W

AVECREST Corporation

OE-2

Optical to Electrical Signal Converter

User’s Guide and Reference Manual

200005-01 REV A

This page intentionally left blank.

WAVECREST

Corporation continually engages in research related to

product improvement. New material, production methods, and design

refinements are introduced into existing products without notice as a

routine expression of that philosophy. For this reason, any current

WAVECREST

product may differ in some respect from its published

description but will always equal or exceed the original design

specifications unless otherwise stated.

Copyright 2002

U.S. Patent Nos. 4,908,784 and 6,185,509, 6,194,925, 6,298,315 B1, 6,356,850

and 6,393,088; other United States and foreign patents pending.

WAVECREST

A Technologies Company

Corporation

7626 Golden Triangle Drive

Eden Prairie, Minnesota 55344

(952) 831-0030

(800) 733-7128

www.wavecrest.com

All Rights Reserved

ATTENTION: USE OF THE SOFTWARE IS SUBJECT TO THE WAVECREST SOFTWARE LICENSE TERMS

SET FORTH BELOW. USING THE SOFTWARE INDICATES YOUR ACCEPTANCE OF THESE LICENSE

TERMS. IF YOU DO NOT ACCEPT THESE LICENSE TERMS, YOU MUST RETURN THE SOFTWARE FOR A

FULL REFUND.

WAVECREST SOFTWARE LICENSE TERMS

The following License Terms govern your use of the accompanying Software unless you have a separate written

agreement with Wavecrest.

License Grant. Wavecrest grants you a license to use one copy of the Software. USE means storing, loading, installing,

executing or displaying the Software. You may not modify the Software or disable any licensing or control features of

the Software.

Ownership. The Software is owned and copyrighted by Wavecrest or its third party suppliers. The Software is the

subject of certain patents pending. Your license confers no title or ownership in the Software and is not a sale of any

rights in the Software.

Copies. You may only make copies of the Software for archival purposes or when copying is an essential step in the

authorized Use of the Software. You must reproduce all copyright notices in the original Software on all copies. You

may not copy the Software onto any bulletin board or similar system. You may not make any changes or modifications

to the Software or reverse engineer, decompile, or disassemble the Software.

Transfer. Your license will automatically terminate upon any transfer of the Software. Upon transfer, you must deliver

the Software, including any copies and related documentation, to the transferee. The transferee must accept

these License Terms as a condition to the transfer.

Termination. Wavecrest may terminate your license upon notice for failure to comply with any of these License

Terms. Upon termination, you must immediately destroy the Software, together with all copies, adaptations and

merged portions in any form.

Limited Warranty and Limitation of Liability. Wavecrest SPECIFICALLY DISCLAIMS ALL OTHER

REPRESENTATIONS, CONDITIONS, OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. ALL OTHER IMPLIED TERMS ARE EXCLUDED. IN NO EVENT WILL

WAVECREST BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES ARISING OUT OF THE USE OF OR INABILITY TO USE THE SOFTWARE, WHETHER OR NOT

WAVECREST MAY BE AWARE OF THE POSSIBILITY OF SUCH DAMAGES. IN PARTICULAR,

WAVECREST IS NOT RESPONSIBLE FOR ANY COSTS INCLUDING, BUT NOT LIMITED TO, THOSE

INCURRED AS THE RESULT OF LOST PROFITS OR REVENUE, LOSS OF THE USE OF THE SOFTWARE,

LOSS OF DATA, THE COSTS OF RECOVERING SUCH SOFTWARE OR DATA, OR FOR OTHER SIMILAR

COSTS. IN NO CASE SHALL WAVECREST'S LIABILITY EXCEED THE AMOUNT OF THE LICENSE FEE

PAID BY YOU FOR THE USE OF THE SOFTWARE.

Export Requirements. You may not export or re-export the Software or any copy or adaptation in violation of

any applicable laws or regulations.

U.S. Government Restricted Rights. The Software and documentation have been developed entirely at private

expense and are provided as Commercial Computer Software or restricted computer software.

They are delivered and licensed as commercial computer software as defined in DFARS 252.227-7013 Oct 1988,

DFARS 252.211-7015 May 1991 or DFARS 252.227.7014 Jun 1995, as a commercial item as defined in FAR 2.101 (a),

or as restricted computer software as defined in FAR 52.227-19 Jun 1987 or any equivalent agency regulations or

contract clause, whichever is applicable.

You have only those rights provided for such Software and Documentation by the applicable FAR or DFARS clause or

the Wavecrest standard software agreement for the product.

OE-2™ User’s Guide and Reference Manual

Table of Contents

Preface Organization and Inspection........................................................... v

SECTION 1 Introduction......................................................................................1

Features..........................................................................................1

How the OE-2 Works......................................................................2

Laser Safety....................................................................................3

SECTION 2 Front and Back Panel Descriptions................................................5

Front Panel Controls and Connectors.............................................5

Back Panel Controls and Connectors..............................................7

SECTION 3 Instrument Set-up and Measurement.............................................9

Test System Requirements.............................................................9

Before Using the

Instrument Setup.............................................................................9

VISI™ Software Setup and Configuration......................................10

Manually Assigning GPIB Addresses............................................11

Automatically Assigning GPIB Addresses.....................................11

Setting Acquire Options.................................................................13

External Calibration.......................................................................15

Output Setting Options..................................................................16

Trigger Options..............................................................................17

View Options.................................................................................17

Taking a Measurement ..................................................................18

Appendix A Specifications and Maintenance................................................19

Appendix B GPIB Commands.........................................................................23

OE-2....................................................................9

Appendix C Preprogrammed Measurement Limits.......................................27

iii

This page intentionally left blank

iv

PREFACE

Organization

The manual is divided into three Sections and three Appendices. The following is a brief description of

the information contained in each section. For quick reference to specific information, refer to the Table

of Contents.

SECTION 1 — Introduction

This section introduces the user to the OE-2. Features and capabilities are described. An overview of the

internal operation of the OE-2 is also included.

SECTION 2 — Description

Describes the front and back panels of the OE-2.

SECTION 3 — Set-up and Measurement

Describes the installation and set-up of the OE-2 as well as using Virtual Instruments Signal Integrity™

software through a

APPENDIX A — Specifications

This section contains a comprehensive set of specifications for the OE-2.

WAVECREST

SIA-3000 or DTS-207x instrument.

APPENDIX B — GPIB Commands

Includes various parameters, values and codes necessary for implementing remote control of the OE-2 via

the IEEE-488 interface.

APPENDIX C — Preprogrammed Measurement Limits

Includes a series of tables that show the preprogrammed measurement limits for each OE-2 model.

WARNING

Operating the OE-2 outside of the maximum operational specifications

published in Appendix A of this manual can damage the instrument.

The Wavecrest Warranty does not cover damage resulting from

improper operation or mishandling of the OE-2.

OE-2 Preface |

v

Inspection

If the contents are incomplete or damaged, contact

Service: 1-800-733-7128.

Inspect the shipping box for damage.

If the shipping box is damaged, or the cushioning materials show signs of stress, notify

the shipping carrier as well as the

WAVECREST Corporation

materials for the carrier’s inspection.

Check for accessories.

Power cord

Two (2) build-out SMA connectors for Dual-channel instrument; one (1) connector

for Single-channel instruments

Two (2) optical build-out connectors for Dual-channel instrument; one (1) connector

for Single-channel instruments

OE-2 User’s Guide and Reference Manual

Inspect the instrument.

If there is mechanical/physical damage, or if the instrument does not power up properly,

notify

inspection.

WAVECREST Corporation

WAVECREST Corporation

option.

WAVECREST Corporation

Customer

office. Keep the shipping

. Keep the shipping materials for the carrier’s

will arrange for repair or replacement at their

vi

| OE-2 Preface

SECTION 1– Introduction

The

WAVECREST

combination with a

jitter measurements on optical signals. The OE-2 can be operated in local mode or it can be

controlled through its GPIB interface using

(VISI) software.

Features

The OE-2 incorporates all of the features needed for making single- or dual-channel, high

performance optical signal measurements.

Fully Calibrated - The

High Bandwidth - Enables measurement of high-speed data communication signals.

Built-in Amplifiers - Boosts low power signals to measurable levels.

Built-in Filters - Used to establish the noise bandwidth of optical signals. Available filter options include Fibre

OE-2 converts optical communications signals into electrical signals. In

WAVECREST

OE-2 is fully calibrated from the optical input to the electrical output permitting

accurate signal level measurements without the need for additional instruments.

Channel, Fibre Channel 2X, Gigabit Ethernet, InfiniBand™, XAUI, and SONET OC-48.

DTS or SIA system, the OE-2 enables accurate, high performance

WAVECREST’s

Virtual Instruments™ Signal Integrity

Power Meter High-Speed Measurements -

GPIB Interface - The

Dual Channel Capability - The

Each channel of the OE-2 includes an average optical power meter.

WAVECREST

accurate jitter measurements.

OE-2 can be run remotely via the GPIB or locally via the front panel.

OE-2 is available in single-channel or dual-channel models.

DTS or SIA system with an OE-2 can quickly make highly

Figure 1 – Dual-Channel OE-2 shown with

WAVECREST

SIA-3000

Section 1 | Introduction |

1

How the OE-2 Works

The OE-2 consists of a high-performance optical-to-electrical converter followed by wide-

bandwidth, signal processing devices. Dual-channel models incorporate two identical channels.

The block diagram below shows the structure of one OE-2 channel.

Figure 2 – Block diagram of an OE-2 channel

The optical input signal is converted to an electrical current using a low-noise, temperaturestabilized photo receiver. The electrical signal is then amplified by a wideband transimpedance

amplifier (TIA) integrated within the photo receiver.

