-16

Figure B-3 Terminal Cable: AirLink Pro T1 Terminal Port

to a DB-9 Terminal Port..................................................B-17

Figure B-4 Modem Cable: AirLink Pro T1 Terminal Port

to a DB-9 Modem Port....................................................B-17

x

Rev. B - 1/97

Page 11

P

REFACE

REFACE

P

About This Guide

About This Guide

The AirLink Pro T1/E1 Rack Mount Installer’s Guide covers the

information needed to unpack, install, configure, and operate the

AirLink Pro T1 or the Airlink Pro E1 system. Begin by reading this

preface for more information about how this guide supports your use

of the AirLink Pro T1/E1 Rack Mount system.

Inside this chapter:

Who Should Read This Manual...............................................xiii

Prerequisite Knowledge .......................................................xiv

Guide Organization..................................................................xiv

Guide Conventions....................................................................xv

Customer Support ............................................................... xvii

Reader Response ................................................................. xviii

Rev. B - 1/97 xi

Page 12

AirLink Pro T1/E1 Rack Mount Installer’s Guide

About This Guide

Who Should Read This Manual

This is an installation guide for persons who must perform or coordinate the

tasks associated with unpacking and installing the AirLink Pro T1/E1 Rack

Mount.

Prerequisite Knowledge

Throughout this guide are explanations and procedures that presume working

familiarity with basic telephone trunking and transmission concepts and

practices, as well as basic digital data communications concepts and practices.

If you are not familiar with the concepts and practices involved in these

disciplines, we recommend that you familiarize yourself with them before

proceeding.

Also, this guide does not attempt to provide any detailed system planning or

installation information on radio frequency (RF) antenna assemblies or Path

analysis . For details about these topics, please refer to the Airlink Applications

and Site Planning Guide.

Guide Organization

Each of the chapters and appendices in this guide begins by introducing the

contents of that chapter or appendix. Before beginning the installation process,

you should read the introductions to all of the guide portions so that you have a

sense of what each portion provides.

When you come to a procedure, you should skim through the entire procedure

before you begin performing the step-by-step instructions. By doing this, you

will know what is coming, and will be prepared with the appropriate

information, equipment, or tools.

The information in this guide is organized according to the sequence of tasks

necessary to plan for unpacking, installing, and configuring, as well as operating

and maintaining the AirLink Pro T1/E1 Rack Mount system.

NOTE The Airlink Pro T1 and the Airlink Pro E1 are similar radio units. The installation, system

administration, and the operational procedures for the two units have therefore been

combined into this manual. The minor differences between the two units are indicated

wherever necessary.

xii

Rev. B - 1/97

Page 13

The guide is divided into the following sections:

Guide Section Description

AirLink Pro T1/E1 Rack Mount Installer’s Guide

About This Manual

Chapter 1:

Product Description

Chapter 2:

Installation and

SystemAdministration

Chapter 3:

Configuring the AirLink Pro

T1/E1 Rack Mount

Chapter 4:

Operations and Maintenance

Appendix A:

Messages

Appendix B:

Specifications

Appendix C:

Commands

Appendix D:

Glossary

Index Provides a quick reference to assist you in locating

Describes the features and capabilities of the AirLink

Pro T1/E1 system.

Outlines the procedures for unpacking and installing the

AirLink Pro T1/E1 Rack Mount system hardware,

connecting the antenna, and performing initial operation

checks.

Provides instructions for configuring the AirLink Pro

T1/E1.

Contains information on the operation and maintenance

of the AirLink Pro T1/E1 system.

Lists the system alarm, status, and error messages.

Contains a quick reference to the AirLink Pro T1/E1

Rack Mount system specifications.

Provides a list of frequently used commands.

Provides definitions for the terms commonly used

throughout this guide.

important topics in the guide.

Guide Conventions

The procedures and instructions in this guide use the following conventions:

❚ Typography that highlights information within text, including screen

displays, figures, and tables.

❚ Keyboard usage conventions.

❚ Notes that add information, point to other important considerations, or

alert you to possible risks to yourself, your equipment, or your data.

Rev. B - 1/97

xiii

Page 14

AirLink Pro T1/E1 Rack Mount Installer’s Guide

About This Guide

Typographic Conventions

❚ Terminal displays are shown as text in the Courier font:

AIRLINK PRO T1> get configuration

Site Name: Sunnyvale 2

Application: 6. Slave unit in a point-to-point Link

Burst Mode: Normal

Coding: B8ZS

Equalization: 0 - 133 ft

PN Code: 1

RF Power: 10 dBm

Alarm Reporting: Immediate

Alarm Level: Status

Date/Time: May 1 1996 10:35:00

❚ Bold Courier font indicates a command keyword or operand that you

are expected to type exactly as shown.

❚ Italic Courier font indicates a command operand that you must

replace with a selected value when you type the command.

❚ Named keys in text are shown enclosed in angle brackets. The notation

<Return> is used to indicate either the Return key or the Enter key.

Keyboard Usage

❚ All command examples shown in text are executed by typing the command

and then pressing <Return>.

❚ Two or more keys that must be pressed simultaneously are shown in text

linked with a plus (+) sign: <Ctrl>+C.

Notes, Cautions, and Warnings

NOTE The standard text note highlights important or additional

CAUTION These notes warn you of situations that could result in damage

information for you to consider.

to your equipment or loss of data if you do not heed the

instructions.

xiv

Rev. B - 1/97

Page 15

WARNING These notes warn you of situations that could endanger your

Customer Support

If after reading this guide you encounter any trouble installing or using the

AirLink Pro T1/E1 Rack Mount, please contact your local distributor. If

problems are not resolved, you can call Cylink’s Customer Service for assistance.

The telephone numbers are:

Domestic (USA)

1-800-545-6608 Sunnyvale, CA

1-800-814-5587 Jersey City, NJ

International

AirLink Pro T1/E1 Rack Mount Installer’s Guide

About This Manual

personal health if you do not heed the instructions.

1-408-735-5822 Sunnyvale, CA

1-201-333-3400 Jersey City, NJ

+65-297-6196 Singapore

+44-1256-841919 United Kingdom

+91-11-301-0090 India

+92-21-215-7264 Pakistan

Domestic and International Customer Service Fax

1-408-735-6641 Sunnyvale, CA

1-201-333-8560 Jersey City, NJ

+65-297-6195 Singapore

+44-1256-24156 United Kingdom

+91-11-379-3584 India

+92-21-587-0065 Pakistan

You can also contact Cylink’s Tech Support through the Internet at the

following address:

support@cylink.com

If you need to return equipment, call Customer Service to obtain a Return

Material Authorization (RMA) number prior to returning the equipment. The

RMA number must be placed on the outside of the shipping carton. Please be

prepared to provide the unit serial number, software version, and a detailed

description of the problem.

