Page 1

Click 100–400 Series

USER GUIDE

Page 2

Click 100–400 Series

USER GUIDE

www.wavetronix.com 78 East 1700 South Provo, Utah 84606 801.734.7200

Page 3

© 2014 Wavetronix LLC. All Rights Reserved.

Wavetronix, SmartSensor, Click, Command, and all associated product names and logos are trademarks of Wavetronix LLC. All other

products or brand names as they appear are trademarks or registered trademarks of their respective holders.

Protected by US Patent Nos. 6,556,916; 6,693,557; 7,426,450; 7,427,930; 7,573,400; 7,889,097; 7,889,098; 7,924,170; 7,991,542;

8,248,272; 8,665,113; Canadian Patent Nos. 2461411; 2434756; 2512689; and European Patent Nos. 1435036; 1438702; 1611458. Other

US and international patents pending.

e Company shall not be liable for any errors contained herein or for any damages arising out of or related to this document or the

information contained therein, even if the Company has been advised of the possibility of such damages.

is document is intended for informational and instructional purposes only. e Company reserves the right to make changes in the

specications and other information contained in this document without prior notication.

FCC Part 15 Compliance: e Wavetronix SmartSensor sensors comply with Part 15 of the Federal Communications Commission

(FCC) rules which state that operation is subject to the following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesirable operation. FCC compliance statements for applicable optional modules are to be found in the module specications. Unauthorized changes or modications

not expressly approved by the party responsible for compliance with the FCC rules could void the user’s authority to operate this

equipment.

Disclaimer: e advertised detection accuracy of the Wavetronix SmartSensor sensors is based on both external and internal testing,

as outlined in each product’s specication document. Although our sensors are very accurate by industry standards, like all other sensor manufacturers we cannot guarantee perfection or assure that no errors will ever occur in any particular applications of our technology. erefore, beyond the express Limited Warranty that accompanies each sensor sold by the company, we oer no additional

representations, warranties, guarantees or remedies to our customers. It is recommended that purchasers and integrators evaluate the

accuracy of each sensor to determine the acceptable margin of error for each application within their particular system(s).

WX-500-0055

04/2012

Page 4

Contents

Introduction 7

Using this Manual 7

Part I Introduction to the Click Series

Chapter 1 The Power Plant 11

Connecting to a Circuit Breaker 12 • Connecting AC Surge

Protection 12 • Connecting Power 13 • Wiring AC Power into

the Click 201/202/204 14

Chapter 2 T-bus Basics 17

Adding a T-bus to the DIN Rail 18 • Mounting Click Devices

18 • Wiring T-buses 18

Chapter 3 Wiring the Devices 21

Working with Screw Terminal Blocks 21 • RS-485 Communication 22 • RS-232 Communication 24

Chapter 4 Installing Click Supervisor 27

Installing Click Supervisor 28 • Microso .NET Framework 31

Chapter 5 Using Click Supervisor 33

Connecting to Your Computer 33 • Accessing the Communication Screen 34 • Serial Communication 35 • IP Communication 37 • Working with Modules 38

Part II Individual Click 100–400 Series Modules

Page 5

Chapter 6 Click 100 — 16 Output Contact Closure 43

Physical Features 44 • Troubleshooting 48

Chapter 7 Click 101 — Multi-sensor to Contact Closure 49

Physical Features 51 • Installation 54 • On-device Conguration 54 • Computer Conguration 55

Chapter 8 Click 104 — 4-channel DIN Rail Contact Closure 61

Physical Features 62 • Installation 64 • Conguration 65 •

Rotary Switch 66 • Front Panel Menu 67 • Click Supervisor 73

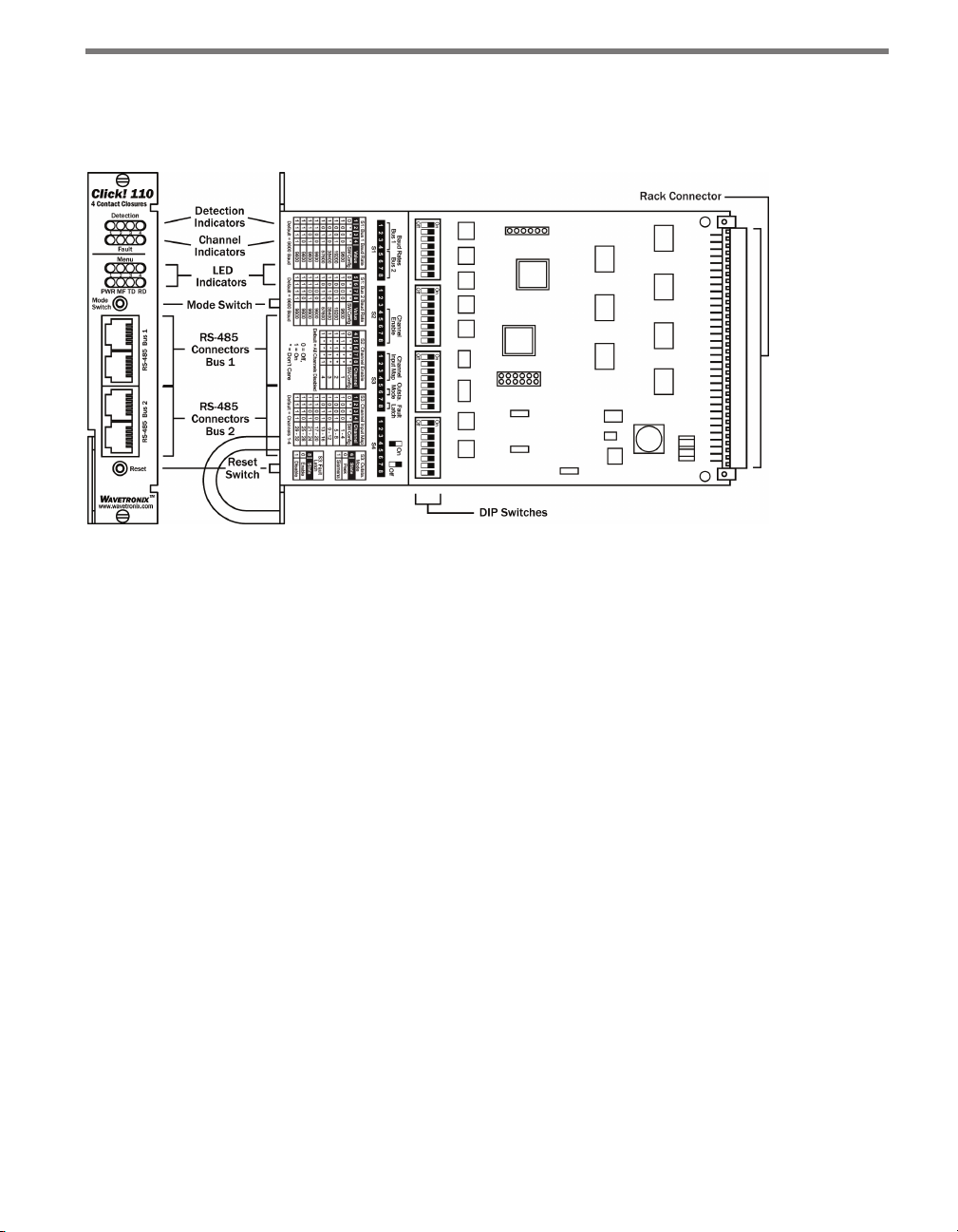

Chapter 9 Click 110 — 4-channel Contact Closure Eurocard 79

Physical Features 80 • Installation and Wiring 82 • Fail-safe

Mode 85 • Conguration 85 • DIP Switches 86 • Front Panel

Menu 92 • Click Supervisor 101

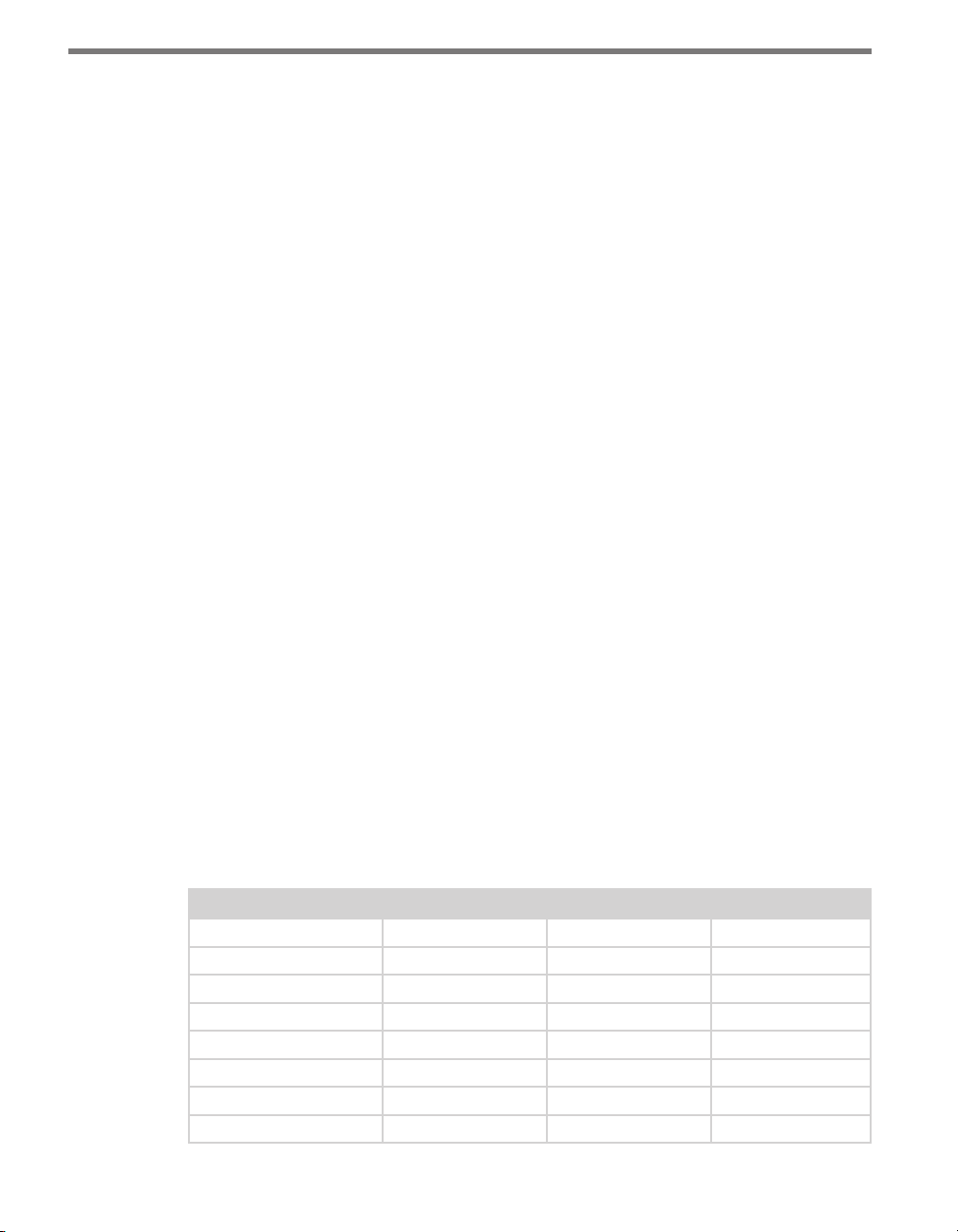

Chapter 10 Click 112/114 — Detector Rack Cards 107

Physical Features 108 • Installation and Wiring 109 • Conguration 111 • DIP Switches 112 • Front Panel Menu 115

Chapter 11 Click 120/121 — Relay 129

Physical Features 130 • Installation 130

Chapter 12 Click 172/174 — Contact Closure Rack Cards 133

Physical Features 134 • Installing and Wiring the Click

172/174 136 • Operation Modes 136 • Power and Conguration 139 • Verify Operation 141 • Fail-safe Mode 142 •

Troubleshooting 143

Chapter 13 Click 200 — Lightning Surge Protector 145

Physical Features 146 • Installation 147

Chapter 14 Click 201/202/204 — AC to DC Power Supply 151

Physical Features 152 • Installation 152

Chapter 15 Click 203 — UPS/Battery 155

Physical Features 156 • Installation 157 • On-device Conguration 158

Page 6

Chapter 16 Click 210 — AC Circuit Breaker 161

Physical Features 162 • Installation 162

Chapter 17 Click 211 — AC Outlet 163

Physical Features 164 • Installation 164

Chapter 18 Click 221 — DC Surge Protector 167

Physical Features 168 • Installation 168

Chapter 19 Click 222 — System Surge Protector 169

Physical Features 170 • Installation 171

Chapter 20 Click 223 — Dual-485 Surge Protector 175

Physical Features 176 • Installation 177

Chapter 21 Click 230 — AC Surge Protector 179

Physical Features 180 • Installation 180

Chapter 22 Click 250 — Wireless Surge Protector 183

Physical Features 184 • Installation 184

Chapter 23 Click 301 — Serial to Ethernet Converter 187

Physical Features 188 • On-device Conguration 189

Chapter 24 Click 304 — RS-232 to RS-485 Converter 207

Physical Features 208 • On-device Conguration 209 • Computer Conguration 210

Chapter 25 Click 330/331 — Unmanaged Switches 219

Physical Features 220 • Installation 221 • Switching Characteristics 222

Chapter 26 Click 340/341/342 — Managed Switches 225

Physical Features 226 • Installation 228

Chapter 27 Click 400 — 900 MHz Radio 229

Page 7

Physical Features 230 • On-device Conguration 231 • Computer Conguration 233

Chapter 28 Click 421 — Serial to Bluetooth® Radio 245

Physical Features 246 • On-device Conguration 247 • Computer Conguration 249

Page 8

Introduction

In the introduction

Using this Manual

Wavetronix Click products are a simple and cost-eective way to connect various trac

components into a single, unied system. With a broad range of easy-to-use products, the

Click line integrates quickly and operates in even the harshest conditions. Click devices

provide the power and communication solutions needed for eective trac control and

management.

e Click series is divided into ve smaller, numerically based series. Each device in a particular series shares common elements, functions, etc.:

Click 100 series – Contact closure devices

Click 200 series – Power and surge protection devices

Click 300 series – Wired communication devices

Click 400 series – Wireless communication devices

Click 500 series – Customizable devices built on our Click 500 platform

is user guide covers the Click 100–400 series. For the Click 500 series, please see the Click

500 Series User Guide.

Using this Manual

is manual is divided into two parts:

Part I: Introduction to the Click Series – is part contains information common to

the Click line, beginning with basic module installation guidelines. It then covers the

Page 9

8 INTRODUCTION CLICK 100–400 SERIES USER GUIDE

Click Supervisor soware, which is used with certain Click devices for conguration.

For a list of Click 100–400 series devices that use Click Supervisor, see the beginning

of Chapter 4.

A few Click devices dier from what is written in the common information chapters

in the way they are installed or the soware used to congure them. In the event that a

Click device departs from what is written in Part I, that dierence will be noted in that

device’s chapter in Part II.

Part II: Individual Click 100–400 Series Modules – is part contains a chapter for

every device (or set of devices, in some cases) in the Click 100–400 series. Each chapter has an introduction to the device along with a description of the device’s physical

features and, when pertinent, sections on installation, conguration, troubleshooting

and more.

Page 10

Part I

Introduction to the Click Series

Chapter 1 – The Power Plant

Chapter 2 – T-bus Basics

Chapter 3 – Wiring the Devices

Chapter 4 – Installing Click Supervisor

Chapter 5 – Using Click Supervisor

Page 11

Page 12

The Power Plant 1

In this chapter

Connecting to a Circuit Breaker

Connecting AC Surge Protection

Connecting Power

1

Power and surge protection are provided to your devices via the Click modules that make

up what is known as the power plant (see Figure 1.1). Assembling the power plant is the rst

step in installing your Click devices.

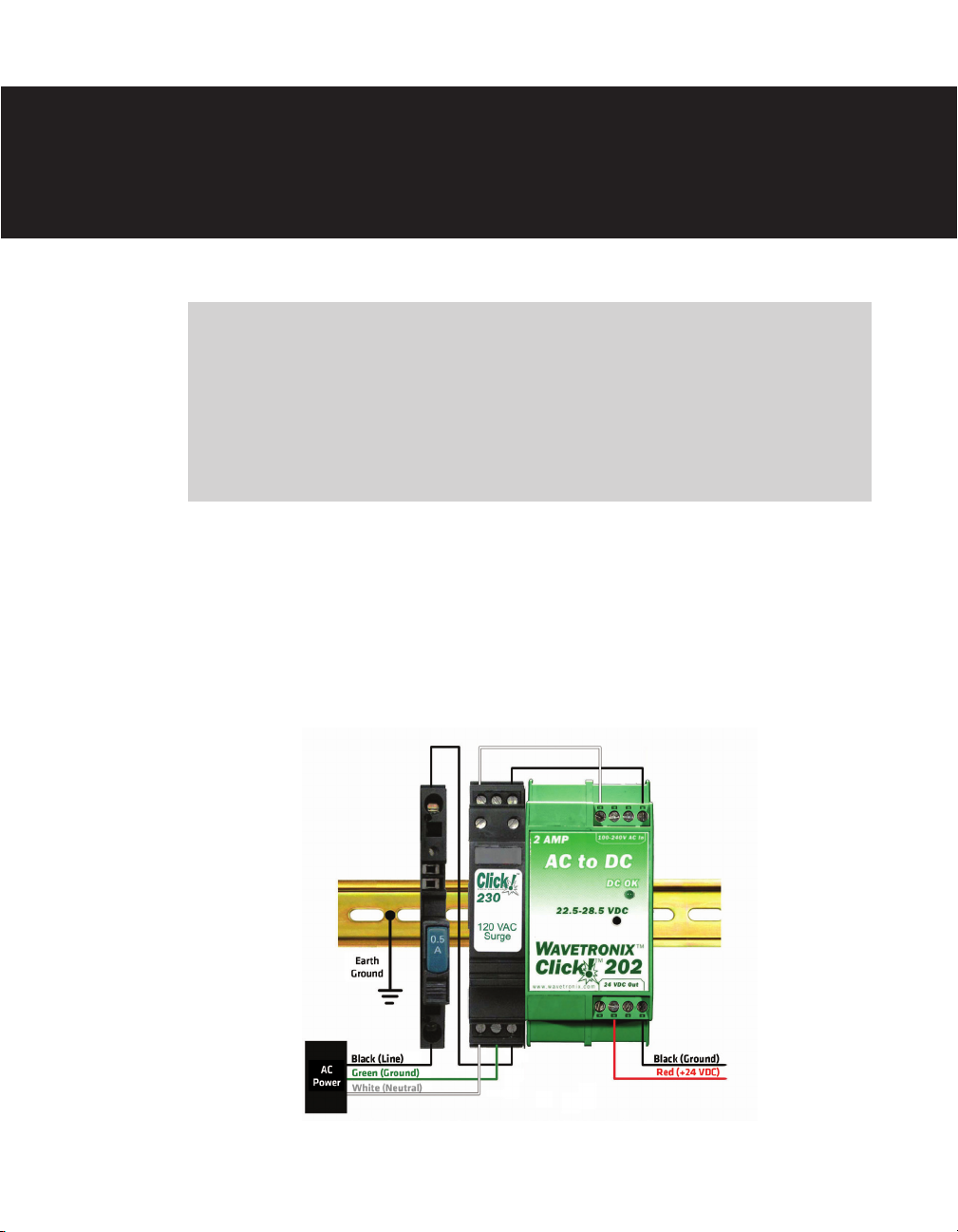

Figure 1.1 – The Click Power Plant

Page 13

12 CHAPTER 1 THE POWER PLANT

Note

The power plant will only be used if your cabinet is supplied with AC power. If DC is

coming into your cabinet, you will need the Click 221 DC surge protector, discussed in

Part II.

