USER GUIDE

Low-Noise QCL Driver — Laboratory Series

1

TABLE OF CONTENTS PAGE

GENERAL OVERVIEW 2

SAFETY 3

QUICK CONNECT GUIDE 4

PIN DESCRIPTIONS 6

EXTERNAL MODULATION TRANSFER FUNCTIONS 6

ELECTRICAL SPECIFICATIONS 7

THEORY OF OPERATION 9

OPERATING INSTRUCTIONS (STAND-ALONE) 9

OPERATING INSTRUCTIONS (REMOTE) 17

TROUBLESHOOTING 22

ADDITIONAL TECHNICAL NOTES 25

MECHANICAL SPECIFICATIONS 27

CE DECLARATION OF CONFORMITY 28

WARRANTY & CERTIFICATION 29

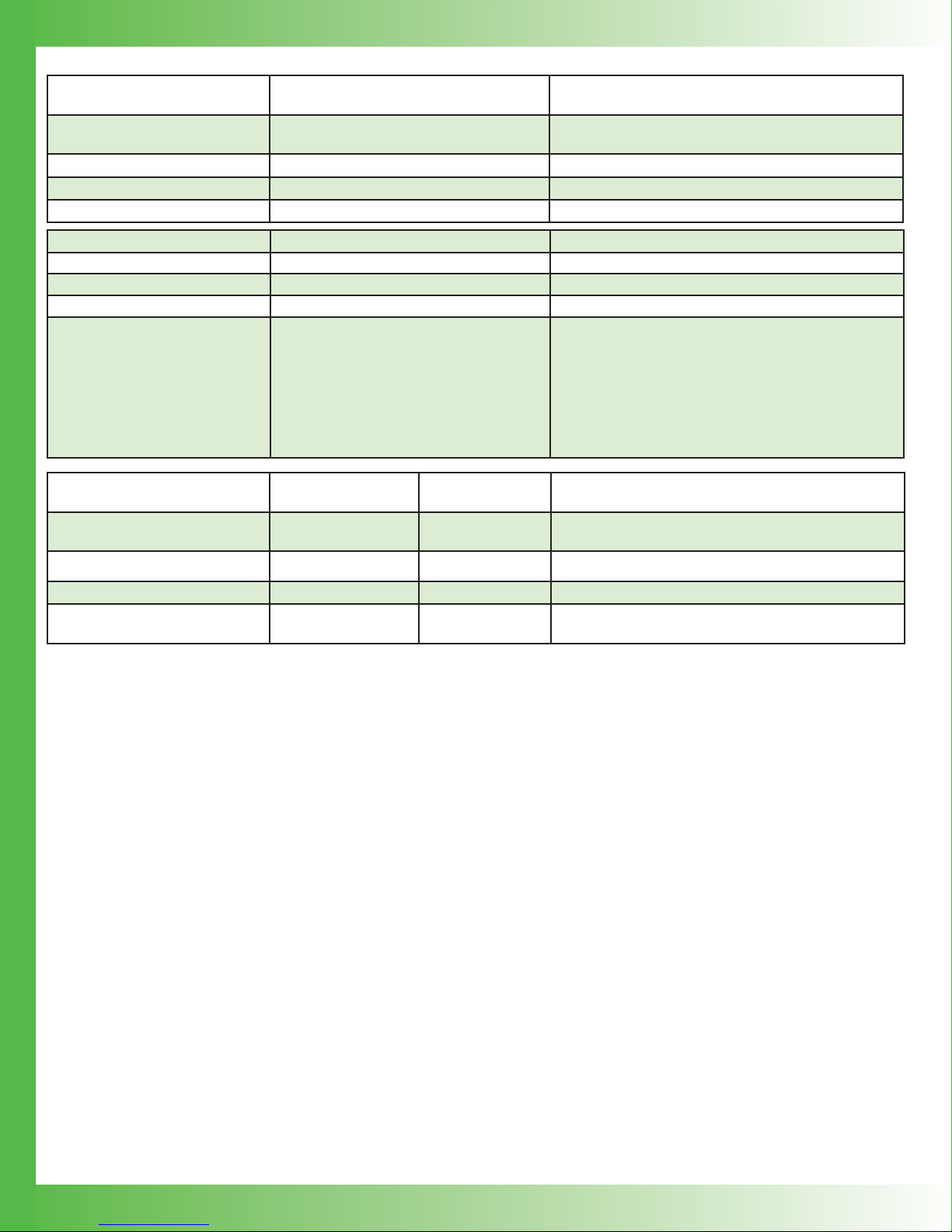

ORDERING INFORMATION

PART NO DESCRIPTION

QCL500 LAB 500 mA Low Noise QCL Instrument

QCL1000 LAB 1.0 A Low Noise QCL Instrument

QCL1500 LAB 1.5 A Low Noise QCL Instrument

QCL2000 LAB 2.0 A Low Noise QCL Instrument

NOISESCAN Noise Characterization Scan

55-110014 SMA-BNC Cable

55-110015 USB Cable

WCB310 Shielded SMA-SMA Cable

QCL TL LOW

QCL TL 1500 Resistive Test Load for QCL1500

QCL TL 2000 Resistive Test Load for QCL2000

RCKMT-LAB SNGL 19” Single Unit Rack Mount Kit

RCKMT-LAB DUAL 19” Double Unit Rack Mount Kit

INTLK REPL KIT

(included with purchase)

Resistive Test Load for QCL500 or

QCL1000

Interlock Replacement Kit with

BNC terminator and modifi ed

D-SUB connector to override

interlocks

Pb

RoHS

1

Covered by U.S. Patents 6,696,887; 6,867,644 and 7,176,755. Licensed from Battelle Memorial Institute

e

Compliant

Applies to Product Revision A

© April 2015

GENERAL OVERVIEW

• Output currents of 500 mA, 1 A, 1.5 A, 2 A

• Low noise: <0.4 A RMS up to 100 kHz

(QCL500, typical)

• Compliance voltage is adjustable, 10 to 20 V

(NOTE: The unit will only deliver the voltage

that the load requires, up to the compliance

voltage limit.)

• Analog modulation up to 2-3 MHz

• Constant Current Mode operation

• Touchscreen with intuitive user interface

• CE compliant, compatible with CDRH laser

regulations

• Feature-rich for research projects

» USB and Ethernet interfaces with software

included

» Auto voltage/current scan function

» Data collection using a computer or USB

fl ash drive

» Field upgradeable fi rmware

» Sophisticated error handling

THE LOWEST-NOISE DRIVER

AVAILABLE

These low noise QCL instruments have the lowest current

noise density of any commercially available. Powering your

QCL with this patented1 driver gives you narrow linewidth,

stable center wavelength, and repeatable scans.

INTUITIVE USER INTERFACE AND

SUPERIOR SOFTWARE CONTROL

With Wavelength’s plug and play instrument, you have the

ability to quickly set the controls using either the instrument or

a remote computer.

PROTECT YOUR QCL INVESTMENT

All the essential control and monitor functions you expect in a

Wavelength laser driver are incorporated into this instrument,

along with protection circuitry to safeguard your QCL from

minor power source faults, over-temperature conditions, and

electrical faults.

The soft-clamping current limit can be set without enabling the

driver output, and uses a brick-wall never-exceed limit circuit

to protect the QCL from potentially damaging overcurrent

situations.

» Save and recall functions for specifi c set

ups

• Rack mountable: 2 U height and ½ rack width

• Safety features protect your QCL investment

F E A T U R E S

» Adjustable soft-clamp current limit, with

Brick-Wall Never-Exceed circuitry

» Password protection available to lock out a

selectable control set

» Key switch, active, and passive interlocks

» Brown-out & overvoltage protection

» Power supply overcurrent protection

» Driver over-temperature protection circuit

» Relay shorts output when current is

disabled

» AC input and patented power supply

fi ltering

» 2 second turn-on delay — adjustable

» 1.5 msec current ramp

OEM VERSION AVAILABLE

Once you have fi nalized your work, the QCL circuitry is

available in compact OEM versions.

APPLICATIONS

Due to their unique construction, QCLs operate with high

power in the near-IR through terahertz ranges. These

wavelengths are particularly suited to detection of molecules

signifi cant to humans.