Because optical signals may have high levels of wideband noise, filters are often used to improve

the signal-to-noise ratio. Communications standards require a fourth-order Bessel-Thomson

low-pass filter characteristic with a cut-off frequency of 75% of the data rate. Each channel of

the OE-2 has four filters—for different communications protocols—selectable by electronic

switches. In addition, a fifth setting bypasses the filters for full-bandwidth operation.

Filter settings can be independently selected for each channel using front panel controls or

through the GPIB interface.

A bank of wideband electronic amplifiers follows the filters. These electronically switched

amplifiers amplify the electrical signal by approximately 10 dB, 20 dB, 30 dB or 40 dB. The

amplifier setting can be independently selected for each channel using front panel controls or

through the GPIB interface.

The average current in the photo receiver is measured to determine the average optical power of

the input signal and is available only through the GPIB interface.

The signal gain in every filter and amplifier path in the OE-2 is measured and stored locally in

the OE-2. These calibration values are used by

WAVECREST’s

VISI software to display accurate

optical signal power levels.

A central processor controls all OE-2 functions. The processor also handles communication with

the GPIB interface port.

| Section 1 | Introduction

2

Laser Safety

Although the

optical signals from laser devices. Therefore, laser signals will be present at the OE-2 inputs.

These signals present retinal and/or personal hazards because they are invisible and might not be

detected until injury to the eye or skin has occurred. To prevent injuries, basic precautions

should be followed.

• NEVER look directly into an optical signal connector. Always assume a laser beam is present.

• NEVER direct an optical output signal connector in a direction that could cause harm to

personnel nearby.

• Always turn optical output signal devices OFF when not in use.

• Where practical, protective eyewear that is designed for the signal wavelengths used should

be worn.

OE-2 optical to electrical converter does not emit laser energy, it does process

Section 1 | Introduction |

3

This page intentionally left blank.

| Section 1 | Introduction

4

SECTION 2 – Front and Back Panel Descriptions

This section describes the front and back controls and connectors of the

1

9

OE-2.

2

3

4 5 6 7

Dual Channel OE-2 Front panel

Front Panel Controls and Connectors

1

2

Filter Selection

The OE-2 routes the converted signal through low-pass filters to establish a finite, repeatable measurement

bandwidth for the

The filter selection knob selects one of the four low pass filters or full bandwidth. Filter options are

described in Appendix A. Filters are independently selected for each channel; dual channel models

can use two different filters.

Filter selection can also be made through the GPIB interface. See Appendix B for GPIB commands.

Amplifier Selection

The amplifier selection knob selects one of the four amplifier settings. The gain is approximately 10dB

per amplifier.

• 10 dB

• 20 dB

• 30 dB

• 40 dB

Amplifier selection can also be made through the GPIB interface. See Appendix B for GPIB commands.

OE-2. Fourth-order Bessel-Thomson low pass filters are exclusively used.

8

Section 2 | Front and Back Panel Descriptions |

5

3

4

Over range LED/Signal LED

Two LEDs on the front of the OE-2 indicate optical input signal status. The lower “SIGNAL” LED is lit

when the

signal power is beyond the input range of the instrument and should be removed to prevent damage to the

optical detector.

If both LEDs are blinking, the O/E receiver temperature stabilization is not within range. Measurements

made during this condition are not valid. If this occurs, turn off the unit for a few minutes and turn it back

on. It may be necessary to move the

be serviced by an authorized

OE-2 senses an optical signal. If the upper “OVERRANGE” LED is blinking red, the optical

OE-2 to a cooler location. If this condition persists, the unit should

WAVECREST

service representative.

Channel 1 Optical Input

This FC/UPC input connector accepts either single-mode or multi-mode (up to 62.5 um) optical fibers.

Optical signals from 770 to 1650 nm can be used.

Before attaching any connector to the

fiber connector cleaner such as the NTT-ME CLETOP.

OE-2, clean all optical connections using an optical

CAUTION: Do not exceed +3 dbm peak optical power.

5

Channel 1 Electrical Output

The electrical output signal is available at this 50 Ohm SMA connector. The converted electrical signal is a

linear representation of the optical signal.

CAUTION: This output port is sensitive to electrostatic discharge. Use ESD protection when

connecting to this port.

6

Channel 2 Optical Input

This FC/UPC input connector accepts either single-mode or multimode (up to 62.5 um) optical fibers.

Optical signals from 770 to 1650 nm can be used.

Before attaching any connector to the

fiber connector cleaner such as the NTT-ME CLETOP.

CAUTION: Do not exceed +3dbm peak optical power.

7

Channel 2 Electrical Output

The electrical output signal is available at this 50 Ohm SMA connector. The converted electrical signal is a

linear representation of the optical signal.

CAUTION: This output port is sensitive to electrostatic discharge. Use ESD protection when

connecting to this port.

8

Front Panel On/Off Switch

The front panel switch turns the internal power supply on or off.

Local/Remote Switch

9

| Section 2 | Front and Back Panel Descriptions

6

The Local/Remote switch selects between local mode and remote GPIB operation. In local mode,

settings are selected using the Filter and Amplifier Selection knobs. In GPIB remote operation, settings

are selected by using

performed at the

is lit when in local operation.

OE-2 -specific commands via the GPIB. Any operation/parameter change

SIA-3000™ will override the GPIB selected settings. The Local/Remote pushbutton

OE-2, clean all optical connections using an optical

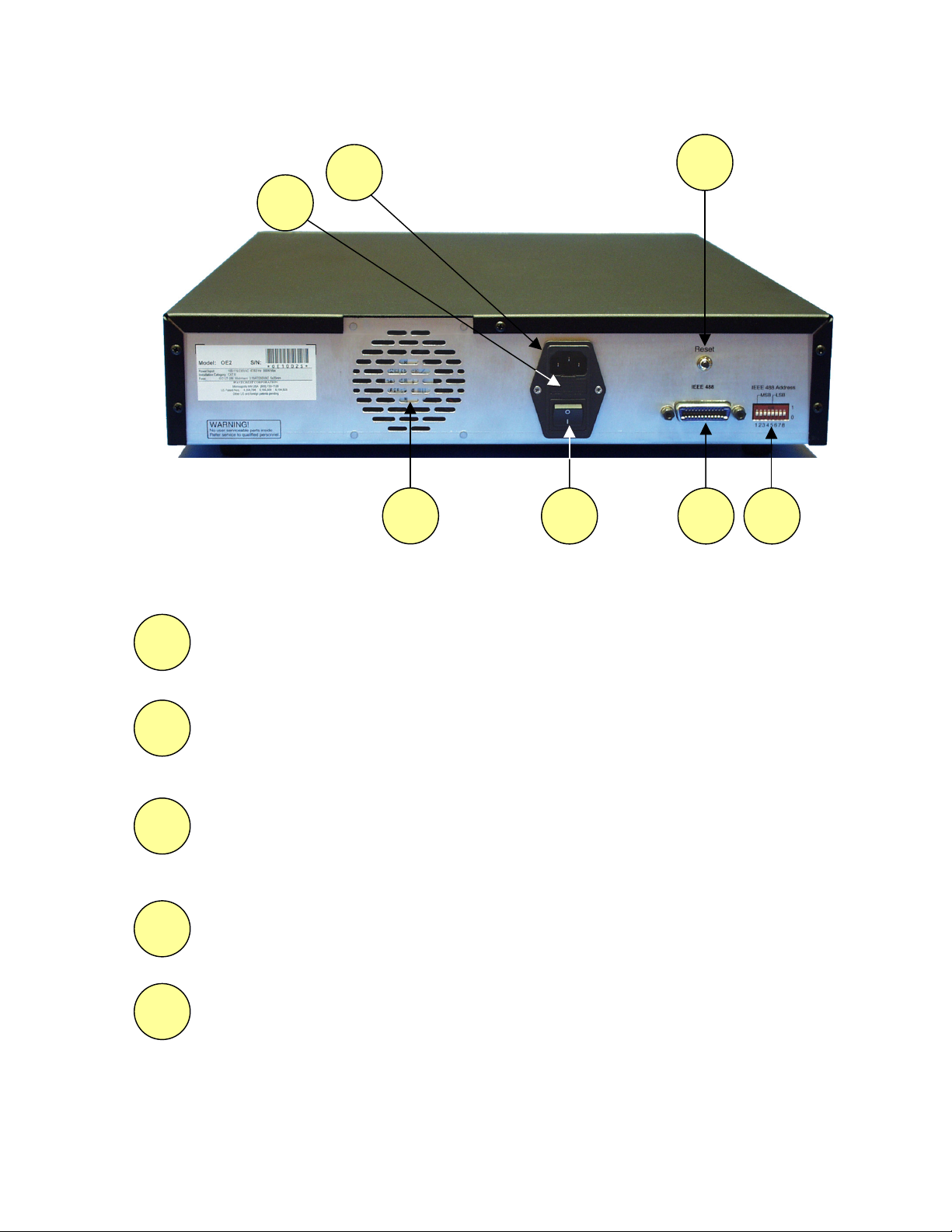

Back Panel Controls and Connectors

11

10

12

13

14

15 16

OE-2 Back Panel

10

11

12

13

AC Input Port

IEC Inlet for AC cord. Connect to an AC source in the range of 100-240 VAC, 47-63 Hz.

Fuse

Primary AC fuse. Located inside of connector housing. Should be replaced with two Wickman

4AT/250V fuses (5x20 mm).