Rev. B - 1/97

xv

Page 16

AirLink Pro T1/E1 Rack Mount Installer’s Guide

About This Guide

Return all equipment to:

Cylink Corporation

1350 Bordeaux Drive

Sunnyvale, CA 94089

Attn: Repair and Return Department

RMA No: xxxxxxxxxx

Reader Response

Cylink’s Technical Publications Department wants its documents to meet your

requirements. To this end, your ideas about the documentation are valuable.

After you have had a chance to read and use the guide, we encourage you to

submit your comments to

Manager, Technical Publications

Cylink Corporation

910 Hermosa Court

Sunnyvale, CA 94086

You may also submit your comments through the Internet at the following

address:

techpubs@cylink.com

Cylink may use or distribute any of the information you supply in any way it

believes appropriate without incurring any obligations whatsoever.

xvi

Rev. B - 1/97

Page 17

C

HAPTER

HAPTER

C

Product Description

Product Description

This chapter introduces the AirLink Pro T1/E1 Rack Mount and

provides an overview of the features and capabilities.

1

1

Inside this chapter:

Introduction to the AirLink Pro

T1/E1 Rack Mount ...........................................................1-2

Features and Capabilities ...................................................1-3

Rev. B - 1/97 1-1

Page 18

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

Introduction to the AirLink Pro

T1/E1 Rack Mount

The AirLink Pro T1 and the AirLink Pro E1 systems are spread-spectrum

transceivers that operate in the license-free 5.725 to 5.850 GHz (C-band)

Industrial Scientific Medical (ISM) band. The AirLink Pro T1/E1 Rack Mount

uses a Spread Spectrum modulation technique to create a high-quality, pointto-point radio link between itself and another AirLink Pro T1/E1 Rack Mount

located many miles away.

The AirLink Pro T1/E1 Rack Mount (Figure 1-1) unit is a rack mount unit that

mounts in a 19 or 23 inch equipment rack or cabinet. The design of the unit can be

aisle or flush mounted. Status and Alarm LEDs are duplicated on the unit’s

rear panel so that it can be flush mounted against a wall.

1-2

Figure 1-1

AirLink Pro T1/E1 Rack Mount - Full View

Rev. B - 1/97

Page 19

Features and Capabilities

The AirLink Pro T1/E1 Rack Mount supports a range of sophisticated control

capabilities and options, including:

❚ Remote control of far-end

❚ Built-In Testing Equipment (BITE)

❚ Flexible, interactive user interface through an ASCII terminal

❚ Easily modified configuration parameters

❚ Local and remote monitoring, diagnostic, and maintenance capabilities

❚ Separate end-to-end communication channel for control and order wire

signals. Control signals and order wire voice signals do not disturb the T1

channel

❚ Every radio-frequency (RF) burst verified by an error-checking algorithm

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

The AirLink Pro T1 and E1 are similar radio units with minor differences in

their internal structures. These are:

❚ The AirLink Pro T1 and E1 have different internal clock oscillators

❚ The AirLink Pro T1 supports the Bipolar with 8-Zero Substitution (B8ZS)

coding format

❚ The AirLink Pro E1 supports the High Density Bipolar 3 (HDB3)

coding format

❚ The AirLink Pro E1 allows an electrical-interface option between Balanced

and Unbalanced

❚ The AirLink Pro T1 operates at 1.544 Mbps and the E1 at 2.048 Mbps

❚ The operating range between two AirLink Pro T1 units is up to 40 km and

that of two E1 units is 35 km

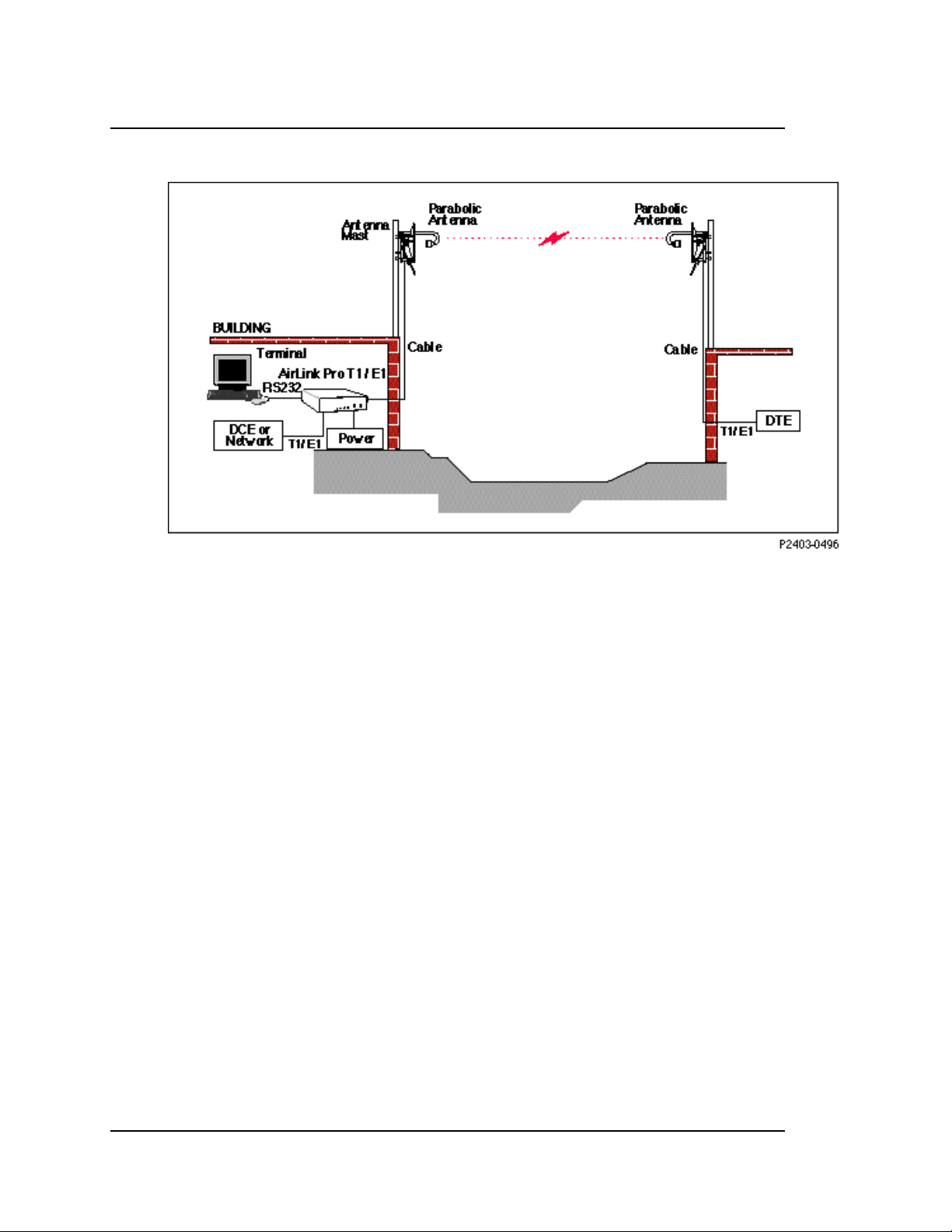

In a typical installation, an AirLink Pro T1 or E1 pair is installed between a

user’s communication facility—Data Circuit Equipment (DCE) or network—and

the Data Terminating Equipment (DTE). Figure 1-2 shows the AirLink Pro

T1/E1 Rack Mount in a typical operating environment.

