Page 1

SmartSensor Advance

USER GUIDE

Page 2

SmartSensor

Advance

USER GUIDE

www.wavetronix.com 78 East 1700 South Provo, Utah 84606 801.734.7200

Page 3

© 2014 Wavetronix LLC. All Rights Reserved.

Wavetronix, SmartSensor, Click, Command, and all associated product names and logos are trademarks of Wavetronix LLC. All other

products or brand names as they appear are trademarks or registered trademarks of their respective holders.

Protected by US Patent Nos. 6,556,916; 6,693,557; 7,426,450; 7,427,930; 7,573,400; 7,889,097; 7,889,098; 7,924,170; 7,991,542;

8,248,272; 8,665,113; Canadian Patent Nos. 2461411; 2434756; 2512689; and European Patent Nos. 1435036; 1438702; 1611458. Other

US and international patents pending.

e Company shall not be liable for any errors contained herein or for any damages arising out of or related to this document or the

information contained therein, even if the Company has been advised of the possibility of such damages.

is document is intended for informational and instructional purposes only. e Company reserves the right to make changes in the

specications and other information contained in this document without prior notication.

FCC Part 15 Compliance: e Wavetronix SmartSensor sensors comply with Part 15 of the Federal Communications Commission

(FCC) rules which state that operation is subject to the following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesirable operation. FCC compliance statements for applicable optional modules are to be found in the module specications. Unauthorized changes or modications

not expressly approved by the party responsible for compliance with the FCC rules could void the user’s authority to operate this

equipment.

Disclaimer: e advertised detection accuracy of the Wavetronix SmartSensor sensors is based on both external and internal testing,

as outlined in each product’s specication document. Although our sensors are very accurate by industry standards, like all other sensor manufacturers we cannot guarantee perfection or assure that no errors will ever occur in any particular applications of our technology. erefore, beyond the express Limited Warranty that accompanies each sensor sold by the company, we oer no additional

representations, warranties, guarantees or remedies to our customers. It is recommended that purchasers and integrators evaluate the

accuracy of each sensor to determine the acceptable margin of error for each application within their particular system(s).

WX-500-0052

10/2012

Page 4

Contents

Introduction 5

SmartSensor Advance Package 6 • Selecting a Detection

Method 6 • Selecting a Mounting Location 7

Part I Installing the SmartSensor Advance

Chapter 1 Installing the SmartSensor Advance 15

Selecting the Mounting Height 15 • Mounting the Sensor 16

• Aligning the Sensor 19 • Applying Silicon Dielectric Compound 24 • Connecting the SmartSensor 6-conductor Cable

24 • Grounding the Sensor 25

Chapter 2 Connecting Power and Surge Protection 27

Mounting the Backplate 28 • Connecting AC Power 28 • Providing System Surge Protection 32 • Terminating the 6-conductor Cables 34 • Contact Closure Connections 36

Part II Using SmartSensor Manager Advance

Chapter 3 Installing SmartSensor ManagerAdvance 39

Installing SSMA 39

Chapter 4 Communication 43

Serial Connection 44 • Internet Connection 45 • Virtual

Connection 46 • Multi-drop Network 49 • Address Book 50 •

Viewing Connection Information 51 • Uploading the Sensor’s

Embedded Soware 54

Page 5

Chapter 5 Sensor Settings 57

General Tab 57 • Communication Tab 59

Chapter 6 Sensor Configuration 61

1. Installation Details 62 • 2. Automatic Radar Conguration

64 • 3. Manual Radar Adjustment 65

Chapter 7 Channels-Alerts-Zones 71

Channels 72 • Alerts 84 • Zones 84

Chapter 8 Verify Channels-Alerts-Zones 91

Right Sidebar 92 • Roadway Display 98 • Le Sidebar 106

Chapter 9 Setup Output Communications 109

Primary Push Manager 110 • Secondary Push Manager 112

Chapter 10 Templates 115

Creating a Channel Template 116 • Importing a Channel Template 116 • Copying/Pasting Channels, Alerts and Zones 118

Chapter 11 Tools 119

Backup/Restore Tool 120 • Beam Alignment Tool 123 • Serial

Terminal 124 • Rack Card Tools 125

Chapter 12 Programming Contact Closures 129

Click 112/114 Contact Closure Cards 129 • Click 172/174

Contact Closure Cards 130 • Click 104 Contact Closure Module 133

Appendix 137

Appendix A – Cable Connector Denitions 137 • Appendix

B – Cable Lengths 139 • Appendix C – Direct Serial Connections 142 • Appendix D – Target Roll Angles for Alignment

143 • Appendix E – Command Line Arguments 145

Page 6

Introduction

In this chapter

SmartSensor Advance Package

Selecting a Detection Method

Selecting a Mounting Location

e Wavetronix SmartSensor Advance™ and Wavetronix SmartSensor Advance Extended

Range detect and continuously monitor the progression of moving trac out to a maximum range of 600 . (182.9 m) and 900 . (274.3 m) respectively.

Both trac sensors are designed for use on the approaches to signalized intersections. ey

are used to alert the trac controller of a vehicle’s arrival based upon the incoming range,

speed, and estimated time-of-arrival of each detected vehicle for applications such as highspeed dilemma zone protection and queue reduction. In addition, SmartSensor Advance

Extended Range allows you to prioritize dilemma zone protection based upon the discovery range of trucks and passenger cars.

SmartSensor Advance and SmartSensor Advance Extended Range monitor vehicle trac

ow through the use of a 10.525 GHz (X band) operating radio frequency. Both sensors

utilize Digital Wave Radar™ technology to provide a reliable Frequency Modulated Continuous Wave. SmartSensor Advance Extended Range uses a new form of frequency modulation to achieve its extended reach.

e SmartSensor Advance User Guide is divided into two parts. Part one provides a step-by-

step process for installing the SmartSensor Advance and the SmartSensor Advance Extended Range, including mounting and alignment guidelines. Part two provides instructions for

installing and using the SmartSensor Manager Advance soware, including instructions for

both automatic and manual sensor congurations. Any questions about the information in

this guide should be directed to Wavetronix or your distributor.

Page 7

6 INTRODUCTION SMARTSENSOR ADVANCE USER GUIDE

Caution

Do not attempt to service or repair this unit. This unit does not contain any components and/or parts serviceable in the field. Any attempt to open this unit, except

as expressly written and directed by Wavetronix, will void the customer warranty.

Wavetronix is not liable for any bodily harm or damage caused if service is attempted

or if the back cover of the SmartSensor unit is opened. Refer all service questions to

Wavetronix or an authorized distributor.

SmartSensor Advance Package

A typical SmartSensor Advance package will commonly include:

10.525 GHz SmartSensor Advance radar trac sensor

SmartSensor mounting kit

SmartSensor 6-conductor cable

SmartSensor Advance preassembled backplate

SmartSensor Manager Advance (SSMA) soware

SmartSensor Advance User Guide

SmartSensor Advance Quick-reference Guides

Check the packing slip for actual contents. If any of these items are missing, note the serial

number located on the back of the sensor and contact your distributor.

Selecting a Detection Method

Consult the Wavetronix guidelines for integration of SmartSensor Advance into your trac

control system. For dilemma zone protection applications, integration guidelines can be

found on the Wavetronix website and Wavetronix application notes. Contact your dealer or

a Wavetronix Technical Services representative if the application-specic documentation

does not fully answer your system integration and conguration questions.

Some examples of trac control applications include:

Dilemma zone protection using green extension

Truck signal priority using green extension

Dilemma zone protection using green extension with an Advanced Warning Sign

(AWS)

Trac signal performance measures

Queue clearance

Ecient green extension

Queue management

Page 8

INTRODUCTION SMARTSENSOR ADVANCE USER GUIDE 7

Note

For queue management the SmartSensor Advance Extended Range is recommended

because it allows you to see a greater range and also provides a view of the stop

bar. The SmartSensor Advance Extended Range is also recommended for wrong-way

detection applications. Contact Wavetronix Technical Services for more information.

If your application is dilemma zone protection and/or truck signal priority, SafeArrival™

technology is recommended because it provides signicant safety and eciency advantages when compared with traditional point-based protection. Conguring SafeArrival

technology for dilemma zone protection is as simple as selecting the arrival times, ranges

and speeds that are unsafe and warrant protection. Conguration SafeArrival technology

for truck signal priority requires the additional conguration of the truck discovery range

threshold available with SmartSensor Advance Extended Range.

For green extension, arrival times between 2.5 and 5.5 seconds, ranges from 100 to 500 .

(30.5 to 152.4 m) and speeds above 35 mph (56 kph) are generally considered unsafe for

passenger vehicles. For truck signal priority, arrival times between 2.5 and 7.5 seconds,

ranges from 100 to 900 . (30.5 to 274.3 m) and speeds above 35 mph (56 kph) are generally

considered unsafe for trucks, buses and other large vehicles.

However, engineering judgment needs to be used in selecting these parameters. For example, 2.5 to 5.5 second arrival times are nominal values based upon general 10% and 90%

stopping probabilities. Your agency may suggest protection of slightly dierent arrival times

for a particular type of high-speed approach.

It may be helpful to consult your agency’s guidelines to verify which trac conditions warrant protection at your intersections. Location of point-detection zones, passage time and

design speed can oen be used to discover the arrival times and ranges that warrant protection. In addition, the minimum speed that would warrant installation of a dilemma zone

protection system may be used as a guideline for the lowest speed to be protected.

If you elect not to use SafeArrival technology, you can also congure SmartSensor Advance

to match your agency’s loop-based dilemma zone protection guidelines. Before doing so, it

is recommended that you explore the benets provided by SafeArrival technology in detail.

Selecting a Mounting Location

Consider the following guidelines when selecting a mounting location:

Detection coverage – Position the sensor so that it will be able to reach all the speci-

ed advanced detection zones. Also consider that the sensor will track vehicles as they

enter and exit desired detection zones. Accordingly, the sensor will oen work better if

Page 9

8 INTRODUCTION SMARTSENSOR ADVANCE USER GUIDE

➋

you position detection coverage to track vehicles for several feet before they reach the

rst zone. e closest detection zone provided by SmartSensor Advance and Smart-

Sensor Advance Extended Range is 50 . (15.2 m) from the location of the sensor. e

farthest detection zone provided by SmartSensor Advance Extended Range is 900 .

(274.3 m). e farthest detection zone provided by SmartSensor Advance is 600 .

(182.9 m). e sensor is usually used to detect incoming trac, but it can detect in-

coming or outgoing trac, and it lters out the opposite direction trac. With Smart-

Sensor Advance Extended Range, incoming large vehicles are typically discovered by

about 750 . (228.6 m) and small vehicles are typically discovered about 600 (182.9

m) from the sensor. With SmartSensor Advance, most incoming large vehicles are dis-

covered by about 500 . (152.4 m) and most small vehicles are discovered about 400

(121.9) from the sensor.