Reset Pushbutton

The Reset Pushbutton resets the OE-2 to the Power-Up state. This state is set to Full Bandwidth, 10DB,

1550NM in the factory. The end user may change this setting remotely by using GPIB commands that

are specified in Appendix B.

Fan Exhaust

Exhaust port for internal cooling fan. Maintain at least 1-inch (2.5 cm) clearance.

14

AC Primary Switch

Controls the AC mains to the instrument.

Section 2 | Front and Back Panel Descriptions |

7

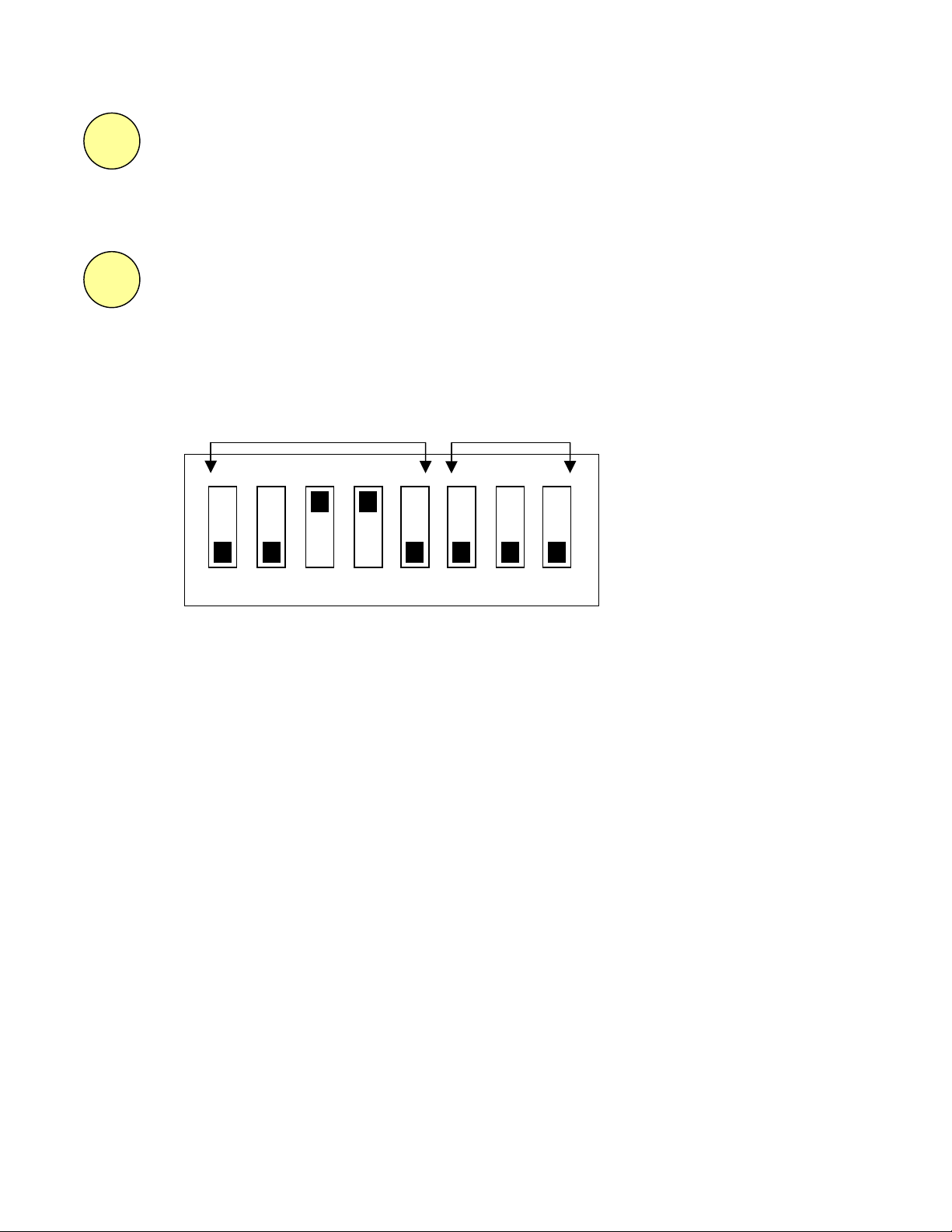

15

16

GPIB Input Connector

Connector for GPIB cable. Used for controlling the OE-2 with a computer or other instrument. A GPIB

device address can be set using the 32-position DIP switch (see below), with address 0 reserved for the

controller and the remainder of the settings available at the user’s discretion. A full GPIB command set is

provided in Section 3.

GPIB Port Address Switch

Sets the address of the GPIB port. The address can be set from 1 to 31. Address 0 is reserved for the

controller; the default OE-2 address is 6.

The switch settings are in binary format as shown in the drawing below. For example, the switch setting

shown below selects port 6. The last three switches are not used.

IEEE-488 Port Address Not Used

1

0

LSB MSB

| Section 2 | Front and Back Panel Descriptions

8

SECTION 3 – Setup and Measurement

This section describes the set-up of the

take a quick measurement for rapid familiarization with the instrument.

In addition, this section describes the Virtual Instrument Signal Integrity™ (VISI) software tools

necessary for using the

the VISI User’s Guide for detailed definitions and instructions of this and other VISI tools.

OE-2 with any

Test System Requirements

To use the OE-2, a complete test system consisting of the following components is needed:

OE-2 and provides instructions that enable the user to

WAVECREST

measurement instrument. Please refer to

WAVECREST

• A

• A

WAVECREST

• A source of optical signals

• Interconnecting cables

Before attaching any connector to the

an optical fiber connector cleaner such as the NTT-ME CLETOP.

To prevent damage to the optical-to-electric (O/E) input connector, a build-out connector is

included with the

A dirty or scratched O/E input connector can severely degrade the input signal, resulting in

inaccurate measurements.

NOTE: If the O/E input connector is damaged, the instrument must be returned to

for repair.

OE-2. The build-out connector can be replaced if it becomes damaged or dirty.

OE-2

SIA or DTS (PC or Workstation with VISI installed) instrument

OE-2, clean all optical connections using

Before Using the OE-2

To ensure the highest accuracy and proper GPIB operation, it is important that:

All OE-2’s are warmed up for at least ½ hour prior to taking a measurement.

All OE-2 GPIB addresses have been correctly assigned (see page 8).

WAVECREST

An external calibration of the OE-2 is performed at least once each day (see page 12).

OE-2 should also be recalibrated if there has been a change of more than 5 C° in

The

ambient temperature.

Instrument Setup

Attach the power cord to the back of the instrument and to an appropriate power source.

See Appendix A for specific power requirements.

Attach the cleaned build-out connector to the OE-2 input.

Attach the cleaned input signal cable to the build-out connector.

Turn on main power on the back of the unit.

Turn on front power switch. The front switch is typically used for daily operations and

also allows easy access to power if the unit is mounted in a rack.

Section 3 | Setup and Measurement |

9

VISI SOFTWARE SETUP

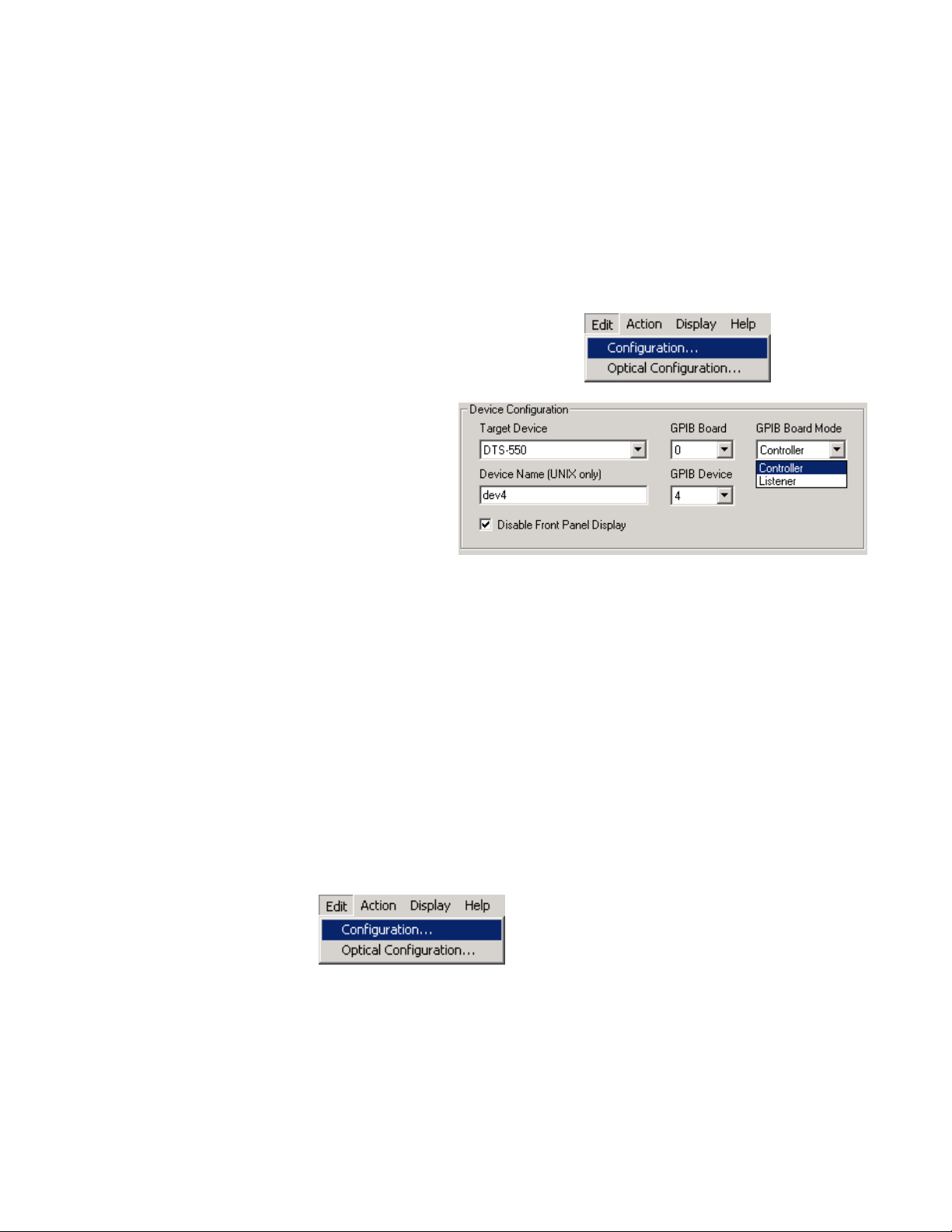

Controller Mode

Edit | Configuration Menu

In order for the OE-2 to communicate with the SIA-3000™ using the GPIB bus, the SIA-

3000

must be in the “Controller” mode. To select Controller mode:

Select Edit Configuration on the

(pull-down) Menu Bar

Select OE-2 in the Target

Device pull-down Menu

Select Controller in the GPIB

Board Mode pull-down menu.

