Page 1

SmartSensor Matrix

USER GUIDE

www.wavetronix.com 78 East 1700 South Provo, Utah 84606 801.734.7200

Page 2

© 2013 Wavetronix LLC. All Rights Reserved.

Wavetronix, SmartSensor, Click, Command, and all associated product names and logos are trademarks of Wavetronix LLC. All other

products or brand names as they appear are trademarks or registered trademarks of their respective holders.

Protected by US Patent Nos. 6,556,916; 6,693,557; 7,426,450; 7,427,930; 7,573,400; 7,889,097; 7,889,098; 7,924,170; 7,991,542;

8,248,272; Canadian Patent Nos. 2461411; 2434756; 2512689; and European Patent Nos. 1435036; 1438702; 1611458. Other US

and international patents pending.

e Company shall not be liable for any errors contained herein or for any damages arising out of or related to this document or the

information contained therein, even if the Company has been advised of the possibility of such damages.

is document is intended for informational and instructional purposes only. e Company reserves the right to make changes in the

specications and other information contained in this document without prior notication.

FCC Part 15 Compliance: e Wavetronix SmartSensor sensors comply with Part 15 of the Federal Communications Commission

(FCC) rules which state that operation is subject to the following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesirable operation. FCC compliance statements for applicable optional modules are to be found in the module specications. Unauthorized changes or modications

not expressly approved by the party responsible for compliance with the FCC rules could void the user’s authority to operate this

equipment.

Disclaimer: e advertised detection accuracy of the Wavetronix SmartSensor sensors is based on both external and internal testing, as

outlined in each product’s specication document. Although our sensors are very accurate by industry standards, like all other sensor

manufacturers we cannot guarantee perfection or assure that no errors will ever occur in any particular applications of our technology.

erefore, beyond the express Limited Warranty that accompanies each sensor sold by the company, we oer no additional representations, warranties, guarantees or remedies to our customers. It is recommended that purchasers and integrators evaluate the accuracy of

each sensor to determine the acceptable margin of error for each application within their particular system(s).

WX-500-0053

1/2013

Page 3

Contents

Introduction 5

SmartSensor Matrix Package 6 • Selecting a Mounting Location 7

Part I Installing the SmartSensor Matrix

Chapter 1 Installing the SmartSensor Matrix 13

Sensor Mounting Guidelines 14 • Attaching the Mount

Bracket to the Pole 15 • Attaching the Sensor to the Mount

Bracket 16 • Aligning the Sensor to the Roadway 16 • Applying the Silicon Dielectric Compound 18 • Connecting the

SmartSensor 6-conductor Cable 18 • Grounding the Sensor

19

Chapter 2 Connecting Power and Surge Protection 21

Mounting the Backplate 22 • Connecting AC Power 22 •

Providing System Surge Protection 26 • Terminating Smart-

Sensor 6-conductor Cables 28

Chapter 3 Contact Closure Communication 31

Using the Click 112/114 DIP Switches 32 • Using the Click

104 Rotary Switch 34 • Attaching and Programming the

Click 112/114 35 • Attaching and Programming the Click

104 37 • Channel Mapping 39

Page 4

Part II Using SmartSensor Manager Matrix

Chapter 4 Installing SmartSensor Manager Matrix 45

Installing SSMM 47 • Microsoft .NET Framework 49

Chapter 5 Communication 51

Serial Connection 53 • Internet Connection 56 • Virtual

Connection 58 • Viewing Connection Information 60 • Up-

grading the Sensor’s Embedded Software 62

Chapter 6 Sensor Settings 65

General Sensor Settings 65 • Sensor Info Screen 67

Chapter 7 Lanes & Stop Bars 69

Display Options 70 • Menu Bar 73 • Automatic Conguration 76 • Manual Conguration 77

Chapter 8 Zones & Channels 81

Menu Bar 82 • Placing Zones 83 • Channel Type 84 • Mapping Zones to Channels 86 • Measuring Zones 89

Chapter 9 Verification 91

Channel Indicators 92 • Verication Menu Bar 93

Chapter 10 Tools 95

Backup/Restore 96 • Rack Cards Tools 97 • Sensor Self Tests

101

Appendix 103

Appendix A – Cable Connector Denitions 103 • Appendix

B – Cable Lengths 105 • Appendix C – Click 221 User Reference Guide 106 • Appendix D – Click 600 Installation 107

• Appendix E – Matrix Extended Range 111

Page 5

Introduction

In this chapter

SmartSensor Matrix Package

Selecting a Mounting Location

e Wavetronix SmartSensor Matrix™ is a stop bar presence detector designed for use at

signalized intersections (see Figure I.1). e SmartSensor Matrix detects vehicles through

the use of a 24.125 GHz (K band) operating radio frequency. Using what is classied as

frequency modulated continuous wave (FMCW) radar, SmartSensor Matrix detects and

reports vehicle presence in as many as 10 lanes simultaneously.

Figure I.1 – Wavetronix SmartSensor Matrix

SmartSensor Matrix is a rst-of-its-kind radar stop bar detector with Radar Vision™. It

delivers the reliability of radar and the simplicity of non-intrusive detection for stop bar

presence detection. In many situations, the sensor is installed on the roadside in order to

prevent the need for lane closures and trac control. Once the unit is installed, the congu-

Page 6

6 INTRODUCTION SMARTSENSOR MATRIX USER GUIDE

ration process is quick and easy. After installation, the sensor will require little or no on-site

maintenance and can be remotely congured.

is user guide outlines the step-by-step process of installing and conguring the SmartSensor Matrix. Any questions about the information in this guide should be directed to

Wavetronix or your distributor.

SmartSensor Matrix Package

A standard SmartSensor Matrix package may contain the following items:

SmartSensor Matrix SS225 detector(s) with installed sensor backplate

Sensor mounting kit(s)

SmartSensor 6-conductor cable(s)

Intersection preassembled backplate

Click 112/114 detector rack card(s) with patch cable(s)

Click 104 four-channel DIN rail contact closure module

SmartSensor Manager Matrix (SSMM) software

SmartSensor Matrix User Guide

Note

Instead of the intersection preassembled backplate, you may be using the Click 600

cabinet interface device, the preassembled 19-inch rack, or the segmented preassembled backplate. The coming chapters will note installation dierences between

these devices and the preassembled backplates where applicable.

SmartSensor Matrix system options include (see Figure I.2):

AC power conversion – Provides reliable power for the sensors and backplate com-

ponents. is option is normally recommended instead of the DC surge protection

because it will not burden the existing DC power modules.

Remote IP connection – Provides a way (via a Click 301 serial to Ethernet converter)

to connect to the sensor from a remote location. e Click 301 is recommended for

remote management.

Page 7

INTRODUCTION SMARTSENSOR MATRIX USER GUIDE 7

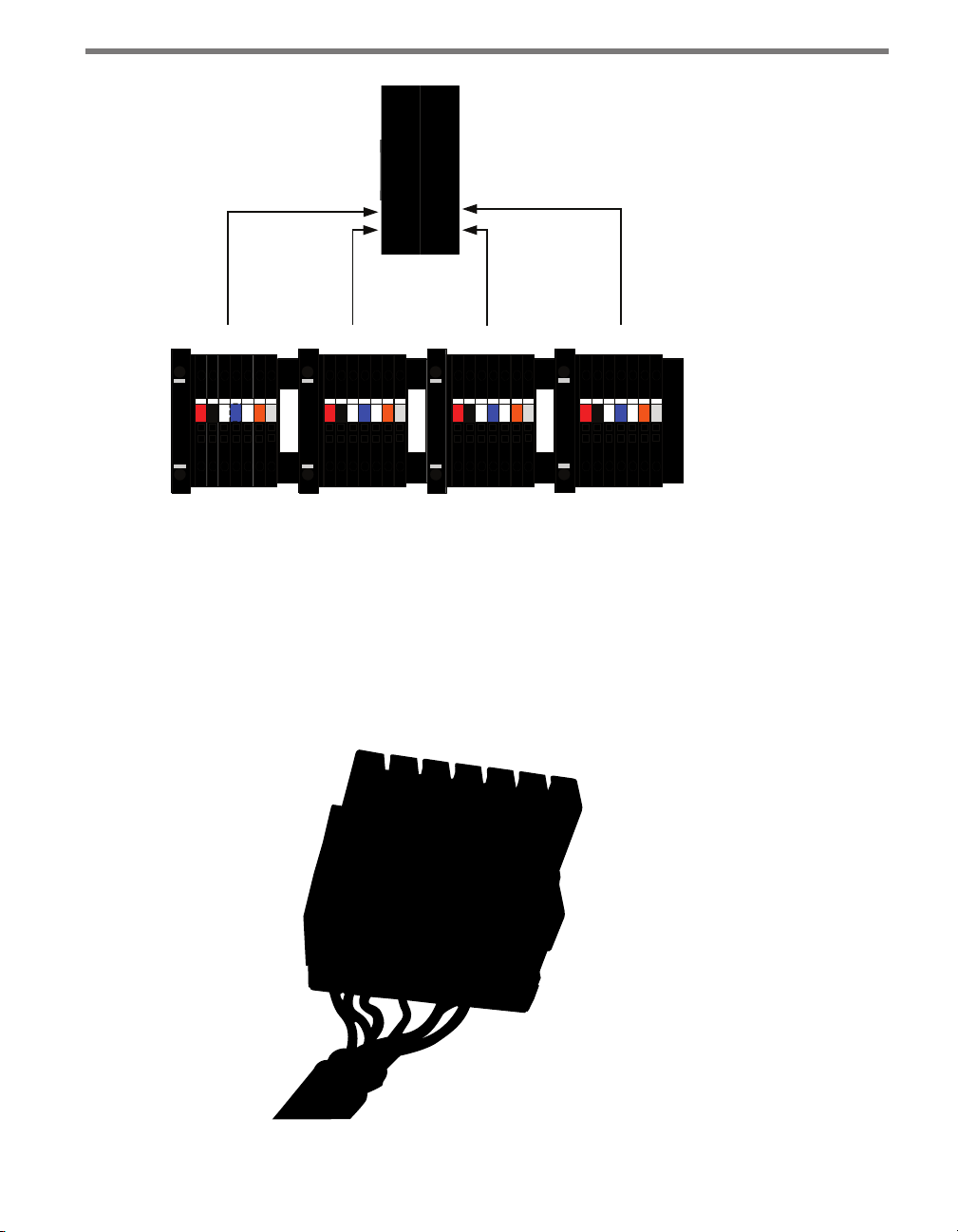

Control Bridge to Rack Cards

Configuration Toolkit

AC Power

Conversion

Option

Control Bridge

on T-bus

(attach to T-bus)

Control Bridge to Sensors

Figure I.2 – SmartSensor Matrix System Options

Remote IP Connection Option

(attach to T-bus)

Note

SmartSensor Matrix systems provide a control bridge to manage all connected

SmartSensor and Click devices. The control bridge is completely separate from the

dedicated channels used for communication of contact closure detection calls in real

time.