Applications for the lower noise QCL driver include: remote

detection of explosive materials, medical diagnosis using the

breath, non-invasive glucose testing, emissions monitoring of

the atmosphere or marine environments, and pharmaceutical

process quality control. Additional applications include

anesthesia and hospital air quality monitoring, leak detection,

and remote imaging.

1

Covered by U.S. Patents 6,696,887; 6,867,644 and

7,176,755. Licensed from Battelle Memorial Institute

2

SAFETY

DEFINITIONS

CHASSIS GROUND Symbol

CAUTION: A condition that has the potential to

cause damage to property or instrument.

WARNING: A condition that has the potential to

cause bodily harm or death.

GENERAL

• Observe all Cautions and Warnings both in the User

Guide and on the instrument.

• Use the QCL instrument as specifi ed in this guide or the

protection provided by this instrument may be impaired

and the warranty will be voided.

• Use good laser safety practices when using the QCL

instrument.

• Before proceeding, it is critical that you take precautions

to prevent electrostatic discharge (ESD) damage to your

laser.

• Locking the instrument with the key switch disables the

output current. The key can only be removed when in the

LOCK position.

FUSES

• Disconnect the power to the QCL instrument before

changing the fuses.

• T o prevent damage to the QCL instrument when replacing

fuses, locate and correct the problem that caused the fuse

to blow before re-applying power.

• To avoid fi re hazard, use only the specifi ed fuse with the

correct type number, voltage, and current ratings, and use

only the recommended replacement parts.

CAUTIONS

The QCL instrument has no user-serviceable parts.

Other than the fuses, the QCL instrument is not

designed to be maintained by the user nor does it

contain any parts that can be repaired by the user.

All maintenance and repairs must be performed by

Wavelength or the warranty will be void.

Use a soft cloth to remove dust from the QCL

instrument. Do not expose the QCL instrument to

any liquids, sprays, or solvents. To avoid electrical

shock, unplug the power cord before cleaning the

instrument.

Before connecting to the power source, make sure

the correct cables and voltage for your area are

set. The voltage selection is available on the back

of the instrument. See the Quick Start Guide for

instructions on changing the voltage.

POWER CORDS

• This equipment is grounded through the AC power cord

grounding conductor.

• Use only the earth-grounded power cords that are

recommended in this user guide.

• Route power cords and other cables so that they cannot

be damaged.

• Position the QCL instrument in a location that makes it

easy to quickly disconnect the power cord.

• To avoid fi re hazard, use only the specifi ed power cords

with the correct grounding, voltage, and current ratings.

WARNINGS

Position the QCL instrument so that access to the

Main Power On/Off switch on the back panel is

easily accessed.

Do not use the QCL instrument if there is evidence

of damage from shipping; damaged equipment

can present signifi cant safety hazards. If you

suspect the QCL instrument is damaged, contact

Wavelength technical support before attempting to

operate the instrument.

To avoid electrical shock, use the recommended

earth-grounded power cables and properly earthgrounded, 3-prong receptacles only. Failure to

follow this precaution can result in severe injury.

To avoid injury, do not tell the engineers how to

do their jobs. Let them muddle through until they

decide to read the User Guide.

3

QUICK CONNECT GUIDE

INSTALL FUSE & SELECT VOLTAGE

Figure 1. Fuse Box and Voltage Selector

1. On the back panel, locate the Fuse Box and Voltage

Selector receptacle. (See the Rear Panel diagram on

page 10 for the location.)

2. Insert a small fl athead screwdriver into the slot (1) at the

top of the receptacle and twist to open faceplate. The red

fuse drawer and fuses are located in the Ship Kit.

3. On the face of the fuse drawer are two voltage choices.

Based on your country, select the proper fuses to install.

VOLTAGE FUSE PART NUMBER

100-120 V

220-240 V

1.25 A, 250 V,

fast blow

0.63 A, 250 V,

fast blow

Littelfuse 5 x 20 mm,

Part #02351.25HXP

Littelfuse 5 x 20 mm,

Part #0217.630MXP

WIRE A TEST LOAD

Use of a test load is recommended for setup of the QCL

instrument. Use the Wavelength test loads listed on page 1, or

when building your own test load, a 10 resistor with a 50 W

power rating is recommended for the QCL500, QCL1000,

and QCL1500. For the QCL2000, a 50 W 5 resistor is

recommended.

• Install the test load by either connecting to the QCL SMA

port or wiring the load to PIN 5 and PIN 9 on the QCL

D-SUB as shown in Figure 3.

12345

6789

1

QCL

SMA

1

NOTE: The SMA case is electrically connected to the QCL chassis.

Figure 3. QCL Wiring Diagram

Pin 9 QCL +

or SMA Outer Ring

QCL D-SUB

QCL

CAUTION: It is imperative that the correct voltage

is used. Serious damage can occur if the incorrect

voltage is selected.

4. Insert the fuses as shown in Figure 2, with a short fuse

at the contact end of the receptacle. Then, turn the drawer

until the correct voltage label is at the top and replace it

in the receptacle. Press fi rmly to make sure the drawer is

completely seated. It should be fl ush with the receptacle.

Figure 2. Fuse Installation and Voltage Selector

5. Close the faceplate, again pressing fi rmly until it is fl ush.

The correct voltage label is shown through the Voltage

Window (2) on the faceplate.

QCL

Pin 5 QCL -

or SMA Center Pin

QCL Driver

Current Sink

-V

Figure 4. QCL Polarity Diagram

4

SETUP INTERLOCKS

ENABLE CURRENT

The Wavelength Interlock Replacement Kit includes a male

D-SUB with the passive interlock pins shorted and a BNC

terminator.

1. For the passive interlock, on the back panel, short PIN 1

and PIN 2 on the QCL D-SUB.

2. For the active interlock, on the back panel, insert a BNC

terminator in the ACTIVE LOCK BNC port.

3. On the front panel, the key switch must be on UNLOCK to

enable the current to the QCL.

TURN ON POWER

1. On the back panel, press the power switch to the |. The

front panel power button light pulses slowly.

2. On the front panel, press the Power button. The button

illuminates, the touchscreen activates, and the Control

screen is active.

3. The front panel displays dashes instead of digits until the

unit has fi nished its power-up sequence (~10 seconds).

Press the ENABLE button. There is a standard 2-second

delay before the button illuminates and the current fl ows.

SHUTDOWN THE INSTRUMENT

If the Enable button is illuminated, current is still fl owing to

the test load. Before shutting down, the current needs to be

turned off.

1. Press the Enable button. The button light will turn off and

current to the QCL test load will stop.

2. On the front panel, press the Power button. The

touchscreen will go black but the button light slowly

pulses blue to indicate that the back Power button is still

on. NOTE: Turning off only the front Power button puts

the instrument in Standby mode.

3. On the back panel, press the power switch to O.

SET LIMITS

1. Press to access the Limit Screen.

2. On the Limit screen, press the blue Limit Current value

and rotate the Adjustment knob to change to the desired

value. The instrument will beep when set.

NOTE: The Max Supply V oltage and Cable Resistance values

can be ignored for now.

ADJUST SETPOINT

1. Press to access the Control Screen.

2. Press the Setpoint current value and turn the Adjustment

knob to change it. The instrument will beep when set.

5

QCL D-SUB

)

QCL

d)

PIN DESCRIPTIONS

Pin 9 QCL +

or SMA Outer Ring

Figure 4. Female 9-Pin D-SUB

Table 1. QCL D-SUB Pin-Out

PIN DESCRIPTION

1, 2 Passive interlock pins (must be shorted to enable

current)

3 Chassis ground

4 Not used

5 * QCL- (negative)

6 Not used

7 Not used

8 Not used

9 * QCL+ (positive)

SHELL Chassis ground

* NOTE: Use Pins 5 and 9 for current to the QCL.