Click “Apply”

Click “Close”

Optical Configuration

The Optical Configuration menu enables the user to:

• Set up the IEEE-488 (GPIB) addresses for one or more OE-2’s (up to five OE-2’s can

be addressed in a single VISI-based system).

• Assign each OE-2 channel to a

• Set preliminary optical measurement parameters.

WAVECREST

SIA or DTS instrument channel.

To access the

down) Menu Bar (see figure below).

| Section 3 | Setup Measurement

10

Optical Configuration menu in VISI, select Edit|Optical Configuration on the (pull-

Manually Assigning GPIB Addresses

The GPIB Address Assignment window will appear (see figure below). The fields in this dialog

box will be blank unless device assignments were previously made. The GPIB Address

Assignments

dialog box manages the address settings for both the GPIB host and all OE-2’s.

Optical Configuration Dialog Box – GPIB Address Assignment

The Optical GPIB Board field controls the host GPIB address, that is, the GPIB address of the SIA

controller or host controller computer. In most installations, this will be set to 0. In cases where a

host computer has more than one GPIB interface bus connected to it, the

address should be set to the card address for the bus connected to the

The

Optical GPIB Device field sets the address of the OE-2’s connected to the GPIB bus. Set

Optical GPIB Device to the DIP switch setting on the back panel of the OE-2 and select the

the

Add Device button. The OE-2 address will appear in the Remote Device List. In the case of

multiple OE-2 installations, each remote device will have to be individually added.

The default address for the

Device Name (UNIX Only) field is not used at this time.

The

OE-2 is 6.

Optical GPIB Board

OE-2’s.

Automatically Assigning GPIB Addresses

To automatically assign GPIB addresses, click on the “OE Device Search” button to have VISI

automatically search the GPIB network and identify all connected

on this button will bring up a pop-up box that asks if existing configurations are to be deleted.

Select the appropriate response.

OE-2’s. In addition, clicking

Section 3 | Setup and Measurement |

11

When all OE-2’s connected to the system are addressed, the next step is to poll the GPIB bus to

see that each

dialog box. Clicking on the

Each correctly addressed OE-2 will be shown in the Optical Input window along with its GPIB

device address.

OE-2 is correctly addressed. This is done with the Optical Channel Assignment

Optical Channel Assignment tab will initiate the polling process.

If a connected

Return to the

Dual-channel

to-electrical channel path in the

the right-hand channel will be named “Port 2.”

OE-2 does not appear in the dialog box, its address may be incorrectly set.

GPIB Address Assignments window to correct the address settings.

OE-2’s will occupy two lines in the Optical Input window - one for each optical-

OE-2. The left-hand OE-2 channel will be named “Port 1” and

Optical Configuration Dialog Box - Optical Channel Assignments

Finally, it is necessary to assign each OE-2 channel to a channel of the

WAVECREST

DTS or

SIA instrument by highlighting one line in the Optical Input field (corresponding to one channel

path) and selecting the DTS or

channel, click the “Active” box.

For example, if you have an optical signal connected to the left hand input port of the

the electrical output of this same channel connected to the channel 3 input on a

SIA input channel in the SIA Channel field. To activate this

OE-2, and

WAVECREST

SIA-3000, the Optical Channel Assignment should read:

OE-2, GPIB Device 6, Port 1 3 Active

Channel Ports left in the inactive state will still pass signals, but VISI software will not recognize

the channel port.

| Section 3 | Setup Measurement

12

Setting Acquire Options

The Acquire Options dialog bar displays the OE-2 settings for optical

signal measurements. In setting the Acquire Options, note that

“channel” refers to the DTS or SIA channel.

To set the Acquire Options:

From the Main Dialog Bar, select Utilities. The Utilities dialog

bar will be displayed.

From the Utilities Dialog Bar, select Optical Interface. The

Optical Interface tool will be displayed.

From the Optical Interface Dialog Bar, select Acquire Options. The

Acquire Options dialog bar will be displayed (see figure to the right).

Section 3 | Setup and Measurement |

13

Select the channel to view. (“Channel” refers to the DTS or SIA

channel.) The software will poll the OE-2 configured to that channel

to determine which filter bank options are installed.

WAVECREST

’s VISI software has preprogrammed set-ups for several

popular communication standards, including Fibre Channel, Gigabit

Ethernet, and Infiniband. When you select one of these filter set-ups,

VISI will automatically select the filter and amplifier in the OE-2 and

set the wavelength for measurements. In addition, VISI will set

measurement limits from the standard’s requirements such as rise and

fall time, extinction ratio, optical modulation amplitude and average

optical power. A Pass or Fail message will appear on the VISI display

indicating whether the signal satisfies the standards limits. The default

values for the preprogrammed settings are listed in Appendix C.

Select the “Standard” drop-down menu. Standards corresponding to

the filters installed in the

window. For example, if the

OE-2 will be listed in the “Standard”

OE-2 has filter option 1, with Fibre

Channel, Gigabit Ethernet and Infiniband filters installed, those

standards will appear in the drop-down list.

Select a protocol from the drop down menu in the “Protocol” field for

the type of signal to be measured. The protocol identifies the subsection of the communication standard. Once the standard and

protocol are selected, the preprogrammed settings will be shaded,

preventing you from changing them.

If “User-Defined” is selected, all settings and limits may be selected or changed.

Select (RUN) and VISI will continuously make measurements.

If the signal level is too low, the gain of the OE-2 amplifier can be increased in the

Amplifier window.

| Section 3 | Setup Measurement

14

External Calibration

An external calibration must be performed for each channel. Keep in mind that, when you press

the “External Calibration” button, only the channel that is selected in the “Channel” field will be

calibrated.

To perform the external calibration:

From the Optical Interface Dialog Bar, click on Acquire Options

Remove the optical signal from the input connector

Select the SIA Channel that you would like to calibrate

On the Acquire Options menu, select the External Calibration button

The calibration will be performed and, when complete, the message, “The calibration was

successfully completed,” will appear. Reconnect your signal after the calibration process is done.

In the event that a calibration error warning appears, repeat the calibration process making sure:

All optical signals are removed from the optical input

The correct channel is selected

The OE-2 GPIB Address and Optical Channel Assignments are correct (under

Edit|Optical Configuration pull-down menu)

OE-2 specifications require an annual factory calibration. A reminder dialog box should appear

within 30 days of the internally recorded, factory calibration anniversary date. Contact

WAVECREST Corporation

to schedule the annual calibration.

Section 3 | Setup and Measurement |

15

Output Setting Options

The Output Settings dialog bar enables the user to set the units of measure, such as milliwatt or

microwatts, for optical measurements. Pass/fail limits for optical power, modulation and rise and

fall time measurements are accessible through this selection.

To access the

Output Settings, select the Output Settings button on the Dialog Bar. Select the

appropriate optical settings from the drop-down menus or enter the desired value into the

available data fields. The following output settings are available when a specific “Protocol” on

the Acquire Options menu has not been selected. The settings are preset when a specific

“Standard” has been selected (see Appendix C).

Power units - Select from units of dBm, µW or mW for all power

measurements.

Average power limit - Pass-Fail limit value.

(The minimum average optical power limit, specified

in [power units])

Modulation Measure - Select either "extinction ratio" or

"optical modulation amplitude". See Appendix A.

Modulation units - Select unit of measure for modulation

When extinction ratio is selected

o Ratio

o dB

o Percentage

When Optical Modulation Amplitude is selected

o Milliwatts

o Microwatts

Modulation limit - Pass/Fail limit for modulation.

(The minimum average extinction ratio or OMA (as

selected), specified in [modulation units])

Rise Time limit

(The maximum rise time in picoseconds)

Fall Time limit

(The maximum fall time in picoseconds)

- Pass-Fail limit for rise time measurement.

- Pass-Fail limit for fall time measurement.

Select any of the devices on the list to display the current settings.

| Section 3 | Setup Measurement

16

Trigger Options

The Trigger Dialog Bar enables the user to set up trigger sources and conditions on the DTS or

SIA instrument.

Trigger - Select trigger source.

Trigger Method - Select Auto to set the trigger threshold voltage to

the 50% voltage point of the Pulsefind values on the selected

trigger channel. Voltage is displayed in "Trigger Voltage." Select

"User" to manually enter a threshold voltage in "trigger Voltage."

