Page 1

SmartSensor 105

USER GUIDE

Page 2

SmartSensor 105

USER GUIDE

www.wavetronix.com 78 East 1700 South Provo, Utah 84606 801.734.7200

Page 3

© 2012 Wavetronix LLC. All Rights Reserved.

Wavetronix, SmartSensor, Click, Command, and all associated product names and logos are trademarks of Wavetronix LLC. All

other products or brand names as they appear are trademarks or registered trademarks of their respective holders.

Protected by U.S. Patent Nos. 6,556,916; 6,693,557; 7,426,450; 7,427,930; 7,573,400; 7,889,097; 7,889,098; 7,991,542; Canadian

Patent No. 2461411; and European Patent Nos. 1435036; 1438702; 1611458. Other U.S. and international patents pending.

e Company shall not be liable for any errors contained herein or for any damages arising out of or related to this document or the

information contained therein, even if the Company has been advised of the possibility of such damages.

is document is intended for informational and instructional purposes only. e Company reserves the right to make changes in the

specications and other information contained in this document without prior notication.

FCC Part 15 Compliance: e Wavetronix SmartSensor sensors comply with Part 15 of the Federal Communications Commission

(FCC) rules which state that operation is subject to the following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesirable operation. FCC compliance statements for applicable optional modules are to be found in the module specications. Unauthorized changes or modications

not expressly approved by the party responsible for compliance with the FCC rules could void the user’s authority to operate this

equipment.

Disclaimer: e advertised detection accuracy of the Wavetronix SmartSensor sensors is based on both external and internal testing, as

outlined in each product’s specication document. Although our sensors are very accurate by industry standards, like all other sensor

manufacturers we cannot guarantee perfection or assure that no errors will ever occur in any particular applications of our technology.

erefore, beyond the express Limited Warranty that accompanies each sensor sold by the company, we oer no additional representations, warranties, guarantees or remedies to our customers. It is recommended that purchasers and integrators evaluate the accuracy of

each sensor to determine the acceptable margin of error for each application within their particular system(s).

WX-500-0050

12/2011

Page 4

Contents

Chapter 1 Introduction 5

SmartSensor 105 Package 6 • Selecting a Mounting Location

6

Part I Installing the SmartSensor 105

Chapter 2 Installing the SmartSensor 105 11

Selecting the Oset and Mounting Height 11 • Attaching the

Mount Bracket to the Pole 13 • Attaching the Sensor to the

Mount Bracket 14 • Aligning the Sensor to the Roadway 15 •

Applying Silicon Dielectric Compound 16 • Connecting the

SmartSensor Cable 16

Chapter 3 Connecting Power and Surge Protection 17

Connecting Lightning Surge Protection 17 • Connecting AC

Power Conversion 21 • Connecting DC Power 24 • Wiring

Communication 26

Part II Using SmartSensor Manager

Chapter 4 Getting Started with SmartSensor Manager 31

Installing SmartSensor Manager 31 • About Screen 32 • Table

of Contents 32

Chapter 5 Communication 35

Serial Connection 36 • Modem Connection 38 • Internet

Page 5

Connection 39 • Firmware Upload 41 • Connection Properties 43 • Address Book 44 • Communication Error 46

Chapter 6 Sensor Settings 49

Sensor Info 49 • Sensor Settings 50 • Sensor Date & Time 56

• Operating Mode 57

Chapter 7 Lane Setup 59

Lane Conguration – Automatic 59 • Lane Conguration –

Manual 62 • Verifying Lane Conguration 67

Chapter 8 Data Collection 73

Data Collection Setup 73 • Data Download 76 • Data Logs

78

Chapter 9 Tools 83

Hyperterminal 83 • Firmware Upload 84

Chapter 10 Contact Closure Communications 87

Selecting the Contact Closure Model 87 • Programming

Sensors for Use with Contact Closures 89 • Programming

Contact Closures 90

Chapter 11 Appendix 91

Appendix A – 9-conductor Cable Denitions 91 • Appendix

B – Old Cable Denitions 93 • Appendix C – Cable Lengths

95 • Appendix D – Direct Serial Connections 97

Page 6

Introduction

In this chapter

SmartSensor Package

Selecting a Mounting Location

e Wavetronix SmartSensor 105 utilizes patented Digital Wave Radar™ technology to

detect lane occupancy, trac volume and average speed in up to eight lanes of trac simul-

taneously. Classied as Frequency Modulated Continuous Wave (FMCW ) radar, SmartSensor collects data using a 10.525 GHz (X-band) operating radio frequency.

e installation and conguration process is quick and easy. Once installed, SmartSensor

congures automatically, requires little or no on-site maintenance and may be remotely recongured. is user guide provides the step-by-step process for installing and conguring

the SmartSensor, including mounting and alignment guidelines and instructions for both

automatic and manual sensor congurations. Any questions about the information in this

guide should be directed to Wavetronix or your distributor.

Caution

Do not attempt to service or repair this unit. This unit does not contain any components and/or parts serviceable in the field. Any attempt to open this unit, except

as expressly written and directed by Wavetronix, will void the customer warranty.

Wavetronix is not liable for any bodily harm or damage caused if service is attempted

or if the back cover of the SmartSensor unit is opened. Refer all service questions to

Wavetronix or an authorized distributor.

Page 7

6 INTRODUCTION SMARTSENSOR 105 USER GUIDE

SmartSensor 105 Package

A typical sensor package contains the following items:

10.525 GHz SmartSensor Radar Trac Sensor

SmartSensor mounting kit

SmartSensor cable

SmartSensor Manager software

SmartSensor User Guide

Caution

Check the packing slip for actual contents. If any of these items are missing, note the

serial number located on the back of the sensor and contact your distributor.

Additional products may be purchased through your distributor. e following optional

items are not included unless specically ordered (check packing list for actual inventory):

Click 172/174™ contact closure adapter

Click 200™ surge protector

Click 201/202™ AC to DC converter

Click 210™ circuit breaker and switch

Click 230™ AC surge module

Selecting a Mounting Location

Consider the following guidelines when selecting a mounting location:

Lane Coverage – Sensor mounting locations should be selected so that all monitored

lanes are within 10 to 200 ft. (3 to 61 m) and run parallel with each other. If more than

eight lanes need to be simultaneously monitored, consider using multiple sensors or

the SmartSensor HD, which can monitor up to 10 lanes simultaneously.

Parallel Lanes – When the sensor is used to collect both mainline and ramp data, the

pole position should be selected so that the on and o ramp lanes run parallel with the

mainline. If lanes are not parallel, installation of multiple SmartSensor units should be

considered to achieve the sensor’s ±2° side-to-side angle requirement.

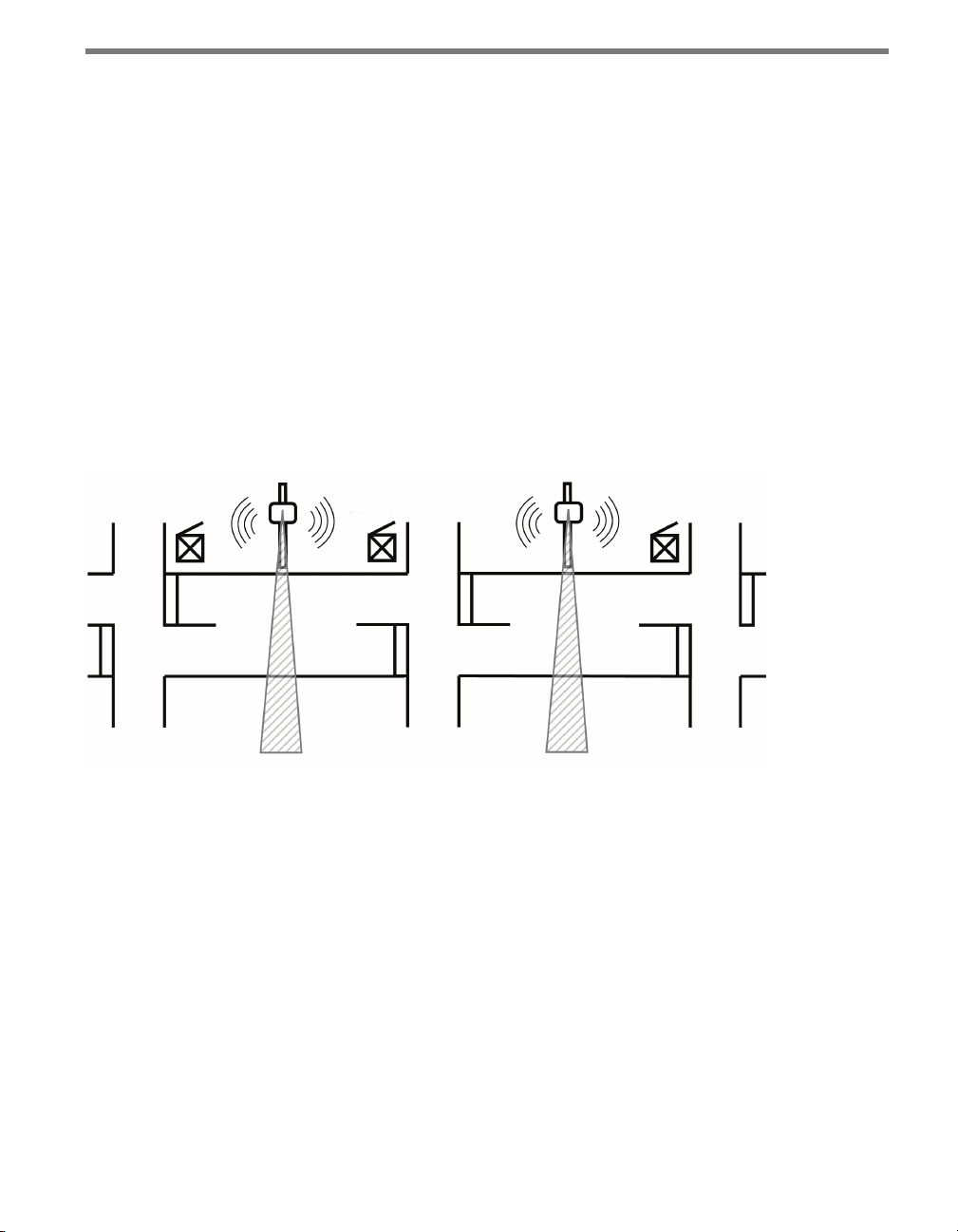

Sensors on the Same Pole – When multiple sensors are mounted on the same pole,

they will not be subject to interference if they are congured to operating using different RF channels and are separated vertically by a few feet. e higher sensor would

typically be used for the lanes further from the pole in order to minimize occlusion.

Sensors on Opposing Poles – SmartSensor units facing each other on opposing poles

should operate on dierent RF channels and be separated by a 40-ft. (12.2-m) lateral

oset, if possible.

Page 8

INTRODUCTION SMARTSENSOR 105 USER GUIDE 7

Line of Sight – e SmartSensor is designed to work accurately in the presence of

barriers, but in general if there is an alternate mounting location that would avoid any

type of structural occlusion, this is preferred. Avoid occlusion by trees, signs, and other

roadside structures.

Neighboring Structures and Parallel Walls – It is also preferred that sensor locations

have a 30-ft. (9.1-m) lateral separation from overhead sign bridges, overpasses, tunnels,

parallel walls and parallel-parked vehicles in order to avoid multiple reection paths

from a single vehicle.

Mounting Height – e mounting height should be based upon the oset from the

lanes of interest. For each oset, the minimum, maximum and recommended range

of heights is shown in Table 1.1, found in chapter 1. In general, the range of recommended heights is between 9 and 50 ft. (2.7 to 15.2 m).

Mounting Oset – e minimum recommended oset from the edge of the rst lane

of interest is 10 ft. (3 m).

Arterial Locations – Sensor sites on arterials or other roadway segments with regu-

lated stop lines should be selected at mid-block positions to increase accuracy by increasing line of sight to stop-and-go vehicles.

9 – 50 ft.

(see

mounting

guidelines)

10 ft. min.

Roadway Roadway

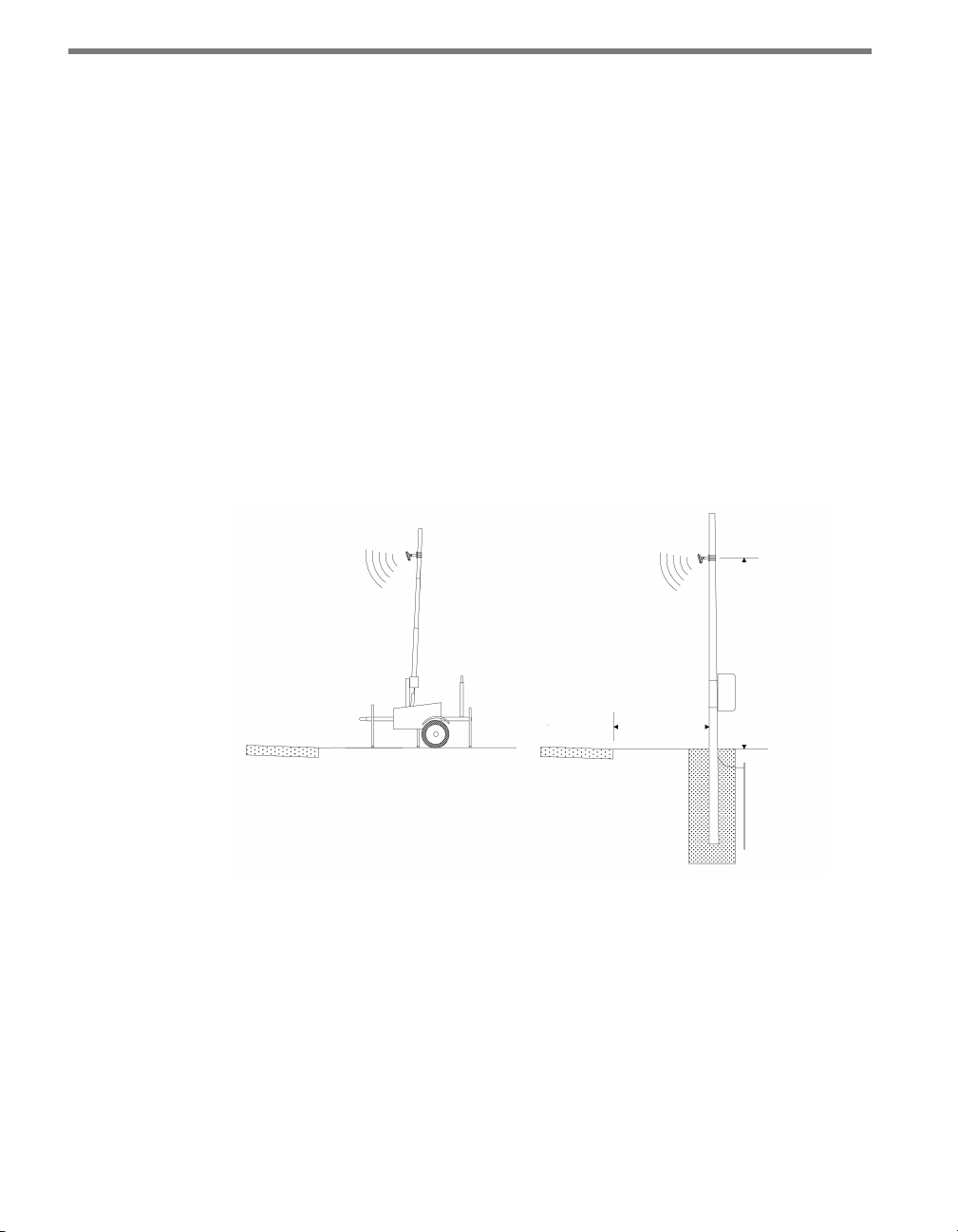

Figure I.1 – Portable (left) and Permanent (right) Sensor Stations

Freeway Locations – SmartSensor is often used at permanent ATR stations. e

number of stations along a single roadway and the distance between stations should

be selected to achieve adequate levels of statistical condence. Permanent ATR stations, which are selected to cover interstate, principal arterial and other national and

state highways, are used to establish seasonal adjustment factors for count data from

temporary collection sites (see Figure I.1).

Cable Lengths – Ensure that you have sucient homerun and sensor cabling. Cable runs

as long as 600 ft. (182.9 m) using 24 VDC operation and RS-485 communications. For

longer connections, alternate wired and wireless options should be considered.

Page 9

Page 10

Part 1

Installing the SmartSensor 105

Chapter 1 – Installing the SmartSensor 105

Chapter 2 – Connecting Power and Surge Protection

Page 11

Page 12

Installing the SmartSensor 105 1

In this chapter

Selecting the Oset and Mounting Height

Attaching the Mount Bracket to the Pole

Attaching the Sensor to the Mount Bracket

Aligning the Sensor to the Roadway

Applying Silicon Dielectric Compound

Connecting the SmartSensor Cable

1

Installing the SmartSensor 105 is quick and easy. Once installed, the SmartSensor requires

little or no on-site maintenance. is chapter will describe the installation process, including how to attach the sensor to the pole and how to correctly align the sensor.

Selecting the Oset and Mounting Height

After selecting a mounting location within the recommended range of osets (see intro-

duction), use Table 1.1 to select a mounting height. See Figure 1.1 for an illustration of

what is meant by oset and mounting height.

