Page 1

WISMO Quik Q2400 series

Q2406 and Q2426

Customer Design Guidelines

Revision: 007

Date: January 2006

Page 2

WISMO Quik Q2400 series

Q2406 and Q2426

Customer Design Guidelines

Reference: WM_PRJ_Q2400_PTS_005

Revision: 007

Date: 18

th

January 2006

Confidential©

This document is the sole and exclusive property of WAVECOM. Not to be distributed or divulged

without prior written agreement.

All rights reserved

Page: 1 / 51

Page 3

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Document Information

Revision Date History of the evolution

001 14 Apr 03 Creation from PTS WM_PRJ_Q2400_PTS_002-002

002 13 Dec 04 Update document legal mentions.

003 26 Feb 05 Add SIM 1.8/3V management

004 26 Feb 05 No content modification; document goes from version 3 to

005 4 March 05 No content modification; document goes from version 4 to

006 25th July

2005

007 18th January

2006

Remove Q2406D and Q2426D of available products list.

Update Power Supply section

Modification of RF connection mode

Modification of figures and mechanical information due to

change of module design

Update of 3V SIM Socket implementation diagram

version 4

version 5

Update §2.1.3.2, §3.2.2, §4 for Lead free introduction(

Update §1.1.1.3 for power supply voltage

Update §1.1.1.4 for module capability

Update §2.2.2.2 for two-wire interface

Update §2.2.1 for serial resistors on digital I/O

Update §2.2.5 for Uart Input level in OFF state and serial

resistors

Update §2.2.6.1 for SIM_VCC capacitor

Update §2.4 for battery type charging and software version

Confidential©

All rights reserved

Page: 2 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 4

WM_PRJ_Q2400_PTS_005 -007

AAA

18th January 2006

Overview

This document gives recommendations for WISMO Quik Q24x6 sub-series

integration in an application and particularly:

• The baseband design rules and typical implementation examples,

• The RF design rules and typical implementation examples

• The mechanical constraints for module fitting,

• The PCB routing recommendations,

• The Test and download recommendations.

It also gives some part references and suppliers.

8 versions of the WISMO Quik Q24x6 sub-series are available:

• Q2406A: E-GSM/GPRS 900/1800 MHz version with 16 Mbits of Flash

memory and 2 Mbits of SRAM (16/2).

• Q2406B: E-GSM/GPRS 900/1800 MHz version with 32 Mbits of Flash

memory and 4 Mbits of SRAM (32/4).

• Q2426A: GSM/GPRS 850/1900 MHz version with 16 Mbits of Flash

memory and 2 Mbits of SRAM (16/2).

• Q2426B: GSM/GPRS 850/1900 MHz version with 32 Mbits of Flash

memory and 4 Mbits of SRAM (32/4).

Please be aware that some of the interfaces provided by the Q24x6 sub-series

can not be handled when using the module driven by AT commands.

TTT

These functions have then to be managed externally i.e using the main

processor of the application.

This symbol is used to indicate the interfaces not available with AT

commands.

Confidential©

All rights reserved

Page: 3 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 5

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Contents

Document Information........................................................................... 2

Overview................................................................................................ 3

Contents................................................................................................ 4

List of Figures........................................................................................ 6

Caution.................................................................................................. 7

Trademarks ........................................................................................... 7

Reference documents ............................................................................ 8

1 General description......................................................................... 9

1.1 General information .................................................................................. 9

1.1.1 Module Features ............................................................................... 9

1.1.2 Module external connection .............................................................. 9

1.1.3 Additional customizing functions .................................................... 10

1.1.4 RoHS compliance............................................................................ 10

2 Baseband Design........................................................................... 11

2.1 Power supply and ground design rules................................................... 11

2.1.1 Electrical constraints ....................................................................... 11

2.1.2 Design Requirements...................................................................... 13

2.1.3 PCB routing constraints .................................................................. 15

2.2 Digital I/O and peripheral implementation ............................................... 16

2.2.1 Electrical information for digital I/O ................................................. 16

2.2.2 LCD interface .................................................................................. 16

2.2.3 SPI Auxiliary bus............................................................................. 17

2.2.4 Keyboard interface .......................................................................... 17

2.2.5 Main serial link (UART1).................................................................. 18

2.2.6 SIM interface .................................................................................. 20

2.3 Analog I/O implementation ..................................................................... 24

2.3.1 Analog to Digital Converter (ADC) inputs ........................................ 24

2.3.2 Audio interface................................................................................ 25

2.4 Battery charging interface....................................................................... 31

2.5 ON / ~OFF .............................................................................................. 32

2.6 BOOT signal (optional) ............................................................................ 33

Confidential©

All rights reserved

Page: 4 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 6

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Reset signal (~RST) ................................................................................ 34

2.7

2.8 External Interrupt (~INTR)....................................................................... 34

2.9 VCC output ............................................................................................. 35

2.10 VCC_RTC (Real Time Clock Supply) ......................................................... 35

2.10.1 General ........................................................................................... 35

2.10.2 Typical implementation................................................................... 36

3 Radio design ................................................................................. 38

3.1 Antenna characteristics .......................................................................... 38

3.2 Antenna implementation ........................................................................ 38

3.2.1 Recommendations .......................................................................... 38

3.2.2 RF connection ................................................................................. 39

4 Mechanical specifications............................................................. 41

5 PCB design.................................................................................... 42

5.1 General design rules ............................................................................... 42

5.2 Design rules for application manufacturing............................................. 42

5.3 Recommendation for lead free soldering........................................... 42

5.4 Power supply.......................................................................................... 42

5.5 Pads design ............................................................................................ 43

6 EMC recommendations ................................................................. 44

7 Firmware upgrade ......................................................................... 45

7.1 Recommendations .................................................................................. 45

7.2 Nominal upgrade procedure.................................................................... 45

7.3 Backup procedure ................................................................................... 46

8 Embedded testability .................................................................... 47

9 Part references and suppliers........................................................ 50

9.1 General Purpose Connector .................................................................... 50

9.2 SIM Card Reader .................................................................................... 50

9.3 Microphone ............................................................................................ 50

9.4 Speaker .................................................................................................. 51

9.5 Antenna Cable ........................................................................................ 51

9.6 GSM antenna ......................................................................................... 51

Confidential©

All rights reserved

Page: 5 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 7

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

List of Figures

Figure 1: Typical power supply voltage in GSM mode ...................................... 11

Figure 2: Maximal voltage ripple (Uripp) vs Frequency in GSM & DCS ............. 13

Figure 3: Burst simulation circuit ...................................................................... 14

Figure 4: Example of SPI Bus typical implementation ....................................... 17

Figure 5: Example of keyboard implementation................................................. 18

Figure 6: Example of RS232 level shifter implementation.................................. 19

Figure 7: Example of Serial Link interface implementation ................................ 19

Figure 8 Example of 3V SIM Socket implementation ......................................... 21

Figure 9: Example of 1.8 V / 3 V SIM interface implementation......................... 22

Figure 10: Example of 3 V / 5 V SIM interface implementation.......................... 23

Figure 11: Example of ADC input implementation............................................. 24

Figure 12: Microphone decoupling capacitor .................................................... 25

Figure 13: Example of main microphone MIC2 implementation (differential

connection) ................................................................................................. 26

Figure 14: MIC1 inputs (differential connection) ............................................... 27

Figure 15: MIC1 inputs (single-ended connection)............................................ 28

Figure 16: Speaker outputs (differential mode).................................................. 29

Figure 17: Speaker outputs (single-ended connection)...................................... 29

Figure 18: Example of Buzzer implementation .................................................. 30

Figure 19: Example of battery implementation.................................................. 31

Figure 20: BOOT pin connection....................................................................... 33

Figure 21: ∼RST pin connection ........................................................................ 34

Figure 22: RTC Supplied by a capacitor ............................................................ 36

Figure 23: RTC supplied by a super capacitor ................................................... 36

Figure 24: RTC supplied by a battery cell with regulator................................... 37

Figure 25: RTC supplied by a non rechargeable battery .................................... 37

Figure 26: Antenna connection......................................................................... 39

Figure 27: Antenna cable preparation (drawing not to scale) ............................ 40

Figure 28: Maximum bulk occupied on the application board ........................... 41

Figure 29: Pads design ..................................................................................... 43

Figure 30: Example of serial link routing for downloading................................. 47

Figure 31: Download cable schematics (1/2)..................................................... 48

Figure 32: Download cable schematics (2/2)..................................................... 49

Confidential©

All rights reserved

Page: 6 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 8

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Caution

Information furnished herein by Wavecom are accurate and reliable. However no

responsibility is assumed for its use. Please read carefully the safety precautions

for a terminal based on WISMO Quik Q24x6 Series.

General information about Wavecom and its range of products is available at the

following internet address: http://www.wavecom.com

Trademarks

®, WAVECOM®, WISMO®, , Open AT® and certain other trademarks and logos

appearing on this document, are filed or registered trademarks of Wavecom S.A.

in France or in other countries. All other company and/or product names

mentioned may be filed or registered trademarks of their respective owners.

