Page 1

IOM-WQ-SmartStream-BCD

Installation, Operation and

Maintenance Manual

254 Nanometer Germicidal

UV Disinfection Systems

Models

WB001 WB002 WB006 WB008 WB012 WC012 WC016

WC020 WC025 WC040 WC050 WD012 WD016 WD020

WD025 WD040 WD050

SmartStream™ UV

Chemical Free Disinfection of Water

!

WARNING

Read this Manual BEFORE using this

equipment. Failure to read and follow

all safety and user information can

result in death, serious personal injury,

property damage, or damage to the equipment.

Keep this Manual for future reference.

This device complies with part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

This device complies with Industry Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that

may cause undesired operation of the device.

Lé present appareil est conforme aux CNR d'Industrie

Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes : (1)

l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur

de l'appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d'en compromettre le

fonctionnement.

Any changes or modifications of this product not approved by

the manufacturer could void the user’s authority to operate the

equipment.

This equipment complies with IC RSS-102 radiation exposure

limits set forth for an uncontrolled environment. This equipment

should be installed and operated with minimum distance 20cm

between the radiator & your body.

Under Industry Canada regulations, this radio transmitter may

only operate using an antenna of a type and maximum (or

lesser) gain approved for the transmitter by Industry Canada. To

reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

!

WARNING

This appliance contains a UV-C emitter (UV

lamp). Unintended use of the appliance or damage to the housing may result in the escape of

dangerous UV-C radiation. UV-C radiation may,

even in little doses, cause harm to the eyes and

skin. Appliances that are obviously damaged

must not be operated. Do not operate the UV-C

emitter when it is removed from the appliance

enclosure. The appliance must be disconnected

from the power supply before replacing the

UV-C emitter. DO NOT look directly at the UV-C

emitter while it is ON. Permanent serious eye

injury could occur.

Table of Contents

Installation Precautions ...................................3

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Product Specification Tables ............................. 5-7

Dimensions ............................................8

Feed Water Requirements .................................9

Installation Procedure ................................. 9-10

Maintenance ..........................................11

Lamp and Quartz Sleeve Replacement ...................... 11

Disinfection Procedure...................................11

Parts List .......................................... 12-13

Troubleshooting........................................14

Controller Identification ..................................15

Overview of Screens ................................. 16-20

Controller Wiring .......................................21

Warranty and Conditions ................................. 24

SmartStream UV is certified by the Water Quality

Association (WQA) to NSF/ANSI Standard 372

for lead free.

Original Instructions

™

Page 2

NOTICE

This system should only be installed and maintained by a qualified professional. Observe all

national, state, and local plumbing and building

codes when installing the system.

Introduction

The Watts SmartStream™ line of ultraviolet disinfection systems

provide protection against microbiological contamination in water for

residential and commercial applications.

Disinfection of water with SmartStream

process. When contaminated water is exposed to SmartStream's

254 nanometer UV light, the UV light penetrates the cell walls of

microorganisms and disrupts their genetic deoxyribonucleic acid

(DNA) material. This quickly inactivates microorganisms by destroying their ability to replicate and infect.

NOTICE

Watts SmartStream™ UV systems are engineered with the highest quality components. If

at anytime a component needs to be replaced,

use only parts recommended and supplied

by Watts. DO NOT add components to or

remove components from this system.

The UV lamp is rated for 9000 hours under

normal operating conditions and should be

replaced annually to keep the UV intensity at

the highest possible output. Quartz sleeves

should be cleaned as needed or replaced as

needed to guarantee the highest possible UV

transmittance into the water.

Use only Watts supplied UV lamps and quartz

sleeves for your specific model. Failure to do

so may result in system failure and will void all

warranty.

DO NOT use this system in a manner that it

is not intended for. This purifier is only for use

in water applications where the feed water,

installation environment and installation method

meets the requirements within this manual.

The system must be properly sized. DO NOT

exceed the rated flow rate capacity of the system. Flow controllers are available from Watts

to ensure system's rated flow is not exceeded.

Follow all product safety labeling.

• DO NOT let the system freeze. System dam-

age may result.

• Install the system on a flat, and level surface.

• The quality of the water to be treated must

meet the feed water guidelines within this

manual. Failure to ensure proper pretreatment will result in inadequate disinfection.

™

is a simple, rapid physical

™

!

WARNING

DO NOT rely solely on this system to make

water safe to drink. SmartStream

™

UV disinfection systems are intended to be used as part of

a well designed water treatment system. Water

that contains microbiological contamination

should be tested regularly to ensure its quality

and safety at the point of use.

NOTICE

This appliance can be used by people aged

from 18 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved. Children

shall not play with the appliance. Cleaning and

user maintenance shall not be made by children.

2

Page 3

!

WARNING

Using SmartStream™ with other water treatment equipment

SmartStream™ UV units can be installed as a

final disinfection method within a water treatment system train or as pretreatment to protect

sensitive components, such as reverse osmosis

membranes, from bio-films.

The injection of chemicals into the water should

be done on the outlet of the SmartStream

™

system to ensure UV light degradation of the

chemical or the introduction of turbidity within

the UV feedstream does not occur.

A 5 micron particle filter should always be

installed immediately before the SmartStream

™

system.

Be certain that the feed water meets all criteria

within the Feed Water Specifications section of

this manual.

!

WARNING

Installation Guidelines

• DO NOT allow this system to remain ON with-

out water in it for extended periods of time.

• DO NOT install the system near any source

of heat. Also, DO NOT install the system near

any device or break out area that would be

adversely effected by water.

• DO NOT install this system higher in elevation

than 10,000 feet above sea level.

• DO NOT install the system backwards with

the feed water line connected to the outlet.

• DO NOT install where system is exposed to

harsh chemicals or may be subjected to being

struck by moving equipment, carts, mops or

any other item that may cause damage.

• DO NOT install the system outdoors. Keep

system away from moisture, rain, and direct

sunlight. Ambient air temperature must remain

below 122°F and relative humidity must

remain below 95%.

• DO NOT allow the system to freeze.

• The system MUST be mounted on a surface

and with mounting hardware that is sturdy

enough to support the weight of the wetted

system.

• The system MUST be plugged into an uninterrupted power supply that matches the rated power

requirement of the system. In European installations, the appliance is to be supplied through a

residual current device (RCD) having a rated residual operating current not exceeding 30 milliamps.

• The system MUST be installed in accordance

with all applicable national, state and local

codes.

• A prefilter with a 5 micron minimum particle

size reduction must be installed on the inlet

line to the system. Additional pretreatment

may be necessary so that the feedwater conforms to the Feed Water Specifications section on page 8.