Rev. B - 1/97

1-3

Page 20

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

Figure 1-2

Typical AirLink Pro T1/E1 Rack Mount Operating Environment

The AirLink Pro T1/E1 Rack Mount link is effectively transparent to the T1/E1

equipment on either end:

❚ Accepts T1/E1 as input

❚ Presents T1/E1 as output

AirLink Pro T1 operation is independent of the protocol used, so the AirLink Pro

T1 supports both the Bipolar with Eight-Zero Substitution (B8ZS) and the

Alternate Mark Inversion (AMI) coding formats. The AirLink Pro E1 supports

both the High Density Bipolar 3 (HDB3, and AMI) coding formats. These

formats do not interfere with the framing and maintenance channel used

between T1/E1 links so the AirLink Pro T1/E1 Rack Mount works with Extended

Frame format, ISDN Primary Rate Services, and so on.

The AirLink Pro T1/E1 Rack Mount provides full-duplex, radio-to-radio

communication that follows a Ping-Pong analogy: while one unit transmits a

radio burst, the other unit receives that burst. After the other unit receives a

complete burst, it waits through a guard interval before turning on its

transmitter and transmitting its burst.

The ping-pong radio-to-radio communication is invisible to the T1/E1

equipment on either end of the link because the digital buffering of the AirLink

Pro T1/E1 Rack Mount produces a smooth T1/E1 bit stream at the user interface.

1-4

Rev. B - 1/97

Page 21

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

Buffering is only a few milliseconds, so no perceptable degradation occurs to

voice or data communications.

AirLink Pro T1/E1 Rack Mount Antenna

The antenna is usually a two-foot or four-foot solid-parabolic dish for the 5.7

GHz C-band, with a narrow beam and high gain. For other kinds of antennas,

contact your distributor.

The AirLink Pro T1/E1 Rack Mount ASCII Terminal User Interface

The AirLink Pro T1/E1 Rack Mount ASCII terminal user interface is an

EIA/TIA-232 interface that allows a terminal device or personal computer to

control and monitor AirLink Pro T1/E1 Rack Mount operation at either end of

the link. The connection to the EIA/TIA-232 interface can be either a direct

connection (device to port), or an indirect connection (device to modem to port)

for dial-up operation.

Programmed Configuration Parameters

AirLink Pro T1/E1 Rack Mount operation is governed by user-selectable

configuration and control parameters that reside in the non-volatile memory of

the unit. These parameters are displayed and controlled through a terminal

device that can access both the local and remote unit. When power is lost and

then restored, the system reconfigures itself from its protected configuration

database.

A long-life lithium battery protects all system configuration settings during

power losses. The battery is part of the non-volatile memory/real-time clock

circuitry on the digital module in the AirLink Pro T1 and has a 10-year storage

life (in the absence of power to the AirLink Pro T1/E1 Rack Mount).

Refer to Chapter 3, Configuration, for more information on changing

configuration parameter settings.

Monitoring and Diagnostic Capabilities

The AirLink Pro T1/E1 Rack Mount system constantly monitors the quality of

the wireless link, checking the receive RF signal level, bit errors, and many

other critical factors. This information is stored in an internal database of

status and performance information that the AirLink Pro T1/E1 Rack Mount

uses, in part, to derive the events that are stored in the event queue. As alarm

events occur, they are signaled through indicators on the front panel of the

Rev. B - 1/97

1-5

Page 22

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

AirLink Pro T1/E1 Rack Mount and are entered in the event queue. To report

alarms, attach a modem and dial-out to the maintenance center.

Using the terminal user interface, query either the local AirLink Pro T1/E1

Rack Mount or the remote AirLink Pro T1/E1 Rack Mount for status, performance

and alarm information, and make configuration changes for either the local or

remote end of the link.

The AirLink Pro T1/E1 Rack Mount also provides bit-error and loopback tests to

isolate problems. Initiate tests in the local AirLink Pro T1/E1 Rack Mount or in

the remote AirLink Pro T1/E1 Rack Mount through the terminal user interface.

Refer to Chapter 4, Operations and Maintenance, for information on monitoring

operation and using diagnostic tools and procedures.