➌

➍

➊

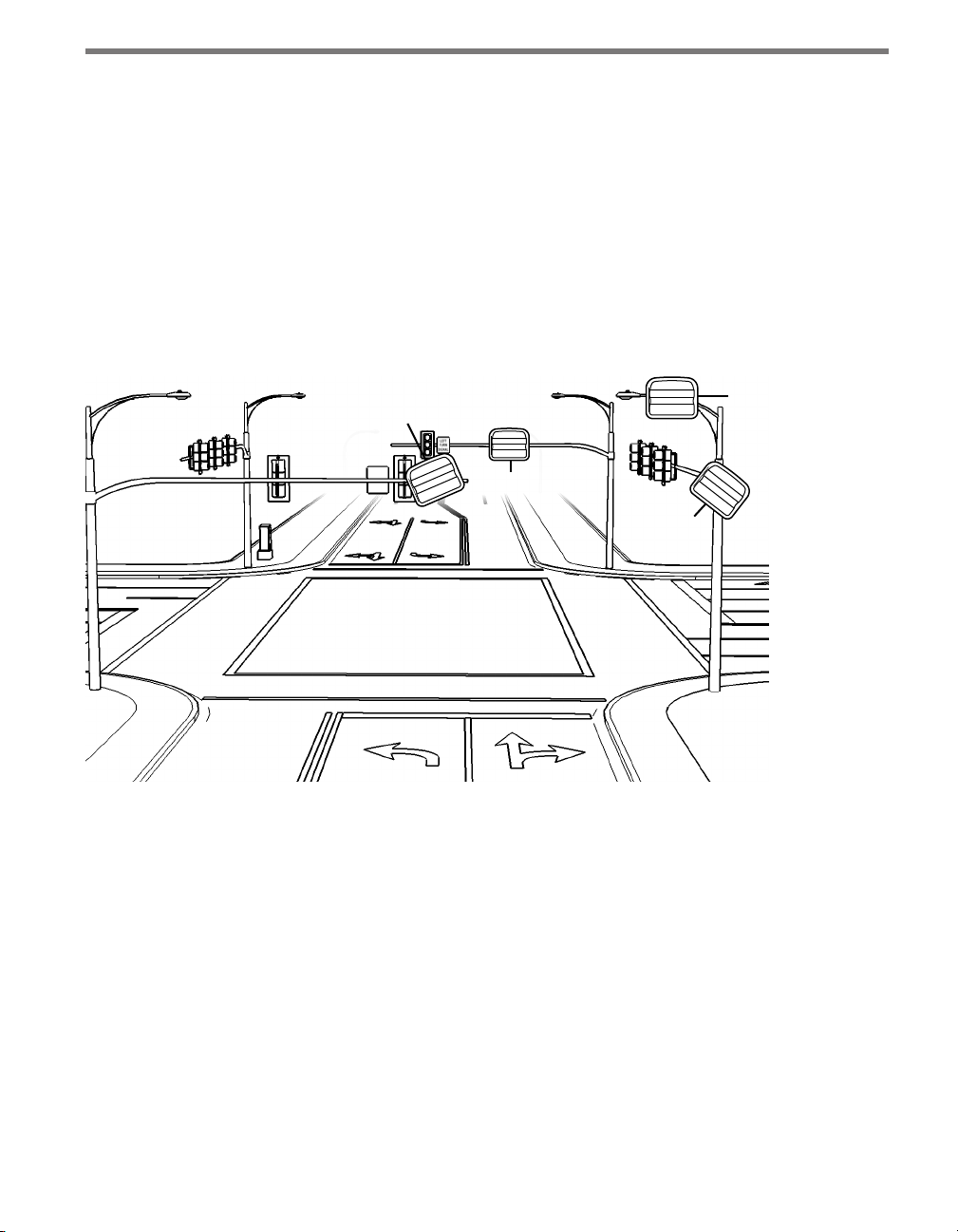

Figure I.1 – Mounting Locations

Line-of-sight – Position the sensor so that it will have line-of-sight to the entire detec-

tion area of interest. Avoid structural occlusion including trees, signs and other road-

side structures.

Closest roadside – If you install the sensor on the side of the road (instead of over-

head), select the location closest to the lanes of interest. is will prevent departing

trac from occluding approaching detections.

Through-Movement Detection – If only through-movement detection is desired, po-

sition the sensor to avoid detection of turn-only lanes. Consider using speed lters to

remove the impact of turning vehicles.

Mounting Height – Mounting the sensor as high as possible is recommended to reduce

same lane occlusion. A maximum of 40 . (12.2 m) and minimum of 17 . (5.2 m) is

recommended. If the sensor is higher than 30 . (9.1 m), the oset should be less than

50 . (15.2 m) to increase accuracy.

Page 10

INTRODUCTION SMARTSENSOR ADVANCE USER GUIDE 9

Mounting Oset – Mounting the sensor closer to the lanes of interest will usually in-

crease detection accuracies. A maximum oset of 50 . (152.4 m) is recommended, but

the sensor will still reliably track vehicles at further osets. Mounting with a smaller

oset will generally increase line-of-sight.

Cable Length – Make sure that you have sucient homerun and sensor cabling. With

the newer models, cable runs as long as 1500 . (457.2 m) are achievable using 24 VDC

operation and RS-485 communications. Older models supported up to 600 . (182.9

m). Consult Appendix B for more information.

Suspended Electrical Cables –e sensor is designed to work in the presence of

suspended power lines and other electrical cabling, however these cables should be

mounted at least ten feet away from the front of the sensor.

Neighboring Structures and Parallel Walls – For best performance, it is preferred that

the sensor be mounted without signs or other at surfaces mounted directly behind it.

is will help reduce multiple reection paths from a single vehicle.

e SmartSensor Advance should be mounted using one of the following options (see Figure I.1):

1 On a vertical pole – e preferred mounting location for the SmartSensor Advance or

SmartSensor Advance Extended Range is oen a vertical pole near the stop bar. Vertical poles are typically installed on the roadside of the approach near the stop bar to

support a mast arm, span wire or luminaire. ese poles oen extend as high as 30 .

(9.1 m) or more, allowing the sensor to be mounted high enough to reduce occlusion.

is mounting location is typically very safe for installation.

2 On a luminaire – is mounting location will oen reduce the oset and increase the

mounting height (a maximum of 40 . (12.2 m) is recommended). Make sure the luminaire can support the load of the sensor. is mounting location is typically very safe

for installation.

3 The backside of the opposing mast arm – By mounting on the backside of the mast

arm, opposite the signal heads for the opposing direction of travel, the sensor can be

placed near the lanes of interest. e minimum mounting height is 17 . (5.2 m), but

higher mounting is recommended to minimize occlusion. When appropriate, a vertical

extension can be used; the extension should have the ability to freely rotate the sensor

for alignment. e sensor should be mounted as far out on the mast arm as possible to

avoid potential occlusion issues with stopped vehicles in a le-turn pocket.

4 The front side of the mast arm – e sensor can be installed on the mast arm with

the signals for the approach of interest. SmartSensor Advance Extended Range is recommended at this mounting location, because typically 100 feet or more of the sensor’s range is used to cross the width of the intersection. For SmartSensor Advance

Extended Range, the eective maximum range of the sensor is still as high as 800 feet

from the stop bar at this mounting location. is mounting location can be helpful if

the minimum green time is so short that vehicles in the queue clearance zone do not

start moving before the minimum green timer expires.

e SmartSensor Advance or SmartSensor Advance Extended Range can also be mounted

at the back of the dilemma zone on an existing luminaire or custom pole if the luminaire

Page 11

10 INTRODUCTION SMARTSENSOR ADVANCE USER GUIDE

already exists, power is available and a wireless communication link can be used to avoid

trenching. Wavetronix has integrated wireless solutions readily available for this type of

installation.

Page 12

Page 13

Page 14

Part 1

Installing the SmartSensor

Advance

Chapter 1 – Installing the SmartSensor Advance

Chapter 2 – Connecting Power and Surge Protection

Page 15

Page 16

Installing the SmartSensor Advance 1

In this chapter

Selecting the Mounting Height

Attaching the Mount Bracket to the Pole

Attaching the Sensor to the Mount Bracket

Aligning the Sensor to the Roadway

Applying Silicon Dielectric Compound

Connecting the SmartSensor Cable to the Sensor

1

Installing the SmartSensor Advance is quick and easy. Once installed, SmartSensor Advance requires little or no on-site maintenance. is chapter describes the installation process, including how to attach the sensor to the pole and how to correctly align the sensor.

Warning

Caution should be used when installing any sensor on or around active roadways.

Serious injury can result when installation is performed using methods that are not

in accordance with authorized local safety policy and procedures. Always maintain an

appropriate awareness of the trac conditions and safety procedures as they relate

to specific locations and installations.

Selecting the Mounting Height

Select a mounting location within the recommended range of osets from the center of the

Page 17

16 CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE

lanes of interest. Use Table 1.1 to determine the mounting height based on the oset. Osets

of less than 50 . (15.2 m) on either side of the center of the desired lanes are recommended.

Height (ft / m)

17 / 5.2 20 / 6.1 25 / 7.6 30 / 9.1 35 / 10.7 40 / 12.2

0 / 0 40 / 12.2 45 / 13.7 55 / 16.8 60 / 18.3 70 / 21.3 75 / 22.9

5 / 1.5 45 / 13.7 45 / 13.7 60 / 18.3 65 / 19.8 70 / 21.3 80 / 24.4

10 / 3 50 / 15.2 50 / 15.2 60 / 18.3 65 / 19.8 75 / 22.9 80 / 24.4

15 / 4.6 50 / 15.2 55 / 16.8 65 / 19.8 70 / 21.3 75 / 22.9 80 / 24.4

20 / 6.1 55 / 16.8 55 / 16.8 65 / 19.8 75 / 22.9 80 / 24.4 90 / 27.4

25 / 7.6 60 / 18.3 65 / 19.8 65 / 19.8 75 / 22.9 80 / 24.4 90 / 27.4

30 / 9.1 65 / 19.8 70 / 21.3 75 / 22.9 80 / 24.4 85 / 25.9 95 / 28.9

Oset (ft / m)

35 / 10.7 70 / 21.3 75 / 22.9 85 / 25.9 85 / 25.9 95 / 28.9 95 / 28.9

40 / 12.2 80 / 24.4 90 / 2 7.4 90 / 27.4 95 / 28.9 95 / 28.9 100 / 30.4

45 / 13.7 95 / 28.9 100 / 30.4 100 / 30.4 100 / 30.4 100 / 30.4 105 / 32

50 / 15.2 100 / 30.4 100 / 30.4 105 / 32 110 / 33.5 115 / 35 120 / 36.6

Table 1.1 – Target Distance (ft / m)

e minimum recommended mounting height is 17 . (5.2 m) and the maximum recommended mounting height is 40 . (12.2 m). Higher than 30-. (9.1-m) mounting heights

are acceptable if the sensor is within 50 . (15.2 m) of the road. Depending on the site and

type of trac, some vehicles may be momentarily occluded by other vehicles. Vehicle-based

occlusion favors detection of large vehicles, which may be acceptable for dilemma zone

protection applications. It may be necessary to increase the height of the sensor to reduce

occlusion, or use controller passage time to bridge the gap caused by occlusion.

Mounting the Sensor

e standard sensor mount has three axes of rotation: straps around pole, vertical swivel

points and horizontal swivel points. During the mounting process, keep the bolt nuts on the

mount loose. Your sensor mount’s degrees of freedom should be adjustable until you have

completed your alignment.

Attaching the Mount Bracket to the Pole

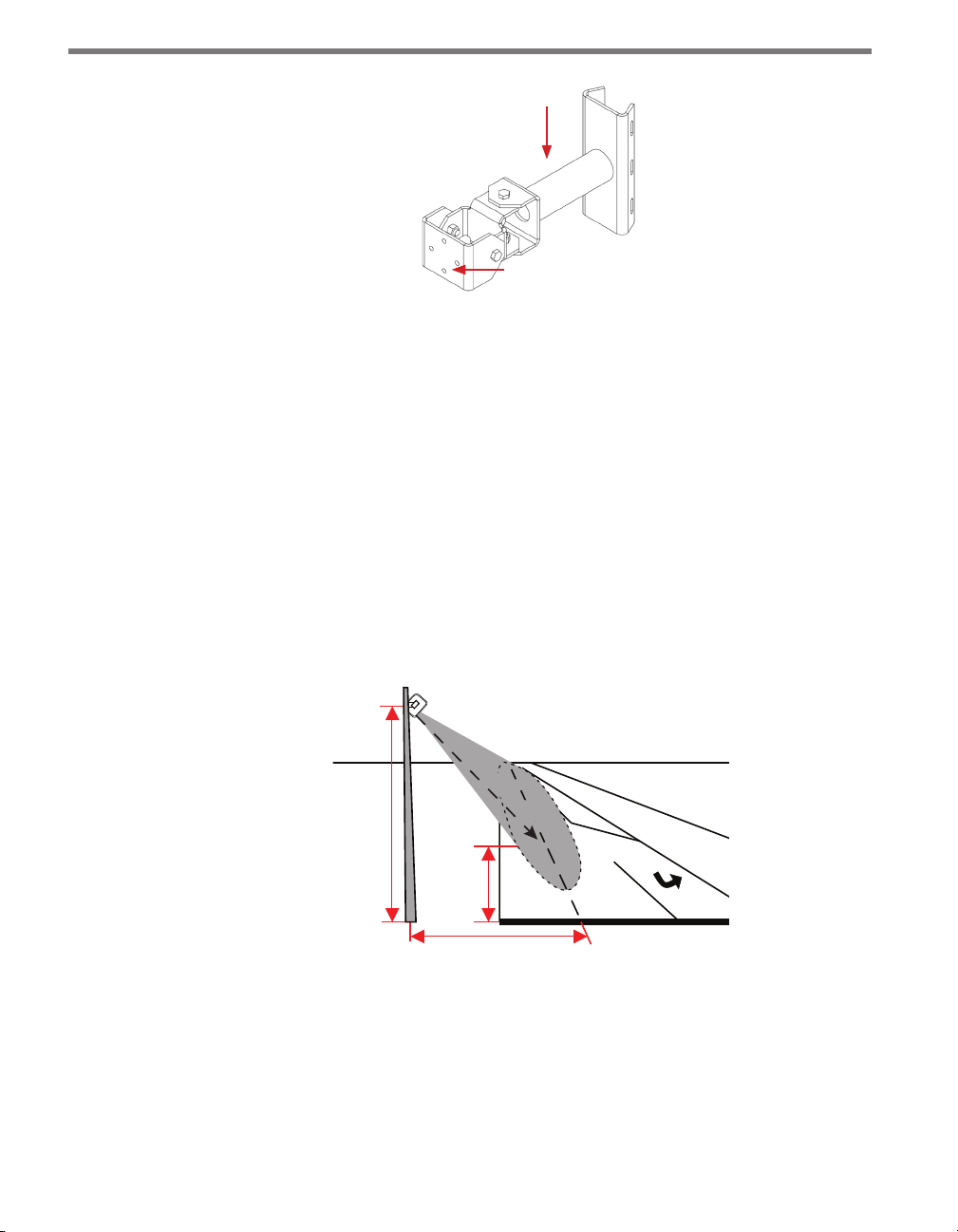

e sensor is mounted to the pole using a mount bracket (see Figure 1.1).