Confidential©

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

All rights reserved

Page: 7 / 51

Page 9

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Reference documents

[1] WISMO Quik Q2406 and q2426 Product Specification

WM_PRJ_Q2400_PTS_002

[2] WISMO Quik Q2400 Series Process Customer Guidelines

WM_PRJ_Q2400_PTS_006

[3] AT Commands Interface Guide

WM_ASW_OAT_UGD_00016

Confidential©

All rights reserved

Page: 8 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 10

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

1 General description

1.1 General information

1.1.1 Module Features

WISMO Quik Q24x6 sub-series is a range of self-contained E-GSM

900/1800 or 850/1900 dual-band modules including the following features:

1.1.1.1 Overall dimensions

• 58.4 x 32.2 x 3.9 mm.

1.1.1.2 Power consumption

• 2 Watts E-GSM 900/GSM 850 radio section running under 3.6 Volts.

• 1 Watt GSM1800/1900 radio section running under 3.6 Volts.

1.1.1.3 Power supply voltage

• Digital section running under 2.8 Volts.

• 3V only SIM interface (for both 1.8 V and 5 V SIM interface with

external adaptation, refer to § 0 and 2.2.6.3 ).

1.1.1.4 Module capability

• Real Time Clock with calendar.

• Battery charge management.

• Echo Cancellation + noise reduction.

• Full GSM or GSM/GPRS software stack.

• Complete shielding.

• Complete interfacing through a 60-pin connector:

o Power supply,

o Serial link,

o Audio,

o SIM card interface,

o Keyboard,

o LCD.

1.1.2 Module external connection

WISMO Quik Q24x6 sub-series has two external connections:

• RF connection pads (to the antenna),

• 60-pin General Purpose Connector (GPC) to Digital, Keyboard, Audio

and Supply.

Confidential©

All rights reserved

Page: 9 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 11

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

1.1.3 Additional customizing functions

WISMO Quik Q24x6 sub-series is designed to fit in very small terminals

and only some custom functions have to be added to make a complete

dual-band solution:

• Keypad and LCD module,

• Earpiece and Microphone,

• Base connector,

• Battery,

• Antenna,

• SIM connector.

1.1.4 RoHS compliance

The WISMO Quik Q24x6 sub-series is now compliant with RoHS

(Restriction of Hazardous Substances in Electrical and Electronic

Equipment) Directive 2002/95/EC which sets limits for the use of certain

restricted hazardous substances. This directive states that “from 1st July

2006, new electrical and electronic equipment put on the market does not

contain lead, mercury, cadmium, hexavalent chromium, polybrominated

biphenyls (PBB) or polybrominated diphenyl ethers (PBDE)”.

Modules which are compliant with this directive are

identified by the RoHS logo on their label.

Confidential©

All rights reserved

Page: 10 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 12

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2 Baseband Design

Note:

Some of the WISMO interface signals are multiplexed in order to limit number of

pins but this architecture implies some limitation.

For example in case of using SPI bus, 2-wire bus can not be used.

Warning:

All external signals must be inactive when the WISMO module is OFF to avoid

any damage when starting and allow WISMO module to start correctly.

2.1 Power supply and ground design rules

2.1.1 Electrical constraints

The power supply is one of the key issues in the design of a GSM terminal. Due

to the bursted emission in GSM / GPRS, the power supply must be able to

deliver high current peaks in a short time and assured that the voltage delivered

to the module remains always under the limits specified in the table “Maximum

voltage ripple (Uripp) vs Frequency in GSM & DCS” hereafter, specially during

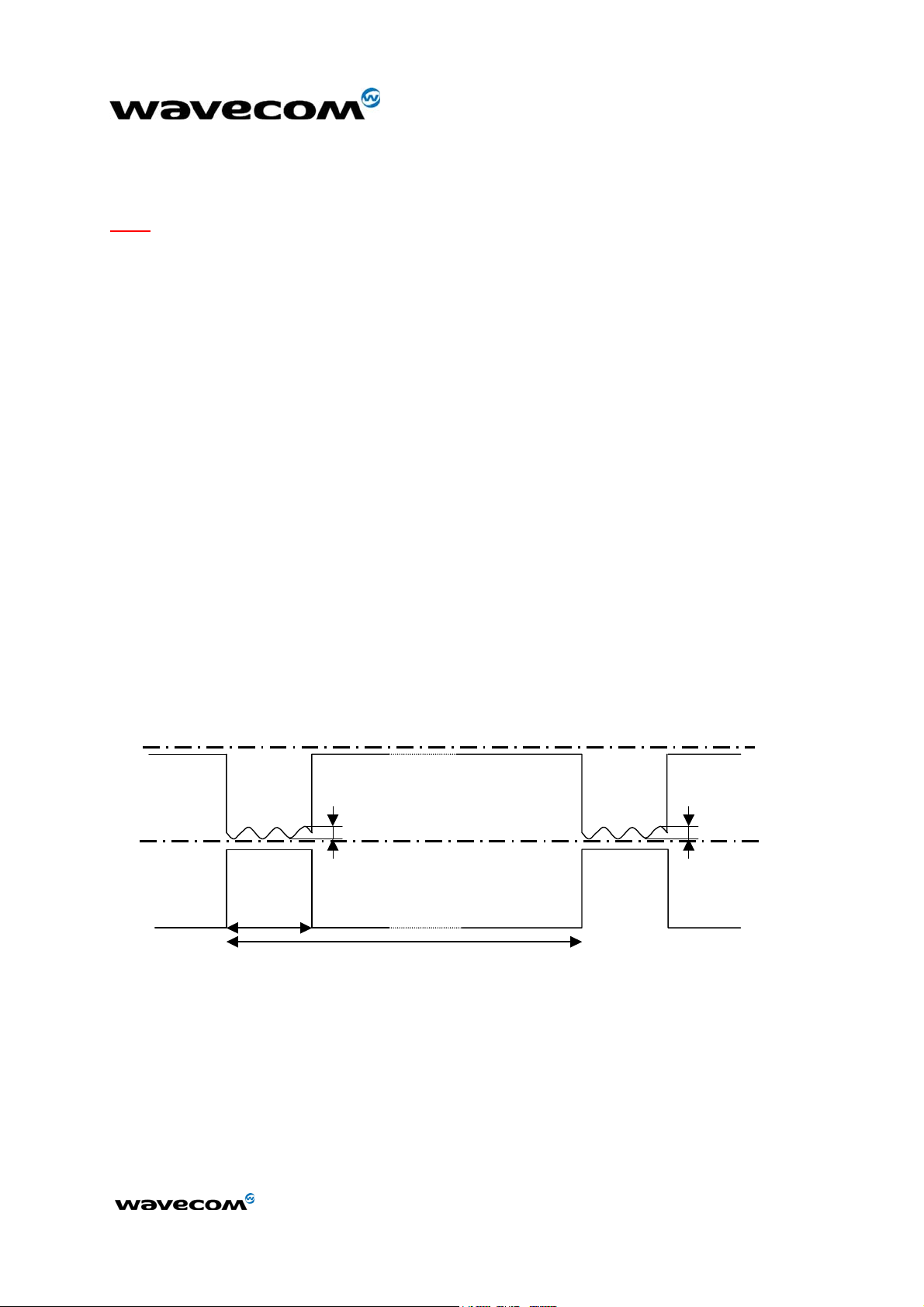

burst while there is a drop of voltage (see Figure 1).

In communication mode, a GSM/GPRS class 2 terminal emits 577 µs radio bursts

every 4.615 ms.

In communication mode, a GPRS class 10 terminal emits 1154 µs radio bursts

every 4.615 ms.

VBATT

IBATT

(1)

or VDD if connected to VBATT

(1)

t = 577 µs

Uripp

T = 4.615 ms

Uripp

Vmax

Vmin

Figure 1: Typical power supply voltage in GSM mode

Two different inputs are provided for the power supply:

• the first one, VBATT is used to supply the RF part,

• the second one, VDD is used to supply the baseband part.

The power supply voltage features given in the table hereafter will guarantee

nominal functioning of the module.

Confidential©

All rights reserved

Page: 11 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 13

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Power Supply Voltage

V

V

MIN

V

NOM

MAX

VBATT 3.3 V (*) 3.6 V 4.5 V (**)

VDD 3.1 V 4.5 V

Table 1: Power supply voltage

(*): This value has to be guaranteed during the burst (with 2.0 A Peak in GSM or

GPRS mode).

(**): max operating Voltage Stationary Wave Ratio (VSWR) 2:1.

When the module is supplied with a battery, the total impedance

(battery+contacts+protections+PCB) should be < 150 mΩ to limit voltage dropout within emission burst.