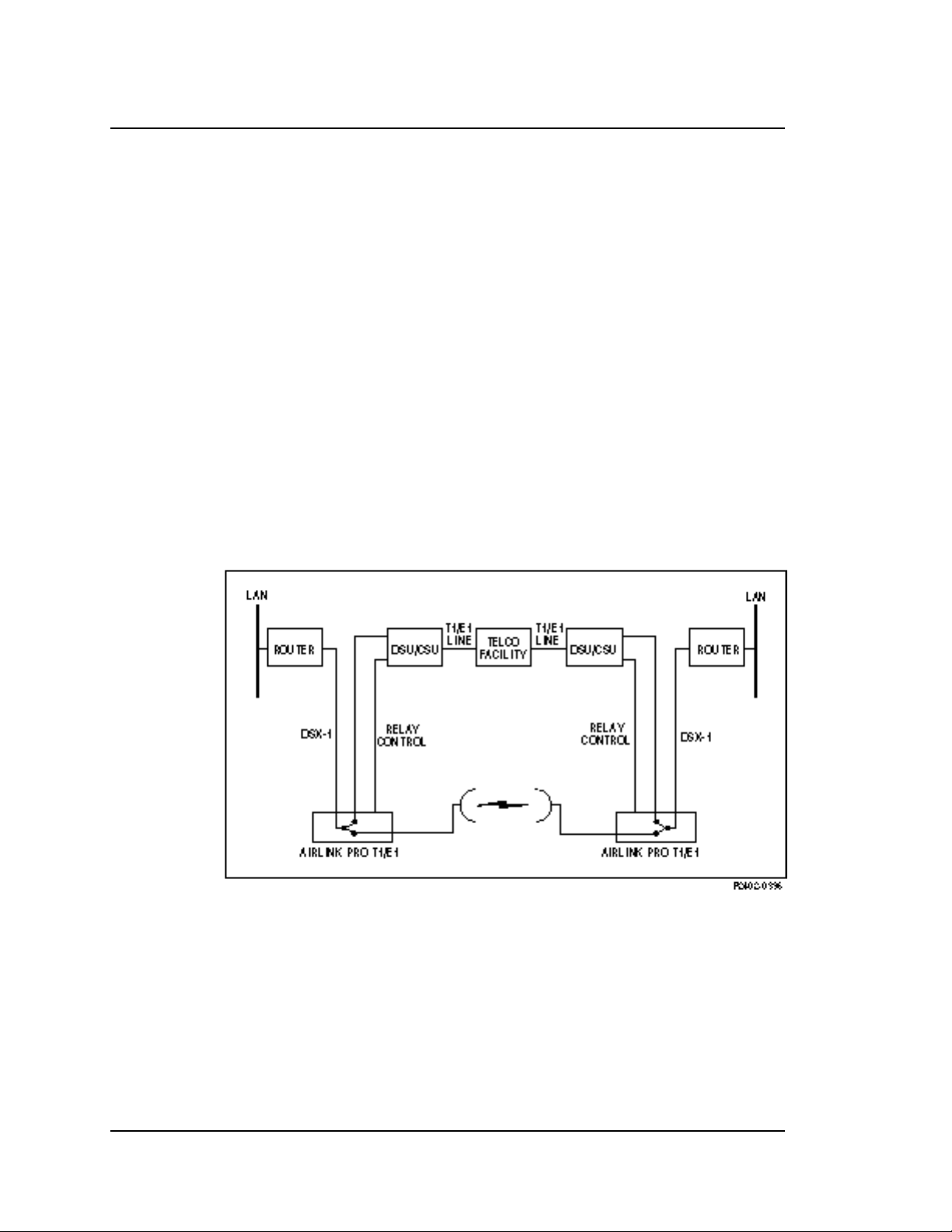

T1/E1 Link Backup Capability

The T1/E1 link backup capability built into the AirLink Pro T1/E1 Rack Mount

enables an AirLink Pro T1/E1 Rack Mount pair to provide a parallel T1/E1

path (the RF link) to a standard T1/E1 line (see Figure 1-3).

1-6

Figure 1-3

A Point-to-Point Backup Link

Under normal operating conditions, the primary (protected) T1/E1 line is routed

to an external device such as a CSU through the AirLink Pro T1/E1 Rack Mount

and carries its normal T1/E1 traffic.

In the event of a fault in the primary T1/E1 link, each DSU/CSU generates a

relay control signal that is transmitted to the attached AirLink Pro T1/E1 Rack

Rev. B - 1/97

Page 23

Mount units. The AirLink Pro T1/E1 Rack Mount pair switch the protected

T1/E1 line to provide a protected bypass T1/E1 path.

The backup switch can be opened or closed by an external switch or relay wired

to the CSU SEL connector on the rear panel of the AirLink Pro T1/E1 Rack

Mount.

Alarm Relay Contacts

Major and minor alarm contacts are built into the AirLink Pro T1/E1 Rack

Mount. If an alarm occurs such that an entry is put into the event queue, the

alarm contacts switch to the alarm state for as long as the alarm event persists.

For more information on the AirLink Pro T1/E1 Rack Mount alarm relay

contacts, refer to Chapter 2, Installation and System Administration.

Order Wire Interface

The Order Wire interface is an end-to-end voice communication channel that is

carried on the radio link between the local and remote AirLink Pro T1/E1 Rack

Mount units. Maintenance and service personnel can connect telephones to order

wire ports on the local and remote AirLink Pro T1 units and have direct voice

communication between the local and the remote site.

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

Order Wire communication can only occur when there is an active radio link

between the local and remote AirLink Pro T1/E1 Rack Mount units (refer to

Chapter 2, Installation and System Administration). The Order Wire channel

is outside of the T1/E1 channel and does not affect the user’s data. The Order

Wire can also be used with 4-wire modems in a large network management

system.

Fail-Safe Link

A reliable link can be created by eliminating all “single points of failure.” This

is illustrated in Figure 3-1 and discussed in detail in Chapter 3, Point-to-Point

Link.

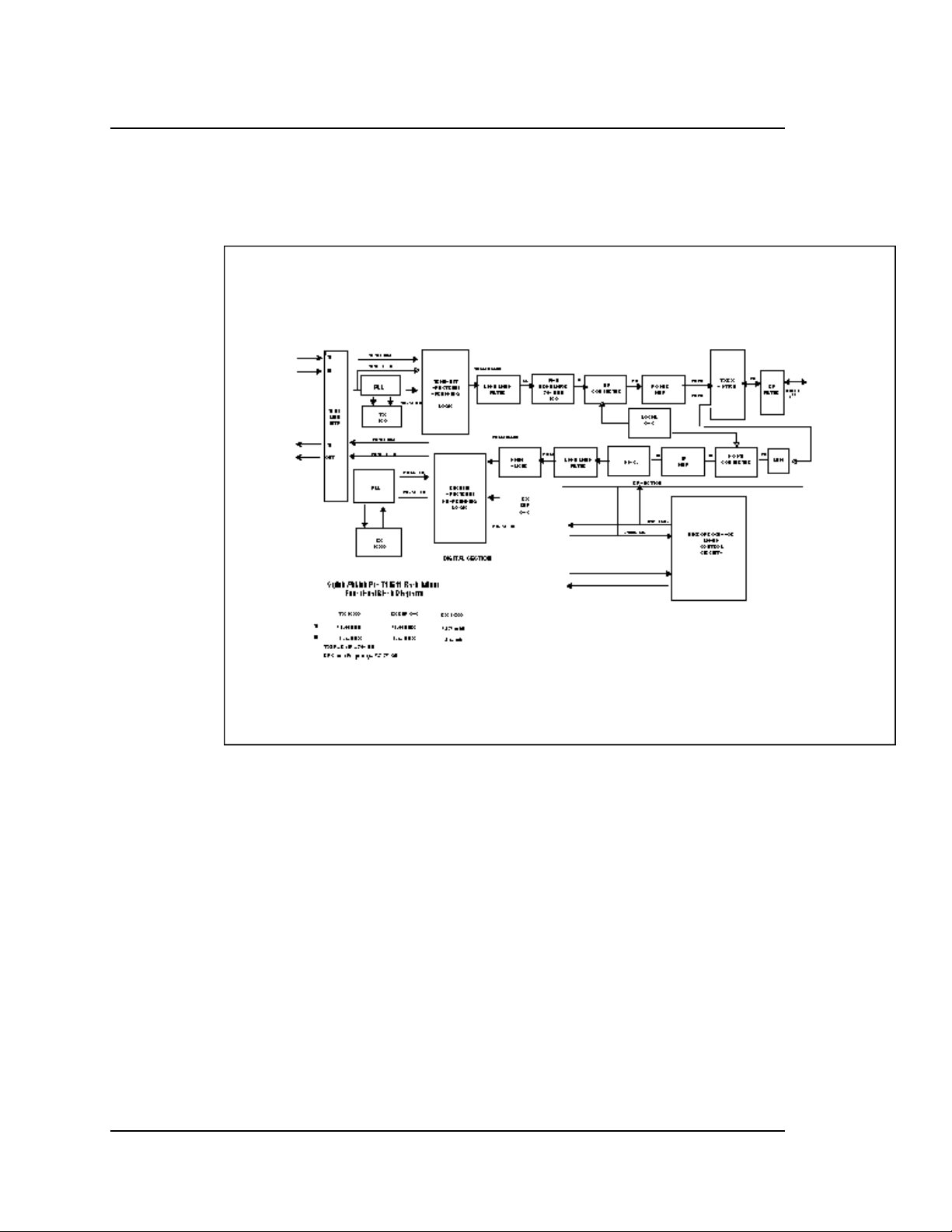

Block Diagram

The following illustration is a functional block diagram of the Cylink AirLink

Pro T1/E1 Rack Mount.