Connecting to a Circuit Breaker

e rst Click module you will connect is the Click 210, a circuit breaker designed to interrupt an electric current under overload conditions. e breaker is trip-free and can be easily

reset aer a current interruption by pushing the reset button (see the Click 210 chapter for

more information on this device).

To add a Click 210 circuit breaker and switch:

1 Using a rocking motion, mount the Click 210 onto the DIN rail.

2 Make sure the reset button on front of the module is pressed down before wiring.

3 Connect the black (line) wire from the terminal block or from the AC cord into one

side of the module.

4 Connect power out of the other side.

Note

It doesn’t matter which side is power in, as long as the opposite end is power out.

Connecting AC Surge Protection

e next module in the power plant is the Click 230, which provides surge protection to

other modules on the DIN rail (see the Click 230 chapter for more information on this device). Use these steps to include AC surge protection in your installation:

1 Using a rocking motion, mount the Click 230 onto the DIN rail next to the Click 210.

2 Connect the wire from the Click 210 to the rightmost screw terminal (terminal 5) on

the side of the Click 230 marked IN (see Figure 1.2).

3 Connect the white (neutral) and green (ground) wires from the AC terminal block or

from the AC cord into screw terminals 1 and 3, respectively, also on the side marked

IN.

4 Connect the outgoing neutral and power wires to screw terminals 2 and 6, respectively,

on the side marked OUT.

Page 14

CHAPTER 1 THE POWER PLANT 13

Figure 1.2 – Click 230 Screw Terminals (labels beneath terminals have been added)

Screw terminals 3 and 4 are directly bonded via the metal mounting foot of the base element to the DIN rail. ere is no need for any additional grounding between terminals 3

and 4 and the DIN rail.

Note

If you are using a Click 211 in your installation, the configuration of the power plant

will dier slightly from what is listed in this chapter, starting at this point in the

installation process. See the Click 211 chapter of this manual for more information.

Connecting Power

e nal component of the power plant is the AC to DC converter. e Click line features

several such converters. e Click 201/202/204 are AC to DC power supplies that provide

DC power to every Click product mounted on the DIN rail. e Click 201 provides 1 A, the

Click 202 provides 2 A and the Click 204 provides 4 A.

e screw terminals on the top and bottom of the Click 201/202/204 can be unplugged

from the module, allowing you to pre-wire power before the nal installation. e screw

terminal blocks are red-keyed, allowing the block to plug back into only one specic jack.

Note

If you prefer, instead of the Click 201/202/204, you can use the Click 203, which is a

combination UPS and battery. This set of modules will convert AC to DC and provide

uninterrupted power to your equipment. See the Click 203 chapter in Part II of this

document for more information.

Page 15

14 CHAPTER 1 THE POWER PLANT

Wiring AC Power into the Click 201/202/204

Use the steps below to properly wire AC power to the top of the Click 201/202/204:

1 Using a rocking motion, mount the Click 202/202/204 to the DIN rail next to the Click

230.

2 Connect the power and neutral wires from the Click 230 into the screw terminals

marked L and N, respectively, on the side of the module marked 100–240V AC In.

Figure 1.3 – Wiring AC Power into the Click 201/202/204

Caution

Make sure power to AC mains is disconnected while wiring the AC input.

Wiring DC Power out of the Click 201/202/204

e screw terminals on the bottom of the devices are slightly dierent. e Click 202 and

204 have a single terminal block, while the Click 201 has two; it doesn’t matter which of

the two terminal blocks on the 201 you wire into. Connect one wire for DC power (red is

standard) to a screw terminal marked +. Connect a second wire as a ground wire (black is

standard) to either of the two terminals marked – (see Figure 1.4).

Note

Do not wire into the DCOK terminal; it provides only 20 mA and should only be used

to monitor the power supply.

Page 16

CHAPTER 1 THE POWER PLANT 15

Figure 1.4 – Wiring DC Power out of the Click 201/202/204

Caution

An authorized electrical technician should perform installation and operation of this

unit. Persons other than authorized and approved electrical technicians should NOT

attempt to connect this unit to a power supply and/or trac control cabinet, as there

is a serious risk of electrical shock through unsafe handling of the power source. Extreme caution should be used when connecting this unit to an active power supply.

Page 17

Page 18

T-bus Basics 2

In this chapter

Adding a T-bus to the DIN Rail

Mounting Click Devices

Wiring T-buses

2

Now that the power plant is complete, the next step in installing your Click modules is adding a T-bus to your DIN rail. A T-bus is made up of small modules called T-bus connectors

that snap onto your DIN rail to provide power and communication connections to your

Click devices. You can connect together as many T-bus connectors as you need to provide

power and communication to all the Click devices on the rail with only a single wiring connection.

Wavetronix has two varieties of T-bus connectors: green connectors, which conduct both

power and communication, and gray connectors, which only conduct power. Gray T-bus

connectors are used when you don’t want certain devices to communicate with each other.

In such a case, a gray connector placed between the two devices would prevent communication while still providing power.

Note

Wavetronix removes the communication lines from the gray T-bus connectors it provides. Gray T-bus connectors obtained from suppliers other than Wavetronix, however, will still have communication capabilities.

Page 19

18 CHAPTER 2 T-BUS BASICS

Adding a T-bus to the DIN Rail

Placing the T-bus on the DIN rail is quick and easy. To attach a T-bus connector to the rail,

simply position the connector over the rail with the male connector pointing to the right.

Hook one arm of the connector over one side of the DIN rail and press the other arm down

over the other side until the connector snaps in place. All the T-bus connectors you connect

together should be facing this direction.

To connect T-bus connectors together, simply slide them toward each other until you hear

them snap into place. To disconnect T-bus connectors, use a small, thin item, like a small

screwdriver, to gently pry the two modules apart.

Mounting Click Devices

To connect a Click device to the DIN rail and T-bus, simply position the device over the Tbus connector and, using the same rocking motion used to connect the devices in the power

plant, snap the device onto the DIN rail.

Note

Not all Click devices use the T-bus this way. Some devices, such as the 330, 331, 340,

341, 342, and those in the power plant, snap onto the DIN rail but not onto the T-bus.

For more information on how to install these devices, see the appropriate chapters in

Part II of this document.

Wiring T-buses

ere are two ways to provide power to a T-bus: wiring through a Click 200 and wiring

through a 5-screw terminal block.

Wiring through a Click 200

e Click 200 is a surge protection device that can be connected to a sensor. e Click 200

is unique among Click devices because it can take power and communications in through

its screw terminals and send it through any T-bus it is currently mounted on.

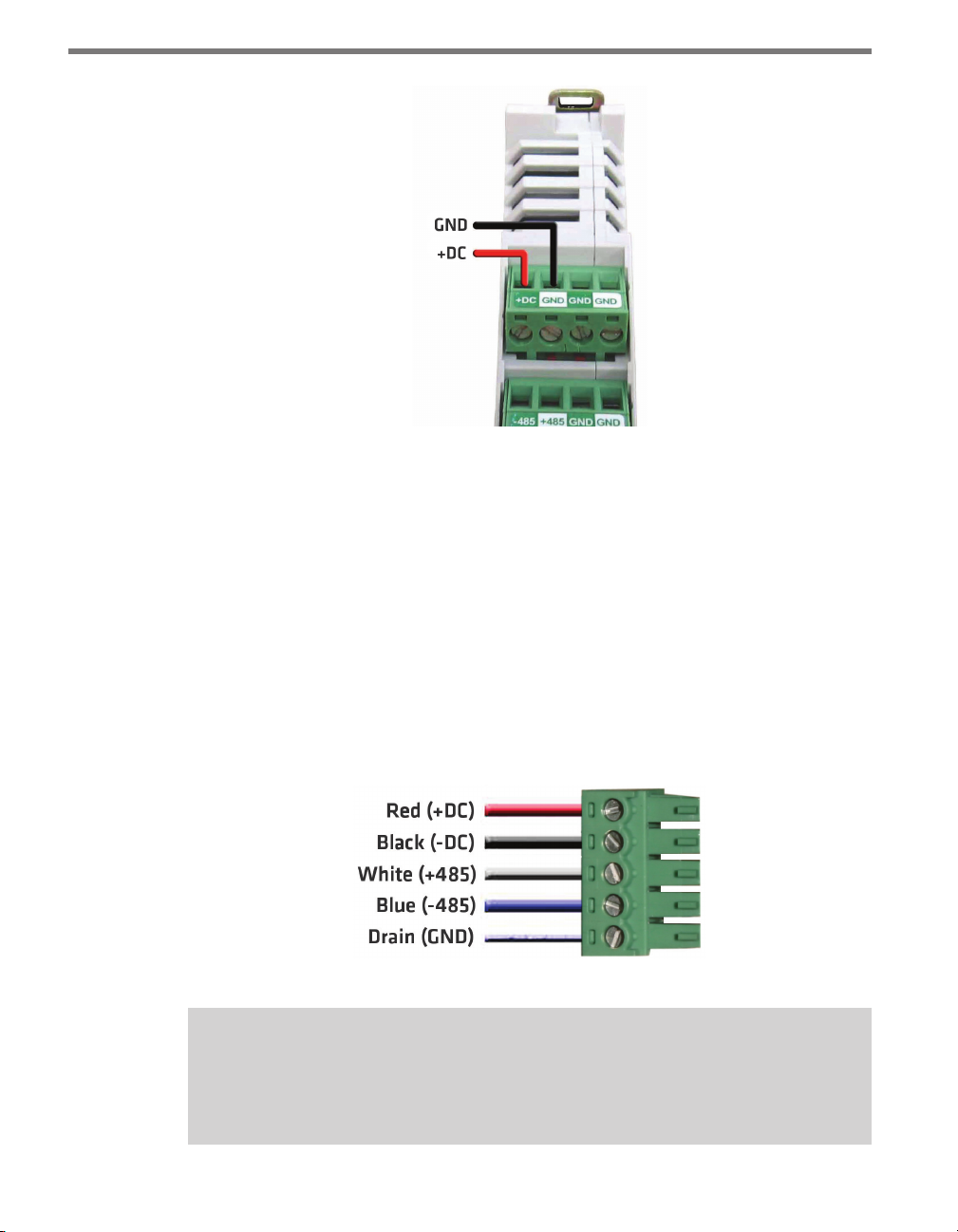

To provide power to a T-bus through a Click 200, follow these steps (see Figure 2.1):

1 Connect a Click 200 to a DIN rail and T-bus.

2 Connect the red (+24 VDC) wire from the Click 201/202/204 into the +DC screw ter-

minal on the side of the Click 200 marked PROTECTED.

3 Connect the black (ground) wire from the Click 201/202/204 into any of the terminals

marked GND on the same screw terminal block as the red wire.

Page 20

CHAPTER 2 T-BUS BASICS 19

Figure 2.1 – Wiring Power into the Click 200

Wiring through a 5-screw Terminal

If you choose not to use a Click 200, or if you have one but prefer not to wire through it,

you can also connect power through a 5-screw terminal block connected to the end of the

T-bus.

To provide power to a T-bus through a 5-screw terminal block, follow these steps:

1 Attach a male 5-screw terminal block to the le end of the T-bus by aligning it with the

rst connector and pushing the modules together.

2 Connect the black (ground) and red (+24 VDC) wires from the Click 201/202/204

into the top two screw terminals in the 5-screw terminal block (see Figure 2.2 for the

5-screw terminal block pinout).

Figure 2.2 – 5-screw Terminal Block Pinout

Note

To disconnect a 5-screw terminal block from a T-bus connector, use a small, thin item,

such as a small screwdriver, to gently pry the two modules apart.

Page 21

20 CHAPTER 2 T-BUS BASICS

Wiring out of a T-bus

Occasionally you will need to provide power and communication to devices in your cabinet

that are not on a DIN rail or on a T-bus. In these cases, you can connect a female 5-screw

terminal block to the right side of your T-bus and wire +DC, ground and communication

from there into the device.

Page 22

Wiring the Devices 3

In this chapter

Working with Screw Terminal Blocks

RS-485 Communication

RS-232 Communication

3

You are now ready to begin adding Click modules to your cabinet. For information on the

unique features of each of the devices in the Click line, see the corresponding chapter in

Part II of this document (or of the Click 500 Series User Guide).

Despite having dierent features, there are certain elements that are similar across devices.

Some of these, such as DIN rail mounting and the use of a T-bus for power and communication, have already been discussed. is chapter will discuss another such element: wiring

communication through the screw terminals.

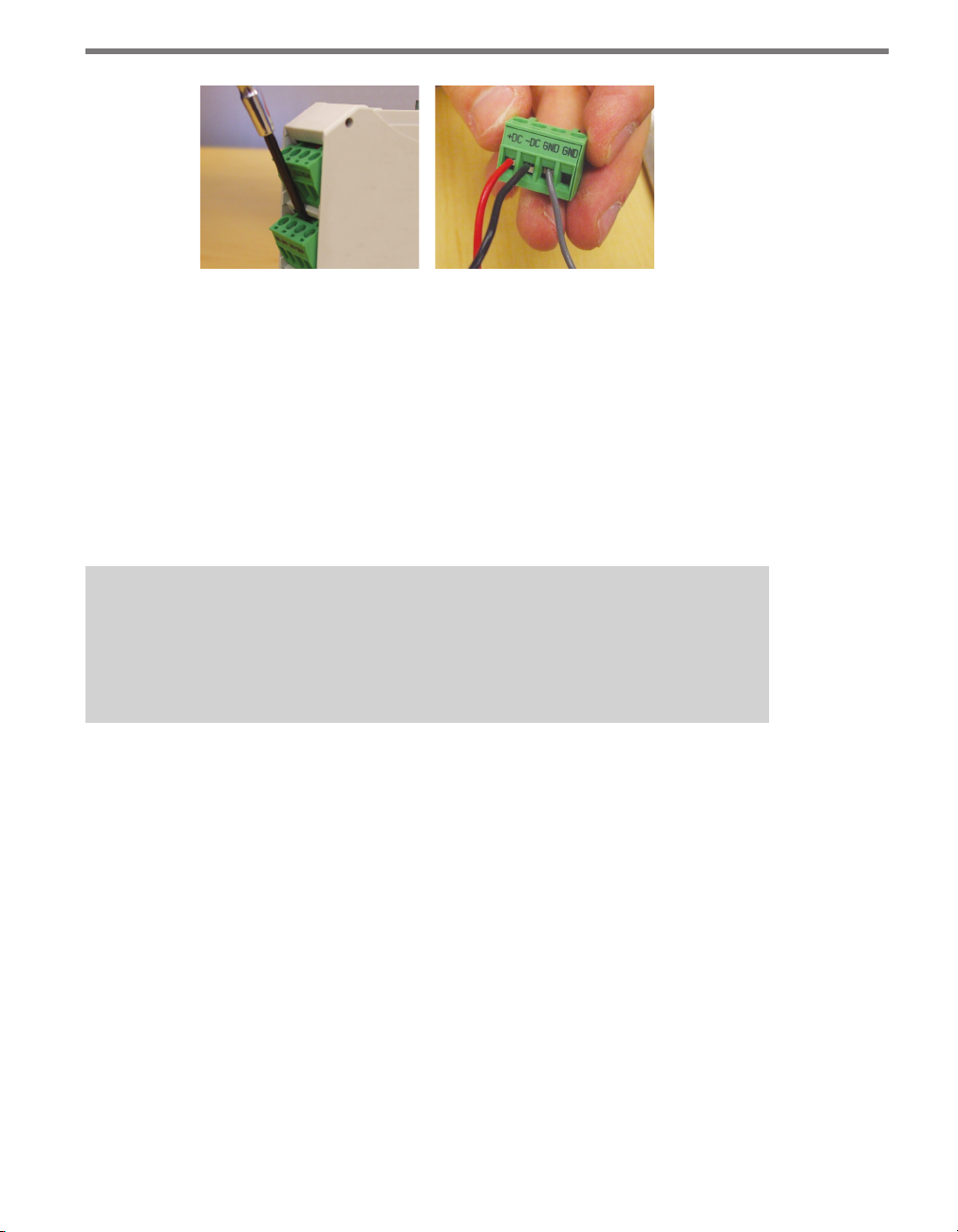

Working with Screw Terminal Blocks

Many Click devices feature screw terminal blocks for wiring connections. ese screw terminal blocks simplify wiring because they can be removed from the Click device, then

wired and reinserted.

To remove a screw terminal block, insert a small, thin item, such as a small screwdriver, into

the gap between the screw terminal block and the Click device (just above the screw heads)

and gently pry the two apart.

Aer wiring, simply reinsert the screw terminal block and push until it snaps into place. e

screw terminal blocks are red-keyed, meaning they will only plug into their specic jacks.

Page 23

22 CHAPTER 3 WIRING THE DEVICES

Figure 3.1 – Removing and Wiring Screw Terminal Blocks

RS-485 Communication

Another feature that is common to many Click devices is RS-485 communication capabilities. RS-485 is important for Click devices because it is carried on the T-bus to all the Click

devices on a given DIN rail.