Selecting a Mounting Location

Consider the following guidelines when selecting a mounting location for each SmartSensor Matrix:

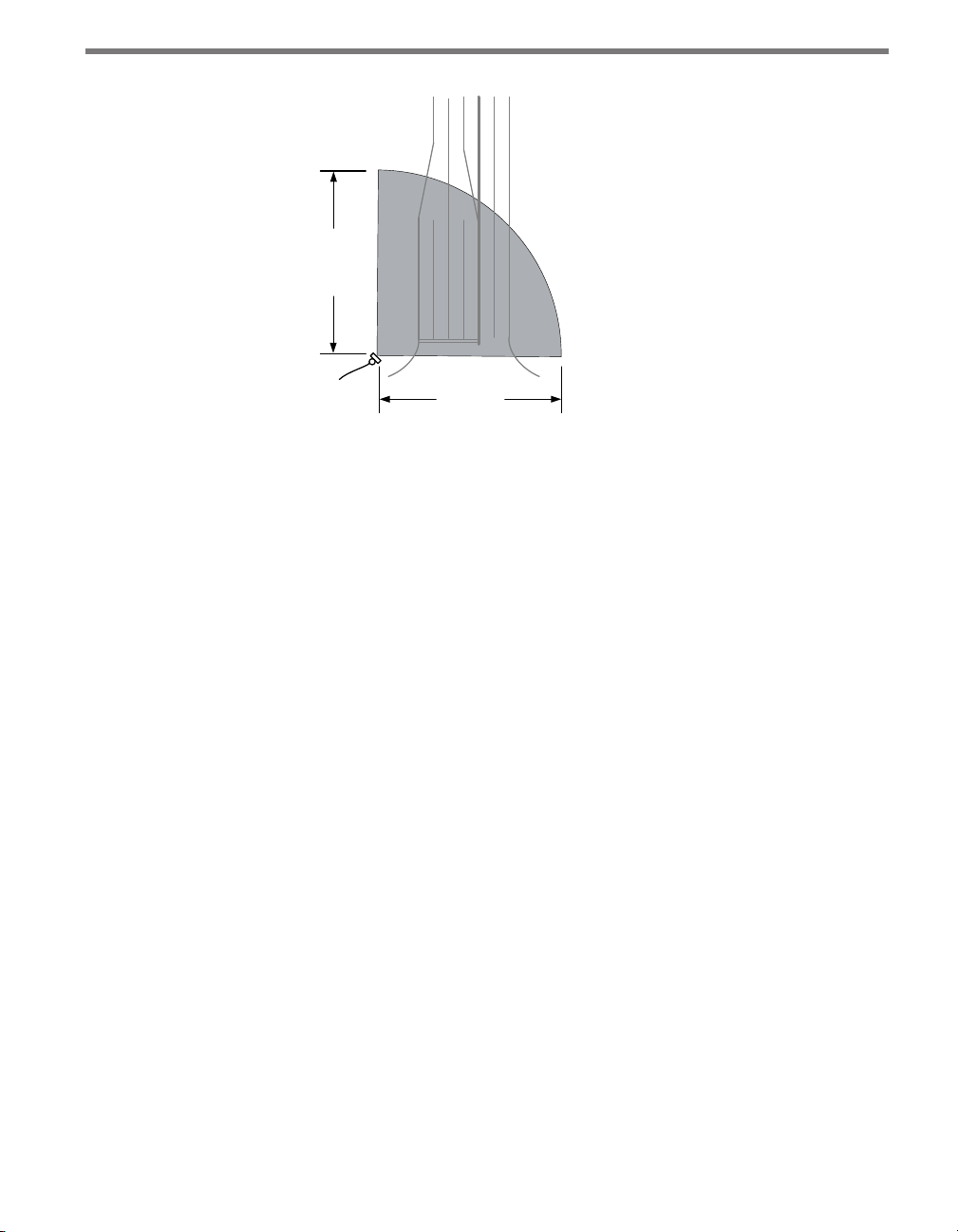

Corner radar – e SmartSensor Matrix is a corner radar device with a panoramic

90°, 140-ft. (42.7-m) view (see Figure I.3). e sensor’s mounting location should

be selected so that all stop bar detection zones on an approach are within a 6–140-ft.

(1.8–42.7-m) radial distance.

Page 8

8 INTRODUCTION SMARTSENSOR MATRIX USER GUIDE

140 ft

Sensor Pole

Figure I.3 – Corner Radar

140 ft

Line of sight – Position the sensor so that it will be able to detect the entire area

of interest. Avoid occlusion by installing the sensor away from trees, signs and other

roadside structures.

Detection coverage – Position the sensor so that it will be able to reach all the specied

stop bar detection zones. e sensor will often work better if you position it so that it

tracks vehicles for several feet before the rst zone in each lane. If the sensor has a view

several feet beyond the stop bar, it is more likely to accurately detect queue dissipation.

Closest roadside – Mount the sensor on the side of the road closest to the lanes of

primary interest. Always mount the sensor high enough to prevent trac from occluding approaching vehicles.

Mounting height – A minimum height of 12 ft. (3.6 m) is recommended. Mounting

the sensor higher will generally improve line of sight and decrease the possibility of

occlusion.

Mounting oset – A minimum oset of 6 ft. (1.8 m) to the rst lane of interest is

required.

Redundant detection – It is possible to have multiple sensors monitoring the same

approach. Multiple sensors are needed when zones are spread over more than 140 ft.

(42.7 m).

Sensor proximity – When multiple sensors are mounted at the same intersection,

interference can be avoided by conguring each sensor to operate on a unique RF

channel.

Departing lanes – ere is usually no need to view trac in departing lanes or to

congure departing lanes. However, if they are congured, then the stop bar should

not be congured.

Suspended electrical cables – e sensor is designed to work in the presence of sus-

pended power lines and other electrical cables. However, these cables should be at least

10 ft. (3 m) away from the front of the sensor.

Neighboring structures and parallel walls – e sensor should not be mounted with

Page 9

INTRODUCTION SMARTSENSOR MATRIX USER GUIDE 9

signs or other at surfaces directly behind it. is will help reduce multiple reection

paths from a single vehicle.

Cable length – Make sure that you have sucient homerun and sensor cabling. Cable

runs as long as 500 ft. (152.4 m) can be achieved using 24 VDC operation and the

system’s native RS-485 communications. If your application requires a cable length

longer than 500 ft. (152.4 m), contact Wavetronix Technical Services for assistance.

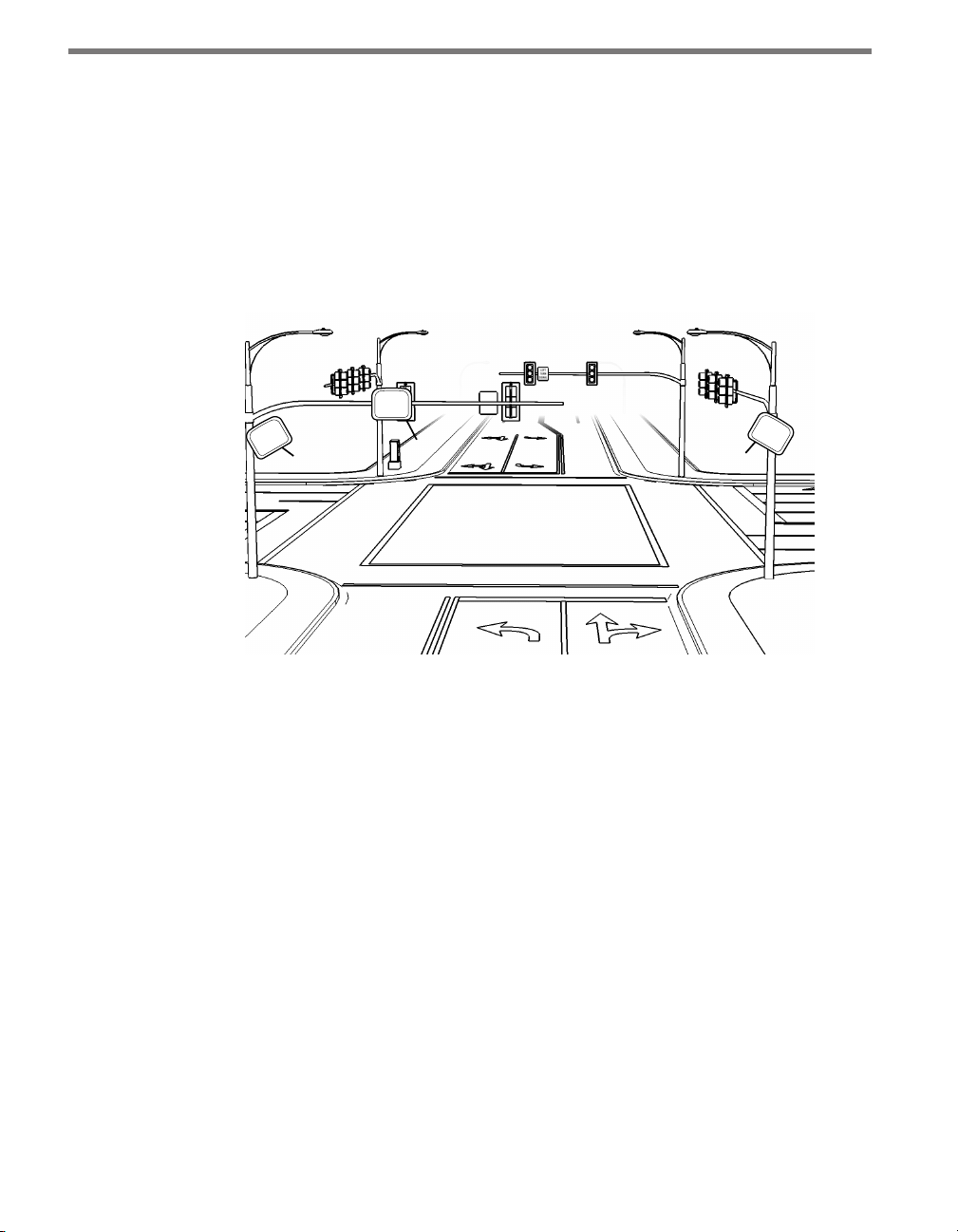

e SmartSensor Matrix should be mounted using one of the following options (see Figure

I.4):

➋

1 The back side of mast arm – is location allows the sensor to be placed near the lanes

of interest and may be the best location option for wide approaches. If you mount the

sensor on the back side of a mast arm, mount it near the end of the arm to reduce the

possibility of the mast arm or departing trac occluding approaching vehicles.

2 The far side of approach – e sensor is usually mounted on a corner vertical mast

pole or strain pole. If the sensor is mounted on a vertical pole with a mast arm, you

can usually avoid occlusion by mounting the sensor away from or below the mast arm.

3 The near side of approach – is mounting location is typically best if detecting the

left turn lane is less important. is location also allows you to mount the sensor high

enough to avoid occlusion.

Other mounting locations may be possible if these are not available at your intersection.

Contact Wavetronix Technical Services for assistance if you would like to use an alternative

mounting location.

➊

➌

Figure I.4 – Mounting locations

Page 10

Page 11

Part I

Installing the SmartSensor

Matrix

Chapter 1 – Installing the SmartSensor Matrix

Chapter 2 – Connecting Power and Surge Protection

Chapter 3 – Contact Closure Communication

Page 12

Page 13

Installing the SmartSensor Matrix 1

In this chapter

Sensor Mounting Guidelines

Attaching the Mount Bracket to the Pole

Attaching the Sensor to the Mount Bracket

Aligning the Sensor to the Roadway

Applying the Silicon Dielectric Compound

Connecting the SmartSensor 6-conductor Cable

Grounding the Sensor

1

e installation process includes attaching the mounting bracket to the pole; attaching the

sensor to the mounting bracket; aligning the sensor; applying a silicon dielectric compound

to the sensor connector; and connecting the SmartSensor 6-conductor cable to the sensor.

