Page 1

SmartSensor HD

USER GUIDE

Page 2

SmartSensor HD

USER GUIDE

www.wavetronix.com 78 East 1700 South Provo, Utah 84606 801.734.7200

Page 3

© 2014 Wavetronix LLC. All Rights Reserved.

Wavetronix, SmartSensor, Click, Command, and all associated product names and logos are trademarks of Wavetronix LLC. All other

products or brand names as they appear are trademarks or registered trademarks of their respective holders.

Protected by US Patent Nos. 6,556,916; 6,693,557; 7,426,450; 7,427,930; 7,573,400; 7,889,097; 7,889,098; 7,924,170; 7,991,542;

8,248,272; 8,665,113; Canadian Patent Nos. 2461411; 2434756; 2512689; and European Patent Nos. 1435036; 1438702; 1611458. Other

US and international patents pending.

e Company shall not be liable for any errors contained herein or for any damages arising out of or related to this document or the

information contained therein, even if the Company has been advised of the possibility of such damages.

is document is intended for informational and instructional purposes only. e Company reserves the right to make changes in the

specications and other information contained in this document without prior notication.

FCC Part 15 Compliance: e Wavetronix SmartSensor sensors comply with Part 15 of the Federal Communications Commission (FCC)

rules which state that operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesirable operation. FCC compliance statements

for applicable optional modules are to be found in the module specications. Unauthorized changes or modications not expressly approved by the party responsible for compliance with the FCC rules could void the user’s authority to operate this equipment.

Hereby, Wavetronix LLC, declares that the FMCW Trac Radar (SmartSensor HD, model number 101-0415) is in accordance with

the 2004/108/EC EMC Directive.

e device has been designed and manufactured to the following standards:

• IEC/EN 60950-1:2006, A11:2009, A1:2010, A12:2011 - Electronic equipment safety requirements.

• EN 300 440-2 - Electromagnetic compatibility and Radio spectrum Matters (ERM); Short range devices; Radio equipment to be

used in the 1 GHz to 40 GHz frequency range; Part 2: Harmonized EN under article 3.2 of the R&TTE Directive.

• EN 301 489-3 - Immunity to RF interference. Compliance with transmission limitations under 1GHz and conducted

trans¬mission over power lines, ESD.

e equipment named above has been tested and found to comply with the relevant sections of the above referenced specications.

e unit complies with all essential requirements of the Directives. is equipment has been evaluated at 2000m.

IP Protection: IP66

For installation into restricted access location.

All interconnecting cables shall be suitable for outdoor use.

Disclaimer: e advertised detection accuracy of the Wavetronix SmartSensor sensors is based on both external and internal testing,

as outlined in each product’s specication document. Although our sensors are very accurate by industry standards, like all other sensor manufacturers we cannot guarantee perfection or assure that no errors will ever occur in any particular applications of our technology. erefore, beyond the express Limited Warranty that accompanies each sensor sold by the company, we oer no additional

representations, warranties, guarantees or remedies to our customers. It is recommended that purchasers and integrators evaluate the

accuracy of each sensor to determine the acceptable margin of error for each application within their particular system(s).

WX-500-0051

5/2014

Page 4

Contents

Introduction 5

SmartSensor HD Package 5 • Selecting a Mounting Location 6

Part I Installing the SmartSensor HD

Chapter 1 Installing the SmartSensor HD 11

Selecting the Mounting Height 12 • Attaching the Mount

Bracket to the Pole 14 • Attaching the Sensor to the Mount

Bracket 14 • Aligning the Sensor to the Roadway 15 • Applying

Silicon Dielectric Compound 16 • Connecting the Cable 17

Chapter 2 Connecting Power and Surge 19

Connecting Lightning Surge Protection 20 • Wiring to Earth

Ground 23 • Installing the Power Plant 24 • Connecting the

Power Plant to Your Installation 28 • Wiring Communication 29

Part II Using SmartSensor Manager HD

Chapter 3 Installing SmartSensor Manager HD 33

Installing SSMHD 33

Chapter 4 Communication 37

Serial Connection 38 • Internet Connection 39 • Virtual Connection 40 • Viewing Connection Information 41 • Installation

Type 43 • Communication Screen Icons 43 • Uploading the

Sensor’s Embedded Soware 45

Page 5

Chapter 5 Settings 47

General Tab 47 • Ports Tab 48 • Outputs Tab 49

Chapter 6 Lanes 53

Conguration 54 • Verication 62

Chapter 7 Data 65

Denitions 66 • Storage 70 • Download 72 • Push 74

Chapter 8 Tools 77

Backup–Restore 78 • License 79 • Power 80

Appendix 81

Appendix A - 10-pin Connector 81 • Appendix B - 26-pin

Connector 82 • Appendix C - Cable Lengths 83 • Appendix

D - Direct Serial Connections 85 • Appendix E - Signaling

Delays 86

Page 6

Introduction

In this chapter

SmartSensor HD Package

Selecting a Mounting Location

1

e Wavetronix SmartSensor HD trac sensor utilizes the latest technology to collect and

deliver trac statistics. e SmartSensor HD collects information through the use of a

24.125 GHz (K band) operating radio frequency and is capable of measuring trac volume and classication, average speed, individual vehicle speed, lane occupancy and presence. e SmartSensor HD uses what is classied as frequency modulated continuous wave

(FMCW) radar; it detects and reports trac conditions simultaneously over as many as 22

lanes of trac.

Once SmartSensor HD is installed, the conguration process is quick and easy. Aer installation, this unit will require little or no on-site maintenance and can be remotely recongured for optimal performance. is user guide outlines the step-by-step process of

installing and conguring the SmartSensor HD. Any questions about the information in

this guide should be directed to Wavetronix or your distributor.

SmartSensor HD Package

A standard SmartSensor HD package contains the following items:

SmartSensor HD SS125 detector with installed backplate

SmartSensor HD quick-reference guides

Page 7

6 INTRODUCTION SMARTSENSOR HD USER GUIDE

e following items are not included but are necessary for installation:

Sensor mount

Sensor cable

Additional products may be purchased through your distributor. e following optional

items are not included unless specically ordered (check packing list for actual inventory):

Contact closure adapter such as the Click 100, 104, 110, or 112/114.

Click 200 surge protector

Click 201/202 AC to DC converter

Click 210 circuit breaker

Click 230 AC surge protector

SmartSensor HD User Guide (doesn’t have to be purchased, but does have to be re-

quested from Wavetronix)

Selecting a Mounting Location

Consider the following guidelines when selecting a mounting location:

Lane Coverage – Sensor mounting locations should be selected so that all monitored

lanes are within 6 to 250 . (1.8 to 76.2 m) of the sensor and run parallel with each

other. Multiple sensors should be considered if more than 10 lanes need to be simultaneously monitored. If lanes do not need to be simultaneously monitored, up to 22 lanes

can be congured for collection by a single sensor.

Parallel Lanes – When the sensor is used to collect both mainline and ramp data, the

pole position should be selected so that the on and o ramp lanes run parallel with

the mainline. If lanes are not parallel, installation of multiple SmartSensor HD units

should be considered.

Sensors on the Same Pole – When multiple sensors are mounted on the same pole,

they will not be subject to interference if they are congured to operate using dierent

RF channels and are separated vertically by a few feet. e higher sensor would typically be used for the lanes farther from the pole in order to minimize occlusion.

Sensors on Opposing Poles – SmartSensor HD units facing each other on opposing

poles should operate on dierent RF channels and be separated by a 70-. (21.3-m)

lateral oset, if possible.

Line of Sight – e SmartSensor HD is designed to work accurately in the presence of

barriers, but in general if there is an alternate mounting location that would avoid any

type of structural occlusion, this is preferred. Avoid occlusion by trees, signs, and other

roadside structures.

Neighboring Structures and Parallel Walls – To eliminate the risk of performance

degradation, the sensor locations should have a 30-. (9.1-m) lateral separation from

overhead signs, overpasses, tunnels, parallel walls, and parallel parked vehicles in order

to avoid multiple reection paths from a single vehicle. is separation removes the

objects from the antenna pattern of the sensor. In practice the sensor has been mounted

much closer to reecting objects with minimal impact in sensor performance. For ex-

Page 8

INTRODUCTION SMARTSENSOR HD USER GUIDE 7

ample, sensors mounted on gantries have successfully met customer requirements when

using a 3-foot extension arm to laterally separate the sensor from the structure. Please

talk with a Wavetronix Technical Support representative about your specic situation.

Mounting Height – e mounting height should be based upon the oset from the

lanes of interest. For each oset, the minimum, maximum, and best heights are shown

in Table 1.1, found in Chapter 1. In general, the range of recommended heights is between 9 and 50 . (2.7 to 15.2 m).

Mounting Oset – e minimum recommended oset (distance from the sensor to

the edge of the rst lane of interest) is 6 . (1.8 m).

Arterial Locations – Sensor sites on arterials or other roadway segments with regulat-

ed stop lines should be selected at midblock positions to increase accuracy by avoiding

positions at which vehicles are oen stopped in front of the sensor.

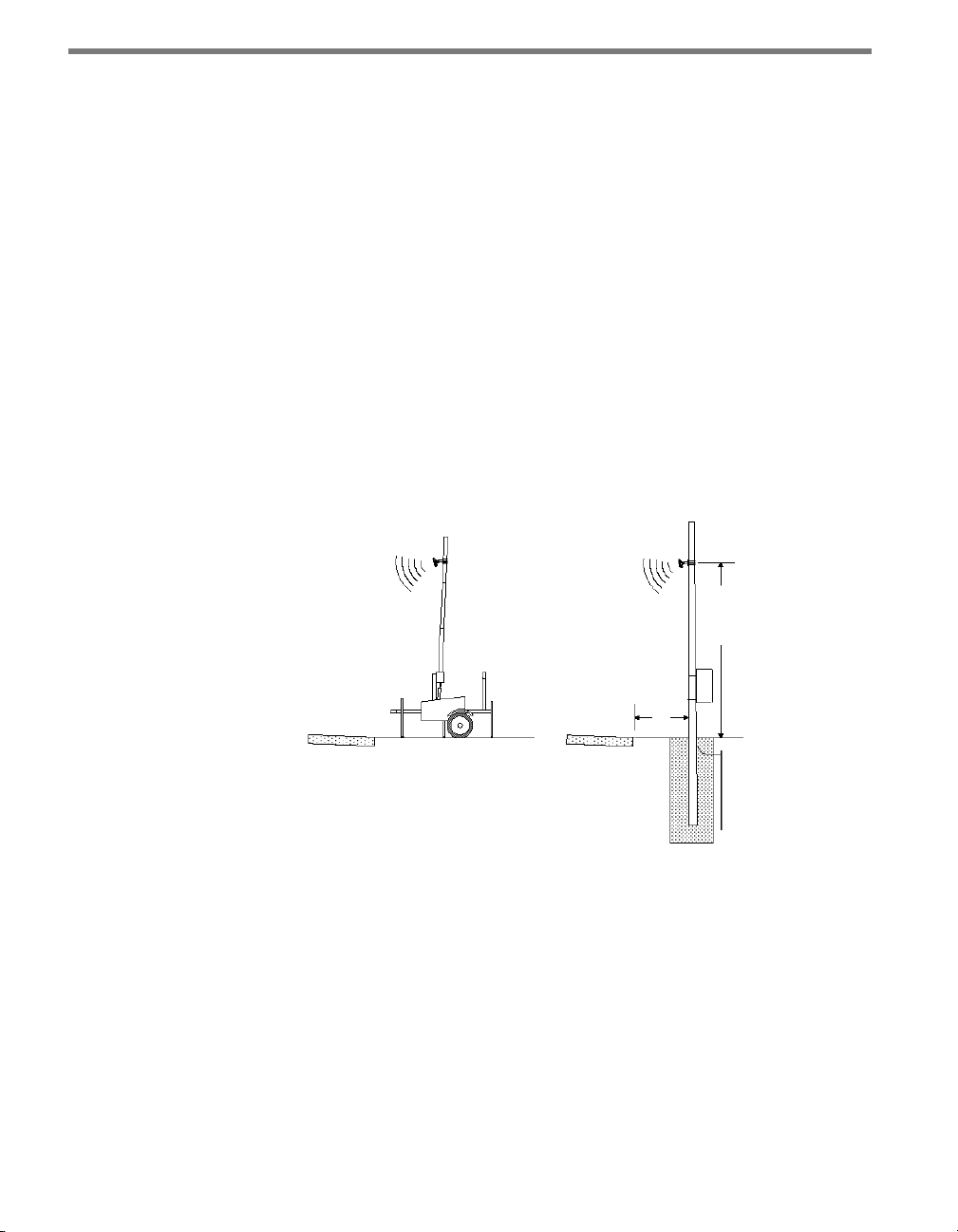

Freeway Locations – e SmartSensor HD is oen used at permanent ATR (auto-

matic trac recorder) stations. e number of stations along a single roadway and the

distance between stations should be selected to achieve adequate levels of statistical

condence. Permanent ATR stations, which are selected to cover interstate, principal

arterial, and other national and state highways, are used to establish seasonal adjustment factors for count data from temporary collection sites (see Figure I.1).