Page 18

CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE 17

Main Shaft

Mount Head

Figure 1.1 – Mount Bracket

Before attaching the mount bracket to the pole, rst make sure that your cables are long

enough to support the sensor height and the distance from the sensor to the cabinet.

Follow the steps below to correctly attach the mount to the pole (see Figure 1.2):

1 Insert the stainless steel straps through the slots in the mount bracket.

2 Position the mount so that it facilitates visual line-of-sight from the sensor to the tar-

get. You will need to have sucient headroom behind the sensor to position your eye

behind the viewnder alignment tool (the next section will go into detail about the

viewnder alignment tool).

For a roadside installation (on a vertical pole) the mount's main sha can be positioned

slightly ahead of perpendicular to the roadway; you can then look from the side of

the pole. For an overhead installation (on a mast arm) the mount's main sha can be

positioned slightly above horizontal; you can then look over the pole (see Figure 1.2).

Line-of-sight to target

Height

Target

Distance

Oset (perpendicular)

Figure 1.2 – Pointing the Sensor

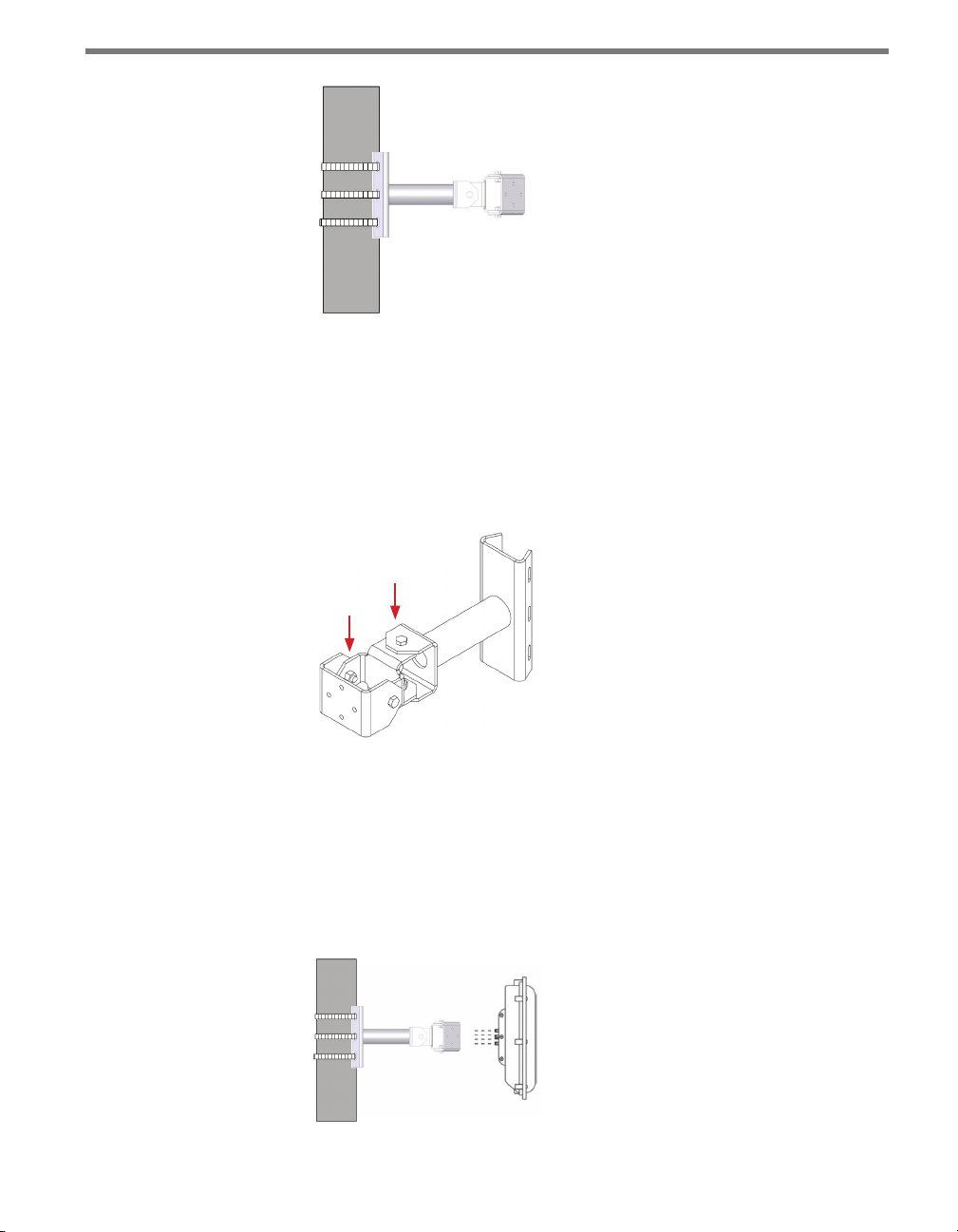

3 Tighten the strap screws (see Figure 1.3).

X

Page 19

18 CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE

Figure 1.3 – Attaching the Mount Bracket to the Pole

4 Using the swivel joints (see Figure 1.4), pan and tilt the mount so that the mount head

points roughly to target distance in the center of the lanes of interest. (e viewnder

will be used later to help you achieve a more precise alignment.)

If the sensor is on a vertical pole, rst use swivel joint 1 to pan, then use swivel joint 2

to tilt. If the sensor is on a horizontal pole, rst use swivel joint 1 to tilt then use swivel

joint 2 to pan.

1

2

Figure 1.4 – Swivel Joints

Attaching the Sensor to the Mount Bracket

1 Align the bolts on the sensor’s backplate with the holes in the mount bracket. e 8-pin

connector on the sensor should be pointing towards the ground.

2 Place the lock washers onto the bolts aer the bolts are in the mount bracket holes.

3 read on the nuts and tighten (see Figure 1.5).

Figure 1.5 – Attaching the Sensor to the Mount Bracket

Page 20

CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE 19

Aligning the Sensor

In most applications, the goal is to position the beam’s elliptical footprint along the roadway.

is is done by pointing the hot spot of the sensor’s beam (middle of the sensor) at a target

location, then rolling the sensor so that the beam’s footprint lines up with the road. Aer

the basic alignment achieved during the mounting process, the viewnder is used to rene

the alignment.

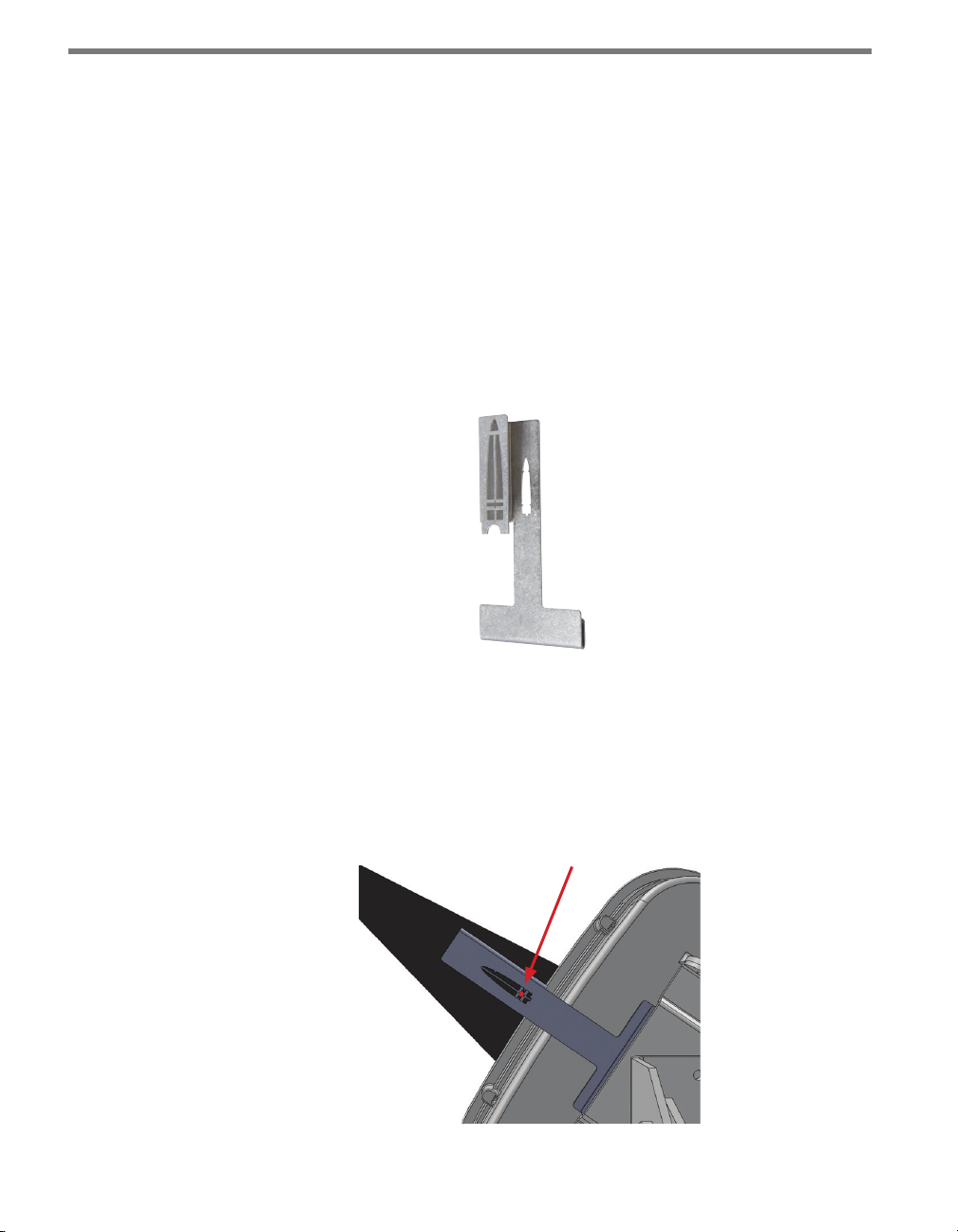

About the Viewfinder

e viewnder is a tool that helps you point the sensor at the target location and align the

sensor with the roadway (see Figure 1.6). It is designed with sighting features and visual

cues to facilitate proper alignment (these features and cues will be introduced from the

vantage point of an installer in a bucket truck).

Figure 1.6 – Viewfinder

e viewnder has two main sighting features:

1 Target crossbars (top and bottom)

2 e long, narrow alignment bar

When the sensor is properly pointed at the target, the target will line up between the two