Caution

Do not attempt to service or repair this unit. This unit does not contain any components and/or parts serviceable in the field. Any attempt to open this unit, except

as expressly written and directed by Wavetronix, will void the customer warranty.

Wavetronix is not liable for any bodily harm or damage caused if service is attempted

or if the back cover of the SmartSensor unit is opened. Refer all service questions to

Wavetronix or an authorized distributor.

Page 14

14 CHAPTER 1 INSTALLING THE SMARTSENSOR MATRIX

Warning

Use caution when installing any sensor on or around active roadways. Serious injury

can result when installation is performed using methods that are not in accordance

with authorized local safety policy and procedures. Always maintain an appropriate

awareness of the trac conditions and safety procedures as they relate to specific

locations and installations.

Sensor Mounting Guidelines

e sensor is fairly insensitive to mounting height, but every site will vary based on lane

conguration and the presence of barriers and structures in and around the detection area.

e following table will help you determine how high to mount the sensor (see Table 1.1).

ese gures are only suggestions, but a good rule to follow is—the farther away the rst

lane is to the sensor, the higher you will want to mount the sensor to avoid occlusion.

Closest Lane Sensor Height

6–15 feet 12–25 feet

15–50 feet 15–25 feet

> 50 feet 25–60 feet

Table 1.1 – Suggested Mounting Guidelines

Note

In certain conditions, lanes that have stop bars or detection zones placed at extended

range may show some loss in performance, even with a proper mounting height. This

is more apparent at locations with many travel lanes or where detection zones are

placed near the far edges of detection. If you have any questions regarding the use

of SmartSensor Matrix at a particular location, please contact Wavetronix Technical

Services or your authorized Wavetronix dealer for more information.

Use the following guidelines to determine the best mounting height, then place your sensor

accordingly:

In general, the sensor should be placed at a height of roughly 20 ft. (6.1 m), give or

take 5 ft. (±1.5 m).

e maximum recommended mounting height for the SmartSensor Matrix is 60 ft.

(18.2 m). e minimum is 12 ft. (3.6 m). Placing the sensor above or below these limits

will adversely aect detection accuracy.

Page 15

CHAPTER 1 INSTALLING THE SMARTSENSOR MATRIX 15

Take into consideration the sensor’s eld of view, which reaches 140 ft. (42.7 m) from

the sensor. Place the sensor so that the eld of view covers all the areas of interest.

e mast arm is frequently a good place to mount the sensor.

e mounting position should have a clear view of the detection area. Poles, mast arms,

signal heads, or other objects should not block the view of the detection area.

Placing the sensor higher will result in less occlusion. Placing it lower could result in

more occlusion. However, if the nearest detection area is less than about 20 ft. (6.1 m)

away, the sensor may perform better with a lower mounting position.

Note

It is possible to mount the sensor lower than 12 ft. (3 m) in some scenarios. The sen-

sor will continue to detect vehicles at lower heights, but missed detections due to

occlusion may become more prevalent or problematic in lanes that are farther away

from the sensor.

Attaching the Mount Bracket to the Pole

Before attaching the mount bracket to the pole, rst make sure that your cables are long enough

to reach the sensor height and to stretch across the distance from the sensor to the cabinet.

Follow the steps below to correctly attach the mount to the pole:

1 Insert the stainless steel straps through the slots in the mount bracket.

2 Position the mount on the pole so that the head of the mount is pointing toward the

lanes of interest at about a 45° angle.

3 Tighten the strap screws.

Figure 1.1 – Attach the Mount Bracket to the Pole

e sensor double-swivel mount may need to be adjusted later to ne-tune the alignment.

Page 16

16 CHAPTER 1 INSTALLING THE SMARTSENSOR MATRIX

One swivel joint is used to pan the sensor eld of view left or right and the other swivel

joint is used to tilt the sensor down towards the roadway. If you are not using the double

swivel-mount, make sure the pole straps are adjustable at this point in the installation

process.

Attaching the Sensor to the Mount Bracket

Use the following steps to securely fasten the sensor to the mount bracket:

1 Align the bolts on the sensor’s backplate with the holes in the mount bracket. e

eight-pin connector receptacle on the bottom of the sensor should be pointing towards

the ground.

2 Place the lock washers onto the bolts after the bolts are in the mount bracket holes.

3 read on the nuts and tighten (see Figure 1.2)

Figure 1.2 – Attach the Sensor to the Mount Bracket

Caution

Do not over-tighten the fasteners.

Aligning the Sensor to the Roadway

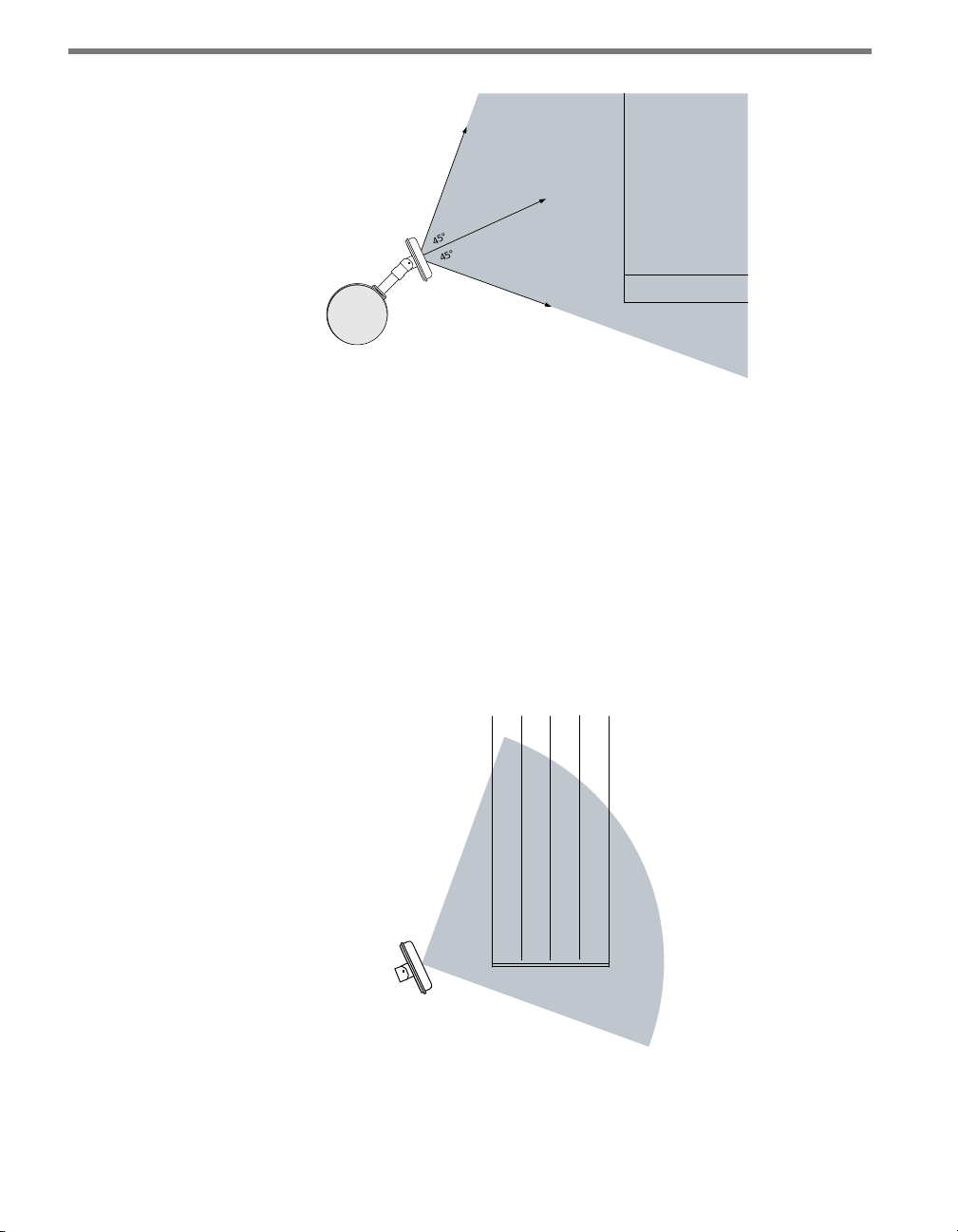

e sensor’s beams fan out 45° to the left and 45° to the right, creating a 90° corner radar

eld of view. In most applications, you will want to position the corner radar so that its 90°

footprint covers all lanes approaching the stop bar (see Figure 1.3).

Page 17

CHAPTER 1 INSTALLING THE SMARTSENSOR MATRIX 17

45°

45°

Edge of first lane of interest

Pan sensor

towards stop bar

Figure 1.3 – Corner Radar Field of View Position

Stop Bar

To visualize the extent of the sensor eld of view, the 90° eld of view is imprinted on the

top and bottom of the sensor case. If more of a visual indicator is needed, then a square

framing tool (e.g. rafter square) or other tool with a right angle can be held above the

sensor. By looking down both edges of the tool, you can visualize the extent of the radar’s

coverage.

Usually the front edge of the sensor’s eld of view is aligned to provide coverage beyond

the stop bar (see Figure 1.4). is allows you to place detection zones beyond the stop bar

to detect those vehicles that do not stop at or behind the stop line and will also allow the

sensor to see vehicles exiting queues. If the sensor pole is upstream from the stop bar, it is

recommended to pan in the direction of the stop bar.

Front edge of field of view

Figure 1.4 – Sensor Aligned by Rotating Towards the Stop Bar

Use the following steps to correctly align the SmartSensor Matrix:

Page 18

18 CHAPTER 1 INSTALLING THE SMARTSENSOR MATRIX

1 Adjust the side-to-side angle so that the front edge of the eld of view provides a view

downstream of the stop bar.

2 Tilt the sensor down so it is aimed at the center of the lanes of interest.

3 If necessary, rotate the sensor so that the bottom edge of the sensor is parallel with

the roadway. is is necessary where the intersection approach has a signicant grade.

Note

To fully complete sensor alignment, you will need to connect to the Matrix sensor

using SmartSensor Manager Matrix and verify that your alignment is detecting the

vehicles in the lanes of interest (see Chapter 8).

Applying the Silicon Dielectric Compound

Use the following steps to correctly apply the silicon dielectric compound to the cable connector:

1 Tear the tab o of the tube of silicon dielectric compound.

2 Squeeze about 25% of the silicon onto the pins of the receptacle side of the connector

at the base of the SmartSensor Matrix (see Figure 1.5). Be sure to wipe o any excess

compound.

Figure 1.5 – Connector Receptacle (left) and Grounding Lug (right)

Connecting the SmartSensor 6-conductor Cable

e next step is to plug the SmartSensor 6-conductor cable into the connector. e sensor

connector is keyed to ensure proper connection (see Figure 1.6); simply twist the plug end

of the connector clockwise until you hear it click into place. To avoid undue movement

from the wind, strap the 6-conductor cable to the pole or run it through a conduit, but leave

a small amount of slack at the top of the cable to reduce cable strain. Route the cable from

the sensor location back to the main trac cabinet.

Page 19

CHAPTER 1 INSTALLING THE SMARTSENSOR MATRIX 19

Figure 1.6 – Sensor 6-conductor Cable Connector

To set up your network in an orderly fashion, it is recommended that labeling be used on

the service end of each SmartSensor 6-conductor cable. A convenient way to label the

cables is to mark the last seven digits of the serial number on each sensor and the direction

of trac monitored (see Figure 1.7).

Figure 1.7 – Service End Labeling

Grounding the Sensor

e SmartSensor Matrix must now be grounded:

1 Connect a grounding wire to the grounding lug on the bottom of the sensor (see

Figure 1.5).