9–50 ft.

(see

mounting

guidelines)

Roadway Roadway

Figure I.1 – Portable (left) and Permanent (right) Sensor Stations

6 ft.

min

Cable Lengths – Ensure that you have sucient homerun and sensor cabling. Cables

can be as long as 600 . (182.9 m) if they’re using 24 VDC operation and RS-485 communications; for longer connections, alternate wired and wireless options should be

considered.

Signaling Delay – Aer a vehicle passes in front of the sensor there will be a slight

delay before the data for that vehicle is sent from the sensor. In a time-sensitive application—for instance, to supply a dynamic message sign with per vehicle warning

messages—it will be necessary to ensure the sensor is suciently far upstream from

the sign that the system has time to collect the data, process it, and send it to the sign

by the time the vehicles reach the problem area. For specics about signaling delay,

see Appendix E.

Page 9

Page 10

Part I

Installing the SmartSensor HD

Chapter 1 – Installing the SmartSensor HD

Chapter 2 – Connecting Power and Surge

Page 11

Page 12

Installing the SmartSensor HD 1

In this chapter

Selecting the Mounting Height

Attaching the Mount Bracket to the Pole

Attaching the Sensor to the Mount Bracket

Aligning the Sensor to the Roadway

Applying Silicon Dielectric Compound

Connecting the Cable

1

Installing the SmartSensor HD is quick and easy. Once installed, the SmartSensor HD congures automatically and requires little or no on-site maintenance.

e installation process includes attaching the mounting bracket to the pole; attaching the

sensor to the mounting bracket; aligning the sensor; applying a silicon dielectric compound

to the sensor connector; and connecting the cable to the sensor.

Warning

Do not attempt to service or repair this unit. This unit does not contain any components and/or parts serviceable in the field. Any attempt to open this unit, except as

expressly written and directed by Wavetronix, will void the customer warranty. Any

visible damage to exterior seal labels will void the warranty. Wavetronix is not liable

for any bodily harm or damage caused if unqualified persons attempt to service or

open the back cover of this unit. Refer all service questions to Wavetronix or an authorized distributor.

Page 13

12 CHAPTER 1 INSTALLING THE SMARTSENSOR HD

Caution

Use caution when installing any sensor on or around active roadways. Serious injury

can result when installation is performed using methods that are not in accordance

with authorized local safety policy and procedures. Always maintain an appropriate

awareness of the trac conditions and safety procedures as they relate to specific

locations and installations.

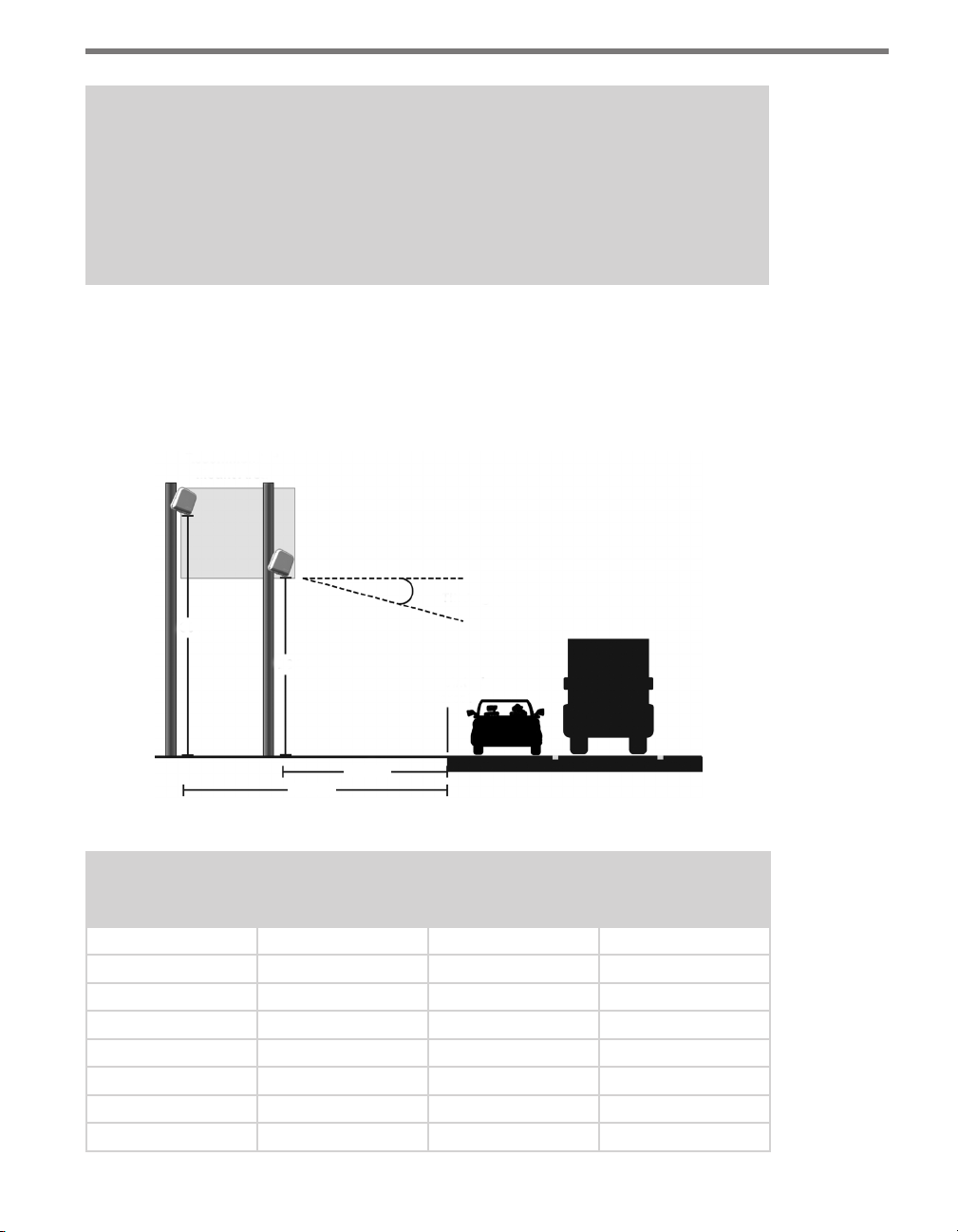

Selecting the Mounting Height

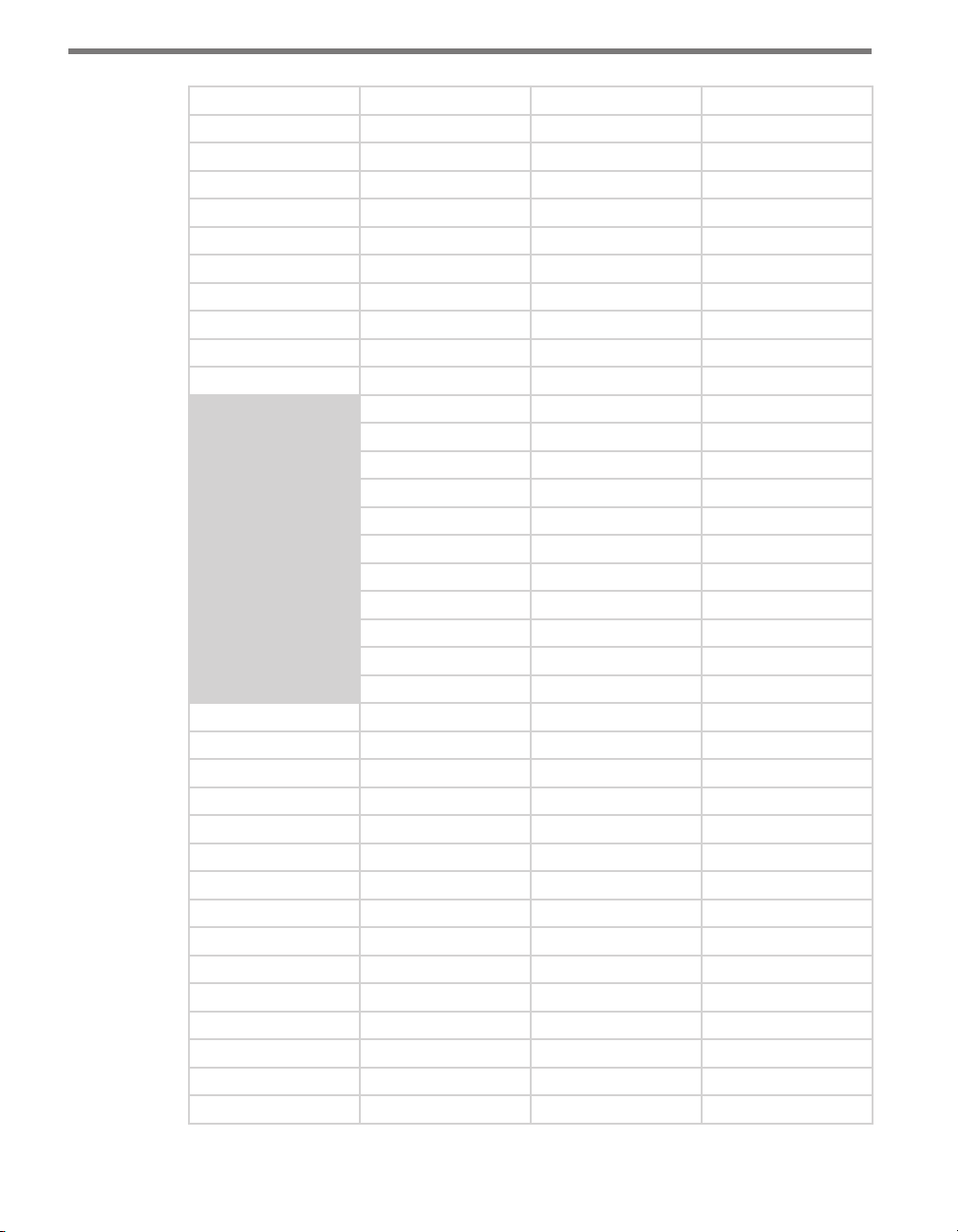

Aer selecting a mounting location within the recommended range of osets (see the introduction and Figure 1.1), use Table 1.1 to select a mounting height.

Recommended

Mount Area

Tilt Angle

30 ft.

26 ft.

25 ft.

35 ft.

Figure 1.1 – Recommended Mounting Height

Oset from first

Detection Lane (ft

/ m)

6 / 1.8 12 / 3.7 9 / 2.7 19 / 5.8*

7 / 2.1 12 / 3.7 9 / 2.7 19 / 5.8*

8 / 2.4 12 / 3.7 9 / 2.7 20 / 6.1*

9 / 2.7 12 / 3.7 9 / 2.7 21 / 6.4

10 / 3 12 / 3.7 9 / 2.7 22 / 6.7

11 / 3.4 12 / 3.7 9 / 2.7 23 / 7

12 / 3.7 13 / 4 10 / 3 24 / 7. 3

13 / 4 13 / 4 11 / 3.4 25 / 7. 6

Recommended

Mounting Height

(ft / m)

1st Point of

Interest

Minimum Mounting Height (ft / m)

Maximum Mounting Height (ft / m)

Page 14

CHAPTER 1 INSTALLING THE SMARTSENSOR HD 13

14 / 4.3 14 / 4.3 11 / 3.4 26 / 7.9

15 / 4.6 15 / 4.6 12 / 3.7 26 / 7.9

16 / 4.9 15 / 4.6 12 / 3.7 27 / 8.2

17 / 5.2 16 / 4.9 13 / 4 28 / 8.5

18 / 5.5 17 / 5.2 14 / 4.3 29 / 8.8

19 / 5.8 17 / 5.2 14 / 4.3 30 / 9.1

20 / 6.1 18 / 5.5 15 / 4.6 30 / 9.1

21 / 6.4 19 / 5.8 15 / 4.6 31 / 9.4

22 / 6.7 20 / 6.1 16 / 4.9 31 / 9.4

23 / 7 22 / 6.7 16 / 4.9 32 / 9.8

24 / 7. 3 24 / 7.3 16 / 4.9 33 / 1 0.1

25 / 7.6 26 / 7. 9 17 / 5.2 33 / 10.1

26 / 7.9 26 / 7. 9 17 / 5.2 34 / 1 0.4

27 / 8.2 27 / 8.2 18 / 5.5 35 / 10.7

28 / 8.5 27 / 8.2 18 / 5.5 35 / 10.7

29 / 8.8 27 / 8.2 18 / 5.5 36 / 11

30 / 9.1 29 / 8.8 19 / 5.8 37 / 11.3

31 / 9.4 29 / 8.8 19 / 5.8 37 / 11.3

32 / 9.8 29 / 8.8 19 / 5.8 38 / 11.6

Recommended Oset

33 / 10.1 30 / 9.1 19 / 5.8 39 / 11.9

34 / 10.4 30 / 9.1 19 / 5.8 39 / 11.9

35 / 10.7 30 / 9.1 20 / 6.1 40 / 12.2

36 / 11 30 / 9.1 20 / 6.1 41 / 12.5

37 / 11.3 31 / 9.4 20 / 6.1 41 / 12.5

38 / 11.6 31 / 9.4 21 / 6.4 42 / 12.8

39 / 11.9 33 / 10.1 21 / 6.4 43 / 13.1

40 / 12.2 33 / 10.1 22 / 6.7 43 / 13.1

41 / 12.5 34 / 10.4 22 / 6.7 44 / 13.4

42 / 12.8 34 / 10.4 22 / 6.7 44 / 1 3.4

43 / 13.1 35 / 10.7 22 / 6.7 45 / 13.7

44 / 13.4 35 / 10.7 23 / 7 46 / 14

45 / 13.7 36 / 11 23 / 7 46 / 14

46 / 14 36 / 11 23 / 7 47 / 14.3

47 / 14.3 36 / 11 24 / 7. 3 48 / 14.6

48 / 14.6 38 / 11.6 24 / 7. 3 48 / 14.6

49 / 14.9 38 / 11.6 24 / 7.3 49 / 14.9

50–230 / 15.2–70.1 39 / 11.9 25 / 7. 6 Must be < oset

Table 1.1 – Mounting Height Guidelines in Feet / Meters

Page 15

14 CHAPTER 1 INSTALLING THE SMARTSENSOR HD

Attaching the Mount Bracket to the Pole

Before attaching the mount bracket to the pole, rst make sure that your cables are long

enough to reach the sensor and to stretch across the distance from the sensor to the cabinet.