Limits are +/- 1.1 volts.

Trigger Voltage - Displays the threshold voltage used to trigger the

instrument. If User is selected in the Trigger Method box, the user

can enter a value. Limits are +/- 1.1 volts.

Trigger Edge - Selects the rising or falling edge to trigger the

instrument.

View Options

The View Options menu enables the user to change the

oscilloscope display. The following settings can be specified

or modified to customize your view:

Mode

Dot Connect - Measurements are displayed as a point-to-point,

straight-line plot.

Persistence - Measurements are displayed as individual dots in

the plot window.

Delay - the minimum time delay from the trigger event to the

measure event

Range - the full time span of the display

Resolution - the granularity of the display

Hits per Measure - Determines the number of time measurements

that will be made for each edge or point on the plot.

The

View pull-down menu at the top of the dialog bar provides

the user with two ways to see the acquired measurement data.

Time – Time domain plot of the signal

Summary – Text in a table format, used for pass/fail testing,

displays the comparisons to the output settings

Section 3 | Setup and Measurement |

17

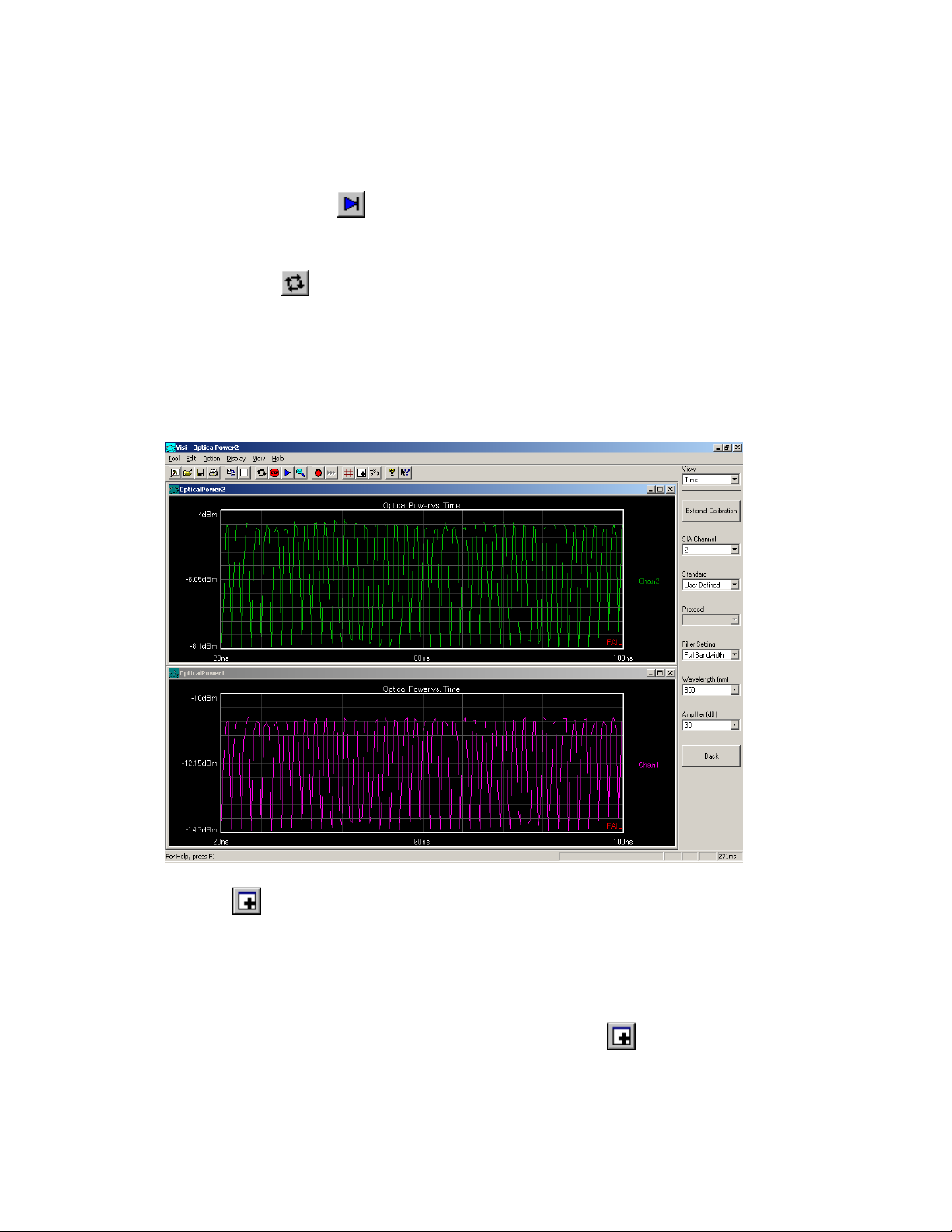

Taking a Measurement

Two types of measurements are available once the setup of the instrument has been completed

and are available from the Tool Bar or the Action pull-down menu.

• Single/Stop command (Action menu)

Use this command to acquire a single measurement in VISI. It is also used to stop a series of measurements

from being taken after the Run command is issued. This command affects the current tool only.

• Run command (Action menu)

Use this command to repetitively acquire new measurements in VISI. Measurements will be acquired until

either the Single/Stop command is issued or an error occurs. This command affects the current tool only.

As shown below, you may also display multiple windows to allow monitoring of more than

one channel.

Adding a view (

) opens a new (default) tool window associated with the active tool. There

may be many opened window views of one tool, but all views reflect any measurements or

settings for that tool.

To see both a measurement plot and summary page:

Open a tool.

Select Add from the View pull-down menu or click on the (New View) button.

Select Summary from the View menu on the Dialog Bar.

| Section 3 | Setup Measurement

18

APPENDIX A –

Specifications and Requirements

OE-2

™

SPECIFICATIONS

Functional Specifications—Optical

Wavelength Range ...................................................770 to 1650 nm

Conversion Gain(850nm)

Conversion Gain(1550nm)

Maximum Input Level

Input Damage Level.................................................+10 dBm

Polarization Dependent Loss

Input Return Loss

Input Connector Type ..............................................FC/UPC Multimode

Input Connector Core Diameter ...............................62.5 µm

Optical Power Measurement Accuracy

4

1,2

......................................5,500 V/W (850 nm/40 dB amp)

1,2

...................................20,000 V/W (1550 nm/40 dB amp)

3

............................................+3 dBm

4

..................................<0.1 dB

....................................................>20 dB

5

...................±0.5 dB

Functional Specifications—Electrical and System

Input Data Rate ........................................................155 Mb/s to 6 Gb/s

Frequency Response

Passband Ripple

Rise time (20-80%)

Intersymbol Interference

Filter Response.........................................................4th Order Bessel-Thompson

Amplifier Block Gain Accuracy

Output Impedance....................................................50 Ohms Nominal

Output Return Loss

Output Return Loss ..................................................>15 dB

Output Connector.....................................................SMA

Notes:

1. Typical value.

2. With maximum amplifier gain selected.

3. Peak operational signal level.

4. Measured in Single Mode fiber.

5. Over the range of –18 to +3 dBm at 850 nm or over the range of –22 to +3 dBm for 1310 and 1550 nm

operation

6. Measured by 650 fs (FWHM) mode-locked laser impulse.

7. Calculated –3 dB frequency response from an FFT of impulse response.

8. Full Bandwidth, 20 dB amplifier positions selected.

9. Measured with 20 GHz oscilloscope.

10. Peak-to-Peak ISI contribution simulated from mode-locked laser response using a 2.5 Gb/s PRBS 2

pattern with the Infiniband filter and 20 dB amplifier positions selected.