2 Connect the other end of the grounding wire to the earth ground for the pole that

the sensor is mounted on. Do not attempt to run the grounding wire back to the main

trac cabinet.

Page 20

Page 21

Connecting Power and

Surge Protection 2

In this chapter

Mounting the Backplate

Connecting AC Power

Providing System Surge Protection

Terminating SmartSensor 6-conductor Cables

2

After installation, each SmartSensor Matrix will need to be integrated into the main trafc cabinet for power and surge protection. is chapter contains information on how to

provide power and surge protection to a preassembled backplate that accommodates four

SmartSensor Matrix sensors (one for each stop bar of a common four-approach intersection).

Note

Also available to use are the intersection preassembled 19-inch rack for server racks,

the intersection segmented preassembled backplate for easier installation in trac

cabinets, and the Click 600 cabinet interface device (which combines all the function-

ality of the backplates in one module). Installation procedures for the rack and the

segmented backplate will be very similar to the instructions that follow; installation

procedures for the Click 600 can be found in Appendix D of this guide.

e standard four-approach preassembled backplate is 11 in. (28 cm) wide and 11.5 in.

(29.2 cm) high. All wiring on the rack and backplates is done using stranded wires with

wire ferrules for screw terminal connections (see Figure 2.1).

Page 22

22 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Figure 2.1 – Intersection Preassembled Backplate

Mounting the Backplate

Use the following steps to mount the backplate in the trac cabinet:

1 Locate the area planned for mounting the backplate. e backplate can usually be

mounted on the side panel of a NEMA-style cabinet.

2 Attach the backplate with the U-channel mounting screws.

Note

If you have a 330 series (170/2070 style cabinet) with a 19-inch EIA rack, please contact Wavetronix Technical Services for assistance. Wavetronix can provide modified

backplates that attach to a 19-inch rack.

Connecting AC Power

Since SmartSensor Matrix operates on 10–28 VDC, the standard preassembled backplates

provide an AC power conversion option. e backplate includes an AC to DC power converter, power surge and circuit breaker.

Page 23

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 23

Warning

Make sure power to AC mains is disconnected while wiring the AC input. If your in-

stallation does not require AC power, you will need to use surplus DC power inside

the trac cabinet. In this case, Wavetronix recommends you use the Click 221 (8 A

DC surge protector) to protect the backplate and SmartSensor Matrix units from DC

surges. See Appendix C for information regarding the Click 221.

Figure 2.2 – Connecting AC Power to the Preassembled Backplate

Use the following steps to connect power to the AC terminal block on the bottom DIN

rail (see Figure 2.2):

1 Connect a neutral wire (usually a white wire) to the bottom side of the terminal block

labeled “N” for neutral.

2 Connect a ground wire (usually a green wire) to the bottom of the terminal block la-

beled “G” for ground. (see the Wiring Protective Earth Ground section below).

3 Connect a line wire (usually a black wire) to the bottom of the terminal block labeled

“L” for line.

4 Turn on AC mains power.

5 Press the circuit breaker switch on the left side of the top DIN rail to switch power to

the backplate. e switch is on if the button is below the level of the device housing;

the switch is o if the button is raised above the surface of the housing.

6 Verify that DC power is properly regulated by making sure the DC OK LEDs are il-

luminated on the Click 201/202/204.

Page 24

24 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Caution

An authorized electrical technician should install the preassembled backplate. Persons other than authorized and approved electrical technicians should NOT attempt

to connect the backplate to a power supply and/or trac control cabinet, as there is a

serious risk of electrical shock through unsafe handling of the power source. Extreme

caution should be used when connecting the backplate to an active power supply.

e AC power conversion section of the backplate will come pre-wired as shown in Figure

2.3. e main three components of the AC power conversion section include:

Click 201/202/204 AC to DC converter – A Click 201 provides 1 A of power and is

capable of powering a single sensor; a Click 202 provides 2 A and can power two sensors; a Click 204 provides 4 A and can power four sensors.

Click 210 circuit breaker – Interrupts power during overload conditions and provides

a convenient way to turn power on and o for the entire system.

Click 230 AC surge protector – Helps protect equipment from current surges on the

power lines.

Figure 2.3 – AC Power Conversion

Wiring Protective Earth Ground

All connections are surge protected when the protective earth ground is wired to the PE

terminal block on the backplate. Normally, the backplate should be mounted to the chassis

of the cabinet to provide a ground path. It is strongly recommended that you provide a low

impedance protective earth connection.

Page 25

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 25

Follow the steps below to provide a low impedance protective earth connection:

1 Connect one end of a protective earth ground wire to the bottom of the PE terminal

block. A 10 AWG stranded wire is recommended for protective earth ground connec-

tions and is also the largest that will t in the terminal block.

2 Connect the other end of the protective earth ground wire to a protective earth screw

terminal within the main trac cabinet.

Controlling DC Power Distribution

e Click 210 circuit breakers provide a convenient way to turn power on or o for each

sensor independently (see Figure 2.4). To enable or disable DC power to the backplate,

switch the main circuit breaker (left side of upper DIN rail); to enable or disable DC power

to an individual sensor, switch the individual circuit breaker (left side of each sensor’s set

of terminal blocks).

Push this

button to

turn power

on or o

Figure 2.4 – DC Power Distribution

Note

The switch is ON when the switch button is level with the device housing; the switch

is OFF when the switch button is raised above the housing.

e four-approach preassembled backplate has 24 VDC power wired from the output of

the AC to DC converter into a 5-position screw terminal on the left side of the T-bus (see

Figure 2.5). e green T-bus conducts DC power and RS-485 communications from the

left to the right side of the modules; the gray T-bus conducts only DC power from the left

to the right side of the modules.

Page 26

26 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

+24V DC

-DC

+RS-485

-RS-485

GND

red wire

( )

black wire

( )

Figure 2.5 – T-bus Pinout Diagram

Power

Green GreenGray

RS-485

Providing System Surge Protection

e Click 222 system surge protector is designed to prevent electrical surges conducted

along underground cables from damaging the cabinet equipment (see Figure 2.6).

Figure 2.6 – Click 222 Faceplate

Note

The SmartSensor Matrix has built-in surge protection and so there is no need to use

a pole-mount box for surge protection on the sensor side of the cable. However, it is

strongly recommended that the sensor be connected to a surge protection device in

the main trac cabinet. If you choose not to use surge protection in your main trac

cabinet, please contact Wavetronix Technical Services for assistance.

When a Click 222 is present, the power and RS-485 serial connections on the T-bus and

faceplate are protected from surges on the incoming SmartSensor 6-conductor cables.

e Click 222 faceplate has four activity indicator LEDs:

PWR – Indicates that the device has power.

DC Surge OK – Indicates that DC surge protection is operational.

Page 27

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 27

TD – Indicates when data is transmitted over the T-bus or over the control bridge. is

LED does not indicate data transmitted on the A or B ports.

RD – Indicates when data is received over the T-bus or over the control bridge. is

LED does not indicate data received on the A or B ports.

Note

If the DC Surge OK LED is not on when the Click 222 is powered, call Wavetronix Technical Services for assistance.

e Click 222 provides the following three independent serial connections:

Topmost jack: control bridge

Middle jack: dedicated communications for sensor 2 detection calls

Lowest jack: dedicated communications for sensor 1 detection calls

e control bridge enables a multi-drop shared communication bus between all sensors

connected to the backplate. is allows control of all SmartSensor Matrix sensors, rack

cards and other connected Click devices. e remaining two serial connection ports provide

communications to only one sensor each, as outlined above.

On a four-sensor preassembled backplate (see Figure 2.7):

e sensor wired into the left-most terminal blocks will be connected to ports A and

C on the Click 222 on the left. Port A is for detection calls and port C is connected

to the control bridge.

e sensor wired to the second set of terminal blocks will be wired to ports B and D

on the Click 222 on the left. Port B is for detection calls and port D is connected to

the control bridge.

e sensor wired to the third set of terminal block from the left will be wired to ports

A and C on the Click 222 on the right.

e sensor wired to the right-most terminal block will be wired to ports B and D on

the Click 222 on the right.

Page 28

28 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Port A & Port C Port B & Port D Port A & Port C Port B & Port D