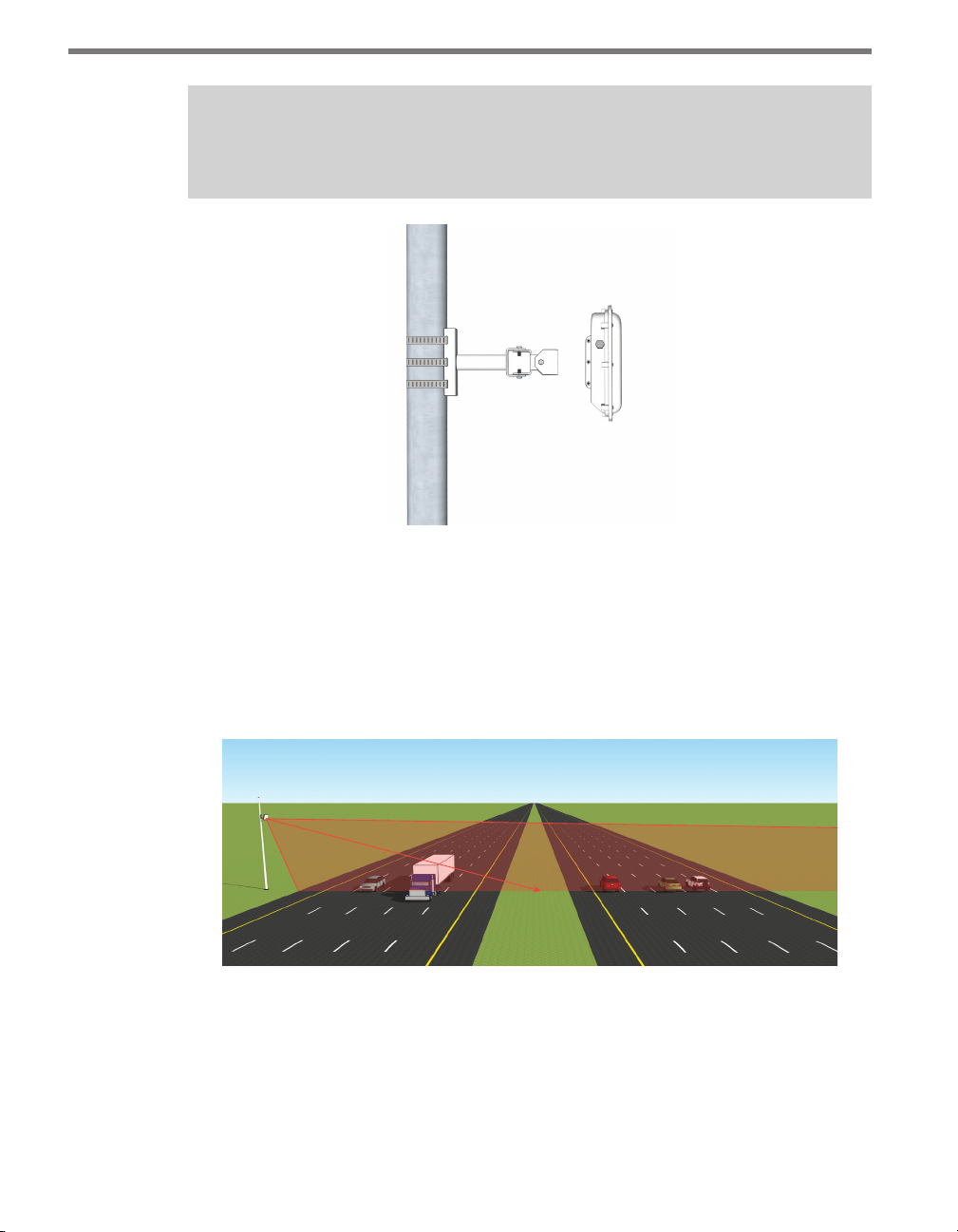

Follow the steps below to correctly attach the mount to the pole (see Figure 1.2):

1 Insert the stainless steel straps through the slots in the mount bracket.

2 Position the mount bracket on the pole so that the head of the mount is pointing to-

wards the middle of the lanes of interest.

3 Tighten the strap screws.

Note

The sensor will need to be adjusted later, to fine-tune the alignment, so be sure to

keep the straps adjustable.

Figure 1.2 – Attaching the Mount Bracket to the Pole

Attaching the Sensor to the Mount Bracket

Use the following steps to securely fasten the sensor to the mount bracket:

1 Align the bolts on the sensor’s backplate with the holes in the mount bracket. e con-

nector at the bottom of the unit should be pointing towards the ground.

2 Place the lock washers onto the bolts aer the bolts are in the mount bracket holes.

3 read on the nuts and tighten (see Figure 1.3).

Page 16

CHAPTER 1 INSTALLING THE SMARTSENSOR HD 15

Note

Do not over-tighten the fasteners.

Figure 1.3 – Attaching the Sensor to the Mount Bracket

Aligning the Sensor to the Roadway

Use the following steps to correctly mount and align the SmartSensor HD:

1 Tilt the sensor down so that the front is aimed at the center of the detection area (see

Figure 1.4).

Figure 1.4 – Up-and-down Positioning

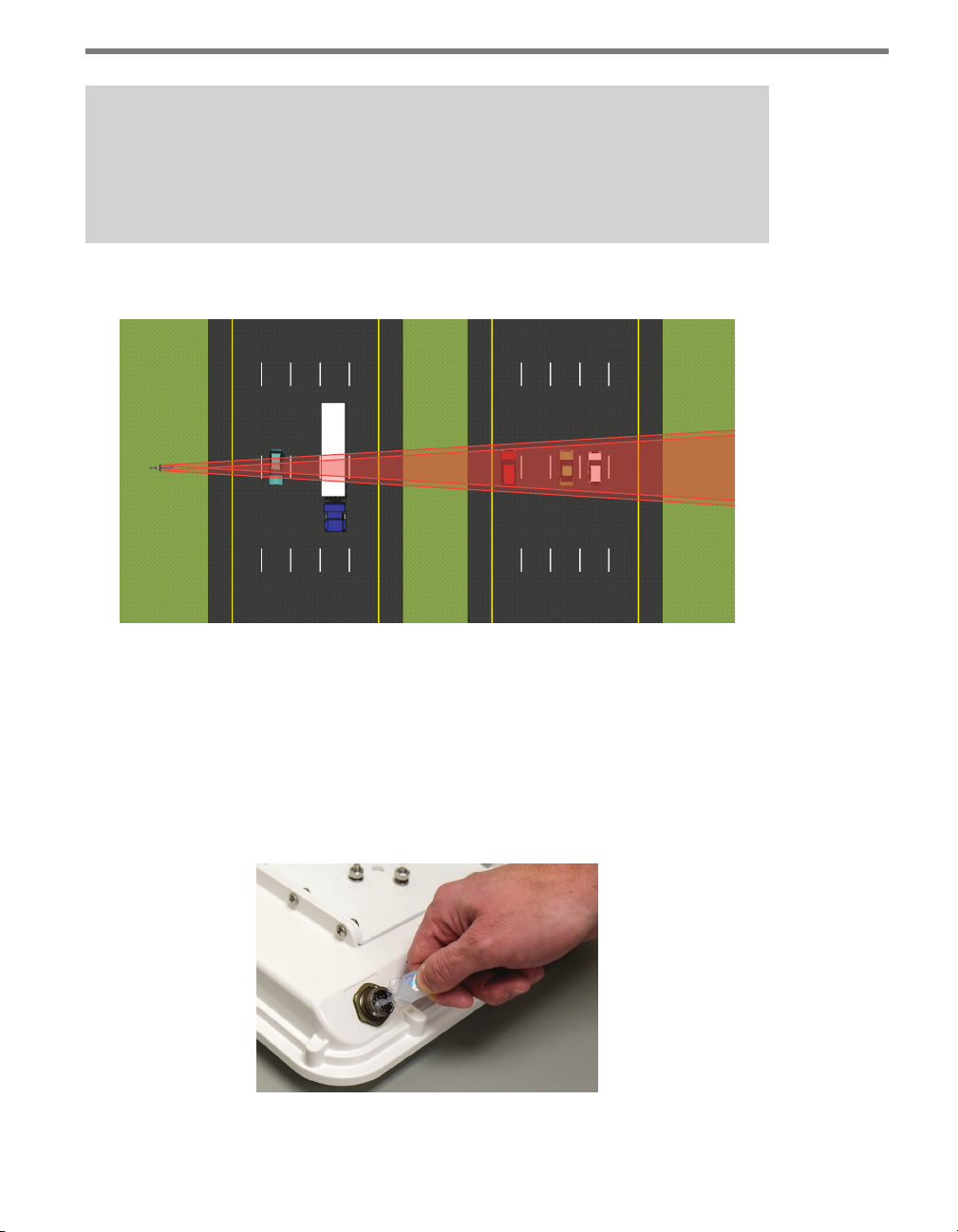

2 Adjust the side-to-side angle so that it is as close to perpendicular to the ow of trac

as possible (see Figure 1.5).

Page 17

16 CHAPTER 1 INSTALLING THE SMARTSENSOR HD

Note

The side-to-side alignment will eventually be fine-tuned for better accuracy using

SmartSensor Manager HD (SSMHD). That step will be addressed in Chapter 6, after

SSMHD has been installed.

Side-to-side alignment should

be perpendicular

Figure 1.5 – Side-to-side Positioning

Applying Silicon Dielectric Compound

Use the following steps to correctly apply the silicon dielectric compound:

1 Tear the tab o of the tube of silicon dielectric compound.

2 Squeeze about 25% of the silicon into the connector at the base of the SmartSensor HD

(see Figure 1.6). Be sure to wipe o any excess compound.

Figure 1.6 – Applying Silicon Dielectric Compound

Page 18

CHAPTER 1 INSTALLING THE SMARTSENSOR HD 17

Connecting the Cable

e sensor connector is keyed to ensure proper connection; once you have plugged the

cable connector into the sensor connector, simply twist the cable connector clockwise until

you hear it click into place. To avoid undue movement from the wind, strap the cable to the

pole or run it through a conduit, but leave a small amount of slack at the top of the cable to

reduce cable strain (see Figure 1.7).

Note

If you run the cable through the pole, do not drill through the sensor mount, as the

sensor and sensor mount may need to be adjusted in the future.

Figure 1.7 – Sensor Connector

e service end of the cable has a +DC and GND for a power supply of 12 to 24 VDC. Two

communication ports (either RS-232 or RS-485) are available to connect the SmartSensor

HD to a modem or other communication device. Typically, one RS-485 and one RS-232

port are available.