Connecting RS-485 communications to the Click devices on a DIN rail can be accomplished in two dierent ways: through a 5-screw terminal on the end of a T-bus, or through

a Click module, which will then communicate with the T-bus.

Note

The steps in this section are specifically for use with a Wavetronix SmartSensor cable. If you are using a dierent cable or wiring system, the colors of the wires used

will be dierent.

To connect through a 5-screw terminal, follow these steps.

1 Connect the +485 (white) wire from the terminal block or cable to the middle screw

terminal on the 5-screw terminal block connector you’re using for the T-bus in question

(see Figure 2.2 in the previous chapter for the pinout of the 5-screw terminal block).

2 Connect the -485 (blue) wire from the terminal block or cable to the middle screw

terminal on the 5-screw terminal block.

3 Plug the 5-screw terminal block into the T-bus.

To connect through any Click device with RS-485 ports, follow these steps:

1 Ensure that the Click device is mounted on a T-bus connector.

2 Connect the +485 (white) wire from the terminal block or cable to the terminal marked

“+485” in the screw terminal blocks (see Figure 3.2).

3 Connect the -485 (blue) wire from the terminal block or cable to the terminal marked

“-485” in the screw terminal blocks.

4 Connect the RS-485 drain wire from the terminal block or cable to a GND terminal in

the screw terminal blocks.

Page 24

CHAPTER 3 WIRING THE DEVICES 23

Note

If you are using a Click 200 in your installation, it is recommended you wire RS-485

through it if you would like to connect to a Click device.

Figure 3.2 – Wiring RS-485 Communication into the Click 200

Wiring RS-485 from a Click Device

Several Click devices—such as the 104, 110, 112/114, 172/174, 200, 301 and 304—also have

RJ-11 jacks for RS-485 communication with a computer or with contact closure cards. To

use, simply use an RJ-11 jumper cable to connect the two devices.

Figure 3.3 – A Click Device Showing RJ-11 and DB-9 Jacks

Page 25

24 CHAPTER 3 WIRING THE DEVICES

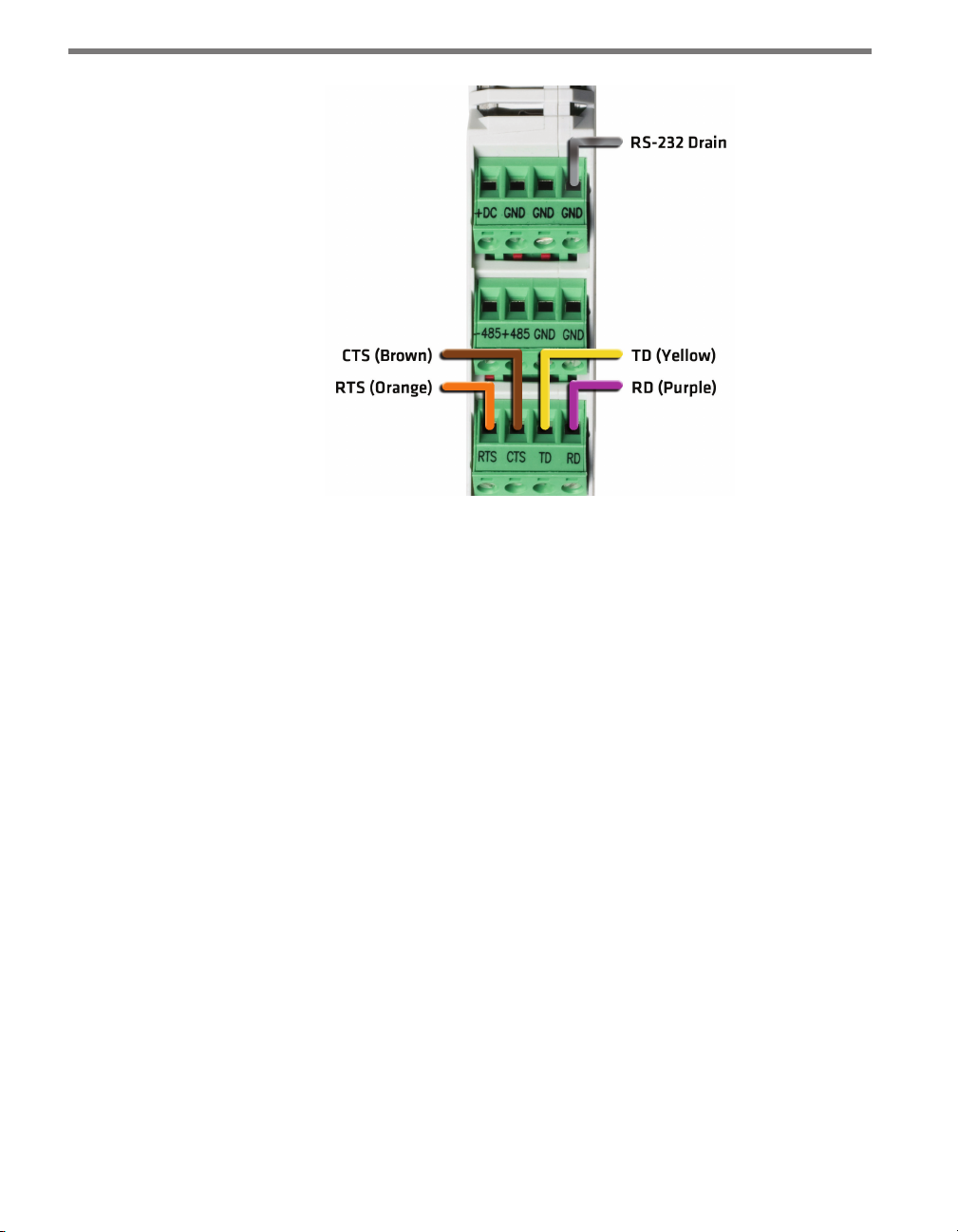

RS-232 Communication

Most Click devices also feature RS-232 communication capabilities. ese modules will

convert the RS-485 communication moving to and from the T-bus to RS-232. See below for

how to connect RS-232 to a laptop.

Several modules also have RS-232 screw terminals.

Note

The steps in this section are specifically for use with a Wavetronix SmartSensor cable. If you are using a dierent cable or wiring system, the colors of the wires used

will be dierent.

To use, follow the steps below:

1 Connect the RTS (orange) wire from the cable or terminal block to the RTS screw ter-

minal on the protected side of the Click device (see Figure 3.4).

2 Connect the CTS (brown) wire to the CTS terminal on the protected side of the Click

device.

3 Connect the TD (yellow) wire to the TD terminal on the protected side of the Click

device.

4 Connect the RD (purple) wire to the RD terminal on the protected side of the Click

device.

5 Connect the RS-232 drain wire to a GND terminal on the protected side of the screw

terminal blocks.

Page 26

CHAPTER 3 WIRING THE DEVICES 25

Figure 3.4 – Wiring RS-232 Communication into the Click 200

Wiring RS-232 from a Click Device

Many Click modules feature an DB-9 jack for RS-232 communication with a laptop or other

such device. To use, simply use a straight-through cable to connect the two devices.

Page 27

Page 28

Installing Click Supervisor 4

In this chapter

Installing Click Supervisor

Microsoft .NET Framework

4

Once your Click devices are installed and wired, the next step is to install Click Supervisor, a computer program that will help you work with your Click modules. Most Click

devices can be congured and monitored to some extent using the buttons and LEDs on

the module, but certain devices can be ne-tuned using Click Supervisor. ese computerprogrammable devices include the following:

Click 101 – Multi-sensor to contact closure module

Click 104 – 4-channel DIN rail contact closure module

Click 110 – 4-channel contact closure Eurocard

Click 112/114 – Detector rack cards

Click 301 – Serial to Ethernet converter

Click 304 – Intelligent RS-485 to RS-232 converter

Click 306 – 1-port terminal server

Click 400 – Autobaud 900 MHz spread spectrum radio

Click 421 – Bluetooth® to serial converter

ere are also a number of Click 500 series devices that can be congured using Click Supervisor; these are discussed in the Click 500 Series User Guide.

Page 29

28 CHAPTER 4 INSTALLING CLICK SUPERVISOR

Note

If you are running Windows® Vista, you must run Click Supervisor in XP Service Pack

2 compatibility mode. To switch to this mode, right-click on the Click Supervisor icon

and select Properties from the drop-down menu. Go to the Compatibility tab. Under

Compatibility mode, click the Run this program in compatibility mode for: checkbox. This will enable the drop-down menu, allowing you to select Windows XP (Service Pack 2). Hit OK.

Installing Click Supervisor

If you have a Wavetronix Install Kit, the handheld computer included in the kit comes with

Click Supervisor already installed, along with sensor soware. If you don’t have an install

kit, or if you want to install on a desktop computer, follow the steps below.

Click Supervisor can be run on a Windows® PC and on ahandheld computer Everything

needed to install Click Supervisor is contained in the Click Supervisor Setup.exe le. e

setup program can install Click Supervisor on a PC, handheld computer or both.

Note

You must have administrator rights to run the setup program.

e soware can be downloaded from the Wavetronix website at www.wavetronix.com. After downloading the setup le, double-click on it to run the Click Supervisor setup wizard

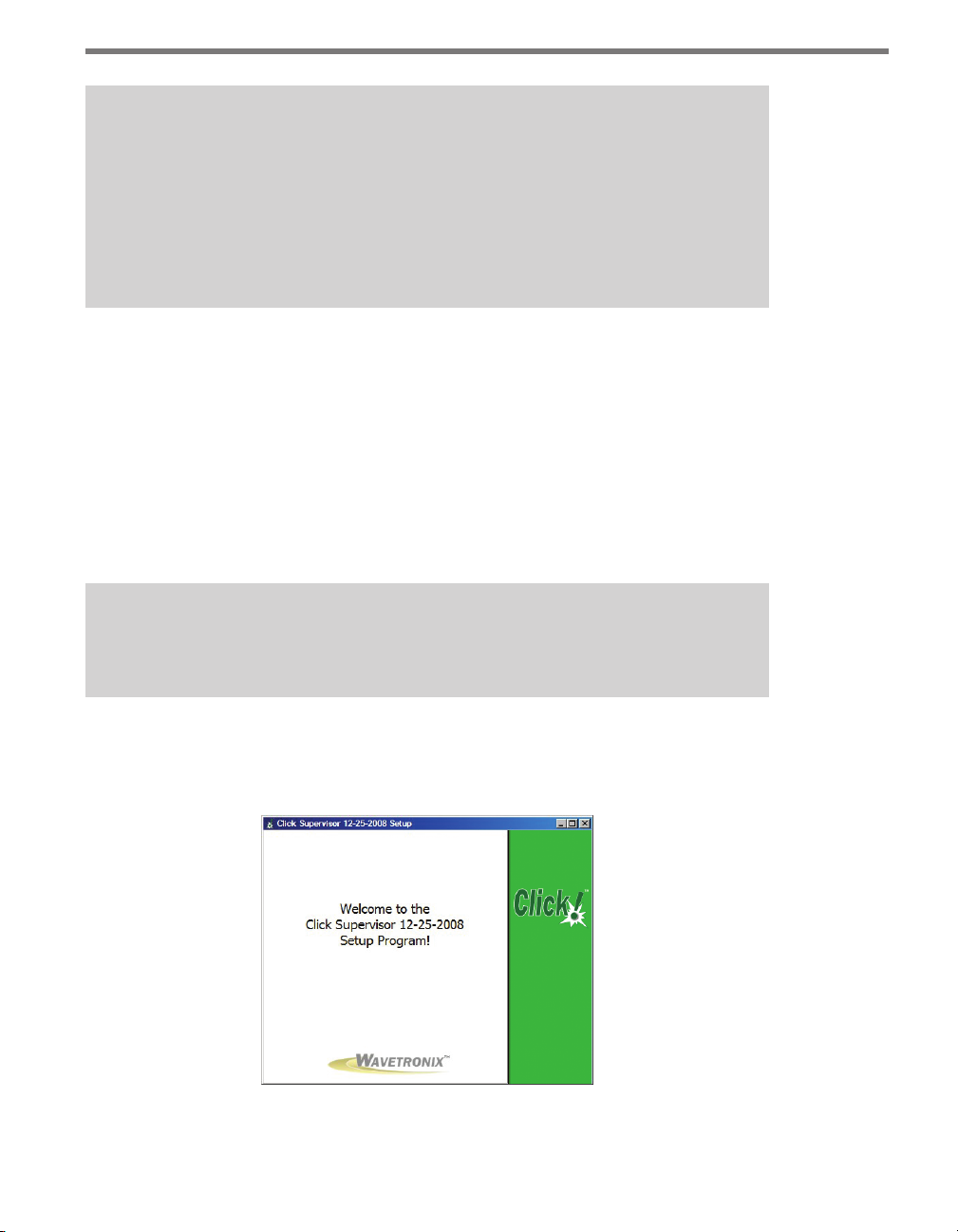

(see Figure 4.1).

Figure 4.1 – Click Supervisor Setup Wizard

Page 30

CHAPTER 4 INSTALLING CLICK SUPERVISOR 29

To install Click Supervisor on a handheld computer, you need to have ActiveSync (on Windows XP or earlier) or Windows Mobile Device Center (on Windows Vista). If you do not

have these programs, they are available for download on the Microso website.

If you do not have ActiveSync or Windows Mobile Device Center installed on your computer, skip to the next section, titled Installing Click Supervisor on a PC.

If you do have ActiveSync or Windows Mobile Device Center installed on your computer,

the setup program will detect this and the next screen that comes up will prompt you to select where you want to install Click Supervisor: a PC, a Pocket PC, or both (see Figure 4.2).

Figure 4.2 – Selecting an Installation

If you select Computer, the program will go through the steps outlined in the next section,

Installing Click Supervisor on a PC. If you select Pocket PC, the program will go through

the steps in the section titled Installing Click Supervisor on a handheld computer. If you

select both, the program will go through both installation processes, beginning with installing on the PC.

Note

Although the software can be installed on most handhelds, because of constantly

changing handheld technologies, Wavetronix can only oer technical support on the

handheld in the kit, which is a Socket Mobile 650.

Installing Click Supervisor on a PC

Follow these steps to install Click Supervisor on a PC:

1 On the screen shown in Figure 4.2, click the checkbox labeled Computer and then

select Next > >.

2 Select an installation location. e default location provided is normally “C:\Program

Files\Wavetronix.” Click Browse to choose another location (see Figure 4.3).

Page 31

30 CHAPTER 4 INSTALLING CLICK SUPERVISOR

Figure 4.3 – Location to Be Installed

3 Click the Install Now button.

4 Aer Click Supervisor is installed, you can create shortcuts to the soware on the desk-

top and in the start menu using the corresponding checkboxes on the nal screen (see

Figure 4.4). If no shortcuts are desired, uncheck the corresponding boxes. If you are

installing on a Pocket PC at the same time, this screen will not appear until both installations are complete.

Figure 4.4 – Shortcut Options

5 Click the View release notes when nished checkbox to view the Click Supervisor

release notes. e release notes contain additional information about the current version of the Click Supervisor soware. A PDF reader program such as Adobe Acrobat

Reader is required to view the release notes.

6 Click Finish to complete the setup process.

Installing Click Supervisor on a Handheld Computer

Although the soware can be installed on many handheld computers, because of constantly

changing handheld technologies, Wavetronix can only oer technical support on the handheld in the kit, which is a Socket Mobile 650.

Page 32

CHAPTER 4 INSTALLING CLICK SUPERVISOR 31

Use these steps to install Click Supervisor on a handheld computer:

1 Ensure that you have ActiveSync or Windows Mobile Device Center installed and that

the handheld is connected to the PC and synced.

2 On the screen shown in Figure 4.2, click the checkbox labeled Pocket PC and then

select Next > >.

3 On the next screen, click Continue > > to start the installation process (see Figure

4.5). e setup program runs the Add/Remove Programs application for Windows

handheld devices. If a handheld device is connected to the computer, Add/Remove

Programs will immediately begin installing Click Supervisor on the handheld device.

If a device is not connected to the computer, Click Supervisor will be downloaded the

next time a handheld device is connected to the computer.

Figure 4.5 – Adding Click Supervisor to a Pocket PC

4 Click OK once the download is complete.

Microsoft .NET Framework

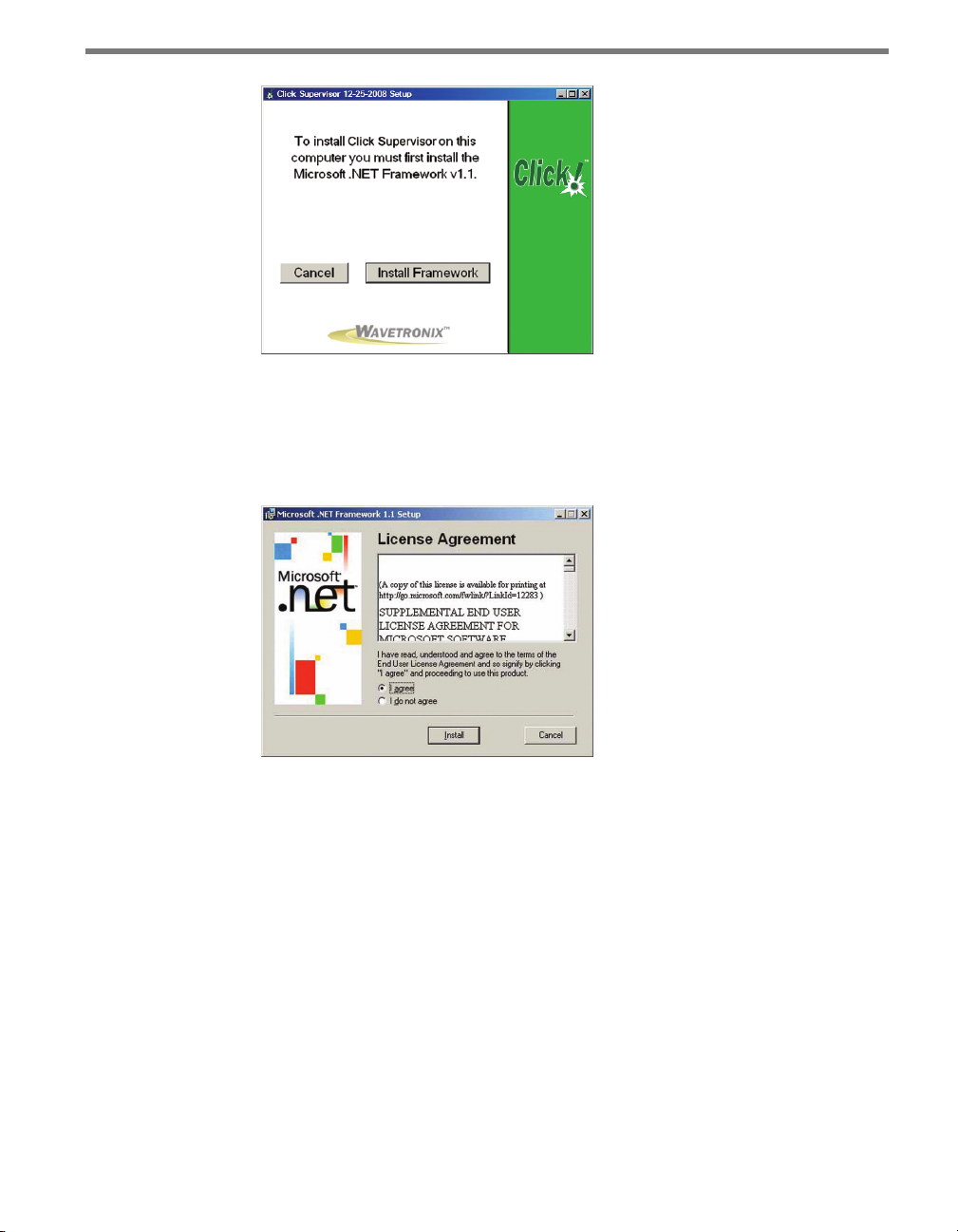

e Click Supervisor setup program will automatically detect whether Microso .NET

Compact Framework v1.1 is installed on your PC. If it is not installed, you will be prompted

to install it (see Figure 4.6).