As the radio power amplifier is directly connected to VBATT, the module is

sensitive to any Alternative Current on lines. When a DC/DC converter is used,

Wavecom recommends to set the converter frequency in such a way that the

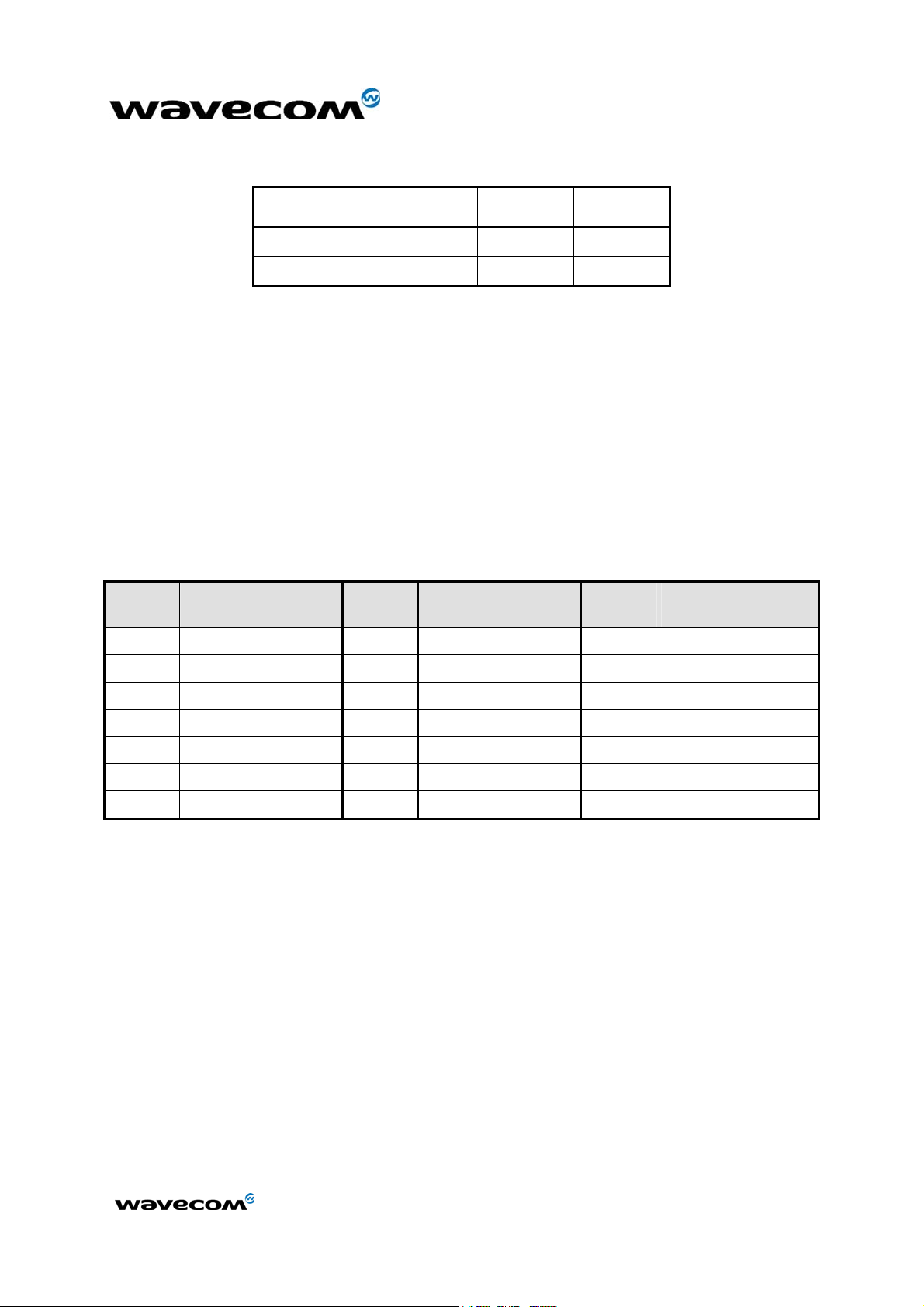

resulting voltage does not exceed the values in following table and Figure 2.

Freq.

(kHz)

U

Max

ripp

(mVpp)

Freq.

(kHz)

U

Max

ripp

(mVpp)

Freq.

(kHz)

U

Max

ripp

(mVpp)

<100 50 800 4 1500 34

200 15.5 900 15.2 1600 33

300 6.8 1000 9.5 1700 37

400 3.9 1100 32 1800 40

500 4 1200 22 >1900 40

600 2 1300 29

700 8.2 1400 30

Table 2: Maximum voltage ripple (Uripp) vs Frequency in GSM & DCS

Confidential©

All rights reserved

Page: 12 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 14

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

50

45

40

35

30

25

20

Uripp (mVpp)

15

10

5

0

200 400 600 800 1000 1200 1400 1600 1800

Input Frequency (kHz)

for f<100kHz U

for f> 1800kHz U

Max = 50mVpp

ripp

Max = 40 mVpp

ripp

Figure 2: Maximal voltage ripple (Uripp) vs Frequency in GSM & DCS

2.1.2 Design Requirements

2.1.2.1 Risk

VBATT supplies directly the RF components with 3.6 V. It is essential to keep a

minimum voltage ripple at this connection in order to avoid any phase error.

Insufficient power supply voltage could dramatically affect some RF

performances:

• TX power of course and modulation spectrum,

• EMC performances (spurious emission),

• Emissions spectrum,

• Phase error and frequency error.

2.1.2.2 General design rules

A careful attention should be paid to:

• Quality of the power supply: capacity to deliver high peak current in a

short time (bursted radio emission), low ripple and low impedance.

• The battery charger line must support 800 mA to comply with the voltage

level required for the product.

• The VBATT lines on the PCB must support peak currents with a voltage

drop below the specified limit.

In order to test the supply tracks, a burst simulation circuit is shown hereafter.

This circuit simulates burst emissions, equivalent to bursts generated when

transmitting at full power.

Confidential©

All rights reserved

Page: 13 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 15

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Warning:

Attention must be paid to the power supply capacity when replacing a

WISMO Quik Q2403 module, on an existing application, by a Q24x6 module as

this last one is more demanding due to GPRS class 10.

Figure 3: Burst simulation circuit

2.1.2.3 Battery for handset integration

In a handset application, the WISMO Quik Q24x6 sub-series may be directly

connected to a Li-Ion battery (3.7 V typical voltage, with internal PCM –

Protection Circuit Module). The internal impedance of the battery must be lower

than 150 mΩ to limit voltage drop-out within emission burst (max. drop 0.3 V @

2W).

Battery internal impedance must take into account:

the internal impedance of the battery cell,

the protection circuit impedance,

the “packaging” impedance (contacts),

the PCB track impedance up to the WISMO module pin.

2.1.2.4 External DC power supply for vertical application

In a vertical application, the WISMO Quik Q24x6 sub-series may be connected to

DC power supply directly or via a DC/DC converter on the mother board. The

internal impedance of the power supply must be lower than 150 mΩ to limit

voltage drop-out within emission burst (max. drop 0.3 V @ 2W).

This impedance must take into account:

the internal impedance of the power supply,

the protection circuit impedance,

the “packaging” impedance (contacts),

the PCB track impedance up to the WISMO module pin.

Confidential©

All rights reserved

Page: 14 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 16

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Linear regulation (recommended) or PWM (Pulse Width Modulation) converter

(usable) are preferred for low noise.

PFM (Power Frequency Modulation) or PSM (Phase Shift Modulation) systems

must be avoided.

2.1.3 PCB routing constraints

2.1.3.1 Power supply routing Constraints

• A ground plane must be provided on the PCB. This plane must not be

parcelled out.

• Attention shall be paid to the power supply tracks and to the ground plane

which supply the module. The tracks and the plane used must support

current peaks.

• Since the maximum peak current can reach 2 A, Wavecom strongly

recommends a large width for the layout of the power supply signal (to

avoid voltage loss between the external power supply and the module

supply. Filtering capacitors, near the module power supply, could also be

added (refer to section 2.1.3.3).

• The routing must be done in such a way that the total impedance line

must be ≤ 10 mΩ @ 217 Hz. This impedance must include the via

impedances.

• Same care shall be taken when routing the ground supply.

• If these design rules are not followed, phase error (peak) and power loss

could occur.

2.1.3.2 Application ground plane and shielding connection

The grounding connection is done through the shielding the four legs have to

be soldered to the ground plane (

soldering in Section 5.3)

.

see Wavecom recommendation for lead free

A ground plane must be available on the application board to provide efficient

connection to the WISMO module shielding.

Best shielding performance will be achieved if the application ground plane is a

complete layer of the application PCB:

• To ensure a good shielding of the module, a complete ground plane layer

must be available, with no trade-off. Connections between other ground

planes shall be done with vias.

• Without this ground plane, external Tx spurious or Rx blockings could

appear.

It is strongly recommended to avoid routing any signals under the module.

Confidential©

All rights reserved

Page: 15 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 17

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.1.3.3 Decoupling of power supply signals

Decoupling capacitors on VBATT and VDD lines are imbedded in the module. So

it should not be necessary to add decoupling capacitors close to the module.

However, in case of EMI/RFI problem, some signals like VBATT and charge line

(CHG_IN) may require some EMI/RFI decoupling: parallel 33 pF capacitor close to

the module or a serial ferrite bead (or both to get better results).

In case a ferrite bead is used, the recommendation given for the power supply

connection must be carefully followed (high current capacity and low

impedance).

2.2 Digital I/O and peripheral implementation

2.2.1 Electrical information for digital I/O

All digital I/O comply with 3Volts CMOS.

To interface the WISMO Quik Q24x6 sub-series digital signals with other logics:

• 3.3 V logic: some serial resistors (more than 11kΩ) can be added on the

lines,

• For higher voltage logics, a resistor bridge or a level shifter IC can be

added.