Page 13

12 CHAPTER 1 INSTALLING THE SMARTSENSOR 105

Center Line

Mounting Height

Oset

Figure 1.1 – Mounting and Aiming a SmartSensor

Oset from 1st

Detection Lane (ft

/ m)

10 / 3 12 / 3.7 9 / 2.7 15 / 4.6

11 / 3.4 12 / 3.7 9 / 2.7 16 / 4.9

12 / 3.7 13 / 4 10 / 3 16 / 4.9

13 / 4 13 / 4 11 / 3.4 17 / 5.2

14 / 4.3 14 / 4.3 11 / 3.4 17 / 5.2

15 / 4.6 15 / 4.6 12 / 3.7 18 / 5.5

16 / 4.9 15 / 4.6 12 / 3.7 18 / 5.5

17 / 5.2 16 / 4.9 13 / 4 18 / 5.5

18 / 5.5 17 / 5.2 14 / 4.3 19 / 5.8

19 / 5.8 17 / 5.2 14 / 4.3 19 / 5.8

20 / 6.1 18 / 5.5 15 / 4.6 20 / 6.1

21 / 6.4 18 / 5.5 15 / 4.6 21 / 6.4

22 / 6.7 18 / 5.5 16 / 4.9 22 / 6.7

23 / 7 19 / 5.8 16 / 4.9 23 / 7

24 / 7. 3 19 / 5.8 16 / 4.9 24 / 7. 3

25 / 7.6 20 / 6.1 17 / 5.2 25 / 7.6

26 / 7.9 20 / 6.1 17 / 5.2 26 / 7.9

27 / 8.2 21 / 6.4 18 / 5.5 27 / 8.2

28 / 8.5 21 / 6.4 18 / 5.5 28 / 8.5

29 / 8.8 21 / 6.4 18 / 5.5 29 / 8.8

30 / 9.1 22 / 6.7 19 / 5.8 30 / 9.1

31 / 9.4 22 / 6.7 19 / 5.8 31 / 9.4

32 / 9.8 22 / 6.7 19 / 5.8 32 / 9.8

Recommended

Mounting Height

(ft / m)

Center of Roadway

Minimum Mounting Height (ft / m)

Maximum Mounting Height (ft / m)

Page 14

CHAPTER 1 INSTALLING THE SMARTSENSOR 105 13

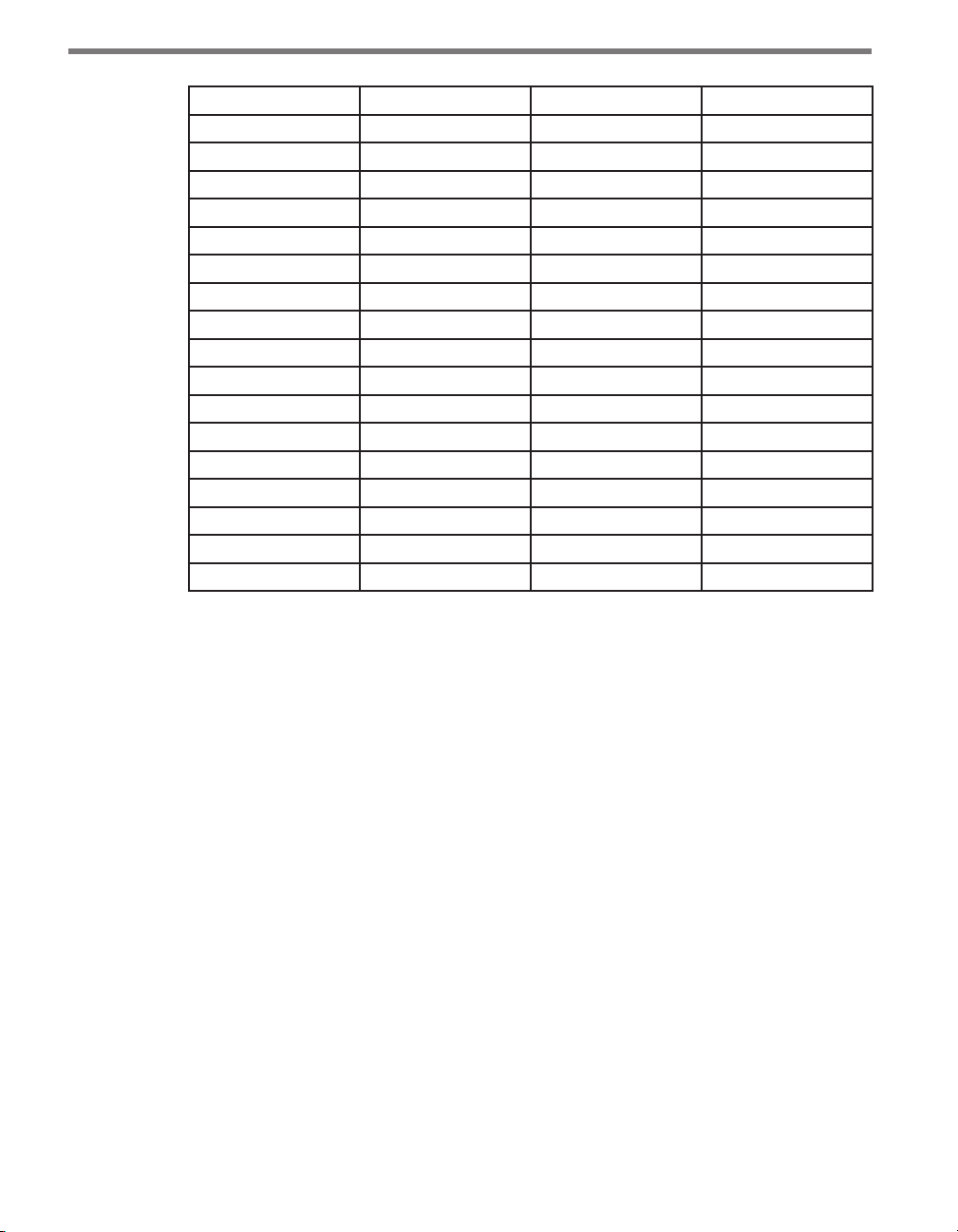

33 / 10.1 23 / 7 19 / 5.8 33 / 10.1

34 / 10.4 23 / 7 19 / 5.8 34 / 10.4

35 / 10.7 23 / 7 20 / 6.1 35 / 10.7

36 / 11 23 / 7 20 / 6.1 36 / 11

37 / 11.3 23 / 7 20 / 6.1 37 / 11.3

38 / 11.6 24 / 7. 3 21 / 6.4 38 / 11.6

39 / 11.9 24 / 7.3 21 / 6.4 39 / 11.9

40 / 12.2 25 / 7.6 22 / 6.7 40 / 12.2

41 / 12.5 25 / 7.6 22 / 6.7 41 / 12.5

42 / 12.8 26 / 7.9 22 / 6.7 42 / 12.8

43 / 13.1 26 / 7.9 22 / 6.7 43 / 13.1

44 / 13.4 27 / 8.2 23 / 7 44 / 13.4

45 / 13.7 27 / 8.2 23 / 7 45 / 13.7

46 / 14 28 / 8.5 23 / 7 46 / 14

47 / 14.3 28 / 8.5 24 / 7. 3 47 / 14.3

48 / 14.6 29 / 8.8 24 / 7. 3 48 / 14.6

49 / 14.9 29 / 8.8 24 / 7.3 49 / 14.9

50–180 / 15.2–54.9 30 / 9.1 25 / 7.6 Must be < oset

Table 1.1 – Mounting Height Guidelines

Attaching the Mount Bracket to the Pole

Before attaching the mount bracket to the pole, rst make sure that your cables are long

enough to reach the sensor height and to stretch across the distance from the sensor to the

cabinet.

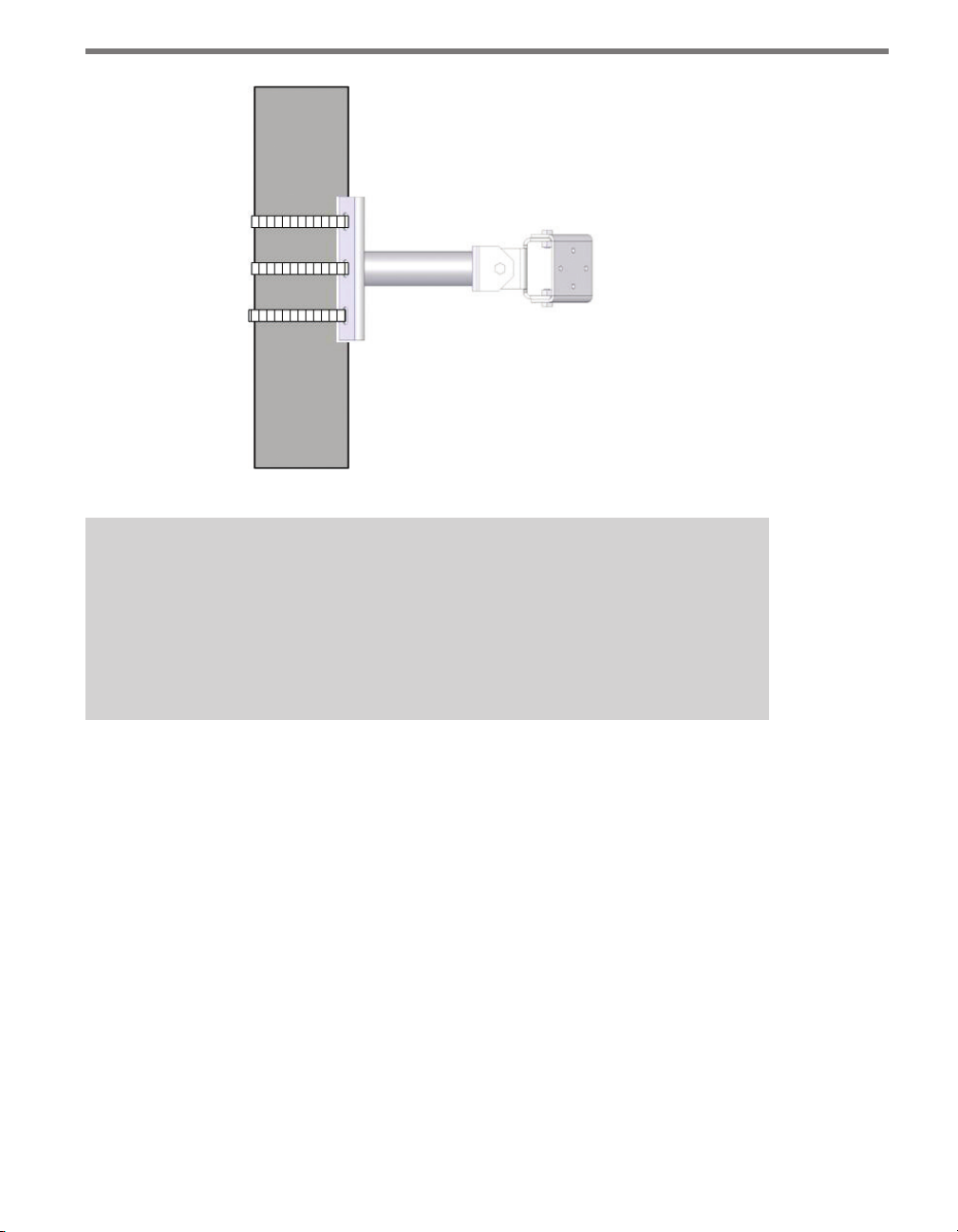

Follow the steps below to correctly attach the mount to the pole (see Figure 1.2):

1 Look up the recommended mounting height from Table 1.1.

2 Insert the stainless steel straps through the slots in the mount bracket.

3 Position the mount on the pole so that the head of the mount is pointing towards the

middle of the lanes of interest.

4 Tighten the strap screws.

Page 15

14 CHAPTER 1 INSTALLING THE SMARTSENSOR 105

Figure 1.2 – Attaching the Mount Bracket to the Pole

Caution

Depending on the site and type of trac, the sensor may tend to over or undercount.

If the sensor is overcounting, reduce the height of the sensor by three ft. (0.9 m) and

reconfigure the sensor. If the sensor is undercounting, increase the height of the sensor by three ft. (0.9 m) and reconfigure. Normally, reducing the height of the sensor

improves performance.

Attaching the Sensor to the Mount Bracket

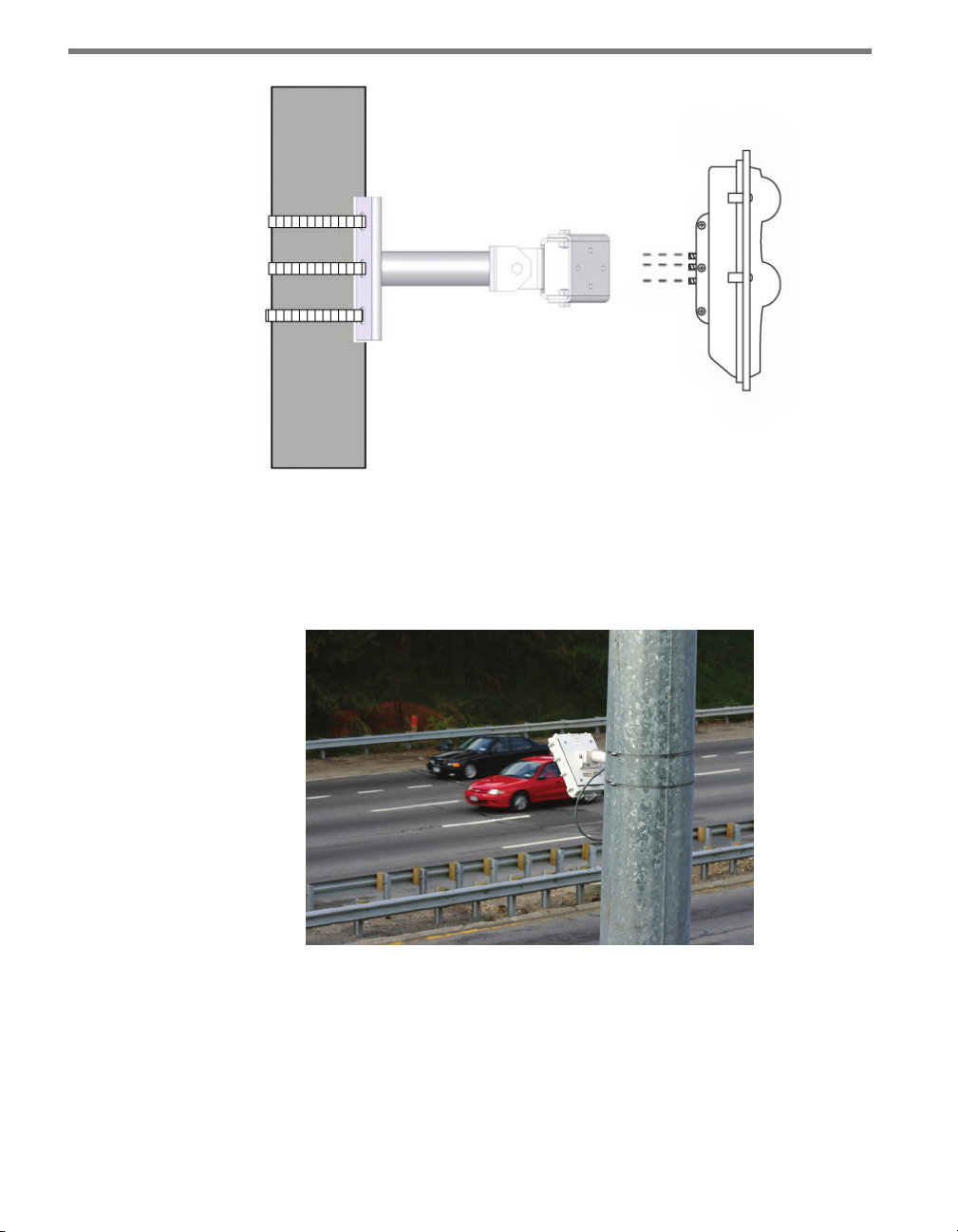

Use the following steps to securely fasten the sensor to the mount bracket (see Figure 1.3).

1 Align the bolts on the back of the SmartSensor with the holes in the mounting brack-

et. e large 25-pin connector on the SmartSensor should be pointing towards the

ground.

2 Place the lock washers onto the bolts after the bolts are in the mounting bracket holes.

3 read on the nuts and tighten.

Page 16

CHAPTER 1 INSTALLING THE SMARTSENSOR 105 15

Figure 1.3 – Attaching the Sensor to the Mounting Bracket

Aligning the Sensor to the Roadway

Follow the steps below to correctly align the SmartSensor (see Figure 1.4):

Figure 1.4 – Aiming the SmartSensor

1 Aim the front of the sensor at the center of the detection area. You may also refer to

Figure 1.1 as an illustration of where to aim the sensor.

2 Adjust the side-to-side angle to within approximately ±2° of perpendicular to the ow

of trac.

3 Tighten mounting bracket bolts.

Page 17

16 CHAPTER 1 INSTALLING THE SMARTSENSOR 105

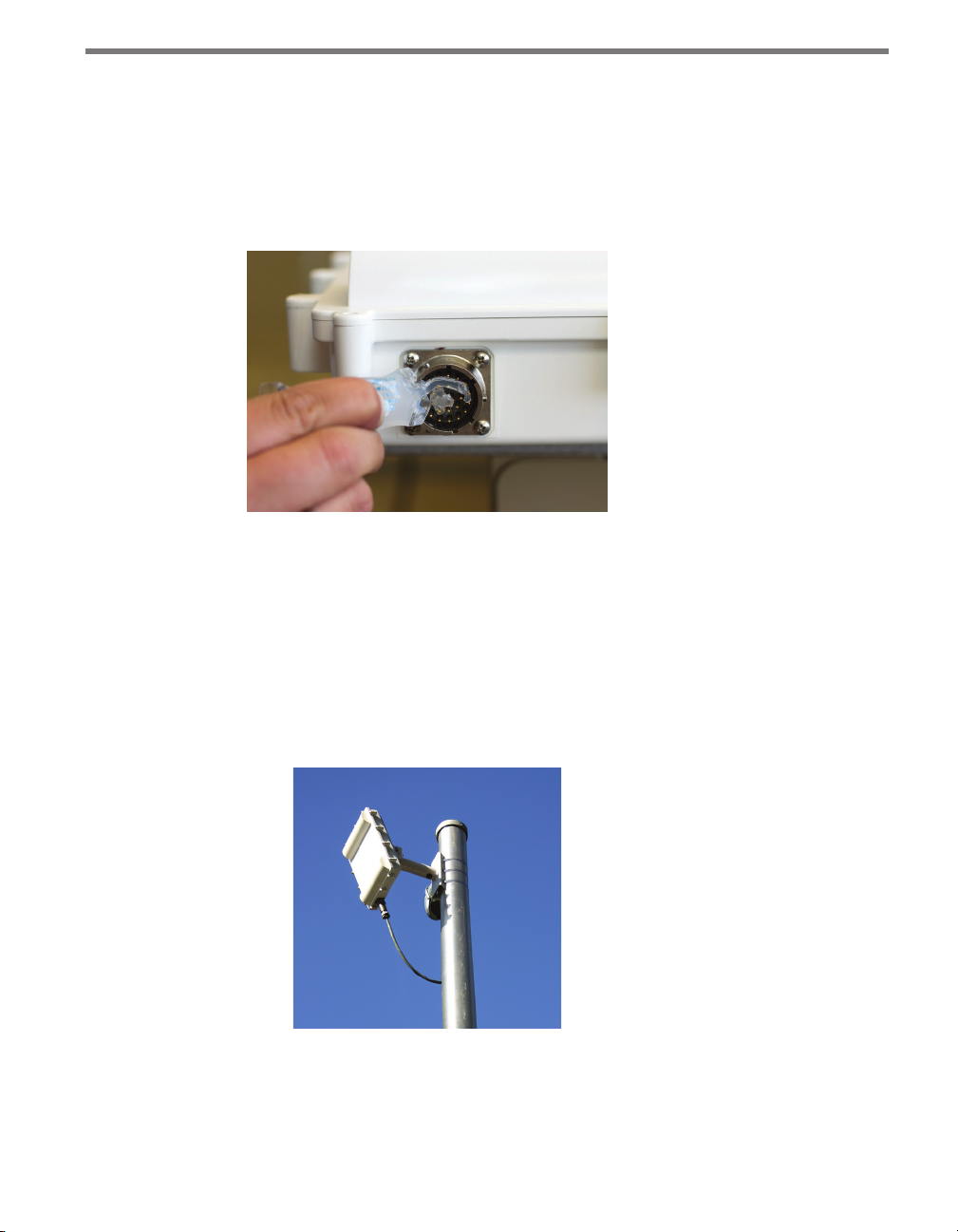

Applying Silicon Dielectric Compound

Use the following steps to correctly apply the silicon dielectric compound:

1 Tear the tab o the tube of silicon dielectric compound.

2 Squeeze about 25% of the silicon into the connector at the base of the SmartSensor as

shown in Figure 1.5. Be sure to wipe o any excess compound.

Figure 1.5 – Applying Silicon Dielectric Compound

Connecting the SmartSensor Cable

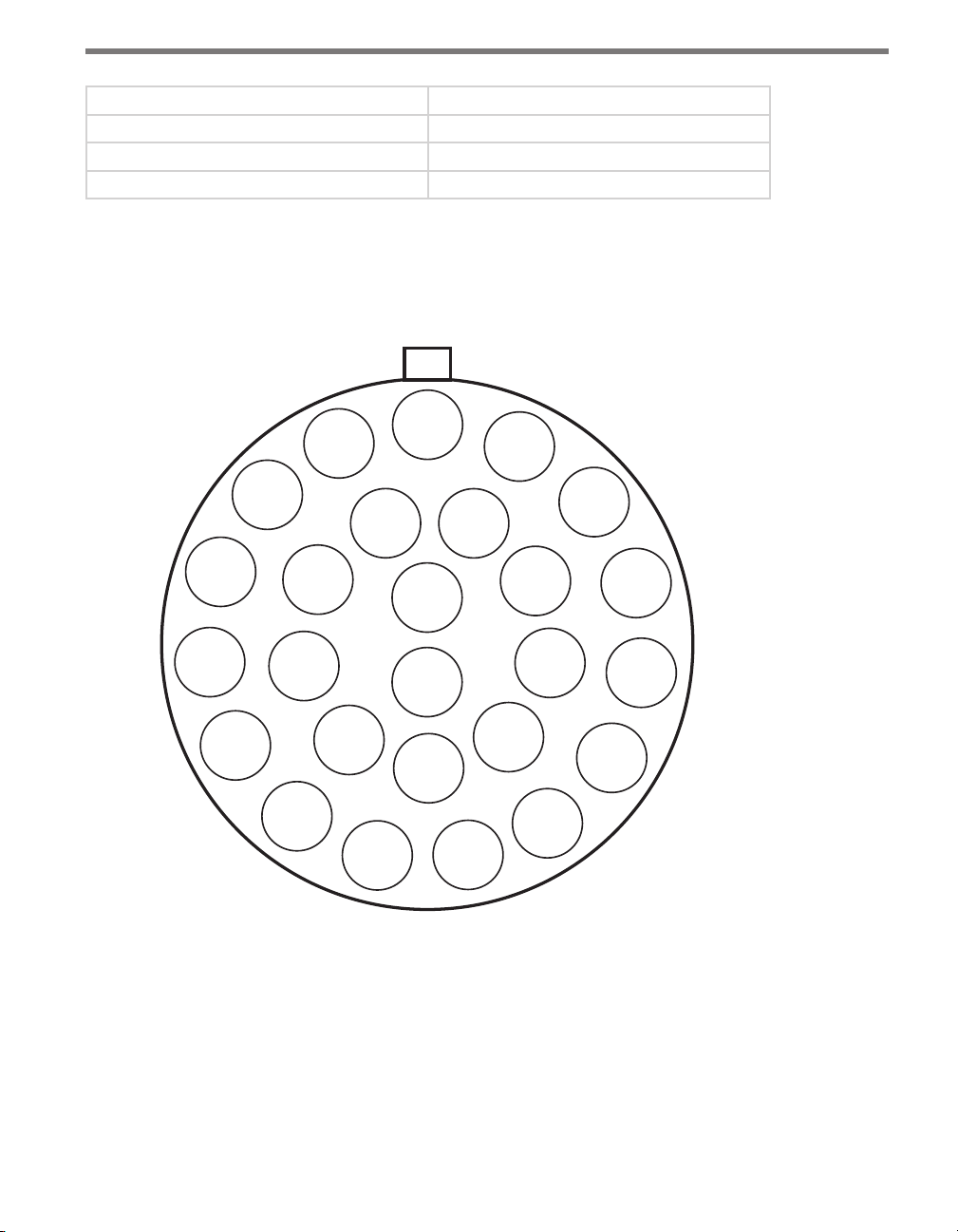

1 Attach the cable connector to the 25-pin connector at the base of the SmartSensor as

shown in Figure 1.6. e SmartSensor connector is keyed to ensure proper connection;

simply twist the connector clockwise until you hear it click into place.