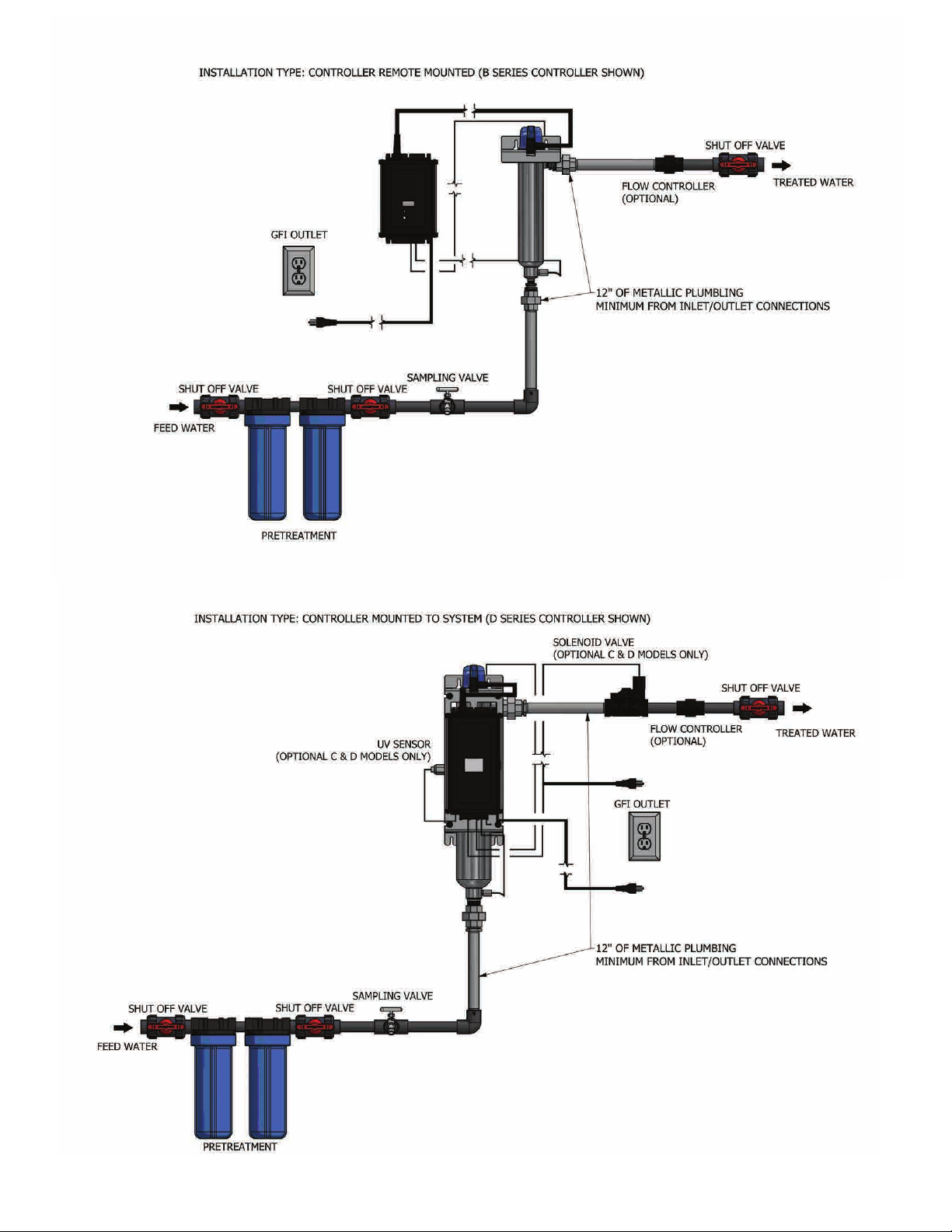

• Plumbing materials sensitive to UV light, typically plastic materials, should not be connected directly to the system. To prevent UV degradation at the plumbing connection points on

the system, use one foot minimum of copper

or stainless steel plumbing material to connect

to the inlet and to the outlet of the system.

• IF water hammer is evident, install water hammer arrestors before the system.

• Always back-up valves and fittings with a

wrench when constructing plumbing to reduce

unnecessary stress on the system and its

plumbing.

Position the system in a suitable location. Make

sure there is enough clearance between the end

of UV chamber and any obstructions, to allow for

the removal of the lamp and quartz sleeve.

™

SmartStream

UV disinfection systems should be

installed as close as possible to the treated water's

point of use.

3

Page 4

System Specifications

SmartStream™ UV System Part Number Identification Key

Prefix "W" "Controller Series" "GPM" "Connection Type" "Pipe Size" "Plug" "Accessories"

Watts Controller Type

B: Controller B

C: Controller C

D: Controller D

Controller Features

Three different controllers are available on various SmartStream™

UV systems. The controllers are identified as "B" "C" or "D" series.

Each controller has unique features and are outlined as follows:

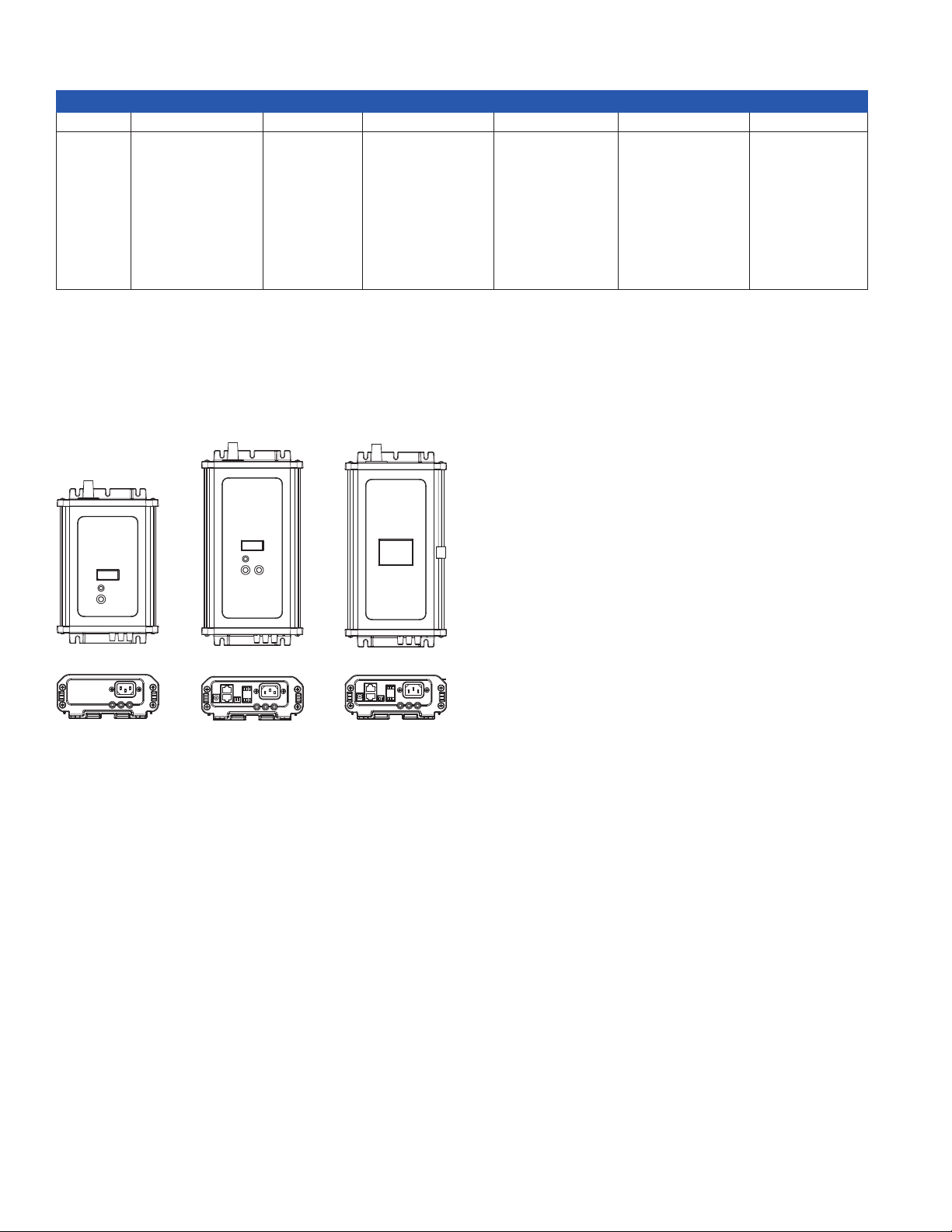

Model B Model C Model D

GPM of System

(3-Digits)

Connection Port

Types:

A: NPT

B: BSP-Tapered

Pipe Size

B: 3/8"

C: 1/2"

D: 3/4"

E: 1"

F: 3/4" Female X 1"

Male Combination

Fitting

G: 1" Female X 1 1/2"

Male Combination

Fitting

A: North American

B: European

C: British U.K.

D: Australian

Accessories

X: No Accessories

(Accessories only

available for systems

using the C and D

type controllers.)