Page 19

Page 20

Connecting Power and Surge 2

In this chapter

Connecting Lightning Surge Protection

Wiring to Earth Ground

Installing the Power Plant

Connecting the Power Plant to Your Installation

Wiring Communication

2

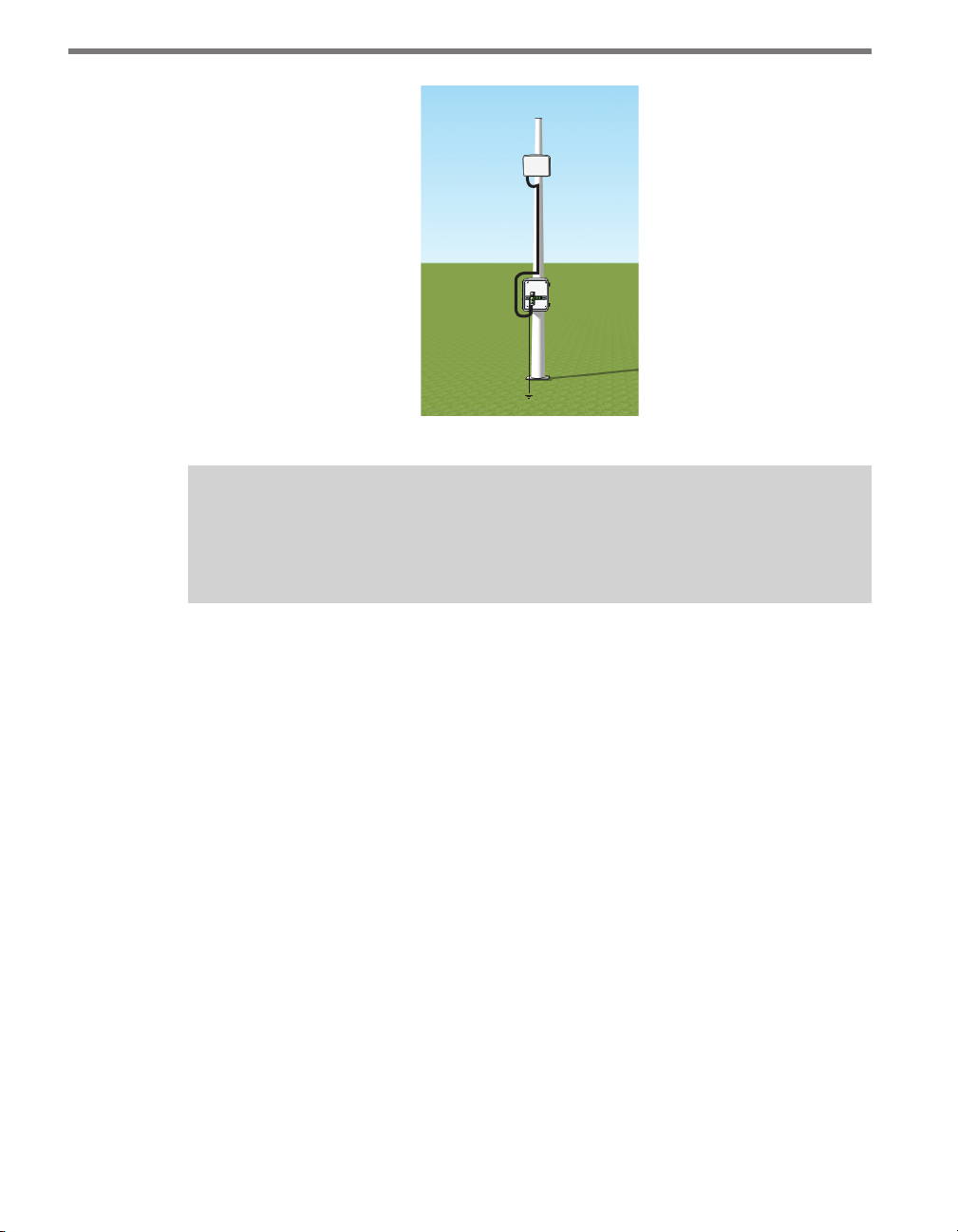

Once the sensor is installed, it will need to be wired for power and surge protection. Wavetronix Click products allow you to quickly and easily include power and surge protection

in your sensor application. Please refer to the Click quick-reference guides for more comprehensive product instructions.

ere are several ways your sensor might be set up:

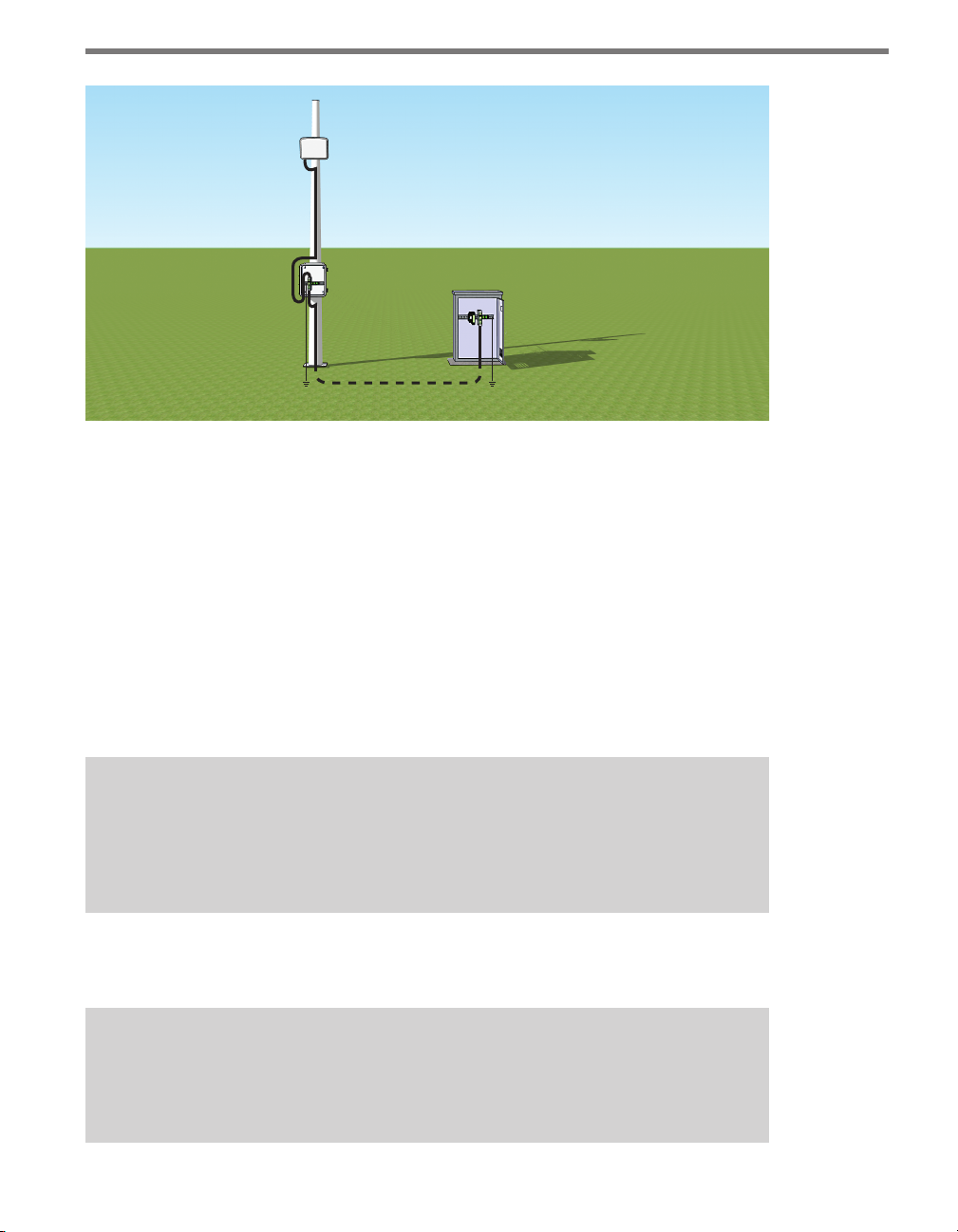

A two-part installation, with components in two areas: rst, a pole by the road holds

your sensor plus a pole-mount box with a surge protector inside. Second, a main trac

cabinet holds power and communications devices. e cabinet and pole are connected

via a homerun cable that runs underground.

Note

This chapter assumes the box and cabinet are connected by an underground cable

run, but in certain circumstances they might not be.

Page 21

20 CHAPTER 2 CONNECTING POWER AND SURGE

A single-part installation, with all components on the same pole. is pole holds your

sensor. Power and communications devices (most likely wireless) are in a pole-mount

box or there is a trac cabinet at the base of the pole; either way there is no underground cable run. Power comes from the pole itself or from a battery and/or solar

panels at the pole.

How you set up the devices in this chapter will vary depending on which of these installations you are using.

Connecting Lightning Surge Protection

e sensor should be connected to at least one surge protection device. e Click 200 and

equivalent devices are designed to prevent electrical surges along cables from damaging the

sensor and/or the cabinet. It is also a convenient spot to terminate the cable coming from

your sensor, as it has terminals for all the wires.

Note

If you choose not to use surge protection in your installation, please contact Wavetronix Technical Services for assistance.

If you are using the one-part installation option—no underground cable run—put a Click 200

in the pole-mount box/trac cabinet (whichever is being employed) as a termination point

for the cable from the sensor, and as a way to protect the box/cabinet. When there is no underground cable run, it is safest practice, as well as Wavetronix standard procedure, to connect

the cable from the sensor in the UNPROTECTED side of the Click 200.

1 Install a Click 200 in the pole-mount cabinet/trac cabinet by snapping it onto the

DIN rail. Your power and communications devices will most likely also be on this DIN

rail; make sure the Click 200 is connected to them via wires or the shared communication bus (connecting power will be covered later in this chapter; for how to connect to

communications devices, see the Click 100–400 Series User Guide).

2 Wire the cable from the sensor to the UNPROTECTED side of the Click 200.

Page 22

CHAPTER 2 CONNECTING POWER AND SURGE 21

Smart

Sensor

Figure 2.1 – Using a Single Click 200

Note

The dierent cables available and how to wire them into the Click 200 will be covered

later in this section.

If you are using the two-part installation option, you’ll have an underground cable run as

part of your installation, connecting the power and comms devices in the main trac cabinet to the pole-mount box and sensor. When there is an underground cable run, it is safest

practice, as well as Wavetronix standard procedure, to use two Click 200s, one on each end

of the cable: one in the main trac cabinet and the other in the pole-mount cabinet. Both

ends of the cable should be connected to the UNPROTECTED side of their Click 200s. is

is important because the underground cable run will be susceptible to surges caused by

lightning striking the ground near it.

If this run is shorter than 600 . (182.9 m), you can use a Wavetronix cable; see Appendix

D for more on cable lengths.

1 Install one Click 200 device in a pole-mount cabinet on the same pole as the sensor

being protected. Install it by snapping it onto the DIN rail.

2 Connect the cable from the sensor to the PROTECTED side of this Click 200. is

cable should be kept as short as possible.

3 Install another Click 200 in the main trac cabinet. You will likely have power and com-

munications devices in this cabinet; make sure the Click 200 is connected to them via wires

or the shared communication bus (connecting power will be covered later in this chapter;

for how to connect to communication devices, see the Click 100–400 Series User Guide).

4 Connect the pole-mount box and the main trac cabinet by running a cable from the

UNPROTECTED side of the Click 200 in the pole-mount box to the UNPROTECTED

side of the Click 200 in the main trac cabinet.

Page 23

22 CHAPTER 2 CONNECTING POWER AND SURGE

Smart

Sensor

Pole-

mount

box

Figure 2.2 – Underground Cable Run

Main trac cabinet

120

VAC

Earth groundEarth ground

Wiring the Click 200

ere are two cables that may be used with your sensor, the 8-conductor cable and the

9-conductor cable. Which one you use is based largely on the connector on your SmartSensor HD—that is, the connector where the cable will be plugged into the sensor.

ere are two dierent connectors that may be found on a SmartSensor HD:

e 10-pin connector is used with the SmartSensor HD. It currently only comes in-

stalled on the 8-conductor cable.

e 26-pin connector is used with SmartSensor HD Legacy and retrotted HDs. It can

be installed on the 8-conductor cable or the old 9-conductor cable.

Note

There may be compatibility issues if you use a 8-conductor/26-pin connector cable

with a SmartSensor HD that was manufactured in or before 2008. Contact Wavetronix Technical Services for details and assistance.

e wiring for these two cables is almost identical; the dierences are pointed out on the

following page.

Note

If you have an underground cable run that stretches more than 600 ft (182.9 m), you will

likely need to use a dierent cable; in that case the colors won't match the figure below.

