Waukesha Bearings CQ Tilting Pad Thrust Bearings User Manual

- 1 -

CQ Tilting Pad Thrust Bearings

Installation and Maintenance Instructions

1. Introduction

The following notes provide installation and assembly instructions for Waukesha

Bearings CQ tilting pad thrust bearings.

Reference should be made to the specific contract drawing for operational information

and special features which may be provided.

2. General Description

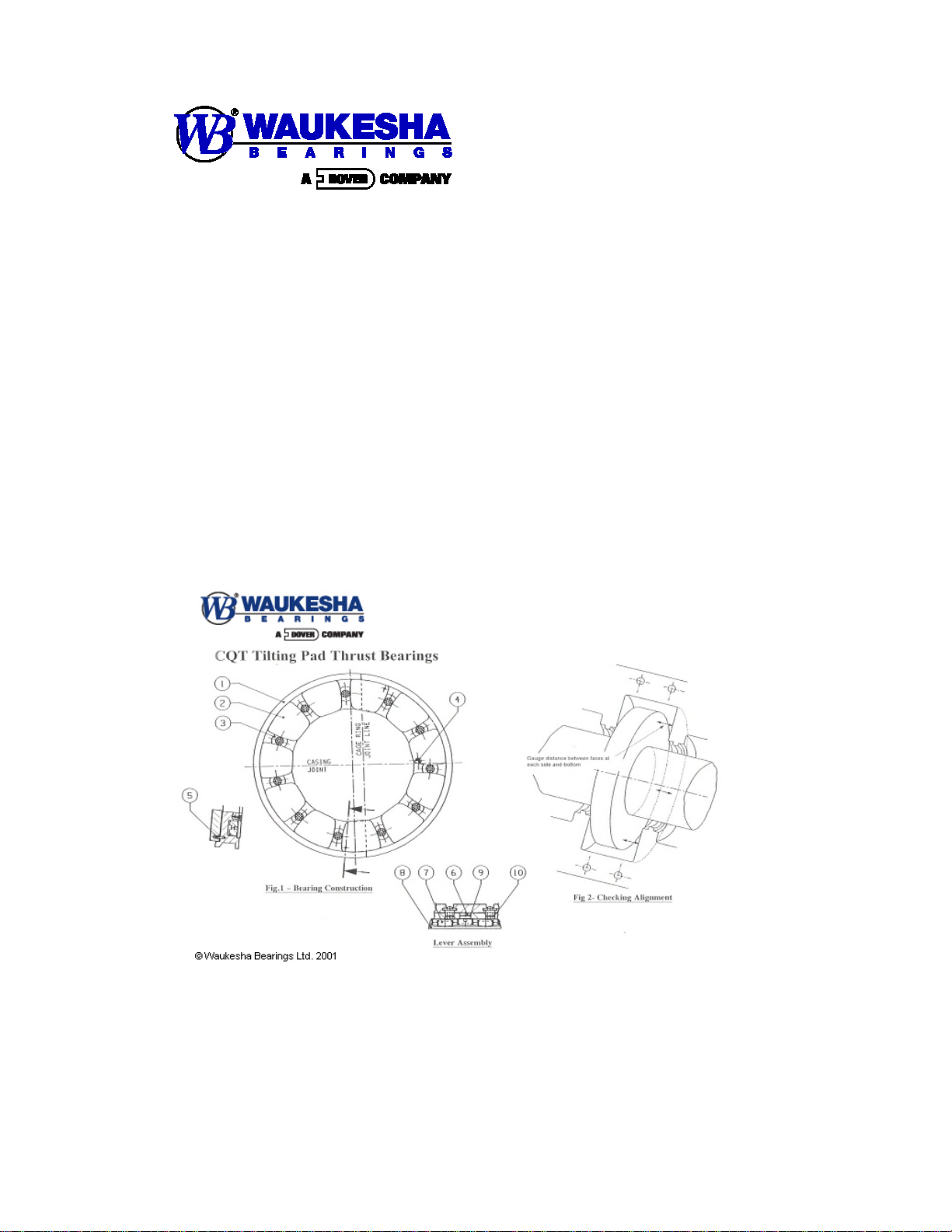

The Waukesha Bearings CQ bearing is shown in Fig 1, and reference is made to this

drawing in the following comments.

The CQ tilting pad thrust bearing consists of a number of thrust pads (item 2)

supported in a cage ring (item 1). Each pad is loosely retained by pad stops (item 3)

so that each pad is free to tilt and it is supported on a system of levers (item 7) to

equalise load sharing between the pads. A screw held spacer plate (item 8) is fixed to

the back face of the cage ring, securing the levers within the cage ring.

- 2 -

The spacer plate, normally supplied with a machining allowance, acts as an adjustable

spacer (for adjusting axial bearing clearance and/or rotor position).

The cage ring can be supplied in a one piece, or in halves construction, with an annular

groove around the bearing outside diameter to receive lubricating oil from the casing.

On bearings with rings in halves, pins (item 5) are provided near the joint line to ensure

security of the pad and levers whilst the two halves of the bearing are separated. 'O' rings

(items 9 and 10) are provided on the pillars and pad stops to retain their position in the

cage ring.

The thrust bearing is prevented from rotating in the casing by an anti-rotation pin

(item 4) situated in the back face of the cage ring.

3. Lubrication

The bearings are designed to be lubricated by a pressurised oil system, with oil supplied

into the cage ring annular groove. The oil then feeds from the annulus to the thrust

bearing chamber via a number of radial holes in the cage ring (which can also be used

for rotating the ring in the casing).

With flooded lubrication

wall of the cage ring, through to the shaft space, providing a continuous flow of oil

which fills the whole bearing chamber.

, oil from the lever chamber is fed via radial holes in the inside

For Directed Lubrication (DL) bearings, the oil feeds from the lever chamber to the

bearing face via spray pad stops. With Directed Lubrication, the bearing housing

should be provided with large drains to prevent an accumulation of oil (see contract

drawing).

4. Pad Design

The thrust pads are normally manufactured from steel lined with a tin based whitemetal

and are either offset pivot (single direction of rotation), or centre pivot (for both

directions of shaft rotation).

NB: In the case of double thrust bearings with an offset pivot arrangement, note that the

main and reverse pads are identical and interchangeable, as the pivot is built into the

cage ring assembly, not the pads.

Pads can be removed from the cage ring by sufficiently raising each pad stop with a

screwdriver or similar lever, whereby each pad can be withdrawn radially outwards.

5. Dismantling

Should it be necessary to completely dismantle the thrust bearing parts from the cage

ring, the procedure is as follows:

Loading...

Loading...