A: UV Sensor

B- Basic controller with lamp dimming, flow switch, lamp out audible alarm, multicolor LED system status indicator, glow cap lamp

indicator, lamp life timer with 3 digit LED display, radio frequency

communication to lamp to verify correct lamp and remaining life of

the lamp. Lamp life timer resets when a new lamp is inserted.

B Series controllers are certified by the Federal Communications

Commission (FCC) listed under identification number

FCC ID: 2AFJT-SMARTSTREAM-B and Industry Canada (IC) listed

under identification number IC: 20623-SMARTSTRMB.

C- All features of the of the B controller plus alarm output for solenoid valve, UV sensor input, 4-20 milliamp output for UV Intensity

(When UV Sensor is used).

C Series controllers are certified by the Federal Communications

Commission (FCC) listed under identification number

FCC ID: 2AFJT-SMARTSTREAM and Industry Canada (IC) listed

under identification number IC: 20623-SMARTSTREAM.

D- All features of the C controller. The display changes from a 3

digit LED display to a graphic touch screen. Total system hours are

displayed along with key operational data.

D Series controllers are certified by the Federal Communications

Commission (FCC) listed under identification number

FCC ID: 2AFJT-SMARTSTREAM and Industry Canada (IC) listed

under IC: 20623-SMARTSTREAM.

4

Page 5

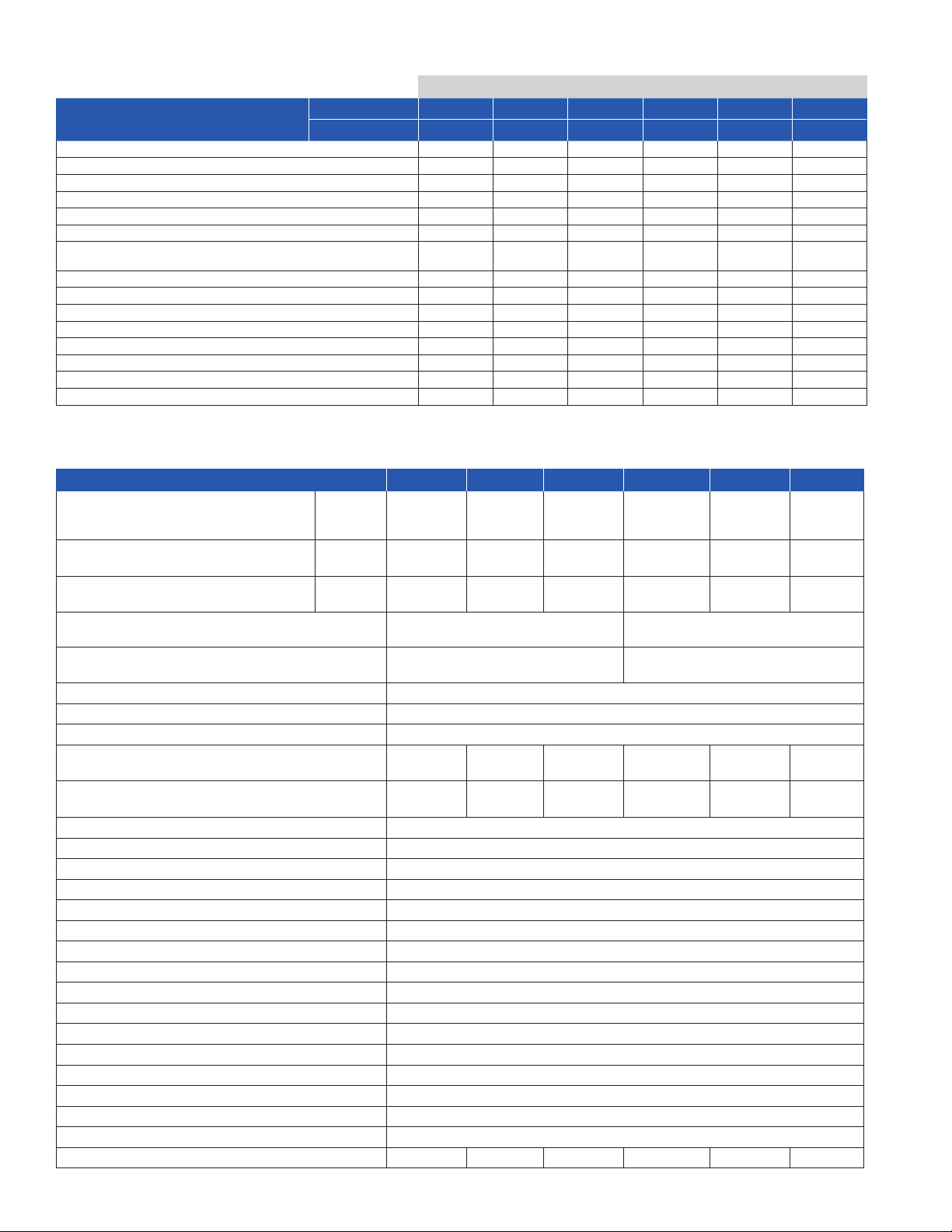

System Features

B Series Controller With Lamp Dimming

FCC ID: 2AFJT-SMARTSTREAM-B GPM Rating 1 2 6 8 12

IC: 20623-SMARTSTRMB System Model # WB001 WB002 WB006 WB008 WB012

Universal Power Input

316 SS Chamber

Audible Alarm

Lamp On Indicator

Glow Cap Lamp Indicator

Lamp Life Timer with 3-digit display

Automatic Lamp Shut Off when

Removed from the Chamber (wireless)

Lamp Dimming

Integrated Bracket Mounting

Alarm Contact Relay (for solenoid valve)

UV Sensor Input

4-20mA Output

12V Power for Chamber Cooling Fan

Graphic Display

Total System Hours Indicator

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4

Product Specifications Table

MODEL WB001

FLOW RATE @ 16mJ

(95%UVT @ EOL)

(may be hydraulically limited)

FLOW RATE @ 30mJ

(95%UVT @ EOL)

FLOW RATE @ 40mJ

(95%UVT @ EOL)

STANDARD NPT INLET / OUTLET PORTS 3/8"NPT-M 3/4"NPT-M

OPTIONAL BSP-T INLET / OUTLET PORTS 3/8"BSP-M 3/4"BSP-M

CHAMBER MATERIAL 316L SS

CONTROLLER MOUNTING Remote from chamber On chamber bracket or remote from chamber

INPUT VOLTAGE 100 to 240VAC 50/60Hz

SYSTEM MAX NOMINAL INPUT POWER (Watts) 11 15 26 34 34

LAMP MAX NOMINAL ELECTRICAL POWER

(Watts)

LAMP TECHNOLOGY

WIRELESS LAMP KEY Standard

LAMP DIMMING / FLOW SWITCH Standard

CHAMBER COOLING FAN Not Applicable

SYSTEM DISPLAY TYPE Seven segment three digit LED

LAMP LIFE MONITOR 3-digit LED Display, auto-reset with new lamp

UV SENSOR Not Applicable

4-20mA OUTPUT Not Applicable

VISUAL ALARM Multi-color status LED

AUDIBLE ALARM Yes

AUDIBLE ALARM MUTE Yes

ALARM RELAY / SOLENOID CONTACTS Not Applicable

ALARM RELAY MANUAL OVER-RIDE Not Applicable

MAXIMUM AMBIENT AIR TEMPERATURE /

HUMIDITY

INLET WATER TEMPERATURE RANGE 34°F ( 1°C) to 113°F ( 45°C)

MAX WATER PRESSURE 125psi (861 kPa)

SHIPPING WEIGHT 11LB (5KG) 11LB (5KG) 17LB (8KG) 18LB (8KG) 19LB (9KG)

usgpm

liters/min

usgpm

liters/min

usgpm

liters/min

2.8 gpm

10.6 lpm

1.5 gpm

5.7 lpm

1.1 gpm

4.2 lpm

10 14 25 32 32

Quartz glass low pressure lamp / ozone free / true pre-heat starting / glow-cap indicator

