Page 1

Click 104 Contact Closure

INSTALLER QUICK-REFERENCE GUIDE

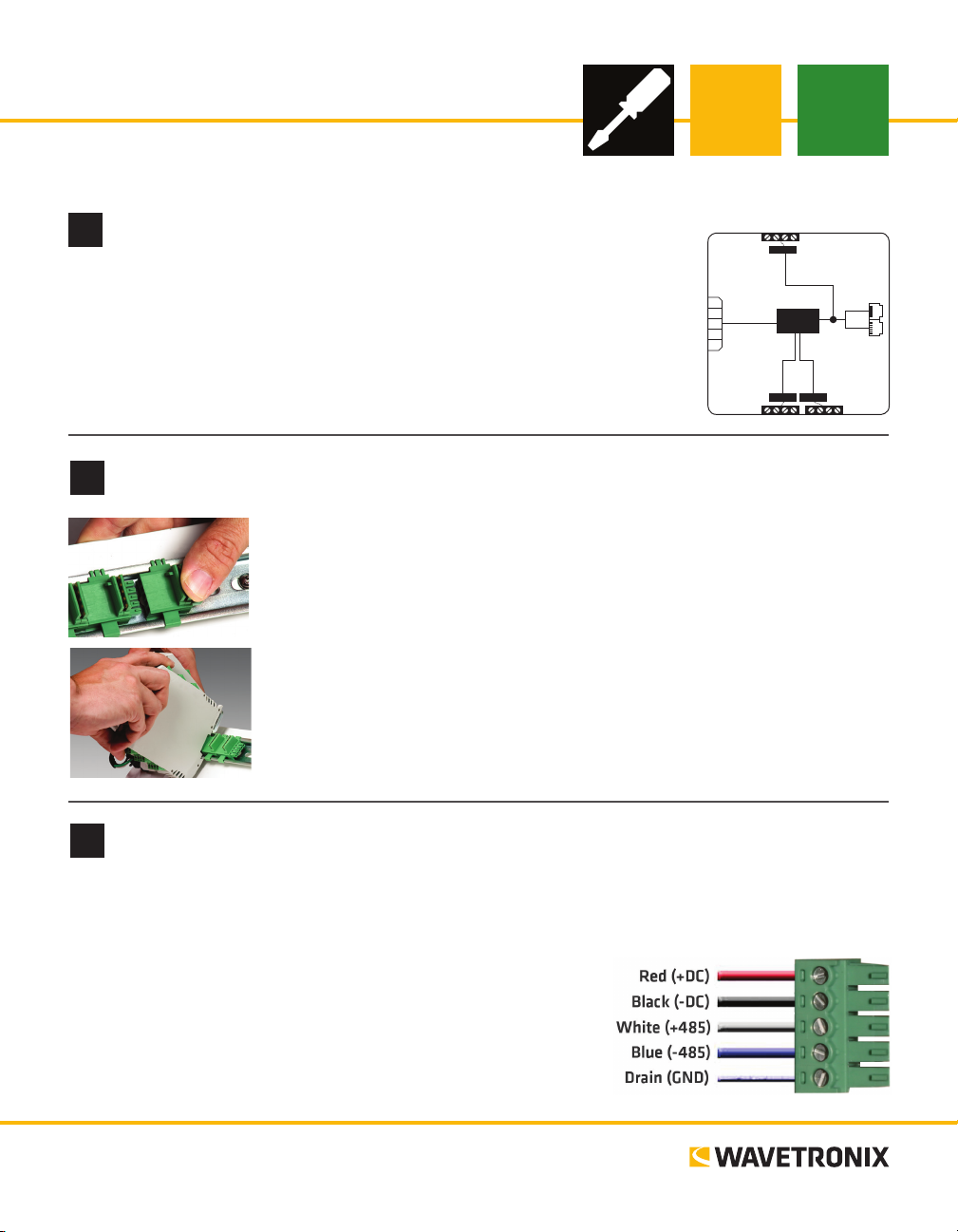

Understand buses

1

e 104 installation process will make more sense if you understand its two buses:

˽ Bus 1: Data – e RJ-11 jacks (for RS-485) and the RS-232 screw terminals

are connected; theyll be used for receiving detection calls

˽ Bus 2: Control – e connector on the back connects to the T-bus (shared

RS-485 bus for multiple Click devices) and is isolated from bus 1; it should be

used to connect to the Click 104 with a computer so you can congure it.

Mount the device

2

e Click 104 mounts over a T-bus for power and for the control bus (bus 2):

1 If the Click 104 was shipped with the T-bus connector attached, remove the

connector from the module.