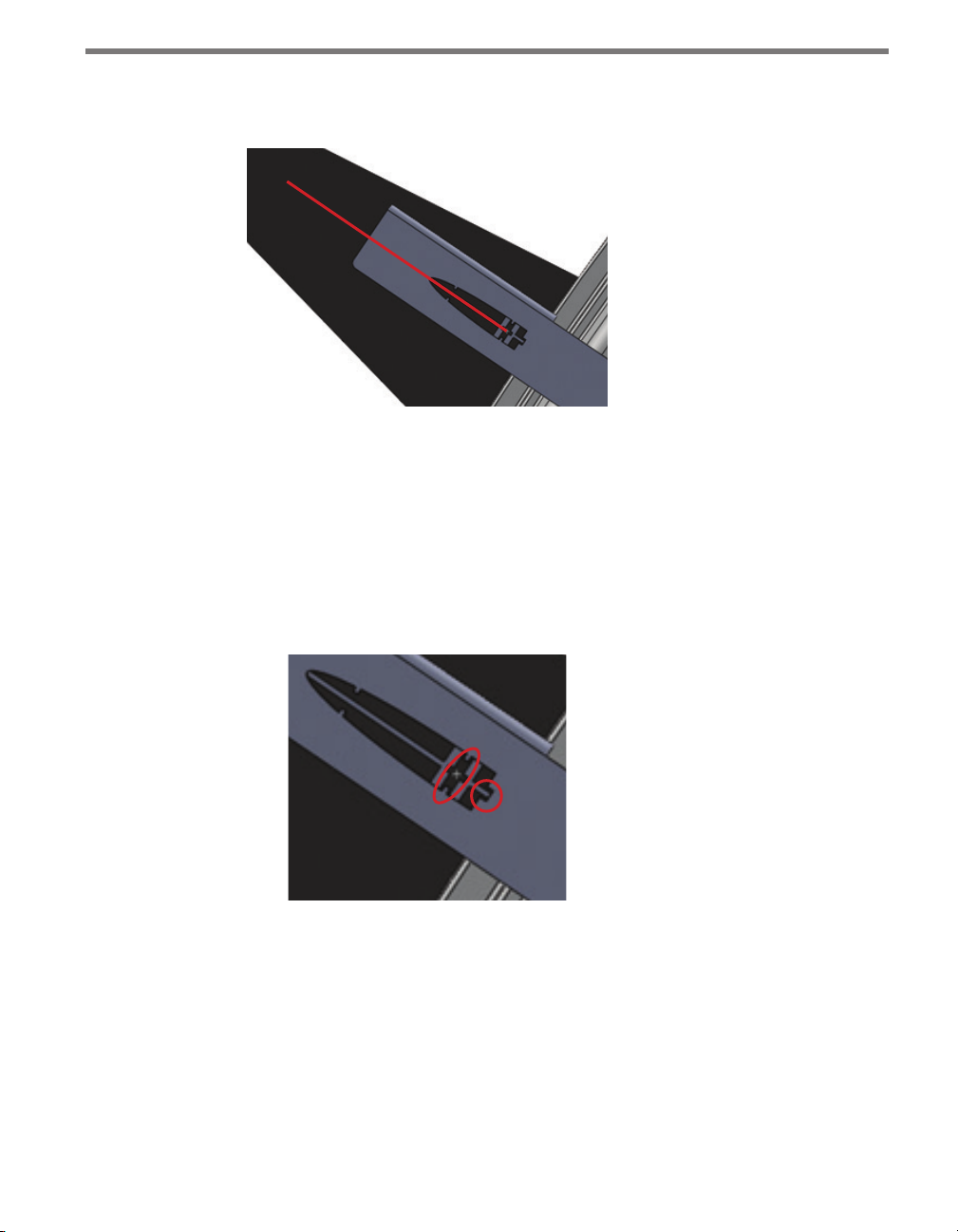

notches in the target crossbars, as shown in Figure 1.7.

Figure 1.7 – Target

Page 21

20 CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE

When the sensor is properly aligned with the roadway, the long, narrow alignment bar will

line up with the center of the lanes of interest (see Figure 1.8).

Figure 1.8 – Long, Narrow Bar Lines Up with Center of Lanes of Interest

In addition to having two main sighting features, the viewnder is used from two dierent

viewpoints:

Viewpoint 1 – Position your eye squarely behind the sensor. It is used to point the sen-

sor at the target and to align the sensor to the roadway.

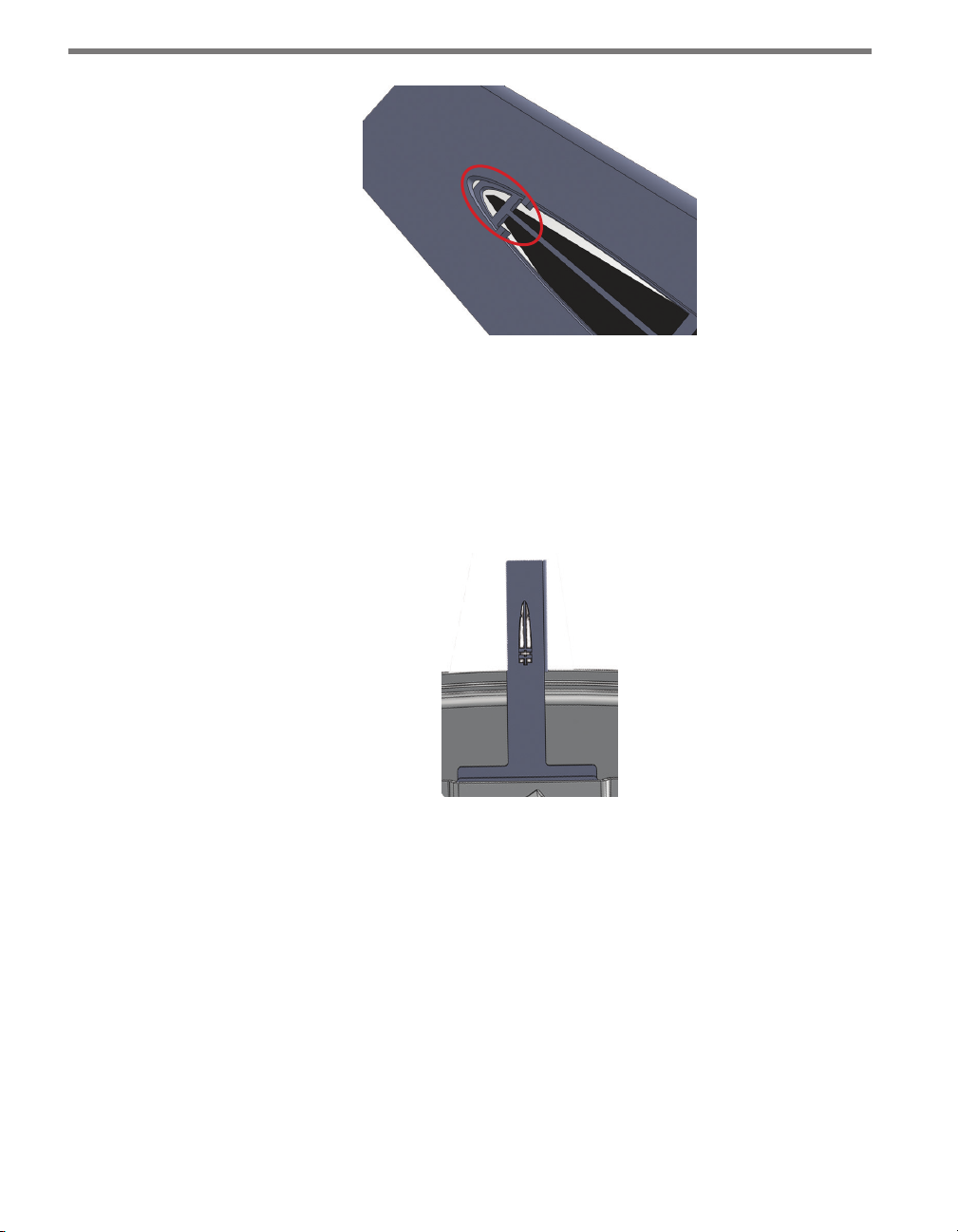

e viewnder has visual cues to help you achieve viewpoint 1: the two bottom side

tabs will line up between the target crossbars, and the bottom section of the long, nar-

row alignment bar will line up within the large notch (see Figure 1.9).

Figure 1.9 – Viewpoint 1

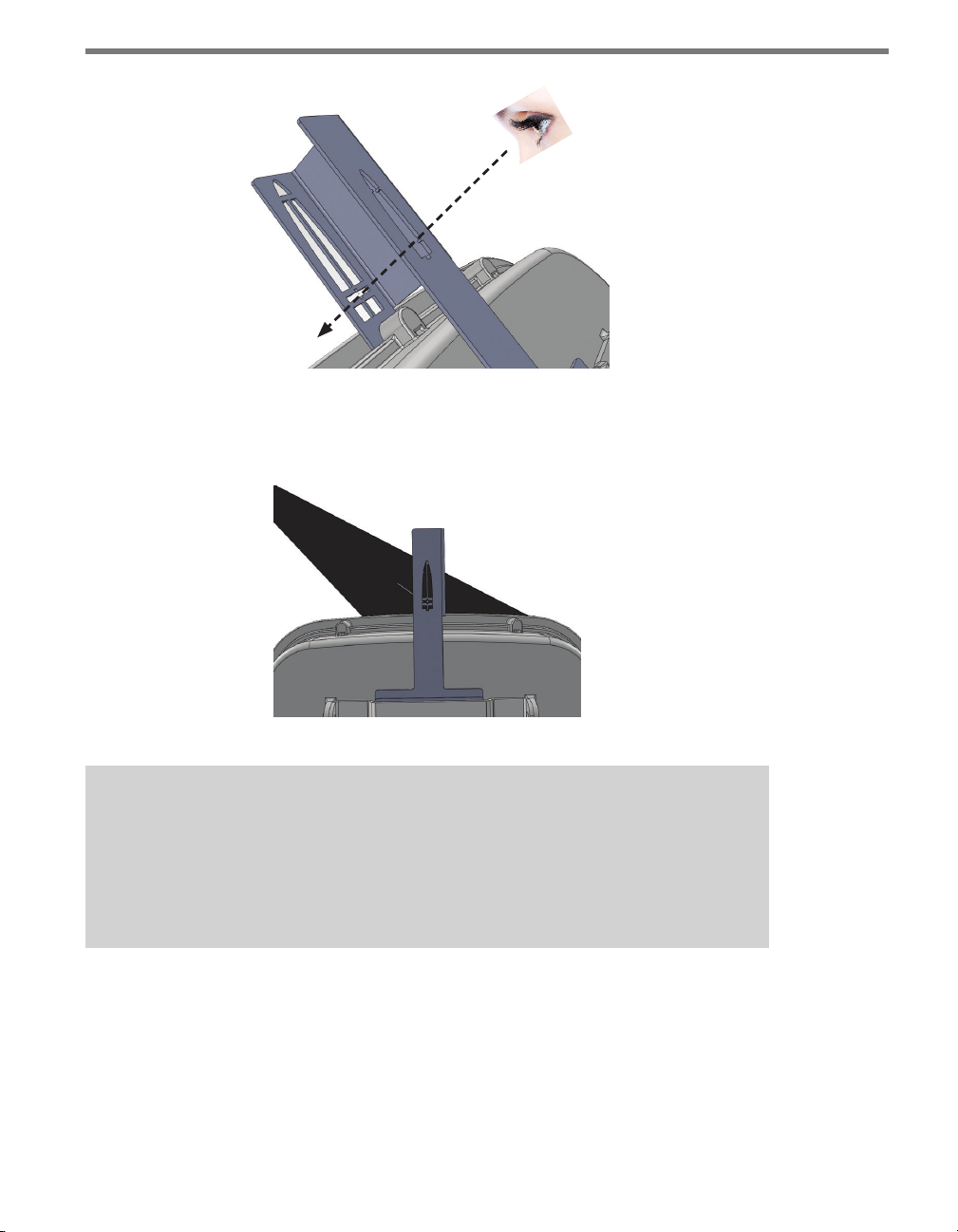

Viewpoint 2 – is viewpoint is used to verify alignment down the center of the lanes

of interest. It allows you to view the upstream detection area of the sensor.

Viewpoint 2 is achieved by moving your eye down and in toward the viewnder so that

the archway framed by the crossbar and the archway framed by the tabs are concentric

and the two top tabs match up with the top crossbar (see Figure #).

Page 22

CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE 21

Figure 1.10 – Viewpoint 2

Using the Viewfinder

With the sensor pointed roughly at the target location, follow these steps to rene the alignment:

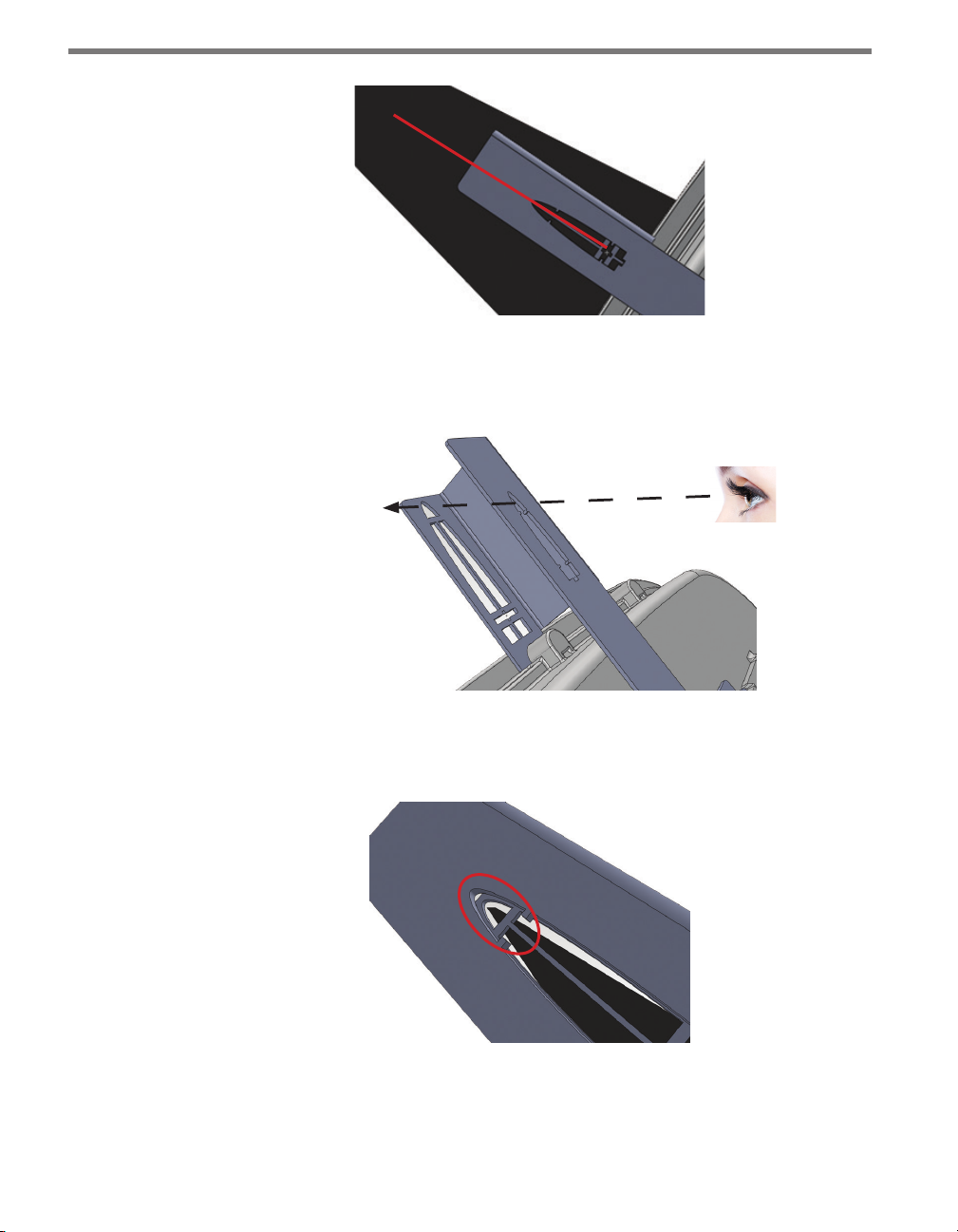

1 Attach the viewnder by centering the arched notch over the top-middle of the sensor

and inserting it securely into position (see Figure 1.11).

Figure 1.11 – Attach Viewfinder

2 With your eyes about one foot from the viewnder, look directly through the target

crossbars (viewpoint 1). Tilt the sensor until the space between the target crossbars is

at the level of the target location (see Figure 1.12).

Page 23

22 CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE

To target

location

Figure 1.12 – Viewpoint 1

3 Pan the sensor until the target location is centered between the notches in the target

crossbars. e target location should now be centered in the target sights.

Figure 1.13 – Target Location Centered in Target Sights

Note

For a better view, close one eye and move closer to the viewfinder.

If there is not enough headroom to look through the viewfinder, you can use a digital

camera directly behind the viewfinder window for visual verification.

4 Roll the sensor until the long narrow bar is parallel with the center of the lanes of inter-

est on the roadway. Vehicle paths should be parallel to the long narrow bar (see Figure

1.14).

Page 24

CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE 23

Figure 1.14 – Vehicle Paths Parallel to Long, Narrow Bar

5 Use viewpoint 2 to verify your alignment. Do this by moving your head down so that

you can see the top crossbar and the archway (see Figure 1.15).

To top of

detection area

Figure 1.15 – Viewpoint 2

Make sure the archways overlap and the top tabs line up with the top crossbar (see

Figure 1.16).

Figure 1.16 – Overlapping Archways

Vehicle paths should still be parallel to the long, narrow bar. If everything lines up,

move on to step 6. If not, your alignment is o and you need to repeat steps 2–4.

Page 25

24 CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE

6 Tighten down the pan and tilt bolts, then tighten down the four bolts on the backplate.

If you are using the sensor on a curved road, you can aim the sensor so that it bisects the

curve of the road and still hits your nearest and farthest ranges of interest. If the sensor is

mounted near the outside edge of the curved road, you may be able to bisect the curve with

little or no roll. If the road curves dramatically, you may need to reduce the down tilt of the

sensor so that the beam fans out more at the far ranges.

Applying Silicon Dielectric Compound

1 Tear the tab o the tube of silicon dielectric compound.

2 Squeeze about 25% of the silicon into the connector at the base of the SmartSensor

Advance (see Figure 1.17).

3 Wipe o any excess compound.

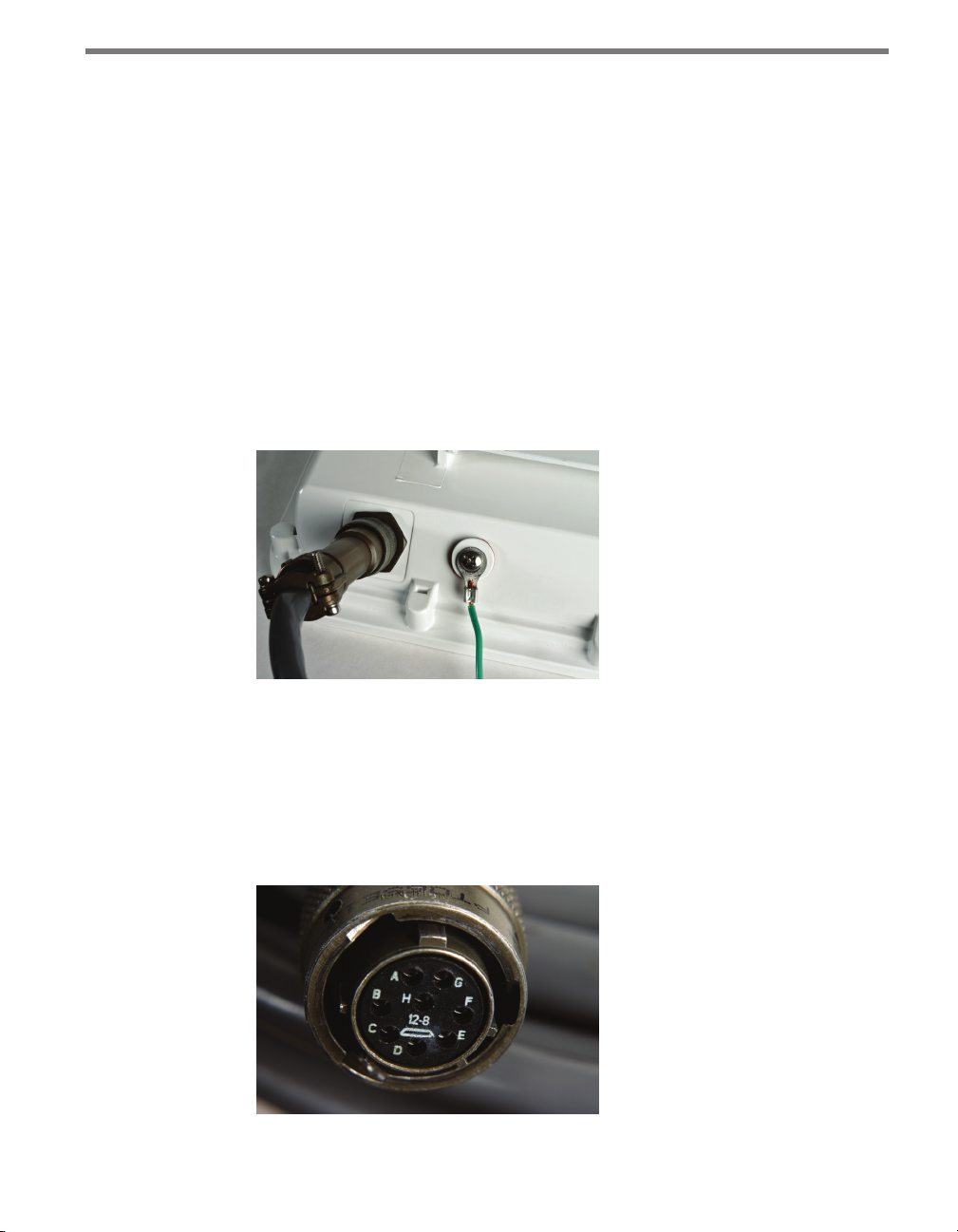

Figure 1.17 – Connector Receptacle (left) and Grounding Lug (right)

Connecting the SmartSensor 6-conductor Cable

e next step is to plug the SmartSensor 6-conductor cable into the connector. e sensor

connector is keyed to ensure proper connection (see Figure 1.18); simply twist the plug end

of the connector clockwise until you hear it click into place.

Figure 1.18 – Sensor 6-conductor Cable Connector

Page 26

CHAPTER 1 INSTALLING THE SMARTSENSOR ADVANCE 25

To avoid undue movement from the wind, strap the 6-conductor cable to the pole or run it

through a conduit, but leave a small amount of slack at the top of the cable to reduce cable

strain. Route the cable from the sensor location back to the main trac cabinet.

To set up your network in an orderly fashion, it is recommended that labeling be used

on the service end of each SmartSensor 6-conductor cable. A convenient way to label the

cables is to mark the last seven digits of the serial number on each sensor and the direction

of trac monitored (see Figure 1.19).

Figure 1.19 – Service End Labeling

Grounding the Sensor

e SmartSensor Advance must now be grounded:

1 Connect a grounding wire to the grounding lug on the bottom of the sensor (see Figure

1.17).

2 Connect the other end of the grounding wire to the earth ground for the pole that the

sensor is mounted on. Do not attempt to run the grounding wire back to the main

trac cabinet.

Page 27

Page 28

Connecting Power and

Surge Protection 2

In this chapter

Mounting the Backplate

Connecting AC Power

Providing System Surge Protection

Terminating the SmartSensor 6-conductor Cable

Contact Closure Connections

2

Aer installation, each SmartSensor Advance will need to be integrated into the main trafc cabinet for power and surge protection. is chapter contains information on how to

provide power and surge protection to the intersection preassembled backplate located in

the main trac cabinet.

e intersection preassembled backplate is 11 in. (28 cm) wide and 11.5 in. (29.2 cm) high.

Also available to use are the intersection preassembled 19-inch rack for server racks and the

intersection segmented preassembled backplate for easier installation in trac cabinets. All

wiring on the rack and backplates is done using stranded wires with wire ferrules for screw

terminal connections (see Figure 2.1).

Page 29

28 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Figure 2.1 – Intersection Preassembled Backplate

Please refer to the Click quick-reference guides for more comprehensive product instructions. Chapter 12 contains information on how Click products make the sensor compatible

with all standard control cabinets.

A pinout diagram showing the sensor cable’s pin-out and appropriate connection points

can be found in Appendix A of this document.

Mounting the Backplate

Use the following steps to mount the backplate in the trac cabinet:

1 Locate the area planned for mounting the backplate. e backplate can usually be

mounted on the side panel of a NEMA-style cabinet.

2 Attach the backplate with the U-channel mounting screws.

Note

If you have a 330 series (170/2070 style cabinet) with a 19-inch EIA rack, please con-

tact Wavetronix Technical Services for assistance. Wavetronix can provide modified

backplates that attach to a 19-inch rack.

Connecting AC Power

Since SmartSensor Advance operates on 10–28 VDC, the intersection preassembled backplates provide an AC power conversion option. e backplate includes an AC to DC power

converter, power surge and circuit breaker.

Page 30

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 29

Warning

Make sure power to AC mains is disconnected while wiring the AC input. If your installation does not require AC power, you will need to use surplus DC power inside

he trac cabinet. In this case, Wavetronix recommends you use the Click 221 (8 AC

surge protector) to protect the backplate and SmartSensor Advance units from DC

surges.

Figure 2.2 – Connecting AC Power to the Preassembled Backplate

Use the following steps to connect power to the AC terminal block on the bottom DIN rail

(see Figure 2.2):

1 Connect a neutral wire (usually a white wire) to the bottom side of the terminal block

labeled “N” for neutral.

2 Connect a ground wire (usually a green wire) to the bottom of the terminal block la-

beled “G” for ground. (see the Wiring Protective Earth Ground section below).

3 Connect a line wire (usually a black wire) to the bottom of the terminal block labeled

“L” for line.

4 Turn on AC mains power.

5 Press the circuit breaker switch on the le side of the top DIN rail to switch power to

the backplate. e switch is on if the button is below the level of the device housing; the

switch is o if the button is raised above the surface of the housing.

6 Verify that DC power is properly regulated by making sure the DC OK LEDs are il-

luminated on the Click 201/202/204.

Page 31

30 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Caution

An authorized electrical technician should install the intersection preassembled

backplate. Persons other than authorized and approved electrical technicians should

NOT attempt to connect the backplate to a power supply and/or trac control cabi-

net, as there is a serious risk of electrical shock through unsafe handling of the power

source. Extreme caution should be used when connecting the backplate to an active

power supply.

e AC power conversion section of the backplate will come pre-wired as shown in Figure

2.3. e three main components of the AC power conversion section include:

Click 201/202/204 AC to DC converter – A Click 201 provides 1 A of power and is ca-

pable of powering a single sensor; a Click 202 provides 2 A and can power two sensors;

a Click 204 provides 4 A and can power four sensors.