WB002 WB006 WB008 WB012

4.7 gpm

17.8 lpm

2.5 gpm

9.5 lpm

1.9 gpm

7.2 lpm

50°C ( 122°F) / 95% RH (non-condensing)

11.4 gpm

43.1 lpm

6.1 gpm

23.1 lpm

4.6 gpm

17.4 lpm

15.0 gpm

56.8 lpm

8.0 gpm

30.3 lpm

6.0 gpm

22.7 lpm

23.4 gpm

88.6 lpm

12.5 gpm

47.3 lpm

9.4 gpm

35.6 lpm

1" NPT-M / 3/4" NPT-F

Combo Ports

1" BSP-M / 3/4" BSP-F

Combo Ports

5

Page 6

System Features

C Series Controller With Lamp Dimming

FCC ID: 2AFJT-SMARTSTREAM GPM Rating 12 16 20 25 40 50

IC: 20623-SMARTSTREAM System Model # WC012 WC016 WC020 WC025 WC040 WC050

Universal Power Input

316 SS Chamber

Audible Alarm

Lamp On Indicator

Glow Cap Lamp Indicator

Lamp Life Timer with 3-digit display

Automatic Lamp Shut Off when

Removed from the Chamber (wireless)

Lamp Dimming

Integrated Bracket Mounting

Alarm Contact Relay (for solenoid valve)

UV Sensor Input

4-20 mA Output (If UV Sensor is used)

12V Power for Chamber Cooling Fan

Graphic Display

Total System Hours Indicator

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

Product Specifications Table

MODEL WC012

FLOW RATE @ 16mJ

(95%UVT @ EOL)

(may be hydraulically limited)

FLOW RATE @ 30mJ

(95%UVT @ EOL)

FLOW RATE @ 40mJ

(95%UVT @ EOL)

STANDARD NPT INLET / OUTLET PORTS

OPTIONAL BSP-T INLET / OUTLET

PORTS

CHAMBER MATERIAL 316L SS

CONTROLLER MOUNTING On chamber bracket or remote from chamber

INPUT VOLTAGE 100 to 240VAC 50/60Hz

SYSTEM MAX NOMINAL INPUT POWER

(Watts)

LAMP MAX NOMINAL ELECTRICAL

POWER (Watts)

LAMP TECHNOLOGY

WIRELESS LAMP KEY Standard

LAMP DIMMING / FLOW SWITCH Standard

CHAMBER COOLING FAN Applicable Option

SYSTEM DISPLAY TYPE Seven segment three digit LED

LAMP LIFE MONITOR 3-digit LED Display, auto-reset with new lamp

UV SENSOR Available Option

4-20mA OUTPUT With UV Sensor Option

VISUAL ALARM Multi-color status LED

AUDIBLE ALARM Yes

AUDIBLE ALARM MUTE Yes

ALARM RELAY / SOLENOID CONTACTS Yes - 24V 5 Amp Maximum

ALARM RELAY MANUAL OVER-RIDE Yes

MAXIMUM AMBIENT AIR TEMPERATURE / HUMIDITY 50°C ( 122°F) / 95% RH (non-condensing)

INLET WATER TEMPERATURE RANGE 34°F ( 1°C) to 113°F ( 45°C)

MAX WATER PRESSURE 125psi (861 kPa)

SHIPPING WEIGHT

usgpm

liters/min

usgpm

liters/min

usgpm

liters/min

24.0 gpm

90.8 lpm

12.8 gpm

48.4 lpm

9.6 gpm

36.3 lpm

47 58 67 67 100 118

45 55 64 64 95 112

Quartz glass low pressure lamp / ozone free / true pre-heat starting / glow-cap indicator

19LB (9KG) 19LB (9KG) 20LB (9KG) 25LB (11KG) 27LB (12KG) 29LB (13KG)

WC016 WC020 WC025 WC040 WC050

31.5 gpm

119.2 lpm

16.8 gpm

63.6 lpm

12.6 gpm

47.7 lpm

1"NPT-M / 3/4"NPT-F

Combo Ports

1"BSP-M / 3/4"BSP-F

Combo Ports

39.0 gpm

147.6 lpm

20.8 gpm

78.7 lpm

15.6 gpm

59.0 lpm

46.9 gpm

177.5 lpm

25.0 gpm

94.6 lpm

18.8 gpm

71.2 lpm

1.5"NPT-M / 1"NPT-F

Combo Ports

1.5"BSP-M / 1"BSP-F

Combo Ports

75.0 gpm

283.9 lpm

40.0 gpm

151.4 lpm

30.0 gpm

113.6 lpm

6

93.8 gpm

355.0 lpm

50.0 gpm

189.3 lpm

37.5 gpm

141.9 lpm

Page 7

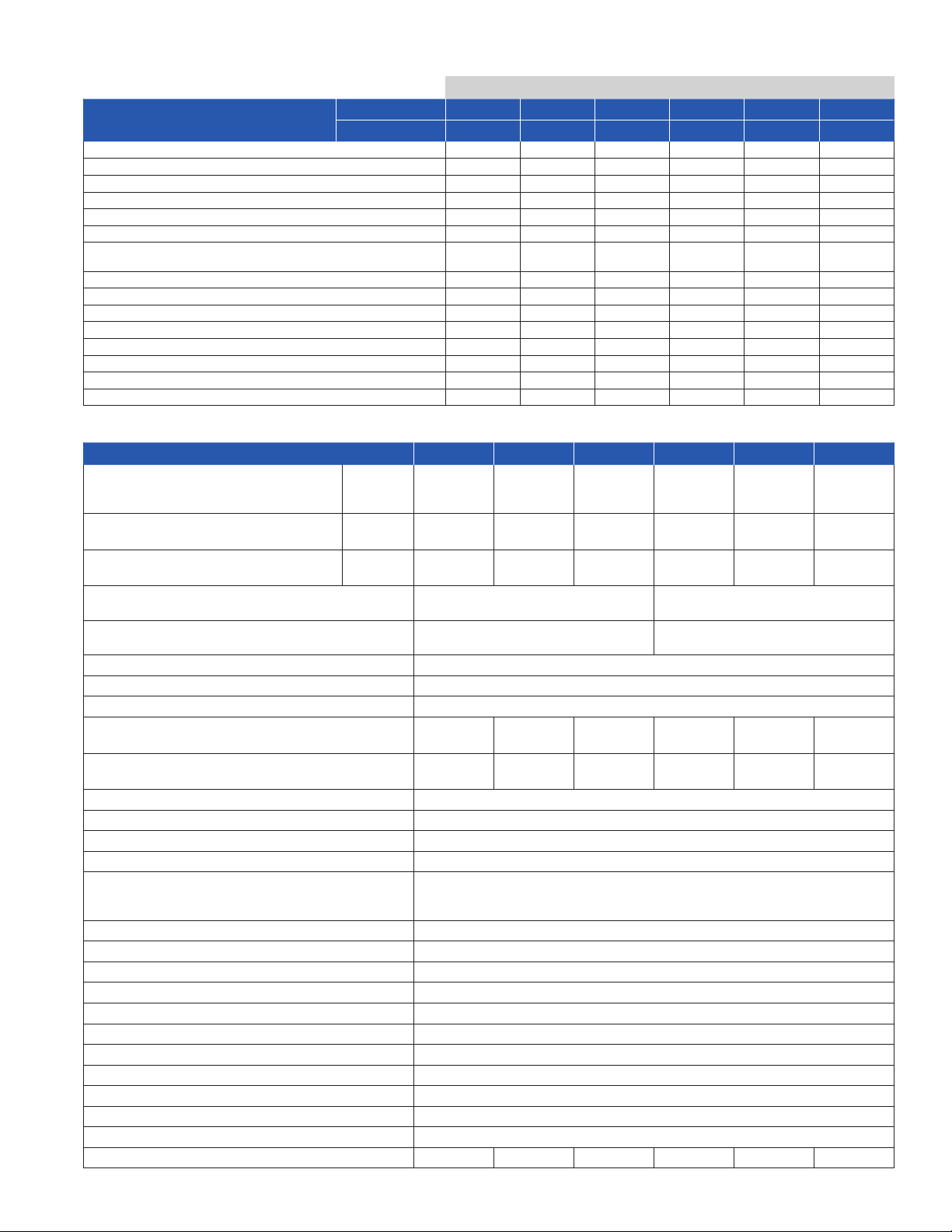

System Features

D Series Controller With Lamp Dimming and Graphics Display

FCC ID: 2AFJT-SMARTSTREAM GPM Rating 12 16 20 25 40 50

IC: 20623-SMARTSTREAM System Model # WD012 WD016 WD020 WD025 WD040 WD050

Universal Power Input

316 SS Chamber

Audible Alarm

Lamp On Indicator

Glow Cap Lamp Indicator

Lamp Life Timer with 3-digit display

Automatic Lamp Shut Off when

Removed from the Chamber (wireless)