11. Per amplifier at 100 MHz.

1,6,7,8

1,6,7,8

.........................................100 kHz – 4 GHz

................................................±0.5 dB

1,6,7,9

...........................................90 ps

1,10

......................................2.6% of UI

11

............................8.5 ±1.0 dB

1

.................................................20 dB

7

-1

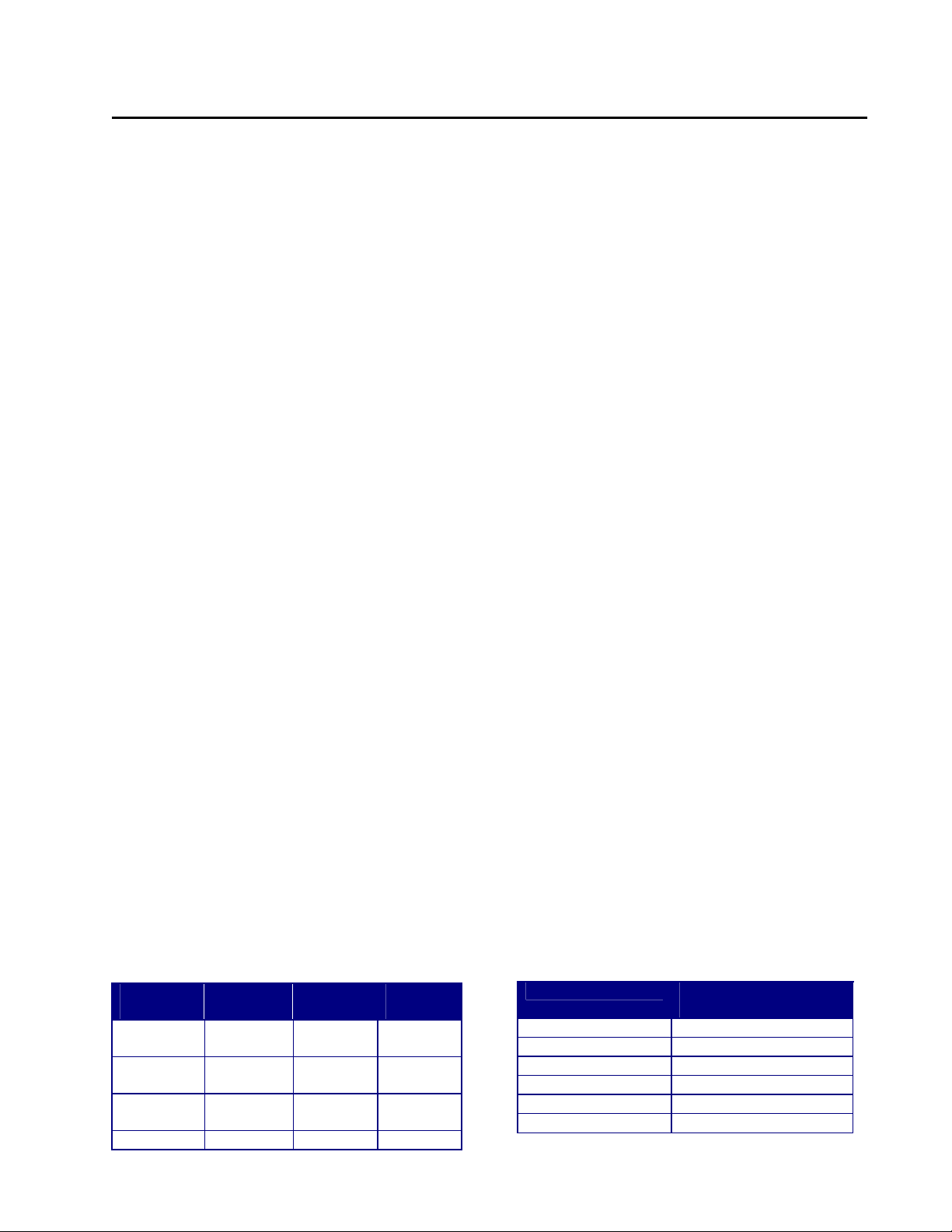

Low Pass Filter Response Characteristics

The OE-2 includes four switchable filters. The following filter options are available. A fifth path provides full-bandwidth

operation (no filter).

Model

OE-2-1

Fibre

Channel

2X Fibre

Channel

Gigabit

Ethernet

Infiniband XAUI XAUI OC-48

Model

OE-2-2

2X Fibre

Channel

Gigabit

Ethernet

Infiniband Gigabit

Model

OE-2-3

Fibre

Channel

2X Fibre

Channel

Ethernet

Model

OE-2-4

Fibre

Channel

2X Fibre

Channel

Gigabit

Ethernet

Standard Design Cut-off

Frequency

Fibre Channel 797 MHz

2X Fibre Channel 1.594 GHz

Gigabit Ethernet 937.5 MHz

Infiniband 1.875 GHz

XAUI 2.344 GHz

SONET OC-48 1.866 GHz

APPENDIX A | Specifications |

19

Calculated Measurement Accuracy

Extinction Ratio12..................................................±1 dB

Optical Modulation Amplitude

Notes:

12. Using an SIA-3000, M3.2 Channel Card, VISI software with

a 100-125 MHz square wave, 850 nm, average optical power

level of –5 dBm (per Fibre Channel or Gigabit Ethernet

standards)

13. Percent of reading.

Miscellaneous Characteristics

Calibration Interval................................................1 year

AC Mains Voltage ..................................... 90-264 VAC

AC Mains Frequency........................................50/60 Hz

12,13

....................... ±12%

Notes:

A. Typical measurements provide non-

warranted information about system

performance or capabilities.

B. Wavecrest continually engages in research

related to product improvement. New

material, production methods, and design

refinements are introduced into existing

products without notice as a routine

expression of that philosophy. For this

reason, the OE-2 may differ in some respect

to the specifications stated in this document.

C. The OE-2 will comply with these

specifications after a 30-minute warm-up

period.

1

0

-1

-2

-3

-4

-5

-6

Responsivity (dB)

-7

-8

-9

700 800 900 1000 1100 1200 1300 1400 1500 1600 1700

Wavelength (nm)

Typical OE-2 Responsivity versus Wavelength.

1.2

1.0

0.8

0.6

0.4

0.2

0.0

-0.2

0 200 400 600 800 1000 1200 1400

Picoseconds

OE-2 Impulse Response to a 650 femtosecond mode-locked

laser impulse (full bandwidth, 20 dB amplifier selected).

0

-1

-2

-3

-4

| APPENDIX A | Specifications

20

-5

-6

012345

OE-2 Frequency Response (calculated from the FFT of a

650 femtosecond mode-locked laser impulse; full bandwidth,

20 dB amplifier selected).

Interface Requirements

The optical inputs are high return loss FC/UPC connectors. Either single mode or multi-mode fibers can

be accepted.

The electrical outputs are SMA connectors.

The OE-2 includes an IEEE-488 interface. The connector and address selection switch are located on the

rear panel of the instrument.

Power Requirements

The OE-2 operates on 100-120 VAC & 200-240 VAC (±10%), 47-63Hz. The OE-2 is rated for 275 Watts.

Fuses: (2) two 2AT/250V, 5 x 20 mm.

Power supply is auto ranging.

The AC input appliance coupler or separable plug on the power cord is the disconnect device. For safe

operation, the OE-2 should be installed to allow easy operator access to the disconnect device.

Communications Requirements

The OE-2 uses English-language IEEE-488.2 commands. The command list is shown in Appendix III.

Environmental Requirements

Temperature Range

Operating .......................... +15°C to +35°C

Storage.............................. -40°C to + 55°C

Humidity.................................. 0-85% RH, non-condensing

Ventilation - A minimum of two inches of unobstructed airflow must be maintained on each side and rear

panel of the instrument (air inlet and exhaust openings) to provide adequate ventilation for the

OE-2. To maintain the highest accuracy, the OE-2 air intake should not be near sources that

would cause ambient temperature fluctuations. Temperature fluctuations greater than 5°C will

require that OE-2 be recalibrated.

Elevation (Altitude) .................to 6500 feet (2000 meters)

Indoor Use Only ......................The OE-2 is intended for indoor use only.

Installation Category................ CAT II

Pollution Degree ...................... 2 per IEC 664

Product Life Requirements

Product lifetime is five years minimum with recommended factory calibration intervals of one year.

APPENDIX A | Specifications |

21

Maintaining Proper Instrument Grounding

Both 120VAC and 230VAC power sources require an earth ground at the power connection. Failure to provide this

safety ground could result in improper measurements and/or electrical shock danger to the operator.

Only qualified service personnel should perform maintenance procedures on the OE-2. When maintenance is

performed, NO protective earth ground connections should be removed.

NOTE: Where this product is installed at areas requiring main power connections other than the three-pronged

North American power plug, the main power cord must be replaced with the cord and plug appropriate to the

location. The main supply cord must be rated to meet or exceed the current rating on the IEC connector (10 amps)

and must meet the requirements of H05VV power cords in IEC 227 or IEC 245. If the appropriate power cord

cannot be obtained locally, contact the

WAVECREST

Corporation factory and one will be provided.

Fuse Replacement

The IEC plug-in at the back of the OE-2 provides the input connection for the AC power cord. A small compartment

on the IEC plug houses two Wickman 2AT/250V fuses (5x20mm). To gain access to the fuses, remove the power to

the OE-2 and disconnect the power cord. With a small screwdriver, pry open the fuse compartment on the IEC plug.

Remove the fuses and install the new fuses prior to closing the compartment and reinstalling the power cord.

Cleaning Instructions

Periodic cleaning of the OE-2 cabinet may be required. Use a clean, lint-free cloth to dust outer surfaces after

electrical power has been removed. If needed, dampen cloth with light amounts of water or alcohol.

Intended Use Of Equipment

The OE-2 should be used only for its intended purpose as outlined in this manual. To avoid possible injury, the OE2 should not be operated with the top cover or other panels removed. Refer installation and maintenance to qualified

service personnel.

To avoid explosion, do not operate the OE-2 in or near an atmosphere of explosive gases

| APPENDIX A | Specifications

22

APPENDIX B -

The following GPIB commands are supported in the OE-2.