2.2.2 LCD interface

The WISMO Quik Q24x6 sub-series can be connected to a LCD module driver

through either a SPI bus or a two-wire interface.

2.2.2.1 SPI bus

The SPI bus includes a CLK signal (SPI_CLK), an I/O signal (SPI_IO) and an EN

signal (SPI_EN) complying with SPI bus standard.

Confidential©

All rights reserved

Page: 16 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 18

A

Typical implementation:

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

VCC

VCC

SPI_IO

SPI_CLK

GPO or GPIO

SPI_EN

RST

Figure 4: Example of SPI Bus typical implementation

T

T

2.2.2.2 Two-wire interface

The two-wire interface includes a CLK signal (SCL) and a DATA signal (SDA)

T

complying with a standard 96 kHz interface. The maximum speed transfer is

400 kbits/s.

Note:

The two-wire interface is reserved for future use. A software emulated

version of this interface using GPIOs is available. See “AT Command Interface

Guide” [3] for more information.

2.2.3 SPI Auxiliary bus

A second SPI Chip Enable (called SPI_AUX) can be used to add a SPI peripheral

to the WISMO Quik Q24x6 sub-series.

2.2.4 Keyboard interface

This interface provides 10 connections:

• 5 rows (ROW0 to ROW4),

• 5 columns (COL0 to COL4).

The scanning is a digital one, and the debouncing is done in the WISMO

module. No discrete components like R, C (Resistor, Capacitor) are needed.

Confidential©

All rights reserved

Page: 17 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 19

Typical Implementation

Figure 5: Example of keyboard implementation

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

:

2.2.5 Main serial link (UART1)

A flexible 6-wire serial interface is available complying with V24 protocol

signaling but not with V28 (electrical interface) due to a 2.8 Volts interface.

The signals are:

• TX data input (CT103/TX),

• RX data output (CT104/RX),

• Request To Send input (CT105/RTS),

• Clear To Send output (CT106/CTS),

• Data Terminal Ready input (CT108-2/DTR),

• Data Set Ready output (CT107/DSR).

Note

: the WISMO Quik Q24x6 module is a DCE (Data Communication

Equipment).

The Q24x6 sub-series has been designed to allow a certain flexibility in the use

of the serial interface signals. However, the use of TX, RX, CTS and RTS signals

is mandatory which is not the case for DTR, DSR, DCD and RI signals which can

be left disconnected if not used.

In particular, it is necessary to use RTS and CTS for hardware flow control in

order to avoid data corruption during transmission.

The rising time and falling time of the reception signals (mainly CT103) have to

be less than 200 ns.

The 2 additional signals are Data Carrier Detect (CT109/DCD) and Ring Indicator

(CT125/RI).

Confidential©

All rights reserved

Page: 18 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 20

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

To enable the module to switch OFF correctly, the level shifter outputs (module

side) or host processor outputs must be set at low level (0V) or in high

impedance.

Typical implementation with a terminal

:

DCE DTE

VCC

R

Figure 6: Example of RS232 level shifter implementation

Typical implementation with a microprocessor:

+3V

+3V

+3V

The figure above shows a typical implementation when the WISMO Quik Q24x6

module is connected to a host microprocessor which is 2.8 V tolerant on the

serial port signals.

Host Microprocessor

Figure 7: Example of Serial Link interface implementation

Confidential©

All rights reserved

Page: 19 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 21

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Typical serial resistors values (R) for signals between application and WISMO

Quik Q2400 (mainly CT103/TX) (see Figure 6).

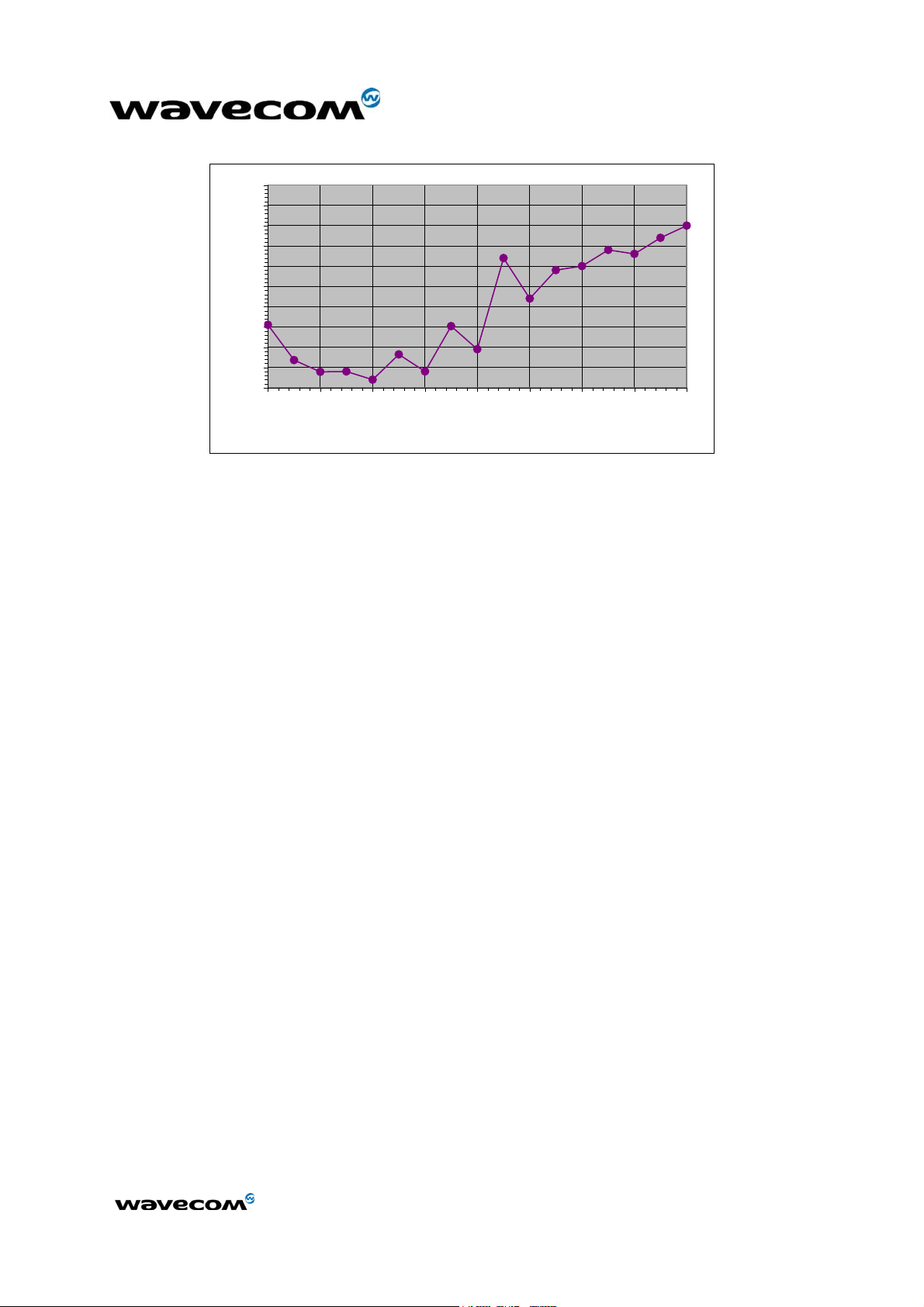

UART baud rate

Host output voltage

<3.1V 3.2V 3.3V

9 600

19 200

38 400

57 600

115 200

R < 62 kΩ 6.8 kΩ< R < 62 kΩ 11 kΩ< R < 62 kΩ

R < 30 kΩ 6.8 kΩ< R < 30 kΩ 11 kΩ< R < 30 kΩ

R < 15 kΩ 6.8 kΩ< R < 15 kΩ 11 kΩ< R < 15 kΩ

R < 10 kΩ 6.8 kΩ< R < 10 kΩ

R < 5.1 kΩ

Not supported Not supported

Not supported

The minimal value is determined to limit the current in the input pin of the

Module and the maximal value is determined by its input capacitance. That

explains why some combinations speed / voltage are incompatible.

2.2.6 SIM interface

2.2.6.1 SIM 3V management

The SIM interface controls a 3 V SIM card only.

Nevertheless, it is possible to manage 1.8V/3V or 3V/5V SIM cards using an

external voltage level shifter controlled by the GPO0 output signal (refer to §

2.2.6.2 and § 2.2.6.3).

It is recommended to add Transient Voltage Suppressor diodes (TVS) on the

signal connected to the SIM socket in order to prevent any Electrostatic

Discharge.

TVS diodes with low capacitance (less than 10 pF) have to be connected on

SIM_CLK and SIM_DATA signals to avoid any disturbance of the rising and

falling edge.

These types of diodes are mandatory for the Full Type Approval. They shall be

placed as close as possible to the SIM socket.

The following references can be used: DALC208SC6 from ST Microelectronics.

Confidential©

All rights reserved

Page: 20 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 22

WM_PRJ_Q2400_PTS_005 -007

A

Typical implementation with SIM detection:

18th January 2006

GND

(1)

GND

(2)

GND

(1) Recommended components: DALC208SC6 (SGS-THOMSON).