Rev. B - 1/97

1-7

Page 24

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Product Description

1-8

Figure 1-4

Block Diagram of the AirLink Pro T1/E1 Rack Mount

Rev. B - 1/97

Page 25

C

HAPTER

HAPTER

C

Installation and

Installation and

System Administration

System Administration

This chapter outlines general planning and the procedures for

unpacking, and installing the AirLink Pro T1/E1 Rack Mount

hardware, connecting cables, and performing power-up checks. This

chapter also contains important instructions regarding safety in setting

up the AirLink Pro T1/E1 Rack Mount system.

2

2

Inside this chapter:

Overview ................................................................................ 2-2

Unpacking .............................................................................. 2-2

Identifying Physical Features ........................................... 2-3

Preparing a Place.................................................................2-4

Setting Up the System ...................................................... 2-6

Checking Operation ........................................................... 2-19

Rev. B - 1/97 2-1

Page 26

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Overview

This chapter discusses the general technical requirements of antenna and RF

transmission line installation,and focuses on the task of installing the AirLink

Pro T1/E1 Rack Mount system at each end of the communication link,

integrating all of the equipment, and performing a system check and alignment

before turning the system over to normal customer traffic.

The components of AirLink Pro T1/E1 Rack Mount system are:

❚ AirLink Pro T1/E1

❚ AirLink Pro T1/E1 Rack Mount antenna and antenna cable

Depending upon your system plan, you will be installing all or some of these

AirLink Pro T1/E1 Rack Mount system components at each end of a link. The

following sections describe both required and optional system components.

Unpacking

The first step in the installation process is to take all of the materials out of

the shipping carton(s) and check that you have everything shown on the

packing list(s). If something is missing, contact your local distributor. Inspect

the unit for any possible damage.

If you discover shipping damage, repack the unit and notify the shipping

representative.

NOTE Save the shipping cartons and packing materials. You will need the carton and materials if

you need to ship your equipment.

After unpacking and confirming the contents of the shipment, place the AirLink

Pro T1/E1 Rack Mount system components on a flat surface to allow enough space

to work around them.

2-2

Rev. B - 1/97

Page 27

Identifying Physical Features

Figure 2-1

AirLink Pro T1/E1 Rack Mount Front Panel

Front Panel

The AirLink Pro T1/E1 Rack Mount front panel (Figure 2-1) consists of a metal

panel that contains five status and alarm LEDs identified with graphical icons

and two RJ-11 jacks.

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Rear Panel

The AirLink Pro T1/E1 Rack Mount rear panel (Figure 2-2) consists of a metal

panel containing four external equipment connectors, seven terminal blocks, and

an n-type antenna connector. Table 2-1 lists the rear-panel connectors and

describes their functions.

Figure 2-2

AirLink Pro T1 /E1 Rack Mount Rear Panel

Rev. B - 1/97

2-3

Page 28

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Table 2-1

AirLink Pro T1/E1 Rack Mount Rear-Panel Connectors

Connector Type Function

Network Management 9-Pin Male

Subminiature D

Terminal RJ - 11 Terminal connection

CSU 6-Pin Captive

Wire Terminal

Block

E1 Out BNC Not used for T1 unit; In E1 unit, used for

DTE 4-Pin Captive

Wire Terminal

Block

E1 In BNC Not used for T1 unit; In E1 unit, used for

Order Wire 4-Pin Captive

Wire Terminal

Block

BSYNC 6 Pin Captive

Wire Terminal

Block

Minor Alarm 4-Pin Captive

Wire Terminal

Block

Major Alarm 6-Pin

CaptiveWire

Terminal Block

Power 6-Pin Captive

Wire Terminal

Block

Antenna N type female Antenna connection

Connects a modem to the AirLink Pro

T1/E1.

Connects the T1/E1 Line from an external

device such as a CSU. Used for wire line

backup only.

configuring Unbalanced Interface option

T1/E1 connection to the DTE

Unbalanced Interface option

Connection for Four wire Order Wire unit

Burst sync connection

Minor alarm relay connection

Major alarm relay connection

Power connection

Preparing a Place

Because of the special planning requirements associated with installing a

microwave system, review some of the general guidelines regarding

installation preparation to ensure that the site is suitable to the purpose.

2-4

Rev. B - 1/97

Page 29

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

General Physical and Environmental Characteristics

The AirLink Pro T1/E1 Rack Mount radio unit measures approximately 17

inches wide, 3 inches high, and 10 inches deep, and weighs approximately 10

pounds.

Lightning Protection

The AirLink Pro T1/E1 Rack Mount is provided with secondary protection on all

signal leads to the printed circuit assemblies in the unit. If the AirLink Pro

T1/E1 Rack Mount system is being installed in an area where lightning can be a

problem, primary protection, such as gas tubes or spark gaps, is required (Cylink

distributors can provide these).

Rack-Mounting

The AirLink Pro T1/E1 Rack Mount mounts indoors in a 19-inch or 23-inch

equipment rack or cabinet. The rack-mount hardware kit, which consists of a

pair of mounting brackets and all required fasteners, is included in the shipping

carton with the AirLink Pro T1/E1 Rack Mount.

Power and Grounding Requirements

The AirLink Pro T1/E1 Rack Mount operates at 24VDC or 48VDC. Either the

positive or negative input is connected to the ground, or left floating. External

circuit protection not exceeding 2 amps is required.

Table 2-2

Power Requirements

Input Voltage 21 to 56 VDC

Input Power 25 Watts

Input Current 1.0 Amps @ 24 Volts

500 Ma @ 48 Volts

Input Polarity Input is floating. Either input may be grounded

Input Protection Nominal fuse = 2.0 A Slow Blow

Input Reverse

Voltage Protection

Provided. Series diode. No current will flow if the

input voltage is reversed.