Page 24

CHAPTER 2 CONNECTING POWER AND SURGE 23

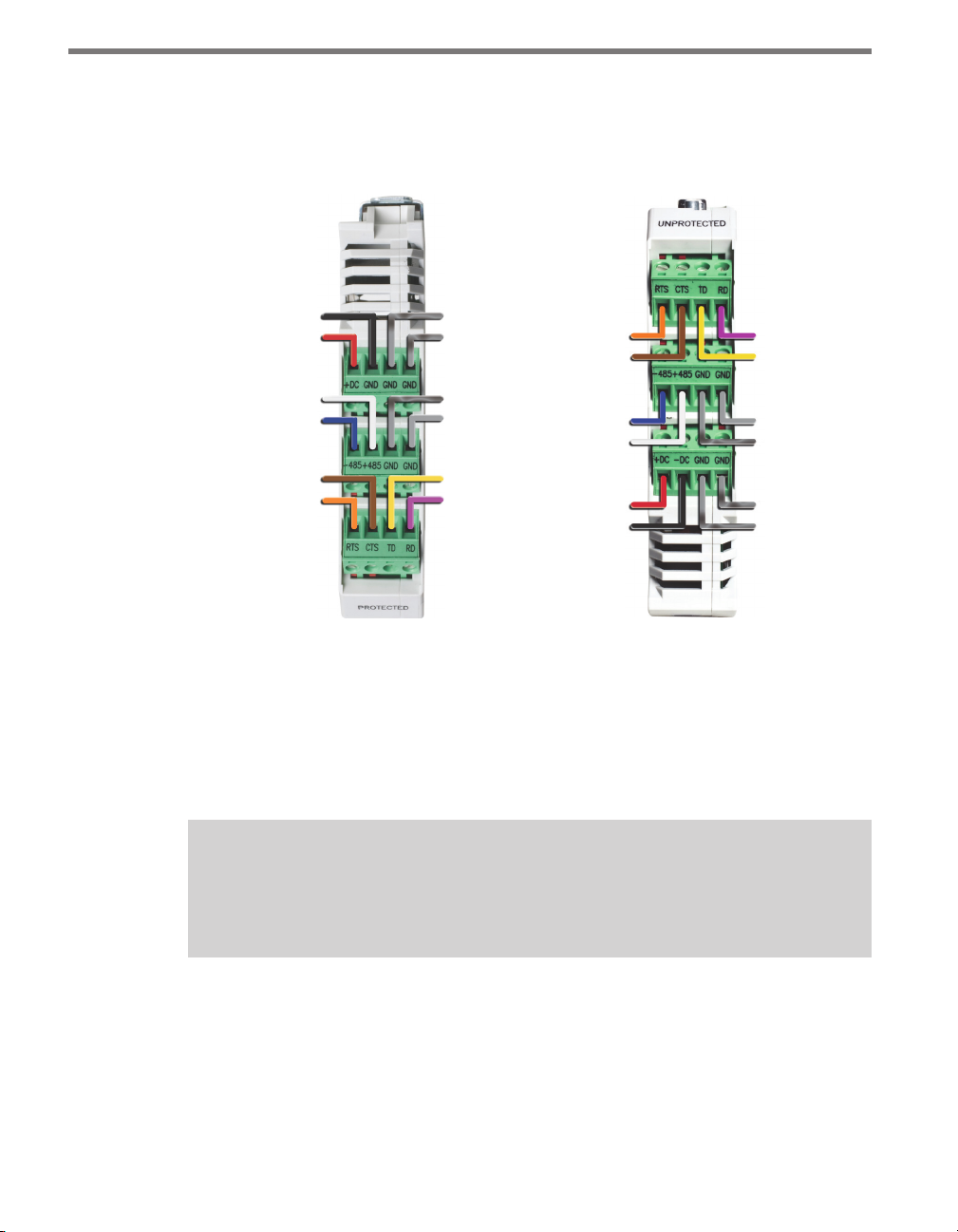

e Click 200 contains three terminal connectors on both the top and the bottom of the

module (see Figure 2.3). e terminal connectors are removable and are red-keyed, allowing each connector to plug into only one specic jack. is both simplies the wiring

process and reduces the possibility of wiring errors.

GND/-DC (Black)

+DC (Red)

+485 (White)

-485 (Blue)

CTS (Brown)

RTS (Orange)

Figure 2.3 – Click 200 Terminal Connections (protected and unprotected sides)

Power Drain

RS-232 Drain

RS-485 Drain

Ground (Gray)

TD (Yellow)

RD (Purple)

RTS (Orange)

CTS (Brown)

-485 (Blue)

+485 (White)

+DC (Red)

-DC (Black)

RD (Purple)

TD (Yellow)

Ground (Gray)

RS-485 Drain

RS-232 Drain

Power Drain

If you have an 8-conductor cable, it will have the following wiring dierences:

ere is no gray ground wire.

Instead of three drains, there is only one. is drain can be connected into any of the

screw terminals marked GND.

e white +485 wire will have a blue stripe.

Note

See Appendices A and B for cable pinout diagrams for the two dierent connectors

found on SmartSensor HDs.

Wiring to Earth Ground

All Click 200 devices should be mounted on a DIN rail that is connected to earth ground

either through an earth-grounded chassis or a 16 AWG or larger grounding wire attached

to a 7-. (2.1-m) grounding rod. Follow the steps below to correctly wire to earth ground:

Page 25

24 CHAPTER 2 CONNECTING POWER AND SURGE

1 Connect the grounding wire from either the DIN rail or a GND screw terminal on the UN-

PROTECTED side of the Click 200 to the lug bolt on the inside of the pole-mount cabinet.

2 Connect another grounding wire from the exterior lug bolt to earth ground (see Figure 2.4).

Figure 2.4 – Earth Ground Connections

Installing the Power Plant

Provide power to your installation using the Click power plant. is set of modules includes

the following:

Click 201/202 AC to DC converter

Click 210 circuit breaker and switch

Click 230 AC surge module

A Click 201 provides 1 A of power and is capable of powering a single sensor, while a Click

202 provides 2 A and can power two sensors. (ere is also a Click 204 which provides 4 A

of power, but that will usually not be necessary in an installation such as the one outlined

below.) e Click 230 helps limit current surges on the power lines; the Click 210 interrupts

power during overload conditions and provides a convenient way to turn power on and o.

e power plant will either be in a pole-mount box or in a main trac cabinet. If it’s in a

trac cabinet, the power will be sent to the pole via an underground cable run. How to install the power plant and then wire to a Click 200 will be covered in the rest of this section.

It should be noted that if you have ordered a Wavetronix preassembled cabinet, all of this

wiring and installation will already be done.

Page 26

CHAPTER 2 CONNECTING POWER AND SURGE 25

Note

An authorized electrical technician should perform installation and operation of this

unit. Persons other than authorized and approved electrical technicians should NOT

attempt to connect this unit to a power supply and/or trac control cabinet, as there

is a serious risk of electrical shock through unsafe handling of the power source. Extreme caution should be used when connecting this unit to an active power supply.

Wiring in AC

e rst step is to get AC power into the enclosure. (Sometimes the power source is actually

DC; to see Wavetronix’s selection of DC power modules, see the Click 100–400 Series User

Guide.) If you’re using a main trac cabinet, wire from its power source; if you’re using a

pole-mount box, the power lines or cable can be brought in through the conduit on the

bottom-le.

Note

Make sure power to AC mains is disconnected while wiring AC input.

Wiring the Click 210

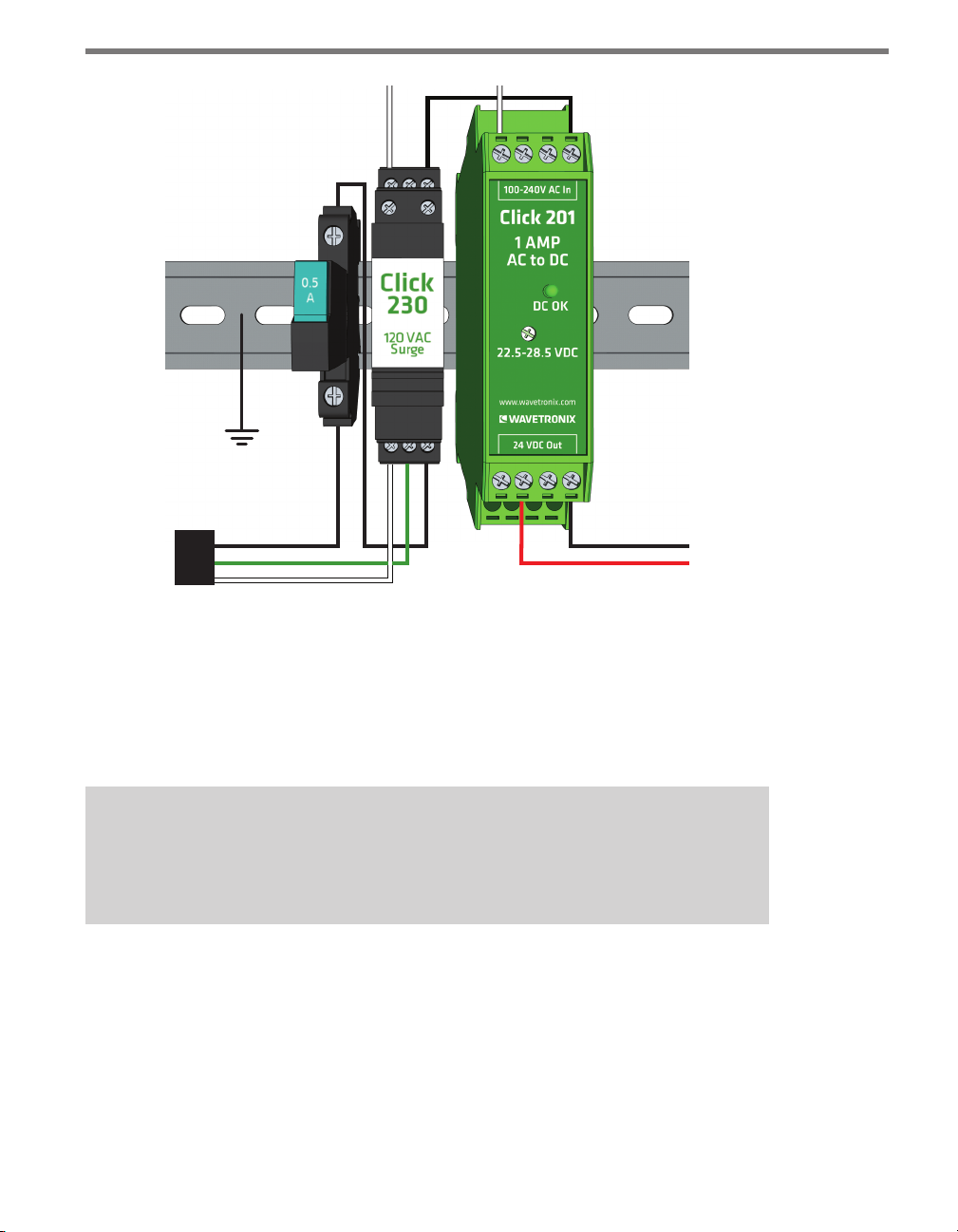

e rst device in the power plant, as seen in Figure 2.5, is the Click 210. is is a compact

circuit breaker DIN rail device designed to interrupt an electric current under overload

conditions. e breaker is trip-free and can be easily reset aer a current interruption by

pushing the reset button.

Page 27

26 CHAPTER 2 CONNECTING POWER AND SURGE

Earth

Ground

Black (Line)

Green (Ground)

White (Neutral)

Figure 2.5 – AC Surge Protection

Black (Ground)

Red (+24VDC)

To add a Click 210 circuit breaker and switch (see the le side of Figure 2.5):

1 Mount the Click 210 onto the DIN rail.

2 Connect the line conductor (usually black) from the AC terminal block or cord in to

either side of the module.

3 Wire out of the other side.

Note

For ease in troubleshooting, it is recommended that you follow the wire color scheme

outlined in this chapter.

Wiring the Click 230

e next device in the power plant is the Click 230, which is the AC surge protector (see

Figure 2.5). To install:

1 Mount the Click 230 onto the DIN rail next to the Click 210.

2 Connect the line conductor (black) from the Click 210 to terminal 5 on the IN side of

the Click 230.

Page 28

CHAPTER 2 CONNECTING POWER AND SURGE 27

3 Connect the neutral (usually white) wire from the AC terminal block or cord to the

terminal marked 1 on the Click 230.

4 Connect the ground wire from the AC terminal block or cord to the terminal marked

3 on the Click 230.

5 Connect an outgoing and protected line wire to the terminal marked 2 on the Click

230. e line wire should be black.

6 Connect an outgoing and protected neutral wire to the terminal marked 6 on the Click

230. e neutral wire should be white.

e terminal blocks 3 and 4 are directly bonded via the metal mounting foot of the base

element to the DIN rail. ere is no need for any additional grounding between terminals

3 and 4 and the DIN rail.

Wiring the Click 201/202

e nal device in the power plant should be either a Click 201 or 202 (as shown in Figure

2.5). ese are AC to DC converters, also occasionally called the power supplies. As noted

above, the dierence between the two is that the Click 201 outputs 1 A and the Click 202

outputs 2 A (the Click 204 outputs 4 A but will probably not be needed for an HD installation). Choose which device suits your installation best, then follow the steps below to install

it (see Figure 2.6):

1 Mount the Click 201/202 onto the DIN rail next to the Click 230.

2 Connect the line (black) wire from the Click 230 into the L screw terminal on the top

of the Click 201/202.

3 Connect the neutral (white) wire from the Click 230 to the N screw terminal to the top

of the Click 201/202.

Figure 2.6 – Wiring AC Power into the Click 201/202

Note

The NC screw terminal is not connected internally. Connecting a wire to a no connect

(NC) terminal simply gives it a convenient termination point.

Page 29

28 CHAPTER 2 CONNECTING POWER AND SURGE

To wire the newly converted DC power out of the Click 201/202:

1 Connect a +DC conductor (usually a red wire) to the + screw terminal on the bottom

of the Click 201/202 (see Figure 2.7).

2 Connect a -DC conductor (usually a black wire) to either of the – screw terminals on

the bottom of the Click 201/202.