2 Strap the cable to the pole or run it through a conduit to avoid undue movement from

wind and reduce cable strain.

Figure 1.6 – Attached Cable

Page 18

Connecting Power and

Surge Protection 2

In this chapter

Connecting Lightning Surge Protection

Connecting AC Power Conversion

Connecting DC Power

Wiring Communication

2

Once the sensor is installed, it will need to be wired for power and surge protection. is

chapter will explain how to connect lightning surge protection, AC power conversion, DC

power and basic communication.

Wavetronix Click products allow you to quickly and easily connect power and surge protection to your sensor application. Please refer to the Click quick-start guides for more comprehensive product instructions. Chapter 9 contains information on how Click products

make the sensor compatible with all standard control cabinets.

A pinout diagram showing the sensor cable’s pinout and appropriate connection points can

be found in Appendix A of this document.

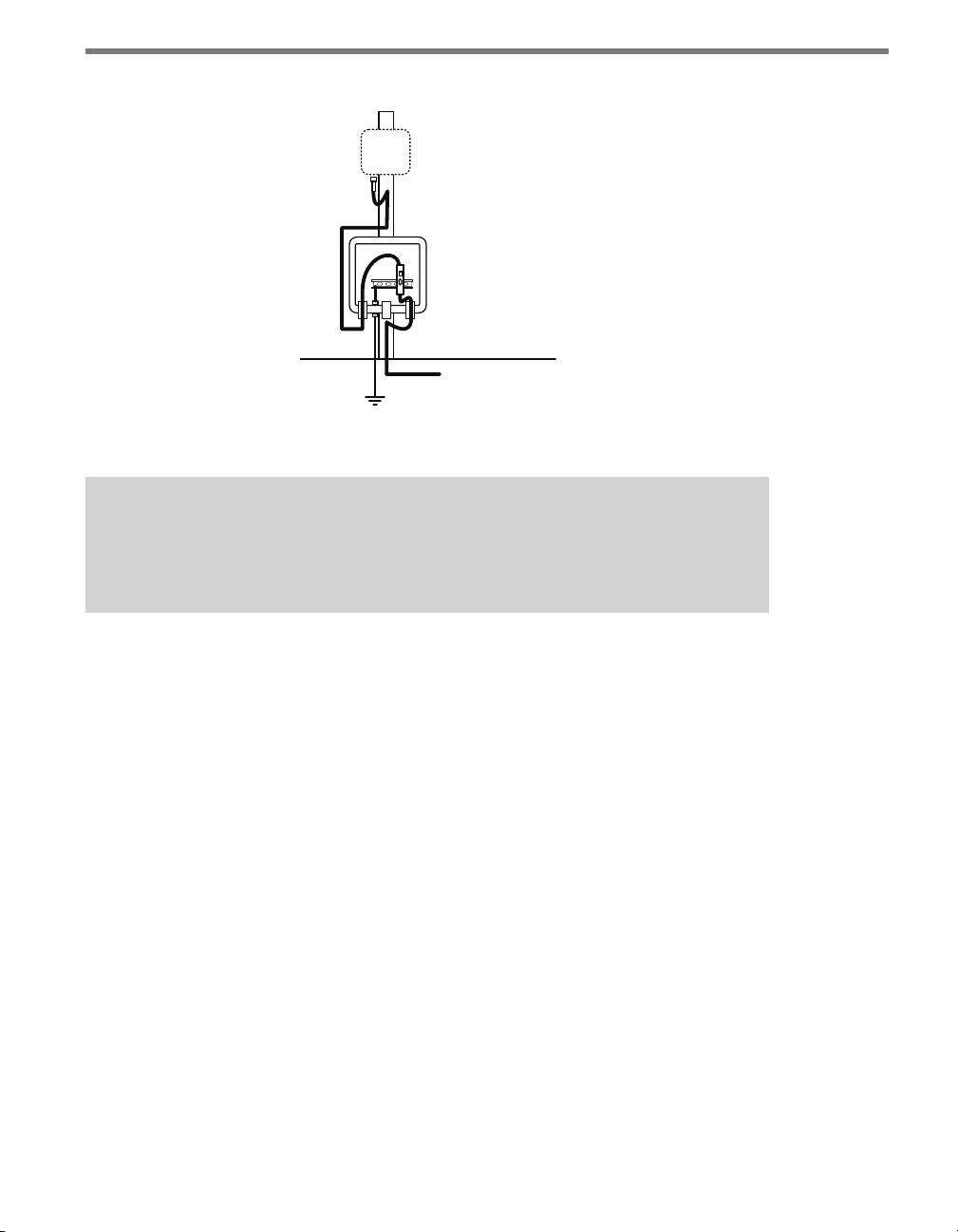

Connecting Lightning Surge Protection

It is strongly recommended that the sensor be connected to a surge protection device. e

Wavetronix Click 200 and equivalent devices are designed to prevent electrical surges conducted along underground cables from damaging the sensor and/or the cabinet. e service

end of the sensor cable should be connected to the PROTECTED side of the Click 200

in a cabinet mounted on the sensor pole. is will help protect the sensor when lightning

strikes the ground in the vicinity of the cabinet (see Figure 2.1).

Page 19

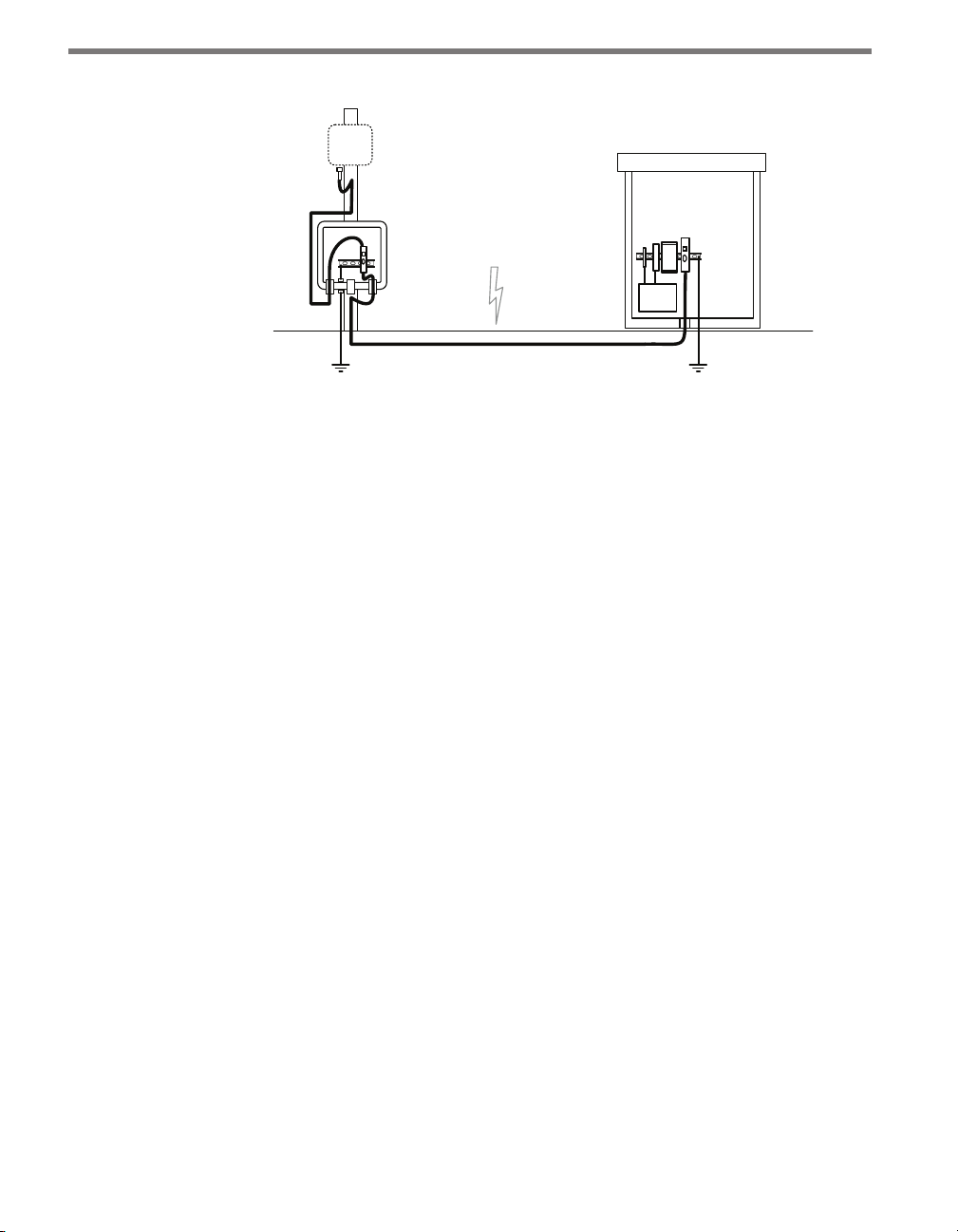

18 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Sensor

Underground

Cable

Figure 2.1 – Protecting the Sensor

Note

If you choose not to use surge protection in your installation, please contact Wavetronix Technical Services for assistance.

In many installations, the pole-mount cabinet is also connected to a main trac cabinet

via an underground homerun cable. To protect the trac cabinet, a second surge device is

strongly recommended. Follow the steps below to include surge protection using Click 200

devices (see Figure 2.2):

1 Install one Click 200 device in a pole-mount box on the same pole as the sensor being

protected.

2 Install another Click 200 in the main trac cabinet.

3 Connect the SmartSensor cable from the sensor to the PROTECTED side of the

Click 200 in the pole-mount cabinet. e SmartSensor cable should be kept as short

as possible.

4 Connect a SmartSensor cable from the UNPROTECTED side of the Click 200 on

the pole to the UNPROTECTED side of the Click 200 in the main trac cabinet.

Page 20

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 19

Main Trac Cabinet

Pole

Mount

Trac

Cabinet

Sensor

Both ends of the home-

run cable connect to the

UNPROTECTED side of the

surge modules

Figure 2.2 – Typical Cable Run

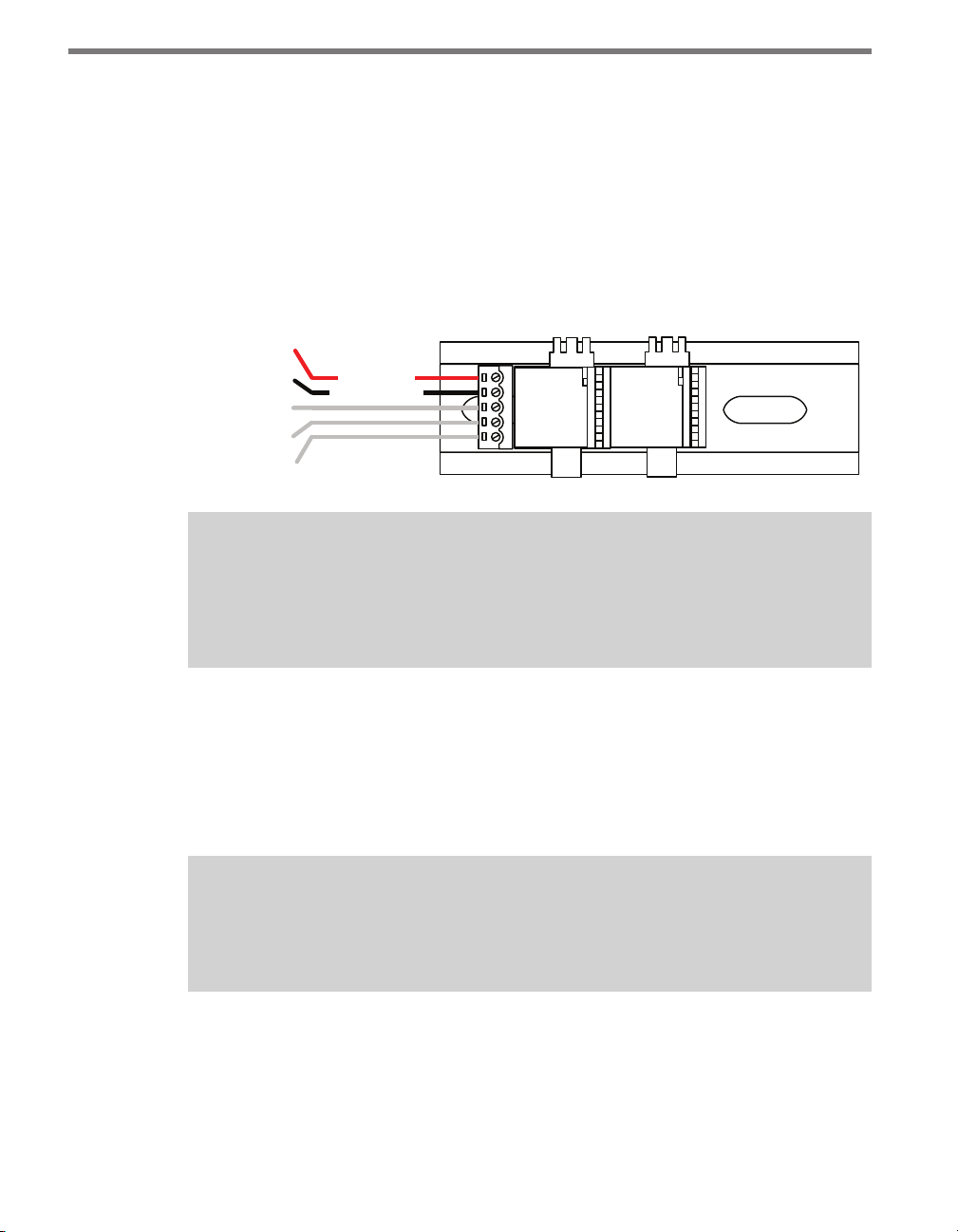

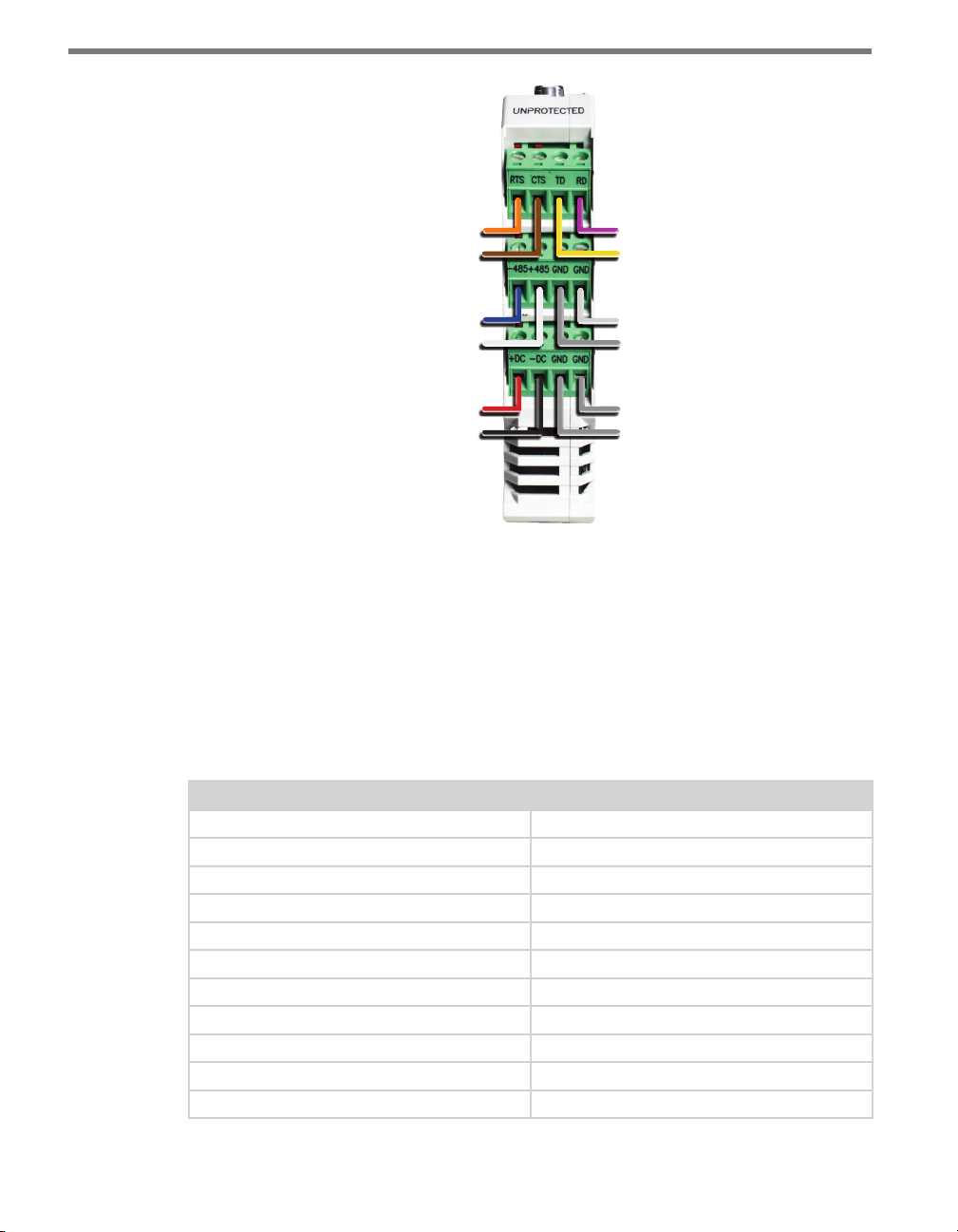

e Click 200 contains three terminal connectors on both the top and the bottom of the

module (see Figure 2.3). e terminal connectors are removable and are red-keyed, allowing the connector to plug into only one specic jack. is both simplies the wiring process

and reduces the possibility of wiring errors.

e back four terminals consist of one +DC power, -DC and two surge ground connections; the middle four terminals are for RS-485 communication and consist of a +485 connection, a -485 connection, an RS-232 ground connection and a surge ground connection;

the front four terminals are for RS-232 communication and consist of TD, RD, CTS and

RTS.