Rev. B - 1/97

2-5

Page 30

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

NOTE No internal fusing is provided, because to do so would violate the specifications of

UL1459 section 70. (No fusing is allowed in the grounded side of a DC input circuit unless

the hot side is also fused.) When the fuse in the hot side blows, the fuse in the grounded

input must also blow. Since this equipment accepts either polarity, external circuit

protection must be provided in the hot side of the feeder circuit.

Setting Up the System

The following sections outline the procedures for installing, cabling, and

bringing up an AirLink Pro T1/E1 Rack Mount system. Some of the steps require

special knowledge, experience, tools, and assistance from another person.

Installing the Antenna

Antennas are generally installed by persons who have the knowledge,

experience, and tools to handle the somewhat specialized task. The following

sections are intended as a general summary of the process, and not as a complete

description. A successful antenna installation effort is the culmination of all

the site and route preparation, and path analysis.

Typical Antenna Mounts

An antenna for a microwave system such as the AirLink Pro T1/E1 Rack Mount

is typically equipped with mounting hardware that allows the antenna to

attach to a length of pipe that can then be mounted in several ways, depending

upon the user requirements, site conditions, and local building codes (see

Figure 2-3).

2-6

Rev. B - 1/97

Page 31

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Rev. B - 1/97

Figure 2-3

Typical Antenna Mounts

2-7

Page 32

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

System Grounding

Direct grounding of the antenna, mast, and tower provides some protection

against lightning strikes and static buildup. A direct electrical connection

should be made to a suitable grounding rod at the base of the tower or mast using

at least #10 AWG ground wire, or its equivalent, and non-corrosive hardware.

For details and safety standards, consult the appropriate electrical code or a

similar document. Use lightning arrestors in appropriate places.

Aligning the Antenna

In order for an AirLink Pro T1/E1 Rack Mount pair to operate correctly, the

local antenna and the remote antenna must be aligned so that the signals from

one antenna are aimed directly at the center of the other antenna. Correct

antenna alignment maximizes the signal received at both ends of the radio

link. An outline of the antenna alignment procedure is at the end of this

chapter.

Installing the AirLink Pro T1/E1 Rack Mount

The following illustration shows how to connect the mounting ears on the unit

(center-mounted or flush-mounted).

2-8

Rev. B - 1/97

Page 33

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Rev. B - 1/97

2-9

Page 34

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

The AirLink Pro T1/E1 Rack Mount can be installed into a standard 19-inch or

23-inch equipment rack using the rack-mount hardware included with the unit.

It requires 4U (7.0”) of rack mounting space, of which 1U space above and below

the unit is necessary for proper ventilation. Two standard blank panels can be

used over the openings.

To mount the AirLink Pro T1/E1 Rack Mount in an equipment rack:

1. Place the AirLink Pro T1/E1 Rack Mount on a table or bench.

2. Lay out the pieces of the rack mount hardware kit.

The rackmount hardware kit should contain the following parts:

❚ Two 1-inch increment mounting brackets for 23-inch rack mount

❚ Two EIA mounting brackets for 19-inch rack mount

❚ Eight 10-32 x 3/8” Phillips pan-head screws, lock washers, and flat

washers

3. Orient the mounting brackets for front- or mid-mounting.

4. Attach the brackets to the AirLink Pro T1/E1 Rack Mount with the screws

provided in the hardware kit.

5. Position the AirLink Pro T1/E1 Rack Mount in the equipment rack and

fasten with screws.

2-10

Rev. B - 1/97

Page 35

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Figure 2-4

23” Rack Mount

Connecting the Antenna Cable

To connect the antenna cable to the AirLink Pro T1/E1:

1. Locate the N-type connector on the rear panel of the AirLink Pro T1/E1

Rack Mount (see Figure 2-2).

2. Plug the RF cable connector firmly into the N-type jack connector and handtighten the cable connector shell onto the jack connector collar.

3. Verify that the cable connector is seated securely and that the cable is not

kinked.

4. Recommend 1/2 or 7/8-inch case. Check the rating for 6 Ghz operation.

5. Recommend using short piece of more flexible coaxial to connect to the

AirLink, such as the RG-6/U or the RG-59/U from Cylink.

Rev. B - 1/97

2-11

Page 36

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

T1 DTE Line Connection

To connect the T1 line cable to the DTE:

1. Locate the DTE terminal block on the Airlink Pro T1/E1 Rack Mount rear

panel (see Figure 2-2).

2. Prepare the cable wire so that individual leads are separate. Strip a small

portion of insulation off each wire lead.

3. With the help of a screw driver, push back one of the plastic levers located

on the terminal block.

The following is a list of some suitable coaxial cables:

Type Manufacturer Part

Number

RG-6/U Belden 9248 22 (7/30) .3 dB CM

RG-6/U Belden 88248 22 (7/30) .3 dB CMP

RG-59/U Belden 9259 18 (solid) .3 dB CM

RG-59/U Belden 88259 18 (solid) .3 dB CMP

1

Attenuation per 100 at 1 Mhz.

2

U1 Rating System:

CM= General purpose, vertical tray. Tested per UL-1581.

CMP=Plenum Rated. Tested per UL-910.

AWG ATTN1UL Rating

2

The following is a list of some suitable cables for the T1 or E1 Balanced.

The cable type usually specified for indoor T1 use is Western Electric ABAM or

equivalent. An equivalent cable is General Cable Specification 4162D. The

characteristics of these two cables are listed in the table. These cables are

rated in-building use and in-vertical risers and are not rated for use in

plenumbs. Both of these cables use solid wire.

Cable Gauge Impedance Loss at 1 Mhz

ATAM 22 100 Ohms 4.0 dB

GT4162 22 100 Ohms 6.0 dB

2-12

A second class of indoor cable is 100 Ohms stranded, shielded 24 ga. These

cables have a characteristic impedance of 100 Ohms and a loss at 1 Mhz of

about 7 dB per 1000’. Representative cables of this type are listed in the

following table. These cables are also suitable for E1 applications.

Rev. B - 1/97

Page 37

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Belden Part No. 8729 (UL Rating CMP (Plenum))

Individually shielded twisted pairs.

Berk-Tek Part No. 230249 (Plenum)

Berk-Tek Part No. 230131 (Non Plenum)

These cables have an overall foil shield.

The recommended E1 cable: The E1 signal can be either unbalanced, in which

case the coaxial cables listed can be used or it can be unbalanced, in which case

the balanced twisted pair cables can be used.

4. While holding it in this position, insert one of the leads of the cable into

the spring pin connector, below the lever.

5. Release the lever.

6. Repeat Steps 3, 4 and 5 to connect each lead.

7. Ensure that each cable lead is securely held by the spring pin connectors.

T1 Backup Connections

1. Locate the CSU terminal block on the AirLink Pro T1/E1 Rack Mount rear

panel (see Figure 3-2).