Click 210 circuit breaker – Interrupts power during overload conditions and provides

a convenient way to turn power on and o for the entire system.

Click 230 AC surge protector – Helps protect equipment from current surges on the

power lines.

Figure 2.3 – AC Power Conversion

Wiring Protective Earth Ground

All connections are surge protected when the protective earth ground is wired to the PE

terminal block on the backplate. Normally, the backplate should be mounted to the chassis

of the cabinet to provide a ground path. It is strongly recommended that you provide a low

impedance protective earth connection.

Page 32

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 31

Follow the steps below to provide a low impedance protective earth connection:

1 Connect one end of a protective earth ground wire to the bottom of the PE terminal

block. A 10 AWG stranded wire is recommended for protective earth ground connections and is also the largest that will t in the terminal block.

2 Connect the other end of the protective earth ground wire to a protective earth screw

terminal within the main trac cabinet.

Controlling DC Power Distribution

e Click 210 circuit breakers provide a convenient way to turn power on or o for each

sensor independently (see Figure 2.4). To enable or disable DC power to the backplate,

press the main circuit breaker (le side of upper DIN rail); to enable or disable DC power

to an individual sensor, press the individual circuit breaker (le side of each sensor’s set of

terminal blocks).

Push this button to

turn power on or o.

Figure 2.4 – DC Power Distribution

Note

The switch is ON when the switch button is level with the device housing; the switch

is OFF when the switch button is raised above the housing.

e four-approach preassembled backplate has 24 VDC power wired from the output of

the AC to DC convertor into a 5-position screw terminal on the le side of the T-bus (see

Figure 2.5). e green T-bus conducts DC power and RS-485 communications from the le

to the right side of the modules; the gray T-bus conducts only DC power from the le to the

right side of the modules.

Page 33

32 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Power

+24 VDC

( )

-DC

+RS-485

-RS-485

GND

red wire

( )

black wire

RS-485

Figure 2.5 – T-bus Pinout Diagram

Providing System Surge Protection

e Click 222 system surge protector is designed to prevent electrical surges conducted

along underground cables from damaging the cabinet equipment (see Figure 2.6).

Figure 2.6 – Click 222 Faceplate

Note

The SmartSensor Advance has built-in surge protection and so there is no need to

use a pole-mount box for surge protection on the sensor side of the cable. However,

it is strongly recommended that the sensor be connected to a surge protection device

in the main trac cabinet. If you choose not to use surge protection in your main

trac cabinet, please contact Wavetronix Technical Services for assistance.

When a Click 222 is present, the power and RS-485 serial connections on the T-bus and

faceplate are protected from surges on the incoming SmartSensor 6-conductor cables.

e Click 222 faceplate has four activity indicator LEDs:

PWR – Indicates that the device has power.

Page 34

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 33

DC Surge OK – Indicates that DC surge protection is operational.

TD – Indicates when data is transmitted over the T-bus or over the control bridge. is

LED does not indicate data transmitted on the A or B ports.

RD – Indicates when data is received over the T-bus or over the control bridge. is

LED does not indicate data received on the A or B ports.

Note

If the DC Surge OK LED is not on when the Click 222 is powered, call Wavetronix Technical Services for assistance.

e Click 222 provides the following three independent serial connections:

Top jack – control bridge

Middle jack – dedicated communications for sensor 2 detection calls

Bottom jack – dedicated communications for sensor 1 detection calls

e control bridge enables a multi-drop shared communication bus between all sensors

connected to the backplate. is allows control of all Advance sensors, rack cards and other

connected Click devices. e remaining two serial connection ports provide communications to only one sensor each, as outlined above.

On a four-sensor preassembled backplate (see Figure 2.7):

e sensor wired into the lemost terminal blocks will be connected to ports A and C

on the Click 222 on the le. Port A is for detection calls and port C is connected to the

control bridge.

e sensor wired to the second set of terminal blocks will be wired to ports B and D

on the Click 222 on the le. Port B is for detection calls and port D is connected to the

control bridge.

e sensor wired to the third set of terminal block from the le will be wired to ports

A and C on the Click 222 on the right.

e sensor wired to the rightmost terminal block will be wired to ports B and D on the

Click 222 on the right.

Page 35

34 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Port A & Port C Port B & Port D Port A & Port C Port B & Port D

x

OUT

S

SAdvance #1

IN

x

x

x

x

x

x

PWR

GND

485+

485-

485+

485-

x

x

x

x

x

x

x

x

x

x

x

x

OUT

SSAdvance #2

DRN

x

x

PWR

IN

x

x

GND

485+

485-

485+

485-

x

x

x

x

x

x

x

x

DRN

x

x

x

x

x

x

OUT

SSAdvance #3

PWR

IN

x

x

GND

485+

485-

485+

485-

x

x

x

x

x

x

x

x

x

SSAdvance #4

DRN

x

x

x

OUT

PWR

GND

485+

IN

x

x

x

x

x

x

x

x

DRN

485-

485+

485-

x

x

x

x

x

Figure 2.7 – Click 222 Ports A, B, C and D

Terminating the 6-conductor Cables

e SmartSensor Advance will receive power once each SmartSensor 6-conductor cable is

correctly landed into the plug-in terminals on the backplate (see Figure 2.8 and Table 2.1).

Each 6-conductor cable has one DC power wire pair, two RS-485 communication pairs and

a drain wire. e service end of the cable connects to plug-in terminals on the backplate

(see Figure 2.8).

Figure 2.8 – Color Label on Plug-in Terminals

Page 36

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 35

Note

Do not strip the service end of the cable until after it has been routed through conduit. The cable should be one continuous run without any splices.

Use the steps below to land the sensor cables:

1 Aer routing your SmartSensor 6-conductor cable into the cabinet, carefully strip back

the cable jacket and shielding on the service end of the cable.

2 Open the insulation displacement connectors on the plug by inserting a small screw-

driver into each square slot and rocking it back.

3 Insert the wire leads into the bottom side of the plug-in terminal according to the color

code shown in Table 2.1 and Figure 2.8. Make sure the wires are completely inserted

in the terminal.

4 Close the insulation displacement connector by reinserting the screwdriver into the

square slot and rocking it forward. e plug-in terminals will automatically complete

the electrical connection. ere is no need to manually strip the insulation on the end

of each wire.

ere are two measures in place to ensure that the plugs are always returned to their correct

terminal block sections.

First, for visual conrmation, one part of the plug is blue (see Figure 2.8) and must be

visually matched up to a blue terminal block. e location of the blue piece rotates in

the dierent plugs and terminal block sections: in the rst, the rst block is blue, in the

second, the second is blue, etc.

Second, the plugs are keyed (see the blue piece in Figure 2.8) so they will only t into

their correct terminal block sections.

Wire Color Signal

Red (PWR) DC+

Black (GND) DC-

White with Blue stripe (485+) Control bridge 485+ (port1)

Blue (485-) Control bridge 485 - (port 1)

White with Orange stripe (485+) Data bus 485+ (port 2)

Orange (485-) Data bus 485- (port 2)

Bare metal (DRN) Drain

Table 2.1 – Cable Wiring Color Code

Page 37

36 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Contact Closure Connections

e SmartSensor Advance now supports both the Click 112/114 and Click 172/174 cards.

SmartSensor Advance Extended Range only supports Click 112/114. Use the data bus ports

(A or B) on the Click 222 to connect to the contact closure cards. In some cases, several

contact closure cards can be daisy-chained together. However, if you are using the Click

172/174 cards, the chain should not be connected until each card has been independently

programmed (see Figure 2.9).

Figure 2.9 – Connecting Contact Closure Modules

Note

Wait to connect contact closure communications until after the sensor is pro-

grammed using the configuration software.

See Chapter 12 for more information on contact closure communications.

Page 38

Part II

Using SmartSensor Manager

Advance

Chapter 3 – Installing SmartSensor Manager Advance

Chapter 4 – Communication

Chapter 5 – Sensor Settings

Chapter 6 – Sensor Configuration

Chapter 7 – Channels-Alerts-Zones

Chapter 8 – Verify Channels-Alerts-Zones

Chapter 9 – Setup Output Communications

Chapter 10 – Templates

Chapter 11 – Tools

Chapter 12 – Programming Contact Closure Cards

Page 39

Page 40

Installing SmartSensor Manager

Advance 3

In this chapter

Installing SSMA

3

Aer the SmartSensor Advance is installed, use SmartSensor Manager Advance (SSMA)

to congure the sensor to the roadway and change sensor settings. SmartSensor Manager

Advance is soware that enables users to congure and interact with the SmartSensor Advance (SS200).

is part of the user guide is designed to illustrate SSMA functionality and describes the

basic steps and procedures needed to correctly congure the SmartSensor Advance.

Installing SSMA

e SSMA soware can be run on a Windows® PC with an operating system of Windows

XP or newer. It can also be run on a handheld computer running Windows Mobile. e

SSM Advance v3.0 Setup.exe le contains the Advance setup le.

Note

You must have administrator rights to run the setup program.

Page 41

40 CHAPTER 3 INSTALLING SMARTSENSOR MANAGER ADVANCE

Note

Microsoft .NET Framework version 3.5 or higher needs to be installed on your com-

puter before installing SSMHD. You can get the .NET Framework from the Microsoft

website.

Follow these steps to install SSMA on a PC:

1 To download the install le, go to the Wavetronix website at www.wavetronix.com.

2 Click the Support link near the top of the page. is will bring up a page with icons

from the three dierent Wavetronix product lines.

3 Click the SmartSensor icon. is will bring up drop-down menus allowing you to se-

lect a product by name or part number.

4 Select SmartSensor Advance and a list of links will appear.

5 Select the SmartSensor Manager Advance link (under Soware) to download the

SSMA install le.

6 Once you’ve downloaded the le, double-click on it. is will execute a setup program

that will copy all the necessary les to the hard drive and place icons in the Start menu

and on the desktop of the PC or laptop (see Figure 3.1).

Figure 3.1 – SSMA Setup Wizard

7 Select an installation location. e default location provided is normally “C:\Program

Files\Wavetronix.” Click Browse to choose another location (see Figure 3.2).

Page 42

CHAPTER 3 INSTALLING SMARTSENSOR MANAGER ADVANCE 41

Figure 3.2 – Location Installation

8 Click the Install Now button.

9 Aer SSMA is installed, you can create shortcuts to the SSMA soware on the desktop

and in the start menu using the corresponding checkboxes (see Figure 3.3). If no shortcuts are desired, uncheck the corresponding boxes.

Figure 3.3 – Shortcut Options

10 Click in the View release notes when nished checkbox to view the SSMA v3 release

notes. e release notes contain additional information about the current version of

the SSMA soware. A PDF reader program (i.e. Adobe Acrobat Reader) is required to

view the release notes.

11 Click Finish to complete the setup process.

Installing SSMA on a Handheld Computer

SSMA can be installed and will function on a handheld computer. Use these steps to install

SSMA on a handheld computer running Windows Mobile:

1 Ensure the handheld computer is connected to the PC and synced.

2 Click on the SSM Advance v3 Setup.exe le to run the setup program on the host

computer. e SSMA Setup Wizard will automatically check the host computer to see

if Microso ActiveSync (Windows XP and older) or Windows Mobile Device Center

(Windows Vista) is installed. ese are programs that are used to communicate with a

handheld device. If one of these programs is found, the option of installing SSMA to a

Page 43

42 CHAPTER 3 INSTALLING SMARTSENSOR MANAGER ADVANCE

Pocket PC device will become available.

3 Click the Pocket PC checkbox and then the Next>> button to install SSMA on a con-

nected Pocket PC device (see Figure 3.4). If both the Computer and Pocket PC boxes

are checked, the setup program will rst install the SSMA soware to the computer.

Figure 3.4 – Pocket PC Installation Program

4 Click Continue>> to start the Pocket PC installation process (see Figure 3.5). e

setup program runs the Add/Remove Programs application for Windows handheld

devices. If a Pocket PC device is connected to the computer, Add/Remove Programs

will immediately begin installing SSMA on the Pocket PC device. If a Pocket PC device

is not connected to the computer, SSMA will be downloaded the next time a Pocket PC

device is connected to the computer.

Figure 3.5 – Adding SSMA to a Pocket PC

5 Click OK once the download is complete.

Page 44

Communication 4

In this chapter

Serial Connection

Internet Connection

Virtual Connection

Multi-drop Network

Address Book

Viewing Connection Information

Uploading the Sensor’s Embedded Software

4

Once the sensors are installed, use the SSMA soware to change settings, view data and

congure the sensors to the roadway.

Launch SSMA by either clicking on the icon that was placed on your desktop or clicking

the icon found in the Start menu. e SSMA main screen shown in Figure 4.1 will appear.