MONITOR D-SUB

QCL

Pin 5 QCL -

or SMA Center Pin

QCL Driver

Current Sink

-V

Figure 7. QCL Polarity Diagram

BNC PINS

GROUND

ACTIVE SIGNAL

Figure 8. BNC Pins

EXTERNAL MODULATION BNC

TRANSFER FUNCTIONS

Figure 5. Male 9-Pin D-SUB

Table 2. Monitor D-SUB Pin-Out

PIN DESCRIPTION

1 Alignment LED (+5 V) can source 250 mA

2 Alignment LED ground

3 QCL current enabled indicator (+5 V TTL)

high = disabled

low, ground = enabled

4 QCL current enabled indicator ground

5 Not used

6 Analog setpoint monitor

7 Analog monitor ground

8 Analog output current monitor

9 Analog monitor ground

QCL SMA

+ (groun

The external modulation input, setpoint monitor, and analog current

monitor transfer functions depend on the QCL instrument model and

are all as follows:

QCL500-LAB: 0.1 A / V.

QCL1000-LAB: 0.2 A / V.

QCL1500-LAB: 0.3 A / V.

QCL2000-LAB: 0.4 A / V.

The input range is always 0 – 5 V.

ACTIVE INTERLOCK BNC

Ground the center pin to the outer shell to override the interlock and

allow the current to fl ow to the QCL. If an external circuit won’t be

used, a 50 or 75 terminator is acceptable.

TRIGGER BNC

See Remote Operation on page 21.

QCL- (negative

Figure 6. SMA Pin-Out

6

ELECTRICAL SPECIFICATIONS

DRIVER OUTPUT CURRENT MIN TYP MAX UNITS NOTES

Output Current 0.5, 1.0, 1.5, or 2.0 A

RMS Noise Current 0.4 1.0 1.3 A RMS QCL1000 at 500 mA output, 100 kHz test bandwidth

Noise Current Density 1 2 4 nA / Hz QCL1000 at 500 mA, 10 test load

Stability, short and long term 5 10 15 ppm 25°C ambient

Temperature Coeffi cient 5 10 18 ppm / °C

Internal Supply Voltage can be adjusted from the front

panel.

Compliance Voltage Range 10 20 V

Slow Start Current Ramp (after

Enabled)

Delayed Start 2 sec User adjustable

EXTERNAL MODULATION MIN TYP MAX UNITS NOTES

Modulation Bandwidth 2 3 MHz Sinewave

Rise/Fall Time 250 / 200 nsec To full scale

Slew Rate 30 V / sec

Depth of Modulation 90 % At 500 kHz

Input Impedance 1 k

External Modulation Input

Damage Threshold

1.5 msec

-10 to +10 V BNC Connector

NOTE: With this current source, the voltage developed

across the load (laser) is not driven by the controller,

but by Ohm’s Law and the resistance of the load

(laser).

To setpoint

MONITORS AND OUTPUTS VALUE UNIT NOTES

Setpoint Resolution 16 bits 5V = fullscale output

Display Accuracy Measurement

Resolution

Accuracy, Current Output

Monitor vs. Actual Current

(display or analog output)

Accuracy, Current Setpoint vs.

Actual Current

Accuracy , Analog Setpoint

1

Monitor

1

Current Setpoint Monitor is a reference signal only, and may deviate from the actual setpoint by up to 5% when the setpoint is greater

than 10% of full scale.

24 Bits

0.2 % > 5% of full scale

0.5 % < 5% of full scale

0.2 % Internal setpoint

0.2 % External modulation

5 % >10% of full scale

25 % <10% of full scale

CONTINUED ON FOLLOWING PAGE

7

POWER SUPPLY

REQUIREMENTS

AC Power Supply and Line

Frequency

100-120 / 220-240 VAC, 2 A, 50-60 Hz

VALUE NOTES

Switch selectable: 100-120 V and 220-240 V,

appropriate power cord supplied

Fuse for 220-240 V 0.63 A, 250 V, fast blow 5 x 20 mm, Part #0217.630MXP, Littelfuse

Fuse for 100-120 V 1.25 A, 250 V, fast blow 5 x 20 mm, Part #02351.25HXP, Littelfuse

Power Consumption 9.8 Watts at idle, no output to QCL load

GENERAL SPECIFICATIONS VALUE NOTES

Warm-up Time 1 Hour

Remote Interface USB, Ethernet

Warranty One (1) Year

Safety Tested To IEC 61000-3-2

IEC 61000-3-3

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

IEC 61000-4-6

IEC 61000-4-8

IEC 61010-1

European Council Directive 2004/108/EC &

European Council Directive 2006/95/EC

ABSOLUTE MAXIMUM

RATINGS

Case Operating Temperature

Range

VALUE UNIT NOTES

-40 to 50 °C

Humidity 80 % Relative humidity at 30°C (non-condensing)

Weight 12 (~5.4) lbs (kg)

Size

3.47 x 8.86 x 17.72

(89 x 226 x 450)

inches (mm)

8

OPERATING INSTRUCTIONS (STAND-ALONE)

WHAT’S IN THE BOX

• QCL Instrument

• Power Cable, type appropriate for fi nal location

• Red fuse tray

• T wo 0.63 A fuses and two 1.25 A fuses for fuse box on the

back panel

• USB Flash Drive, includes all necessary software,

instrument documentation, and additional storage space

• Keys for the key switch

• Interlock Replacement Kit (interlocks for QCL D-SUB and

Active Interlock BNC)

These instructions are for operating the QCL Laboratory

Series instrument. Fuses are provided but not installed. After

installing the fuses in the fuse box, be sure to install the fuse

box so the correct voltage for your country is showing. We

also recommend using a test load until you are familiar with

operation of the instrument.

REQUIRED AND OPTIONAL

EQUIPMENT

FOR SET UP

THEORY OF OPERATION

The QCL Series low noise drivers are designed expressly to

drive quantum cascade lasers, and utilize patented1 circuitry

to deliver ultra-low noise current and still maintain a wide

modulation bandwidth.

The QCL drivers are controlled current sources; they deliver

the current commanded by the setpoint. The current source

continually monitors the actual output current, compares it to

the setpoint, and adjusts the current if there is a difference

between the two signals.

As current is driven through the load, there is a voltage drop

across the load proportional to the load resistance and current.

As the current increases, the voltage drop may increase to

the point that it reaches the Compliance Voltage limit of the

current source. Once that occurs the current source is no

longer able to increase the current driven to the load even if

you increase the setpoint.

The QCL driver includes features that help protect your laser,

and also make the driver more versatile in a wide array of

applications. These features are explained in detail in the

Operating Instructions.

• The user-adjustable current limit prevents overdriving the

laser even if the external modulation signal is above the

maximum drive current for the laser.

• Over- and under-voltage protection circuits protect the

driver and QCL if the power supply voltages fall outside of

the acceptable operating range.

• Small, narrow headed fl athead screwdriver (required)

• Test load (optional)

• Wavelength Interlock Replacement Kit with interlock

overrides (optional)

COMPUTER REQUIREMENTS FOR

REMOTE OPERATION ONLY (OPTIONAL)

Hardware

• 1 GHz or faster 32-bit (x86) OR 64-bit (x64) processor

• 1 GB RAM 32-bit or 2 GB RAM 64-bit

• 16 GB available hard disk space for 32-bit or 20 GB for

64-bit DirectX 9 graphics device with WDDM 1.0 or higher

driver

Software

• Windows 8, 7 SP1, or Vista SP2 Operating System 4.5

.NET framework

ESD INFORMATION

Before proceeding, it is critical that you take precautions to

prevent electrostatic discharge (ESD) damage to the load.

ESD damage can result from improper handling of sensitive

electronics, and is easily preventable with simple precautions.

• Over-temperature protection circuits safely shut down

the output if the internal temperature of the QCL driver

rises to an unsafe level. The fan turns on to manage the

internal temperature.

• Output slow-start ramps the current to setpoint over

1.5 msec.

• A mechanical relay shorts the output connections when

the output is disabled, and when the QCL driver is

powered off.

1

Covered by U.S. Patents 6,696,887; 6,867,644 and

7,176,755. Licensed from Battelle Memorial Institute.

9

REAR PANEL

1

2

CAUTION:

No user serviceable parts. Do

not remove cover.

Covered by U.S. Patents:

6,696,887

6,867,644

7,176,755

3

4

!

SERIAL #

WARNING: Before powering on

device, verify voltage setting is

correct and proper fuses are

installed.