Lamp Dimming

Integrated Bracket Mounting

Alarm Contact Relay (for solenoid valve)

UV Sensor Input

4-20 mA Output (if UV Sensor is used)

12V Power for Chamber Cooling Fan

Graphic Display

Total System Hours Indicator

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

Product Specifications Table

MODEL WD012

FLOW RATE @ 16mJ

(95%UVT @ EOL)

(may be hydraulically limited)

FLOW RATE @ 30mJ

(95%UVT @ EOL)

FLOW RATE @ 40mJ

(95%UVT @ EOL)

STANDARD NPT INLET / OUTLET PORTS

OPTIONAL BSP-T INLET / OUTLET PORTS

CHAMBER MATERIAL 316L SS

CONTROLLER MOUNTING On chamber bracket or remote from chamber

INPUT VOLTAGE 100 to 240VAC 50/60Hz

SYSTEM MAX NOMINAL INPUT POWER

(Watts)

LAMP MAX NOMINAL ELECTRICAL

POWER (Watts)

LAMP TECHNOLOGY

WIRELESS LAMP KEY Standard

LAMP DIMMING / FLOW SWITCH Standard

CHAMBER COOLING FAN Available Option

SYSTEM DISPLAY TYPE Color Touch Screen with multiple languages, intuitive screen navigation, detailed

LAMP LIFE MONITOR Display on graphic touch screen, auto-reset with new lamp

UV SENSOR Available Option

4-20mA OUTPUT With UV Sensor Option

VISUAL ALARM Animated icons and text messages on graphic display

AUDIBLE ALARM Yes

AUDIBLE ALARM MUTE Yes

ALARM RELAY / SOLENOID CONTACTS Yes- 24V 5 Amp Maximum

ALARM RELAY MANUAL OVER-RIDE Ye s

MAXIMUM AMBIENT AIR TEMPERATURE / HUMIDITY 50°C ( 122°F) / 95% RH (non-condensing)

INLET WATER TEMPERATURE RANGE 34°F ( 1°C) to 113°F ( 45°C)

MAX WATER PRESSURE 125psi (861 kPa)

SHIPPING WEIGHT

usgpm

liters/min

usgpm

liters/min

usgpm

liters/min

24.0 gpm

90.8 lpm

12.8 gpm

48.4 lpm

9.6 gpm

36.3 lpm

47 58 67 67 100 118

45 55 64 64 95 112

Quartz glass low pressure lamp / ozone free / true pre-heat starting / glow-cap indicator

system status messages, maintenance/diagnostic, and dealer programmable

19LB (9KG) 19LB (9KG) 20LB (9KG) 25LB (11KG) 27LB (12KG) 29LB (13KG)

WD016 WD020 WD025 WD040 WD050

31.5 gpm

119.2 lpm

16.8 gpm

63.6 lpm

12.6 gpm

47.7 lpm

1"NPT-M / 3/4"NPT-F

Combo Ports

1"BSP-M / 3/4"BSP-F

Combo Ports

with website/contact information/QR codes

39.0 gpm

147.6 lpm

20.8 gpm

78.7 lpm

15.6 gpm

59.0 lpm

46.9 gpm

177.5 lpm

25.0 gpm

94.6 lpm

18.8 gpm

71.2 lpm

1.5"NPT-M / 1"NPT-F

1.5"BSP-M / 1"BSP-F

75.0 gpm

283.9 lpm

40.0 gpm

151.4 lpm

30.0 gpm

113.6 lpm

Combo Ports

Combo Ports

7

93.8 gpm

355.0 lpm

50.0 gpm

189.3 lpm

37.5 gpm

141.9 lpm

Page 8

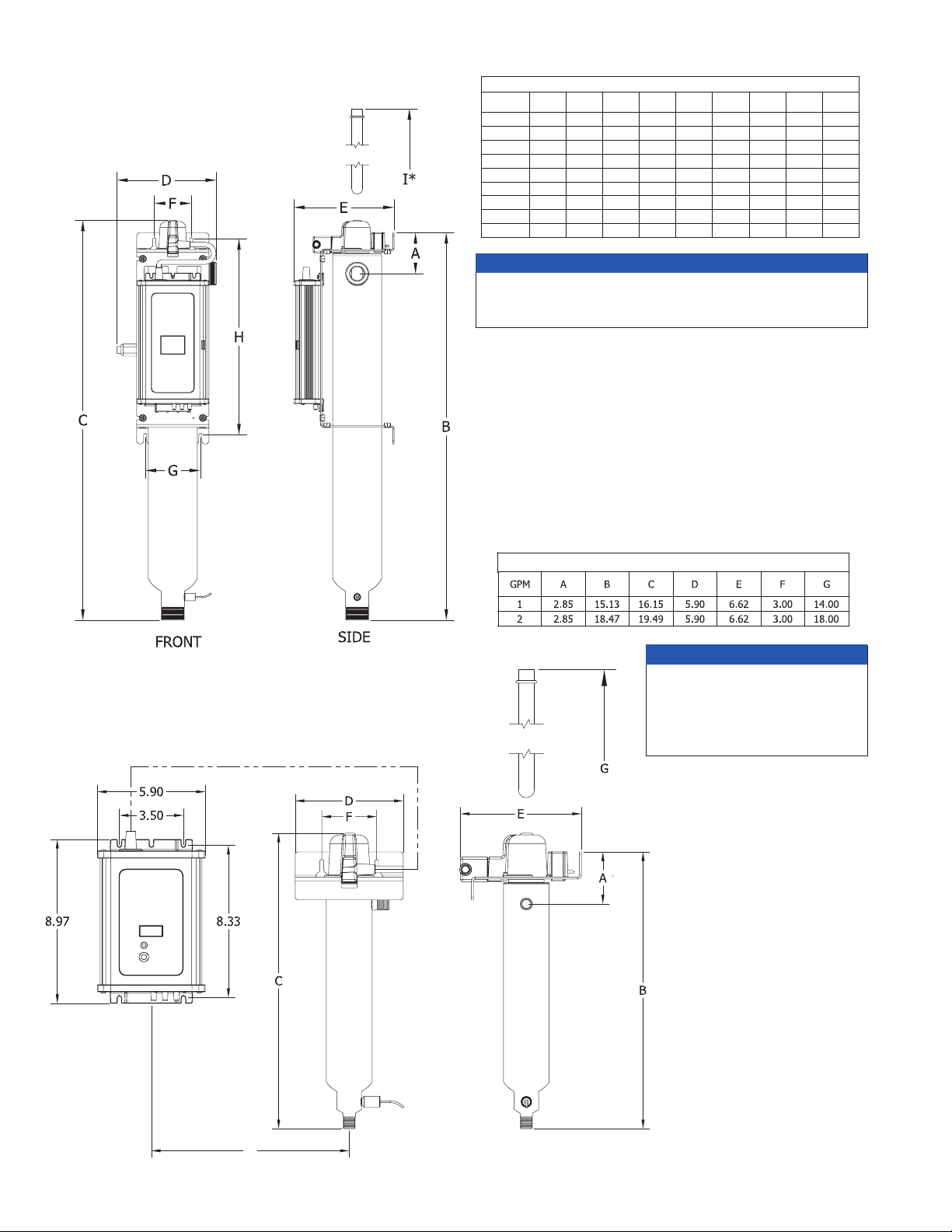

Dimensions

All dimensions are in inches.