If you are using SSMA on a laptop computer, you can use the panel in the lower le of the

main screen to change the size of the user interface on your computer. Click any of the three

squares to increase or decrease the size of the user interface.

Page 45

44 CHAPTER 4 COMMUNICATION

Figure 4.1 – SSMA Main Screen

e rst step is to make a connection to the sensor. e following three types of connections

can be made:

Serial connection – Made using RS-485 communication.

Internet connection – Made using an IP address and Serial-to-Ethernet adapter.

Virtual connection – Made for convenience in learning and demonstrating SSMA

functionality.

Communication settings are stored in the system registry each time a connection is established. Aer the rst connection is made to the SmartSensor Advance, the SSMA soware

will save the connection settings that were used. Click the lightning bolt icon on the right

side of the communication job area to make a connection using the most-recently-used

parameters stored in the registry.

Serial Connection

1 Click on Communication to access the Communication window (see Figure 4.2).

2 Select the Serial tab.

3 Set Port and Speed to the desired settings. e SSMA soware defaults to 9600 baud;

this baud rate is recommended and most likely will not need to be changed. Click the

Advanced… button for additional serial settings.

4 Click the Connect button.

Page 46

CHAPTER 4 COMMUNICATION 45

Figure 4.2 – Serial Connection (left) and Advanced Settings (right)

e Advanced Settings screen contains the following elds:

Timeout (ms) – Allows you to set an additional amount of time (in milliseconds) that

SSMA will wait for a response when communicating with the sensor.

Buer (bytes) – Contains the number of bytes used by SSMA to store data received

from the sensor.

Parity – is should always be set to None.

Stop Bits – is should always be set to 1.

Data Bits – is should always be set to 8.

Note

When a connection is made using the Isolated Sensor tab instead of the Multi-drop

Network tab, the software will connect to the first sensor it finds. If you have multi-

ple sensors and want to be able to connect to each one, use the Multi-drop Network

tab (see Multi-drop Network section below).

Internet Connection

1 Click on Communication.

2 Select the Internet tab (see Figure 4.3).

3 Enter the IP address of the Serial-to-Ethernet adapter to which the sensor of interest is

connected, or the domain name associated with the sensor in the Address eld. e IP

address is four octets, each ranging from 0-255, separated by dots (“.”). An URL address

can also be entered into this eld (i.e. sensor.earlink.com).

4 Enter the port number assigned to the Ethernet-to-Serial adapter in the Port eld. is

will be an integer value in the range of 0-65536. If you are using a Click 301 device,

the default port number will be 10001. Click the Advanced… button for additional

Page 47

46 CHAPTER 4 COMMUNICATION

Internet settings.

5 Click the Connect button.

Figure 4.3 – Internet Connection (left) and Advanced Settings (right)

e Advanced Settings screen contains the following elds:

Timeout (ms) – Allows you to set an additional amount of time (in milliseconds) that

SSMA will wait for a response when communicating with the sensor.

Buer (bytes) – Contains the number of bytes used by SSMA to store data received

from the sensor.

Virtual Connection

A virtual connection allows you to use the SSMA soware without being connected to an

actual sensor. Making a virtual connection can be useful for the following reasons:

To view a saved sensor setup le.

To play back previously logged trac.

To demonstrate functionality for dierent applications.

To create channel templates.

To review how the soware works.

To make a virtual connection:

1 Click the Communication button.

2 Select the Virtual tab (see Figure 4.4).

3 Select a virtual sensor le by clicking the magnifying glass icon. Click the Options…

button to select a tracker log le.

4 Click the Connect button.

Page 48

CHAPTER 4 COMMUNICATION 47

Figure 4.4 – Virtual Connection and Additional Options Screen

Virtual Sensor File

Since a virtual connection is not made to an actual sensor, a virtual sensor le (.vsf ) is used

to save the conguration settings much like an actual sensor’s Flash memory. If you are

making a virtual connection for the rst time, you will need to create a virtual sensor le by

clicking on the magnifying glass icon and entering a le name.

When you create a new virtual sensor, you will need to complete two steps. First, you need

to open the new le (see Figure 4.5).

Figure 4.5 – Open New File

Second, you will need to decide whether the new sensor is to be a virtual SmartSensor Advance Extended Range device of a virtual SmartSensor Advance device (see Figure 4.6). If

you would like the virtual sensor to emulate SmartSensor Advance Extended Range, answer

Yes to the second prompt. If you would like the virtual sensor to emulate SmartSensor Advance answer No to the second prompt.

Figure 4.6 – Type of Virtual Sensor

Page 49

48 CHAPTER 4 COMMUNICATION

Note

When you are connected using a virtual sensor file, changes that would normally be

saved to a sensor’s Flash memory will automatically be saved to the virtual sensor

file.

Backing up a virtual sensor le will change the le to a sensor setup le (.ssc) that can be

restored to an actual sensor. To convert a sensor setup le to a virtual sensor le, make a virtual connection and then use the Restore Sensor Setup tool in the Tools menu. To convert a

virtual sensor le to a sensor setup le, use the Back-up Sensor Setup tool.

Note

If you want to configure channels, alerts and zones for a future installation, you can

connect using a virtual connection, create a virtual sensor file and then back up the

configuration settings that you created. After the file is successfully backed up, the

virtual sensor file will change to a sensor setup file and can be restored to any sensor

in the field.

Selecting a Tracker Log File

A tracker log le is used to play back recorded trac. To select a tracker log le, click the

Options… button, click on the magnifying glass icon and select the tracker log le from a

list of existing les. If a tracker log le doesn’t exist, the SSMA soware will create a generic

looping trac pattern (see the Setup Channels-Alerts-Zones screen for instructions on how

to create a tracker log le).

Note

If a successful connection uses the sensor’s Com port that was being used to push

data, the data push will be suspended during the duration of the connection.

When a connection is made to the SmartSensor Advance, the main menu will appear and

all conguration options will become available (see Figure 4.7).

Page 50

CHAPTER 4 COMMUNICATION 49

Figure 4.7 – SSMA Main Menu (Connected)

If you have problems connecting:

1 Make sure that all power and communication wiring is correct.

2 Check the port settings (baud rate, port ID).

Connection failure can occur for various reasons; if a failure occurs repeatedly, call Wavetronix Technical Support at 801-764-0277 for assistance.

Multi-drop Network

e SSMA soware automatically discovers the multi-drop ID of sensors over the selected

port (normally you will auto-discover addresses over port 1).

Figure 4.8 – Multi-drop Network

Click the Automatically detect sensors radio button and then click the Connect button.

e Auto-Discovery window will appear with a list of each detected sensor and its device

ID, location and description (see Figure 4.9).

Page 51

50 CHAPTER 4 COMMUNICATION

Figure 4.9 – Auto-Discovery Window

e device IDs are based on the last four digits of the sensor’s serial number. If the sensor

IDs conict, they can be changed in the auto-discovery window by clicking on the desired

row. e Change sensor ID window will appear allowing you to change the sensor ID.

Address Book

e address book allows you to save device connection settings for future use. Click the

Address Book button located at the bottom of the Communication page to add new connection settings to the address book (see Figure 4.10).

Filters Address Books by serial

or Internet connection

Edits the

selected device

Adds a device to

the Address Book

Deletes a device

from an Address

Book

Deletes an

Address Book

Imports an

Address Book

Exports an

Address

Book

Figure 4.10 – Address Book and Address Book Filter

e following elds are recorded in the address book:

Device (e.g. SS200)

Serial Number (e.g. SS200 U100000570)

Device ID (e.g. 0570)

Connection (e.g. Internet, 10.234.6.76, 2103 or Serial,COM4,115200 bps)

Description (e.g. Springville, US-37 & Main, EB)

e description eld is 100 characters wide and can contain information such as the city,

intersection street names, approach indicator (eastbound/westbound/northbound/south-

Page 52

CHAPTER 4 COMMUNICATION 51

bound) all within a single eld. If the descriptions are entered in a uniform fashion this can

help when using the sort function to nd items in the list.

Warning

The address book file is a question mark delimited file. Do not enter question marks

into the address book fields or you will have problems loading the file.

Navigating and Customizing the Address Book

e following is true about navigating the address book list:

You can move up/down through the row list entries by clicking on a row in the list and

dragging the cursor up or down. (is action takes the place of a vertical scroll bar so

that you can view more than the rst 13 items in the address book.)

You can move le-right through the list entry columns by clicking on a row in the list

and dragging the cursor le for right. (is action takes the place of a horizontal scroll

bar so that you can view all the information in each column.)

e following is true about the columns in the address book:

You can sort columns alphanumerically by clicking on the column header.

You can show/hide columns by right clicking on the column headers and then selecting

the appropriate option.

You can widen/narrow columns using the arrow on the right-side of each column

header.

You can re-arrange columns by clicking in the middle of the corresponding column

header and dragging it to the le or right beyond the next column.

Note

As an alternative to using an address book, you can also organize the information

pertaining to your network of sensors with an external program or service and then

use the external program or service to launch SSMA. See Appendix E for more information.

Viewing Connection Information

Once connected, you can view additional information about the connection you have established by clicking on the moving arrows icon on the top-right of the main menu page or

on the bottom-right of the Communication screen (see Figure 4.11).

Page 53

52 CHAPTER 4 COMMUNICATION

Figure 4.11 – Connection Info Screen

Below is a list of the information available on the Connection Info screen:

Status – Shows that you are connected.

Device – Shows the Subnet and sensor ID.

Type – Shows the type of connection and baud rate.

Duration – Shows how long you have been connected.

Failures – Shows the amount of failures during the connection, the percentage rate of

failure and a link to the Communication Error Log.

Check Hardware

Aer you have connected to a sensor, you can check its hardware type by right-clicking

below the Tools menu option and selecting Sensor Versions (see Figure 4.12).

Figure 4.12 – Check Sensor Version

e two current hardware types are SmartSensor Advance and SmartSensor Advance Extended Range.

Page 54

CHAPTER 4 COMMUNICATION 53

Figure 4.13 – Sensor Versions Window for Advance (left) and Advance Extended Range (right)

Once connected, the hardware type can also be determined from the title bar. If the sensor

is and Extended Range sensor, it will say "(Ext. Range)" in the title bar of SSMA.

Communication Error Log

e error log contains all errors stored in the sensor’s memory buer. If you are having

trouble connecting, using the error log may be helpful in the troubleshooting process. If you

continue having trouble, save the error log le and contact Wavetronix Technical Services.

Note

You will need to save the error log file or it will be overwritten.

Click the View Error Log link to view the communications error log (see Figure 4.14). e

error log can also be accessed by clicking on the Error Log icon at the bottom of the Communication screen.

Figure 4.14 – Error Log

Page 55

54 CHAPTER 4 COMMUNICATION

Uploading the Sensor’s Embedded Software

Aer clicking the Connect button, the Version Control screen may appear notifying you

that the sensor’s embedded soware and the rmware embedded in the SSMA soware are

not the same version (see Figure 4.15). To view more soware version information, rightclick on the SSMA main menu page and select from the options that appear.

Figure 4.15 – Sensor’s Embedded Software Upgrade (left) and Details Table (right)

Click the Details button to view the rmware versions of both the SSMA soware and the

sensor.

Once the Version Control screen appears, you can do one of the following:

1 Upgrade the sensor’s embedded soware by clicking the INSTALL UPGRADE button.

2 Click the close button and continue the conguration process.

3 Find the version of SSMA soware that is compatible with the sensor’s embedded so-

ware.

Note

Clicking the close button and continuing configuration without upgrading may cause

problems with functionality.

Install the rmware upgrade if the SSMA rmware version date is more recent than the

sensor’s embedded soware version date. If the sensor’s rmware date is more recent than

the SSMA rmware version date, a warning will appear notifying the user that the sensor

rmware could be downgraded (see Figure 4.16).

Page 56

CHAPTER 4 COMMUNICATION 55

Figure 4.16 – Sensor Firmware Downgrade

e most recent version of SSMA can be obtained from the Wavetronix website (www.

wavetronix.com) under the Support tab.

Converting Detection Zones from Previous Software Versions

Previous versions of the SSMA soware supported 8 zones. SSMA version 2.0 and later supports 128 zones (8 channels, 4 alerts per channel and 4 zones per alert).

During the rmware upgrade process, SSMA will determine if the sensor is running any

previous versions. If this is the case, the SSMA soware will display a message asking you

to convert the conguration. If you choose to convert the conguration, the SSMA soware

will create a new conguration out of the previous existing conguration; if you choose

NOT to convert, a default conguration will be created.

Note

You can use command line arguments to perform a batch upgrade of sensors. See

Appendix E for information about command line arguments.

Page 57

Page 58

Sensor Settings 5

In this chapter

General Tab

Communication Tab

5

Click the Sensor Settings link on the main menu to change and save settings on the sensor.

e Sensor Settings window contains General and Communication tabs (see Figure 5.1).