CHASSIS

GND

QCL

5

Figure 9. Rear Panel

QCL

MONITORS

8

6

9

MOD

7

10

ACTIVE

LOCK

11

FUSE ~250V, 1.25AF (5 x 20mm)

100-120 VAC, 1.25 A, 50-60 Hz

ETHERNETUSB

12

TRIGGEREXT

FUSE ~250V, 0.63AF (5 x 20mm)

220-240 VAC, 0.63 A, 50-60 Hz

13

Table 3. Rear Panel Functions

NAME DESCRIPTION

1 Fan Vent Do not block air fl ow.

2 Chassis Ground Physical connection to chassis and electrical earth ground.

3 QCL SMA SMA connector, alternate connection to QCL.

4 QCL D-SUB 9-Pin female D-SUB connector.

5 Monitors 9-Pin male D-SUB connector.

6 USB USB port, connection between instrument and a computer.

7 Ethernet Ethernet port, connection between instrument and a computer or network.

8 EXT MOD External Modulation: BNC connector, setpoint signal generator input.

9 Active Lock BNC connector, active interlock, tie center pin to GND to enable output.

10 Trigger

11

12 Power Switch AC power switch that powers the instrument.

13 Power Plug IEC AC line input.

Fuse Box and Voltage

Selector

BNC connector output, allows instrument to trigger external device for synchronizing

measurement.

Removable fuse drawer allows user to switch between 115 V and 230 V. Fuses need to be

installed prior to operation.

10

INSTALL FUSES AND SELECT

PROPER VOLTAGE

Figure 10. Fuse Box and Voltage Selector

1. On the back panel, locate the Fuse Box and Voltage

Selector receptacle. (See the Rear Panel diagram on

page 10 for the location.)

2. Insert a small fl athead screwdriver into the slot (1) at the

top of the receptacle and twist to open faceplate. The red

fuse drawer and fuses are located in the Ship Kit.

3. On the face of the fuse drawer are two voltage choices.

Based on your country, select the proper fuses to install.

CONNECT POWER

Insert the female end of the IEC AC power cord into the Power

receptacle on the back panel and then plug the male end into

the power source.

WIRE A TEST LOAD

Use of a test load is recommended for setup of the QCL

instrument. Use the Wavelength test loads listed on page 1, or

when building your own test load, a 10 resistor with a 50 W

power rating is recommended for the QCL500, QCL1000,

and QCL1500. For the QCL2000, a 50 W 5 resistor is

recommended.

• Install the test load by either connecting to the QCL SMA

port or wiring the load to PIN 5 and PIN 9 on the QCL

D-SUB as shown in Figure 12.

12345

6789

QCL D-SUB

VOLTAGE FUSE PART NUMBER

100-120 V

220-240 V

1.25 A, 250 V,

fast blow

0.63 A, 250 V,

fast blow

Littelfuse 5 x 20 mm,

Part #02351.25HXP

Littelfuse 5 x 20 mm,

Part #0217.630MXP

CAUTION: It is imperative that the correct voltage

is used. Serious damage can occur if the incorrect

voltage is selected.

4. Insert the fuses as shown in Figure 11, with a short fuse

at the contact end of the receptacle. Then, turn the drawer

until the correct voltage label is at the top and replace it

in the receptacle. Press fi rmly to make sure the drawer is

completely seated. It should be fl ush with the receptacle.

1

QCL

SMA

1

NOTE: The SMA case is electrically connected to the QCL chassis.

QCL

Figure 12. QCL Wiring Diagram

Pin 9 QCL +

or SMA Outer Ring

Test Load

Pin 5 QCL -

or SMA Center Pin

QCL Driver

Current Sink

-V

Figure 13. Test Load Polarity Diagram

Figure 11. Fuse Installation and Voltage Selector

5. Close the faceplate, again pressing fi rmly until it is fl ush.

The correct voltage label is shown through the Voltage

Window (2) on the faceplate.

11

SET UP INTERLOCKS

TEXT AND ICON COLOR KEY

The Wavelength Interlock Replacement Kit includes a male

D-SUB with the passive interlock pins shorted and a BNC

terminator.

1. For the passive interlock, on the back panel, short PIN 1

and PIN 2 on the QCL D-SUB.

2. For the active interlock, on the back panel, insert a BNC

terminator in the ACTIVE LOCK BNC port.

3. On the front panel, the key switch must be on UNLOCK to

enable the current to the QCL.

NOTE: To disable operation, turn the key switch to the

LOCKED position. The key can only be removed when in the

locked position.

FRONT PANEL

TEXT

Text indicates current state.

White, Green Uneditable fi eld, for information only.

Blue Editable fi eld, touch to select or toggle fi eld

(text highlights and changes color), adjust

using either the touchscreen or adjustment

knob. Instrument beeps and text returns to

blue when values are set. Touch again to

cancel selection.

ICONS

Icon color indicates current state.

Blue Screen is active.

Grey Screen is inactive, touch icon to access that screen.

3

QCL1000

LAB

4

ENABLE

POWER

DATA

1

2

5

Figure 14. Front Panel

Table 4.

Table 5. Front Panel Functions

NAME DESCRIPTION

1 Power Button

2 Adjustment Knob Turn to adjust the numeric values. Instrument beeps when values are set.

3 Enable Button Allows instrument to deliver current to the QCL. Glows blue when current is enabled.

4 Keylock Switch

5 Data Port

Powers the application electronics. Glows blue when application electronics power is on and unit

is operational, slow pulses blue when on Standby and only the back panel power switch is on.

UNLOCK allows laser output current to fl ow, LOCK disables laser output current. NOTE: The

key can be removed only in LOCK position.

USB fl ash drive, used to update the fi rmware or save data. This is not used for remote USB

control of the instrument.

12

TURN ON QCL INSTRUMENT

1. Press the Power switch on the back panel to |. The front

panel power button light slowly pulses.

2. Press the Power button on the front panel, the button

illuminates, touchscreen is activated, and the Control

screen is active.

NOTE: Turning off front Power button powers down the

application electronics and puts the unit into standby

mode. Turning off rear Power switch powers down all

electronics and settings return to factory default.

3. The front panel displays dashes instead of digits until the

unit has fi nished its power-up sequence (~10 seconds).

SET LIMITS

1. Press to access the Limit Screen.

ADJUST THE SETPOINT

1. Press to access the Control Screen.

2. Press the Setpoint value and turn the Adjustment knob

until the desired operating current is displayed.

2. Press Limit Current, Maximum Supply Voltage, and/or

Cable Resistance values and rotate the Adjustment knob

to change each value. The instrument will beep when set.

Figure 15. Limit Screen

NOTES:

• The Limit Current should not exceed the damage current

threshold of your QCL.

• The Maximum Internal Supply Voltage can be lowered

to minimize internal instrument temperature or to act as a

compliance voltage clamp on the QCL output current. See

Additional Technical Notes on page 25 for optimization

instructions.

• The Cable Resistance range is 0 – 1 .

QCL Voltage displays the voltage at the QCL DSUB or

SMA terminals. To account for voltage loss across the

cable to the QCL, you can enter a non-zero value for

Cable Resistance.

The QCL Voltage will now display as:

Voltage Displayed = Voltage@Pins - (Cable Resistance x Operating Current)

• The minimum limit current is about 8% of full scale.

Figure 16. Control Screen

NOTE: The Control screen is on by default when the

instrument is turned on. The Mode is Constant Current by

default and cannot be changed.

DISPLAY EXISTING CURRENT AND

VOLTAGE VALUES

Press to access the Monitor Screen.

Values on this screen cannot be changed and are for

information only.

Figure 17. Monitor Screen

13

ENABLE THE QCL INSTRUMENT

Press the Enable button on the front panel. The button will

glow blue only when current is delivered to the load. There is

a standard 2-second delay before the button illuminates and

current fl ows.

VI SCAN

1. On the Control screen, press to access the VI

scan screen.

2. Press the Current Start value to select the current at

which to start the scan. Turn the Adjustment knob to

change it.

NOTES:

• The step interval time is approximate. In the scan fi les,

time intervals are slightly more than the step interval

indicated on the instrument. Each interval builds on the

previous one.