GPIB Commands

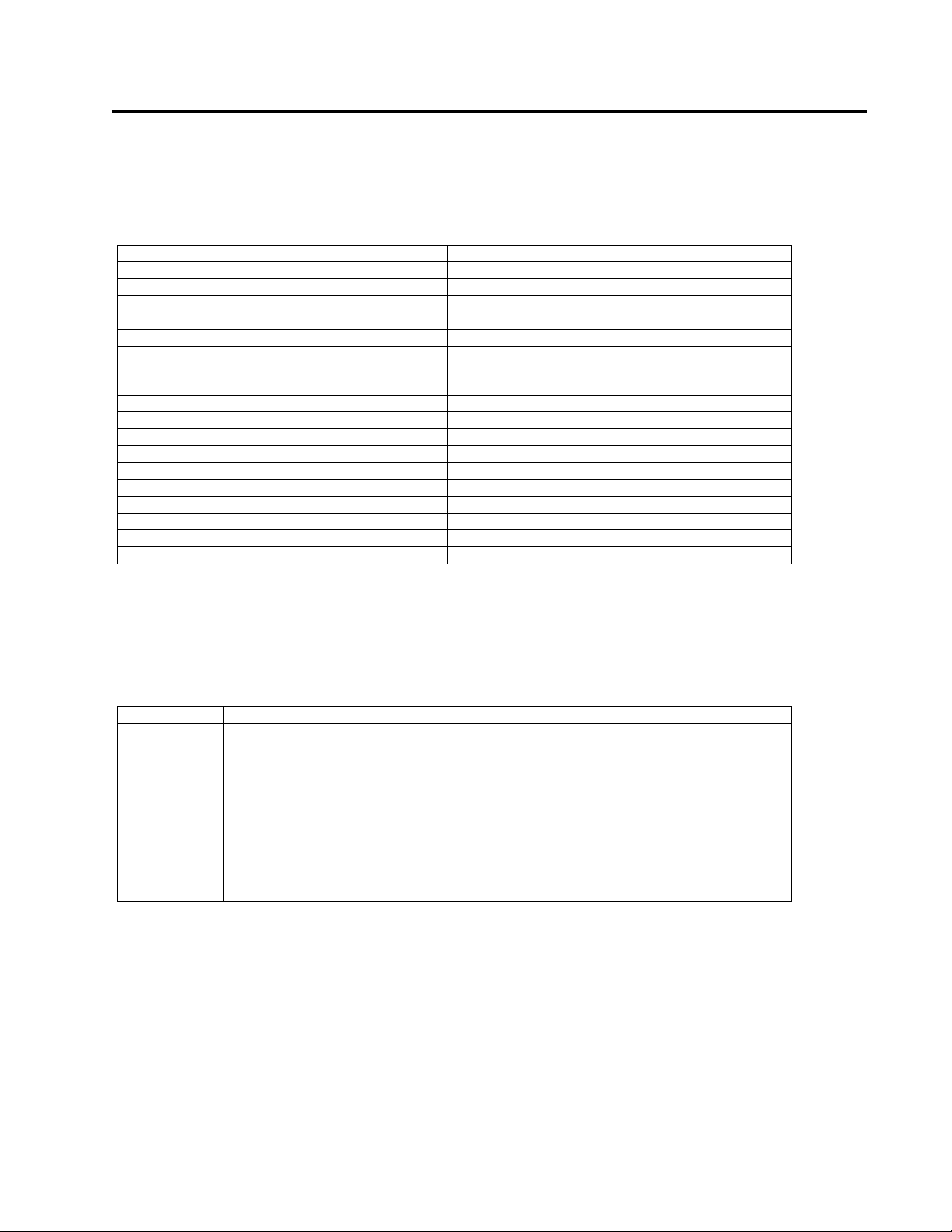

Table B1. IEEE.2 Common Commands

Command Definition

*CLS Clear Status

*ESR? Event Status Register Query

*LRN? NS

*OPC? Operation Complete Query

*RCL *rcl <0/1> Recall settings from register 0 or register 1

*SAV *sav <0/1> Save current Filter/Amplifier/Wavelength

settings to register 0 or 1. Register 0 is the Power-up

state of the OE-2.

*STB? Status Byte Query

*TST? NS

*ESE NS

*IDN? Identification Query

*OPC Operation Complete Command

*OPT? NS

*RST Reset

*SRE NS

*TRG NS

*WAI NS

Note: NS = Not Supported

Table B2.

WAVECREST

Common Commands

Command Command Syntax Query Syntax

SYSTEM

HEADer

LONGform

VERsion

:SYSTEM

:HEADER<ON|OFF|1|0>

:LONGFORM<ON|OFF|1|0>

:SYSTEM

:HEADER ?

:LONGFORM ?

:VERSION ?

WAVECREST,

MODEL#,

NN.NN

APPENDIX B | GPIB Commands |

23

Table B3. OE-2 Specific Commands

Command Command Syntax Query Syntax

CHANnel (Root

command)

INStalled

FILTer

AMPLifier

WAVElength

ACResponse

AVEPwr

TYPE

1

A floating-point number is given in scientific notation format as X.XXXXXXE-YY or X.XXXXXXE+YY.

:CHANnel <string>

Valid strings:

1 - Channel1,

2 – Channel2

No write command.

:FILTer <string>

Valid strings:

:AMPLifier <string>

Valid strings:

30DB - 30 dB Gain

40DB - 40 dB Gain

:WAVElength<Float

Floating point string representing a wavelength from

770E-9 to

1650E-9 m.

:ACResponse<Float>

Written only during calibration.

(units: W/V)

No write command.

No write command.

FC - Fibre Channel

FC2X - Fibre Channel 2X

GBE - Gigabit Ethernet

IB - Infiniband

XAUI - XAUI

OC48 - SONET OC48

FBW - Full Bandwidth

10DB - 10 dB Gain

20DB - 20 dB Gain

1

>

| APPENDIX B | GPIB Commands

24

CHANnel ?

:INStalled ?

Return value: comma delimited string as follows:

<TYPE, FILT, AMPL,WAVE,MODEL,VERSION>

TYPE, FILT,AMPL,WAVE are defined later in the table.

MODEL refers to the # of channels, SING or DUAL.

VERSION refers to the hardware release (6 charactrers,

BXX.XX for Beta and RXX.XX for production.

:FILTer ?

Return the current filter setting string.

:AMPLifier ?

Return the current amplifier setting string.

:WAVElength ?

Returns a string representing the floating point value of

the wavelength.

:ACResponse ?

Returns a string representing the AC Response for the

current filter, amplifier and wavelength settings.

:AVEPwr ?

Returns a string representing the floating point value of

the current average optical power into the OE-2. The

measurement units are selected by the ADF System

subcommand and should be set to watts unless a

calibration is underway.

:TYPE

Return value :

delimited ASCII String representing the type of RFM

installed

FC/FC2X/GBE/IB/FBW

FC2X/GBE/IB/XAUI/FBW

FC/FC2X/GBE/XAUI/FBW

FC/FC2X/GBE/OC48/FBW

Table B3. OE-2 Specific Commands cont.

Command Command Syntax Query Syntax

NULLoffset

System (root

command)

ADFormat

CALibrate (root

command)

CALType

:NULLoffset<Float>

Used to calibrate the OE-2 when no optical power is

present. When using a short calibration no string is

required. When using a long cal the string represents the

null offset in bits.

:ADF <string>

Valid Strings:

BITS - A/D Counts

VOLTS - A/D Output Voltage

AMPS - O/E Detector Current

WATTS - OE-2 Optical Input Power

:

CALType <string>

Valid strings:

0 – Short cal

1 – Long cal

SHORT – short cal

LONG – long cal

:NULLoffset ?

Return value: Floating point value representing the last

stored null offset of the OE-2. The measurement units

are selected by the ADF System subcommand and should

be set to watts unless a calibration is underway. See

example calibration in the CALIBRATE root command

description.

:ADF ?

return a string representing the current format.

:CALType ?

return a string representing the current calibration

type.

OE-2 Specific Commands Description

CHANnel (CHANx): Root command that specifies the channel to which a subcommand applies. On a Dual Channel OE-2,

‘x’ may take on values of ‘1’ or ‘2’. On a Single Channel OE-2, ‘x’ may only take on a value of ‘1’.

ACResponse: Channel subcommand that provides a query response only. The AC response of the OE-2 Channel is

determined from the current wavelength, filter, and amplifier settings. This constant, in units of W/V, is used to

convert the electrical output of the OE-2 in volts to optical input power. When combined with the average

power reading the level and magnitude of the input optical signal can be determined. The AC Response is valid

at 100MHz. Example read: ‘:CHAN1:ACR?’.

AMPLifier: Channel subcommand that sets the amplifier for the specified channel or reads the current setting.

Valid amplifier settings are ‘10DB’, ‘20DB’, ‘30DB’, and ‘40DB’. Example write: ‘CHAN1:AMPL 20DB’.

AVEPwr: Channel subcommand that provides a query response only. The average power of the input optical signal

is returned in units of watts. Example read: ‘:CHAN1:AVEP?’. The measurement is returned in the units

specified by the ADF System subcommand. To obtain the average power of the input optical signal the selected

units should be WATTS.

FILTer: Channel subcommand that sets the filter for the specified channel or reads the current setting. Valid filter

settings depend upon the type of channel that is installed in the OE-2. Valid settings can be determined from

the TYPE field of the INStalled query. Example read: ‘:CHAN1:FILT?’.

APPENDIX B | GPIB Commands |

25

INStalled: Channel subcommand that provides a query response only. When queried the command returns a comma

delimited field with information pertaining to the specified channel. The fields returned are channel type (or

option), current filter setting, current amplifier setting, current wavelength setting, OE-2 Channel Status

(Single/Dual), and OE-2 release (B01.00 – Beta 1.00, R01.00 Production 1.00). Example read: ‘:CHAN1:INS?’.

NULLoffset: Channel subcommand that sets or reads the null offset of the specified channel. The null offset value

is computed from a calibration that is performed when the specified channel’s optical input is dark. The null

offset is then used to compensate the power monitor for this ‘null’ condition. When performing a NULL Offset

calibration the selected units must be BITS. The null offset value should be cleared (set to 0) before the

calibration is started. See the calibration example under the CALIBRATE root command.

TYPE: Channel subcommand that provides a query response only. The type (or option) of the OE-2 channel is

returned in a ‘/’ delimited field. The return string contains the filter positions that are available for the specified

channel. Valid strings are given in the chart above. Example read: ‘:CHAN1:TYPE?’.

WAVElength: Channel subcommand that set the wavelength for the specified channel or reads the current setting.

The wavelength setting determines the calibration constant that is used in the average power measurement. Any

wavelength setting that does not match the input optical wavelength will result in an incorrect average power

reading. Wavelength units are meters. Example write: ‘:CHAN1:WAVE 1550E-9’.

SYSTEM: Root command for system wide commands.