Figure 5.1 – Sensor Settings Screen

General Tab

e General tab contains the following elds (see Figure 5.2):

Page 59

58 CHAPTER 5 SENSOR SETTINGS

Serial Number – Contains the sensor serial number and can only be edited if you are

in the Advanced Sensor Setup mode (conatct Wavetronix Technical Services for more

information).

Sensor ID – Allows you to enter a multi-drop address for the sensor. e ID default

is the last four digits of the sensor serial number. e sensor ID can be changed, but

no two sensors should have the same ID; the ID must be unique for all sensors on a

multi-drop bus.

Description – Allows you to enter a description for each sensor (i.e. its function, ap-

plication or intended use). Limited to 32 characters.

Location – Allows you to enter the location of the sensor or the approach. Limited to

32 characters.

RF Channel – Displays which radio frequency channel (or non-interference channel)

the device is transmitting on. Using multiple SmartSensor Advance devices in close

proximity will require each one to be set to a dierent RF channel. Similarly, using

multiple SmartSensor Advance Extended Range devices in close proximity will require

each one to be set to a dierent RF channel. However, a SmartSensor Advance device

will not interfere with a SmartSensor Advance Extended Range device, even if they

are on the same RF channel. is is because the hardware used to transmit the Digital

Wave Radar signal is congured dierently on the dierent devices.

Figure 5.2 – General Tab

Note

It is recommended that the sensor's detection sensitivity be reconfigured after

changing from one RF channel to another.

Page 60

CHAPTER 5 SENSOR SETTINGS 59

Note

The RF Channel drop-down list allows you to select whether the PGA starts at a value

of 7 or remains fixed during the auto-configuration process.

Units – Allows you to display either English (mph/feet) or metric (kph/meters) units.

Source – In normal use, the source is always the radar Antenna. However, in some

cases, other sources may be used for demonstrations or evaluations. When the source

is switched to Diagnostic, the antenna is no longer used. Instead, a predetermined sequence of trac will appear. is setting will always return to Antenna aer rebooting

the sensor.

Communication Tab

e Communication tab is used to specify baud rate and response delay for the sensor’s

RS-485 ports (see Figure 5.3).

Figure 5.3 – Communication Tab

e Communication tab contains the following settings:

Baud Rate – is section allows you to set the baud rate for ports 1 and 2. e green

arrow indicates the communication link (Port) on which SSMA is connected. e default value is 9600 bps.

Page 61

60 CHAPTER 5 SENSOR SETTINGS

Note

If you are using a Click communication device, the baud rate for the sensor and the

Click device must be the same. Port 2 is designated as the data bus and is normally

left at 9600 bps in order to match the default setting on a Click 112/114 card. If you

change this baud rate on the sensor, you will also need to change it on the rack card.

Response Delay – is is used to congure how long the sensor will wait before re-

sponding to a message received. is is useful for some communications devices that

are unable to quickly change transmission direction. e default value is 4 milliseconds

for ports 1 and 2.

Remove Multi-drop Prefix – You will only need to turn this switch ON if you are using

a device that does NOT support the use of a multi-drop prex (i.e. Click 100).

Page 62

Sensor Configuration 6

In this chapter

1. Installation Details

2. Automatic Radar Configuration

3. Manual Radar Adjustment

6

e Sensor Conguration screen contains installation details, an automatic conguration

feature and manual conguration tools (see Figure 6.1).

Figure 6.1 – Sensor Configuration Screen

Click the lighting bolt icon on the bottom right corner of the screen to save the current conguration to the sensor’s ash memory. e sensor’s ash memory is non-volatile memory.

Page 63

62 CHAPTER 6 SENSOR CONFIGURATION

1. Installation Details

e Installation Details screen allows you to position the sensor relative to the stop bar and

determine the direction of trac to be monitored (see Figure 6.2).

Direction of trac

Stop bar

SmartSensor

Advance

Figure 6.2 – Installation Details Screen

Changes

direction of

trac

Changes

location of

stop bar

Changes

position of

sensor

Height of

sensor

e roadway part of the screen is used to illustrate the sensor’s position relative to the stop

bar; the controls on the right side of the screen allow you to specify the direction of trac

to be monitored and the sensor’s position. e distance units are displayed in the bottomright corner of the screen.

e OK button saves the settings to the sensor; the Undo button restores the settings to the

screen’s initial values; and the Cancel button closes the screen without saving changes to

the sensor.

Changing the Trac Direction

e SmartSensor Advance can be congured to detect trac moving towards or away from

the sensor, but will not detect stationary vehicles.

e arrow displayed on the roadway represents the direction of trac ow being detected

by the sensor. Click the Tra c button to change the monitored trac direction. e direction of the arrow displayed on the button shows the direction that will be selected if the

button is clicked, and always points in the opposite direction as the arrow on the roadway.

Positioning the Stop Bar

e ability to move the stop bar up and down the display adds exibility in representing the

relative location of the sensor to the stop bar and the direction of trac ow. e location

of the stop bar is always represented as a distance of zero (the sensor range is relative to the

stop bar).

Position the stop bar by clicking on the stop bar or its label and dragging it anywhere on the

Page 64

CHAPTER 6 SENSOR CONFIGURATION 63

roadway, or by clicking the Stop Bar up/down arrows.

Positioning the Sensor

Position the sensor by clicking on the sensor or its label and dragging it anywhere on the

roadway, or by clicking the Sensor arrow buttons.

e top number, shown in the sensor position display (next to the blue triangle), represents

the sensor’s position to the right or le of the center of the lanes being monitored (Cartesian

x coordinate); the bottom number represents the sensor’s position in front of or behind the

stop bar (Cartesian y coordinate), together forming a Cartesian coordinate pair (x, y). e

sensor’s height is specied by setting the Height value and reects the sensor’s mounting

height above the roadway (Cartesian z coordinate).

e resulting (x, y, z) coordinates describe the sensor’s position relative to the roadway and

are used to translate the sensor’s native range measurements to range measurements that

are relative to the roadway’s frame of reference. e sensor position is also used in the Beam

Alignment tool (see Tools).

Note

The sensor’s range is updated whenever the stop bar is moved.

Resetting Zones After Sensor Relocation

When the sensor location is changed, existing zones may no longer be within the sensor’s

detection range and the message below will appear (see Figure 6.3):

Figure 6.3 – Sensor Location Changed

It is always recommended to rst position the sensor and then congure detection zones.

However, if the sensor location is modied aer zone conguration, you can do one of the

following:

1 Manually check all detection zones and modify zones as needed (recommended). All

zones will still be available and their location relative to the sensor will be preserved.

If le uncorrected, the zones may no longer perform the desired detection function.

2 Reload only the channel conguration from a backup le created from the existing

conguration (the out-of-range zones will be deleted and the desired detection functions may be compromised).

Page 65

64 CHAPTER 6 SENSOR CONFIGURATION

3 Reload the individual channel template les used in the current conguration (the

out-of-range zones will be deleted and the desired detection functions may be com-

promised).

2. Automatic Radar Configuration

Click the Automatic Radar Conguration button and the Automatic Radar Conguration

screen will appear (see Figure 6.4).

Figure 6.4 – Automatic Radar Configuration Screen for Advance (left)

and Advance Extended Range (right)

Note

The ranges displayed in the Automatic Radar Configuration window will depend upon

whether you have SmartSensor Advance or SmartSensor Advance Extended Range.

The scale on the right side of the road view indicates the ranges.

Click the Play button to begin the auto-conguration process. e playing time will be shown

in the top-le corner of the screen. Aer approximately three minutes, trackers (sensor detections) will begin to appear on the roadway and the process will change to Step 2 Adjusting

resholds. e Pause button pauses the auto-conguration process; the Stop button will

terminate auto-conguration. e Close button closes the screen and returns to the Sensor

Conguration job menu. If the conguration process is running, it will continue to run aer

closing. To terminate the automatic radar conguration process, press the Stop button.

e semi-transparent message window can be toggled on/o by clicking the Show>> and

<<Hide labels. e roadway range scale can be toggled on/o by clicking the feet label.

e following is a list of tracker display data that can be viewed by clicking the Range ()

display bar at the base of the roadway:

Page 66

CHAPTER 6 SENSOR CONFIGURATION 65

Range – Shows the distance from the stop bar.

Speed – Shows the speed.

Estimated Time of Arrival – Shows the estimated time it will take to arrive at the stop

bar.

Tracker ID – Shows the ID number for each tracker.

Blank – (no tracker data shown)

Disabled – (no tracker shown)

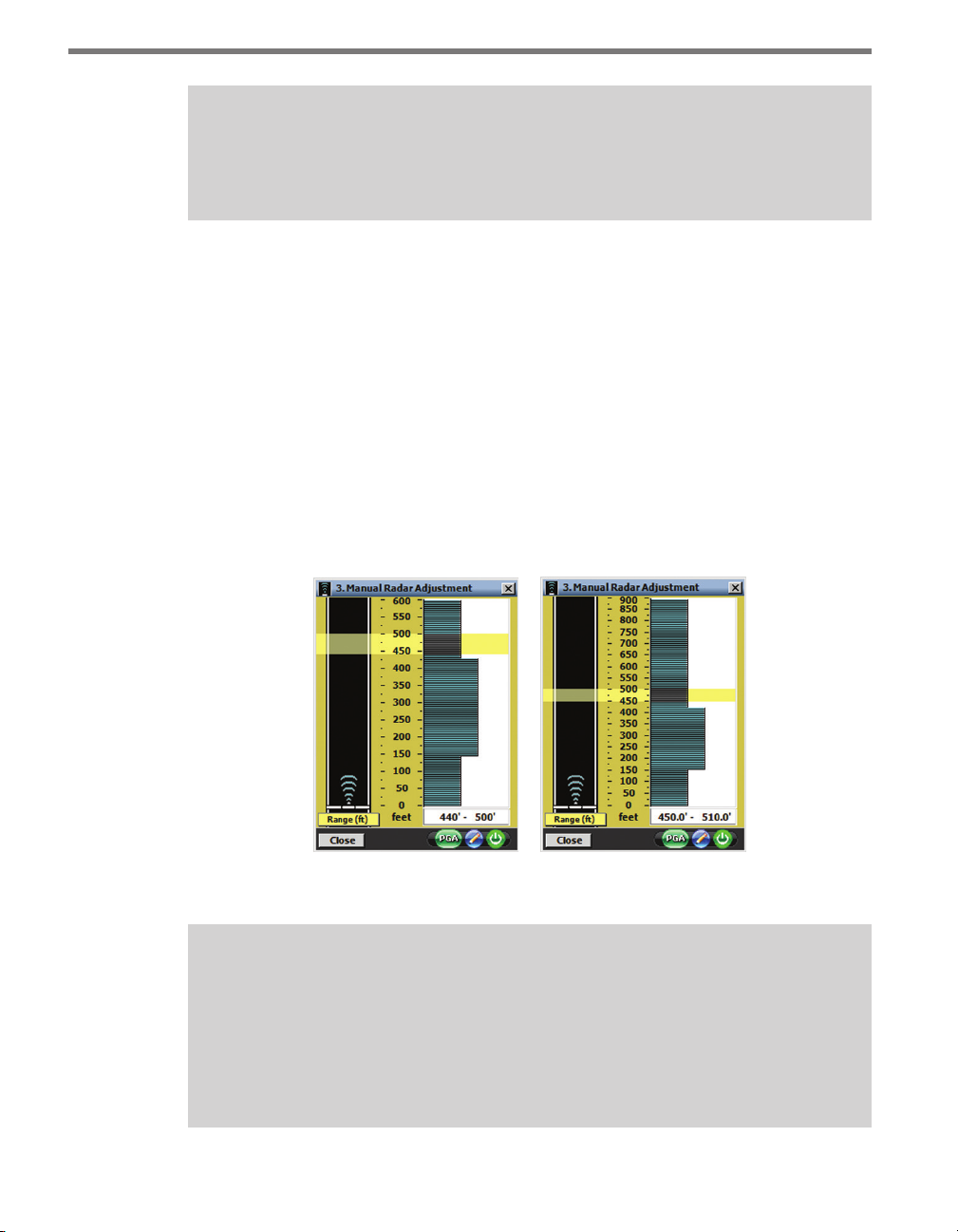

3. Manual Radar Adjustment

e Manual Radar Adjustment screen is used to ne-tune the results of the automatic radar

conguration process (see Figure 6.5).

Figure 6.5 – Manual Radar Adjustment Screen for Advance (left)

and Advance Extended Range (right)

Note

The ranges displayed in the Manual Radar Adjustment window will depend upon

whether you have SmartSensor Advance or SmartSensor Advance Extended Range.

The scale on the right side of the road view indicates the ranges. The SmartSensor

Advance has 5-ft increments up to 600 ft, and the SmartSensor Advance Extended

Range has 7.5-ft increments up to 900 ft.