2 Snap the connector onto the DIN rail by positioning it over the rail with the

male connector pointing to the right. Hook one arm over the edge of the

DIN rail and press down on the other arm until it snaps into place.

3 Connect the T-bus connector to the rest of the T-bus by sliding them to-

gether until you hear them snap into place.

4 Mount the Click 104 onto the DIN rail: position it properly over the T-bus

connector, hook the lip over the lower edge of the DIN rail, and use a rocking motion to snap the module into place.

RS-232

Bus 1

Data

+DC

Bus 2

-DC

Control

+485

-485

GND

Click

104

Contact

Closures

3-4 1-2

Bus 1

Data

RS-485

Wire power and RS-485 communication

3

If you are using a Click 200 surge protector with the Click 104, power and communication are provided to

the Click 104 through the T-bus (see the Click 200 Quick-reference Guide). If you don’t have a Click 200

surge protector, use the following steps to wire power and communication into the Click 104:

1 Plug a T-bus 5-screw terminal block into the rst T-bus connector.

2 Wire DC power (9–28 V) from the power supply into the rst

screw terminal on the 5-screw terminal block; wire -DC into the

second screw terminal.

3 Connect RS-485 communication (+485, -485 and GND) to the

remaining three screw terminals on the 5-screw terminal block.

www.wavetronix.com

801.734.7200

Page 2

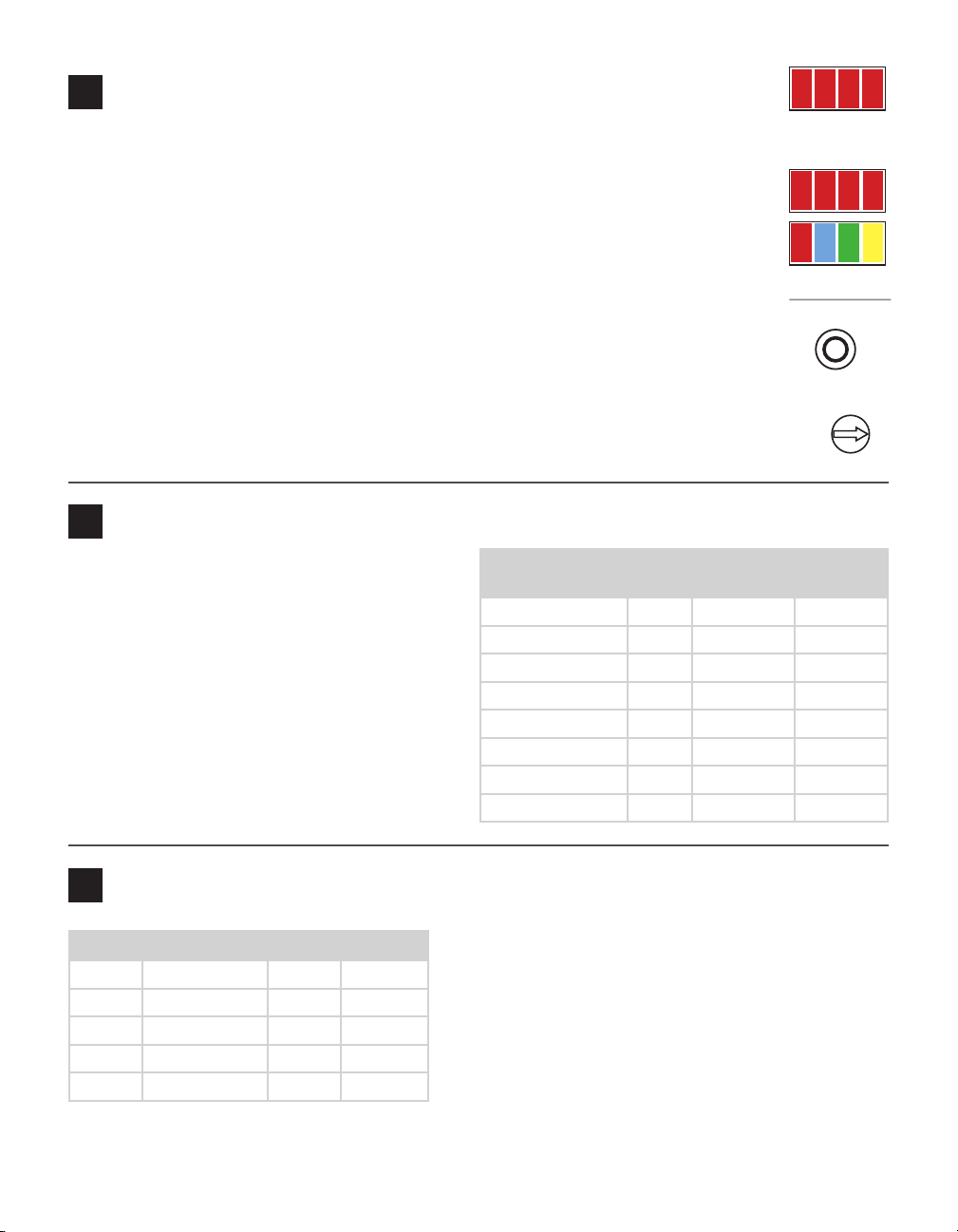

Understand the device’s configuration features

4

e following physical features allow you to congure the Click 104:

˽ Channel LEDs – e top bank of LEDs; these light up to indicate vehicle detection.

˽ Level 2 LEDs – Light up to indicate conguration options. When the device is not in

menu mode, these LEDs are o.

˽ Level 1 LEDs – Light up to indicate menu options while cycling through the menu. ey

also have the following functions:

˿ Red (PWR) – Indicates the presence of power to the device.

˿ Blue (OK) – Indicates the device is operating properly; this LED goes out if the

device is in fail-safe mode.

˿ Green (TD) – Indicates serial communication transmit data on RS-485 bus 1 or 2.

˿ Yellow (RD) – Indicates serial communication receive data on RS-485 bus 1 or 2.

˽ Mode Switch – Lets you cycle through and select menu and conguration options.

˽ Rotary Switch – Aids in input channel mapping.

Select configuration method

5

e Click 104 can be congured in one of three

ways: Click Supervisor, the front panel menu and

the rotary switch. Each option has pros and cons,

and each lets you change dierent parameters;

some parameters can only be set via one option,

while others can be set using any of the three. e

table at right gives you an idea of which parameters