x

x

x

x

x

OUT

x

PWR

GND

485+

485-

485+

x

x

x

x

x

x

x

OUT

SSMatrix #2

DRN

485-

x

PWR

GND

485+

485-

485+

x

x

x

DRN

485-

x

x

x

x

x

OUT

SSMatrix #3

PWR

x

GND

485+

485-

485+

485-

x

x

x

DRN

x

OUT

SSMatrix #4

PWR

GND

x

x

x

x

x

DRN

485+

485-

485+

485-

IN

x

x

x

x

x

x

IN

x

x

x

x

x

x

x

x

IN

x

x

x

x

x

x

x

x

IN

x

x

x

x

x

x

x

x

x

x

Figure 2.7 – Click 222 Ports A, B, C and D

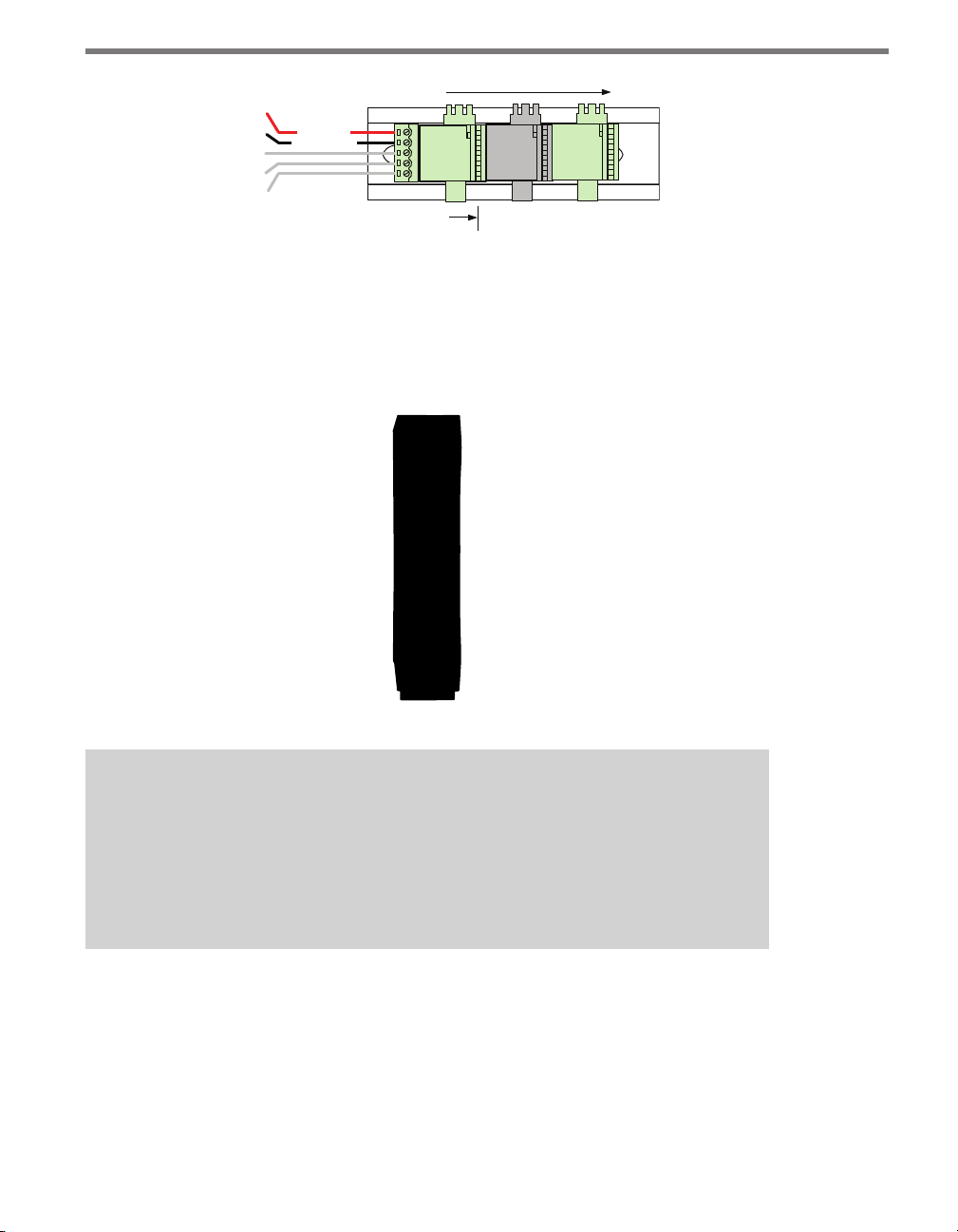

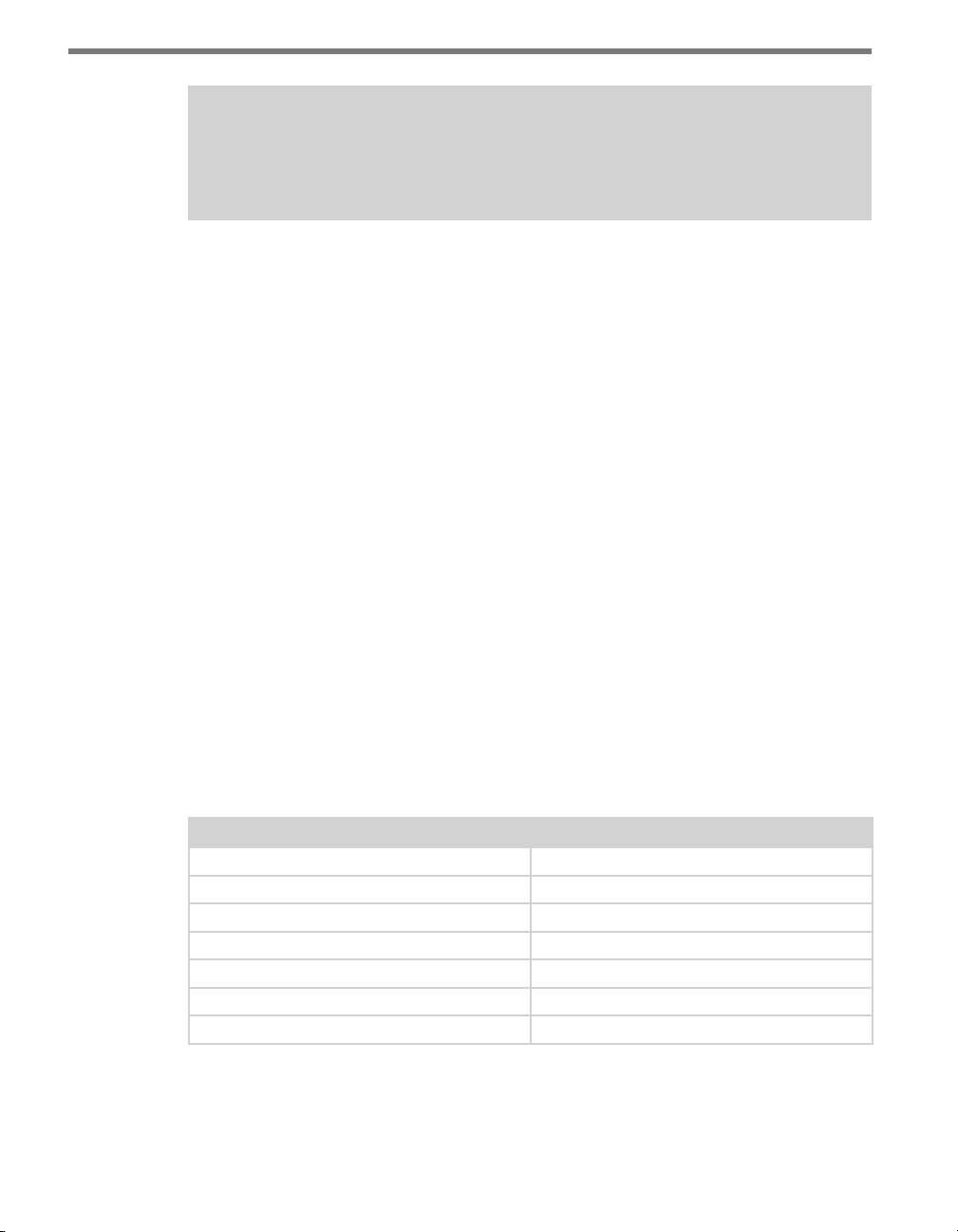

Terminating SmartSensor 6-conductor Cables

e SmartSensor Matrix will receive power once each SmartSensor 6-conductor cable is

correctly landed into the plug-in terminals on the backplate (see Figure 2.8 and Table 2.1).

Each 6-conductor cable has one DC power wire pair, two RS-485 communication pairs,

and a drain wire. e service end of the cable connects to plug-in terminals on the preassembled backplate (see Figure 2.8).

Figure 2.8 – Color Label on Plug-in Terminals

Page 29

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 29

Note

Do not strip the service end of the cable until after it has been routed through conduit. The cable should be one continuous run without any splices.

Use the steps below to land the sensor cables:

1 After routing your SmartSensor 6-conductor cable into the cabinet, carefully strip

back the cable jacket and shielding on the service end of the cable.

2 Open the insulation displacement connectors on the plug by inserting a small screw-

driver into each square slot and rocking it back.

3 Insert the wire leads into the bottom side of the plug-in terminal according to the

color code shown in Table 2.1 and Figure 2.8. Make sure the wires are completely

inserted in the terminal.

4 Close the insulation displacement connector by reinserting the screwdriver into the

square slot and rocking it forward. e plug-in terminals will automatically complete

the electrical connection. ere is no need to manually strip the insulation on the end

of each wire.

ere are two measures in place to ensure that the plugs are always returned to their correct

terminal block sections.

First, for visual conrmation, one part of the plug is blue (see Figure 2.8) and must be

visually matched up to a blue terminal block. e location of the blue piece rotates in the

dierent plugs and terminal block sections: in the rst, the rst block is blue, in the second,

the second is blue, etc.

Second, the plugs are keyed (see the blue piece in Figure 2.8) so they will only t into their

correct terminal block sections.

Wire Color Signal

Red (PWR) DC+

Black (GND) DC-

White with Blue stripe (485+) Control bridge 485+ (port1)

Blue (485-) Control bridge 485 - (port 1)

White with Orange stripe (485+) Data bus 485+ (port 2)

Orange (485-) Data bus 485- (port 2)

Bare metal (DRN) Drain

Table 2.1 – Cable Wiring Color Code

Page 30

Page 31

Contact Closure Communication 3

In this chapter

Using the Click 112/114 DIP Switches

Using the Click 104 Rotary Switch

Attaching and Programming the Click 112/114

Attaching and Programming the Click 104

Channel Mapping

3

Each SmartSensor Matrix communicates with standard trac cabinets using either the

Click 104 DIN rail contact closure module or the Click 112/114 detector rack cards (see

Figure 3.1). During real-time operations, up to four channels from each sensor can be signaled to a Click 114 or Click 104 (or to a pair of Click 112 cards daisy-chained together).

Figure 3.1 – Click 104 (left) and Click 112/114 Rack Cards (right)

Page 32

32 CHAPTER 3 CONTACT CLOSURE COMMUNICATION

14356781234

56782

Note

See the Click 100–400 Series User Guide for complete information on how to connect and configure the Click 104 DIN rail contact closure module and the Click 112/114

detector rack cards.

Each SmartSensor Matrix could potentially use up to 16 channels using a combination of

Click 104/112/114 contact closure modules. is means that a standard four-approach stop

bar detection system can be accommodated by a 64-channel detector rack.

e Click 112/114 cards can be congured using DIP switches on the circuit board, the

front panel menu on the faceplate or Click Supervisor. e Click 104 can be congured

using the rotary switch, the front panel menu on the faceplate or Click Supervisor.

Using the Click 112/114 DIP Switches

e DIP switches allow you to program the baud rate and input mapping using the hardware. If the Click 112/114 cards are programmed using the DIP switches, the settings can

be viewed, but not modied, using the front panel menu or Click Supervisor.

If you are planning to use either the front panel menu or Click Supervisor to program the

device settings, then you will need to rst make sure that the DIP switches are set to allow for software conguration; to set this, simply make sure that all relevant switches are

turned o (see Figure 3.2).

Input Mapping Switches

S4

Channel

Group

Makes channel group selection software configurable

Figure 3.2 – DIP Switch Setting for Software Configuration Mode (left)

Baud Rate Switches

S5

On

O

Bus 1 Bus 2

ere is no need to change the baud rate of the Click 112/114 cards from the factory default of 9600 baud. e settings for the input mapping, however, will need to be set. is

process is explained in the following sections.

Page 33

CHAPTER 3 CONTACT CLOSURE COMMUNICATION 33

123456781

234

567

8

Note

An advantage of using the DIP switches for configuration is that if you ever need to

replace a Click 112/114, you can simply set the DIP switches on the new card to match

the pattern of the DIP switches on the card you are replacing, then slide the new one

into the same slot in the detector rack.

Click 114 Input Mapping DIP Switch Settings

On a Click 114, channel group 1 comprises input channels 1–4. When this channel group

is selected; sensor channel 1 will be mapped to output channel 1; sensor channel 2 will be

mapped to output channel 2; sensor channel 3 will be mapped to output channel 3; and

sensor channel 4 will be mapped to output channel 4.

Use Figure 3.3 below to set the DIP switch settings to select channel group 1:

Input Mapping Switches Baud Rate Switches

S4 S5

On

O

Channel

Group

Click 114 – Selects Matrix channels 1 through 4 for output

Figure 3.3 – Click 114 DIP Switch Settings

Bus 1 Bus 2

Click 112 DIP Switch Settings

On a Click 112, channel group 1 comprises input channels 1 and 2, where sensor channel 1

will be mapped to output channel 1 and sensor channel 2 will be mapped to output channel 2. In order to map sensor channel 3 to output channel 1 and sensor channel 4 to output

channel 2, you will need to select channel group 2.

If you are using two Click 112 devices, you will need to set the DIP switches dierently for

each card and daisy-chain the cards together using bus 1.

Figure 3.4 below shows how to set the DIP switches on the Click 112 card on the left. is

will select Matrix output channels 1 and 2 for output.

Page 34

34 CHAPTER 3 CONTACT CLOSURE COMMUNICATION

123456781

234

567

8

124356781

234

567

8

Input Mapping Switches Baud Rate Switches

S4 S5

On

O

Channel

Group

Bus 1 Bus 2

Click 112 –Selects channels 1 & 2

Figure 3.4 – Click 112 DIP Switches for Channels 1 and 2

Figure 3.5 shows how to set the DIP switches on the Click 112 on the right. is will assign sensor output channels 3 and 4 for output.