2. Follow the same procedure used for connecting T1/E1 DTE line.

3. Locate the fault signal cable connector from the external device.

4. Connect the fault signal cable to the CSU -SEL connector on the major

Alarm terminal block.

In the event of a fault in the primary T1/E1 link, each CSU generates a relay

control signal that is transmitted to the attached AirLink Pro T1/E1 Rack

Mount. The T1/E1 pair switch the protected primary line in, to provide a

protected bypass T1/E1 path.

Alarm Relay Contact Connections

If you have an application that uses the alarm relay contacts in the MAJOR &

MINOR ALARM captive-wire terminal block on the rear panel of the AirLink

Pro T1/E1 Rack Mount, connect the device cable to the ALARM-C and ALARMNC or ALARM-NO contacts in the MAJOR & MINOR ALARM captive-wire

terminal block (see Figure 2-5).

Rev. B - 1/97

2-13

Page 38

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

2-14

Figure 2-5

Alarm Relay Contacts

The major and minor alarm contacts built into the AirLink Pro T1 are SPDT

relay contacts rated at 8 VA (0.25 A maximum at 100 VDC maximum) isolated

from the ground. The alarm relays are de-energized when the AirLink Pro

T1/E1 Rack Mount is in an alarm state: the NO contact is closed; the NC contact

is open.

If an alarm occurs such that an entry is put into the event queue, the alarm

contacts switch to the alarm state for as long as the alarm event persists or until

the alarm is reset.

Terminal Connection

A simple ASCII terminal or personal computer can be connected to the RJ-11

Terminal Jack on the front or rear panels of the AirLink Pro T1/E1 Rack Mount

to monitor and configure its operation. A DB9 to RJ-11 adapter is included. In a

hub installation involving a number of AirLink Pro T1/E1 Rack Mount pairs, the

Rev. B - 1/97

Page 39

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

terminal device can be “shared” across all the AirLink Pro T1 systems by a

terminal switching device.

A terminal device or a personal computer can have specific data cabling

requirements (refer to Appendix B, Specifications, for connector pin

assignments), and usually requires a grounded alternating current power outlet.

An adapter kit that connects between the AirLink Pro T1/E1 Rack Mount

terminal port and a male DB-9 connector is shipped with the equipment.

Figure 2-6

Terminal Connection to the AirLink Pro T1/E1 Rack Mount

Remote Connection

A remote terminal or personal computer can be connected to the Terminal port on

the front or rear panels of the AirLink Pro T1/E1 Rack Mount unit through a

modem (Figure 2-6). A modem requires a dedicated telephone line with a

modular RJ-11 jack as well as a source of power, usually a standard 115 VAC

grounded outlet.

Rev. B - 1/97

2-15

Page 40

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Figure 2-7

Modem Connection to the AirLink Pro T1/E1 Rack Mount

Order Wire Connection

The Order Wire interface is a 64 kbps pulse modulation (PCM) voice

communication channel. This part of the AirLink Pro T1/E1 Rack Mount RF

protocol does not use any part of the 1.544 Mbps T1 channel or the 2.048 Mbps E1

channel. The Order Wire interface meets V.21 and V.32 modem specifications.

A standard telephone (2 wire interface) can be plugged in to the Order Wire

jack on the front panel ( Figure 2-3). A telephone is required at each end of the

link.

2-16

Rev. B - 1/97

Page 41

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Figure 2-8

Two-Wire Order Wire Connection

Order Wire communication can only occur when there is an active radio link

between the local and remote AirLink Pro T1/E1 Rack Mount units and the RSQ

is 6 or higher. Communication across the order wire interface is initiated by

picking up the telephone at either end of the link. When the RSQ is below 6,

the AirLink Pro T1/E1 Rack Mount software mutes the order wire. Picking up

the order-wire telephone causes an audible tone (beeping ) at the remote

Airlink Pro T1/E1 Rack Mount. This tone continues until the telephone at the

remote end is picked up.

An external order wire unit can be connected to the designated terminal block on

the rear panel. When an external 4 wire interface is used, the order wire unit

provides its own signaling. The 4-wire interface allows multiple T1/E1 units at

a hub to be connected through a 4-way or 8-way 4-wire bridge (Figure 2-11).

Connect the input pair of the order wire to the T & R located on the ORDER

WIRE terminal block and connect the output pair to the T1 & R1.

Set the external order wire to transmit and receive at 0 dBm. The type of order

wire interface (2 or 4-wire) is selected from the Command Line Interface

Configuration screen. (See “Setting Link Parameters” in Chapter 3,

Configuration).

Rev. B - 1/97

2-17

Page 42

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Figure 2-9

Four-Wire Order Wire Connection

CAUTION The order wire interface must not be connected directly to the Public Switched

Telecommunications Network.

2-18

Rev. B - 1/97

Page 43

External Power Supply Connection

Figure 2-10

ELPAC Power Supply

For the ELPAC Power Supply

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

1. Locate the Power terminal block on the unit’s rear panel and insert the red

wire of the power supply into the +V spring pin connector of the terminal

block.

2. Insert the white wire into the -V spring pin connector of the terminal block.

3. Ensure that the two wires are securely held by the connectors.

Rev. B - 1/97

2-19

Page 44

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Figure 2-11

FORTRON Power Supply

For the FORTRON Power Supply

1. Locate the Power terminal block on the rear panel of the unit and insert the

brown wire of the power supply into the +V of the terminal block.

2. Insert the black wire into the -V spring pin connector of the terminal block.

3. Ensure that the two wires are securely held by the connectors.

Wiring for Burst Synchronization

When you have either a hub configuration or a repeater site (more than one

AirLink Pro T1/E1 Rack Mount unit operating from the same central site), one of

the units must be set up as the source for burst synchronization. Refer to Chapter

3, Configuration, for Hub and Repeater configurations.

Installing the Burst Sync Wiring

The burst synchronization connections are made using unshielded twisted pair

wires. The equipment should be physically located as shown in Figure 2-12.

The primary and the backup masters should be the first units in the group. If

the distance between the primary master and the last secondary master is

greater than 100 ft, the burst sync bus(es) should be terminated at this unit (the

last secondary master).

2-20

Rev. B - 1/97

Page 45

Figure 2-12

Burst Sync Wiring

Terminating the Burst Sync Bus

The burst sync bus is terminated by inserting a short jumper wire in the TERM A

and TERM B locations as defined by the rear panel labels.

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Checking Operation

During start-up an AirLink Pro T1/E1 Rack Mount pair:

❚ Establishes the radio link between the two radio units

❚ Starts transferring data

When each radio unit is powered up, a power-on self-test begins that

determines whether the unit’s hardware and software are operating within

the required limits. When the test succeeds, the designated master unit begins

transmitting, attempting to establish a RF link with the slave unit.