• Should the Step Size interval not fi nish at the Stop Current,

the reading is still taken and recorded. For example, if

the Start Current is 250 mA and the Stop Current is 1.04

A with a Current Step of 250 mA, a reading is taken at

1000 mA (1 A) and 1040 mA (1. 04A) but not at 1250 mA

(1.25 A).

• After a VI scan is completed, the output is disabled and

the setpoint is zeroed.

SAVE OR RECALL SETTINGS

Press to access the Save/Recall Screen.

Figure 18. Scan Screen

3. Press the Current Stop value to select the current at

which to stop the scan.

4. Press the Step Size value to select the current interval at

which to take a measurement. The maximum interval is

10% of full scale. Minimum step is 1% of full scale.

5. Press the Time Interval value to select the amount of time

to allow the current to settle. For the best data accuracy,

use a Time Interval of 2 seconds or more. The minimum

time interval is 0.1 seconds.

6. Insert the USB fl ash drive in the USB slot on the front

panel.

7. Press the green Run button to start the scan. When

fi nished, data is saved to the USB fl ash drive with

the fi lename viscanxx.txt, where xx starts at 00 and

increments.

8. To stop mid-scan, press the red Stop button to abort the

scan. Any data collected during the aborted scan is saved

to the USB fl ash drive.

Under Save Settings to, press the blue text

to toggle through the Profi le options, select

one, and then press the Save icon.

The following variables are saved:

OPERATION SETTINGS VI SCAN SETTINGS

Setpoint VI Start Current

Current Limit VI Stop Current

Max Supply Voltage VI Step Size

Cable Resistance VI Time Interval

Display Brightness

Beeper Status

Figure 19. Save / Recall Screen

14

Under Recall Settings from, press the

blue text to toggle through the saved Profi le

options, and then press the Recall icon to

recall the saved settings. Select Factory to

restore the settings to the factory defaults.

SETTINGS SCREEN

Press to access the Settings Screen

Move the slider bar on the touchscreen to change the display

brightness. Press the blue text to toggle the Beeper on-off

setting.

EXTERNAL MODULATION

(EXT MOD) BNC

This is the external modulation input. The voltage input on

this BNC sums with the DC value on the screen. The input

impedance is 1 k . To calculate the external modulation

signal voltage, see the next section for the transfer function,

and use the following equation:

EXT_MOD

= I

CAUTION: Connect the oscilloscope across the

test load only — never connect the oscilloscope

across a quantum cascade laser.

V

If the external modulation input causes the driver to reach the

current limit, the output signal will be clamped at the limit level

but will not switch off.

The bandwidth of the Current Monitor is lower than the

bandwidth of the output. To monitor the actual output

waveform at high frequencies, connect an oscilloscope across

the output pin on the MONITOR D-SUB, Pin 8 (positive), and

Pin 9 (ground) while using the resistor test load.

/ Transfer Function

SETPOINT

Figure 20. Settings Screen

LOCK OR UNLOCK SETTINGS

(OPTIONAL)

Settings are not locked.

This is the default. Critical values set with the

Adjustment knob can be locked. Press to lock

the settings.

Settings are locked.

Press to unlock the settings.

Settings are locked and password protected.

Locked settings that are password protected

can only be locked and unlocked using a remote

computer.

EXTERNAL MODULATION BNC

TRANSFER FUNCTIONS

The external modulation transfer function depends on the

QCL instrument model and is as follows:

QCL500-LAB: 0.1 A / V.

QCL1000-LAB: 0.2 A / V.

QCL1500-LAB: 0.3 A / V.

QCL2000-LAB: 0.4 A / V.

The input range is always 0 – 5 V.

15

ADDITIONAL CAPABILITIES

ANALOG CURRENT MONITOR

This signal is the sum of the DC setpoint as shown on the

screen and the external modulation input.

To monitor the analog current level:

1. Connect the Analog output Current Monitor (PIN 8) on the

MONITOR D-SUB to an oscilloscope.

2. Connect an Analog Monitor Ground (PIN 7 or PIN 9) to

oscilloscope ground.

SETPOINT CURRENT MONITOR

This is a reference only and can be off by as much as 5%

when setpoint is >10% of full scale.

To monitor the setpoint current:

1. Measure the voltage on the Analog Setpoint Monitor (PIN 6).

2. Ground for that measurement is the Analog Monitor Ground

(PIN 7 or PIN 9).

The setpoint monitor and analog current monitor transfer

functions depend on the QCL instrument model and are all

as follows:

QCL500-LAB: 0.1 A / V.

QCL1000-LAB: 0.2 A / V.

QCL1500-LAB: 0.3 A / V.

QCL2000-LAB: 0.4 A / V.

The input range is always 0 – 5 V.

ALIGNMENT LED DRIVE

+5 V, up to 250 mA sourced.

To drive an alignment LED, on the MONITOR D-SUB

1. Connect an LED to the Alignment LED +5V (PIN 1).

2. Ground the LED at the Alignment LED Ground (PIN 2).

ENABLE STATUS INDICATOR

This is a +5 V TTL indicator. If current to the QCL output

is enabled, the voltage between PIN 3 and PIN 4 on the

MONITORS D-SUB will be low. It will be high if current is

disabled.

16

OPERATING INSTRUCTIONS (REMOTE)

http://www.teamwavelength.com/support/software.php.

http://www.teamwavelength.com/support/software.php

INSTALL THE LAB QUICKCONNECT

APPLICATION SOFTWARE

The QuickConnect software is necessary for remote operation

of the instrument. The software can be installed on the remote

computer from either the USB fl ash drive included with your

instrument or from the Wavelength website.

• On the USB fl ash drive, the software is located in the

\ setup folder.

• On the Wavelength website, the link to the software is

located at

http://www.teamwavelength.com/support/software.php.

NOTE: .NET 4.5 software is required to run the application. If

it is not currently installed on the remote computer, it will be

installed automatically when you insert the fl ash drive.

TO INSTALL THE SOFTWARE,

1. From the USB fl ash drive or the Wavelength website

and in the fi le dialog box, select the software version that

corresponds to your computer system type, either 32-bit

or 64-bit. NOTE: If the incorrect system type is selected,

an error message will appear and the software will not

install.

2. Click the computer system’s setupxx.exe fi le, where “xx”

refers to the system type. The Preparing to Install dialog

box opens and the software automatically extracts the fi le.

3. On the Welcome window, click Next.

4. On the Destination Folder window, click Next to accept

the default Wavelength folder or Change to select a

different folder. When the new folder has been selected,

click Next.

5. On the Ready to Install window , review the settings, click

Install.

6. On the Windows Security window, click Install.

7. On the Completed window, select the Launch the

program checkbox to open the application and then click

Finish.

The fi le is found at:

http://www.teamwavelength.com/support/software.php

3. Extract the fi le on the fl ash drive. It should contain the

following fi les:

\INSTALL.INI

\QCLxx\ABL.IMG

\QCLxx\APP.IMG

\QCLxx\INSTALL.INI

NOTE: “QCLxx” is replaced with the instrument model number,

such as QCL2000.

4. Insert the fl ash drive into the front DATA port on the

instrument. The update automatically begins installation.

5. At the Apply the fi rmware screen, click Yes. The fi rmware

update installs.

6. Once the update is complete, click OK and reboot the

instrument by turning off the front and rear panel power

buttons and turning them back on again.

7. (Optional) To confi rm the latest version is installed on

the instrument, after the instrument is on, swipe the

touchscreen to show the system information screen. The

new version number is displayed.

CONNECT AN INSTRUMENT TO A

REMOTE COMPUTER

1. Connect the QCL instrument to a power source. See

the Stand Alone operation instructions on page 11 for

more information.

2. Connect the instrument to the computer using a USB or

Ethernet cable. If connecting more than one instrument, a

USB or Ethernet hub may be required.

3. Turn on the rear panel Power switch. The front panel

Power button pulses blue.

4. Turn on the front panel Power button. The button glows

steadily blue and the touchscreen activates.

UPDATE THE INSTRUMENT

FIRMWARE

Updates to the instrument fi rmware are available on the

Wavelength website.

1. Turn the instrument completely off at both the front and

rear panels, and then turn it completely on again.