Input Mapping Switches Baud Rate Switches

S4

S5

On

O

Channel

Group

Bus 1 Bus 2

Click 112 – Selects channels 3 & 4

Figure 3.5 – Click 112 DIP Switches for Channels 3 and 4

For information on how to use other DIP switch conguration options, as well as the front

panel menu and Click Supervisor, see the Click 112/114 chapter in the Click Series User

Guide.

Using the Click 104 Rotary Switch

e rotary switch is located on the lower part of the faceplate and can be used to change

the channel input mapping. e switch can be twisted by inserting a small screwdriver into

the arrow slot.

If you use this switch to set the channel input mapping, you won’t be able to use the Click

Supervisor software or the front panel menu to change this particular parameter (although

you will still be able to use them to change other parameters).

If the switch is set to 0, the device is in Software mode. is means that all parameters are

set by the front panel menu or Click Supervisor. If the switch is set to any other number,

the device is in Hardware mode, meaning that the channel input mapping is set by the

rotary switch.

e Click 104 has four output channels; if you need more than this, you’ll need to use multiple devices daisy-chained together.

Page 35

CHAPTER 3 CONTACT CLOSURE COMMUNICATION 35

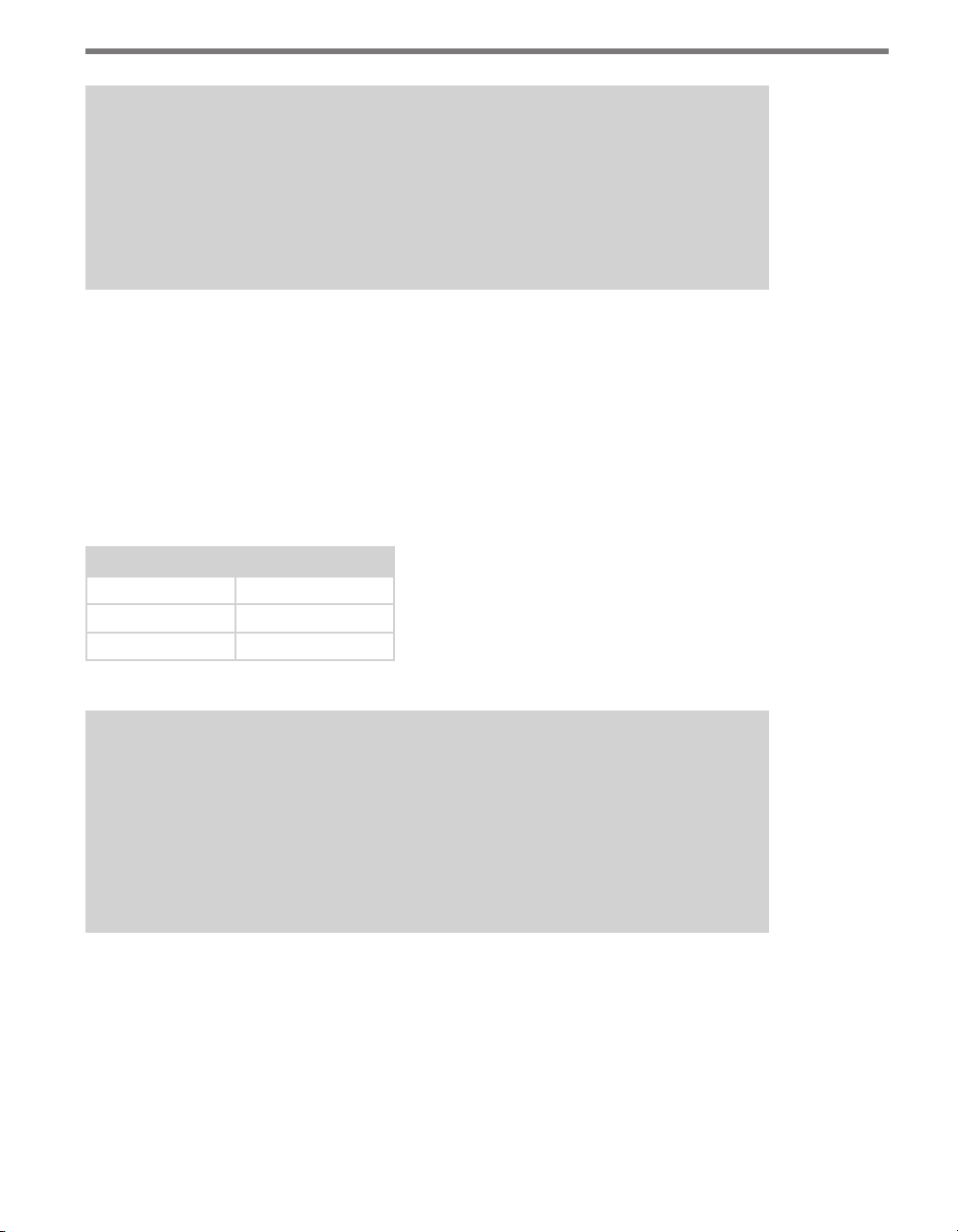

As shown in the table below, the outputs are mapped sequentially—that is, they can only

be mapped in numerically ordered groups of four (1–4, 5–8, etc.). If you set the switch to 3,

for 9–12, then sensor channel 9 would be mapped to output 1, sensor channel 10 would be

mapped to output 2, sensor channel 11 would be mapped to output 3, and sensor channel

12 would be mapped to output 4.

Switch Channels

0 Software mode

1 1–4

2 5–8

3 9–12

4 13–16

5 17–20

6 21–24

7 25–28

8 29–32

9 33–36

Table 3.1 – Click 104 Rotary Switch Channel Input Map Settings

Attaching and Programming the Click 112/114

Use the following steps to set up the contact closure rack cards for each sensor:

1 Make sure the DIP switches are set according to Figure 3.3 for a Click 114 and Fig-

ures 3.4 and 3.5 for Click 112 cards.

2 Power all the cards by plugging them into the detector rack.

Figure 3.6 – Wiring the Click 112/114 Rack Cards

3 Connect a 6-ft. (1.8-m) patch cord from the Click 222 RS-485 A port to a bus 1 port

on the appropriate rack card (see Figure 3.6).

Page 36

36 CHAPTER 3 CONTACT CLOSURE COMMUNICATION

4 Connect a 6-ft. (1.8-m) patch cord from the Click 222 RS-485 B port to a bus 1 port

on another rack card.

5 If you are using Click 112 cards, use an 6-in. (15-cm) patch cord to share bus 1 be-

tween cards dedicated to the same sensor. Also, congure one card to use Matrix channels 1 and 2 and congure the other card to use Matrix channels 3 and 4. If you have

more than two sensors in your system, repeat steps 2–4 to connect bus 1 for all remaining rack cards.

6 Connect a 5-ft. (1.5-m) patch cord from one of the Click 222 bridge ports to bus 2 of

the rack cards.

7 Use the 6-in. (15 cm) patch cords to create a daisy-chain that shares bus 2 between all

of the rack cards. Bus 2 will be used for device conguration.

Click 112/114 LEDs

Once you have completed the wiring, check the Menu Level 1 LEDs, which have both

menu-indicating and general status–indicating functions. e list below contains information on the general status–indicating functions of the LEDs:

PWR (red) – Indicates the device is powered.

PU (blue) – is LED is not associated with any general status function and should

remain o while the card is in normal operating mode.

TD (green) – Indicates the card is transmitting serial communication.

RD (yellow) – Indicates the card is receiving serial communications.

e red LED should be on, showing the card is powered and operating normally.

e list below contains additional information about the rest of the LEDs:

Detection Channel LEDs (red) – Indicates when a call is placed on the corresponding

contact closure output channel.

Menu Level 2 – Used for the conguration menu that is activated using the Mode

switch.

General Status (Menu Level 1) – In addition to the functions listed above, these are

used to cycle through and select options from the front panel menu.

Page 37

CHAPTER 3 CONTACT CLOSURE COMMUNICATION 37

Detection

Channel

Menu Level 2

Menu Level 1

Mode Switch

Figure 3.7 – Click 112/114 Menu

Normally, a SmartSensor Matrix sensor will send 10 contact closure messages each second.

If a rack card does not receive communications from a sensor within 10 seconds, the rack

card will go into fail-safe mode and all of the contact closures will be activated and the corresponding detection channel LEDs on the faceplate will turn on.

Attaching and Programming the Click 104

Use the following steps to set up the DIN rail contact closure module for each sensor:

1 Mount the Click 104 on a DIN rail over a T-bus connector. is connects the device’s

control bus (bus 2) to the installation’s shared communication bus; you can connect

your computer to another device on this shared bus, such as the Click 305 USB converter, to access the Click 104 to congure it using Click Supervisor. Mounting the

Click 104 on the T-bus also connects it to the power source.

Figure 3.8 – Wiring the Click 104 Module

2 Send detection data to the data bus (bus 1). Connect a Click 222 to the Click 104 by

connecting jumper cables from the RJ-11 jacks on the faceplate of the Click 222 to the

RJ-11 jacks on the faceplate of the Click 104 (see Figure 3.8).

Page 38

38 CHAPTER 3 CONTACT CLOSURE COMMUNICATION

3 If needed, daisy-chain multiple Click 104 devices together by utilizing both RJ-11

jacks on each device’s faceplate.

Click 104 LEDs

e front panel of the device features a push-button and three banks of LEDs for on-device

conguration and monitoring. e rst bank of LEDs, labeled Channel, displays the state

of the contact closure outputs (see Figure 3.8).

Channel

1 2 3 4

Menu

PWR OK TD RD

Figure 3.9 – Click 104 LEDs

e two lower banks of LEDs, labeled Menu, and the push-button, labeled Mode Switch,

are used for navigating through Menu mode.

e lower bank of LEDs will be referred to as Level 1 and is used in selecting menu options. e upper bank will be referred to as Level 2 and is used in conguring the menu options. Level 2 LEDs only light up when a menu selection is made using the Level 1 LEDs.

e mode switch push-button is used to enter Menu mode (see Figure 3.9). To use the

menu:

1 2 3 4

Menu

Level 2

Level 1

PWR

OK TD RD

Mode Switch

Figure 3.10 – Click 104 LED Menu

1 Press and hold the mode switch to enter Menu mode. e Level 1 LEDs will start to

light up to indicate that the device is cycling through all menu options.

2 Release the mode switch when you reach the desired menu option. (Pressing and hold-

ing again will resume cycling through menu options.)

3 Quickly press and release the mode switch to select the current menu option. Once it’s

selected, the Level 2 LEDs will start to let you congure the options for the selected

Page 39

CHAPTER 3 CONTACT CLOSURE COMMUNICATION 39

2

5

1

6

4

7

3

menu option.

4 Press and hold the mode switch to cycle through the submenu. e Level 2 LEDs will

light to indicate that the device is cycling though all conguration options.

5 Release the mode switch once the desired conguration option is reached.

6 Quickly press and release the mode switch to select the current conguration option.

e device will exit Menu mode, and either the selected function will run or the selected conguration will be set and saved to the device.

Channel Mapping

Once the Click 104/112/114 devices are installed, make sure that each detector rack channel is properly mapped to the correct trac phase in the trac controller. e general

NEMA standard for 8-phase numbering is presented in Figure 3.8. Many intersections

will not have eight phases, and in some cases they may not even follow the NEMA convention. Check the plans in the trac signal cabinet to verify how the phases are numbered at

each intersection.

Figure 3.11 – Standard NEMA 8-phase Number Scheme

Phases 1, 2, 5 and 6 are often used for the “main” street, and phases 3, 4, 7 and 8 are often

used for the “side” street as shown in Figure 3.8.