AirLink Pro T1/E1 Rack Mount units leave the factory configured as master

units in a point-to-point configuration; configure one of the units as a slave.

Initial Unit Configuration

In a new point-to-point link installation, the configuration on one end must be

changed to application 6 (Slave Unit in a Point-to-Point Link, refer to

“Application” in Chapter 3).

Rev. B - 1/97

2-21

Page 46

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

In a new hub installation, the units at the hub must all be masters, and the

corresponding remote units must be slaves. At a hub, set up each individual link

first as a point-to-point link and then align each link separately with all the

other AirLink Pro T1/E1 Rack Mount units turned off. After all the link pairs

have been configured and aligned as point-to-point links, you can then change

configurations for hub operation.

In a new repeater installation, treat each link segment as a point-to-point link,

progressing from the near-end to the far-end sites. After all the link pairs have

been configured and aligned as point-to-point links, you can change

configuration for repeater operation.

For more information about applications and burst synchronization, refer to

“Application Examples” in Chapter 3, Configuration.

No radio link exists until the AirLink Pro T1 pairs have been configured and

aligned, all system configuration must be done individually at each unit. After

a radio link is established between the units of an AirLink Pro T1 pair, the

remote unit can be configured from the local site across the radio link.

To configure one end of the link as a slave:

1. Connect a terminal to the Terminal port on the slave AirLink Pro T1/E1

Rack Mount or to the Terminal port on the AirLink Pro T1/E1 Rack Mount

attached to the slave unit.

The terminal must be set up to operate according to the attributes described

in “ Connecting a Terminal,” in this chapter.

2. Type the following command at the prompt:

AIRLINK PRO T1/E1> set application 6

The text you type is in boldfaced type; enter the spaces as shown.

3. To verify the configuration change, type the following command at the

prompt:

AIRLINK PRO T1/E1> get configuration

The terminal displays the configuration of the unit, similar to the

following:

AIRLINK PRO T1/E1> Get Configuration

Site Name:

Application: 6. Slave Unit in a Point-to-Point Link

Burst Mode: Normal

Coding: B8ZS or (HDB3)

2-22

Rev. B - 1/97

Page 47

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

Equalization: 0 - 133 feet

PN Code: 1

RF Power: 10 dBm

Alarm Reporting: Immediate

Alarm Level: Status

Date/Time: May 1 1996 10:35:00

NOTE You might need to alter more configuration values in order to ensure correct operation,

during your AirLink Pro T1/E1 Rack Mount installation. Refer to Chapter 3 for more

information on configuring the AirLink Pro T1/E1 Rack Mount.

Aligning the Antenna

After the link pair has been turned on and configured, the antennas must be

aligned. Since most AirLink Pro T1/E1 Rack Mount paths will be line-of-sight

paths, visually align the initial antenna. In most cases, this rough alignment is

sufficient for radio units to acquire radio synchronization lock.

NOTE When the radio link between two units is active, telephones can be plugged into the OW

jacks on the AirLink Pro T1/E1 Rack Mount units permitting persons at the two sites to talk

to one another. Picking up the order wire telephone causes an audible tone (pulsed

beeping) at the remote AirLink Pro T1/E1 Rack Mount unit. This tone continues until the

telephone at the other end is picked up.

To “fine tune” the antenna alignment, perform the following procedure:

1. Insert the probes of a DC voltmeter into test points (RSS) and (ground) on

the AirLink Pro T1/E1 Rack Mount (see Figure 2-11).

Rev. B - 1/97

2-23

Page 48

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

2-24

Figure 2-13

Test Point Locations

2. Swing the antennas on both ends of the link horizontally and vertically

(but not at the same time!) until the observed voltage peaks.

Swing the antennas through the main lobe and both side lobes to check that

the antenna is aligned on the main lobe and not one of the side lobes.

After you align the antenna, use the terminal query status and query

performance commands to check the receive signal strength (Rx Power) and

the receive signal quality (RSQ). Compare the receive signal level to the

expected signal level based on the path calculations.

3. Type the following command at the AirLink Pro T1/E1 Rack Mount prompt:

AIRLINK PRO T1/E1> query status

Rev. B - 1/97

Page 49

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Installation and System Administration

The system displays a list of status information similar to the following:

AIRLINK PRO T1/E1> query status

Site Name: Sunnyvale 2

DTE Loss: NO

Radio Sync Loss: NO

Burst Sync Loss: N/A

Test in Progress: FE Radio Remote Loop

DTE AIS: OFF

RF AIS: OFF

Tx Fail: NO

Rx Power: -60.5 dBm

Tx Power: 12.0 dBm

Temperature: 5 C

4. Type the following command at the AirLink Pro T1/E1 Rack Mount prompt:

AIRLINK PRO T1/E1> query performance

The system displays a list of status information similar to the following:

AIRLINK PRO T1/E1> query performance

Site Name: Sunnyvale 2

UWER BER: <10E-08

QRSS BER: Unavailable

1 HR ES: 1

1 HR UAS: 0

24 HR ES: 1

24 HR UAS: 0

RSQ: 10

The Receive Signal Quality (RSQ) is a figure of merit that is normalized on a

scale of 1 to 10, and is a function of the receive signal-to-noise and signal-tointerference ratio. A very strong signal that is severely corrupted with

interference results in a normal receive signal power indication and a low RSQ

number.

Assuming that the T1/E1 lines to and from the AirLink Pro T1/E1 Rack Mount

units are okay, T1/E1 data transfer begins as soon as the RF link is established.

If you need to alter other configuration values, refer to Chapter 3,

Configuration, for configuration procedures.

Rev. B - 1/97

2-25

Page 50

C

HAPTER

HAPTER

C

Configuration

Configuration

This chapter describes how to use the AirLink Pro T1/E1 Rack Mount

command-line terminal user interface to set and change configuration

parameters. The information in this chapter includes descriptions of all

the AirLink Pro T1/E1 Rack Mount configuration commands and

options, and lists the default configuration settings.

3

3

Inside this chapter:

Overview ................................................................................ 3-2

Using the ASCII Terminal Interface ................................ 3-2

Setting Administrative Parameters ............................... 3-5

Setting T1/E1 Line Parameters .................................... 3-11

Setting Link Parameters ................................................. 3-13

Setting Alarm Control Parameters ............................. 3-28

Setting Modem Parameters.............................................3-22

Getting AirLink Pro T1 Configuration

Information .................................................................... 3-30

Command Keywords and

Operands ....................................................................... 3-41

Rev. B - 1/97 3-1

Page 51

AirLink Pro T1/E1 Rack Mount Installer’s Guide

Configuration

Overview

To configure the AirLink Pro T1/E1 Rack Mount, connect an ASCII terminal or a

personal computer to the Terminal port of the AirLink Pro T1/E1 Rack Mount.

The AirLink Pro T1/E1 Rack Mount ASCII terminal interface provides a