Page 21

20 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

GND/-DC (Black)

+DC (Red)

+485 (White)

-485 (Blue)

CTS (Brown)

RTS (Orange)

Figure 2.3 – Surge Protected Terminal Connections (Top)

Power Drain

232 Drain

485 Drain

Ground (Gray)

TD (Yellow)

RD (Purple)

Figure 2.3 above shows the PROTECTED side of the Click 200. e UNPROTECTED

side of the Click 200 contains the same screw terminal connections, but are reversed from

left to right.

Note

See Appendix B for a description of how to wire the Click 200 using the old SmartSensor cable as well as for a cable connector pin out diagram.

Wiring to Earth Ground

ALL Click 200 devices should be mounted on a DIN rail that is connected to earth ground

either through an earth-grounded chassis or a 16 AWG or larger grounding wire attached

to a 7-ft. (2.1-m) grounding rod. Follow the steps below to correctly wire to earth ground:

1 Connect the grounding wire from either the DIN rail or a GND screw terminal on

the UNPROTECTED side of the Click 200 to the lug bolt on the inside of the pole-

mount box.

2 Connect another grounding wire from the exterior lug bolt to earth ground (see Figure

2.4).

Page 22

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 21

Figure 2.4 – Earth Ground Connections

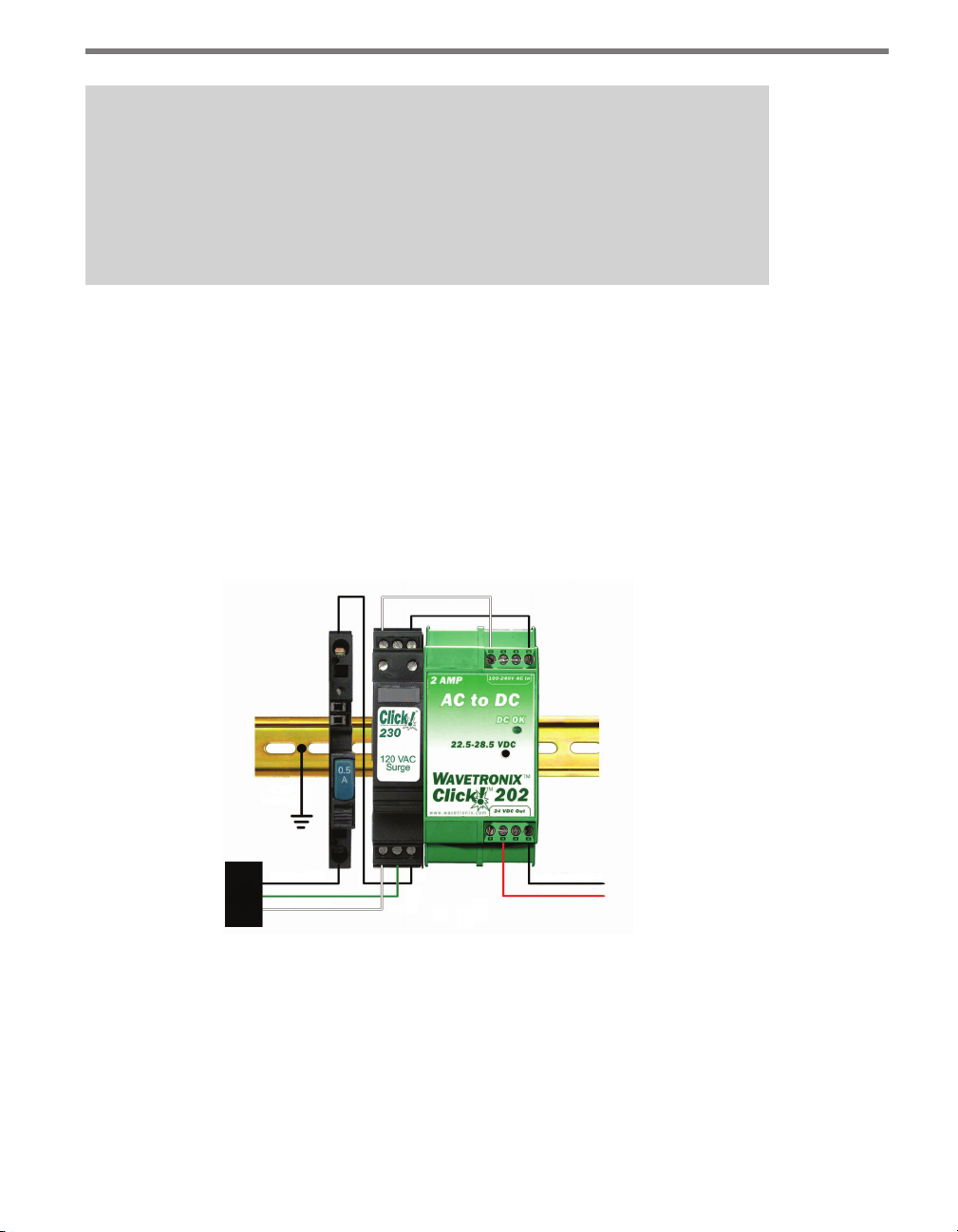

Connecting AC Power Conversion

Since the sensor operates on 10-30 VDC, it is necessary to provide AC power conversion

when reliable DC power is not already available. Wavetronix recommends using the following three Click components:

Click 201/202 AC to DC converter

Click 230 AC surge module

Click 210 circuit breaker and switch

Warning

Make sure power to AC mains is disconnected while wiring the AC input.

A Click 201 provides 1 amp of power and is capable of powering a single sensor, while a

Click 202 provides 2 amps and can power two sensors. e Click 230 helps limit current

surges on the power lines; the Click 210 interrupts power during overload conditions and

provides a convenient way to turn power on and o.

Depending on your conguration, these Click modules may be mounted in the pole-mount

cabinet or the main trac cabinet. When mounted in the main trac cabinet, a homerun

cable is used to conduct DC power and communication signals to the pole-mount cabinet.

For connections shorter than 600 ft. (182.9 m), use the SmartSensor cable as your homerun

cable. is will simplify the wiring process and ensure reliable connections.

Page 23

22 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Caution

An authorized electrical technician should perform installation and operation of this

unit. Persons other than authorized and approved electrical technicians should NOT

attempt to connect this unit to a power supply and/or trac control cabinet, as there

is a serious risk of electrical shock through unsafe handling of the power source. Extreme caution should be used when connecting this unit to an active power supply.

Wiring a Circuit Breaker and Switch

e Click 210 is a compact circuit breaker DIN rail device designed to interrupt an electric

current under overload conditions. e breaker is trip-free and can be easily reset after a

current interruption by pushing the reset button.

To add a Click 210 circuit breaker and switch (see Figure 2.5):

1 Mount the Click 210 onto the DIN rail.

2 Connect power in to either side of the module.

3 Connect power out to the other side.

Earth

Ground

Black (Line)

Green (Ground)

White (Neutral)

Figure 2.5 – AC Surge Protection

Black (Ground)

Red (+24 VDC)

Wiring AC Surge Protection

To include AC surge protection in your installation (see Figure 2.3):

1 Mount the Click 230 onto the DIN rail.

2 Connect the line conductor (hot) from the Click 210 to terminal 5 on the IN side of

the Click 230.

Page 24

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 23

3 Connect the neutral wire from the AC terminal block or cord to the terminal marked

1 on the Click 230.

4 Connect the ground wire from the AC terminal block or cord to the terminal marked

3 on the Click 230.

5 Connect the outgoing and protected line wire to the terminal marked 2 on the Click

230.

6 Connect the outgoing and protected neutral wire to the terminal marked 6 on the

Click 230.

e terminal blocks 3 and 4 are directly bonded via the metal mounting foot of the base

element to the DIN rail. ere is no need for any additional grounding between terminals

3 and 4 and the DIN rail.

Wiring AC Power Into the Click 201/202

Follow the steps below to properly wire an AC to DC power conversion module (see Figure

2.6):

1 Mount the Click 201/202 onto the DIN rail.

2 Connect the line (hot) wire from the Click 230 into the L screw terminal on the top

of the Click 201/202. e line wire is usually black.

3 Connect the neutral wire from the Click 230 to the N screw terminal to the top of the

Click 201/202. e neutral wire is usually white.

Figure 2.6 – Wiring AC Power into the Click 201/202

Note

The NC screw terminal is not connected internally. Connecting a wire to a no connect

(NC) terminal simply gives it a convenient termination point.

Page 25

24 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

Wiring DC Power Out of the Click 201/202

1 Connect a +DC conductor (usually a red wire) to the + screw terminal on the bottom

of the Click 201/202 (see Figure 2.7).

2 Connect a -DC conductor (usually a black wire) to either of the - screw terminals on

the bottom of the Click 201/202.

Figure 2.7 – Wiring DC Power Out of the Click 201/202

Note

Do not use the screw terminal marked DCOK; it provides only 20 mA and should be

used only for monitoring the power supply.

e screw terminal connectors on the top and bottom of the module are removable to simplify wiring and are red-keyed, allowing the connector to plug into only one correct jack.

Connecting DC Power

To power the sensor, 10-30 VDC needs to be connected to the Click 200 in the pole-

mount cabinet. Additionally, if there is a main trac cabinet connected by a homerun cable,

you will need to connect DC power to the Click 200 in that cabinet.

In the Pole-Mount Cabinet

Whether DC voltage comes from a homerun cable or from a Click 201/202 within the polemount cabinet, you can always wire the DC wires to the last screw terminal on the UNPRO-

TECTED side of the Click 200 module. is will protect your sensor from surges.

To wire DC power into the Click 200:

1 Connect +DC (usually a red wire) to the +DC screw terminal.

Page 26

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 25

2 Connect -DC (usually a black wire) to the GND screw terminal next to the +DC

terminal.

If the DC power comes from a Click 201/202 in the pole-mount cabinet that is surge pro-

tected using a Click 230, you can also connect power to the T-bus using a 5-position screw

terminal. To wire DC power directly into a 5-position screw terminal (see Figure 2.8):

1 Connect +DC (24 VDC) to the top screw terminal.

2 Connect –DC to the second screw terminal.

3 Connecting Power Directly to the T-bus

+24 VDC

-DC

+485

-485

GND

(red wire)

(black wire)

(Green)

(Gray)

Note

Green T-bus connectors provide power and communication connectivity on the DIN

rail backplane; gray T-bus connectors only provide power connectivity and are used to

distribute power without connecting communication.

In the Main Trac Cabinet

If DC voltage is sent across a homerun connection, AC power conversion is provided in the

main cabinet. In the main cabinet, the DC wires out of the Click 201/202 should be wired

to the PROTECTED side and the homerun cable should be connected to the UNPROTECTED side of the Click 200.

Note

The purpose of the Click 200 in the main cabinet is not to protect the sensor, but the

electrical equipment inside of the main cabinet.

e last screw terminal block on the PROTECTED side of the Click 200 module contains

a +DC, -DC and two surge ground connections (see Figure 2.9).

1 Connect +DC (usually a red wire) to the +DC screw terminal.

2 Connect -DC (usually a black wire) to the GND screw terminal next to the +DC

terminal.

Page 27

26 CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION

GND

+DC

Figure 2.8 – Wiring DC Power into the Click 200

Wiring Communication

After wiring the sensor cable into the PROTECTED side of the Click 200 in the pole

mount cabinet, two isolated serial connections are available. e sensor’s native RS-232

port is available via the DB-9 connector on the faceplate.

In addition, the sensor’s native RS-485 connection is available in the pole mount cabinet

via the following three ports on the Click 200:

Screw terminals on the bottom

RJ-11 connector on the faceplate

T-bus backplane

Note

The Click 200 does not convert RS-232 communication to RS-485. It simply provides

surge protection for these two independent connections.

One common way to connect communications back to a main cabinet is to use a SmartSensor cable as your homerun cable. See Appendix C for information about maximum

cable lengths for wired communication. Wavetronix Click products facilitate a wide variety

of additional wired and wireless communication options. Contact a Wavetronix-authorized

technical representative to nd out which options are best suited for your application.

Contact Closure Connections

While any of the RS-485 ports on the Click 200 can be connected to contact closure modules, it is often easiest to connect from the RJ-11 port. In some cases, several contact closure

cards can be daisy-chained together. However, the chain should not be connected until each

Page 28

CHAPTER 2 CONNECTING POWER AND SURGE PROTECTION 27

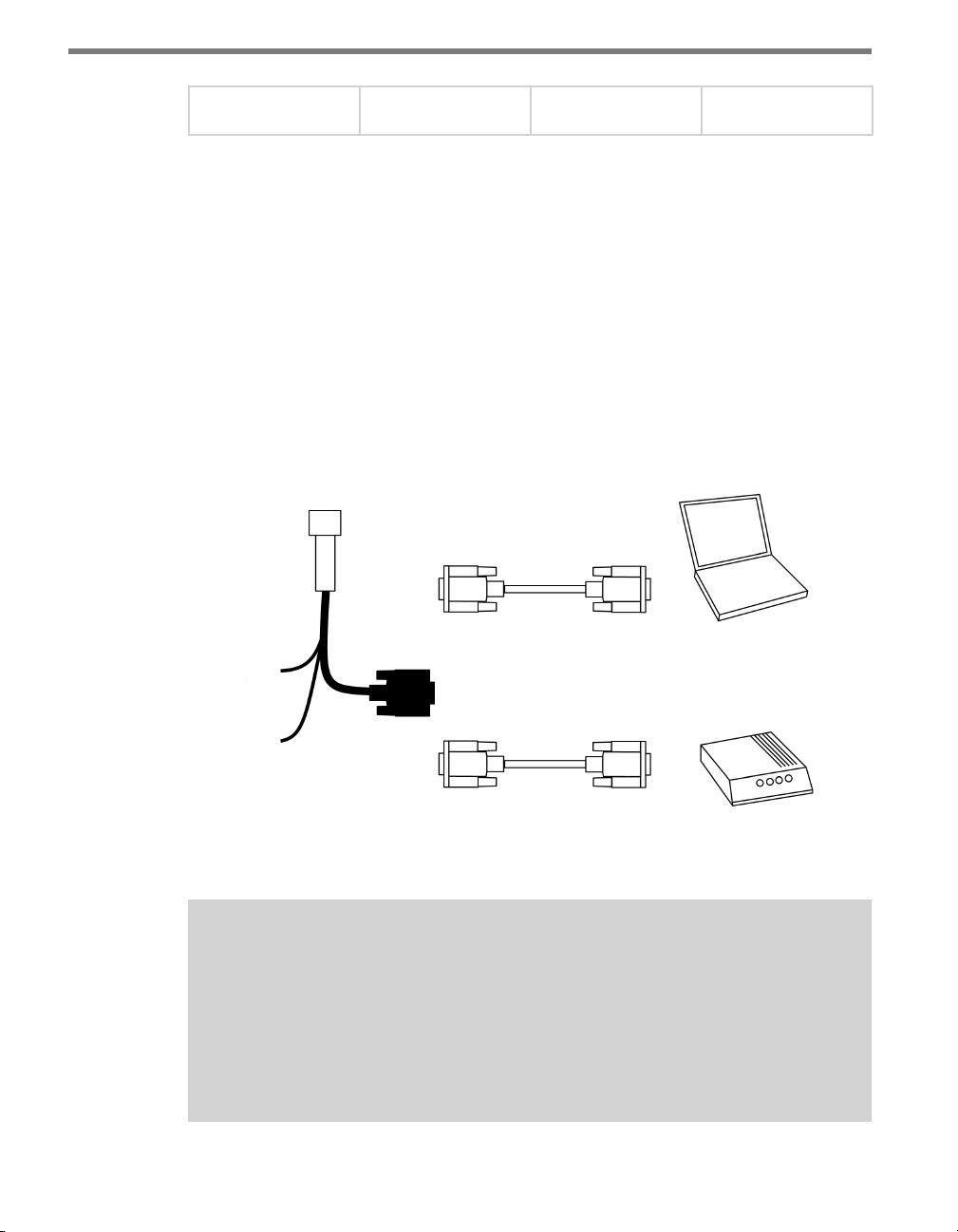

card has been independently programmed (see Figure 2.10).

Figure 2.9 – Connecting Contact Closure Modules

Note

Wait to connect contact closure communications until after the sensor is programmed using the configuration software.

See Chapter 9 for more information on contact closure communications.

Page 29

Page 30

Part II

Using SmartSensor Manager

Chapter 3 – Getting Started with SmartSensor Manager

Chapter 4 – Communication

Chapter 5 – Sensor Settings

Chapter 6 – Lane Setup

Chapter 7 – Data Collection

Chapter 8 – Tools

Chapter 9 – Contact Closure Communications

Page 31

Page 32

Getting Started with SmartSensor

Manager 3

In this chapter

Installing SmartSensor Manager

About Screen

Table of Contents

3

After the SmartSensor is installed, it must be congured to the roadway for proper opera-

tion. e SmartSensor Manager (SSM) software is used to perform this conguration.

SmartSensor Manager brings increased user-friendliness and improved functionality to

the ITS industry’s only patented auto-conguration and auto-calibration process. e new

features found in SmartSensor Manager 2.2.8 include a redesigned New Connection page,

a reorganized menu bar with new options, and expanded help capabilities to assist you in

navigating SmartSensor Manager and performing basic operations.

Installing SmartSensor Manager

Follow these steps to install SSM on a PC:

1 To download the install le, go to the Wavetronix website at www.wavetronix.com.

2 Click the Support link near the top of the page. is will bring up a page with icons

from the three dierent Wavetronix product lines.

3 Click the SmartSensor icon. is will bring up drop-down menus allowing you to

select a product by name or part number.

4 Select SmartSensor 105 or WX-SS-105. A list of links will appear.

5 Select the SmartSensor Manager link (it will be near the top) to download the SSM

install le.

Page 33

32 CHAPTER 3 GETTING STARTED WITH SMARTSENSOR MANAGER

6 A File Download window will pop up. Click Save.

7 In the Save As window, select where you would like the le to be saved, then click Save.

8 Once you’ve downloaded the le, double-click on it to open SmartSensor Manager.

About Screen

To access information about the version of SmartSensor Manager you are using, as well as

copyright information, go to Help>About SmartSensor Manager (see Figure 3.1).

Figure 3.1 – About SmartSensor Manager

Note

The newest version of SSM is always available on the Wavetronix website.

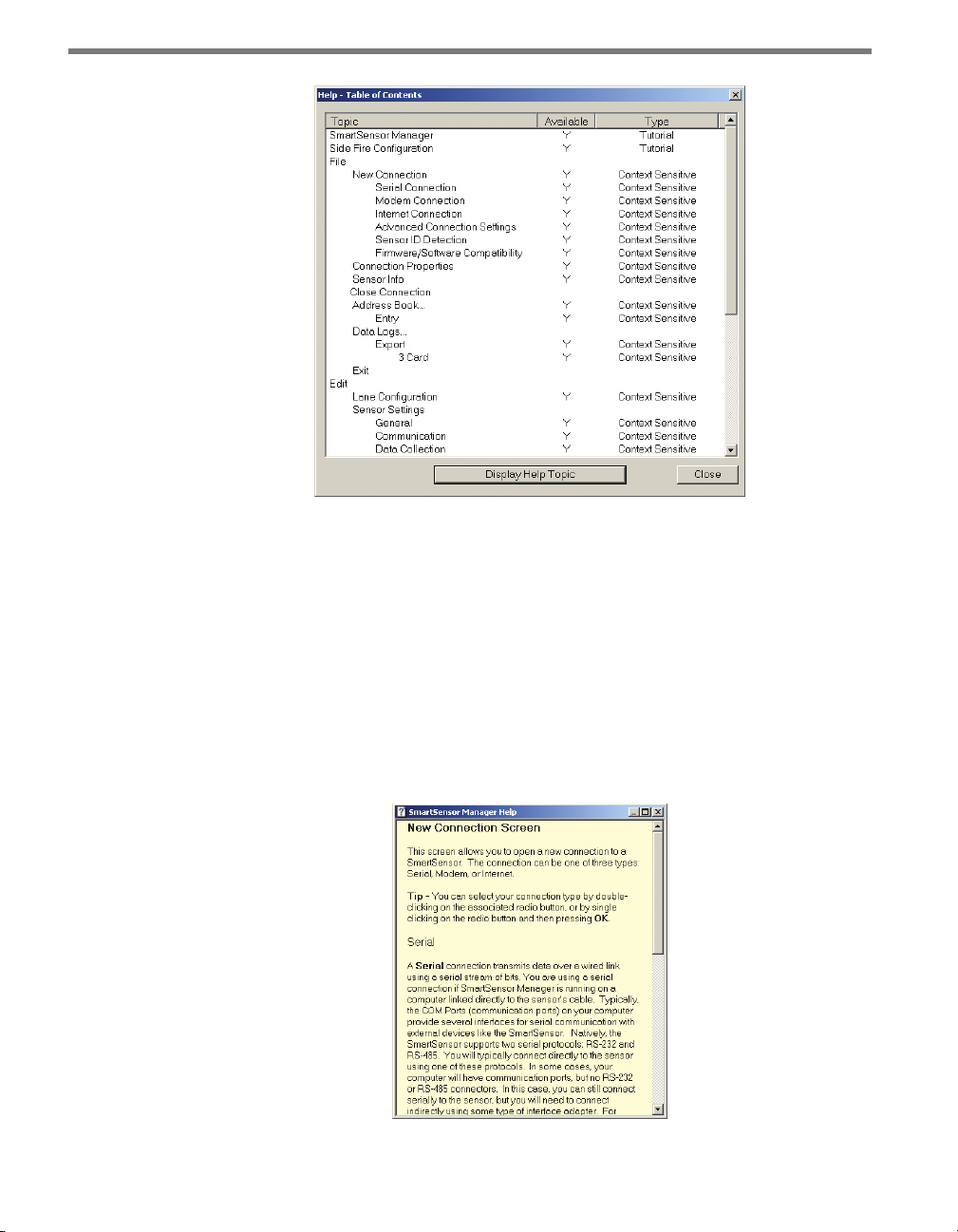

Table of Contents

is user guide presents the features of SmartSensor Manager in the order that they should

be used when setting up and using your sensor. If you’d like to access information about

features organized according to the way the software is laid out, however, you can use the

Table of Contents feature.