Note

Chapter 10 contains a section about Rack Card Tools which explains how the channelto-phase mapping can be verified with or without the sensors installed.

Since each Matrix sensor often detects both the left-turn phase and the through-movement phase for a single approach, the associated rack card will have often have channels

that correspond to one of the following phase (ф) pairs: ф2 and ф5; ф6 and ф1; ф4 and ф7;

ф8 and ф3.

Page 40

40 CHAPTER 3 CONTACT CLOSURE COMMUNICATION

C1

↓

Φ

1

C2

↓

Φ

6

C3

↓

Φ

6

C4

↓

Φ

6

C5

↓

Φ

5

C6

↓

Φ

2

C7

↓

Φ

2

C8

↓

Φ

2

C9

↓

Φ

3

C10

↓

Φ

8

C11

↓

Φ

8

C12

↓

Φ

8

C13

↓

Φ

7

C14

↓

Φ

4

C15

↓

Φ

4

C16

↓

Φ

4

NEMA TS2, 2070 and other advanced trac cabinet systems usually allow software programming of the detector card channel outputs to trac phases via a channel-to-phase

mapping grid in the controller menu. Figure 3.9 illustrates how the detector channels 1 to

16 of a NEMA TS-2 rack can be assigned to the standard eight phases using four Click

114 cards. e rack card slots are numbered across the top and the controller’s detection

channels are represented by the gray labels C1–C16.

Slot 1 Slot 2 Slot 3 Slot 4 Slot 5 Slot 6 Slot 7 Slot 8

Figure 3.12 – NEMA TS-2 Type 1 Rack Channel to Trac Phase Example

In Figure 3.9, four channels are used from each SmartSensor Matrix. In this example,

channel 1 from the rst sensor is mapped to trac phase 1 (left-turn phase on main street).

Channels 2, 3 and 4 from the rst sensor are mapped to trac phase 6. is represents a

case where detections from three through-movement lanes are brought in separately. is

type of lane-by-lane detection can be benecial in some situations. Wavetronix typically

recommends the use of 4-channel cards because it oers greater exibility of signaling

contact closures.

Note

With NEMA TS1 and other legacy systems, the programming is often done via a wiring panel on the side of the controller cabinet. With wired systems, you will need to

verify that the wiring on the detector programming panel provides the proper mapping from the rack channel outputs to the controller input wires dedicated for ф1–ф8

detector calls.

Page 41

Page 42

Page 43

Part II

Using SmartSensor Manager

Matrix

Chapter 4 – Installing SmartSensor Manager Matrix

Chapter 5 – Communication

Chapter 6 – Sensor Settings

Chapter 7 – Lanes & Stop Bars

Chapter 8 – Zones & Channels

Chapter 9 – Verification

Chapter 10 – Tools

Page 44

Page 45

Installing SmartSensor

Manager Matrix 4

In this chapter

Installing SSMM

Microsoft .NET Framework

4

e SmartSensor Manager Matrix (SSMM) software enables you to congure and interact

with the SmartSensor Matrix. SSMM can be run on a Windows® PC and on a Socket

Mobile 650 handheld computer.

e software can be downloaded on other computers by going to www.wavetronix.com.

is chapter explains how to download and install the SSMM software.

Using the Click 421

e Click 421 converts wired or wireless serial data to RS-485 communication and sends

it to all devices on a shared multi-drop communication bus on the backplate. is allows

control of all SmartSensor Matrix units from a single access point.

You can make a wired connection using a USB-to-serial converter and a USB adapter

cable; alternatively, you can make a wireless connection using a precongured Bluetooth

link. A whip antenna can be attached to the Click 421 to increase the distance and reliability of the wireless link.

Follow the steps below to use the Click 421 to communicate with the SmartSensor Matrix:

1 Rock the Click 421 device onto the green T-bus to the left of the gray T-bus connector

on the second DIN rail on the backplate.

Page 46

46 CHAPTER 4 INSTALLING SMARTSENSOR MANAGER MATRIX

2 Make a wired (using the serial port on the front of the device) or wireless (Bluetooth)

connection between the Click 421 and the handheld computer.

If you wish to establish a wired connection with a laptop computer instead of the handheld

device, use the laptop’s native RS-232 serial port to connect to the Click 421, or a USBto-serial converter if the laptop does not have an RS-232 serial port. You can also establish

a Bluetooth connection from your laptop to the Click 421. To do so, consult your laptop’s

software guidelines on how to discover Bluetooth devices and congure a Bluetooth serial

connection.

An RJ-11 patch cord with a pigtail on one end can be wired to the RS-485 screw terminal

on the Click 421 and used to patch into RJ-11 sockets on the rack cards or backplate for

troubleshooting.

Once you’ve connected to the Click 421, you can connect to the sensor using SmartSensor

Manager Matrix, as outlined in the next chapter.

Installing SSMM

You can install SSMM to your PC or laptop. Everything needed for this installation is

contained in the SSMM Setup.exe le.

Note

You must have Administrator rights to run the setup program.

Follow these steps to install SSMM on a PC or laptop:

1 To download the install le, go to the Wavetronix website at www.wavetronix.com.

2 Click the Support link near the top of the page and follow the controls to nd the

correct link for the SmartSensor Manager Matrix install le.

3 Once you’ve downloaded the le, double-click on it. Opening it executes a setup pro-

gram that will copy all the necessary les to the hard drive and place icons in the Start

menu and on the desktop of the PC or laptop (see Figure 4.2).

Page 47

CHAPTER 4 INSTALLING SMARTSENSOR MANAGER MATRIX 47

Figure 4.1 – SSMM Setup Wizard

4 Select an installation location. e default location provided is normally “C:\Program

Files\Wavetronix.” If desired, click Browse to choose another location (see Figure 4.3).

Figure 4.2 – Location to be Installed

5 Click the Install Now button.

6 After SSMM is installed, you can create shortcuts to the SSMM software on the desk-

top and in the Start menu using the corresponding checkboxes (see Figure 4.4). If no

shortcuts are desired, uncheck the corresponding boxes.

Figure 4.3 – Shortcut Options

7 Click the View release notes when nished checkbox to view the SSMM release

notes. e release notes contain additional information about the current version of

Page 48

48 CHAPTER 4 INSTALLING SMARTSENSOR MANAGER MATRIX

the SSMM software. A PDF reader program (i.e. Adobe Acrobat Reader) is required

to view the release notes.

8 Click Finish to complete the setup process.

Note

SSMM is designed for the 96 DPI display setting. The application may not display text

properly, and may not function properly in general, if the display is not set to 96 DPI.

Installing SSMM on a Handheld Computer

SSMM can also be installed and on a handheld computer. Use these steps to install SSMM

on a handheld computer running Windows Mobile:

1 Ensure the handheld computer is connected to the PC and synced.

2 Click on the SSMM Setup.exe le to run the setup program on the host computer.

e SSMM Setup Wizard will automatically check the host computer to see if Microsoft ActiveSync is installed (ActiveSync is a program that is used to communicate

with a handheld device). If the ActiveSync program is found, the option of installing

SSMM to a handheld device will become available.

3 Click the Pocket PC checkbox and then the Next>> button to install SSMM on a

connected handheld device (see Figure 4.5). If both the Computer and Pocket PC

boxes are checked, the setup program will rst install the SSMM software to the PC.

Figure 4.4 – Destination Selection

4 Click Continue>> to start the handheld computer installation process. e setup pro-

gram runs the Add/Remove Programs application for Windows handheld devices. If

a handheld device is connected to the computer, Add/Remove Programs will immediately begin installing SSMM on the handheld device. If a handheld device is not connected to the computer, SSMM will be downloaded the next time a handheld device

is connected to the computer.

Page 49

CHAPTER 4 INSTALLING SMARTSENSOR MANAGER MATRIX 49

5 Click OK once the download is complete.

Microsoft .NET Framework

e SSMM setup program will automatically detect whether Microsoft .NET Compact

Framework v3.5 is installed on your PC. If it is not installed, you will be prompted to install

it (see Figure 4.7).

Figure 4.5 – Microsoft .NET Framework V2.0 Prompt

Click the Install Framework button and you will be taken to the Microsoft Website where

you can install the latest version of Microsoft .NET Framework.

Page 50

Page 51

Communication 5

In this chapter

Serial Connection

Internet Connection

Virtual Connection

Viewing Connection Info

Upgrading the Sensor’s Embedded Software

5

Once the sensors are installed, use the SSMM software to change settings, view data and

congure the sensors to the roadway.

Launch SSMM by either clicking on the icon that was placed on your desktop or clicking

the icon found in the Start menu. e SSMM splash screen and then main screen shown

in Figure 5.1 will appear.

Page 52

52 CHAPTER 5 COMMUNICATION

Figure 5.1 – SSMM Splash Screen (left) and Main Screen (right)

You can always view the version of SSMM you are using by right-clicking (click and hold

on handheld) on the main screen and then clicking SSM Matrix Version. To see the ver-

sion, date and timestamp of the individual components that make up the program, select

Component Version (see Figure 5.2).

Figure 5.2 – Matrix Version (top) and Component Version (bottom)

After you are connected to a sensor, you can also view the dates the rmware components

were created by clicking Firmware Versions. Information on the two main hardware components, the DSP and RF board, can be viewed by clicking Hardware Version (see Figure 5.3).

Page 53

CHAPTER 5 COMMUNICATION 53

Figure 5.3 – Firmware Versions (left) and Hardware Versions (right)

If you are using SSMM on a computer, you can use the panel in the lower left of the main

screen to change the size of the user interface on your computer. Click any of the three

squares to increase or decrease the size of the user interface.

e rst step is to make a connection to the sensor. e following three types of connections can be made:

Serial connection – Made using Bluetooth, RS-232, or RS-485 communication.

Internet connection – Made using an IP address and a serial to Ethernet converter.

Virtual connection – Made for convenience in learning and demonstrating SSMM

functionality.

Communication settings are stored in the system registry each time a connection is established. After the rst connection is made to the SS225, the SSMM software will save the

connection settings that were used. Click the magnifying glass icon on the right side of

the communication link to connect using the most recently used parameters stored in the

registry.

Serial Connection

1 Click on Communication to access the Communication window (see Figure 5.2).

2 Select the Serial tab.

3 Set Port and Timeout to the desired settings.

4 Select the type of search (Full or Quick) you would like to perform. A full search will

nd all SmartSensor Matrix units on the selected RS-485 control bus and can take

up to 30 seconds; a quick search can be used after the rst time a full search has been

performed.

Page 54

54 CHAPTER 5 COMMUNICATION

Note

A quick search should not be used the first time you connect to sensors on an RS-485

control bus. If you add or replace a sensor on an existing control bus, a full search will

need to be performed before a quick search can be made.

Note

If you perform a full search and then cancel before the search is complete, the sensors not discovered before the full search was terminated will also not be visible after

a quick search. You will then need to perform a full search to completion before all

sensors can be discovered using a quick search.

5 Click the Search button.

6 Click on the desired sensor row from the list to select a sensor (see Figure 5.4). e

sensor list shows the sensor ID, location, and approach of each discovered sensor.

7 Click the Connect button. You will be directed back to the home page once a connec-

tion is established.

Figure 5.4 – Serial Connection

After you have connected to a sensor, the next time you would like to connect you

can simply click the magnifying glass icon in the upper right corner of the screen.

is will take you to the last connection settings you used to connect to a sensor.

e rst time you connect to a sensor, the default Sensor ID will be the last seven digits of

the sensor’s serial number. However, the names in the Location and Approach elds will

Page 55

CHAPTER 5 COMMUNICATION 55

be set to default values.