Controller Mounted on Chamber- 6 to 50 GPM

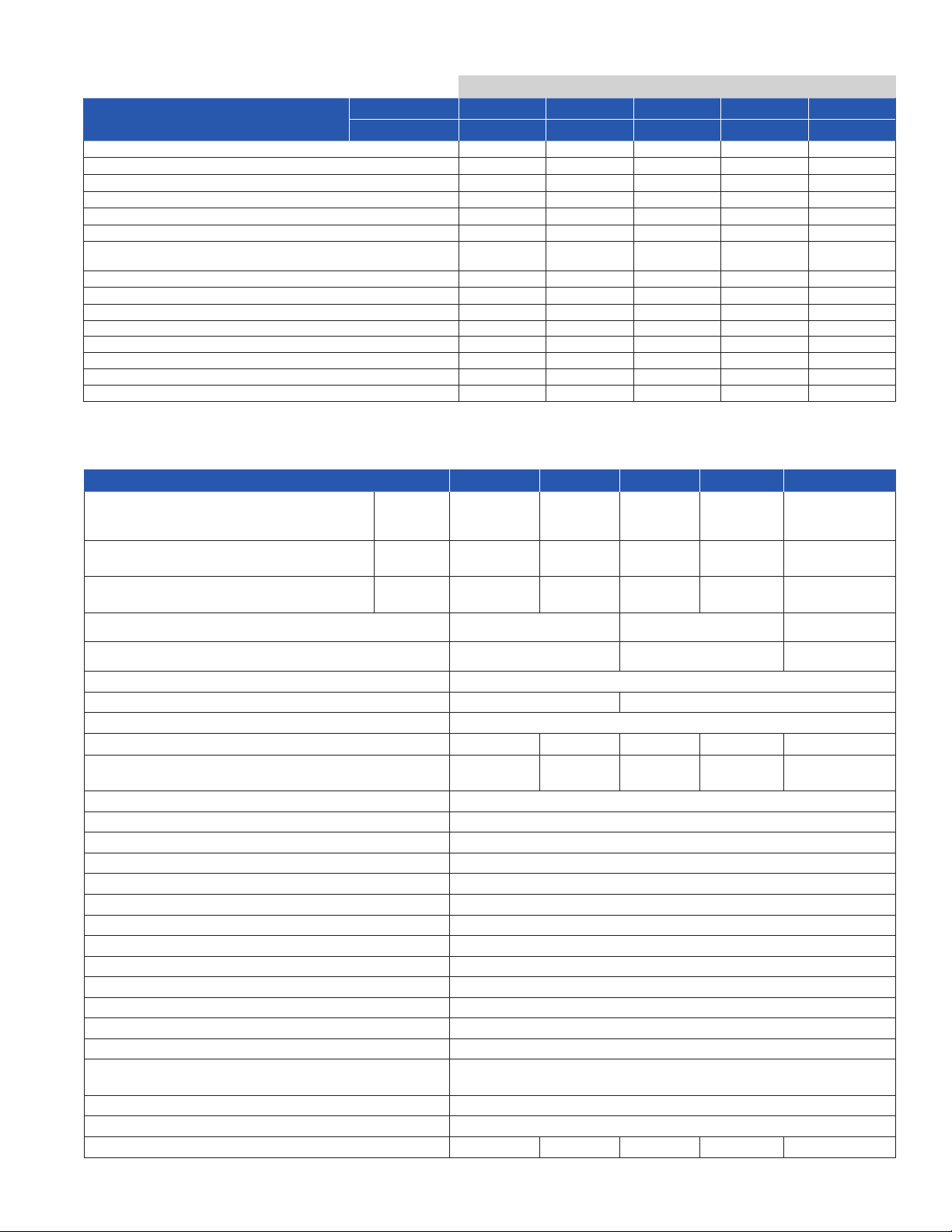

GPM A B C D E F G H I

6 2.85 27.75 28.77 5.90 8.29 3.00 4.50 13.67 27.00

8 2.85 32.87 33.89 5.90 8.29 3.00 4.50 13.67 32.00

12 (B) 3.34 33.37 34.40 5.90 8.29 3.00 4.50 16.00 32.00

12 (C&D) 3.34 23.92 24.95 7.63 8.29 3.00 4.50 16.00 22.00

16 3.34 27.86 28.89 7.63 8.29 3.00 4.50 16.00 26.00

20 3.34 31.40 32.43 7.63 8.29 3.00 4.50 16.00 30.00

25 3.34 31.64 32.67 8.13 8.29 3.00 4.50 16.00 30.00

40 3.34 43.02 44.05 8.13 8.29 3.00 4.50 16.00 41.00

50 3.34 50.14 51.17 8.13 8.29 3.00 4.50 16.00 48.00

NOTICE

* Allow this amount of overhead clearance for

the removal of lamp and quartz sleeve.

Remote Mounted Controller- 1 and 2 GPM Systems

NOTICE

* Allow this amount of

overhead clearance for

the removal of lamp and

quartz sleeve.