To access the Table of Contents, go to Help > Table of Contents. is will open the Table

of Contents, which is a list of help subjects organized according to the layout of the SSM

menu bar. e list is divided into the following three columns (see Figure 3.2):

Page 34

CHAPTER 3 GETTING STARTED WITH SMARTSENSOR MANAGER 33

Figure 3.2 – Table of Contents Page

Topic – Lists the available topics according to the setup of the software.

Availability – Shows whether the information is available. If it is available, this column

will show a Y. If it is not, this column and the one to the right of it will be blank.

Type – Shows the type of information contained on the page. Pages marked Tutorial

provide overview information; pages marked Context Sensitive have information specic to a particular function or operation.

Open the desired information from the Table of Contents by either double-clicking on the

subject in the list, or by highlighting the item and clicking the Display Help Topic button

(see Figure 3.3).

Figure 3.3 – Help Screen

Page 35

34 CHAPTER 3 GETTING STARTED WITH SMARTSENSOR MANAGER

Note

You can also access the Table of Contents help information for a given page by pressing the F1 key while on that page. Additionally, some pages have question marks in

the upper right-hand corner that lead to their Table of Contents help pages.

You can access the Table of Contents page from anywhere in SmartSensor Manager; an

active sensor connection is not needed. is enables you to get help information at any time,

especially if information about connecting to a sensor is needed.

Release Notes

e last entry in the Table of Contents is Release Notes, which, when selected, displays

information on the current and previous versions of SSM. is information includes the

version number, date of release (in YY/MM/DD format), and the new features added and

issues resolved in each release.

Page 36

Communication 4

In this chapter

Serial Connection

Modem Connection

Internet Connection

Firmware Upload

Connection Properties

Address Book

Communication Error

4

When the SmartSensor Manager application is opened, you will be taken to the New

Connection page, where you will be able to connect using one of three connection options:

serial, modem, or Internet. Choose the desired method of connection and click OK. e

Serial (COM Port) radio button will be selected by default (see Figure 4.1).

You can also access the three connection options at any time by going to File > New Con-

nection.

Note

Selecting a connection type under File > New Connection while you are already onnected will terminate your current connection. You can also end a connection by going

to File > Close Connection.

Page 37

36 CHAPTER 4 COMMUNICATION

Figure 4.1 – New Connection Page

Clicking OK opens a connection page unique to each connection option. Each connection

page contains three function buttons: Advanced, Cancel and one that allows you to con-

nect or dial. e advanced functions for each connection option are specic for each option.

Serial Connection

To make a serial connection, click the Serial (COM Port) radio button and then OK. e

message below will appear (see Figure 4.2):

Figure 4.2 – Serial Connection

e three action buttons appear near the bottom of the page. e CONNECT button will

attempt to connect to the sensor using the current settings. e Cancel button cancels the

action and returns you to the New Connection page.

A message bar at the bottom, identied by the icon, displays the serial settings being

used for this connection. If the default settings are used, then the message bar will display

the following:

COM - Auto; Baud - Auto; ID - Simple; Synchronize - Yes; Wait - 0

Page 38

CHAPTER 4 COMMUNICATION 37

Advanced Serial Settings

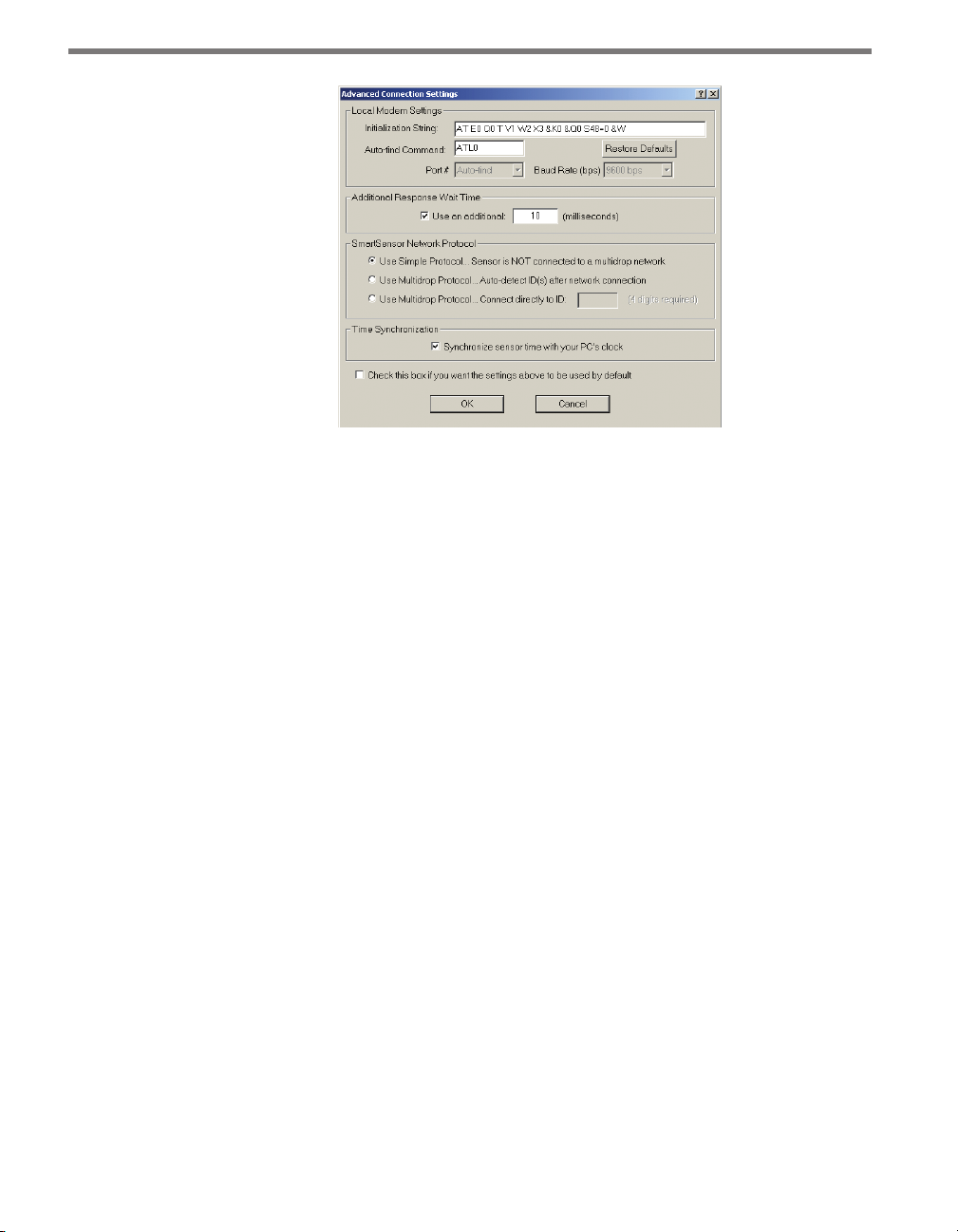

Click the Advanced button to change the Advanced Connection settings (see Figure 4.3).

Figure 4.3 – Advanced Connection Settings

PC Com Port Settings – By default, SSM is set to automatically detect PC com port

& baud rate settings. To manually congure these settings, click the Specify PC com

port & baud rate settings radio button. is will activate the Port # and Baud Rate

(bps) drop-down lists.

Additional Response Wait Time – By default, SmartSensor Manager waits a few mil-

liseconds to receive a response from the sensor before timing out and displaying a

communication error message. You can add additional milliseconds to the response

wait time to give the program more time to make a connection. Click the Use an addi-

tional: check box to activate the milliseconds text eld and enter the number of addi-

tional milliseconds SmartSensor Manager should wait for a response from the sensor.

SmartSensor Network Protocol – ese options can be used to identify sensors that

are part of a multi-drop network. e Simple protocol option refers to sensors that are

not part of a multi-drop environment. If the sensor is part of a multi-drop network,

SmartSensor Manager can either auto-detect the multi-drop ID, or you can enter the

four-digit ID. Clicking the Use Multidrop Protocol… Connect Directly to ID: radio

button will activate the text box so you can enter the ID number.

Time Synchronization – Click the check box to have SmartSensor automatically syn-

chronize with the PC clock.

Click on the check box at the bottom of the Advanced Connection Settings page to use

the new settings as default. Click OK to save the new settings or Cancel to return to default; both buttons will return you to the Serial Connection page. e new settings will be

reected in the message bar at the bottom of the page.

Page 39

38 CHAPTER 4 COMMUNICATION

Modem Connection

Clicking the Modem (Phone #) radio button on the New Connection page and then clicking OK will allow you to connect to the SmartSensor using a modem. e Modem Connection page has a text box in which you can enter the phone number for the sensor’s

modem (see Figure 4.4).

Figure 4.4 – Modem Connection

e phone book icon to the right of the text eld allows you to browse for numbers pre-

viously saved in the SmartSensor Manager address book (for more information, see the

Address Book section later in this chapter). If you’d prefer to dial manually, click the Dial

Manually check box beneath the text eld, then click on Dial. At this point you will need

to pick up the telephone receiver and manually dial the phone number.

Note

When this window is first opened, the modem connection phone number you used

most recently will automatically appear in the text field.

Once the number is entered, click Dial to make a connection. Click Cancel to stop the

action and return to the New Connection page.

e message bar at the bottom of the page, identied by the icon, shows the modem

settings being used. If the default settings are used, the message bar will display the following:

ID - Simple; Synchronize - Yes; Wait - 0

Advanced Modem Settings

e following settings are part of the modem connection’s advanced functions and can be

found by clicking the Advanced button (see Figure 4.5):

Page 40

CHAPTER 4 COMMUNICATION 39

Figure 4.5 – Advanced Modem Settings

Local Modem Settings – e initialization string and auto-nd command can be en-

tered in their respective text elds in the Local Modem Settings section. e Restore

Defaults button will return these functions to their default settings. e port number

and baud rate will be automatically detected by SmartSensor Manager, so these settings cannot be changed.

Additional Response Wait Time – By default, SmartSensor Manager waits a few mil-

liseconds to receive a response from the sensor before timing out and displaying a

communication error message. You can add additional milliseconds to the response

wait time to give the program more time to make a connection. Click the Use an addi-

tional: check box to activate the milliseconds text eld and enter the number of addi-

tional milliseconds SmartSensor Manager should wait for a response from the sensor.

SmartSensor Network Protocol – ese options can be used to identify sensors that

are part of a multi-drop network. e Simple protocol option refers to sensors that are

not part of a multi-drop environment. If the sensor is part of a multi-drop network,

SmartSensor Manager can either auto-detect the multi-drop ID, or you can enter the

four-digit ID. Clicking the Use Multidrop Protocol… Connect Directly to ID: radio

button will activate the text box so you can enter the ID number.

Time Synchronization – Click the check box to have SmartSensor automatically syn-

chronize with the PC clock.

Click the check box near the bottom of the Advanced Connection Settings page to use

the new settings as default. e OK button saves the new settings and the Cancel button

cancels the changes; both buttons return you to the Modem Connection page. e new

settings will be displayed in the message bar at the bottom of the page.

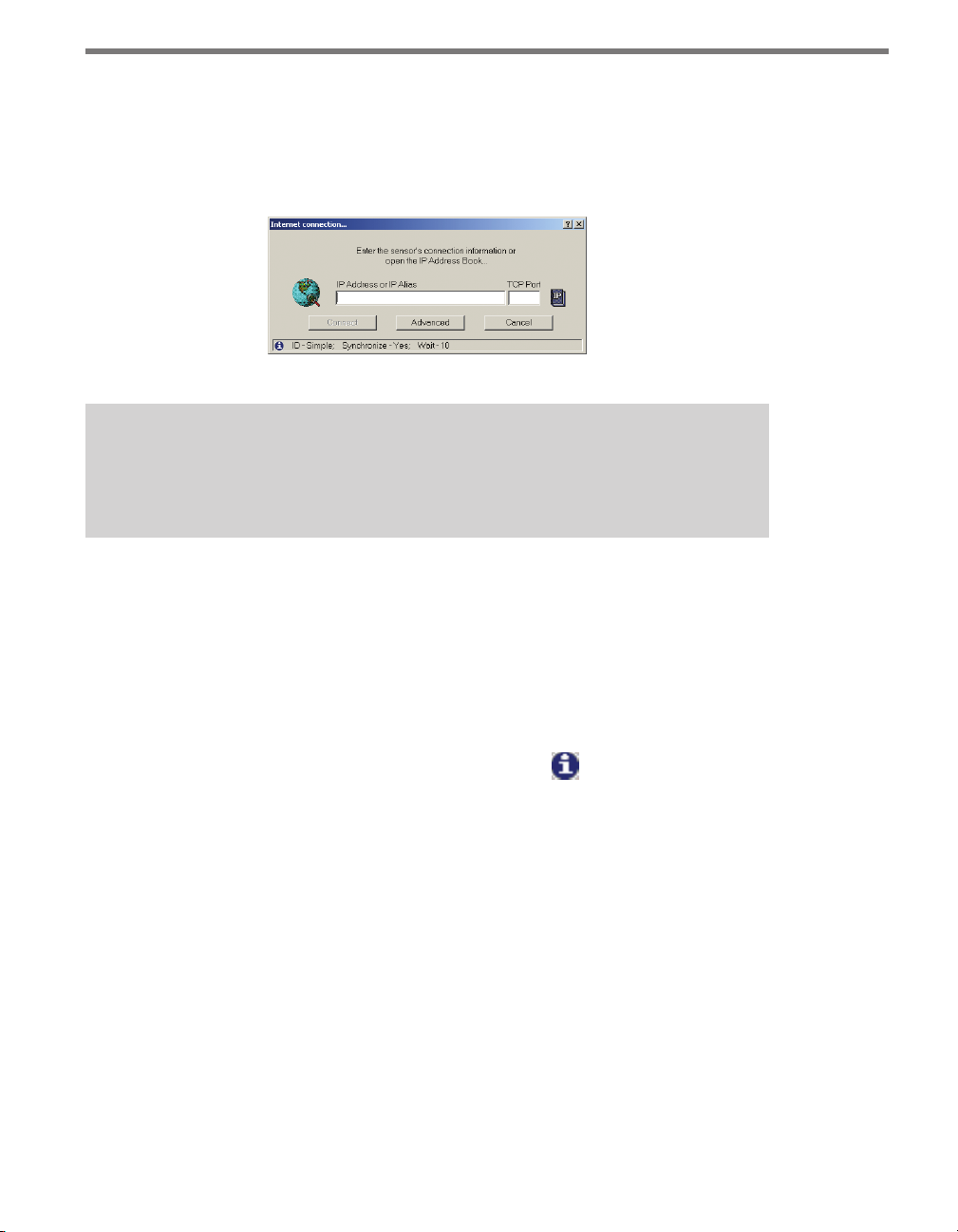

Internet Connection

e Internet (TCP/IP) option will allow you to connect to the SmartSensor using the

Page 41

40 CHAPTER 4 COMMUNICATION

sensor’s IP address. e Internet Connection page has two text boxes in which you can

enter the sensor IP address and port number (see Figure 4.6). e Connect button does

not become active until both the IP address and port number boxes are lled. You can also

establish an Internet connection using a domain name by entering that domain name in

the IP address text eld.

Figure 4.6 – Internet Connection

Note

When this window is first opened, the connection properties for the Internet connection you used most recently will automatically appear in the text fields.

e IP icon next to the text elds allows you to browse through previously saved addresses

in the SSM address book, which is especially useful if you are connecting to more than one

sensor using an Internet connection. For more information, see the Address Book section

of this chapter.

Once the IP address and port number are entered, click Connect to make a connection.

Click Cancel to stop the action and return to the New Connection page.

e message bar at the bottom of the page, identied by the icon, shows the Internet

settings being used. If the default settings are used, the message bar will display the following:

ID - Simple; Synchronize - Yes; Wait - 0

Advanced Internet Settings

e following settings are part of the Internet connection advanced functions and can be

found by clicking the Advanced button (see Figure 4.7):

Page 42

CHAPTER 4 COMMUNICATION 41

Figure 4.7 – Advanced Internet Settings

Additional Response Wait Time – By default, SmartSensor Manager waits a few mil-

liseconds to receive a response from the sensor before timing out and displaying a

communication error message. You can add additional milliseconds to the response

wait time to give the program more time to make a connection. Click the Use an addi-

tional: check box to activate the milliseconds text eld and enter the number of addi-

tional milliseconds SmartSensor Manager should wait for a response from the sensor.

SmartSensor Network Protocol – ese options can be used to identify sensors that

are part of a multi-drop network. e Simple protocol option refers to sensors that are

not part of a multi-drop environment. If the sensor is part of a multi-drop network,

SmartSensor Manager can either auto-detect the multi-drop ID, or you can enter the

four-digit ID. Clicking the Use Multidrop Protocol… Connect Directly to ID: radio

button will activate the text box so you can enter the ID number.

Time Synchronization – Click the check box to have SmartSensor automatically syn-

chronize with the PC clock.

Click the check box near the bottom of the Advanced Connection Settings page to use

the new settings as default. e OK button saves the new settings and the Cancel button

cancels the changes; both buttons return you to the Internet Connection page. e new

settings will be displayed in the message bar at the bottom of the page.

Firmware Upload

If the rmware installed onboard the SmartSensor is not the same as the rmware bundled

with the SSM software, the Firmware/Software Compatibility screen may appear after

you’ve nished connecting. is screen gives you four options: Upload, Exit SmartSensor

Manager, Continue w/o upload, and View Details (see Figure 4.8).

Page 43

42 CHAPTER 4 COMMUNICATION

Figure 4.8 – Firmware/Software Compatibility Screen

Upload

Selecting Upload will upload the bundled rmware to the sensor, thereby eliminating any

compatibility problems. e amount of time it takes to complete the upload depends primarily on your connection speed, but usually varies from 1 to 10 minutes.

During the upload process, you can cancel at any time. However, if the FPGA rmware was

incompatible and the new version was not fully loaded before you clicked Cancel, the sensor will revert back to a factory-installed version of the FPGA rmware upon reboot of the

sensor. e factory-installed version of the FPGA rmware may not be the same as the last

version you were running on the sensor. In this case, you will need to re-upload the version

of FPGA rmware you’d like to have on the sensor (see chapter 8 for information on how

to do this). is does not occur when you cancel an upload of DSP rmware.