(2) Recommended components: ESDA6V1SC6 (ST).

Figure 8 Example of 3V SIM Socket implementation

SIM socket connection:

SIM socket pin description

Signal Pin number Description

VCC 1 SIM_VCC

C

100 nF

SIM_VCC 1

SIM_RST 2

SIM_CLK 3

VCC 4

SIM_DAT

SIM_PRES 8

470pf

GND

5

7

100

kΩ

VCC

RST

CLK

CC4

GND

VPP

I / O

CC8

RST 2 SIM_RST

CLK 3 SIM_CLK

CC4 4 VCC module

GND 5 GROUND

VPP 6 Not connected

I/O 7 SIM_DATA

CC8 8

SIM_PRES with 100 kΩ pull down resistor

The capacitance value on the SIM_VCC must not exceed 100nF.

It is possible to use a capacitor value greater than 100nF but less than 330nF on

SIM_VCC, if an additional capacitor with a minimum value of 27µF (ESR <100

mΩ, X5R ceramic) is placed between VCC output (pin 40) and the GND.

Confidential©

All rights reserved

Page: 21 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 23

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.2.6.2 SIM 1.8 V / 3 V management

It is possible to manage 1.8 V and 3 V SIM cards using an external level shifter

device (see Figure below).

In this case, depending on the type of SIM detected, the module firmware

triggers the GPO0 output signal (pin #26) in order to properly set the external

SIM driver level (1.8 V or 3 V).

As for 3 V SIM, it is recommended to add Transient Voltage Suppressors on the

signals connected to the SIM socket (refer to Figure 9).

Typical implementation:

SIM_CLK

SIM_RST

SIM_DATA

VCC

GPO0

WISMO

SIM_VCC

Q2400

SIM_PRES

Truth

table:

M0

0V

0V

DVCC

DVCC

DVCC

M1

0V

DVCC

0V

0V

DVCC

VCC

2.8 V

LEVEL SHIFTER

1

CIN

2

RIN

3

DATA

4

DDRV

5

DVCC

6

M2

7

M1

8

M0

LTC1555L-1.8

DVCC = 2.8 V

M2

0V or DVCC

0V or DVCC

0V

DVCC

0V or DVCC

Operating Mode

Shutdown (VCC = 0V)

VCC = VIN

VCC = 3 V

VCC = 1.8 V

VCC = 5 V

CLK

RST

I/O

VCC

VIN

C1+

C1-

GND

16

15

14

13

12

11

10

VCC

2.8 V

SIM

1 Ω

to

4.7 Ω

1 µF

9

100 nF

3

2

7

1

6

4

VCC

8

100 kΩ

470 pF

5

Socket

CLK

RST

I/O

VCC = 1.8 V or 3 V

IVCC = 10 mA

2.2 µF

VPP

CC4

CC8

GND

Figure 9: Example of 1.8 V / 3 V SIM interface implementation

Confidential©

All rights reserved

Page: 22 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 24

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.2.6.3 SIM 3 V / 5 V management

It is possible to manage 3 V and 5 V SIM cards using an external level shifter

device (see Figure below).

In this case, depending on the type of SIM detected, the module firmware

triggers the GPO0 output signal (pin #26) in order to properly set the external

SIM driver level (3 V or 5 V).

As for 3 V SIM, it is recommended to add Transient Voltage Suppressors on the

signals connected to the SIM socket (refer to Figure 10).

Typical implementation:

WISMO

Q2400

SIM_CLK

SIM_RST

SIM_DATA

VCC

GPO0

SIM_VCC

SIM_PRES

M0

0V

0V

DVCC

DVCC

DVCC

VCC

2.8 V

Truth

table:

M1

0V

DVCC

0V

0V

DVCC

LEVEL SHIFTER

1

CIN

2

RIN

3

DATA

4

DDRV

5

DVCC

6

M2

7

M1

8

M0

LTC1555L-1.8

DVCC = 2.8 V

M2

0V or DVCC

0V or DVCC

0V

DVCC

0V or DVCC

Operating Mode

Shutdown (VCC = 0V)

VCC = VIN

VCC = 3 V

VCC = 1.8 V

VCC = 5 V

CLK

RST

I/O

VCC

VIN

C1+

C1-

GND

16

15

14

13

12

11

10

VCC

2.8 V

SIM

1 Ω

to

4.7 Ω

1 µF

9

100 nF

3

2

7

1

6

4

VCC

8

100 kΩ

470 pF

5

Socket

CLK

RST

I/O

VCC = 3 V or 5 V

IVCC = 10 mA

2.2 µF

VPP

CC4

CC8

GND

Figure 10: Example of 3 V / 5 V SIM interface implementation

Confidential©

All rights reserved

Page: 23 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 25

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.2.6.4 PCB constraints for SIM interface

• For the SIM interface, length of the track between the WISMO module and

the SIM connector should be as short as possible. Maximum length

recommended is 10 cm.

• ESD protection is mandatory on the SIM lines if access from outside of the

SIM connector is possible.

2.3 Analog I/O implementation

2.3.1 Analog to Digital Converter (ADC) inputs

Two Analog to Digital Converter are available on the WISMO Quik Q24x6 subseries:

The first one (AUXV0) is a general purpose converter,

The second one (BAT_TEMP) is used for battery temperature monitoring.

These converters have a 10-bit resolution, ranging from 0 to 2.8 V.

Typical application:

VCC

NTC

GND

Figure 11: Example of ADC input implementation

AUXV0

General

purpose

ADC input

VCC

GND

NTC

BAT_TEMP

Battery

temperature

monitoring

Confidential©

All rights reserved

Page: 24 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 26

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.3.2 Audio interface

Two different microphone inputs and two different speaker outputs are

supported.

An echo cancellation feature, for hands-free application, is also available. In

some cases, ESD protection must be added on the audio interface lines.

2.3.2.1 Microphone inputs

2.3.2.1.1 General

The MIC2 inputs already include the biasing for an electret microphone allowing

an easy connection to a handset.

The MIC1 inputs do not include an internal bias. MIC1/SPK1 is then appropriate

for a hands-free application or a handset with biasing external to the module.

2.3.2.1.2 Recommended characteristics for the microphones

• 2 V – 0.5 mA.

• 2 kΩ.

• Sensitivity -40 to –50 dB.

• SNR > 50 dB.

• Frequency response compatible with the GSM specifications.

For possible references, see § 9.3.

Microphone must be decoupled by a capacitor CM. This one must be as close as

possible to the microphone. Some microphone manufacturers provide this

capacitor directly soldered on the device

CM

Figure 12: Microphone decoupling capacitor

Confidential©

All rights reserved

Page: 25 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 27

WM_PRJ_Q2400_PTS_005 -007

C2 C4 C3

18th January 2006

2.3.2.1.3 Main Microphone Inputs (MIC2)

The MIC2 inputs are differential ones. They already include the convenient

biasing for an electret microphone (0.5 mA and 2 Volts). This electret

microphone can be directly connected on these inputs.

The impedance of the microphone 2 has to be around 2 kΩ. These inputs are the

standard ones for an handset design while MIC1 inputs can be connected to an

external headset or a hands-free kit.

AC coupling is already embedded in the module.

Typical implementation:

L1

MIC2P

C1

L2

MIC2N

Figure 13: Example of main microphone MIC2 implementation

(differential connection)

C1 = 33 pF to 47 pF

C2 = C3 = C4 = 47 pF to 100 pF

L1 = L2 = 100 nH

C1 has to be the nearest possible to the microphone. Microphone manufacturers

provide this capacitor directly soldered on the microphone.

C2 has to be very close to the WISMO module connector.

L1, L2, C3 and C4 has to be put near the WISMO module connector and can be

removed according to their environment (ground plane, shielding, etc…).

The best way is to plan all the components and to remove those which are not

necessary to filter out the TDMA noise on the audio path.

2.3.2.1.4 Auxiliary Microphone Inputs (MIC1)

The MIC1 inputs are differential and they do not include internal bias. To use

these inputs with an electret microphone, bias has to be generated outside the

WISMO module according to the characteristic of this electret microphone.

These inputs are the standard ones used for an external headset or a hands-free

kit.

AC coupling is already embedded in the module.

Confidential©

All rights reserved

Page: 26 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 28

WM_PRJ_Q2400_PTS_005 -007

A/ Differential connection

Impedance of the microphone input in differential mode:

18th January 2006

• Module ON: R

• Module OFF: R

Typical implementation:

= 10 kΩ +/-10 %

in

>1 MΩ +/-10 %

in

R1

R2

C5

R3

R4

VCC

C3

L1

MIC1P

C1 C2

L2

MIC1N

C4

Figure 14: MIC1 inputs (differential connection)

R1 = R4 = from 100 to 330 Ω.

R2 = R3 = usually between 1 kΩ and 3.3 kΩ as per the microphone

characteristics.

C1 = 33 pF to 47 pF.

C2 = C3 = C4 = 47 F to 100 pF.

C5 = 47 µF.

L1 = L2 = 100 nH.

R1 and R4 are used as a voltage supply filter with C5.