can be set using which conguration options.

NOTE: If the channel input mapping is set by the

rotary switch, it can’t be changed by the front panel

menu or by Click Supervisor.

Rotary

Switch

Baud Rate No Yes Yes

Channel Input Map Yes Yes Yes

Autobaud No Yes No

Reset to Default No Yes Yes

Description No No Yes

Location No No Yes

Device ID No No Yes

Fail-safe Settings No No Yes

Front Panel

Menu

Channel

1 2 3 4

Menu

PWR OK TD RD

Mode Switch

Mapping

8

7

9

6

0

5

1

4

2

3

Click

Supervisor

Configuration option 1: rotary switch

6

Switch Channels Switch Channels

0 Software mode 5 17–20

1 1–4 6 21–24

2 5–8 7 25–28

3 9–12 8 29–32

4 13–16 9 33–36

e rotary switch on the faceplate lets you congure the

channel input mapping—that is, you can map four of the

input data channels coming from the sensor to the Click

104’s four output channels. e outputs are assigned

sequentially, so if you set the switch to 3, then input 9

will be mapped to channel 1, input 10 will be mapped to

channel 2, and so on. See the table at the right for switch/

input channel information.

NOTE: 0 (Soware mode) means that if mapping isn’t set by the rotary switch, it can be changed via the

front panel menu or Click Supervisor.

Page 3

Configuration option 2: front panel menu

Menu Operation

•

7

e front panel menu allows you to congure input mapping and baud rates. It can also reset the device to

factory defaults, and is the only place on the device to access the autobaud function.

Menu and conguration options are displayed on the Level 1 and Level 2 LEDs on the faceplate. Navigate

through the menu using the mode switch:

1 Press and hold the mode switch to enter Menu mode. e Level 1 LEDs will start to light up to indicate

that the device is cycling through all menu options.

2 When the LEDs light up in the way that indicates the menu option you want (see the gure below),

release the mode switch.

3 Quickly press and release the mode switch to select the current menu option. e Level 2 LEDs will

light up to let you congure the options for the selected menu option.

4 Press and hold the mode switch to cycle through available values for the selected menu option. e

Level 2 LEDs display the currently selected value.

5 Press and release the mode switch to accept the displayed value. e device will exit the menu.

See the gure below for how to use the LEDs to congure the parameter.

Channel Input Mapping

is function lets you map four of the input

data channels coming from the sensor to the

= LED O

= LED Flashing

= LED On

four output channels on the device. See part 5

for more information.

NOTE: If this is set with the rotary switch, you

won’t be able to change it with the front panel

menu.