*

22

8

Page 9

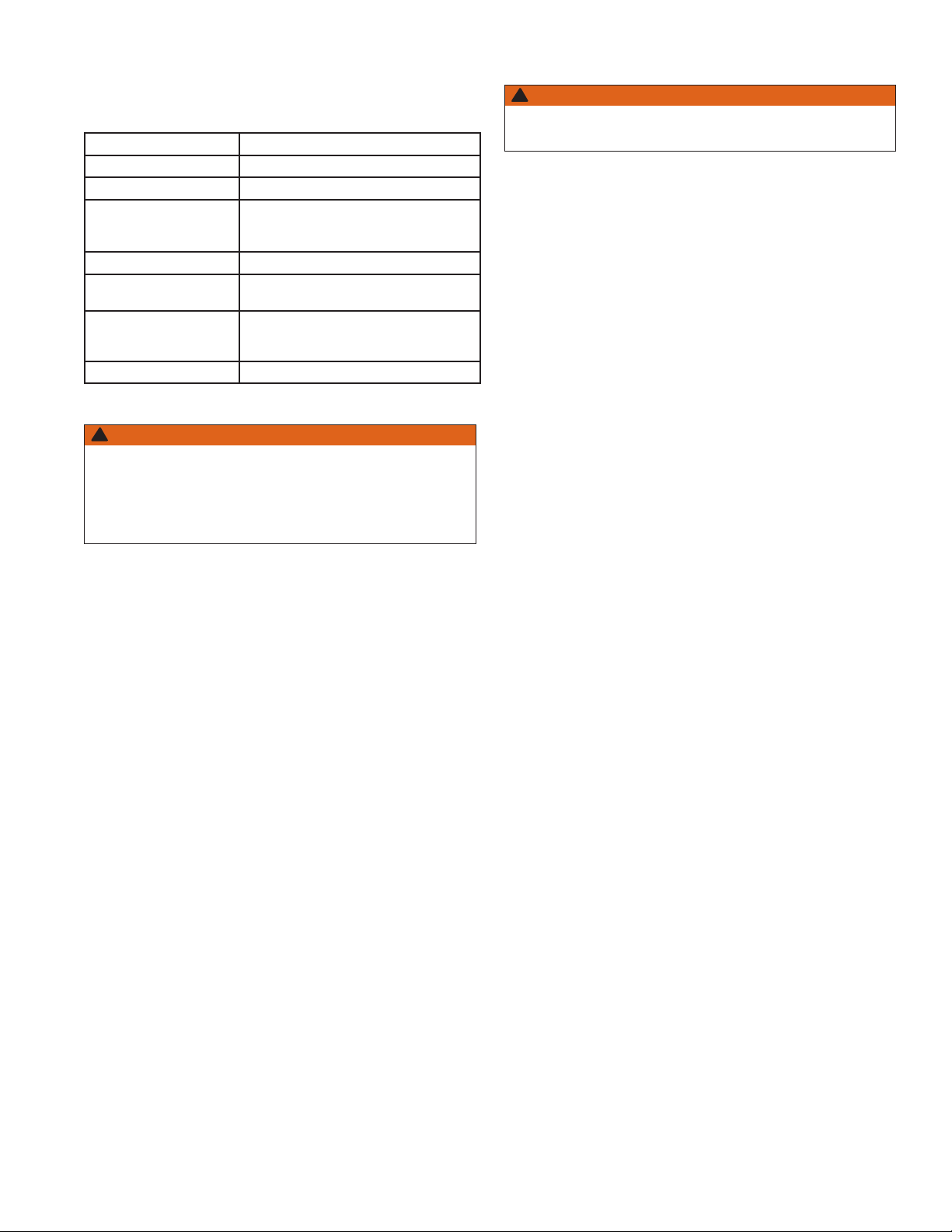

Feed Water Requirements

Please review operating pressures, temperatures and water

chemistry limitations to ensure compatibility.

Hardness (maximum) 7 Grains (120 mg/L as CaCO3)

Water Pressure 5psi to 125psi (34.5 kPa to 861 kPa)

Water Temperature 34°F ( 1°C) to 113°F ( 45°C)

Turbidity

Total Suspended Solids

Iron (maximum) 0.3 mg/l

Manganese (maximum) 0.05 mg/l

Maximum Ambient

Atmospheric

Conditions

Oil & H2S None allowed

!

WARNING

Support the Piping

The full weight of the piping and valves must be

supported by uni-strut, pipe hangers or other

means.

<5 Nephelometric Turbidity Units (NTU)

<10 mg/L

Temperature 122°F / 50°C

95% Relative Humidity

Non-Condensing

Installation

!

WARNING

Inspect wall for hidden wiring before drilling any

holes or installing screws.

1. Remove all system components from packaging and

inspect for any damage. Confirm that the system being

installed matches the flow rate for the application.

2. Turn off water heater(s).

3. Turn off the main water supply valve to the pipe the system

will be installed in.

4. Relieve pressure within plumbing system by opening then

closing both the hot and cold sides of a faucet until water

ceases to dispense from faucet.

5. If equipped with isolation valves, isolate the water heater(s)

by closing its inlet and outlet valves.

6. Mount the UV system on its installation surface using

appropriate hardware for your mounting surface type. The

system comes with 1" wood screws for mounting to wooden

surfaces. If system is being mounted to anything other than

wood then the installer must provide the appropriate mounting hardware. The mounting surface and hardware must be

sturdy enough to support the weight of the wetted system.

7. Connect the water supply pipe to the inlet of the UV system.

8. Install a supply valve in this supply line.

9. Install an adequately sized 5 micron cartridge filter in this

supply line after the supply valve. The cartridge filter must

have a higher flow rate rating than the UV system.

10. Connect the outlet of the system to the outlet plumbing.

11. Install the solenoid safety shut off valve in this outlet plumbing line (optional).

12. Install a flow controller in this outlet plumbing line after the

solenoid valve (optional).

13. Install an outlet valve in this outlet plumbing line. This valve

should be located after any optional devices such as the

solenoid valve or flow control.

14*. Install the quartz sleeve into the UV chamber. DO NOT touch

the quartz sleeve with your fingers. Hold it with a paper towel.

15*. Install the quartz sleeve o-ring onto the visible end of the

quartz sleeve. Screw the quartz sleeve nut onto the quartz

sleeve port thread and tighten hand tight.

16*. Install the ultraviolet lamp into the quartz sleeve. DO NOT

touch the lamp with your fingers. Hold it with a paper towel.

17*. Insert the lamp power lead wire into the receptacle on the

lamp's glow cap.

18**. If using the solenoid valve safety shut off feature, connect

the solenoid valve's power wires to the solenoid valve

power output on UV system controller. Then plug the solenoid valve transformer into a power outlet. Use only Watts

supplied solenoid valve kit part number T7401001 for 20

GPM systems and below and part T7401002 for 25 GPM

systems and above.

19. Open water supply valves.

20. Check for leaks and repair as needed.

21. Plug in power cord.

22. Open outlet valve.

23. Purge air from plumbing system out of the nearest cold

water faucet to the UV system.

24. Open inlet and outlet isolation valves on water heaters(s)

and turn water heaters back on.

25. Perform the sterilization procedure within this manual.

* For assistance with installation steps 14, 15, 16 and 17 see

replacement procedures for lamp and quartz sleeve within

this manual.

** For assistance with installation step 18 see controller wiring

9

diagram.

Page 10

10

Page 11

NOTICE

Maintenance

UV Lamps have a 1 year (9000 Hour) life span under normal

operating conditions.

Quartz sleeves should be cleaned with vinegar, citric acid, or a

lime scale removing chemical annually and replaced no less than

once every 3 years. If the quartz sleeve can not be cleaned, or if

it is discolored, is must be replaced.

Pre filters should be maintained according to the manufactur-

ers instructions to ensure feed water requirements within this

manual are met.