Figure 2.7 – Wiring DC Power Out of the Click 201/202

Note

Do not wire into the screw terminal marked DC OK; it provides only 20 mA and should

be used only for monitoring the power supply.

e screw terminal connectors on the top and bottom of the module are removable to simplify wiring and are red-keyed, allowing the connector to plug into only one correct jack.

Connecting the Power Plant to Your Installation

Now the power plant is complete and you have reliable, safe DC power. e next step is to

get that power to the rest of the installation.

If the power plant is in a pole-mount box, this involves getting that power onto the T-bus; from

there it will power any communication devices that may be on it. It will also power the Click 200,

which will send the necessary 10–30 VDC, along with communications, to the sensor.

If the power plant is in a main trac cabinet, this also will involve getting DC from the

power plant on the T-bus; from there it will power any communication devices on that bus.

It will also power the Click 200, which will send that power, along with communications,

along the homerun cable to the Click 200 in the pole-mount box. at Click 200 will put

the power (and communications) onto the T-bus, powering any communication devices

that may be on it. It will also send the necessary 10–30 VDC, along with communications,

to the sensor.

Page 30

CHAPTER 2 CONNECTING POWER AND SURGE 29

To put power on the T-bus, you will rst need to connect a 5-screw terminal block to the

end of the T-bus, then follow the steps below to wire DC to it:

1 Connect +DC (red) from the Click 201/202 to the top screw terminal on the 5-screw

terminal block.

2 Connect –DC (black) to the second screw terminal.

+24V DC

-DC

+485

-485

GND

(red wire)

(black wire)

Figure 2.8 – Connecting Power Directly to the T-bus

Green

Gray

Note

Green T-bus connectors conduct power and communication on the DIN rail backplate;

gray T-bus connectors only conduct power and are used to distribute power without

connecting communication.

You can also wire DC to the Click 200 itself; it will then put that power on the T-bus. If you’d

like to do that, follow these steps:

1 Connect +DC (red) from the Click 201/202 to the +DC screw terminal.

2 Connect -DC (black) to a GND screw terminal.

GND

+DC

Figure 2.9 – Wiring DC Power into the Click 200

Wiring Communication

e last thing to do is decide how to communicate with the sensor. How you do this will

vary based on your installation. If your sensor is connected to a Click 200 in a pole-mount

Page 31

30 CHAPTER 2 CONNECTING POWER AND SURGE

box, and you want to access that sensor from a main trac cabinet or from the trac operations center, you will need some kind of communication between the two spots: either with

the homerun cable, which can carry both RS-232 and RS-485 communications, or by using

a Wavetronix Click communication device.

Wavetronix has a variety of wired and wireless communication devices, such as the Click

301 serial to Ethernet converter, which lets you communicate with the sensor via Ethernet,

or the Click 400, which is a 900 MHz radio that communicates wirelessly with other radios.

See the Click Catalog, Click Series User Guide, or ITS Designer Training Guide for more

information.

e Click 200 has several ports for other methods of communication. e faceplate has a

DB-9 port you could connect to for RS-232 communication. ere are also several RS-485

connections:

T-bus backplane: puts RS-485 on the T-bus. Because the Click 200 is connected to the

sensor, this T-bus connection means the sensor, the Click 200, and any other device on

the T-bus all communicate with each other.

RJ-11 connector on the faceplate for connecting to contact closure devices, if desired.

Note

The Click 200 does not convert RS-232 communication to RS-485. It simply provides

surge protection for these two independent connections.

Page 32

Part II

Using SmartSensor Manager HD

Chapter 3 – Installing SmartSensor Manager HD

Chapter 4 – Communication

Chapter 5 – Settings

Chapter 6 – Lanes

Chapter 7 – Data

Chapter 8 – Tools

Page 33

Page 34

Installing SmartSensor Manager HD 3

In this chapter

Installing SSMHD

3

Aer the SmartSensor HD is installed, use SmartSensor Manager HD (SSMHD) to congure the sensor to the roadway and change sensor settings. SmartSensor Manager HD is

soware that enables users to congure and interact with the SmartSensor HD.

Installing SSMHD

SSMHD can be installed on a Windows® PC. Everything needed to install SSMHD to a PC

is contained in the SSMHD Setup.exe le.

Note

You must have administrator rights to run the setup program.

Note

Microsoft .NET Framework version 3.5 or higher needs to be installed on your computer before installing SSMHD. You can get the .NET Framework from the Microsoft

website.

Page 35

34 CHAPTER 3 INSTALLING SMARTSENSOR MANAGER HD

Follow these steps to install SSMHD on a PC:

1 To download the install le, go to the Wavetronix website at www.wavetronix.com.

2 Click the Support link near the top of the page. is will bring up a page allowing you

to select by product line or by document category.

3 Click SmartSensor in the Start by drop-down list.

4 Select SmartSensor HD and a list of links will appear.

5 Select the SmartSensor Manager HD link (at the top) to download the SSMHD install

le.

6 Once you’ve downloaded the le, double-click on it. Opening it executes a setup pro-

gram that will copy all the necessary les to your hard drive and place icons in the Start

menu and on the desktop of the PC or laptop (see Figure 3.1).

Figure 3.1 – SSMHD Setup Wizard

7 Select an installation location. e default location provided is normally “C:\Program

Files\Wavetronix.” Click Browse to choose another location (see Figure 3.2).

Figure 3.2 – Location to Be Installed

8 Click the Install Now button.

9 Aer SSMHD is installed, you can create shortcuts to the SSMHD soware on the

desktop and in the start menu using the corresponding checkboxes (see Figure 3.3). If

no shortcuts are desired, uncheck the corresponding boxes.

Page 36

CHAPTER 3 INSTALLING SMARTSENSOR MANAGER HD 35

Figure 3.3 – Shortcut Options

10 Click the View release notes when nished checkbox to view the SSMHD release

notes. e release notes contain additional information about the current version of

the SSMHD soware. A PDF reader program (i.e. Adobe Acrobat Reader) is required

to view the release notes.

11 Click Finish to complete the setup process.

Note

SSMHD is designed to display text with Normal Size display resolution (96 dpi). If

your test is too big and does not display properly, you can edit the Advanced Display

property settings on your PC to reduce the display resolution from 120 dpi down to

96 dpi.

Page 37

Page 38

Communication 4

In this chapter

Serial Connection

Internet Connection

Virtual Connection

Viewing Connection Information

Installation Type

Communication Screen Icons

Uploading the Sensor's Embedded Software

4

Use the SSMHD soware to change settings, view data and congure the sensor to the

roadway.

First, physically connect your computer or handheld computer to the sensor. Next, launch

SSMHD by either clicking on the icon that was placed on your desktop or clicking the icon

found in the Start menu. e SSMHD main screen shown in Figure 4.1 will appear.

e green globe in the lower le corner allows you to select the language for SSMHD. To

change the language, click on the image and select the desired language from the dropdown list.

e control to the right of the globe image allows you to change the size of the window.

ere are three options; click on a box to change the window to the corresponding size.

Page 39

38 CHAPTER 4 COMMUNICATION

Figure 4.1 – SSMHD Main Screen

To interact with and congure the sensor in SmartSensor Manager HD, connect to the sensor through one of the following three types of connections:

Serial connection – Made using RS-232 or RS-485 communication.

Internet connection – Made using an IP address and a serial to Ethernet converter.

Virtual connection – Can be made for convenience in learning and demonstrating

SSMHD functionality.

Serial Connection

1 Click on the Serial icon

2 Set Port and Speed to the desired settings. It is recommended that the speed be set to

9600 bps.

3 Click the Connect button.

(see Figure 4.2).

Figure 4.2 – Serial Connection

Page 40

CHAPTER 4 COMMUNICATION 39

Advanced Settings

Below is a list of some advanced settings also available on this screen:

Flow Control – Is usually only used if you are connecting through a RS-232 device that

requires hardware handshaking.

Timeout – Allows you to set an additional amount of time (in milliseconds) that

SSMHD will wait for a response when communicating with the sensor.

Note

When connecting directly from a computer running SmartSensor Manager HD to a

SmartSensor HD unit (with no modem in between), you should not attempt to connect unless the Flow Control setting is set to None. Otherwise you may not be able

to successfully connect.

Internet Connection

e SmartSensor HD can be connected to the Internet, allowing access to the sensor from

anywhere with Internet access. Below is a list of a couple ways to connect the SmartSensor

HD to the Internet:

Serial to Ethernet Converter – e SmartSensor HD can be connected to a local area

network (LAN) by using a serial to Ethernet converter. As an option, the SmartSensor

HD can be shipped with a Click 301 serial to Ethernet converter that is Internet addressable, which makes it possible to connect to the sensor from anywhere the adapter’s address is accessible.

Internet Service Providers – Cellular providers of wireless Internet services maintain

networks in most metropolitan areas in the United States and coverage continues to

expand. e SmartSensor HD can be equipped with an optional external modems—for

example, CDMA, GMS or GPRS—and assigned an Internet address on these networks.

Use the steps below to connect to the SmartSensor HD using an Internet connection:

1 Click on the Internet icon (see Figure 4.3)

2 Enter the IP address or URL of the sensor of interest in the Network Address eld. e IP

address consists of four numbers ranging from 0–255 separated by dots. Enter the IP address assigned to either the CDMA modem or the Click 301 serial to Ethernet converter.

3 Enter the port number assigned to the CDMA modem or the Click 301 serial to Eth-

ernet converter in the Port eld. is will be an integer value in the range of 0–65536.

e Click 301 port number automatically defaults to 10001.

4 Click the Connect button to connect to the sensor.

Page 41

40 CHAPTER 4 COMMUNICATION

Figure 4.3 – Internet Connection

e Timeout eld allows you to set an additional amount of time (in milliseconds) that

SSMHD will use when communicating with the sensor.

Virtual Connection

A virtual connection allows you to use the SSMHD soware without being connected to an

actual sensor. Making a virtual connection can be useful for the following reasons:

To view a saved sensor setup le.

To demonstrate functionality for dierent applications.

To review how the soware works.

Use the following steps to make a virtual connection:

1 Click the Virtual button (see Figure 4.4).

2 Select or create a virtual sensor le (.sim) by clicking the magnifying glass icon.

3 Click the Connect button.

Page 42

CHAPTER 4 COMMUNICATION 41

Figure 4.4 – Virtual Connection

Additional Settings

e Trac Properties section contains the following settings:

Style – is section allows you to set random or patterned trac for the simulator.

Flow – Allows you to set the trac volume for the simulated trac.

Average Speed – Allows you to set the average trac speed for the simulated trac.

Virtual Sensor File

Since a virtual connection is not made to an actual sensor, a virtual sensor le (.sim) is

used to save the conguration settings much like an actual sensor’s ash memory. If you are

making a virtual connection for the rst time, you will need to create a virtual sensor le by

clicking on the magnifying glass icon and entering a le name.

Note

When you are connected using a virtual sensor file, changes that would normally be

saved to a sensor's flash memory will automatically be saved to the virtual sensor file.

Backing up a virtual sensor le will change the le to a sensor setup le (.ssc) that can be

restored to an actual sensor. To convert a sensor setup le to a virtual sensor le, make a virtual connection and then use the Restore Sensor Setup tool in the Too ls menu. To convert

a virtual sensor le to a sensor setup le, use the Back-up Sensor Setup tool.

Viewing Connection Information

Once a connection is made to the SmartSensor HD, the main menu will appear and all

Page 43

42 CHAPTER 4 COMMUNICATION

conguration options will become available (see Figure 4.5).

Figure 4.5 – SSMHD Main Screen (connected)

Once connected, you can view additional information about the connection you have established by clicking on the moving arrows on the top le of the main screen (see Figure 4.6).

Figure 4.6 – Connection Info Screen

Below is a list of the information available on the Connection Info screen:

Status – Shows that you are connected.

Device – Shows the subnet and sensor ID.

Speed – Shows the baud rate.

Duration – Shows how long you have been connected.

Troubleshooting Connections

If you have problems connecting, use the following steps to nd the problem:

Page 44

CHAPTER 4 COMMUNICATION 43

1 Make sure that all power and communication wiring is correct.

2 Check the port settings (baud rate, port ID).

3 Make sure that the sensor ID is correct.

Connection failure can occur for various reasons; if a failure occurs repeatedly, call Wavetronix Technical Services at 801-764-0277 for assistance.

Installation Type

Once the communication parameters are selected, choose the installation type to be used

for the connection.

Connecting to an Isolated Sensor

is protocol option is recommended when only one sensor exists on the remote end of the

connection (see Figure 4.7).

Figure 4.7 – Isolated Sensor

Connecting to a Sensor in a Multi-drop Network

Connecting to a sensor in a multi-drop network is recommended when more than one

sensor exists on the remote end of a connection. To connect to a sensor on a multi-drop

network, select Multi-drop Network from the drop-down list and enter the multi-drop

sensor ID of the sensor you are connecting to (see Figure 4.8).

Figure 4.8 – Multi-drop Network

If you do not know the sensor ID, click on the sensor and magnifying glass at the end of the

Sensor ID eld to do a search for all sensors on the serial bus.

Communication Screen Icons

At the bottom of the serial and Internet connection screens there is a white bar with icons.

is section will explain the purpose of those icons.