C1 has to be the nearest possible to the microphone. Microphone manufacturers

provide this capacitor directly soldered on the microphone.

C2 has to be very close to the WISMO module connector.

L1, L2, C3 and C4 has to be put near the WISMO module connector and can be

removed according to their environment (ground plane, shielding ...etc). The

best way is to plan all the components and to remove those which are not

necessary to filter out the TDMA noise on the audio path.

Confidential©

All rights reserved

Page: 27 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 29

C2

R1 R2

C5

B/ Single-ended connection

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Typical implementation:

C4

AUDIO

V

C3

L2

C1

L1

Figure 15: MIC1 inputs (single-ended connection)

Note:

VAUDIO must be very “clean” in single-ended connection (for example, VCC

plus filter cell like RC or LC).

R1 = from 100 Ω to 330 Ω.

R2 = usually between 1 kΩ and 3.3 kΩ as per the V

microphone characteristics.

C1 = 10 pF to 33 pF.

C2 = C3 = C5 = 47 pF to 100 pF.

MIC1P

MIC1N

AUDIO voltage level and the

C4 = 47 µF.

L1 = L2 = 100 nH.

R1 is used as a voltage supply filter with C4.

C5 has to be the nearest possible to the microphone. Microphone manufacturers

provide this capacitor directly soldered on the microphone.

C1, C2, C3 have to be very close to the WISMO module connector.

L1, and L2 has to be put near the WISMO module connector and can be

removed according to their environment (ground plane, shielding ...etc). The

best way is to plan all the components and to remove those which are not

necessary to filter out the TDMA noise on the audio path.

Confidential©

All rights reserved

Page: 28 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 30

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.3.2.2 Speaker outputs

2.3.2.2.1 Common speaker output characteristics

The connection can be differential or single-ended but using a differential

connection to reject common mode noise and TDMA noise is strongly

recommended. Moreover in single-ended mode, ½ of the power is lost

.

When using a single-ended connection, be sure to have a very good ground

plane, a very good filtering as well as shielding in order to avoid any disturbance

on the audio path.

Speaker outputs SPK2 are push-pull amplifiers and can be loaded down to 150 Ω

.

and up to 1 nF

These outputs are differential and the output power can be

adjusted by step of 2 dB. The output can be directly connected to a speaker.

Differential Connection:

Impedance of the speaker amplifier output in differential mode : R ≤ 1Ω +/-10 %

SPKxP

SPKxN

Figure 16: Speaker outputs (differential mode)

Single-ended Connection:

Typical implementation:

C1

SPKxP

Speaker

ZHP

C3

33 to

100 pF

+

C2

R1

SPKxN

+

Figure 17: Speaker outputs (single-ended connection)

C1 = from 4.7 µF to 47 µF as per the speaker characteristics and the output

power.

C1=C2; R1= Speaker Impedance.

Nevertheless in a 32 Ω speaker case, you should use a cheaper and smaller

solution : R1 = 82 Ω et C2 = 4.7 µF (ceramic).

Confidential©

All rights reserved

Page: 29 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 31

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Recommended characteristics for the speaker:

• Type: 10 mW, electro-magnetic.

• Impedance: 32 to 150 Ω.

• Sensitivity: 110 dB SPL min. (0 dB = 20 µPa).

• Frequency response compatible with the GSM specifications.

For possible references, see chapter § 9.4.

2.3.2.3 Buzzer Output

The buzzer output (BUZ) is a digital one. A buzzer can be directly connected

between this output and VBATT. The maximum current is 80 mA (PEAK).

A diode against transient peak voltage must be connected as described below.

Typical implementation:

R1

D1

C1

VBATT

BUZ

Figure 18: Example of Buzzer implementation

R1 must be chosen in order to limit the current at I

max (recommended

PEAK

values 10 Ω to 50 Ω).

C1 = 0 to 100 nF (depending on the buzzer type).

Recommended characteristics for the buzzer:

• Type: electro-magnetic.

• Impedance: 7 to 30 Ω.

• Sensitivity: 90 dB SPL min @ 10 cm.

2.3.2.4 Routing constraints

To get better acoustic performances, basic recommendations are the following:

• The SPKxx lines must be routed in parallel, without any wire in between.

• The MICxx lines must be routed in parallel, without any wire in between.

• All the filtering components (RLC) must be placed as close as possible to

the associated MICxx and SPKxx pins.

Confidential©

All rights reserved

Page: 30 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 32

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.4 Battery charging interface

The WISMO Quik Q24x6 sub-series module has a battery charging interface.

The table below summarizes the battery types supported according to the

software version:

Battery types supported versus software version

Battery type OS version

Before X55 X55 and after

Ni-Cd Supported Supported

Ni-Mh Supported Supported

Li-Ion Not Supported Supported

Warning:

Charging a Li-Ion battery with an OS version prior to X55 may cause damage

to the battery.

This circuit uses an interface which consists of a current source inputs (CHG_IN)

where the constant current has to flow in order to charge the battery.

This current value depends on the battery capacity. It is recommended to

provide a current equal to the value of the capacity plus 50 mA. For a 550 mA

battery the current will be 600 mA. The maximum current is 800 mA.

The WISMO Quik Q24x6 sub-series module monitors the battery voltage to

detect the end of the charge.

It also monitors the temperature of the battery (for security reasons) through the

BAT_TEMP pin which has to be connected to a temperature sensor inside the

battery pack (an NTC resistor for instance).

Typical Implementation:

Internal Battery

Impedance

Safety

Circuit

BATTERY

+VBATT

VCC

R1

BAT_TEMP

NTC

GND

C1

Figure 19: Example of battery implementation

Confidential©

All rights reserved

Page: 31 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 33

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

How to choose R1 and C1:

How to choose R1:

R1 has to be chosen to have a full range of BAT_TEMP (from 0 V to 2.8 V)

when the CTN value changes from the minimum to the maximum

temperature.

How to choose C1:

C1 has to be chosen to have a RC filter with a time constant lower than

2 ms.

Calculation examples:

CTN(+25 °C) = 47 kΩ

CTN(+55 °C) = 10 kΩ

CTN(-10 °C) = 300 kΩ

CTN(-10 °C) x VCC = ( CTN(-10 °C) + R1 ) x BAT_TEMP (full range)

R1= 47 kΩ BAT_TEMP(-20 °C) = 2.42 V

BAT_TEMP(+55 °C) = 0.49 V

R(-20 °C) = R1//CTN(-10 °C) = 40 kΩ

R(+55 °C) = 8 kΩ

With C= 10 nF:

RC(-20 °C) = 400 µs

RC(+55 °C) = 80 µs

2.5 ON / ~OFF

This input is used to switch ON or OFF the WISMO module. A high level signal

has to be provided on the pin ON/~OFF to switch ON the module. The level of

the voltage of this signal has to be maintained between 2.4 V and VDD during a

minimum of 1 s. This signal can be left at high level until switch OFF.

Confidential©

All rights reserved

Page: 32 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 34

WM_PRJ_Q2400_PTS_005 -007

K

Ω

Ω

18th January 2006

2.6 BOOT signal (optional)

This input can be used to download a software in the Flash memory of the

WISMO module.

The internal boot procedure is started when this pin is low during the reset of

the module.

In normal mode this pin has to be left open.

In Internal boot mode, low level has to be set through a 1 kΩ resistor.

If used, this input has to be driven by an open collector or an open drain output.

Switch BOOT

1

1 k

BOOT : Pin 12

BOOT: Pin 12

Figure 20: BOOT pin connection

• If Switch BOOT = 1, Boot pin 12 = 0, for download mode

• If Switch BOOT = 0, Boot pin 12 = 1, for normal mode

Confidential©

All rights reserved

Page: 33 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 35

WM_PRJ_Q2400_PTS_005 -007

∼

18th January 2006

2.7 Reset signal (~RST)

This signal is used to force a reset procedure by providing low level during at

least 500 µs.

This signal has to be considered as an emergency reset only.

A reset procedure is already driven by an internal hardware during the power-up

sequence.

This signal can also be used to provide a reset to an external device. It then

behaves as an output.

If no external reset is necessary this input can be left open. If used (emergency

reset), it has to be driven by an open collector or an open drain output.

BOOT : Pin 12

RST: Pin 14

Switch RESET

Figure 21: ∼RST pin connection

• If Switch RESET = 1, ∼RST pin 14 = 0, for Module Reset

• If Switch RESET = 0, ∼RST pin 14 = 1, for normal mode

2.8 External Interrupt (~INTR)

The WISMO Quik Q24x6 sub-series provides an external interrupt input (~INTR).

This input is very sensitive and an interrupt is activated on high to low edge.

If this signal is not used, it can be left open. If used this input has to be driven by

an open collector or an open drain.

This input is used for instance to power OFF automatically the module.

Confidential©

All rights reserved

Page: 34 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 36

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

2.9 VCC output

This output can be used to power some external functions. VCC has to be used

as a digital power supply. This power supply is available when the module is on.

Operating conditions

Parameter Condition Min Max Unit

Output voltage I = 10 mA 2.74 2.86 V

Output Current 10 mA

2.10 VCC_RTC (Real Time Clock Supply)

2.10.1 General

VCC_RTC input is used to provide a back-up power supply for the internal Real

Time Clock.