Page 33

32 CHAPTER 4 INSTALLING CLICK SUPERVISOR

Figure 4.6 – Microsoft .NET Framework Prompt

Use the following steps to install Microso .NET Framework:

1 Click the Install Framework button.

2 Click the I Agree radio button when the License Agreement appears (see Figure 4.7).

Figure 4.7 – Microsoft .NET License Agreement

3 Click Install. A window will appear stating that the .NET Framework has been in-

stalled successfully.

4 Click OK and you will be returned to the Click Supervisor setup program.

Page 34

Using Click Supervisor 5

In this chapter

Connecting to Your Computer

Accessing the Communication Screen

Serial Communication

IP Communication

Working with Modules

5

Once you have Click Supervisor installed on your computer, you can begin using it to congure and monitor your Click devices.

Connecting to Your Computer

e rst step is to connect your computer to the Click modules on your DIN rail so that

Click Supervisor can see them. Click Supervisor can detect all computer-programmable

devices that are connected together by either a wired or wireless connection.

You can do this one of two ways. If you are using an Ethernet connection, you must be on

the same network with the Click device. Plug the Ethernet cable from your computer or

switch to the RJ-45 jack on the front of the Click 301. You must use a crossover cable to

connect your computer to the Click 301 via Ethernet.

If you are using a serial RS-232 connection, the computer needs to be connected by a

straight-through serial cable to the DB-9 connector on the front of any one of the computer-programmable devices on the T-bus. See the beginning of Chapter 4 for a list of Click

100–400 series devices that can be congured using Click Supervisor.

Page 35

34 CHAPTER 5 USING CLICK SUPERVISOR

Connecting the computer to another device that has a RS-232 port but is not computerprogrammable, such as the Click 200, will not allow Click Supervisor to communicate with

the other computer-programmable devices on the T-bus.

Accessing the Communication Screen

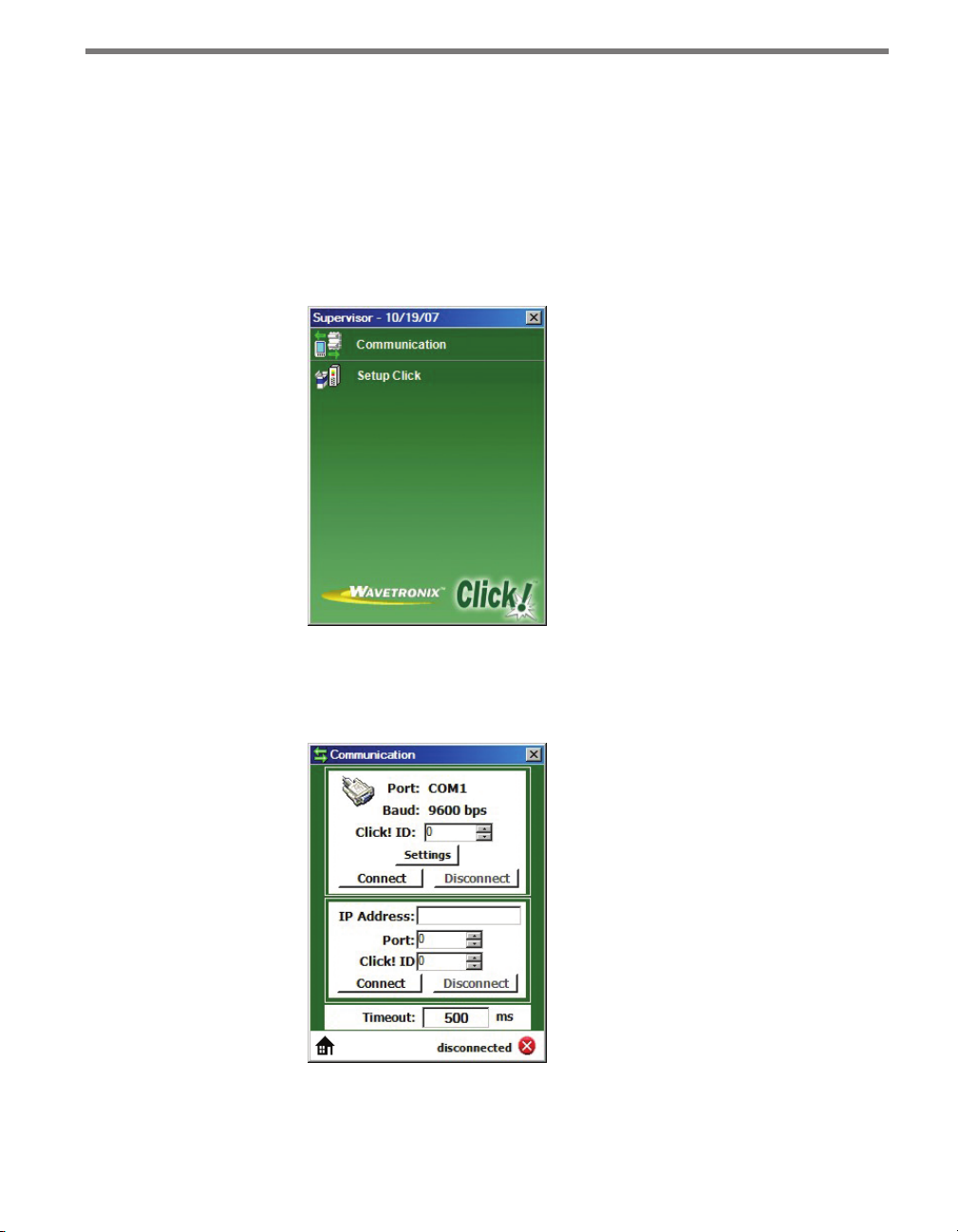

To connect to your devices with Click Supervisor, open the program by double-clicking on

it. It will bring you to the Click Supervisor main screen (see Figure 5.1).

Figure 5.1 – Click Supervisor Main Screen

Click on Communication to access the Communication screen (see Figure 5.2). ere are

two ways to connect to your Click devices: through a serial connection or an IP connection.

Figure 5.2 – Communication Screen

Page 36

CHAPTER 5 USING CLICK SUPERVISOR 35

Serial Communication

e rst section on the Communication screen is Serial Communication. Here you can

connect to a Click device through an RS-232 cable.

Changing Settings

Click Settings to bring up the Serial Settings screen (see Figure 5.3).

Figure 5.3 – Serial Settings Screen

COM Port – Allows you to change the serial connection port.

Baud Rate – Allows you to change the baud rate or set it to auto-detect.

Flow Control – Is usually only used if you are connecting your computer to an RS-232

device that requires hardware handshaking.

Parity – Allows you to set parity error checking.

Stop Bits – Allows you to set the number of stop bits.

Data Bits –Allows you to set the number of data bits being sent.

Note

The flow control, parity, stop bits and data bits settings should not be changed unless you have been instructed to do so by Wavetronix Technical Services.

Click the Save as default settings checkbox to tell the soware to remember your setup. Click

OK to return to the Communication screen or Cancel to exit without saving your settings.

On the Communication screen, you can see the settings reected in the Port: and Baud:

entries. Port: shows the port you’ve set the program to communicate through, and Baud:

shows the baud rate, as set under Settings or as automatically detected.

Page 37

36 CHAPTER 5 USING CLICK SUPERVISOR

Connecting to a Device

Click Supervisor can talk to one device at a time. ere are two ways to select which module

to talk to.

Follow these steps if you know the Click ID number of the device:

1 Enter the ve-digit ID number in the Click ID text eld, either by typing or by using

the arrows to the right of the box.

2 Click Connect. Aer downloading the communication le, the program will return

you to the Click Supervisor main screen.

Note

You can find the Click ID number of your device by looking at the number beneath

the barcode. The ID number is the last five digits of this number. Each device on a rail

must have a unique number. The number it’s been assigned should be unique, but if

it is not, you can change it after connecting to the device. See that device’s chapter in

Part II of this guide for more information.

Alternatively, you can connect without the ID number:

1 Leave a 0 in the Click ID text eld. Click Supervisor will look for all connected devices

on the network.

2 Click Connect. e Device Selection screen will appear (see Figure 5.4). e comput-

er-programmable devices on the network will appear as they are detected. e device

list is divided into three columns: ID shows the ID number of the device, Click shows

the product number of the device, and Description shows the user-dened description

of the device.

Figure 5.4 – Device Selection

Page 38

CHAPTER 5 USING CLICK SUPERVISOR 37

3 Click on the device you’d like to connect to and hit Select. Aer downloading the com-

munication le, the program will return you to the Click Supervisor main screen.

Note

After connecting, you may see a dialog box asking if you’d like to upgrade. Each version of Click Supervisor has the newest firmware for all the Click devices, and when it

connects to a device it will check to see if the firmware in the program is newer than

that in the device. If it is, you will see the dialog box. If you’d like to upgrade your

device with the newest firmware, click Yes .

IP Communication

e second section on the Communication screen is IP Communication. To connect to

the devices on your network, rst enter the IP address assigned to the Click 301 (or other

Ethernet communication device connected to your modules), then enter the port number.

e default port number for the Click 301, as well as many other such devices, is 10001. e

default IP address is 172.16.0.13.

Once a connection is made, Click Supervisor will remember the information so you don’t

have to type it the next time.

Connecting to a Device

As with a serial connection, you must choose which device Click Supervisor will connect

to. ere are two ways to select which device to talk to.

Follow these steps if you know the Click ID number of the device:

1 Enter the ve-digit ID number in the Click ID text eld, either by typing or by using

the arrows to the right of the box.

2 Click Connect. Aer downloading the communication le, the program will return

you to the Click Supervisor main screen.

Note

You can find the Click ID number of your device by looking at the number beneath

the barcode. The ID number is the last five digits of this number. Each device on a rail

must have a unique number. The number it’s been assigned should be unique, but if

it is not, you can change it after connecting to the device. See that device’s chapter in

Part II of this guide for more information.

Page 39

38 CHAPTER 5 USING CLICK SUPERVISOR

Alternatively, you can connect without the ID number:

1 Leave a 0 in the Click ID text eld. Click Supervisor will look for all connected devices

on the network.

2 Click Connect. e Device Selection screen will appear, and aer a few moments, the

list will be populated with the computer-programmable devices on the network. e

list is divided into three columns: ID shows the ID number of the device, Click shows

the product number of the device, and Description shows the name of the device.

3 Click on the device you’d like to connect to and hit Select. Aer downloading the com-

munication le, the program will return you to the Click Supervisor main screen.

Note

After connecting, you may see a dialog box asking if you’d like to upgrade. Each version of Click Supervisor has the newest firmware for all the Click devices, and when it

connects to a device it will check to see if the firmware in the program is newer than

that in the device. If it is, you will see the dialog box. If you’d like to upgrade your

device with the newest firmware, click Yes .

Working with Modules

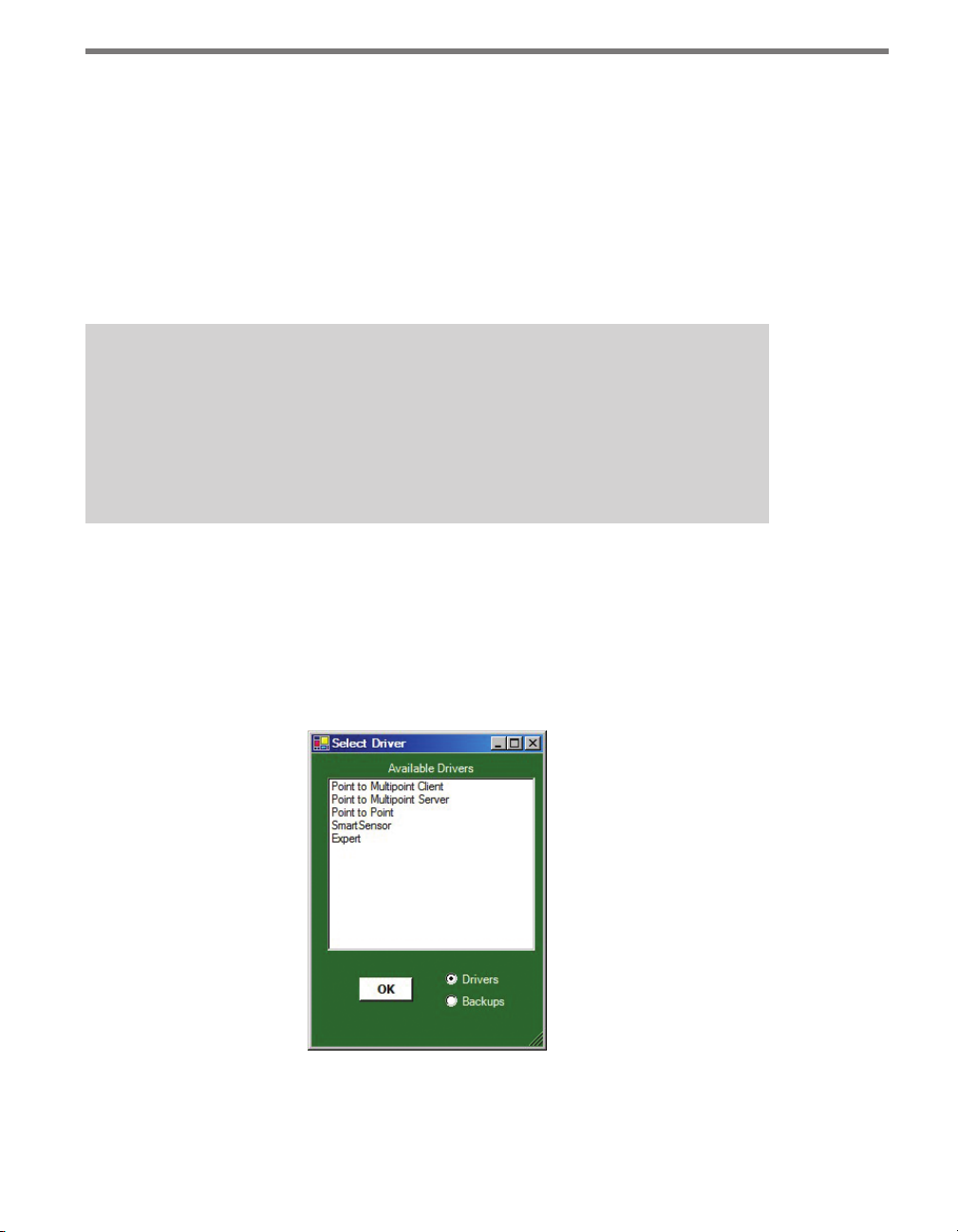

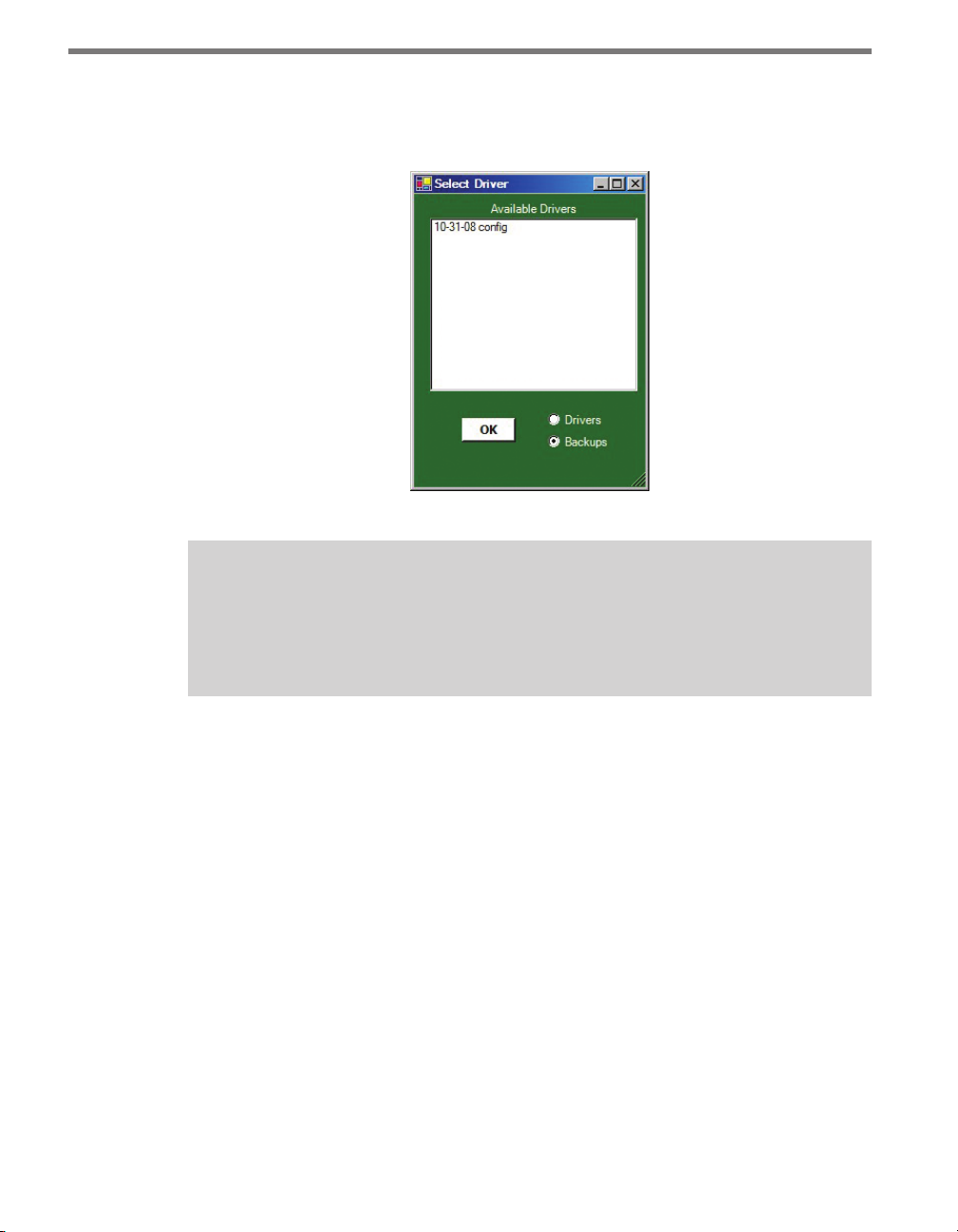

You will now be able to select Setup Click and choose a driver to start working with the

device (see Figure 5.5). e drivers under Setup Click will be dierent for every device you

connect to. For information on how to congure each device through Click Supervisor, see

that device’s chapter in Part II or in the Click 500 Series User Guide for more information.