If the upload completes successfully, the sensor will need to reboot and restart before the

new rmware will take eect. e restart should take about 15 seconds.

Exit SmartSensor Manager

If you are unsure what to do, you should click the Exit SmartSensor Manager button.

When you have decided what to do, you can reconnect to the sensor.

In some cases, you may have simply connected to the sensor with the wrong version of

SmartSensor Manager. Click the Exit SmartSensor Manager button to close your current

connection and quit the program. Once you have quit this version of SmartSensor Man-

ager, you can then connect up with the version you originally intended.

Continue w/o upload

If you are determined to continue using this version of SmartSensor Manager to interact

with the sensor, but have good reason not to upload the bundled rmware, you can click

the Continue w/o Upload button. With this choice, SmartSensor Manager nishes estab-

lishing the connection and continues normal execution. However, depending on the nature

of incompatibilities between the sensor’s rmware and SmartSensor Manager, unexpected

errors may result.

Page 44

CHAPTER 4 COMMUNICATION 43

View Details

Dierences between the sensor’s rmware and the rmware bundled with SmartSensor

Manager can be viewed by clicking on View Details. e dierences between the two ver-

sions will be highlighted in red. Knowing the details of the detected dierences may help

you make a more informed decision about how to proceed (see Figure 4.9).

Figure 4.9 – View Details

Version – Shows the software version.

Programmable Hardware – Shows the FPGA version.

Year – Shows the year of of the version’s release in YY format.

Algorithm/Month – Shows the month of the version’s release in MM format, as well

as the operating mode; this will appear as an S for side re mode and an F for forward

re mode.

Day.Application – Shows the day of the version’s release in DD format as well as the

current application; this will appear as an S for sensor or a D for diagnostic.

Connection Properties

Information about the current connection can be accessed on the Current Connection

Properties page, which is found under File > Properties (see Figure 4.10).

Figure 4.10 – Current Connection Properties

Page 45

44 CHAPTER 4 COMMUNICATION

e page shows the following information about your connection:

Type – Shows the type of connection (serial, modem or Internet). is will say Discon-

nected if the software is not currently connected to a sensor.

Port / Phone # / Address – Displays information about the connection endpoint. is

will vary based on the kind of connection made.

Protocol – Indicates whether sensor is on a multi-drop network or a simple sensor

network.

Response Wait Time – Shows the wait time information for each sensor. e rst box

shows the number of milliseconds SmartSensor Manager will automatically wait for

a response from a specic sensor. SmartSensor Manager determines this number by

averaging recent sensor response times, so this number may uctuate slightly when

the Re-calculate button is clicked. e second box shows the number of additional

seconds you have added under the Advanced Settings page for your connection; this

number can be changed on this screen. e third box shows the total number of seconds SSM will wait for a response. Click the Save As Default button to save the new

settings as default.

Click OK to close the window.

Address Book

e address book can save connection information for both modem and Internet connections, allowing you to access this information later and connect quickly without reentering

IP addresses, modem numbers and so on.

Accessing the Address Book

e address book can be accessed in two ways:

1 Go to File > Address Book. is will give you two options: New and Open. Selecting

New will open a directory box where you can create a new address book le (.abf ).

Creating an address book le will not immediately open the new le.

Select Open to access the most recently created or accessed address book le. is

option is divided into two choices, Modem Entries and Internet Entries (see Figure

4.11). Selecting these will allow you to access all the modem or Internet entries in the

address book. If you have not yet created an address book le, you will be prompted to

do so now.

Figure 4.11 – Accessing Address Book through the Menu Bar

Page 46

CHAPTER 4 COMMUNICATION 45

2 Begin to make a new modem or Internet connection, either through File > New Con-

nection or the New Connection screen. In the connection screen that comes up, click

the book icon next to the text eld. is will access the address book specic to that

type of connection. If you have not yet created an address book le, you will be asked

to do so.

Note

By default, accessing the address book will open the address book file (.abf) that you

most recently had open. As a single .abf can store both modem and Internet connection information, it will usually not be necessary to have multiple address book files

stored on your computer. If you do have more than one file, however, you can switch

back and forth by going to File > Address Book > New. Instead of creating a new file,

however, select the file you wish to access and click OK. Now when you go to File >

Address Book > Open or you select the address book icon on a connection screen, it

will default to this most recently opened file.

Using the Address Book

No matter how you access the address book, using it is the same. e information available

and visible will dier, however, based on what kind of connection you’re making. If you’re

looking at modem entries, the screen will display three columns: Phone Number, Sensor

ID and Description (see Figure 4.12). e Internet entries have ve columns: IP Alias, IP

Address, TCP Port, Sensor ID and Description.

Figure 4.12 – Address Book for Modem Entries

Use the buttons in the address book to work with entries and make connections:

Select – Selects an entry to use to connect. When you have chosen the entry you would

like to use to connect, highlight it in the list and click Select. is will close the address

book and enter the desired information into the connection page.

Page 47

46 CHAPTER 4 COMMUNICATION

Note

When accessing the Address Book screen using the menu options, the Select button

is disabled. You will be able to edit the address book entries, but will not be able to

connect unless you use the Modem or Internet Connection Screens.

New – Creates a new entry. Select New and enter the desired information. In a modem

connection, this is the phone number of the modem, the sensor ID number and a description of the connection for your own information.

If you are adding an Internet connection entry, you have two options for the address:

an IP address or a domain name. With both options you must also specify the TCP

port number. If you use a domain name, the domain name must be entered as the IP

alias and you should not enter an IP address, since the domain name may resolve to

one or more dynamic IP addresses. When you enter both an IP address and an IP

alias, SmartSensor Manager will add an entry to the Windows HOSTS le on your

computer. In this case, the IP alias can be a simple text string (or a domain name that

is tied to a xed IP address). You may want to use a simple text string to help identify

IP addresses that do not have a domain name.

Edit – Allows you to edit the information contained in a highlighted entry.

Delete – Deletes the selected entry.

Close – Exits out of the address book.

Communication Error

e Communication Error screen will appear if SmartSensor Manager can no longer communicate with the sensor. If such an error occurs, the Communication Error screen will

give you the following options (see Figure 4.13):

Retry – Tells SSM to try to communicate with the sensor again.

Cancel – Stops the current operation as well as other operations that may be in process.

Details – Shows error details.

Figure 4.13 – Communication Error with Details Screen

Page 48

CHAPTER 4 COMMUNICATION 47

Clicking the Details button will access additional information specic to this problem:

Operation – Shows the operation SSM is trying to accomplish.

Response Error – Shows the response error SSM has encountered.

Error Code – Gives the error code related to the specic error.

Reliability – Indicates the percentage of communication attempts that were success-

fully completed.

Automatic Retries – Shows the number of times the SSM automatically attempts to

reconnect before showing the communication error screen.

Response Timeout – Displays the total number of milliseconds that SSM waited

before timing out the requested operation.

If you retry multiple times to communicate with the sensor and it still doesn’t work, the

problem can often be xed by editing the additional response wait time, found in the Advanced Settings page for your connection.

Page 49

Page 50

Sensor Settings 5

In this chapter

Sensor Info

Sensor Settings

Sensor Date & Time

Operating Mode

5

ere are several ways to access and change sensor settings using SSM.

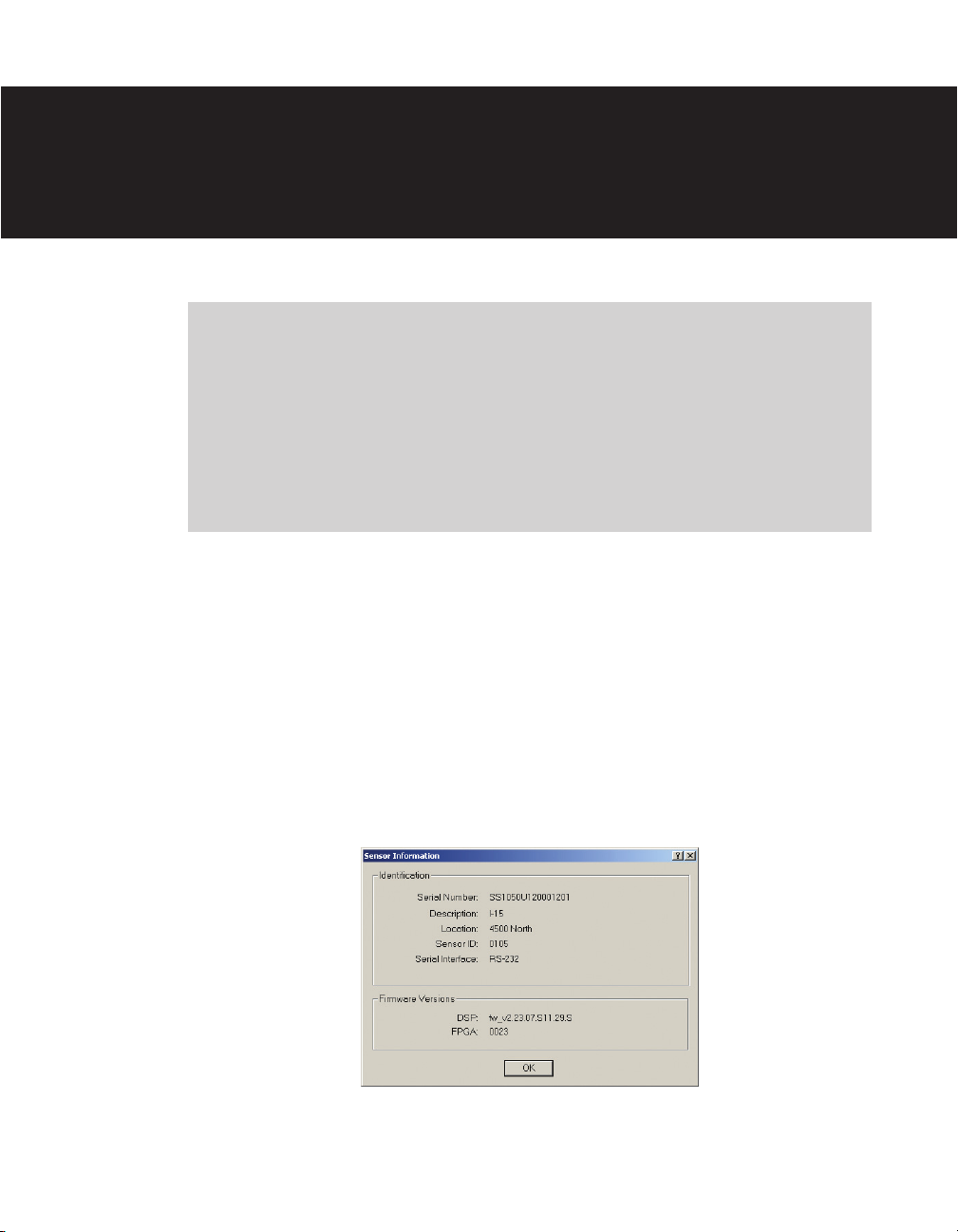

Sensor Info

Going to File > Sensor Info opens the Sensor Information page, which displays the properties unique to each sensor (see Figure 5.1).

Figure 5.1 – Sensor Information

Page 51

50 CHAPTER 5 SENSOR SETTINGS

Although the information cannot be edited, there must be an active connection to view

the Sensor Information page. e page is divided into two sections, Identication and

Firmware Versions.

e Identication section information includes the following:

Serial Number – Shows the 16-digit serial number given to the sensor by the manu-

facturer. It can be used to uniquely identify the sensor.

Description – Shows the 32-character, user-created sensor description as set using the

Sensor Settings screen (for more information, see the Sensor Settings section later in

this chapter). It is used to describe the sensor and/or the installation site.

Location – Displays the 32-character, user-created location description as set using the

Sensor Settings screen (for more information, see the Sensor Settings section later in

this chapter). It is used to describe the location of the sensor.

Sensor ID – Shows the 4-digit numeric string used to identify the sensor on a multi-

drop network. You can set this ID number using the Sensor Settings screen (for more

information, see the Sensor Settings section later in this chapter). e SmartSensor

Multi-drop protocol uses the sensor ID to uniquely address sensors on a shared bus.

Serial Interface – Indicates which of the sensor’s four ports it is using to communicate.

e four ports are RS-232, RS-485, EXP-A, and EXP-B.

Note

The two expansion ports (EXP-A and B) are currently not available for use.

e Firmware Versions section shows on which versions of DSP (Digital Field Processing)

and FPGA (Field Programmable Gain Amplier) the sensor is operating.

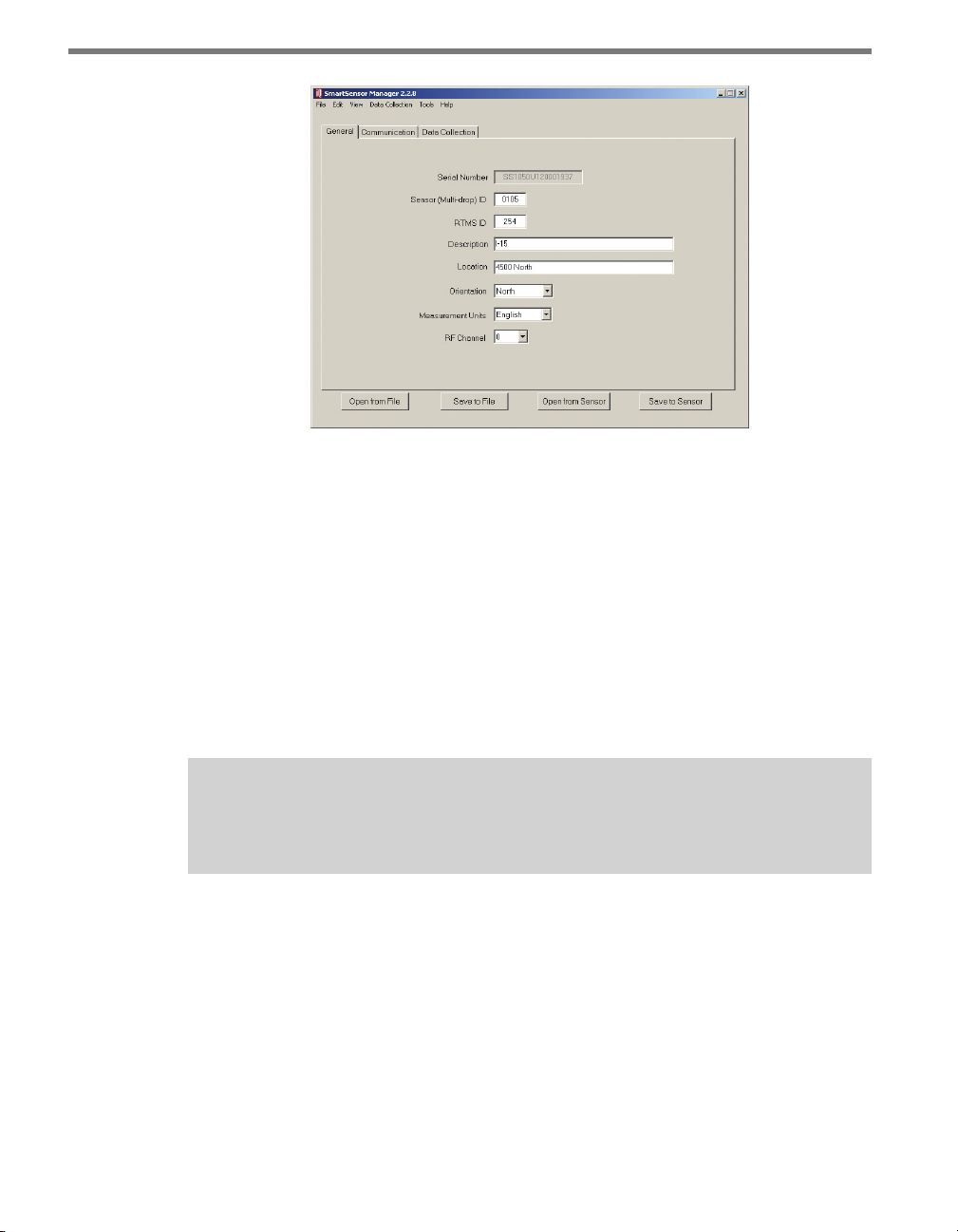

Sensor Settings

You can both view and change certain sensor options and information in the Sensor Settings page. To access this page, go to Edit > Sensor Settings. If no sensor connection is

active, selecting this will open a directory box, allowing you to nd SmartSensor conguration (.ssc) les that are saved on your computer. You can also use this directory box to create

a new .ssc le.

e Sensor Settings page is divided into three tabs: General, Communication and Data

Collection. Only the General and Communication tabs will be discussed here; the Data

Collection tab will be discussed in chapter 7.

General Tab

e General tab allows you to edit the following settings (see Figure 5.2):

Page 52

CHAPTER 5 SENSOR SETTINGS 51

Figure 5.2 – General Tab

Serial Number – Shows the 16-digit serial number given to the sensor by the manu-

facturer, used to uniquely identify the sensor. is is the only setting on this screen that

cannot be edited.

SmartSensor (Multidrop) ID – Allows you to enter a 4-character ID number. is

number is used to identify the sensor on a multi-drop network. Each sensor on such

a network must have a unique ID number. is number is referred to on the Sensor

Information page as the sensor ID.

RTMS ID – Lets you change the RTMS ID. e SmartSensor has been designed to

utilize other protocols for those cases when there might already be a project built

around another type of sensor. If you choose to communicate using the RTMS protocol, all you need is the RTMS ID.

Note

The RTMS ID number 13 cannot be used for polled communications.

Description – Allows you to create a description of the sensor and/or installation site

for identication purposes. e description may be up to 32 characters long and will

be displayed on the Sensor Information page.

Location – Allows you to enter the location of the sensor for identication purposes.

e location may be up to 32 characters long and will be displayed on the Sensor Information page.

Orientation – Lets you select, from a drop-down menu, the direction the sensor is

facing. e orientation does not aect sensor operation or alignment and is simply for

your information.

Measurement Units – Allows you to choose between English and metric measure-

Page 53

52 CHAPTER 5 SENSOR SETTINGS

ments. Metric units are entered in decimeters so that the metric and English units can

be converted more accurately.

RF Channel – is allows you to assign specic RF channels to sensors that are in-

stalled in close proximity to each other to prevent the sensors from interfering with

each other.

Communication Tab

e Communication tab allow you to change the following settings (see Figure 5.3):

Figure 5.3 – Communications Tab

Baud Rates – Allows you to set the baud rate for the each of the sensor’s four connec-

tion ports. To change the baud rate, simply click on the drop-down menu and select

the desired rate. Besides the standard RS-232 and RS-485 ports, there are also two

other expansion ports. ese expansion ports are currently not available for use.

Response Delays (milliseconds) – Allows you to change the number of milliseconds

that the sensor will delay before responding. is is useful if you ever attach the sensor to communication equipment that cannot handle the speed with which the sensor

responds to message requests. You can change the response delay for each of the four

connection ports separately by entering the desired number of milliseconds. If you are

not able to determine the amount of delay required by consulting the communication

equipment’s documentation, you will need to determine this number by trial and error.

Note

If you increase the response delay, you should also increase the additional response

wait time that SmartSensor Manager uses when communicating to the sensor.

Page 54

CHAPTER 5 SENSOR SETTINGS 53

Advanced Comm Register – e Advanced Comm Register on the SmartSensor

holds two settings: Simple Protocol and Flow Control.

e rst setting selects whether Simple SmartSensor protocol is enabled or disabled.

By default Simple protocol is enabled. Networks comprised of simply one sensor can

use the Simple protocol. However, if there is more than one sensor on the network, this

protocol can cause communication messages to be broadcast unintentionally. ese

messages can result in collisions and even ongoing chatter between sensors on a multidrop network. If you are setting up a multi-drop network of sensors, you should con-

nect to them one by one and disable Simple protocol. To disable Simple protocol,

select Disabled from the drop-down list. Simple protocol must also be disabled if you

plan on using RTMS protocol.

e second setting selects whether ow control handshaking is enabled or disabled on

the sensor. Flow control is a hardware handshaking protocol used by some communication equipment. If your communication equipment requires handshaking, you will

need to enable this by selecting RTS/CTS from the drop down menu.