2. On the Wavelength website, download the ZIP fi le that is

specifi c to your QCL Laboratory Series model and save

the update fi le to a fl ash drive.

ACCESS THE INSTRUMENT ON A

REMOTE COMPUTER

1. On the computer and from the Start Menu, click All

Programs, then click Wavelength Electronics, and then

LAB QuickConnect. The LAB QuickConnect Application

window opens.

2. In the LAB QuickConnect Application window, click

Open Instrument.

3. In the Choose Instrument To Open window, select the

instrument to connect to and click Open.

17

Figure 20. Include USB Devices window

NOTES:

• The Include USB Devices checkbox is selected by

default and any powered instruments currently connected

to the computer via a USB cable appear in the list.

• If you are unsure which instrument to select, on the

instrument, swipe the touchscreen fi rmly from left to

right. The instrument details screen, including the serial

number, appears.

• Instruments that are connected to subnets can be added

to the list.

1. Select the Include Network Devices checkbox, add

the IP address or host name of the subnet, and then

click Add Host.

2. Click Refresh. Any instruments connected to that

subnet appear in the list.

Figure 22. Remote Computer Control screen

Figure 23. Instrument touchscreen when controlled remotely

CHANGE THE TURN-ON DELA Y

The default delay between the time the current to the laser

is enabled and the current actually fl ows is 2 seconds. This

turn-on delay can be set to a minimum of 0 seconds and a

maximum of 5 seconds.

1. On the Operation Tab, click on the blue text below Turn-

On Delay.

2. Change the value and tab to a new editable fi eld to save

the change.

Figure 21. Include Network Devices window

3. On the Instrument Operation tab, in the lower left, click

Seize. Control of the instrument will transfer from the

instrument to the computer and a screen of all editable

fi elds appears. The computer screen is editable and the

instrument screen is not.

NOTE: One instrument can be controlled remotely at a time.

CONTEXTUAL HELP

At any time, contextual Help Information appears on the right

side of the window when the pointer is placed over a button

or screen element. Technical Support information, such as the

instrument serial number and Wavelength contact information

is available when the pointer is placed over the grey frame

surrounding the window.

18

SUPER USER VS. NORMAL USER

PERMISSIONS

There are two levels of permissions when modifying the

instrument controls, Super User and Normal User.

Super User: The Super User has the ability to modify any

remote operation and to assign permissions for Normal

Users. A password is required to access Super User features.

Upon fi rst sign in, the password entered is the new Super

User password and is required for subsequent sign ins.

Normal User: The Normal User is primarily used for Local

operation. The Super User can restrict access to specifi c

inputs on the instrument.

ACCESS SUPER USER MODE

When control of the instrument is fi rst seized, it is in Normal

User mode.

1. On the Instrument Operation tab and at the bottom, click

Super User.

2. Type the password in the text box and click OK. Select

the Show Password checkbox to type the password as

text.

NOTE: Upon fi rst sign in, the password typed becomes the

password for subsequent sign ins.

EDIT INSTRUMENT PROFILES

Profi les can be edited in Super User mode or when Normal

Users are not restricted from saving profi les.

1. In the Profi le Editor Window and in the Available

Profi les menu, select a profi le. The factory default profi le,

Profi le 0: Factory Default, cannot be changed.

2. Type values in the Profi le Data boxes.

3. (Optional) In the Description Line 1 and 2, type a

description of the profi le. This text replaces the Save-

Recall Profi le text on the instrument. A maximum of 14

characters are saved.

4. (Optional) To grant Normal Users read-write permissions,

select the appropriate checkbox.

• Local User Can Save/Modify This Profi le: Allows

any user to change any preset profi le value on the

instrument.

• Normal User Can Recall: Allows any user to recall

preset profi les. This is selected by default.

5. Click Apply to Instrument and/or Save.

• Click Apply to Instrument to change the values

on the instrument but not save the changes to the

Profi le.

• Click Save to save changes to the Profi le but not

change the values on the instrument.

• Click Apply to Instrument and then Save, to apply

changes to the instrument and then save the changes

to the Profi le.

Figure 24. Enter Password window

6. .

Figure 25. QCL-LAB Profi le Editor window

19

EDIT ADV ANCED OPTIONS

CHANGE SUPER USER PASSWORD

Advanced Options can only be edited in Super User mode.

Figure 26. Advanced Options window

CHANGE PERMISSIONS

Permissions can only be modifi ed in Super User mode and

apply only to Normal User mode.

1. Under Permissions, select Apply Restrictions To

Instrument.

NOTE: To apply the restriction changes to the instrument,

this checkbox must be selected when the selections are

saved.

2. Select the appropriate checkbox to restrict access to those

values. Click All to select all the checkboxes or None to

clear them. All restrictions apply to Normal Users when

the instrument is in Normal User mode or when operated

in local mode.

3. Click Save.

NOTES:

• Restrictions checkboxes can be selected and saved

without applying the changes to the instrument.

• To apply the local Save Profi le and Recall Profi le

options to the instrument, the local user Save/Modify and

Recall checkboxes on the Profi le Editor must also be

checked, as well as the Apply Restrictions checkbox on

the Advanced Options dialog box.

1. On the Instrument Operation tab, click Super User.

2. Type the password in the text box and click OK. Select

the Show Password checkbox to type the password as

text.

3. Under Permissions, click Change Super User

Password.

4. Type a new password and then click OK.

CHANGE NETWORK

CONFIGURATION SETTINGS

Network confi gurations can only be changed in Super User

mode.

1. Under Network Confi gurations, click Edit Network

Confi guration.

2. Type the new information into the text boxes and click

Save.

POWER INSTRUMENT ON OR OFF

The front panel can be turned on or off using a remote

computer. When the front panel Power button is turned on,

the button displays a blue circle and the screen displays all

editable values on the instrument. When it is turned off, the

screen is black and only the Power button, without the blue

circle, is available. This is equivalent to pressing the front

panel Power button.

• On the Instrument Operation tab, click the Power button.

Figure 27. Power button on Figure 28. Power button off

20

CHANGE VALUES ON INSTRUMENT

RUN A VI SCAN

Blue and yellow text denotes editable values, green and white

text is not. Press TAB to move to the next editable fi eld.

1. On the Instrument Operation tab, click the blue text to

edit. The text turns yellow when in editing mode.

2. Tab to or click on blue text to edit the value.

NOTE: Tabbing to a new editable text fi eld saves changes

made to the previous value. Manually moving the cursor to a

new fi eld does not save the change, which reverts to the last

saved value.

1. On the Instrument Operation tab, click the green arrow.

A Specify Data File window opens.

2. Navigate to the location to save the scan data, name the

fi le as desired, and click Save.

3. A new window opens showing the scan in progress.

• To stop the scan, click Stop Scan. Data collected up

to the point the scan was stopped is recorded in the

data fi le.

4. To dismiss the scan window, click Close.

Figure 29. Text color indicates ability to edit

ENABLE OR DISABLE CURRENT TO

THE LASER

Current to the laser can be enabled or disabled using a

remote computer. When the current is enabled, the Enable

button glows blue.

• On the Instrument Operation tab, click the Enable

button.

Figure 30. Enable button on Figure 31. Enable button off

Figure 32. VI Scan screen

END REMOTE OPERATION

Returning the instrument to local operation is accomplished

one of two ways:

• On the Instrument Operations tab and at the bottom,

click Close Instrument.

• On the instrument, tap Press For Local.

USE THE TRIGGER SIGNAL

A trigger signal is provided so that external measurement

equipment can be synchronized with laser current. Exactly

10 msec after a remote change in setpoint, a 20 sec positive

going pulse appears on the Trigger BNC plug.

To use the Trigger, connect a BNC cable to the TRIGGER

BNC output.

21

TROUBLESHOOTING

Table 5. Troubleshooting

PROBLEM POTENTIAL CAUSES SOLUTIONS

The button has been pushed on and

Front panel Power button does not turn on

The Enable button does not turn on

The instrument is on but the front panel

display is blank

The date and time on my VI scan fi le are

wrong

The VI scan fi les are not in the order that

they were created

Unable to create new VI scans

I can’t fi nd my VI scan fi les VI scan fi les are named sequentially.

The fan keeps coming on

off within 3 seconds.