The RTC is supported by the module when powered on but a back-up power

supply is needed to save date and time information when the module is

switched off.

If the RTC is not used this pin can be left open.

Back-up Power Supply can be provided by:

a capacitor,

a super capacitor,

a non rechargeable battery,

a battery cell with regulator.

Confidential©

All rights reserved

Page: 35 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 37

WM_PRJ_Q2400_PTS_005 -007

1K

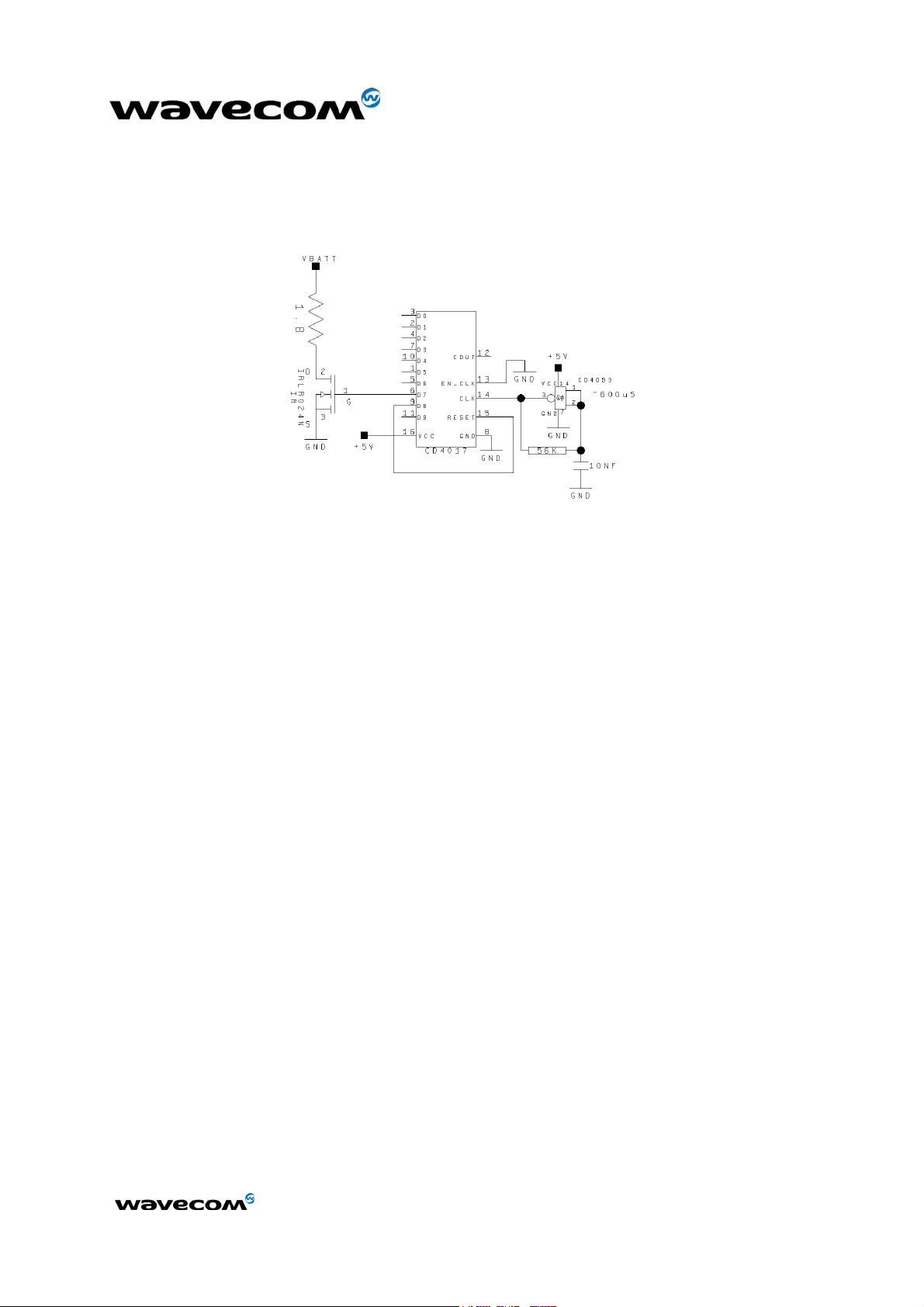

2.10.2 Typical implementation

2.10.2.1 Capacitor

18th January 2006

Shottky

Diode

+VBATT

Vin

En

(With very Low Iq)

Vout

Gnd

Regulator

2.5 V ±10%

470

Figure 22: RTC Supplied by a capacitor

Estimated range with 470 µF Capacitor: ~30 seconds.

2.10.2.2 Super Capacitor

Shottky

Diode

+

VBATT

Vin

En

Vout

Gnd

470

Regulator

2.5 V ±10%

(With very Low Iq)

Figure 23: RTC supplied by a super capacitor

1K

VCC_RTC

Ex: 470uF

VCC_RTC

Ex: EECE0EL474S

(Panasonic)

Estimated range with 0.47 Farad Gold Capacitor: 2 hours min.

Note: the Gold Capacitor maximum voltage is 2.5 V.

Confidential©

All rights reserved

Page: 36 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 38

WM_PRJ_Q2400_PTS_005 -007

2.10.2.3 Battery cell with regulator

18th January 2006

Shottky

Diode

+VBATT

Vin

En

Vout

Gnd

2 K

1K

VCC_RTC

Regulator

2.5 V ±10%

(With very Low Iq)

Figure 24: RTC supplied by a battery cell with regulator

Estimated range with 2 mAh rechargeable battery: ~3 days.

Warning:

Before battery cell assembly insure that cell voltage is lower than 2.75V to

avoid any damage to the WISMO module.

2.10.2.4 Non Rechargeable battery

This is the less recommended solution.

Diode (Ex: BAS16)

10

VCC_RTC

(2.75 V max)

Ex: CR2016

(VARTA)

Figure 25: RTC supplied by a non rechargeable battery

Estimated range with 85 mAh battery: 4000 h minimum.

Note: The “non rechargeable battery” is always active, except when the module

is ON.

Confidential©

All rights reserved

Page: 37 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 39

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

3 Radio design

3.1 Antenna characteristics

WAVECOM recommends to use an antenna with the following characteristics:

Characteristic

Q2406 Q2426

E-GSM 900 DCS 1800 GSM 850 PCS 1900

Frequency TX

Frequency RX

880 to 915 MHz 1710 to 1785 MHz 824 to 849 MHz 1850 to 1910 MHz

925 to 960 MHz 1805 to 1880 MHz 869 to 894 MHz 1930 to 1990 MHz

Impedance 50 ohms

VSWR

Rx max 1.5 :1

Tx max 1.5 :1

Typical

radiated gain

0 dBi in one direction at least

Frequency depends on application. A dual-Band antenna shall work in all these

frequency bands.

3.2 Antenna implementation

The impedance is 50 Ω nominal and the DC impedance is 0 Ω.

3.2.1 Recommendations

Antenna sub-system and integration in the application is a major issue.

Attention should be paid to:

• the design of the antenna line on the application PCB,

• the antenna connector (type + losses),

• the antenna choice.

These elements could affect GSM performances such as sensitivity and emitted

power.

The antenna should be isolated as much as possible from the digital circuitry

(including the interface signals) it is strongly recommended to shield the

terminal.

On terminals including the antenna, a poor shielding could dramatically affect

the sensitivity of the terminal. Moreover, the power emitted through the antenna

could affect the application.

Confidential©

All rights reserved

Page: 38 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 40

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Warning:

Wavecom strongly recommends to work with an antenna manufacturer either to

develop an antenna adapted to the application or to adapt an existing solution to

the application. The antenna adaptation (mechanical and electrical adaptation) is

one of the key issues in the design of a GSM terminal.

• As a general recommendation, all components or chips operated at high

frequencies (microprocessors, memories, DC/DC converter), or other active

RF parts shall not be placed too close to the module. In such a case,

correct supply and ground decoupling areas shall be designed and

validated.

• One shall avoid placing components around the RF connection and close

to the RF line (between the module and the antenna).

• RF lines and cables shall be as short as possible.

• The coaxial cable shall not be placed close to devices operated at low

frequencies.

• Some signals like VBATT and charger line may require some EMI/RFI

decoupling: parallel 33 pF capacitor close to the module, or a serial ferrite

bead (or both to get better results). In case a ferrite bead is used, the

recommendations given for the power supply connection must be

carefully followed (high current capacity and low impedance).

3.2.2 RF connection

The antenna is connected to the module through a 50 Ω coaxial cable. The

coaxial cable must be connected to both the "Antenna pad" (or Round pad) and

the "Ground pad" (see Figure 26).

It is recommended to use a RG178 coaxial cable with the following stripping and

mounting guidelines:

1. The antenna cable and connector should be chosen in order to minimize

losses in the frequency bands used for GSM 850/E-GSM 900MHz and

DCS 1800/PCS 1900MHz.

2. To get a good ground connection, the ground of the cable must be

connected to the ground pad, as shown in Figure 26.