Figure 5.5 – Selecting a Driver

From the Select Driver screen, you can also access backups you’ve made of settings (how to

save these settings is discussed in each chapter in Part II that deals with Click Supervisor).

Page 40

CHAPTER 5 USING CLICK SUPERVISOR 39

To open a backup, select the Backups radio button in the lower righthand corner of the

screen. All the backups currently saved in the correct folder will appear (see Figure 5.6).

Select the backup you wish to open and click OK.

Figure 5.6 – Selecting a Backup

Note

The default folder to save backups in is C:\Program Files\Wavetronix\ClickHome\

Drivers\ [model number] \User. If you try to save the files elsewhere, the program will

still save them in the User folder.

Aer you’ve nished conguring a device, you can connect to another one by returning to

the Communication screen, closing the connection, and connecting to a dierent device.

Page 41

Page 42

Part II

Individual Click 100–400

Series Modules

Chapter 6 – Click 100

Chapter 7 – Click 101

Chapter 8 – Click 104

Chapter 9 – Click 110

Chapter 10 – Click 112/114

Chapter 11 – Click 120/121

Chapter 12 – Click 172/174

Chapter 13 – Click 200

Chapter 14 – Click 201/202/204

Chapter 15 – Click 203

Chapter 16 – Click 210

Chapter 17 – Click 211

Chapter 18 – Click 221

Chapter 19 – Click 222

Chapter 20 – Click 223

Chapter 21 – Click 230

Chapter 22 – Click 250

Chapter 23 – Click 301

Chapter 24 – Click 304

Chapter 25 – Click 306

Chapter 26 – Click 330/331

Chapter 27 – Click 340/341/342

Chapter 28 – Click 400

Chapter 29 – Click 421

Page 43

Page 44

Click 100 —

16 Output Contact Closure 6

In this chapter

Physical Features

On-device Configuration

Troubleshooting

6

e Click 100 is a hot-swappable contact closure module for use with the Wavetronix

SmartSensor. It mounts onto a DIN rail and is connected to the SmartSensor through the

Click 200 surge protection module.

Figure 6.1 – The Click 100

Page 45

44 CHAPTER 6 CLICK 100

Physical Features

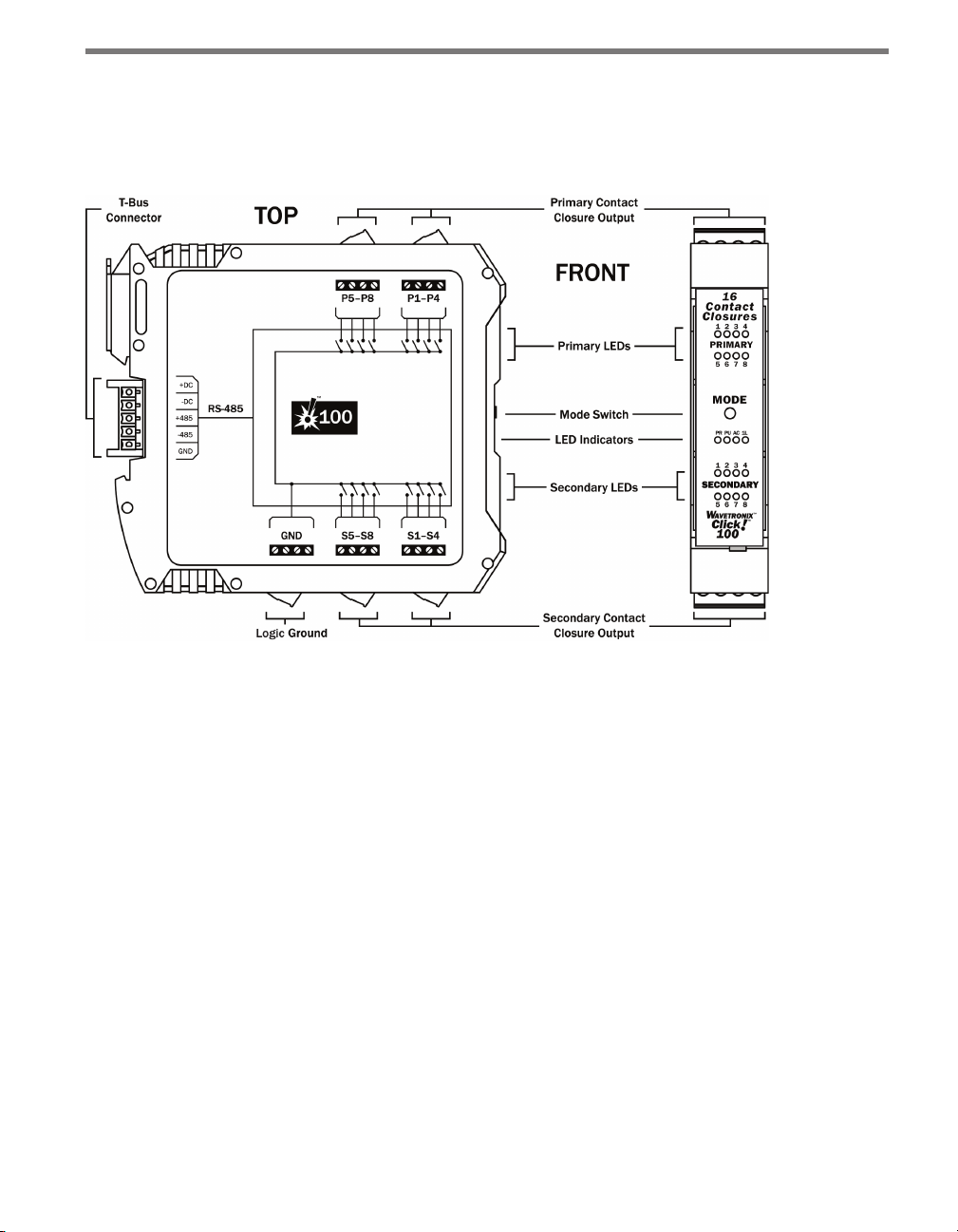

e Click 100 has eight primary and eight secondary contact outputs, which all share a logic

ground (see Figure 6.2).

Figure 6.2 – Diagram of Click 100

Communication Port

e back of the Click 100 features a 5-position connector that plugs into a T-bus connector

and provides power and RS-485 communication to the device. It also passes RS-485 communication from the Click 100 to all other devices on the T-bus when pressing the Mode

button during conguration (see the On-device Conguration section of this chapter for

more information).

Screw Terminals

e contact closure outputs are wired to a controller, data logger or BIU (Bus Interface

Unit) using the pluggable screw terminals on the top and bottom of the Click 100. e top

screw terminals are labeled 1–8 and represent the primary outputs. Primary 1 (P1) represents the lane closest to a side-re SmartSensor and the remaining outputs represent the

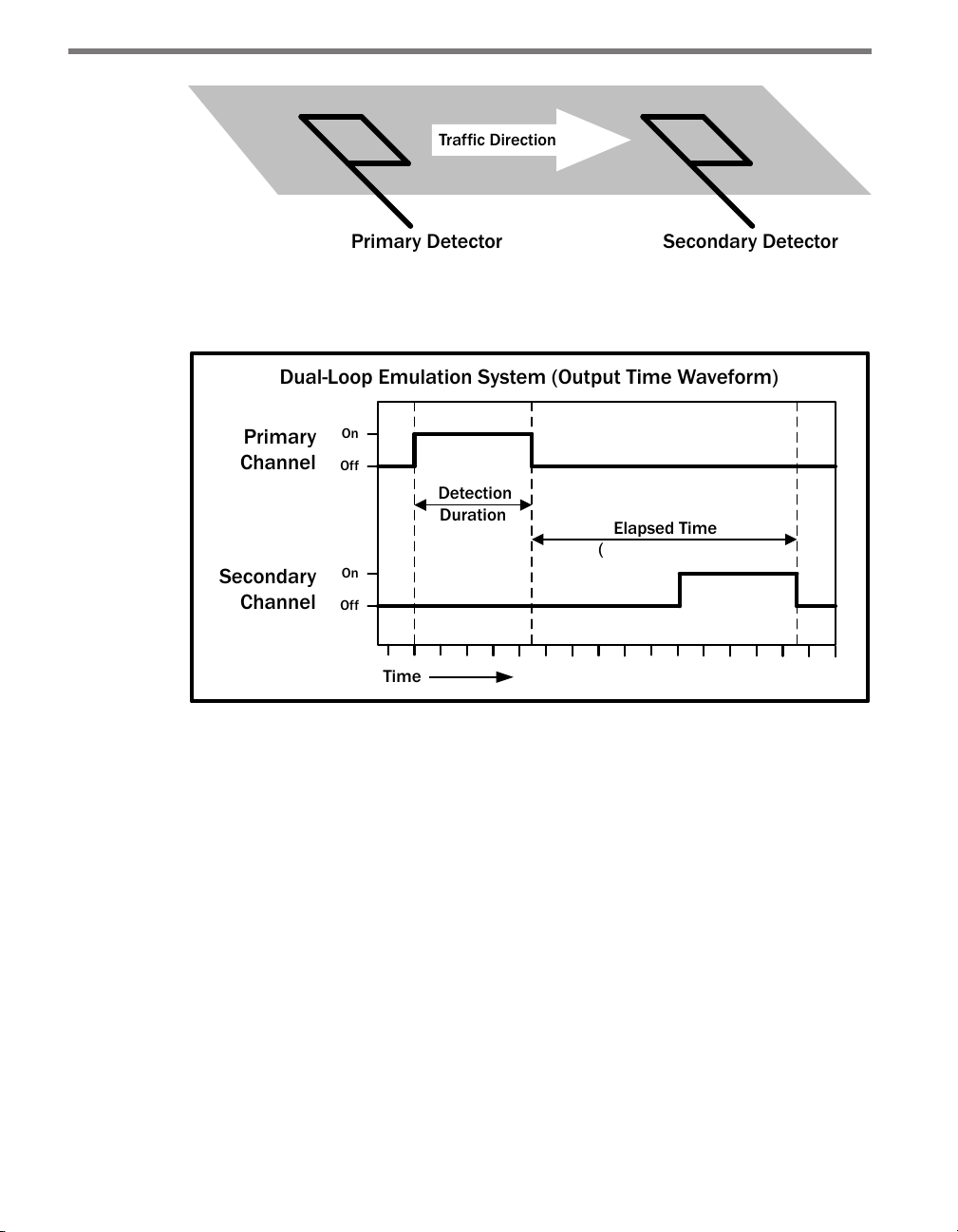

lanes as they sequentially get further from the sensor. For dual-loop emulation, the contact

closure outputs must be wired with the primary always leading the secondary (see Figure

6.3).

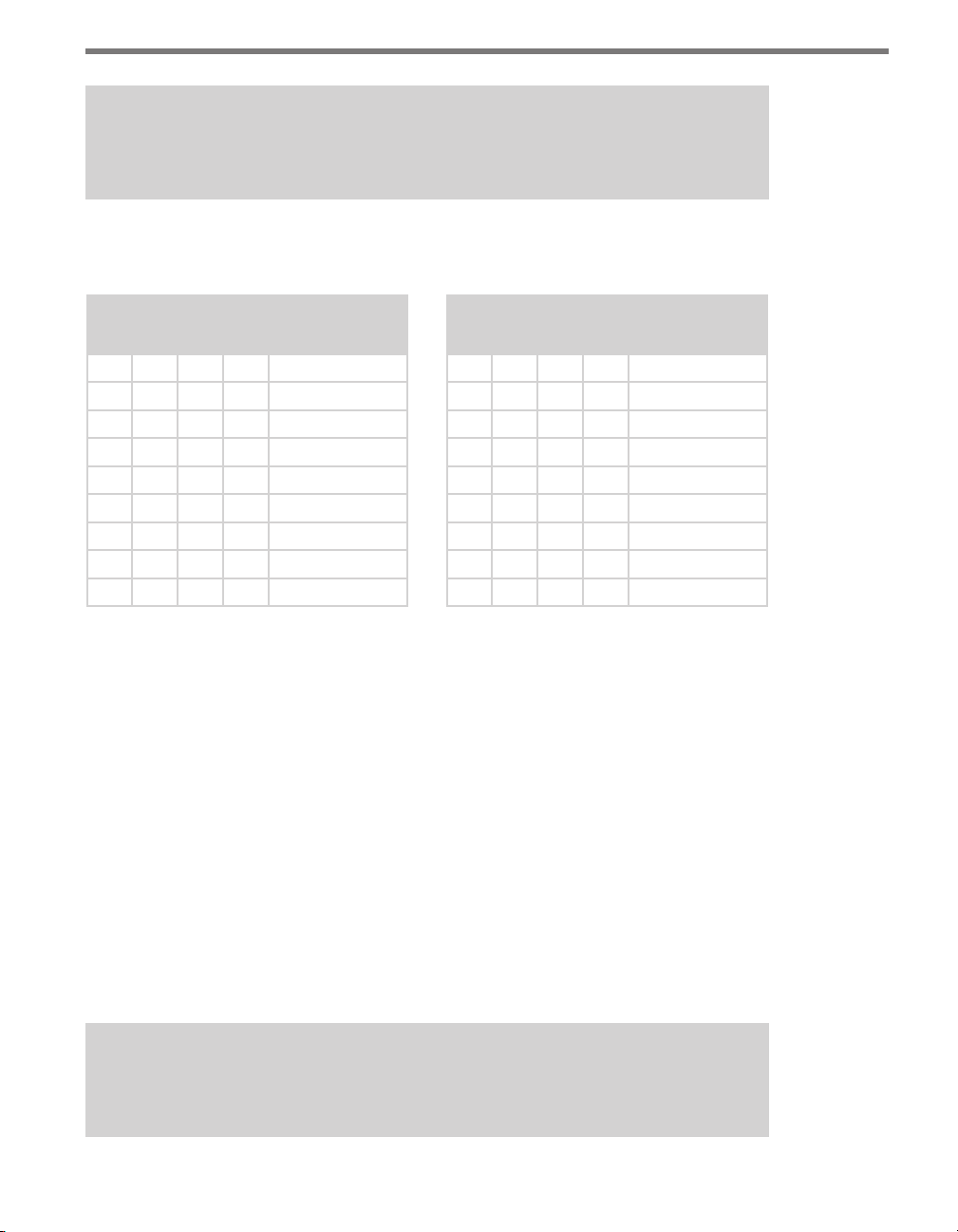

Page 46

CHAPTER 6 CLICK 100 45

Primary Detector

Secondary Detector

Traffic Direction

Primary

Channel

Secondary

Channel

Time

Dual-Loop Emulation System (Output Time Waveform)

Elapsed Time

(

Detection

Duration

On

Off

On

Off

Figure 6.3 – Primary and Secondary Outputs

Figure 6.4 below shows a diagram of the output signal time waveforms of the two detectors.

Indicates Speed)

Figure 6.4 – Emulation System Output Waveforms

e bottom screw terminals are also labeled 1–8 and represent the secondary outputs, with

secondary one (S1) representing the lane closest to the SmartSensor. e remaining four

screw terminal connections are labeled GND and are a common logic ground for all 16

contact closure outputs. You must provide a connection from the GND terminals to a logic

ground to make the primary and secondary outputs operational.

e screw terminal connectors can also be unplugged from the Click 100 allowing you to

pre-wire the Click 100 before nal installation.

Configuration Features

e four LEDs located right below the push-button are used to indicate operation modes,

which will be discussed later in the On-device Conguration section of this chapter. Below

is a list of the four LEDs:

PR (Presence) – Red

PU (Pulse) – Orange

Page 47

46 CHAPTER 6 CLICK 100

AC (Actuation) – Green

1L (One Loop Speed) – Ye l low

e front also has a push-button labeled Mode Switch, which is used to cycle the Click 100

through operation modes. is will be discussed in the On-device Conguration section.

LEDs

e Click 100 module has sixteen contact closure outputs. Each output represents a primary or secondary channel and has a corresponding LED on the front of the Click 100 module.

e eight red LEDs on the top of the faceplate correspond to the primary outputs and the

eight yellow LEDs on the bottom of the faceplate correspond to the secondary outputs.

On-device Configuration

e Click 100 can be congured using the push-button in the middle of the faceplate.