Autobaud

Input Mapping

Menu LEDs

1 2 3 4

is function initiates an autobaud on the

RS-485 bus you select. If the autobaud is successful, the LEDs will display the baud rate

found, using the same LED patterns used for

the baud rate (see gure above). If it fails, all

four LEDs will ash, and then the device will

exit the menu.

Baud Rate for Bus 1 and Bus 2

is function lets you set the baud rate for bus

1 and bus 2. e two buses can be congured separately.

PUSH and HOLD Mode Switch to

cycle through menus and options.

R B G Y

Reset to Default

Menu LEDs

1 2 3 4

Cancel

Reset

R B G Y

Bus 2 Baud Rate

Menu LEDs

1 2 3 4

Cancel

9600

19200

38400

57600

R B G Y

Cancel

1-4

5-8

9-12

13-16

17-20

21-24

25-28

29-32

33-36

R B G Y

Autobaud

Menu LEDs

1 2 3 4

Cancel

Bus 1

Bus 2

R B G Y

Bus 1 Baud Rate

Menu LEDs

1 2 3 4

Cancel

9600

19200

38400

57600

This label is also on the side of the Click 104

• PUSH and

RELEASE

Mode Switch

to make

selections.

• 1 minute of

inactivity exits

menu.

Rotary

Switch

1

2

3

4

5

6

7

8

9

= SW0

= 1-4

= 5-8

= 9-12

= 13-16

= 17-20

= 21-24

= 25-28

= 29-32

= 33-36

8

7

9

6

5

4

2

3

0

1

Reset to Default

is function will restore all conguration settings to factory defaults (even those not congured using the

front panel menu): baud rate, channel map, description eld, location eld and device ID.

Page 4

Configuration option 3: Click Supervisor

8

Click Supervisor is the third available way to congure the Click 104. To install it, download the setup le

from www.wavetronix.com (under Support) and double-click on the le to run the setup wizard.

Make a connection and select a driver

1 Make sure the Click 104 is mounted on the same T-bus as a device that’s connected to your computer.

2 Run the soware and click Communication. Use the serial option (unless it’s an Ethernet connection).

3 Change any needed settings under the Settings link. Click Connect. (Keep the Click ID set to 0.)

4 In the next screen, Click Supervisor will display all the devices it discovers. When the desired Click 104

appears, select it and click Select. Click Supervisor will connect to the device.

5 Select Setup Click on the main screen. In the next screen, select the Expert driver and click OK.

Configure the module

e System > General tab has text parameters that cannot be changed anywhere

else: description/location, which are for informational purposes only; and device

ID, which usually shouldn’t be changed.

e Settings tab lets you set channel input mapping and select baud rates for the two

buses. Failsafe Enabled sets whether or not your device can enter fail-safe mode.

NOTE: Remember that if channel input mapping is set by the rotary switches, you

will only be able to view, not change, it here.

Complete wiring

9

Now you need to connect the Click 104 to the sensor (so that it can receive detection

data) and to the controller or other contact closure device.

To get detection data to bus 1:

˽ For a SmartSensor Matrix or Advance (meaning a Click 222 or 223 surge pro-

tector): connect a jumper cable to the Click 222 RJ-11 jack for the sensor you

want to get data from. Connect the other end to either of the RJ-11 jacks on the

faceplate of the Click 104. If you need more than four output channels for that

sensor, daisy-chain multiple 104s together, as shown at right.

˽ For a SmartSensor HD (meaning a Click 200): set the HD to push Z4 data on the

RS-232 port. Attach wires to the TD and RD screw terminals on the protected side

of the Click 200; attach the other ends to the TD and TD screw terminals on the

104. If needed, daisy-chain multiple 104s together with jumper cables.

How you wire the contact closures will vary based on the controller or other device you use.

Just be aware there are eight output screw terminals: a + and a – for each output channel.

© 2014 Wavetronix LLC. All rights reserved. Protected by US Pat. Nos. 6,556,916; 6,693,557; 7,426,450; 7,427,930; 7,573,400; 7,889,097; 7,889,098; 7,924,170; 7,991,542; 8,248,272;

8,665,113; and Cdn. Pat. Nos. 2,461,411; 2,434,756; 2,512,689; and Euro. Pat. Nos. 1435036; 1438702; 1611458. Other US and international patents pending. Wavetronix, SmartSensor, Click,

Command and all associated logos are trademarks of Wavetronix LLC. All other product or brand names as they appear are trademarks or registered trademarks of their respective holders. Product specifications are subject to change without notice. This material is provided for informational purposes only; Wavetronix assumes no liability related to its use.

WX-500-0252

Loading...

Loading...