ADFormat: System subcommand that sets or reads the current A/D format. When set to BITS the AVEP command

returns the counts from the A/D converter in the power monitor circuit. VOLTS specifies the voltage at the

input of the A/D converter. AMPS specifies the current flowing into the O/E receiver. WATTS specifies the

OE-2 input average optical power. The BITS setting is used for NULL calibration. The VOLTS/AMPS settings

are used in the factory. The WATTS setting is the default.

CALIBRATE: Root command for calibration commands.

CALType: Calibrate subcommand that sets or reads the current calibration type. A short calibration does not

require any external readings but may be less accurate than a long cal. During a long cal the ADFormat is set to

BITS and readings are taken with the AVEPwr command. The readings can be averaged over several seconds

to improve the accuracy of the calibration. The averaged value (in BITS) is then written using the NULLoffset

command. Example Cal sequence:

Short Cal:

:CAL:CALT SHORT

:CHAN1:NULL

Long Cal:

:CAL:CALT LONG (set long cal mode)

:SYSTEM:ADFORMAT BITS (set format to BITS)

:CHAN1:NULL 0 (Zero out the current null)

:CHAN1:AVEP? (Read this multiple times over a period of several seconds and average the results)

:CHAN1:NULL <AVERAGED DATA> (write the averaged data)

:SYSTEM:ADFORMAT WATTS (return format to WATTS)

| APPENDIX B | GPIB Commands

26

APPENDIX C –

Preprogrammed Measurement Limits

The following Charts show the preprogrammed measurement limits for each OE-2 model. See Section 3 for more

information on the measurement limit presets.

Table C1. OE-2 Option 1

Protocol

“User Defined”

Defaults “Filter 1” 850 nm dBm (1) OMA uW (1) (1)

Gigabit Ethernet

1000BASE-SX

Gigabit Ethernet

1000BASE-LX

Single Mode GE 1300 nm dBm -11.0 ER dB 9 260

Gigabit Ethernet

1000BASE-LX

Multimode

Fibre Channel

100-SM-LC-L FC 1300 nm dBm -9.5 OMA mW (4) 320

Fibre Channel

200-SM-LC-L FC2X 1300 nm dBm -11.7 OMA mW (4) 160

Fibre Channel

100-M5-SN-I

Fibre Channel

100-M6-SN-I FC 850 nm dBm -10 OMA mW 0.156 300

Fibre Channel

200-M5-SN-I

Fibre Channel

200-M6-SN-I FC2X 850 nm dBm -10 OMA mW 0.196 150

Infiniband

1X-SX IB 850 nm dBm (2) OMA mW 0.196 150

Infiniband

1X-LX IB 1300 nm dBm (2) OMA mW 0.186 150

Infiniband

4X-SX

Infiniband

12X-SX

Filter Wavelength

GE 850 nm dBm -9.5 ER dB 9

GE 1300 nm dBm -11.5 ER dB 9 260

FC 850 nm dBm -10 OMA mW 0.156 300

FC2X 850 nm dBm -10 OMA mW 0.196 150

IB 850 nm dBm (2) OMA mW 0.150 150

IB 850 nm dBm (2) OMA mW 0.150 150

Power Units

Average Power

Limit

Modulation

Measure

Modulation

Units

Modulation

Limit

Rise/Fall times

Limits (in ps)

260 rise

210 fall

(1) Leave blank for user setting

(2) Not specified or multiple specs in the standard. The user must establish the limit.

(3) The Fibre Channel standard offers a tradeoff between spectral center wavelength, RMS spectral width, and

minimum OMA. The user must establish the limit.

APPENDIX C | Preprogrammed Measurement Limits |

27

Table C1. OE-2 Option 2

Protocol

“User Defined”

Defaults

Gigabit Ethernet

1000BASE-SX GE 850 nm dBm -9.5 ER dB 9

Gigabit Ethernet

1000BASE-LX

Single Mode GE 1300 nm dBm -11.0 ER dB 9 260

Gigabit Ethernet

1000BASE-LX

Multimode

Fibre Channel

200-SM-LC-L

Fibre Channel

200-M5-SN-I FC2X 850 nm dBm -10 OMA mW 0.196 150

Fibre Channel

200-M6-SN-I

Infiniband

1X-SX

Infiniband

1X-LX

Infiniband

4X-SX IB 850 nm dBm (2) OMA mW 0.150 150

Infiniband

12X-SX IB 850 nm dBm (2) OMA mW 0.150 150

Filter Wavelength

“Filter 1” 850 nm dBm (1) OMA uW (1) (1)

GE 1300 nm dBm -11.5 ER dB 9 260

FC2X 1300 nm dBm -11.7 OMA mW (4) 160

FC2X 850 nm dBm -10 OMA mW 0.196 150

IB 850 nm dBm (2) OMA mW 0.196 150

IB 1300 nm dBm (2) OMA mW 0.186 150

Power

Units

Average Power

Limit

Modulation

Measure

Modulation

Units

Modulation

LImit

Rise/Fall times

Limits (in ps)

260 rise

210 fall

(1) Leave blank for user setting

(2) Not specified or multiple specs in the standard—leave blank

(3) Future product—reserved. Do not show in OE-2 software, available with SIA-3000

(4) The Fibre Channel standard offers a tradeoff between spectral center wavelength, RMS spectral width, and

minimum OMA. Leave OMA limit blank for user to input a limit.

| APPENDIX C | Preprogrammed Measurement Limits

28

Table C1. OE-2 Option 3

Protocol

“User Defined”

Defaults

Gigabit Ethernet

1000BASE-SX GE 850 nm dBm -9.5 ER dB 9

Gigabit Ethernet

1000BASE-LX

Single Mode GE 1300 nm dBm -11.0 ER dB 9 260

Gigabit Ethernet

1000BASE-LX

Multimode

Fibre Channel

100-SM-LC-L

Fibre Channel

200-SM-LC-L

Fibre Channel

100-M5-SN-I FC 850 nm dBm -10 OMA mW 0.156 300

Fibre Channel

100-M6-SN-I

Fibre Channel

200-M5-SN-I FC2X 850 nm dBm -10 OMA mW 0.196 150

Fibre Channel

200-M6-SN-I

Filter Wavelength

“Filter 1” 850 nm dBm (1) OMA uW (1) (1)

GE 1300 nm dBm -11.5 ER dB 9 260

FC 1300 nm dBm -9.5 OMA mW (4) 320

FC2X 1300 nm dBm -11.7 OMA mW (4) 160

FC 850 nm dBm -10 OMA mW 0.156 300

FC2X 850 nm dBm -10 OMA mW 0.196 150

Power

Units

Average Power

Limit

Modulation

Measure

Modulation

Units

Modulation

Limit

Rise/Fall times

Limits (in ps)

260 rise

210 fall

(1) Leave blank for user setting

(2) Not specified or multiple specs in the standard—leave blank

(3) Future product—reserved. Do not show in OE-2 software, available with SIA-3000

(4) The Fibre Channel standard offers a tradeoff between spectral center wavelength, RMS spectral width, and

minimum OMA. Leave OMA limit blank for user to input a limit.

APPENDIX C | Preprogrammed Measurement Limits |

29

Table C1. OE-2 Option 4

Power

Protocol

“User Defined”

Defaults

Gigabit Ethernet

1000BASE-SX GE 850 nm dBm -9.5 ER dB 9

Gigabit Ethernet

1000BASE-LX

Single Mode GE 1300 nm dBm -11.0 ER dB 9 260

Gigabit Ethernet

1000BASE-LX

Multimode

Fibre Channel

100-SM-LC-L

Fibre Channel

200-SM-LC-L

Fibre Channel

100-M5-SN-I FC 850 nm dBm -10 OMA mW 0.156 300

Fibre Channel

100-M6-SN-I

Fibre Channel

200-M5-SN-I FC2X 850 nm dBm -10 OMA mW 0.196 150

Fibre Channel

200-M6-SN-I

Filter Wavelength

“Filter 1” 850 nm dBm (1) OMA uW (1) (1)

GE 1300 nm dBm -11.5 ER dB 9 260

FC 1300 nm dBm -9.5 OMA mW (4) 320

FC2X 1300 nm dBm -11.7 OMA mW (4) 160

FC 850 nm dBm -10 OMA mW 0.156 300

FC2X 850 nm dBm -10 OMA mW 0.196 150

Units

Average Power

Limit

Modulation

Measure

Modulation

Units

Modulation

Limit

Rise/Fall times

(1) Leave blank for user setting

(2) Not specified or multiple specs in the standard—leave blank

(3) Future product—reserved. Do not show in OE-2 software, available with SIA-3000

(4) The Fibre Channel standard offers a tradeoff between spectral center wavelength, RMS spectral width, and

minimum OMA. Leave OMA limit blank for user to input a limit.

Limits (in ps)

260 rise

210 fall

| APPENDIX C | Preprogrammed Measurement Limits

30

WAVECREST Corporation

World Headquarters: West Coast Office: Europe Office: Japan Office:

7626 Golden Triangle Drive 1735 Technology Drive, Ste. 400 Hansastrasse 136 Otsuka Sentcore Building, 6F

Eden Prairie, MN 55344 San Jose, CA 95110 D-81373 München 3-46-3 Minami-Otsuka

TEL: (952) 831-0030 TEL: (408) 436-9000 TEL: +49 (0)89 32225330 Toshima-Ku, Tokyo

FAX: (952) 831-4474 FAX: (408) 436-9001 FAX: +49 (0)89 32225333 170-0005, Japan

Toll Free: 1-800-733-7128 1-800-821-2272 TEL: +81-03-5960-5770

www.wavecrest.com

FAX: +81-03-5960-5773

200005-01 REV A

Loading...

Loading...