Page 45

44 CHAPTER 4 COMMUNICATION

Address Book

e Address Book allows you to save device connection settings for future use. Click the

book icon located at the bottom of the screen to add new connection settings to the Address

Book (see Figure 4.9).

Filters Address Books

Deletes an Address Book

Imports an Address Book

Exports an Address Book

Edits the Selected Device

Deletes the Selected Device

Adds Device to Address Book

Figure 4.9 – Address Book

Password

e key icon allows you to create a password for SSMHD. Passwords are associated with the

sensor in order to keep the connection and conguration secure. Aer clicking the icon,

enter the desired password and click OK. is password will now have to be entered each

time you attempt to make a connection (see Figure 4.10).

Figure 4.10 – Enter Password Window

If you forget the sensor password, use the Click Here link and a new window will open

providing information about how to get a new password.

Communication Error Log

e error log contains all errors stored in the sensor’s memory buer. If you are having

Page 46

CHAPTER 4 COMMUNICATION 45

trouble connecting, using the error log may be helpful in the troubleshooting process. If you

continue having trouble, save the error log le and contact Wavetronix Technical Services.

Note

The error log is cleared every time you close SSMHD, so if you need to save the file, do

so before shutting the program down.

Click the View Error Log link to view the communications error log (see Figure 4.11). e error

log can also be accessed by clicking on the error log icon at the bottom of the connection screen.

Figure 4.11 – Communication Error Log

Uploading the Sensor’s Embedded Software

Aer clicking the Connect button, the soware will check to see if your soware version

matches the version of the sensor’s embedded soware. If a discrepancy is detected, the Version Control screen may appear asking you to install rmware upgrades (see Figure 4.12).

If you think you have reached this screen in error, clicking the Recheck button will have

the soware retry and ensure that there has not been a communication issue. Clicking the

Details button will display the current sensor and soware information. Click the Install

Upgrade button to upgrade the soware.

Figure 4.12 – Version Control (left) and Software Upgrade Details (right)

Page 47

46 CHAPTER 4 COMMUNICATION

Note

Clicking the Close button and continuing configuration may cause problems with

functionality.

e gure below shows how the rmware numbers are interpreted (see Figure 4.13). e

month number is written in hexadecimal, meaning the months of October, November and

December will be written as A, B and C respectively.

Month

(July)

Year

(2007)

Figure 4.13 – Install Upgrade Numbers

Day

(5th)

If the row marked Digital is highlighted in red, the rmware upgrade may need to be installed. Compare the sensor number with the SSMHD number in the digital row of the

details table. If the SSMHD rmware version date is more recent than the sensor rmware

version date, the rmware upgrade will need to be installed; if the sensor’s rmware date is

more recent than the SSMHD rmware version date, a warning will appear notifying you

that the sensor rmware could be downgraded (see Figure 4.14).

Figure 4.14 – Downgrading the Sensor

If the downgrade message appears, it simply means that the sensor rmware is newer

than the version of SSMHD that was used to connect to the sensor. e newest version of

SSMHD can be updated by downloading the soware from www.wavetronix.com.

Click the INSTALL UPGRADE button to install the rmware embedded in SSMHD onto

the SmartSensor HD. e Recheck button will query the sensor to see if the rmware bundled in SSMHD is dierent from the version running on the sensor.

Page 48

Settings 5

In this chapter

General Tab

Ports Tab

Outputs Tab

5

Click the Settings link on the main menu to change and save settings on the sensor. e

Settings window contains the General, Ports and Outputs tabs.

General Tab

e General tab contains the following elds (see Figure 5.1):

Figure 5.1 – General Tab

Page 49

48 CHAPTER 5 SETTINGS

Serial Number – Contains the sensor serial number and cannot be edited.

Subnet/ID – Allows you to enter the subnet and ID. A subnet can be used to create

groupings of sensors. e subnet default is 000 and the ID default is the last ve digits

of the sensor serial number. e ID can be changed, but no two sensors should have the

same ID. e ID must be unique for all sensors on a multi-drop bus.

Description – Allows you to enter a description for each sensor. Limited to 32 characters.

Location – Allows you to enter the location of the sensor. Limited to 32 characters.

Orientation – Allows you to enter the direction the sensor is pointing. is eld is

purely for informational purposes and has no eect on performance or the sensor’s

physical mounting.

Units – Allows you to display either English (mph/feet) or metric (kph/meters) units.

Date & Time – To sync the sensor date and time with the computer, click the Sync to

this computer checkbox. e sensor itself stores time in Coordinated Universal Time

(UTC), formerly known as Greenwich Mean Time (GMT), and does not account for

daylight saving time. SSMHD uses the local setting of the computer it is running on to

display the date and time in local units.

Example

If someone in Pacific Standard Time (PST) connect to a sensor and synchronizes the

time, then when someone in Mountain Standard Time (MST) connects to the same

sensor the time will be correctly displayed as MST. If the settings on either PC adjusts

for daylight savings, then this adjustment will also be correctly displayed.

Ports Tab

e Ports tab contains the following settings (see Figure 5.2):

Figure 5.2 – Ports Tab

Page 50

CHAPTER 5 SETTINGS 49

Green highlight – is indicates the communication link (port) on which SSMHD is

connected.

RS-485 – Allows you to set the baud rate for RS-485 communication. e Response

Delay setting is used to congure how long the sensor will wait before responding to

a message received. is is useful for some communications devices that are unable to

quickly change transmission direction. e default value is 10 milliseconds.

e Termination checkbox allows you to electronically turn RS-485 communication

bus termination on or o. Only the end devices on a RS-485 bus should be terminated.

In general, the termination can be le unchecked until a multi-drop bus becomes overloaded.

RS-232 – Allows you to set the baud rate for RS-232 communication. e Response

Delay setting works the same as the RS-485 section.

e HW Handshaking checkbox should be selected if you are connecting your sensor to

an RS-232 device (such as some modems). ese devices sometimes require ow control

handshaking because they cannot keep up with the data rates of higher-performance

devices like personal computers and SmartSensor HD. SmartSensor Manager HD and

SmartSensor HD have built-in support for RS-232 ow control hardware handshaking;

this support allows the SmartSensor HD and SmartSensor Manager HD to work with

these slower modem connections. Table 5.1 gives a brief description of each RS-232 line.

Line Description

TX Transmit data line

RX Data receive line

RTS Request to send flow control hardware handshaking line

CTS Clear to send flow control hardware handshaking line

Table 5.1 – RS-232 Lines

In order to use hardware handshaking, the sensor’s RTS and CTS signals must be properly

connected. If the Flow Control option under the Serial connection screen is set to Hard-

ware, you will not be able to connect if the sensor’s HW handshaking setting has been

previously turned o. e reason you cannot connect is that the sensor’s RTS line is not

asserted; as that line is connected to the computer’s CTS line, the computer will not forward

data messages it is given by SmartSensor Manager HD. To successfully connect, simply

change the Flow Control setting to None.

Outputs Tab

e Outputs tab contains the following settings (see Figure 5.4):

Page 51

50 CHAPTER 5 SETTINGS

Source – Allows you to determine what information is reported. ere are two options:

Antenna reports data as detected by the antenna in the sensor, and Diagnotic creates

detection events for testing and training purposes.

Note

If the sensor is in Diagnostic or Replay mode, it will not detect live trac.

Figure 5.3 – Outputs Tab

RF Channel – Displays which radio frequency channel the sensor is transmitting on.

Using multiple sensors in close proximity will require each sensor to be set to a dierent RF channel (see the introduction for more information about mounting sensors in

close proximity).

Loop Emulation – is section allows you to set loop size and spacing to allow Smart-

Sensor HD to emulate dual loops. e settings changed on this screen will apply to all

congured lanes. ese settings are read by a Click contact closure device and used so

that the contact closures can be properly timed to emulate a given loop size and spacing. e loop size is also used by the sensor in the occupancy calculation. For example,

larger loop sizes will result in higher occupancy numbers in the interval data. However,

adjusting these parameters will not modify the reported vehicle length or speed (see

Chapter 6 of this user guide to accomplish these tasks).

Legacy Protocols – e SS105 protocol must be selected when being used with Click

communication and contact closure devices (it is not necessary if you are only using

Click surge and power devices). is does not turn o native SSHD protocol.

e RTMS (X3): ID checkbox allows you to turn RTMS protocol emulation on or o;

only a subset of RTMS data reporting commands are emulated. is does not turn o

native SSHD protocol. e RTMS ID eld will only be editable if the RTMS Protocol

checkbox is selected.

Page 52

CHAPTER 5 SETTINGS 51

Note

If you are using a SmartSensor HD in an RTMS-based system, there are two ways

to collect data from the sensor. If your system is set up to poll the sensor, the RTMS

protocol must be turned on so the sensor can respond to RTMS commands. If your

system is simply listening for data pushes from the sensor, the RTMS protocol does

not need to be turned on. See Chapter 7 for more information on data push.

Page 53

Page 54

Lanes 6

In this chapter

Configuration

Verification

6

Click the Lanes link on the main menu to align and congure the sensor, and to verify

functionality (see Figure 6.1).

Configuration – Allows you to automatically congure the sensor, manually adjust the

lanes (if needed) and edit and save the conguration.

Verification – Allows you to verify that the sensor is detecting accurately and to mod-

ify individual lane performance.

Page 55

54 CHAPTER 6 LANES

Figure 6.1 – Lanes Screen

Configuration

e Conguration screen can be used to automatically or manually congure the roadway,

manipulate lanes, and control how you see the information onscreen. To reach the screen,

click the Conguration button.

Sensor Alignment

e sensor should be properly aligned before beginning lane conguration, so SSMHD includes

an alignment feature that gives visual conrmation when the perpendicular alignment of a sensor is correct (see Figure 6.2). SSMHD gives you three dierent ways to check sensor alignment:

the arrow coming out of the sensor; the color on the detected vehicles; and in the sidebar.

Once you open the Conguration screen, you should see alignment arrows. If there are no

alignment arrows, click on the magnifying glass icon and then select Show Alignment.

Figure 6.2 – Sensor Alignment

Adjust the sensor according to the arrow displayed in the Conguration window. A green

Page 56

CHAPTER 6 LANES 55

arrow means the sensor is correctly positioned for optimal performance; a yellow or red

arrow means the sensor is NOT correctly aligned with the roadway.

Note

In order for the sensor alignment tool to function properly, trac must be flowing

freely. Also, if the sensor is not already aligned close to perpendicular to the flow of

trac, the sensor alignment tool will display a question mark indicating that the

sensor is too far out of alignment for the tool to function properly. Realign the sensor

manually and then fine-tune the alignment with the tool. After each adjustment of

the sensor, several vehicles must pass before the alignment tool's output is valid.

It may be dicult to align the sensor if there are non-parallel lanes of trac. In this case,

mark the non-parallel lanes as Inactive or Excluded in the lane conguration screen, and

the sensor alignment tool will ignore vehicles traveling in these lanes.

Note

In cases where trac lanes are not exactly parallel, the percentage of vehicles with

reported speeds may decrease in the lanes that are skewed.

Auto-Configuration

One of the advantages of the SmartSensor HD is the fast and simple lane auto-conguration function, where the sensor automatically congures the roadway and sets up the lanes

based on passing trac.

Follow the steps below to automatically congure the SmartSensor HD (see Figure 6.3):

1 Once the Conguration window appears, click the Tools icon and select Clear Edit

Area.

2 Click the Tools icon again and then click Restart Auto Cfg.

Page 57

56 CHAPTER 6 LANES

Tools Menu

Figure 6.3 – Buttons Used in Automatic Lane Configuration

Note

You may need to click on the magnifying glass icon and select Show Auto Lanes for

the automatically discovered lanes to appear.

Sidebar

Tools Icon

Depending on where the sensor is mounted and on the amount of trac, the conguration

process could take a few minutes. Once the SmartSensor HD has detected vehicles and

created the appropriate lanes, click OK and a window will appear asking you to save the

changes to the conguration. Click Yes and the conguration will be saved.

Follow the steps below if only a portion of the automatically dened lanes are desired:

1 Click anywhere in the Conguration screen.

2 Check the Hide Auto-Lanes box and the automatically congured lanes will disappear.

3 Click on the desired automatic lane in the sidebar (when the sidebar is set to 1) and the

Automatic Lane window will appear (see Figure 6.4). is window allows you to select

the lanes you want to appear in the roadway. To have all lanes appear in the roadway,

click the Copy Sidebar button; to have individual lanes appear in the roadway, click the

Copy Lane button. You can also copy the entire sidebar and then delete the unwanted

lanes by clicking on them and selecting Delete.

Page 58

CHAPTER 6 LANES 57

Figure 6.4 – Automatic Lane Window

Manual Configuration

e Conguration screen can also be used to manually congure and adjust lanes (see

Figure 6.5). e following functions and tools are available on the Conguration screen.

Shoulder

Roadway

Vehicle Display

Tools

Figure 6.5 – Configuration Screen

Magnifying

Glass

Sidebar

Sidebar Button

Sidebars

e sidebar buttons on either side of the Conguration screen control the sidebar display.