To automatically congure the Click 100, press and hold the push-button until the green

LED ashes four times. e green LED and contact closure LEDs will ash during the autoconguration process, which normally takes 5–30 seconds. e auto-conguration process

matches the Click 100 with the sensor’s baud rate, loop size and loop spacing.

e rst four primary LEDs indicate the current baud rate at which the Click 100 is trying

to congure. e following table shows what the dierent ashing LEDs represent:

Primary LED Baud Rate

1 9400 bps

2 19200 bps

3 38400 bps

4 57600 bps

Table 6.1 – List of Baud Rates

Note

The maximum baud rate that can be used is 57600. If the sensor’s RS-485 bus is set

higher than 57600, no data will be seen on the Click 100.

e yellow LED will ash four times indicating the end of the auto-conguration process.

Once the Click 100 is congured, the device will be set to Presence (PR) mode.

Press the push-button until the desired operation mode is selected.

Page 48

CHAPTER 6 CLICK 100 47

Operation Modes

Press and hold the push-button to cycle through the dierent operation modes; release the

button when the desired mode is reached. A quick press and release of the push-button will

exit out of any mode and return the unit back to normal operation.

Table 6.2 describes the dierent operating modes. To use dual-loop emulation, you must

wire both the primary and secondary outputs; to use single-loop emulation, you must only

wire the primary output.

Mode LED Definition

PR (Presence) Red Outputs contact closures for single-loop or dual-loop

emulation. Dual-loop emulation will signal the radar’s

speed and duration measurements. Speed is signaled

as the elapsed time between the primary and secondary outputs. Duration in the radar beam is signaled as

the duration of the outputs. Single-loop emulation

will simply signal the radar’s duration measurement

(no speed information).

PU (Pulse) Orange Outputs contact closures for single-loop or dual-loop

emulation. Dual-loop emulation will signal the radar’s

speed measurement using the time elapsed between

the onset of the primary and secondary outputs, but

not the radar’s duration measurement. Instead the

outputs will be held active for precisely 125 milliseconds for every vehicle detected. This fixed period

of time is necessary when integrating with some

systems and is often used in counting applications.

Single-loop emulation will simply signal that the radar

detected a vehicle (no duration or speed information).

AC (Actuation) Green Outputs contact closures for single-loop emulation.

This mode of single-loop emulation is used both with

true presence and continuous passage detectors.

True presence detectors signal the existence of a

stopped or moving vehicle within the detector beam.

Continuous passage detectors signal the existence

of a moving vehicle meeting specific criteria (speed,

range, ETA) within the detector beam. When a vehicle

within the detector beam meets the requirements of

the true presence or continuous passage detector, the

associated rack card output will be closed. This is the

only mode used by SmartSensor Advance. With sidefire radar sensors this mode is used for occupancy

data collection.

Page 49

48 CHAPTER 6 CLICK 100

1L (One Loop Speed) Yellow Outputs contact closures for single-loop emulation.

The duration of each contact closure output is based

upon the speed of the detected vehicle (instead of the

duration of the vehicle in the beam). The duration of

each contact output is based on the formula: duration

in seconds = nominal vehicle length in feet / actual

speed in feet per second. The nominal vehicle length

is read from the sensor when this mode is selected.

To set the nominal vehicle length, use the SmartSensor Manager software. The nominal length in feet is

entered in the default loop spacing field.

Autobaud Green (flashing) Autobauds to the connected SmartSensor; also polls

it for loop spacing. These values are saved to flash

memory. While autobauding, the green and yellow

LEDs will flash intermittently, as well as the 16 digital

output LEDs. If the autobauding is unsuccessful, the

LEDs will remain in that state indefinitely. If the autobauding is successful, the yellow LED will flash, then

the device will return to its normal state and default

to the Presence mode.

Table 6.2 – Click 100 Mode Definitions

Troubleshooting

e Click 100 conguration will fail if the communication link is lost or if another device

is active on the communication link (usually the sensor’s native RS-485 port). For example,

the conguration will fail if SmartSensor Manager remains actively connected and communicating over the same link as the Click 100. To avoid this issue, connect SmartSensor

Manager to the sensor’s native RS-232 port or simply shutdown SmartSensor Manager during Click 100 conguration.

If you choose to use the sensor’s native RS-232 port by connecting to the DB-9 connector

on the associated Click 200, this link will become unreliable if the cable run is longer than

200 feet. Contact Wavetronix Technical Services for assistance if you would like both of the

sensor’s ports to be reliable over distances greater than 200 feet.

One thing to be aware of is that the relays take ve milliseconds to open or close; they physically cannot react any faster than the messages they receive.

Page 50

Click 101 —

Multi-sensor to Contact Closure 7

In this chapter

Physical Features

Installation

On-device Configuration

Computer Configuration

7

e Click 101 is a contact closure module that is capable of collecting lane-by-lane data

from multiple Wavetronix SmartSensors in real time. e Click 101 device is designed to

collect volume and occupancy data from all midblock stations pertaining to a signalized

intersection.

Figure 7.1 – The Click 101

Page 51

50 CHAPTER 7 CLICK 101

Traffic

Controller

Each side-re sensor can use its two communication ports to send real-time trac data to

both cabinets for which it is collecting data (see Figure 7.2). e real-time data is used to

control intersections using distributed and centralized strategies.

Note

The Click 101 data protocol used to poll sensors is supported by SmartSensor HD v1.3

or greater; likewise this protocol is supported in SmartSensor 105 v2.8 or greater.

Figure 7.2 – Each Side-fire SmartSensor Communicates with Two Trac Controllers

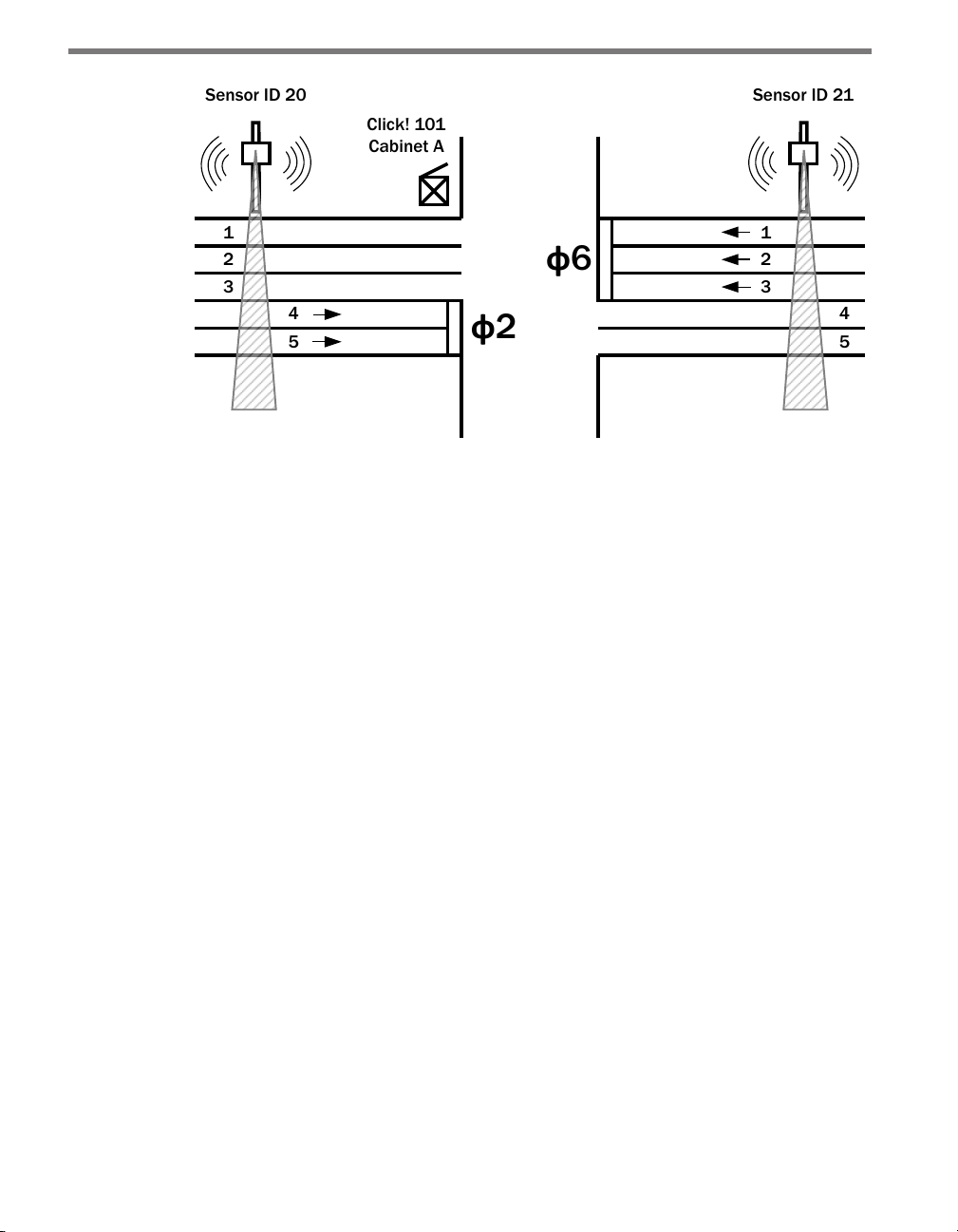

To collect the data at a particular intersection, the Click 101 polls each sensor for real-time

lane-by-lane volume and occupancy data detected since the last polling period. Each polling period typically takes a few seconds. is data is signalized to the trac controller or

data logger using up to 16 contact closure outputs.

Figure 7.3 illustrates an example where the Click 101 in Cabinet A can retrieve lane-bylane volume and occupancy data from Sensor ID 20 and 21. e data from lanes 4 and 5 of

Sensor ID 20 is used to control phase 2 of the intersection, and the data from lanes 1–3 of

Sensor ID 21 is used to control phase 6. e other lanes from Sensor ID 20 and 21 can be

retrieved by Click 101 devices in cabinets at the adjacent arterial intersections.

Page 52

CHAPTER 7 CLICK 101 51

Sensor ID 21

1

2

3

4

5

Sensor ID 20

Click! 101

Cabinet A

1

2

3

4

5

ф

2

ф

6

Figure 7.3 – The Click 101 Collects from Multiple Sensors

More sensors can be used to control all the phases at each intersection along an arterial or

within a city grid. Each sensor has two dierent buers for the lane-by-lane volume and

occupancy data. ere will be no loss of data on the sensor as long as each Click 101 communicates over a dierent serial port.

During its normal polling routine, the Click 101 can collect trac data from up to ten sidere units. e normal polling routine will request new lane-by-lane volume and occupancy

data every time it cycles through the list of sensors. If a sensor does not respond aer ten

cycles, the Click 101 will suspend data queries to that sensor for one minute. Aer one minute, the Click 101 will retry data queries twice. If those queries are unsuccessful, the Click

101 will suspend queries for another minute. is feature prevents unresponsive sensors

from unnecessarily slowing down the polling routine.

A Click 101 will not execute its normal polling routine if:

It is being programmed with Click Supervisor or the push-button.

It is being used for RS-232 to RS-485 conversion.

A device connected to the RS-485 bus has sent a passcode message to temporarily

suspend polling.

Lane outputs from any one of the side-re sensors can be mapped to any of the 16 digital

outputs. Mapping multiple lanes to a single output it also possible.

Physical Features

e Click 101 has 2 communication ports, 16 LEDs, 16 digital outputs and a push-button

(see Figure 7.4).

Page 53

52 CHAPTER 7 CLICK 101

Figure 7.4 – Diagram of the Click 101

Communication Ports

e back of the Click 101 features a 5-position connector that plugs into a T-bus connector

and provides DC power and half-duplex RS-485 communication to the device. e RS-485

communication port on the T-bus allows the Click 101 to serve as the polling master on a

multi-drop RS-485 bus. e sensors act as clients on the RS-485 bus, only responding to

requests from the Click 101. Any devices connected to the T-bus will also have connectivity

over the shared RS-485 lines; however, when a Click 101 is being used, it is expected that

none of the sensors or other devices on the bus will push data. is will help avoid communication message collisions on the RS-485 bus.

Note

It is recommended that the sensors not be connected to the T-bus while programming this device with Click Supervisor.

e front of the Click 101 features a DB-9 connector for RS-232 communication. is connector is used for device conguration using Click Supervisor. A straight-through cable can

be used to connect from this port to a computer.

Page 54

CHAPTER 7 CLICK 101 53

Note

After you have completed programming the device using Click Supervisor, remove

the RS-232 serial cable from the DB-9 port. This will prevent computer equipment

(like docking stations) from holding the RS-232 TD line high. If the TD line is inadvertently held high, the Click 101 will transmit on the RS-485 bus, but will not receive any

data from connected sensors.

Like many of the other Click devices, the Click 101 also acts as an RS-232 to RS-485 converter. To disable the normal polling routine and enable serial conversion, a passcode message must rst be sent over one of the ports. SmartSensor Manager automatically sends

a passcode message when a connection is made to a side-re sensor. is allows you to

congure any of the sensors on the RS-485 bus via the DB-9 connector on the front of the

Click 101. e normal polling routine will resume operation aer 10 seconds of inactivity

on the ports. SmartSensor Manager HD sends a passcode message once every few seconds

to keep the normal polling routine of the Click 101 suspended. SmartSensor Manager for

the 105 sensor only sends passcode messages on some screens, so you may run into situations where normal polling will resume while connected to a 105 sensor.

e passcode message can be one of those shown in Table 7.1:

C String Format Hex Byte Format

“X5/r” 0x58 0x35 0x0D

“Z1/r” 0x5A 0x31 0x0D

“Z2/r” 0x5A 0x32 0x0D

Table 7.1 – Passcode Messages that Enable Serial Conversion

LEDs

e Click 101 faceplate contains 16 LEDS. During normal polling, each LED lights up when

the associated digital output is active.

If normal polling is suspended and the device is powered, the PWR (red) LED will light up

and the RD (yellow) LED will activate each time data is received on a communication port.

e TD (green) LED will not activate each time data is transmitted on a communication

port. e green LED is used during normal polling to indicate that output 15 is active, and

it is also used during manual conguration to select the autobaud conguration task.

Screw Terminals

e screw terminals labeled 1–16 on the top and bottom of the Click 101 are contact closure

outputs that can be connected to a trac controller or data logger. ese digital outputs are

contact closure outputs that require a logical ground connection.

Page 55

54 CHAPTER 7 CLICK 101

e screw terminals labeled C1–C4 represent the common lines for each contact closure

output pluggable screw terminal block (see Figure 7.4):

C1 – e common terminal for digital outputs 1–4.

C2 – e common terminal for digital outputs 5–8.

C3 – e common terminal for digital outputs 9–12.

C4 – e common terminal for digital outputs 13–16.

Configuration Features

e lower section of the faceplate has a push-button labeled Mode Switch, which is used to

initiate conguration tasks. ese tasks will be discussed in the On-device Conguration

section of this chapter.

Installation

Wire the outputs of the Click 101 to a trac controller or other contact closure input. Make

sure that each bank of the four outputs shares a single common wire. Tie each bank’s common wire to either Logic Ground or the proper common connection.

Note

It is recommended that the sensors not be connected to the T-bus while programming this device with Click Supervisor.

On-device Configuration

e Click 101 can be partially congured using the Mode Switch push-button. is pushbutton cycles through two device conguration tasks: autobaud conguration and reset to

factory defaults.

To select a task, hold the push-button down until the corresponding red or green LED

turns on. Once a conguration task has nished, the Click 101 will return to normal polling mode. During normal polling, the LEDs on the bottom row are used to signal contact

closure outputs.

e autobaud task is initiated by holding the push-button until the green LED lights up.

is task will set the polling baud rate to match that of one of the 10 possible sensor connections. All sensor connections must be at the same baud rate. e default baud rate of the

sensors and the Click 101 is 9600 bps. However, communication modems or other devices

in between the sensor and the Click 101 may dictate the baud rate.

Page 56

CHAPTER 7 CLICK 101 55

Note

You will only be able to communicate properly if the Click 101 and each sensor’s RS485 baud rate match.

To reset the module to factory defaults, hold the push-button down for 10-15 seconds until

the red LED ashes. During the reset process, the rst 12 red LEDs will light up momentarily.

Computer Configuration

You must use Click Supervisor to customize the polling parameters, output mapping and

other important settings. See Chapters 4 and 5 for instructions on how to download and

install Click Supervisor and how to connect to your device using the soware.

You will usually select the Expert driver to congure a Click 101. e Expert driver does not

modify Click 101 settings unless you save changes to the device. You should not connect

to your device using other drivers, unless you are sure that driver has been specically designed for your application. Other drivers may inadvertently overwrite the settings on your

module. Once you have nished conguring your device, save the settings to a backup le.

Aer you have made conguration changes on a driver and saved it to the Click device, the

word “current” will appear aer that driver to indicate the driver that is currently loaded

onto the device.

Note

Some settings appear on multiple drivers. Changing one of those settings on any

driver and saving them to the Click device will change that setting on all other drivers.

Expert Driver

e Expert driver allows you to see all possible settings and elds, both those available in

other drivers and those available only through this driver. e driver is divided into three

tabs—System, Contact Closures and Diagnostics—which are then subdivided further.

e System > General tab allows you to change the settings aecting the setup of the device

(see Figure 7.5 and Table 7.2).

Page 57

56 CHAPTER 7 CLICK 101

Setting Description

Module

Driver

Description

Location

Serial #

Firmware Version

Subnet ID

Device ID

Table 7.2 – Expert Driver General Tab

Figure 7.5 – Expert Driver General Tab

Allows you to enter a name and description of the device.

Names the driver you are currently working with.

Shows a description of the device being configured. This is only for

your information and does not aect the operation of the device.

Displays the location of the device being configured. This is only for

your information and does not aect the operation of the device.

Displays the serial number of your device.

Shows the version of firmware your device currently has installed. If

Click Supervisor detects a discrepancy between this version and the

most current version it currently has access to, you will be prompted

to upgrade when you connect to the device.

Shows the subnet ID number. This option is currently not available.

Gives the ID number of the device being configured, which is used

to identify the device when you are connecting to it. By default, this

number is the last five digits of the serial number, which can be found

under the About tab or on the barcode sticker on the bottom of the

device. It is recommended that you do not change this number unless

another device on your network has the same ID number.