Note

If you have established a serial connection, enabling RTS/CTS handshaking will cause

you to lose communication with SmartSensor Manager unless you first short the

RTS/CTS lines on the sensor.

Data Push Setup – Allows you to enable and congure data push. SmartSensor com-

municates trac data in either Data Polled mode or Data Push mode. By default the

SmartSensor is in Data Polled mode. In Data Polled mode, a trac data collection

device must periodically poll the sensor to retrieve the most recent information. Data

Polled mode is preferred if multiple sensors share the same data bus, so that the data

transmitted over the connection will not be corrupted or lost by collisions.

In Data Push mode, the sensor is set up to transmit any new data it generates automatically (without any prompting by the collection device). In Data Push mode there

is no arbitration of the data bus, and data messages sent by dierent sensors can collide,

causing information to be lost. However, if there is only one sensor connected to the

data bus, there should be no collisions in data push mode.

Before you change to Data Push mode, select the desired port and data type from the

drop-down lists provided. You can set the sensor up to push data over more than one

port. You can also set it up to push multiple types of data over the same port. To change

to Data Push mode, click on the Enabled checkbox next to each one of the four ports

you wish to enable.

Data Collection Tab

e Data Collection tab allows you to edit the following settings (see Figure 5.7):

Page 55

54 CHAPTER 5 SENSOR SETTINGS

Figure 5.4 – Data Collection Tab

Interval Data – Allows you to specify the length of your intervals as well as how those

intervals are stored. e interval refers to the time (in seconds) that trac data is aggregated (minimum interval is ve seconds). Interval data is stored directly into the

sensor’s SRAM memory, which is volatile and will not persist after a power cycle. e

number of intervals is limited to 246. You can also tell the sensor to move the data

from SRAM to the sensor’s ash memory by clicking the Store in Flash Memory

check box. is protects the data because ash memory persists after power cycles. e

capacity in ash is about ten times greater than SRAM. If the Store in Flash Memory

box is not checked, the interval data will remain in SRAM until it is overwritten. Flash

storage management features are explained in greater depth in the Data Collection

Setup section of chapter 7.

Vehicle Classification – Lets you customize vehicle classications by length. Enter the

maximum length amounts for small and medium class vehicles in the active text boxes

and SmartSensor Manager will automatically determine the minimum lengths.

Lane Setup – Allows you to change specic lane information such as lane name and

direction of travel, for your own information and for identication.

You can also change scale occupancy (loop size) and scale speed (loop spacing). e

entry in these columns for each lane represents the manual scaling applied to the occupancy/duration and speed data. e occupancy scale factor is the ratio of each lane’s

loop size to the default loop size. e speed scale factor is the ratio of each lane’s loop

spacing to that of the default loop spacing. You can modify the scale factors by clicking

on the arrows to the right of each box.

Page 56

CHAPTER 5 SENSOR SETTINGS 55

Note

Interval occupancy is derived from event duration, so the occupancy scale factor

scales both the duration and the occupancy. Additionally, the length-based event

classification is derived from the event duration and the event speed, so scaling either the speed or the duration will impact the classification results.

e Show Loop Values button allows you to toggle quickly between the loop values

and the corresponding scale factors.

Default Loop Size & Spacing – Lets you enter default values which, when applied, will

automatically update the information for each lane. e terms “loop size” and “loop

spacing” are used since in many cases you will be using these values to scale the occupancy and speed to match those of dual loops. e loop size and loop spacing (space

between loops) are specied in inches or centimeters.

Extension Time – Allows you to increase the time, in milliseconds, on the countdown

timer that the sensor uses in detection. Adding time can help reduce the occurrence of

vehicles with trailers being detected twice. However, increasing the time also increases

the likelihood that one vehicle being tailgated by another will result in a single detection.

Note

The lane name, lane direction, and interval data settings on this page can also be

changed on other pages. The rest of the settings can only be changed here.

Saving and Restoring Sensor Settings

Once you have made changes to your settings, use the four buttons at the bottom of the

screen to save the changes from all three tabs. You can also use these buttons to discard all

your changes and return to the old settings.

Save to Sensor – Saves the changes you’ve just made to the sensor. If you do not push

this button after making changes, they will be lost when you navigate away from this

page.

Open from Sensor – Returns all settings to those currently saved on the sensor.

Save to File – Saves the settings currently entered in the Sensor Settings screens to

a SmartSensor conguration le (.ssc) on your computer. is setting can be used

to back up your settings; additionally, if you’re not connected to your sensor, you can

change settings, save them to a le, and use the le to update your sensor once you’re

connected again.

Page 57

56 CHAPTER 5 SENSOR SETTINGS

Note

Using the Save to File function does not save the changes to your sensor. If you want

to update and then back up your sensor, you need to use both Save to File and Save

to Sensor.

Open from File – Restores settings from an existing .ssc le. Once the settings have

been restored, you must click Save to Sensor if you want the sensor updated with the

restored settings.

Note

Return to this page to back up your sensor after you’ve completed the steps to configure your lanes and data collection.

Sensor Date & Time

To ensure that the data collected is timestamped correctly, use the Sensor Date & Time

screen, located at Edit > Sensor Date & Time (see Figure 5.5).

Change the date by selecting the correct date from the drop-down lists (month, day, and

year) or use the calendar to scroll to the correct date. Change the time by selecting the correct time (hour, minutes, and seconds) from the drop-down lists.

Click the check box below the calendar to automatically adjust for local computer time and

daylight savings time settings. e check box at the bottom of the page will automatically

synchronize sensor to PC UTC time at a certain interval you can dene in the text eld.

Page 58

CHAPTER 5 SENSOR SETTINGS 57

Figure 5.5 – Sensor Date & Time

e Sensor Date & Time page includes the following three function buttons:

Clocks icon – Performs a one-time synch of the sensor to the PC’s UTC time.

Disk icon – Saves the new settings.

Arrow icon – Undoes the changes.

Operating Mode

Selecting Edit > Operating Mode allows you to switch between Side Fire and Forward

Fire operation modes. While Side Fire mode is standard, Forward Fire mode allows you

to detect trac from a forward-facing position, such as when the sensor is mounted on a

bridge across the road. With this setup, however, the sensor can only detect one lane at a

time and cannot detect cars until after they’ve passed the mounting location. If you’re interested in a forward-facing sensor, consider the SmartSensor Advance, which can detect

vehicles in multiple lanes up to 500 ft. (152.4 m) in advance.

If you would like to use the SmartSensor 105 in Forward Fire mode, call Wavetronix Technical Services at 801-764-0277 for assistance and further instruction.

Page 59

58 CHAPTER 5 SENSOR SETTINGS

Page 60

Lane Setup 6

In this chapter

Lane Configuration – Automatic

Lane Configuration – Manual

Verifying Lane Configuration

6

Setting up lanes is simple in SmartSensor Manager because the software will do it for you

with the click of a button. Additionally, if SmartSensor Manager is unable to correctly

congure due to barriers, obstacles or irregular lanes, you can use the Manual Congura-

tion mode to adjust.

Note

Free-flowing trac in each lane is required for proper configuration. Light or sporadic

trac may result in slower configurations.

Lane Configuration – Automatic

Follow the steps below to automatically congure lanes in SmartSensor Manager:

1 Select Edit > Lane Conguration.

2 Once the Lane Conguration page opens, click on the Automatic button.

3 If you would like to set constraints on the conguration through the Edit Range

Blinders or Manage Gain buttons, do so now. For more information on these options

see the sections on them in the following pages.

Page 61

60 CHAPTER 6 LANE SETUP

4 Click the Restart button at the lower right.

5 Conrm the conguration restart by clicking Yes in the box that appears (see Figure

6.1). SmartSensor Manager will now automatically begin detecting and conguring

lanes, and the screen will show a visual depiction of the lanes and vehicle detections

in real time.

Figure 6.1 – Confirming Automatic Lane Configuration

6 After the lanes have been detected and congured correctly, save the conguration

by clicking the Finished button. e time required for conguration depends on the

volume of trac present in the lanes, but is typically only a few minutes.

Note

After clicking the Finished button, wait for one minute before turning o the sensor.

During this time the sensor is completing adjustments of the configuration thresholds. Typically this is not a problem because verification may be needed in Trac

View after clicking Finished. The verification process will normally be longer than

one minute.

Edit Range Blinders

Range blinders are an optional setting available in Automatic mode. Using range blinders

will narrow the search area of the automatic lane conguration process (range blinders

have no eect in Manual Conguration mode), allowing you to congure faster and avoid

conguring undesired lanes such as frontage roads. Use the steps below to successfully edit

the range blinders:

1 Click the Range Blinders button. Red bars (range blinders) will appear at the top and

bottom of the roadway display and any previously displayed roadways will be cleared.

Page 62

CHAPTER 6 LANE SETUP 61

2 Click on one of the range blinders and drag its edge to the desired range (refer to the

range markers on the left side of the screen).

3 Repeat Step 2 for the other range blinder if necessary.

4 Click the Restart button to apply the range blinders. When the range blinders are ap-

plied, they will turn from a red color to a dark khaki color. To cancel and use the default

ranges, or to start over, or click the Range Blinders button again.

5 After the lanes are detected and congured correctly, save the conguration by clicking

the Finished button. After clicking the Finished button, the SmartSensor will begin

storing vehicle data. e time required for conguration depends on the volume of

trac present in the lanes, but is typically only a few minutes.

Note

After clicking the Restart button, detected vehicles (represented by moving blue

rectangles) will be displayed only if a range blinder does not cover the lane center. If

the edge of a range blinder lies between two lanes of the same road, some manual

adjustment of the gray line (usually reserved to indicate a road shoulder) may need to

be made. The edge of the road shown in the display is really a lane divider.

Manage Gain

Managing gain is an optional setting available in Automatic mode. During the automatic

conguration process, the sensor’s gain is automatically adjusted in order to best process

the radar signal at that particular installation site. In some locations the reections from

vehicles may be stronger than in other locations, and the gain will need to be lowered in

order to optimize detection accuracy.

For the gain to be optimally adjusted by the automatic process, the sensor needs to be:

Aligned almost exactly perpendicular to all the lanes of the roadway.

Still conguring while several large vehicles (that return strong reections) pass

through the beam in the lanes closest to the sensor.

In some locations, and at particular times of the day, it may be dicult to meet these two

requirements. In these cases, click the Manage Gain button to change the starting point of