Click and hold the button to see a list of the following dierent display modes (see Figure

6.6):

Page 59

58 CHAPTER 6 LANES

Figure 6.6 – Lane Configuration Sidebar Options

Auto Cfg – Shows the lanes that are automatically congured by the sensor.

Saved Cfg – Shows the lanes that are saved on the sensor.

Scale – Shows the distance from the SmartSensor HD to each lane.

Centers – Shows the relative occurrence of events. Larger arrows indicate a greater

number of vehicles at a given range.

Tracks – Shows a track for each detected vehicle; a line is drawn at the center of each

vehicle that passes. is sidebar is very useful for manually adding lanes. Click on the

tracks sidebar to clear all tracks and start again.

Vehicle Display

e Vehicle Display button opens a menu that allows you to congure how vehicles are drawn and what information is displayed on them.

In range mode, vehicles are drawn at the correct range regardless of lane denitions. In lane

mode, only vehicles detected in congured lanes will be displayed.

SSMHD is able to display the detected speed, length, length-based class (see Denitions in

Chapter 7) or no information for each vehicle (see Figure 6.7). To choose to show no information for the vehicle, click again on the option that is currently checked to deselect all options.

Figure 6.7 – Vehicle Display Options

Tools

e Tools button opens a menu that allows you to automatically congure the sensor, save and load congurations to les and reboot the sensor (see Figure 6.8). Saving or

Page 60

CHAPTER 6 LANES 59

loading the conguration only saves or loads lane conguration information (see the Tools

section on the main menu to save all sensor conguration parameters).

Figure 6.8 – Tools Options

Magnifying Glass

e Magnifying Glass button opens a menu that allows you to show or hide automatically congured lanes, lane names, vehicle direction, and sensor alignment; you can also

view a compass (see Figure 6.9). Many of these options can also be turned on or o simply

by clicking on them in the edit area.

Figure 6.9 – Show/Hide Lanes

Note

The orientation of the compass is based on the orientation chosen under Settings

(see Chapter 5). Changes to the orientation there will result in the compass in the

Configuration screen changing to match; conversely, changing the orientation of the

compass on the Configuration screen (done by clicking on it) will change the orientation setting under Settings. The orientation does not aect the alignment or operation of the sensor and is simply for your information.

Page 61

60 CHAPTER 6 LANES

Shoulder Area

Click in the shoulder and the Shoulder Area window will appear, allowing you to add or

exclude the shoulder you just clicked on (see Figure 6.10). is is useful when aligning the

sensor when there are non-parallel lanes in its eld of view. Alternatively, it can also stop

events from being generated in any non-lane areas. In the Verication screen, and when the

sensor is reporting data, any vehicles in non-lane dened areas will not be shown regardless

of whether the area is excluded or not. Click in an excluded area and the Excluded Area

window will appear, allowing you to include the area again.

Figure 6.10 – Edit Area Window

Lane Window

Click anywhere on a lane and the Lane window will appear, allowing you to change the

name, direction and activity of a lane (see Figure 6.11). SSMHD uses “LANE_xx” as the default lane name where “xx” is the number of the lane in range, beginning with “LANE_01.”

When a new lane is added, all lanes with the default lane name format will automatically be

renamed to indicate their increasing number in range. If this is not desired, the lane names

can be changed in any way; lane names are case and symbol sensitive and are limited to

eight characters.

Note

If you rename a lane with a new lane number, the software won't let you leave the

name in the form of LANE_XX. One easy way to get around this is to lowercase the

word "LANE." For example, to change the lane currently numbered as 1 to number 6,

change the name from LANE_01 to Lane_06.

For RTMS and Z4 data push types, the mapping of the lanes may be changed using the notation #xx (e.g. #08), where 08 is a lane number between 1 and 99. In this case, ALL lanes in

the conguration must be assigned a lane number using the #xx notation in order for the

new lane mapping to take eect.

Page 62

CHAPTER 6 LANES 61

Figure 6.11 – Lane Adjustment Window

e direction button allows you to set the direction for the lane—Le, Right or Bidirectional. e direction chosen determines what data is shown: if Right is the set direction for a

lane, only trac going to the right will be detected; and if Le is the set direction for a lane,

only trac going to the le will be detected (when Direction Protection is on). If the lane is

set to Bidirectional, data will be reported for trac going both directions. is is useful for

lanes that change direction depending on the time of day. Selecting Bidirectional is essentially the same as turning o Direction Protection for that lane (see the Lane Adjustments

section in Chapter 6 for more information on Direction Protection).

Note

All detected vehicles are shown on the Lane Configuration screen, regardless of direction.

Click the Exclude button to exclude a lane (the lane will turn red once it has been excluded) or click the Delete button to delete a lane. Excluded lanes will not be congured and

SSMHD will stop showing events in those particular lanes. Click the excluded lane and click

the Include Area button to include the lane.

e Lane window also allows you to set a lane as active or inactive. Inactive lanes are useful

when a lane has been correctly congured and tuned, but data reporting for the lane is not

desired. By making the lane inactive instead of deleting it, the lane may be turned on at any

time and will retain the proper conguration and tuning.

Saving the Configuration

Follow the steps below to save the conguration to a le:

1 Click on the Tools button on the bottom right of the Conguration screen.

2 Select Save to File.

Undoing Manual Changes

To undo changes you have made to the conguration, click on the Tools button in the Conguration screen and select Undo Last Edit from the choices displayed. To undo all changes

made to the conguration, click the Too ls button and then select Clear Edit Area.

Page 63

62 CHAPTER 6 LANES

Verification

To verify that the lanes were congured properly, close the Conguration screen and select

Verication from the Lanes menu.

e Verication screen allows you to monitor lane detection accuracy and to adjust the lane

properties for better detection.

Sidebars

Click and hold the sidebar buttons on either side of the Lane Verication window

to view the following options (see Figure 6.12):

Presence – Displays buttons to the side of each lane that will light up while the vehicle

is being detected.

Volume – Displays the number of events in each lane.

Speed – Shows the average speed of each individual lane.

Classes 1–8 – Show count for each length-based class, which can be created using the

Class Denitions feature. e number of class bins that appear in this window will be

the same number of class bins that were created (see Denitions in Chapter 7).

Figure 6.12 – Lane Verification Sidebars with Four Classes

Vehicle Display

e Vehicle Display button in the Verication window opens a menu that allows

you to view associated speed, length, length-based class or no additional data. To switch

the display, click on the Vehicle Display button and choose which method to display (see

Figure 6.13).

Figure 6.13 – Vehicle Display Window

Page 64

CHAPTER 6 LANES 63

Play/Pause/Stop Buttons

e Play, Pause and Stop buttons allow you to control the data display. When

Pause is selected, vehicles traveling on the screen will not be included in the presence, vol-

ume, speed or class sidebars. Click the Play button to add new vehicles to the running totals

for all sidebars; click the Stop button to reset all volume, speed and class numbers to zero.

Lane Adjustment

Lane performance can be adjusted by clicking anywhere inside a lane and using the Lane

Adjustment tool (see Figure 6.14). e drop-down list allows you to adjust lane volume, detection, speed, length, extension time or direction protection. To return to default settings,

select Set Defaults from the drop-down list and click the OK button. Each lane adjustment

is independent of other lanes; setting one lane back to defaults using the Set Defaults op-

tion will not aect the other lanes.

Figure 6.14 – Lane Adjustment Window

Volume – is setting should be adjusted rst when a problem with count accuracy is ob-

served. e default is 100%. is setting adjusts the aggressiveness of trac radar-specic

algorithms and is not an arbitrary scale factor. By increasing the percentage by 10% to

15%, you are likely to begin to increase the number of detection, and by decreasing the

percentage by 10% to 15%, you are likely to begin to decrease the number of detections.

Small adjustments of only 1% or 2% may actually have no impact on the detection performance. Practical values for this setting are typically between 20% and 190%. If the volume lane adjustment is below 20%, many detections in that lane will probably be missed;

if it is set greater than 190%, many false detections will probably occur.

Detection – Raises or lowers the threshold for detecting vehicles. e sensor auto-

matically determines where the threshold will be placed, and then adds in this tuning

parameter. Entering a larger number will result in fewer detections; entering a small

number will result in more detections. e default is 0 dB.

Note

Changing the detection tuning parameter can drastically eect vehicle detection.

Page 65

64 CHAPTER 6 LANES

Speed – Raises or lowers the speed calculated for all vehicles in each lane. e sensor

calculates the speed, and then multiplies the speed by this factor. e default is 100%.

Length – Increases or decreases the length for all vehicles in each lane. e sensor

calculates the length and then adds the length factor. e default is 0 (feet or meters

depending on sensor units used). Since the occupancy metric that is reported in the

interval data is calculated using length, a change in the length tuning parameter will

also change the occupancy that is reported. See page 69 for the equation that is used to

calculate occupancy and for a more detailed explanation.

Extension Time – Changes the extension time, which the sensor uses to prevent ve-

hicles with trailers from being broken into multiple detections. A longer extension time

will prevent this, but can lead to multiple vehicles being merged into a single detection.

e sensor automatically determines the extension time and then multiplies by this

factor. e default value is 100%.

Note

There must be a minimum of 5.5 ft (1.68 m) between vehicles in order for them to be

detected as separate vehicles. This separation requirement may increase as vehicle

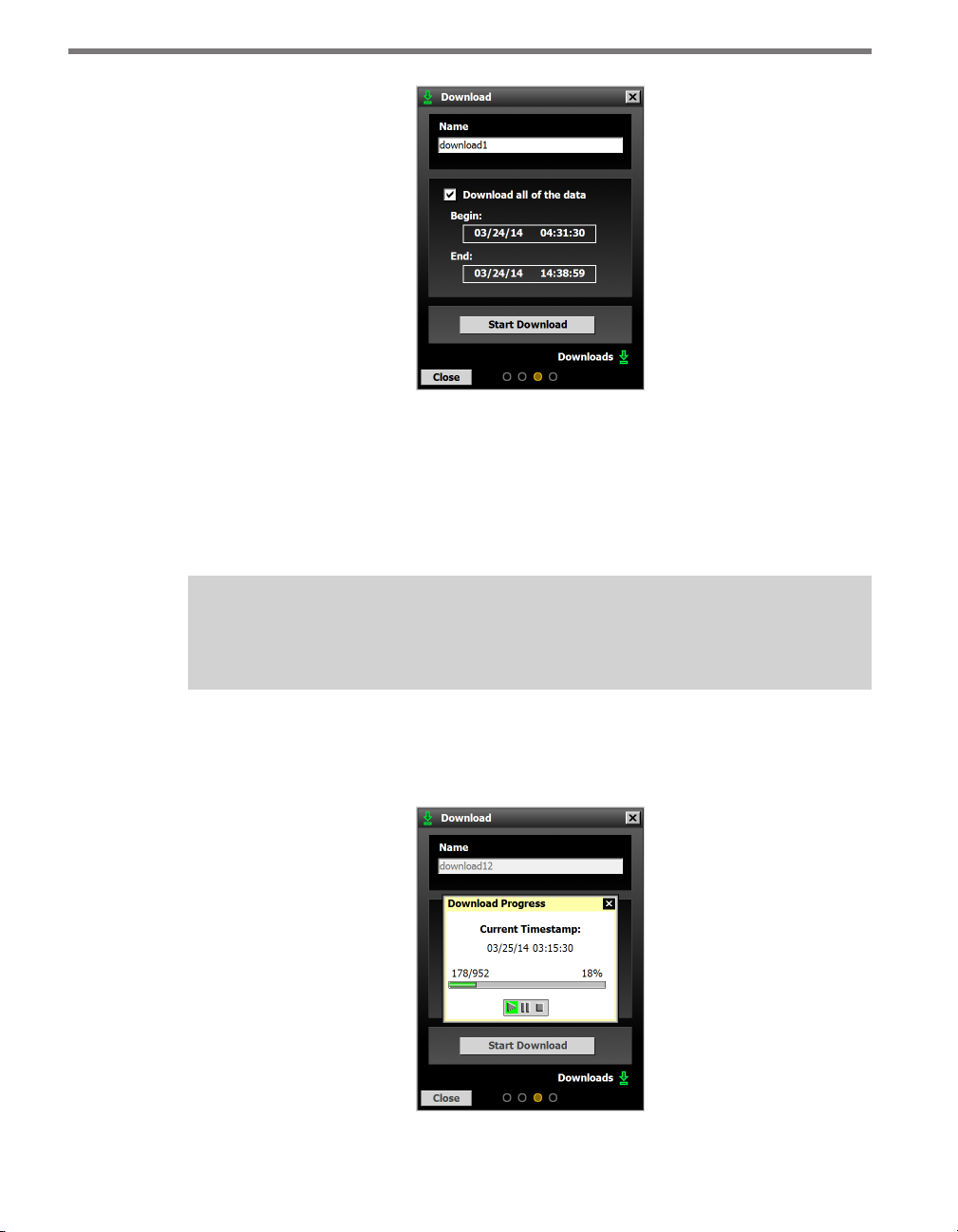

speeds increase.