Note

It is recommended that you label the service end of each SmartSensor Matrix cable

when the cable is pulled so that the approach the sensor is monitoring can be documented. You may need to power down all sensors except for the one you are configuring in order to determine which approach it is monitoring.

If you have problems connecting:

1 Make sure that all power and communication wiring is correct.

2 Check the port settings (Port ID).

Connection failure can occur for various reasons; if a failure occurs repeatedly, call Wavetro-

nix Technical Support at 801-734-7200 for assistance.

Once you have selected a sensor from the device list, you can click again on that

row to bring up a Sensor Info pop-up (see Figure 5.5). To bring up the Sensor Info

pop-up, you can also click on the sensor icon that appears in the upper right corner

of the screen (see Figure 5.4). e information in the Sensor Info screen cannot be edited.

Figure 5.5 – Sensor Info Screen

e Sensor Info screen lists the following sensor settings and version information:

Sensor ID – e last seven digits of the sensor serial number. is eld is not editable.

Description – Used to describe the application (e.g. stop bar detection); can also be

used for GPS coordinates. is eld is not editable from this screen.

Location – Used to describe the intersection where the sensor is located. is eld is

Page 56

56 CHAPTER 5 COMMUNICATION

not editable from this screen.

Approach – Used to indicate which approach of the intersection the sensor monitors.

is eld is not editable from this screen.

Sensor Version – Overall sensor product version, which represents a released combi-

nation of the DSP, Algorithm, FPGA and FPAA subcomponent versions.

DSP Rev – DSP code version date (YYYY-MM-DD).

Algorithms Rev – Algorithm code version date (YYYY-MM-DD).

FPGA Version – FPGA version date (YYYY-MM-DD).

FPAA Version – FPAA version date (YYYY-MM-DD).

Signal Rack Cards – When the switch is on, any rack cards connected to this sensor’s

data port will identify themselves by ashing a blink sequence on the main menu

LEDs of the rack card.

Internet Connection

e SmartSensor Matrix can be connected to the Internet, allowing access to the sensor

from anywhere with Internet access. e following is a list of ways to connect the SmartSensor Matrix to the Internet:

Serial to Ethernet Converter – e SmartSensor Matrix can be connected to a local

area network (LAN) by using a Click 301 serial to Ethernet converter.

Serial to 802.11b Wireless – e SmartSensor Matrix can be connected using a Click

420 serial to 802.11b converter. e Click 420 provides serial devices with an IP address on a wireless 802.11b network.

Internet Service Providers – e SmartSensor Matrix can be equipped with optional

external modems (CDMA, GMS or GPRS) and assigned an Internet address on these

networks. (Please contact Wavetronix Technical Services for assistance.)

Note

The Internet connection is made to the control bridge and NOT to the data ports.

Use the steps below to connect to the SmartSensor Matrix using an Internet connection:

1 Click on Communication.

2 Click the Internet tab and the Internet setting options will appear (see Figure 5.6).

Page 57

CHAPTER 5 COMMUNICATION 57

Figure 5.6 – Internet Connection Screen

3 Enter the IP address or URL of the sensor of interest. Enter the IP address assigned to

either the CDMA modem or the Click 301 serial to Ethernet converter.

4 Enter the port number assigned to the CDMA modem or the Click 301 serial to Eth-

ernet converter in the Port eld. is will be an integer value in the range of 0–65536.

e Click 301 port number automatically defaults to 10001.

5 Set the Timeout value to 1000.

6 Select the type of search (Full or Quick) you would like to perform (see the Serial

Connection section of this chapter for more on these two searches).

7 Click the Search button. is may take up to 30 seconds while the sensors on your

control bus are discovered and listed. (You can click Cancel as soon as the sensor of

interest is listed.)

8 Click on the desired row from the list to select a sensor (see Figure 5.7).

Figure 5.7 – Internet Connection Screen

Page 58

58 CHAPTER 5 COMMUNICATION

9 Click the Connect button. When a connection is established you will be directed back

to the home page.

If you have problems connecting:

1 Make sure that all power and communication wiring is correct.

2 Check the address and port number.

Connection failure can occur for various reasons; if a failure occurs repeatedly, call Wa-

vetronix Technical Support at 801-764-0277 for assistance.

Address Book

e Address Book is available on the Internet connection tab and allows you to save IP

connection settings for future use.

Click the Address Book button located at the bottom of the Communication page to add

new connection settings to the Address Book (see Figure 5.8).

Deletes an

Address Book

Edits the

Selected Device

Adds a Device to

the Address Book

Deletes a Device from

the Address Book

Figure 5.8 – Address Book

Imports an

Address Book

Exports an

Address Book

Virtual Connection

A virtual connection allows you to use the SSMM software without being connected to an

actual sensor. Making a virtual connection can be useful for the following reasons:

To view a saved sensor setup le

To play back previously logged trac

To demonstrate functionality for dierent trac applications

Page 59

CHAPTER 5 COMMUNICATION 59

To review how the software works

Use the following steps to make a virtual connection:

1 Click the Communication button.

2 Select the Virtual tab (see Figure 5.9).

Figure 5.9 – Virtual Connection Screen

3 Select or create a virtual sensor le (.vsf ) by clicking the magnifying glass icon.

4 Click the Search button. is may take up to 30 seconds while the sensors on your

virtual control bus are discovered and listed. (You can click Cancel if the sensor of

interest has already been listed.)

5 Click on the desired row from the list to select a sensor.

6 Click the Connect button. When a connection is established you will be directed back

to the home page.

Virtual Sensor File

Since a virtual connection is not made to an actual sensor, a virtual sensor le (.vsf ) is used

to save the conguration settings much like an actual sensor’s ash memory. SSMM comes

with default virtual les that you can see once you click the Search button. If you create

your own virtual sensor le, you will have to nd it in the virtual les directory by clicking

the magnifying glass icon under the Virtual Sensor Files Location heading.

Note

When you are connected using a virtual sensor file, changes that would normally be

saved to a sensor’s flash memory will automatically be saved to the virtual sensor

file.

Page 60

60 CHAPTER 5 COMMUNICATION

Virtual sensor les can be converted to sensor setup les and can be restored to an actual

sensor; sensor setup les that have been backed up from a sensor can also be converted

to virtual sensor les. To convert a sensor setup le to a virtual sensor le, make a virtual

connection and then use the Restore Sensor Setup tool in the Tools menu. To convert a

virtual sensor le to a sensor setup le, use the Back-up Sensor Setup tool.

Note

To configure channels for a future installation, connect using a virtual connection,

create a virtual sensor file and then back up the configuration settings that you created. After the file is successfully backed up, the virtual sensor file will change to a

sensor setup file and can be restored to any sensor in the field.

When a connection is made to the SmartSensor Matrix, the main menu will appear and all

conguration options will become available (see Figure 5.10).

Figure 5.10 – Main Menu (Connected)

Viewing Connection Information

Once connected, you can view additional information about the connection you have established by clicking on the moving arrows icon on the top right of the main menu page or

on the bottom right of the Communication screen (see Figure 5.11). ese arrows are only

visible when there is an established connection.

Page 61

CHAPTER 5 COMMUNICATION 61

Figure 5.11 – Connection Info Screen

Below is a list of the information available on the Connection Info screen:

Status – Shows that you are connected.

Sensor – Shows the subnet and sensor ID.

Type – Shows the type of connection.

Duration – Shows how long you have been connected.

Failures – Shows the amount of failures during the connection, the percentage rate of

failure and a link to the communication error log.

Communication Error Log

e error log contains all errors stored in the sensor’s memory buer. If you are having

trouble connecting, using the error log may be helpful in the troubleshooting process. If you

continue having trouble, save the error log le and contact Wavetronix Technical Services.

Note

The error log is cleared every time you close SSMM, so if you need to save the file, do

so before shutting the program down.

Click the View Error Log link to view the communications error log (see Figure 5.12).

e error log can also be accessed by clicking on the Error Log icon at the bottom of the

Communication screen.

Page 62

62 CHAPTER 5 COMMUNICATION

Figure 5.12 – Error Log

Upgrading the Sensor’s Embedded Software

After clicking the Connect button, the software will check to see if your software version

matches the version of the sensor’s embedded software. If a discrepancy is detected, the

Version Control screen may appear asking you to install rmware upgrades (see Figure

5.13). If you think you have reached this screen in error, clicking the Recheck button will

have the software retry and ensure that there has not been a communication issue. Clicking the Details button will display the current sensor and software information. Click the

UPLOAD FIRMWARE button to upgrade the software.

Checking the Upload to all sensors checkbox will broadcast the upgrade to all the sensors

on the control bridge. Check the Disable fast pacing checkbox if you are connected using

Bluetooth or other devices with a slow connection speed (see Figure 5.13).

Figure 5.13 – Sensor’s Embedded Software Upgrade (left) and Details Table (right)

Page 63

CHAPTER 5 COMMUNICATION 63

Click the Details button to view the rmware versions of both the SSMM software and

the SmartSensor Matrix.

Once the Version Control screen appears, you can do one of the following:

Upgrade the sensor’s embedded software by clicking the UPLOAD FIRMWARE

button.

Click the Close button and continue the conguration process.

Find the version of SSMM software that is compatible with the sensor’s embedded

software.

Note

Clicking the Close button and continuing configuration without upgrading may cause

problems with functionality.

If any row is highlighted in red, the rmware upgrade may need to be installed. Compare

the sensor number with the SSMM number in the Digital row of the details table. If the

SSMM rmware version date is more recent than the sensor rmware version date, the

newer rmware will need to be installed; if the sensor’s rmware date is more recent than

the SSMM rmware version date, a warning will appear notifying you that older rmware

will be uploaded to the sensor (see Figure 5.14).

Figure 5.14 – Sensor Firmware Downgrade (left) Back Up Configuration (right)

If the downgrade message appears, it means that the sensor rmware is newer than the version of SSMM that was used to connect to the sensor. e newest version of SSMM can

be downloaded from www.wavetronix.com.

If you are upgrading from certain versions of SSMM, the upgrade may cause you to lose

Page 64

64 CHAPTER 5 COMMUNICATION

your sensor conguration. Follow the steps in the back up message to back up your sensor’s

conguration.

Note

If you are upgrading the software, it is always a good idea to back up your sensor configuration. There is always a chance that the sensor conguration could be lost after

upgrading. You can create a back up file by going to the Tools screen (see Chapter 10).

Click the UPLOAD FIRMWARE button to install the rmware embedded in SSMM

onto the SmartSensor Matrix. e Recheck button will query the sensor to see if the rmware bundled in SSMM is dierent than the version running on the sensor.

Page 65

Sensor Settings 6

In this chapter

Sensor Settings Screen

Sensor Info Screen

6

Click the Sensor Settings link on the main menu to change and save settings on the sensor.

General Sensor Settings

e General tab of the Sensor Settings screen allows you to change the sensor description,

RF channel, wash-out time, and other settings (see Figure 6.1).

Figure 6.1 – Serial Settings Window

Page 66

66 CHAPTER 6 SENSOR SETTINGS

e General tab contains the following elds:

Serial Number – Contains the sensor serial number and cannot be edited.

Sensor ID – Contains the ID used to uniquely identify all sensors on a multi-drop bus.

is ID is the last seven digits of the sensor’s serial number and cannot be edited.