Ground

pad

Antenna pad

Figure 26: Antenna connection

Note: For the assembly of RF cable on the Module see Wavecom

recommendation for manual lead free soldering in section 5.3.

Confidential©

All rights reserved

Page: 39 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 41

WM_PRJ_Q2400_PTS_005 -007

3. Antenna cable preparation is shown in Figure 27.

18th January 2006

Figure 27: Antenna cable preparation (drawing not to scale)

Note:

• The WISMO Quik Q24x6 sub-series does not include any antenna switch

for a car kit but this function can be implemented externally and it can be

driven using a GPIO.

• 0.5 dB can be considered as a maximum value for loss between the

module and an external connector.

Confidential©

All rights reserved

Page: 40 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 42

WM_PRJ_Q2400_PTS_005 -007

4 Mechanical specifications

Attention should be paid to:

• Antenna cable integration (bending, length, position, etc),

18th January 2006

• Legs of the module to be soldered on the Ground plane (

recommendation for lead free soldering in Section 5.3)

.

see Wavecom

Figure 28 gives the overall dimension of the module, taking into account the PCB

dimension and placement tolerances.

It is important to assure that no component or mechanical element will enter in

contact with the module even in case of vibration or manipulation of the final

product.

These contacts may produce bad electrical connection on the 60-pin general

purpose connector.

Figure 28: Maximum bulk occupied on the application board

Confidential©

All rights reserved

Page: 41 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 43

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

5 PCB design

5.1 General design rules

Clocks and other high frequency digital signals (e.g parallel and serial buses)

should be routed as far as possible from the WISMO analog signals.

If the application design makes it possible, all analog signals should be

separated from digital signals by a ground line on the PCB.

It is recommended to protect clock signals with a ground belt.

Refer to the following sections for other constraints:

2.1.3 for the Power Supply,

2.2.6.4 for the SIM interface,

2.3.2.4 for the audio interface.

5.2 Design rules for application manufacturing

The WISMO Quik Q24x6 sub-series does not support any reflow soldering.

5.3 Recommendation for lead free soldering

In order to maintain the RoHS status of the module, Wavecom recommend, for

the assembly of the module on the mother board and the assembly of RF cable

on the Module to use

For example:

lead free solder wire and flux.

o Solder Wire : Kester 245 Cored 58 (Sn96.5Ag3Cu0.5)

o Flux : Kester 952-D6.

5.4 Power supply

Refer to § 2.1.3.

Confidential©

All rights reserved

Page: 42 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 44

5.5 Pads design

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Figure 29: Pads design

Confidential©

All rights reserved

Page: 43 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 45

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

6 EMC recommendations

The EMC tests have to be performed as soon as possible on the application to

detect any possible problem.

When designing, special attention should be paid to:

• Possible spurious emission radiated by the application to the RF receiver

in the receiver band

• ESD protection on SIM (if accessible from outside), serial link, etc. Refer to

section 2.2.6 SIM interface.

• Length of the SIM interface lines (preferably <10cm)

• EMC protection on audio input/output (filters against 900 MHz emissions),

refer to section 2.3.2 audio interface.

• Bias of the Microphone inputs, refer to section 2.3.2 audio interface.

• Ground plane : WAVECOM recommends to have a common ground plane

for analog / digital / RF grounds.

• Metallic case or plastic casing with conductive paint are recommended

Note

:

The module does not include any protection against overvoltage.

Confidential©

All rights reserved

Page: 44 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 46

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

7 Firmware upgrade

7.1 Recommendations

The WISMO Quik Q24x6 sub-series firmware is stored in flash memory and it

can easily be upgraded.

In order to follow the regular evolutions of the GPRS standard and to offer state

of the art software, Wavecom recommends that the application designed around

a WISMO (or WISMO based product) allows easy firmware upgrades on the

module via the standard Xmodem protocol. Therefore, the application shall either

allow a direct access to the WISMO serial link through an external connector or

implement any mechanism allowing the WISMO firmware to be downloaded via

Xmodem.

Warning:

The application must allow the WISMO serial link signals + the BOOT, the

RESET and the ON/∼OFF module signals to be easily accessed thus allowing the

module firmware to be upgraded.

Two upgrade procedures are available:

Nominal upgrade procedure,

Backup procedure.

7.2 Nominal upgrade procedure

The firmware file can be downloaded into the modem using the Xmodem

protocol.

To enter this mode, the AT+WDWL command (see description in the AT

command manual) has to be sent.

The necessary serial signals to proceed with the Xmodem downloading are:

Rx, Tx, RTS, CTS and GND.

Confidential©

All rights reserved

Page: 45 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 47

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

7.3 Backup procedure

In case the nominal upgrade mode is not possible (due to critical corruption on

the flash memory), a backup procedure is also available. It requires a WAVECOM

specific software to download the firmware file into the modem.

This tool has to run on a PC connected to the serial bus of the modem.

The necessary signals to proceed with the downloading are: Rx, Tx, RTS, CTS

and GND.

Prior to running the WAVECOM downloader, the modem has to be set in

download mode.

For this, the BOOT signal has to be set to low while powering ON (or resetting)

the modem.

Advise :

To reduce the time of the download, it’s possible to change the speed

of the serial link at 115200 bits/s. for that, you have to execute the AT command

below :

1) AT+IPR=115200

2) AT+WDWL

3) file transfer

4) AT+CFUN=1 (reset of the module)

Make attention that after the last command (AT+CFUN=1), the speed of the

serial link depends on the configuration of the binary file downloaded in the

module.

Confidential©

All rights reserved

Page: 46 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 48

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

8 Embedded testability

As for the upgrade procedure, the first thing to be checked is the possibility to

download easily a new software version or a test software in the module. The

necessary signals to proceed with the downloading are: RX, TX, RTS, CTS,

BOOT, ON/OFF, RESET and GND.

Prior to running the Wavecom downloader, the module has to be set in

download mode. For this, the BOOT signal has to be set to low while powering

ON (or resetting) the modem.

Typical implementation:

The first of the following diagrams specifies the way to route the specified

signals from the module to a connector on which will be connected the data

cable. This diagram has to be implemented on the application board.

The second diagram gives a typical data cable electrical scheme.

On the application Board:

VBATT

CHG_IN

BOOT

CT105 / RTS

CT104 / RX

CT108-2 / DTR

CT106 / CTS

GPIO_SDA

GPIO_SCL

CT103 / TX

GND

GND

GNDGND

Figure 30: Example of serial link routing for downloading

Confidential©

All rights reserved

Page: 47 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 49

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Cable length 10 cm (Max.)

VBATT

GND

10 cm (Max.)

CT103 / TXD

GPIO_SCL

GPIO_SDA

CT106 / CTS

CT108-2 / DTR

CT104 / RXD

CT105 / RTS

NC_BOOT

NC_CHARGER_IN

Figure 31: Download cable schematics (1/2)

Confidential©

All rights reserved

Page: 48 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 50

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

Figure 32: Download cable schematics (2/2)

Confidential©

All rights reserved

Page: 49 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 51

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

9 Part references and suppliers

9.1 General Purpose Connector

The GPC is a 60-pin connector with 0.5mm pitch from KYOCERA / AVX group

with the following reference:

14 5087 060 930 861.

The matting connector has the following reference :

24 5087 060 X00 861, with X=2 or 9.

The stacking height is 3.0 mm.

For further details see GPC data sheets in appendix. More information is also

available from http://www.avxcorp.com

9.2 SIM Card Reader

• ITT CANNON CCM03 series (see http://www.ittcannon.com )

• AMPHENOL C707 series (see http://www.amphenol.com

• JAE (see http://www.jae.com

)

)

Drawer type:

• MOLEX 99228-0002 (connector) / MOLEX 91236-0002 (holder) (see

http://www.molex.com

)

9.3 Microphone

Possible suppliers:

• HOSIDEN

• PANASONIC

Confidential©

All rights reserved

Page: 50 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 52

WM_PRJ_Q2400_PTS_005 -007

18th January 2006

9.4 Speaker

Possible suppliers:

• SANYO

• HOSIDEN

• PRIMO

• PHILIPS

9.5 Antenna Cable

The following cable reference has been qualified for being mounted on WISMO

Quik Q24x6 sub-series:

• RG178

9.6 GSM antenna

GSM antennas and support for antenna adaptation can be obtained from

manufacturers such as:

• ALLGON (http://www.allgon.com

• MOTECO (http://www.moteco.com

• GALTRONICS (http://www.galtronics.com

)

)

)

Confidential©

All rights reserved

Page: 51 / 51

This document is the sole and exclusive property of WAVECOM. Not to be

distributed or divulged without prior written agreement.

Page 53

WAVECOM S.A. - 3 esplanade du Foncet - 92442 Issy-les-Moulineaux Cedex - France - Tel: +33(0)1 46 29 08 00 - Fax: +33(0)1 46 29 08 08

Wavecom, Inc. - 4810 Eastgate Mall - Second Floor - San Diego, CA 92121 - USA - Tel: +1 858 362 0101 - Fax: +1 858 558 5485

WAVECOM Asia Pacific Ltd. - 4/F, Shui On Centre - 6/8 Harbour Road - Hong Kong - Tel: +852 2824 0254 - Fax: +852 2824 025

Loading...

Loading...