The rear panel switch is off.

The button has been turned on and off

within 2 seconds.

The QCL D-SUB interlock or Active

Interlock connections are open, or the

keyswitch is in the LOCKED position

The instrument experienced an

internal fault.

(See Error Messages on page 24.)

The instrument heatsink temperature

has exceeded 70ºC.

The front panel Power button is not

on.

The instrument experienced an

internal fault.

(See Error Messages on page 24.)

The internal temperature has reached

an unsafe level.

The front panel Power button is

pulsing on and off in standby mode.

Some fi les may have been deleted off

of the USB fl ash drive.

The interlocks may not be satisfi ed.

There are too many fi les on the USB

fl ash drive.

The internal temperature is being

regulated.

The front panel Power button has a 3 second

delay between when it is turned off and on in

rapid succession. This is a safety mechanism

to ensure there is no damage to either the

QCL instrument or the attached load.

Turn the rear panel switch to the on or |

position.

The button cannot be pressed faster than

every 2 seconds.

• Make sure PIN 1 and PIN 2 on the QCL

D-SUB are shorted.

• The “Active Lock” BNC connector may

be open. Install a BNC shorting plug.

• Rotate the key to the UNLOCKED

position.

The instrument will remain disabled until

manually powered off and then on using the

rear panel power switch.

Allow the instrument to cool down and then

press the front panel power button.

Press the Power button on the front panel to

enable the display.

Switch the back panel power button off and

then on again, and turn the front panel power

button on.

Allow the instrument to cool down and then

switch the back panel power button off and

then on again, and turn the front panel power

button on.

Press the Power button on the front panel to

enable the display.

The QCL instrument does not have a realtime

clock. When a VI scan fi le is created, the date

and time stamp are randomly chosen.

When fi les are deleted off of the USB fl ash

drive and new fi les are saved to it, the new

fi les are given sequentially the names of the

deleted fi les.

Turn the keyswitch to UNLOCKED, or

install the ACTIVE LOCK BNC and passive

interlocks.

Delete fi les from the USB fl ash

If fi les have been deleted from the fl ash drive,

any new fi les added are named sequentially

and have the names of the deleted fi les.

To reduce internal heat generation, choose a

lower supply voltage. The instrument will shut

down if the internal temperature gets too hot.

drive.

22

PROBLEM POTENTIAL CAUSES SOLUTIONS

http://www.teamwavelength.com/downloads/

notes/an-ld08.pdf

http://www.teamwavelength.com/downloads/

notes/an-ld09.pdf

There may be ground loops in the

system; some system components

Noise current is higher than expected.

The output switched off unexpectedly

20 kHz noise is in the output current QCL driver is operating in current limit.

If I run my QCL at about 5% of maximum

output current, the transfer function

becomes non-linear and I see distortion in

my output current waveform.

My instrument doesn’t show up in the list.

(Remote Only)

Actual current does not match the setpoint.

may be higher noise than expected;

cabling and shielding may be

inadequate.

The instrument detected an internal

error

.

(See Error Messages on page 24.)

The internal temperature has

exceeded 70ºC.

QCL driver resolution is too low.

Your instrument may not be turned on.

Your instrument may not be plugged in

to the computer.

Your instrument may be on a different

sub-net.

The setpoint exceeds the limit current

setting.

The QCL is compliance voltage

limited.

Refer to Wavelength Electronics Application

Note AN-LD08: “Manage Grounding to

Minimize Noise with the QCL Drivers”:

http://www.teamwavelength.com/downloads/

notes/an-ld08.pdf

Also reference AN-LD09: “Troubleshooting

Low Noise Systems”:

http://www.teamwavelength.com/downloads/

notes/an-ld09.pdf

Switch the back panel power button off and

then on again, and turn the front panel power

button on.

Allow the instrument to cool down and then

press the front panel power button.

If safe for the quantum cascade laser,

increase the output current limit setting.

When actively operating in current limit, the

safety circuits add noise to the output.

Select a QCL driver with a much lower

maximum output current. For example,

to run 50 mA, request a QCL125 (125 mA

maximum output).

Power up the instrument and click Refresh

on the Choose Instrument window.

Check that either a USB or Ethernet cable is

tightly connected to the instrument and to the

computer.

Add the sub-net to the Choose Instrument

window and then click Refresh.

If the limit current can be increased without

damage to the QCL, increase the limit

current setting.

Increase the Max Supply Voltage slightly to

see if actual current increases. Follow the

instructions on page 25 to optimally set

the Max Supply Voltage.

23

Table 6. Error Messages

To clear error text, fi x the cause then press any icon or the Enable button.

ERROR POTENTIAL CAUSES SOLUTION

The USB fl ash drive is missing or not

accessible. Please make sure that a USB

fl ash drive is inserted into the front panel.

The USB fl ash drive was removed. The

scan has been aborted.

Output current is disabled. The keyswitch

is in the locked position.

Output current disabled. Pins 1 & 2 on the

QCL D-SUB are not tied.

Output current disabled. The Active

Interlock is not shorted.

The internal temperature limit of the

instrument has been exceeded. Output

current has been disabled to protect the

laser.

The VI scan was canceled by the user.

Scan was canceled because output

current is disabled.

An open circuit was detected at the

load. Please verify the load and load

connections.

A short circuit was detected at the load

terminals. Please verify the load and load

connections.

An internal error occurred while reading

data from hardware. Please contact the

factory for further assistance.

A timeout occurred waiting for output.

Make sure the load is connected and

interlocks are satisfi ed.

An internal error was detected. Please

contact the factory for further assistance.

A fault in the internal +5V supply was

detected. Please contact the factory.

A fault in the internal +15V supply was

detected. Please contact the factory.

A fault in the internal -15V supply was

detected. Please contact the factory.

A timeout occurred waiting for the internal

load power supply to stabilize. Please

contact the factory.

A problem has been detected in the

instrument power supply. Please contact

the factory for further assistance.

A current surge has been detected in the

instrument. Output has been disabled to

protect the laser.

To run a local VI scan, a USB fl ash drive

must be in place.

To run a local VI scan, a USB fl ash drive

must be in place.

The keyswitch is horizontal or in the locked

position.

The passive interlock is not shorted. Short Pin 1 and Pin 2 on the QCL D-SUB.

The active interlock is not grounded.

The ambient air temperature is too high for

the instrument.

The Stop button was pressed during the

scan.

The Enable button was pressed during a

scan, cutting current to the load.

The instrument cannot drive current

through the load.

The instrument is detecting that there is no

resistance where the load should be.

Insert a USB fl ash drive in the data port on

the front panel.

Insert a USB fl ash drive in the data port on

the front panel.

Turn the keyswitch to the vertical or

unlocked position.

Ground the center pin of the Active Lock

BNC.

Reduce the ambient air temperature to

50ºC or less.

Make sure the QCL SMA or Pins 5 & 9 of

the QCL D-SUB are connected.

Make sure the QCL SMA or Pins 5 & 9 of

the QCL D-SUB are connected.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact Wavelength technical support for

further assistance.

Contact W

further assistance.

avelength technical support for

24

ADDITIONAL TECHNICAL NOTES

This section includes useful technical information on these

topics:

• Reduce internal temperature or provide compliance

voltage limit

• Use Passive and Active interlocks

• Soft-clamp current limit

• Square wave response

• Remove the bail and feet from an instrument

REDUCE INTERNAL TEMPERATURE

OR PROVIDE COMPLIANCE

VOLTAGE LIMIT

At full current, the Maximum Compliance Voltage available

to the QCL is about 7.5 V below the maximum supply

voltage. This 7.5 V estimate decreases as operating current

decreases. To determine the best internal supply voltage for

your application, follow these steps:

1. Wire your QCL to the instrument and adjust the current

limit on the Limit screen and setpoint on the Control

screen for your application.

2. Press the Enable button to enable the output current. The

actual current displayed should match the setpoint.

3. On the Limit screen, select the blue MAX Supply Voltage

value and, using the Adjustment knob, adjust it down

slowly until the actual current starts to decrease. The QCL

current is now limited by the compliance voltage of the

instrument.

4. Using the Adjustment knob, now increase the MAX

Supply Voltage value until the current is no longer below

the setpoint. This is the optimal maximum supply voltage

for your setup.