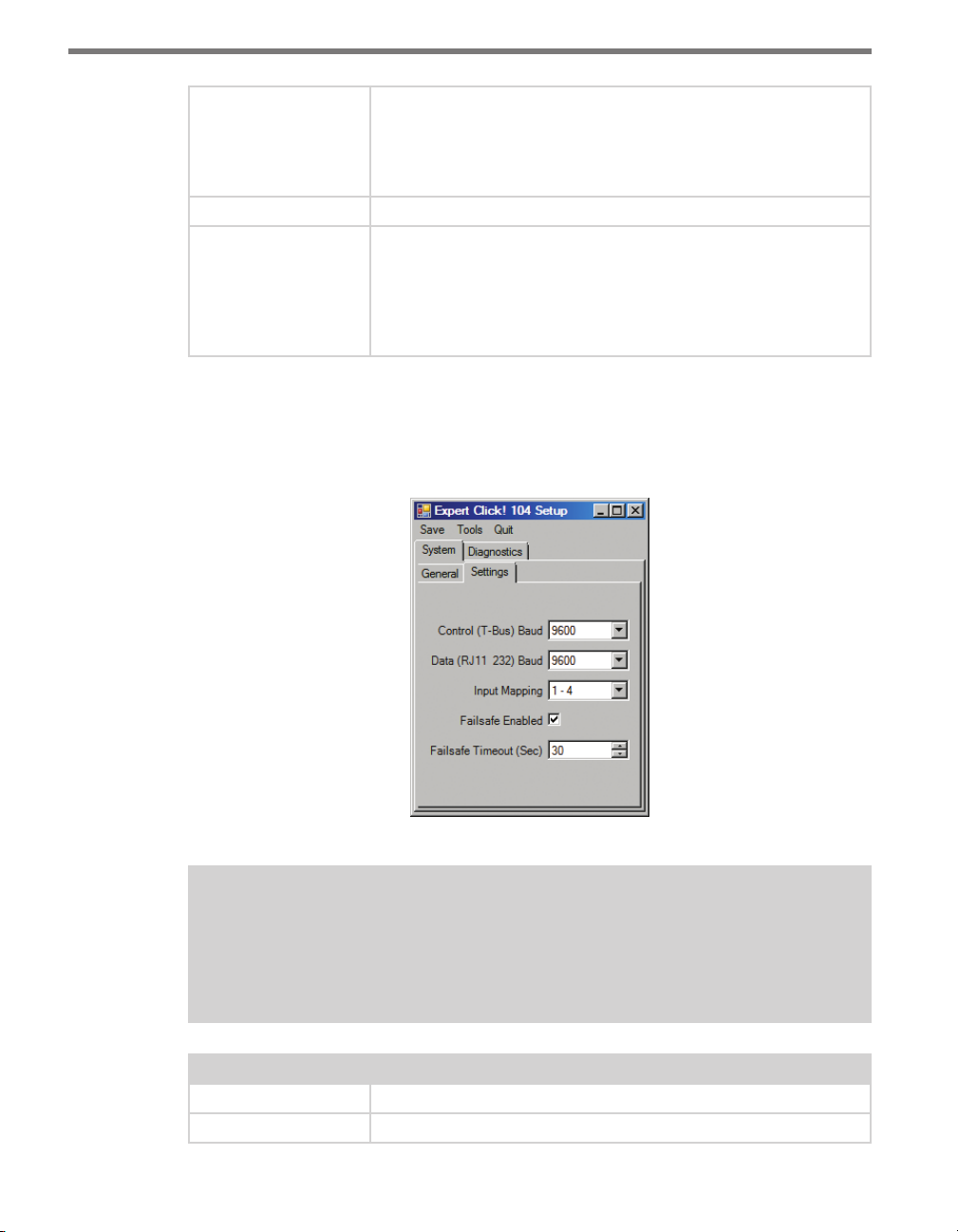

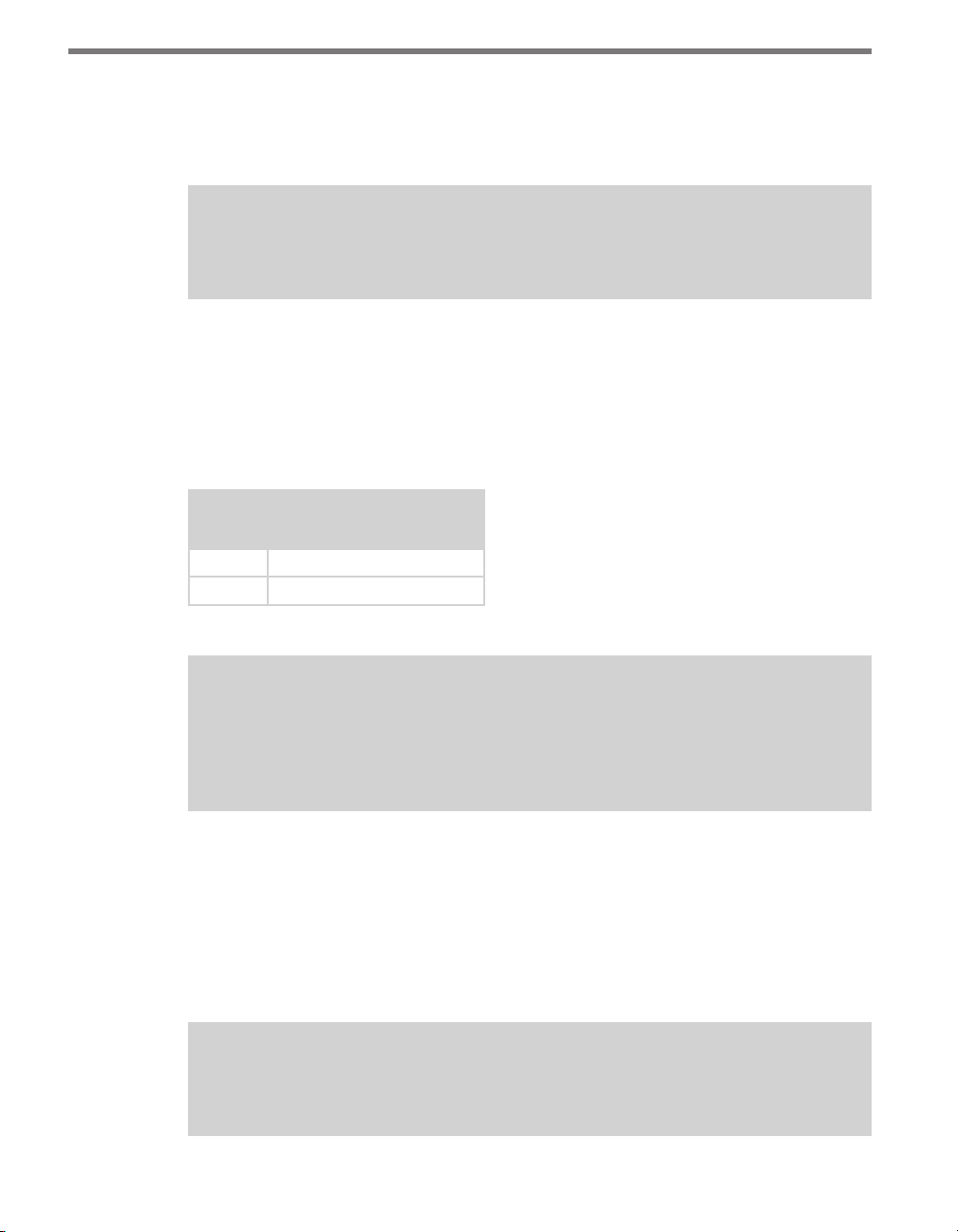

e System > Comm tab allows you to congure how the Click device communicates (see

Figure 7.6 and Table 7.3).

Page 58

CHAPTER 7 CLICK 101 57

Figure 7.6 – Expert Driver Comm Tab

Setting Description

Baud Rate

Flow Control

Parity

Stop Bits

Data Bits

Active Port

Latency

Table 7.3 – Expert Driver Comm Tab

Allows you to change the baud rate for both the RS-485 and RS-232

communication ports.

Is used for configuring hardware handshaking. This option is currently

not available.

Allows you to set parity error checking.

Allows you to set the number of stop bits.

Shows you the number of data bits being sent. This option currently

cannot be changed.

Indicates on which port you are communicating with one of the sensors on the multi-drop RS-485 bus. When you communicate to more

than one sensor, the port may be dierent on each sensor. To change

the connection port, you will have to physically change the connection

of the communications link.

Indicates the latency between the sensor and the Click device. This

option cannot be changed.

e System > Autobaud tab allows you to congure how the device autobauds (see Figure

7.7 and Table 7.4).

Page 59

58 CHAPTER 7 CLICK 101

Setting Description

Command

Response

SmartSensor ID

Server/Client

Table 7.4 – Expert Driver Autobaud Tab

Figure 7.7 – Expert Driver Autobaud Tab

Allows you to set the command sent from the device during the

autobaud process.

Shows the response the device is expecting from the above command.

Shows the ID number of one of the sensors with which the Click

device is currently communicating. This only shows the number after

you have autobauded the Click device; when the Click device is not

communicating with a sensor, this option will display a 0.

This setting is not used by the Click 101.

e Contact Closures > Sensor tab allows you to change contact closure outputs and the

normal polling routine (see Figure 7.8 and Table 7.5).

Figure 7.8 – Expert Driver Sensor 1 Tab

Page 60

CHAPTER 7 CLICK 101 59

Setting Description

Sensor ID

Contact Closure

Outputs

Table 7.5 – Expert Driver Sensor 1 Tab

The sensor’s multi-drop communication ID.

Allows you to set the Click 101 output for lanes 1-10 of each sensor.

SmartSensor HD has 10 lanes per sensor; SmartSensor 105 only has 8

lane per sensor. Assignments made for Lanes 9 and 10 of a SmartSensor 105 unit will have no impact. Multiple lanes from one or more

sensors can also be assigned to the same output.

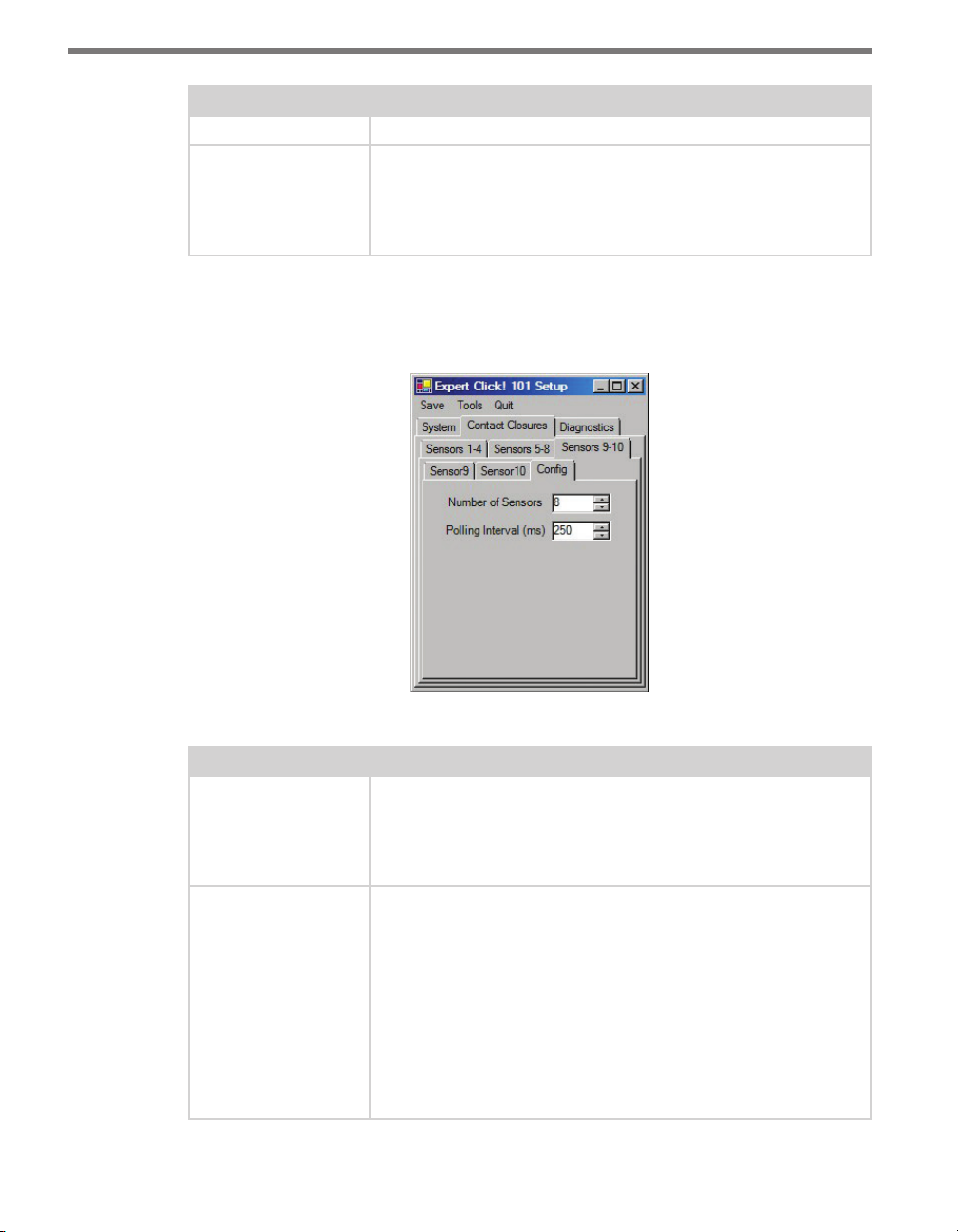

e Contact Closures > Cong tab is located under the Sensors 9-10 tab and allows you

to select the number of sensors and set the polling interval (see Figure 7.9 and Table 7.6).

Figure 7.9 – Expert Driver Config Tab

Setting Description

Number of Sensors This indicates how many of the 10 possible sensors you would like to

include in the current polling list. If you select only 1, then only sensor

1 will be polled for data. If you select 2, then only sensors 1 and 2 will

be polled for data. In other words, sensors 1–X will be polled, where X

is the value entered in this field.

Polling Interval (ms) The amount of time allotted for each sensor in the polling list to re-

spond. If a sensor responds more quickly, the Click 101 will continue to

wait until the full time interval has expired. In other words, if you poll

8 sensors with an interval of 250 ms, you will query each sensor every

2 seconds. This two seconds represents the time required to poll all

sensors on the list. This is defined as the total list poll time. The total

list poll time is variable when sensors are momentarily dropped from

the polling list. Unresponsive sensors are dropped from the poll list

for one minute. For example, if 1 of 8 devices is not responding to

requests, then the total list poll time will be 1.75 seconds (during the

cycles that the unresponsive sensor is dropped from the list).

Table 7.6 – Expert Driver Config Tab

Page 61

60 CHAPTER 7 CLICK 101

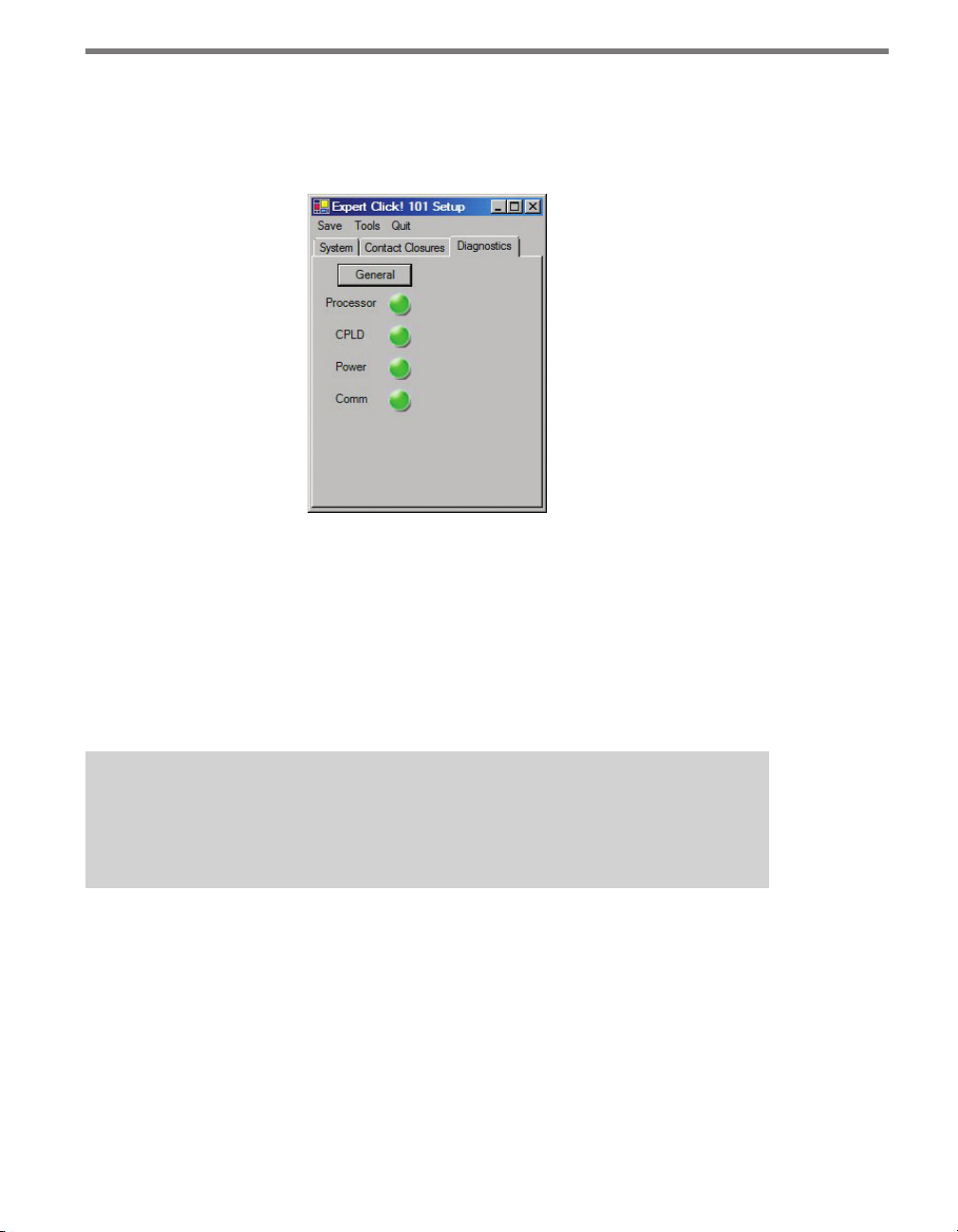

Under the Diagnostics tab, you can run diagnostics on your device (see Figure 7.10). Click

the General button to run diagnostics on the items listed below the button. If a problem is

detected, the program will display a red square next to the item in question. If no problems

are detected, a green circle will appear.