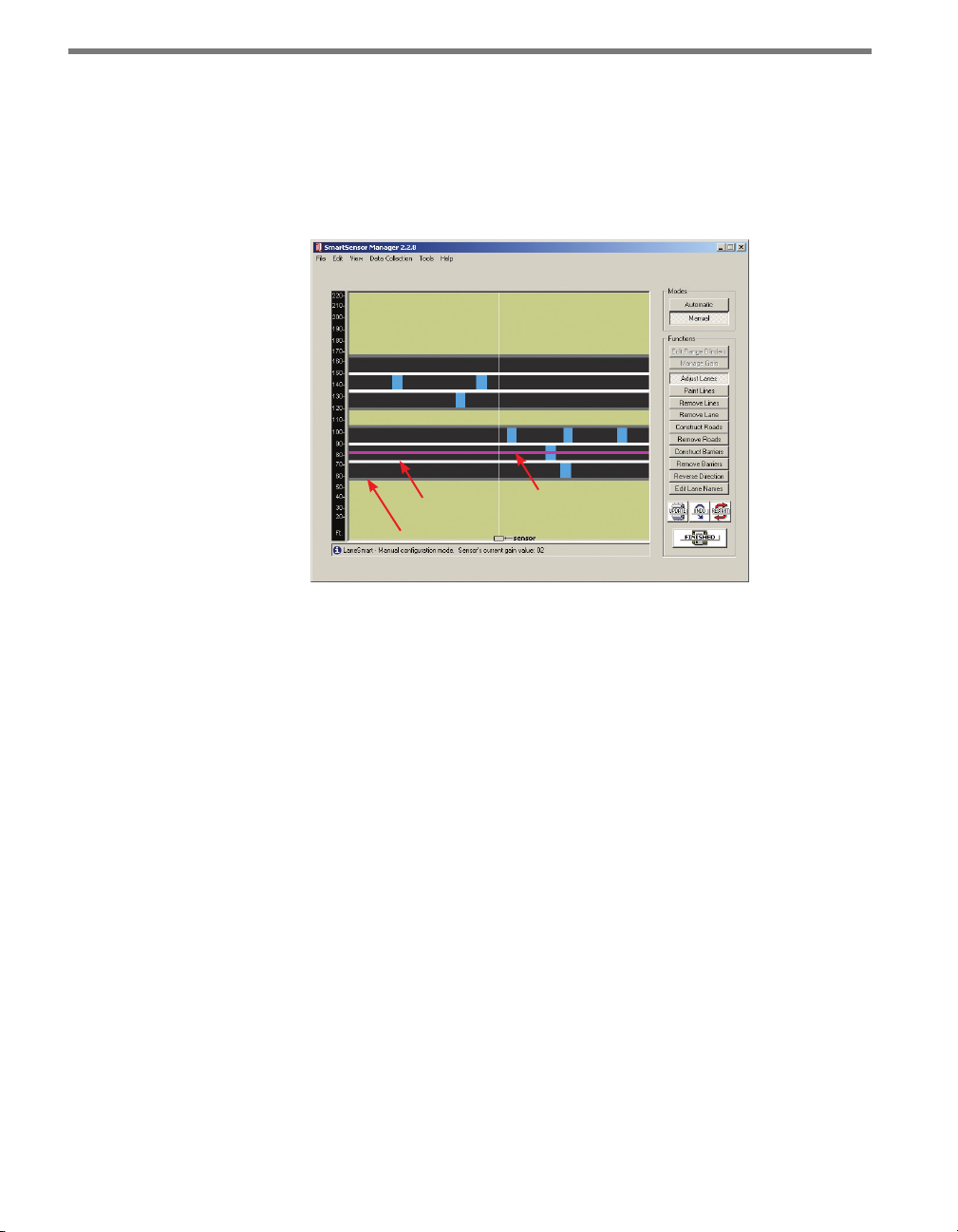

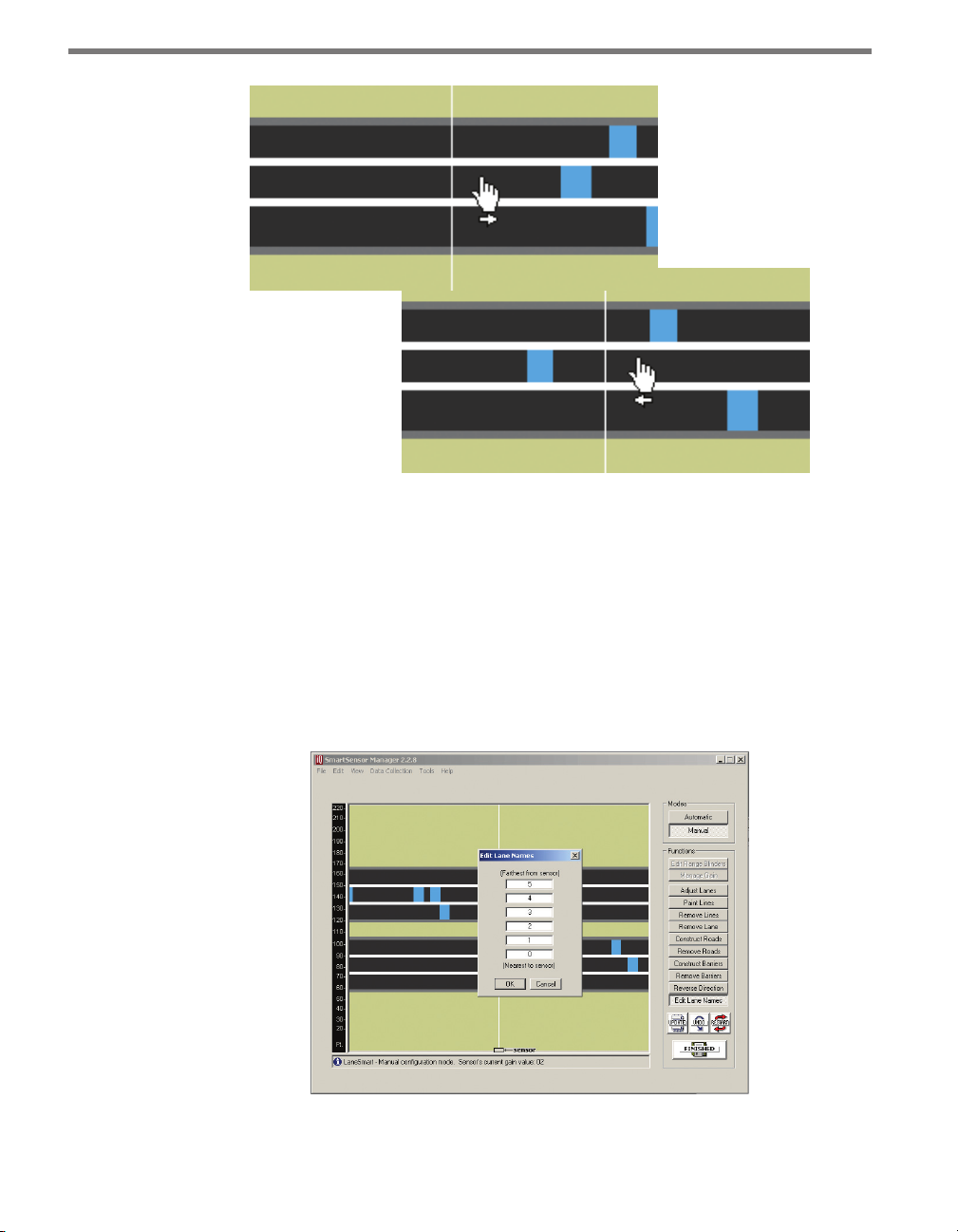

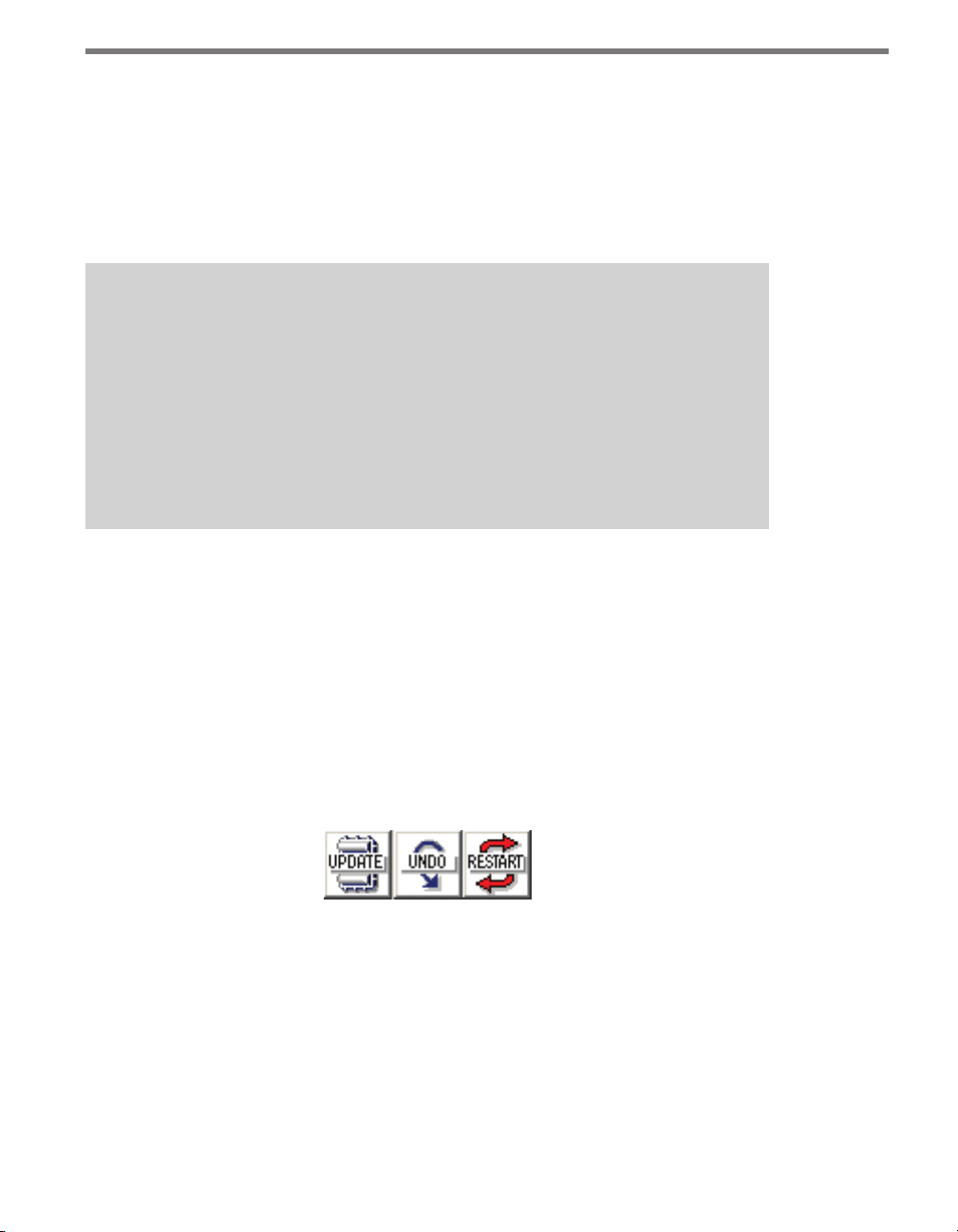

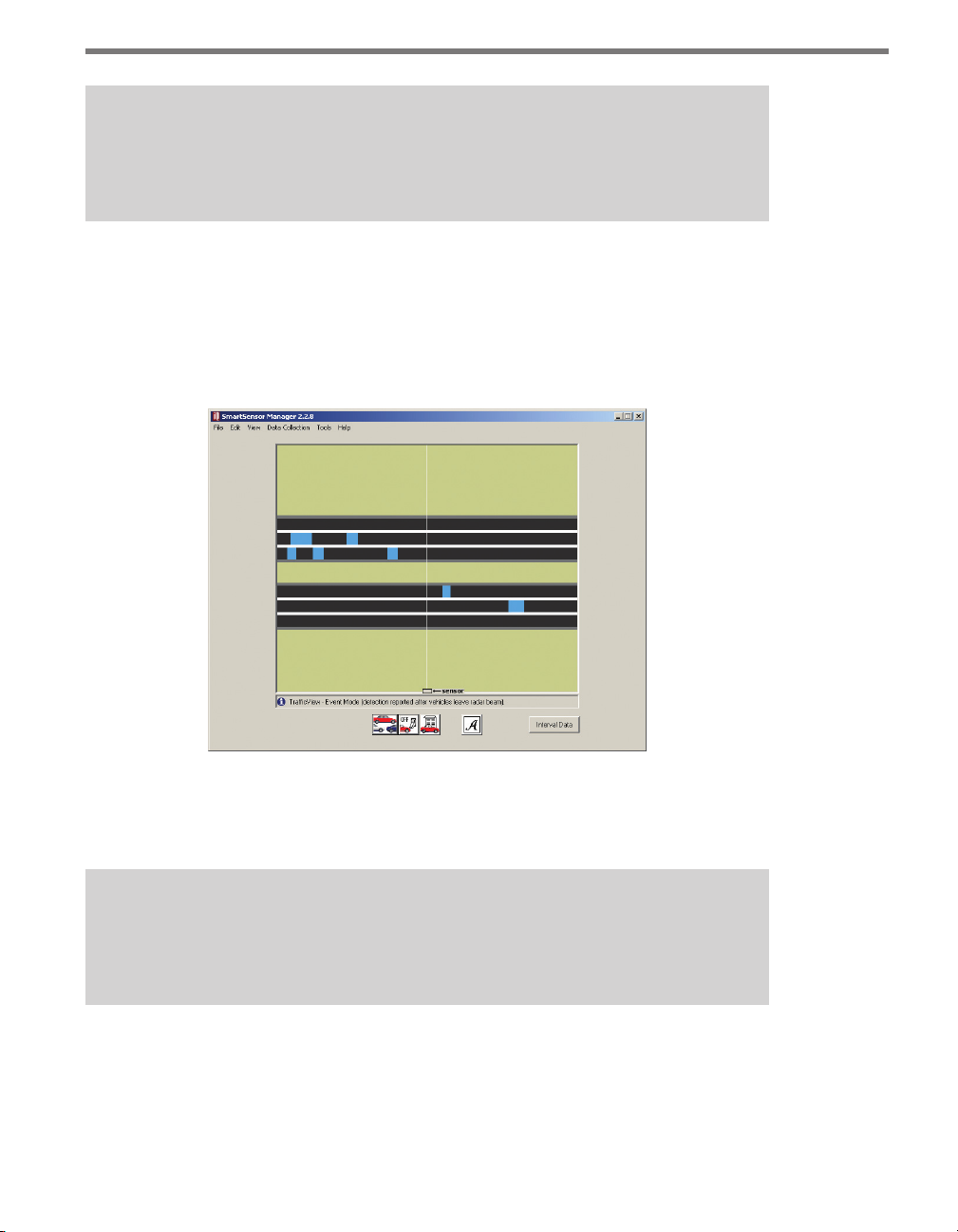

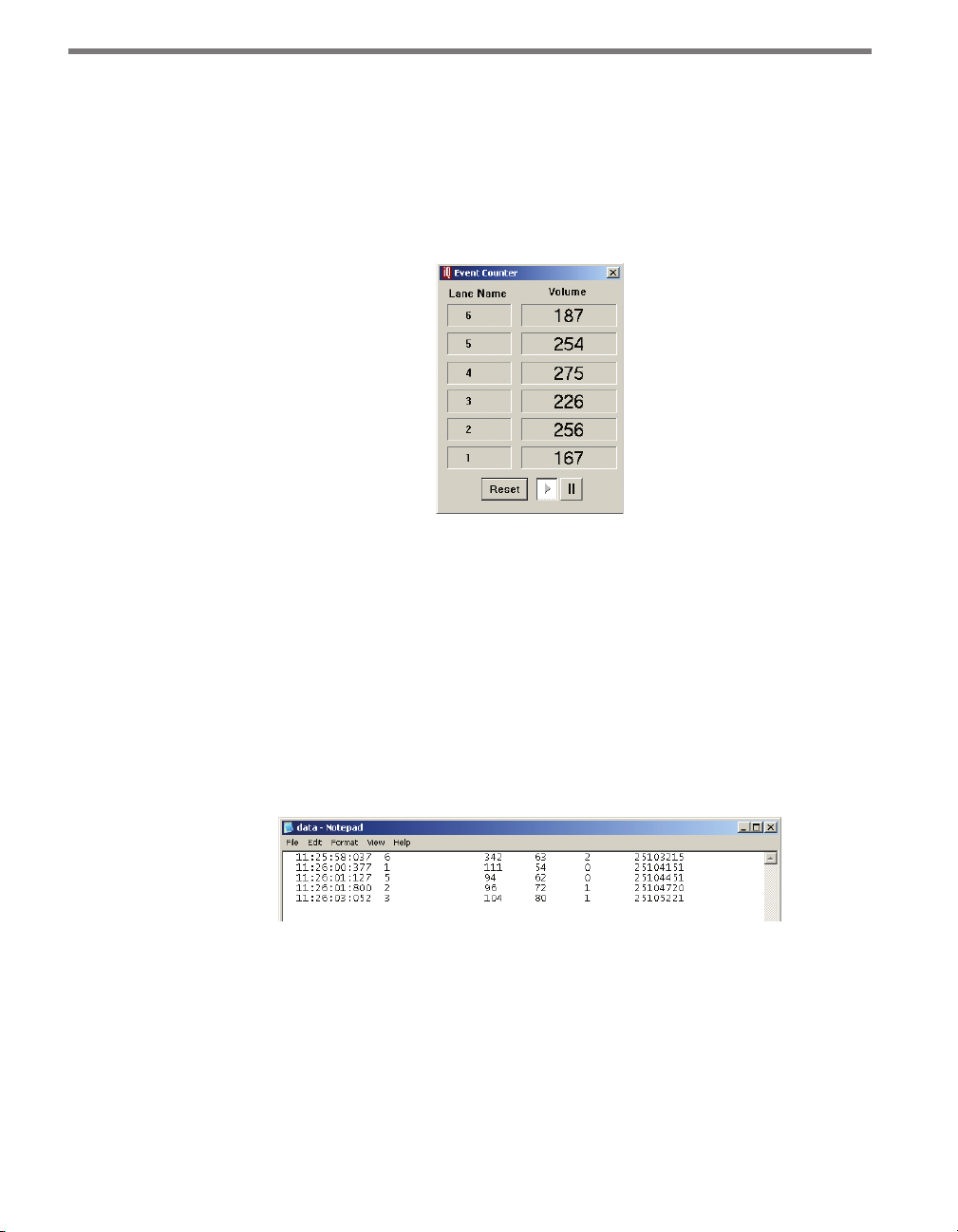

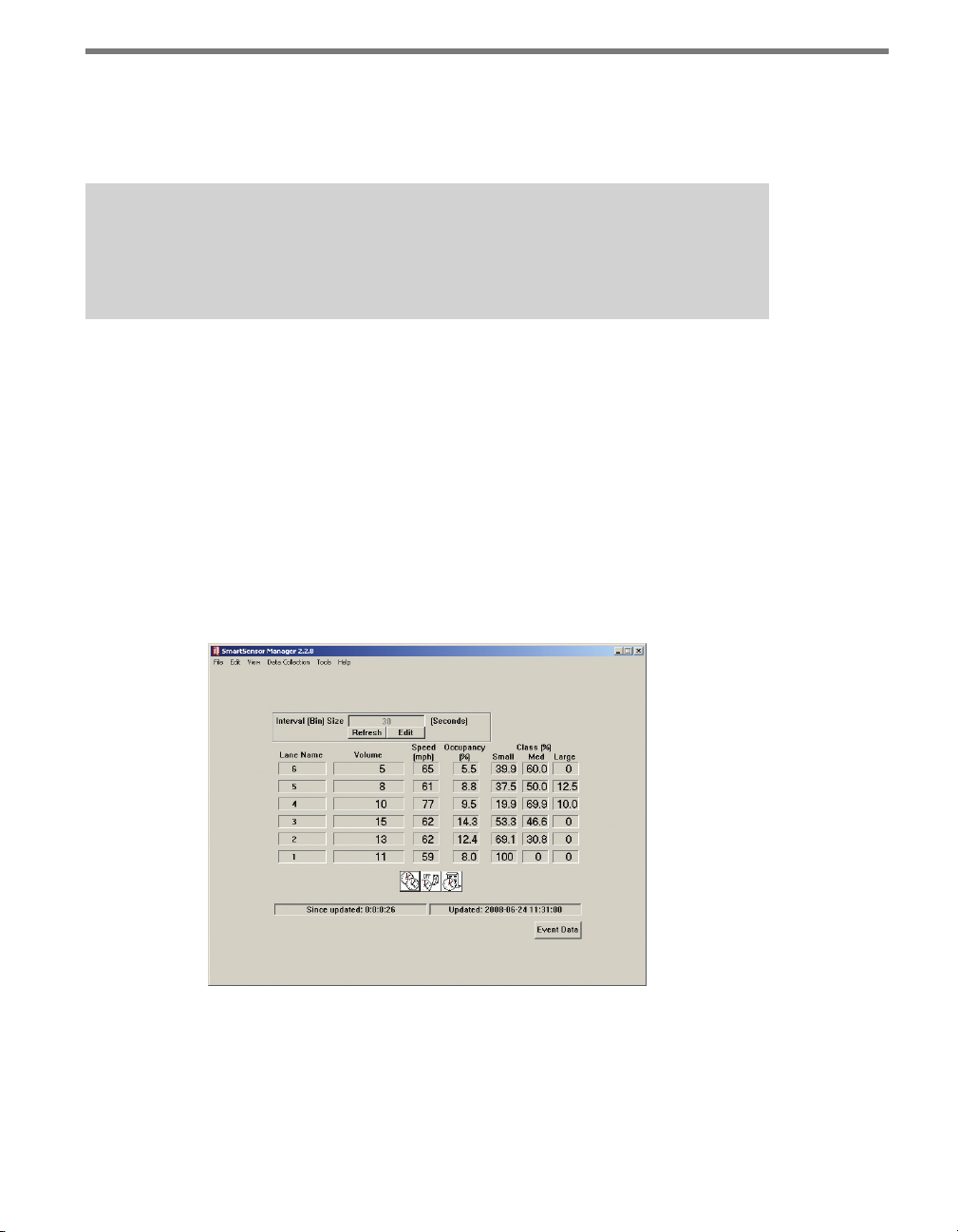

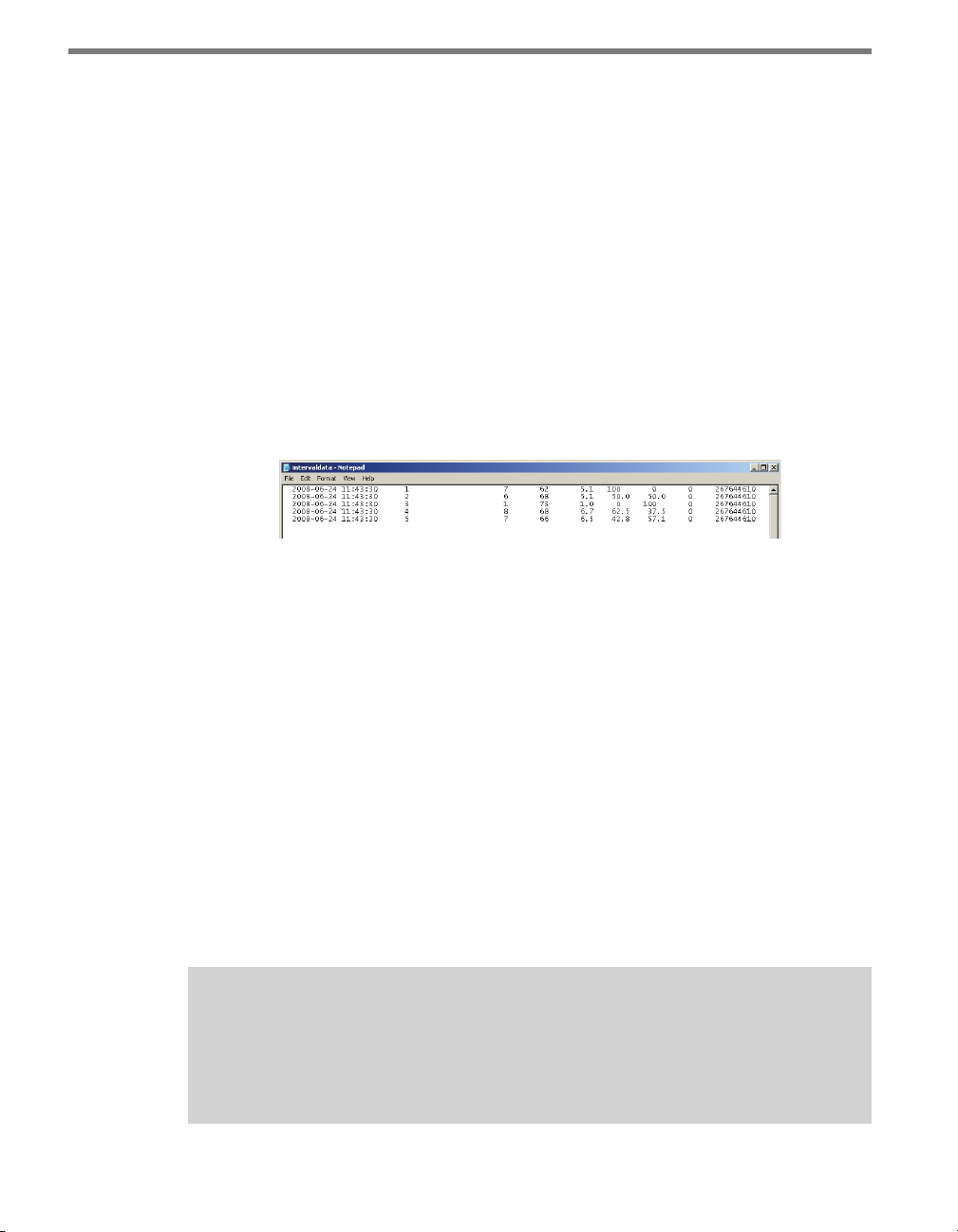

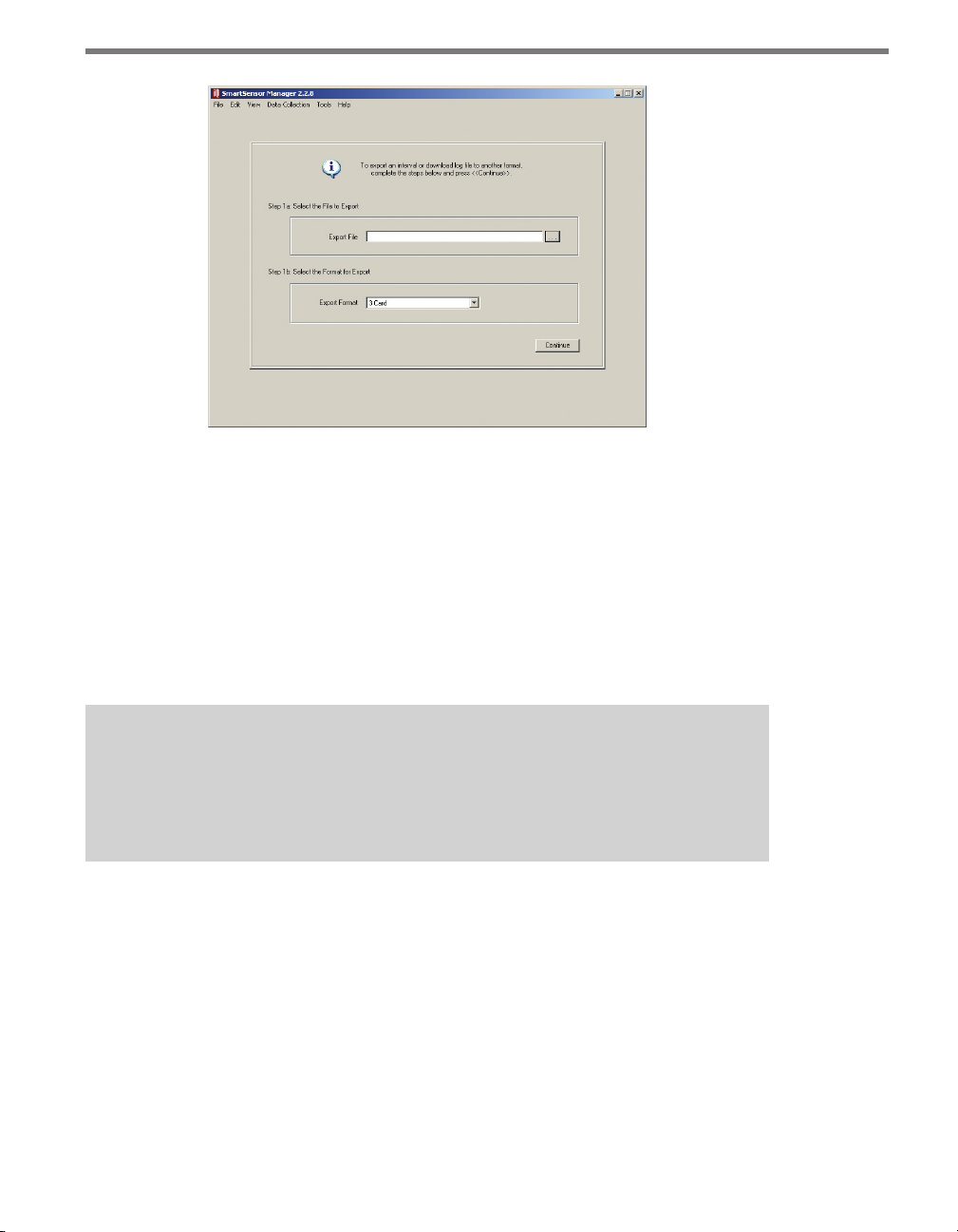

the automatic gain adjustment process. e default starting point is a gain value of 5. e