5. On the Monitor screen, observe the QCL Voltage. This is

the voltage across the QCL at this operating current and

is the effective voltage limit to the QCL for your setup.

NOTE: If you reach 18 V on the MAX Supply Voltage

input and the current is still not compliance voltage limited,

the instrument is operating at its lowest voltage and the

voltage limit cannot be reduced further.

SOFT-CLAMP CURRENT LIMIT

The QCL driver employs a soft-clamping current limit that

begins to act at a current lower than the calculated absolute

current limit.

The Limit Current is the absolute current limit, which is the

current that will not be exceeded under any circumstance.

Because of the soft-clamp circuit, the actual current where the

limit circuit begins to act is 20% below the absolute current

limit.

If the output current is between this point and the Absolute

Current Limit, the output response to the analog input

setpoint is nonlinear. The result is that the drive current will

asymptotically approach the absolute current limit, and will

never exceed it even if the external modulation setpoint

voltage far exceeds the current limit.

Figure 33 illustrates the behavior of the soft-clamp current

limit. In this case the analog input voltage setpoint signal is

a triangle wave, with the amplitude set so that the driver will

attempt to overdrive the current limit.

Figure 33. Soft Clamping Current Limit Behavior

USE P ASSIVE AND ACTIVE

INTERLOCKS

The passive interlock is designed to trigger if Pins 1 and 2 on

the QCL D-SUB are not shorted. Use this interlock with doors

and enclosures that trigger an open circuit when opened.

The active interlock (ACTIVE LOCK BNC) can be used with

a temperature controller or other active system component to

disable the current output if the QCL exceeds an acceptable

temperature operating range.

25

SQUARE WAVE RESPONSE

Figure 34 and Figure 35 illustrate the modulation response of

the QCL1500 driven at 1.15 A into a 10 test load.

Figure 34. 10 kHz Output Plot

QCL1500 at 1.15 A with 10 Ω Test Load

Figure 35. 600 kHz Output Plot

QCL1500 at 1.15 A with 10 Ω Test Load

REMOVE THE BAIL AND FEET FROM

AN INSTRUMENT

To make sure there is the proper clearance between stacked

instruments when rack mounting, the feet and bail must be

removed.

On the underside of the instrument, using a Phillips head

screwdriver, unscrew the four rubber feet.

26

MECHANICAL SPECIFICATIONS

3.47

[88.14]

16.35

[415]

8.860

[225.0]

0.66

[16.8]

3.92

[99.6]

6.10

[154.9]

8.860

[225.0]

3.47

[88.14]

8.49

[215.6]

17.72 [450]

16.35

[415]

0.72

[3.89]

Dimensions are in inches [mm].

Tolerance is ±5%.

27

CE DECLARATION OF CONFORMITY

CONFORMING PRODUCTS

MODEL NUMBER PRODUCT

QCL500-LAB 500 mA QCL Driver Laboratory Instrument

QCL1000-LAB 1000 mA QCL Driver Laboratory Instrument

QCL1500-LAB 1500 mA QCL Driver Laboratory Instrument

QCL2000-LAB 2000 mA QCL Driver Laboratory Instrument

DECLARATION

The undersigned hereby declares, on behalf of Wavelength Electronics, Inc. (Wavelength) of Bozeman, Montana, that the

products listed in the table above, to which this Declaration applies, are in conformity with the provisions of:

APPLICABLE REGULATIONS

• European Council Directive 2004/108/EC (December 15, 2004) on Electromagnetic Compatibility, tested to:

» IEC 61000-3-2 and IEC 61000-3-3

» IEC 61000-4-2, IEC 61000-4-3, IEC 61000-4-4, IEC 61000-4-5, IEC 61000-4-6, and IEC 61000-4-8

• European Council Directive 2006/95/EC (December 12, 2006) on Low-Voltage Equipment Safety, tested to:

» IEC 61010-1

• European Council Directive 2011/65/EU (June 8, 2011) on Restriction of the use of certain hazardous substances in

electrical and electronic equipment (RoHS)

TECHNICAL FILE

The Technical Construction Files for the listed products, as required by this Declaration, are maintained at Wavelength

corporate headquarters: 51 Evergreen Drive, Bozeman, Montana.

18-Nov-14

Mary Johnson, CEO Date

28

WARRANTY & CERTIFICATION

CERTIFICATION

Wavelength Electronics, Inc. (Wavelength) certifi es that this product

met its published specifi cations at the time of shipment. Wavelength

further certifi es that its calibration measurements are traceable to

the United States National Institute of Standards and Technology, to

the extent allowed by that organization’s calibration facilities, and to

the calibration facilities of other International Standards Organization

members.

WARRANTY

This Wavelength product is warranted against defects in materials

and workmanship for a period of one (1) year from date of shipment.

During the warranty period, Wavelength will, at its option, either

repair or replace products which prove to be defective. Warranty is

void if label is removed from back panel.

WARRANTY SERVICE

For warranty service or repair, this product must be returned to the

factory. An RMA is required for products returned to Wavelength

for warranty service. The Buyer shall prepay shipping charges to

Wavelength and Wavelength shall pay shipping charges to return

the product to the Buyer upon determination of defective materials

or workmanship. However, the Buyer shall pay all shipping charges,

duties, and taxes for products returned to Wavelength from another

country.

LIFE SUPPORT POLICY

This important safety information applies to all Wavelength electrical

and electronic products and accessories:

As a general policy, Wavelength Electronics, Inc. does not

recommend the use of any of its products in life support applications

where the failure or malfunction of the Wavelength product can be

reasonably expected to cause failure of the life support device or

to signifi cantly affect its safety or effectiveness. Wavelength will

not knowingly sell its products for use in such applications unless it

receives written assurances satisfactory to Wavelength that the risks

of injury or damage have been minimized, the customer assumes all

such risks, and there is no product liability for Wavelength. Examples

of devices considered to be life support devices are:

neonatal oxygen analyzers, nerve stimulators (for

any use), auto-transfusion devices, blood pumps,

defi brillators, arrhythmia detectors and alarms,

pacemakers, hemodialysis systems, peritoneal dialysis

systems, ventilators of all types, and infusion pumps as

well as other devices designated as “critical” by the FDA.

The above are representative examples only and are not

intended to be conclusive or exclusive of any

other life support device.

LIMITATIONS OF WARRANTY

The warranty shall not apply to defects resulting from improper use or

misuse of the product or operation outside published specifi cations.

Warranty for the QCL instrument is invalid if the instrument cover

has been removed for any reason. No other warranty is expressed

or implied. Wavelength specifi cally disclaims the implied warranties

of merchantability and fi tness for a particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are the Buyer’s sole and exclusive

remedies. Wavelength shall not be liable for any direct, indirect,

special, incidental, or consequential damages, whether based on

contract, tort, or any other legal theory.

REVERSE ENGINEERING PROHIBITED

Buyer, End-User, or Third-Party Reseller are expressly prohibited

from reverse engineering, decompiling, or disassembling this

product.

NOTICE

The information contained in this document is subject to change

without notice. Wavelength will not be liable for errors contained

herein or for incidental or consequential damages in connection with

the furnishing, performance, or use of this material. No part of this

document may be translated to another language without the prior

written consent of Wavelength.

SAFETY

There are no user-serviceable parts inside this product. Return the

product to Wavelength Electronics for service and

repair to ensure that safety features are maintained.

TECHNICAL SUPPORT & CONTACT

INFORMATION

WAVELE

n

GTH

ELECTRONICS

51 Evergreen Drive

Bozeman, Montana 59771

406-587-4910 (tel)

406-587-4911 (fax)

Sales & Tech Support

sales@teamWavelength.com

techsupport@teamWavelength.com

REVISION HISTORY

Document Number:

REVISION DATE NOTES

C 8-Dec-14 Initial Release

D 19-Jan-15 Updated Specs

E Apr 2015

KEYWORDS

QCL1000, QCL500, QCL1500, QCL2000, quantum cascade laser driver, qcl

laser driver, qcl controller, quantum cascade laser controller

QCL1000-LA400

Updated Transfer Functions,

Fuse Installation

29

Loading...

Loading...