Figure 7.10 – Expert Driver Diagnostics Tab

Once you have nished, use the menu bar at the top of the screen to save your settings,

return to the Select Driver screen, and more.

e Save menu allows you to save your settings. Select Save to File to save your set-

tings to a le. Selecting this will open a directory box, allowing you to name your

settings le. is le will always be saved in the Wavetronix folder created when you

installed Click Supervisor, under Wavetronix > ClickHome > Drivers > 101 > User. You

can also select Save to Device to save your settings to your Click 101.

Note

If you do not save your settings to your Click 101, they will be lost the next time you

power the device down.

e To o l s menu contains ve options for working with your device. Reset > System

power cycles your device, while Reset > Factory Default restores your device to the

settings with which it was shipped. Restore will restore the driver to the settings currently saved on the Click 101, erasing any unsaved changes. Upgrade can be used to

manually upgrade to the most current rmware for your device. Hex View changes the

view of certain settings in the driver to hexadecimal.

Clicking the Quit menu exits the driver and returns you to the Click Supervisor main

page.

Page 62

Click 104 —

4-channel DIN Rail Contact Closure 8

In this chapter

Physical Features

Installation

Configuration

Rotary Switch

Front Panel Menu

Click Supervisor

8

e Click 104 is a 4-channel contact closure module for use with sensors that use Z4 protocol: HD, Advance and Matrix. It mounts on a DIN rail for power and communication.

Figure 8.1 – The Click 104

Page 63

62 CHAPTER 4 CLICK 104

Physical Features

e Click 104 has the following physical features.

T-Bus

Connector

TOP

RS-232 Connector

FRONT

RS-232

+DC

-DC

+485

-485

GND

Bus 2

Control

Bus 1

Data

Click

104

Contact

Closures

3-4 1-2

Bus 1

Data

LEDs

RS-485

Mode

Switch

Rotary

Switch

Outputs 1-2 Connector

Outputs 3-4 Connector

LED Indicators

RS-485

Connector

Mode Switch

Rotary Switch

Figure 8.2 – Diagram of Click 104

Communication Ports

e Click 104 has two independent serial communications buses. Bus 1, also referred to

as the data bus, should be used to report vehicle data; its associated communication ports

consist of two RJ-11 jacks, for RS-485, on the faceplate and one screw terminal, for RS-232,

on the top of the device.

Bus 2, also referred to as the control bus, should be used for conguration. Its associated

communication port is the a 5-position connector, located on the back of the Click 104, that

plugs into a T-bus connector and provides power and RS-485 communication to the device.

It also passes RS-485 communication from the Click 104 to all other devices on the T-bus.

Contact Closure Outputs

e contact closure outputs should be wired to a controller, data logger or BIU (Bus Interface Unit) using the pluggable screw terminals on the bottom of the Click 104. ere

are two screw terminal blocks; the one closer to the faceplate has outputs 1 and 2, and the

farther one has outputs 3 and 4. Each output consists of two terminals, one + and one –.

e screw terminal connectors can also be unplugged from the Click 104 allowing you to

Page 64

CHAPTER 4 CLICK 104 63

pre-wire the Click 104 before nal installation.

Rotary Switch

On the faceplate of the device is a rotary switch, numbered 0–9. is switch, which can be

twisted by inserting a small screwdriver into the arrow slot, is used to congure channels.

Mode Switch

e faceplate of the Click 104 features a push-button labeled Mode Switch, which is used to

cycle through and select menu and conguration options.

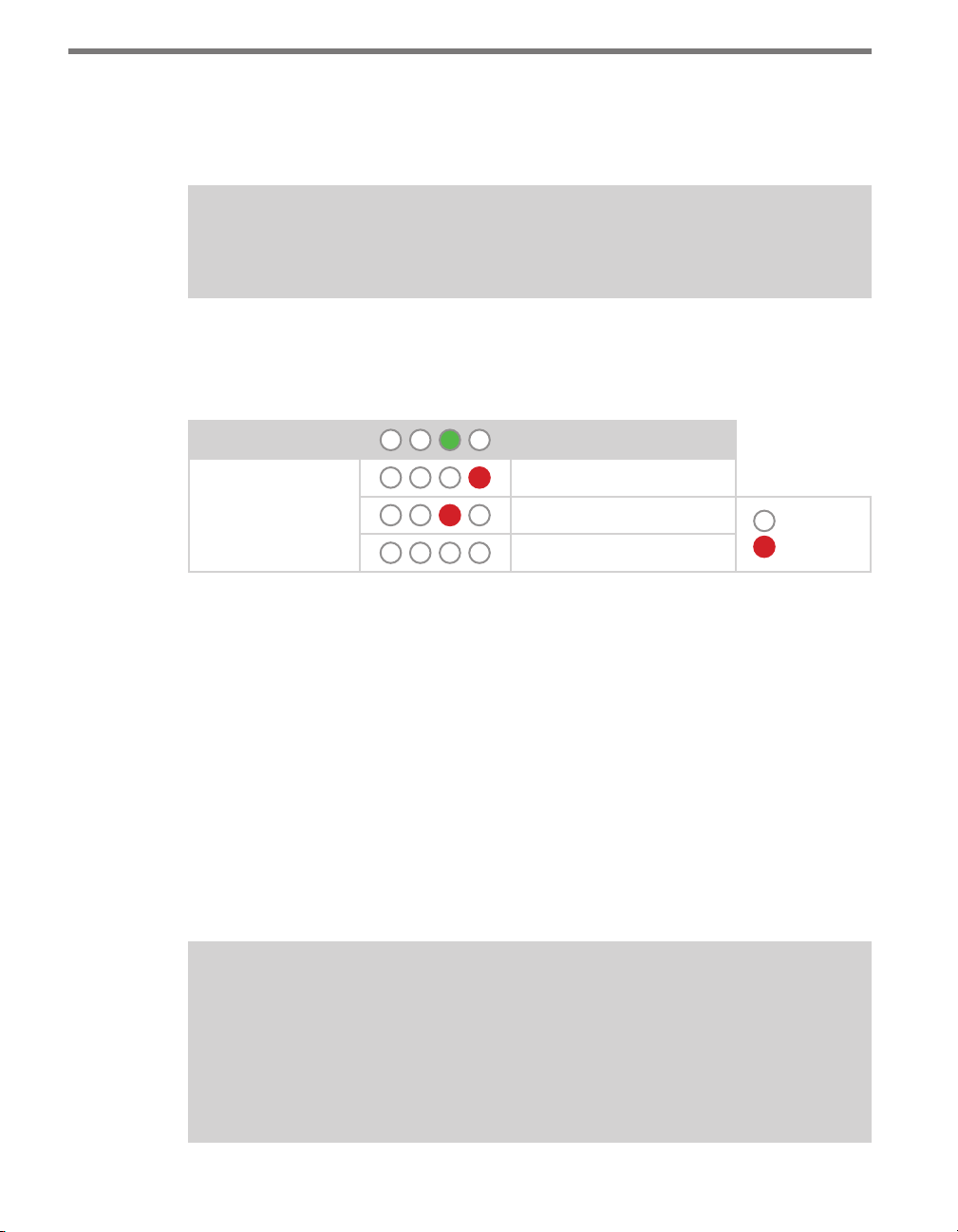

LEDs

e faceplate of the Click 104 has three banks of LEDs. e top bank is used for detection

indication, the second bank menu indication, and the third for menu indication as well as

operation states.

Channel

1 2 3 4

Menu

PWR OK TD RD

Figure 8.3 – Click 104 LEDs

e Channel LEDs are detection indicators; they consist of four red LEDs numbered 1–4,

each representing a channel (see Figure 8.3). An illuminated LED indicates that the associated contact is being closed (this can mean either a vehicle detection or fail-safe mode,

which will be discussed later in this chapter). ese indicators are dedicated to detection

and have no other display purposes.

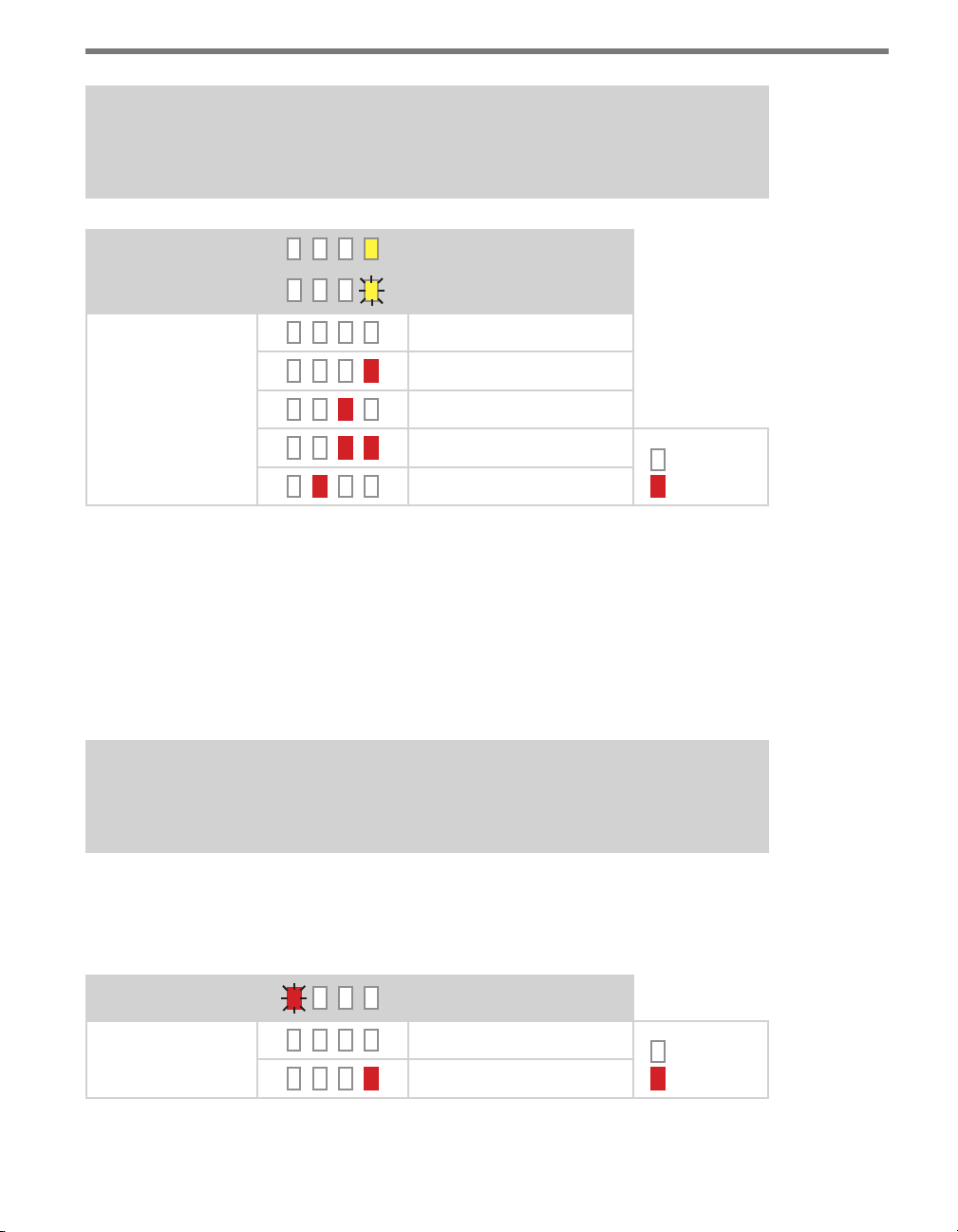

e menu indicator LEDs include two rows of LEDs (see Figure 8.3). e lower row contains Level 1 indicators, while the upper row contains Level 2 indicators. Each level consists

of four LEDs numbered 1–4 (le to right). Level 1 LEDs (the multicolored row) display

which menu item is active. ese Level 1 LEDs are dual-purpose, each indicating both

menu selection as well as a normal operation state when not in Menu mode. e normal

operation state functions include:

Red (PWR) – Indicates the presence of power to the device.

Blue (OK) – Indicates proper system operation; it extinguishes during fail-safe mode.

Green (TD) – Indicates serial communication transmit data (from the Click 104) on

either bus 1 (data) or bus 2 (control).

Yellow (RD) – Indicates serial communication receive data (to the Click 104) on either

Page 65

64 CHAPTER 4 CLICK 104

bus 1 (data) or bus 2 (control).

Level 2 LEDs display conguration options for the menu items selected via the level 1 LEDs.

All level 2 LEDs are red. ese LEDs are dedicated to menu operation, and are extinguished

when the menu is not active.

Installation

1 Mount the Click 104 on a DIN rail over a T-bus connector. is connects the device’s

control bus (bus 2) to the installation’s shared communication bus; you can connect

your computer to another device on this shared bus, such as the Click 305 USB converter, to access the Click 104 to congure it using Click Supervisor. Mounting the

Click 104 on the T-bus also connects it to the power source.

2 Send detection data to the data bus (bus 1) in one of two ways. If you’re using a Smart-

Sensor Advance or Matrix, and therefore a Click 222 or 223, connect it to the Click 104

by connecting jumper cables from the RJ-11 jacks on the faceplate of the Click 222 or

223 to the RJ-11 jacks on the faceplate of the Click 104.

If you’re using a SmartSensor HD, rst set the sensor to push data on the RS-232 port.

en connect wires between the TD and RD screw terminals on the protected side of

the Click 200 to the TD and RD screw terminals on the Click 104.

3 If needed, daisy-chain multiple Click 104 devices together by utilizing both RJ-11 jacks

on each device’s faceplate.

Contact Closure Outputs

Part of installing the device is wiring its contact closure outputs to the trac controller

(or data logger or other device). It’s recommended, however, that you not do this until the

device is done being congured, to avoid sending any incorrect contact closures to the

controller

ere are four contact closure outputs, for the four channels the Click 104 can handle. Each

output has two screw terminals, one + and one –. e + terminals are for data, while the

– are ground, or common. Each – terminal is isolated from all the other grounds; if your

installation requires a common ground for each contact closure output, you’ll need to tie

together the wires from those four terminals yourself.

Fail-safe Mode

e Click 104 receives datagrams from the connected SmartSensor. ese datagrams must

be mapped to device outputs, as will be discussed later in this chapter. If the Click 104 does

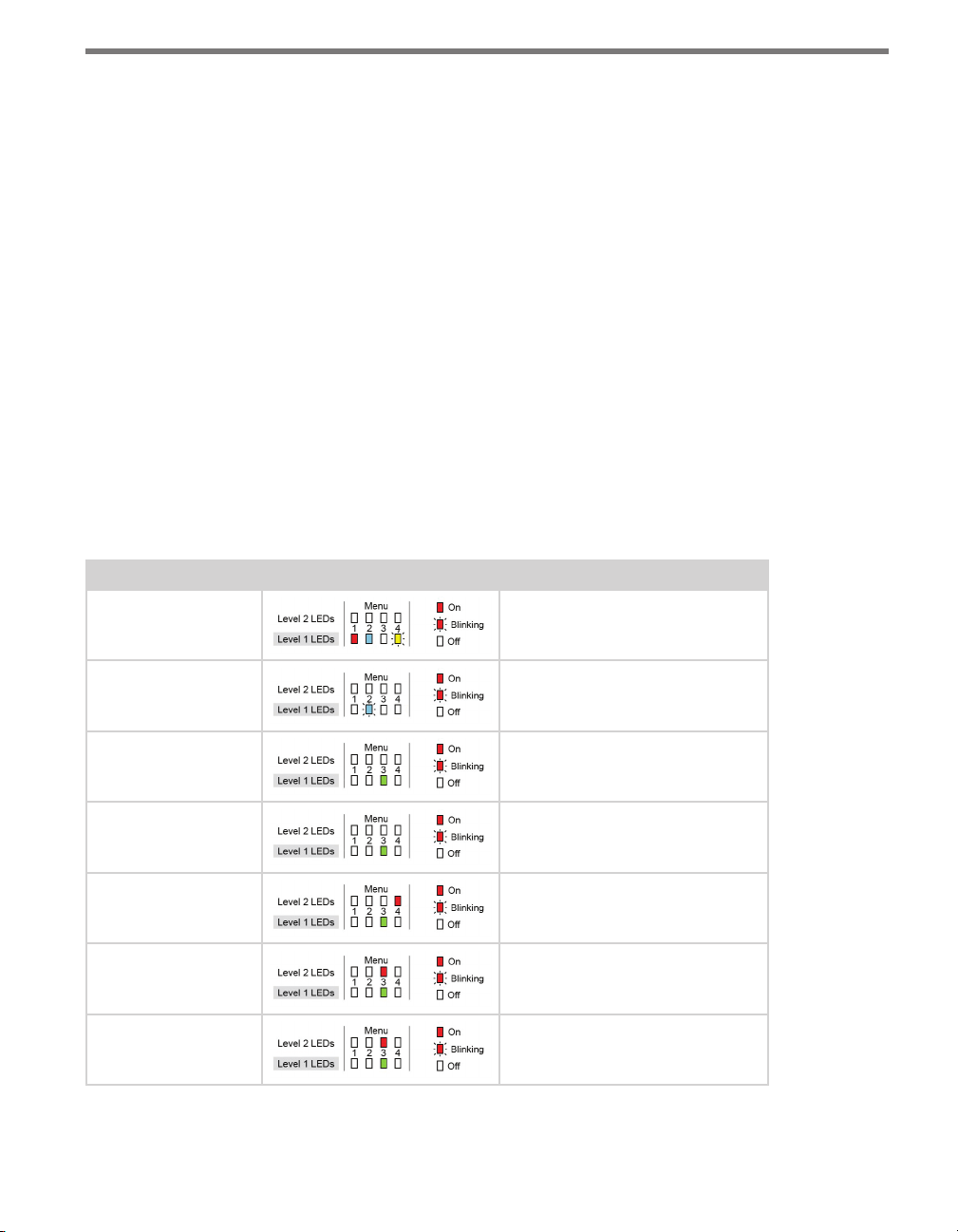

not receive a datagram describing the device’s channels for ten seconds, the device will enter