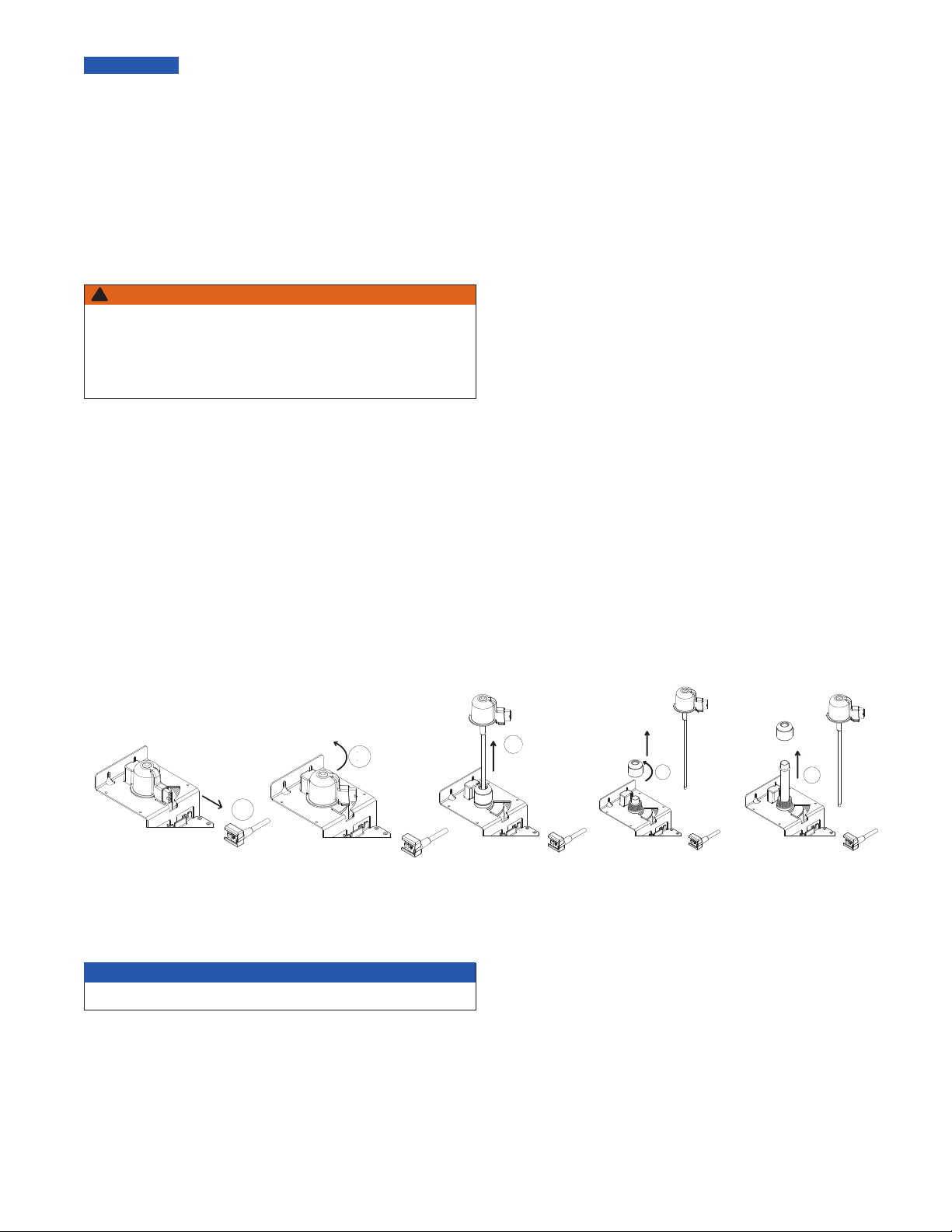

Lamp and Quartz Sleeve Replacement Procedure

!

WARNING

If any water comes in contact with any electrical components, dry the components immediately. DO NOT energize a system with damp

or wet electrical components.

1. Disconnect the power supply from the wall outlet.

2. Turn off the inlet valve and outlet isolation valves.

3. Disconnect the lamp lead wire from the glow cap electrical

port. # 1

4. Rotate the glow cap counter clockwise to unlock it from the

mounting bracket. # 2

5. Pull up on the glow cap to remove the lamp from the quartz

sleeve #3. If not replacing the quartz sleeve proceed to step

#11.

6. De-pressurize the system.

7. Grip the quartz sleeve nut with your hand and unscrew counter clockwise until it can be lifted from the reactor chamber's

threaded port. # 4

8. Remove the quartz sleeve from the reactor chamber. # 5

9. Fully insert a new quartz sleeve into the reactor chamber

and install the o-ring over the quartz sleeve. Press the o-ring

down over the quartz sleeve until it is seated in the bevel of

the stainless steel reactor chamber's threaded port.

10. Install the quartz sleeve nut onto the threaded port of the

reactor chamber. Screw the nut on clockwise and tighten

hand tight.

11. Insert a new lamp into the quartz sleeve.

12. Gently press down on the glow cap and rotate it clockwise

until it locks in place on the mounting bracket

13. Reconnect the lamp lead wire to the new lamp.

14. Turn on the inlet valve and check for leaks. Repair leaks as

needed.

15. Restore power to the system.

16. Verify new bulb has 365 days remaining on the controller

screen.

Immediately after replacement of the UV lamp, and/or quartz

sleeve, follow the disinfection procedure below.

2

1

Disinfection Procedure

NOTICE

DO NOT unplug the system.

1. Shut off the isolation valves on the cartridge prefilter.

2. De-pressurize the cartridge prefilter and unscrew the

housing.

3. Install a new prefilter cartridge and pour 1 cup of 6% bleach

into the housing. If an activated carbon cartridge is part of

the prefiltration system it must be removed during the disinfection procedure.

3

4

4. Reinstall the filter housing and open up the prefilter isolation

valves.

5. Flush 2 reactor chamber volumes of water through the UV

system then stop and let the solution remain in the UV system for 30 minutes.

6. After 30 minutes, flow enough water through the system to

flush all of the residual chlorine from the system. During this

time DO NOT exceed the rated flow rate of the UV system.

If applicable install a new activated carbon cartridge into the

prefilter housing at this time.

11

5

Page 12

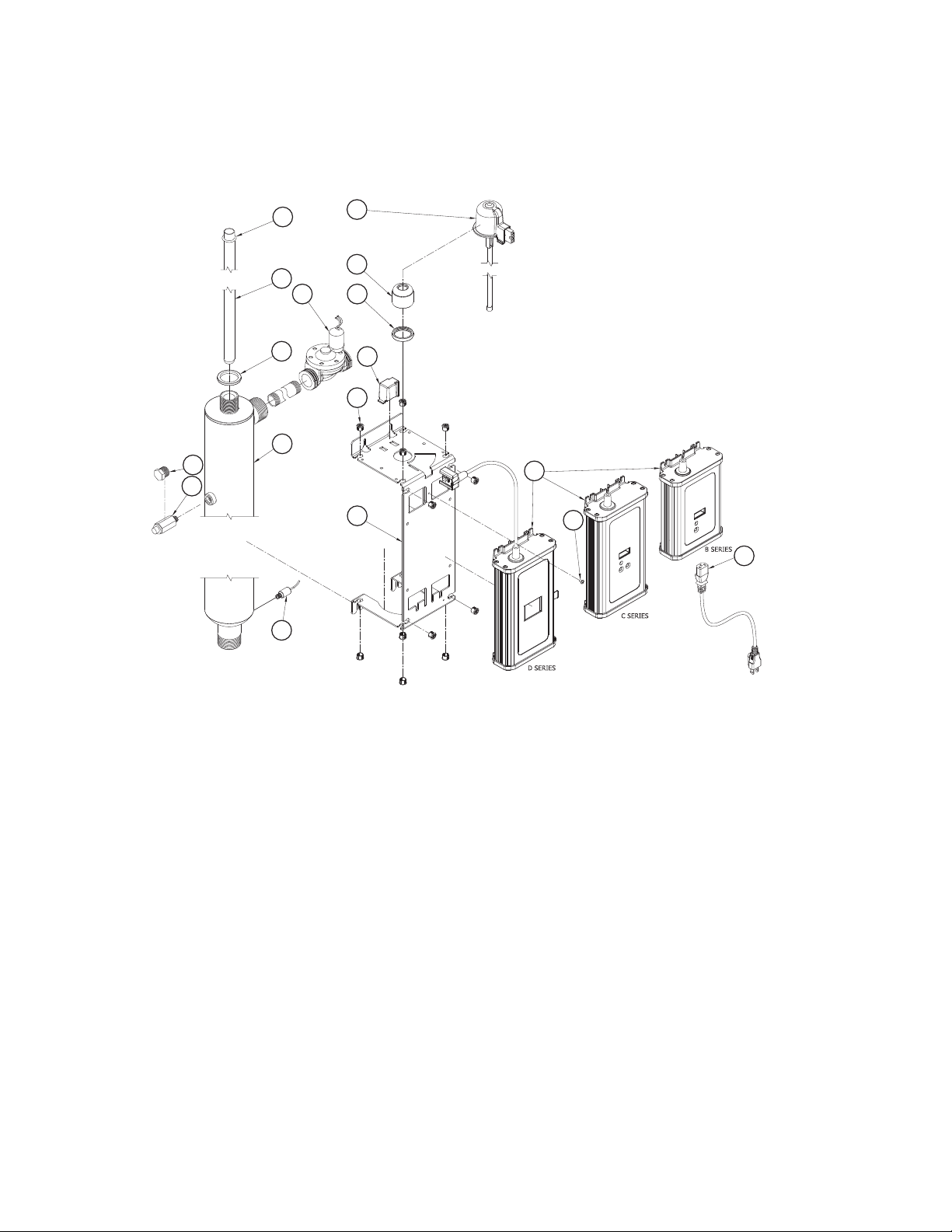

Replacement Parts Diagram

4b

4a

7

8

9

6

16

5

10

11

12

2

13

1

14

15

3

12

Page 13

Parts List

ITEM QTY. ORDERING CODE DESCRIPTION

1a 1 T7402050 Bracket for Mounting 1-2 GPM UV Chamber

1b 1 T7402044 Bracket for Mounting 6-8 GPM UV Chamber

1c 1 T7402039 Bracket for Mounting 12-20 GPM UV Chamber

1d 1 T7402038 Bracket for Mounting 25-50 GPM UV Chamber

2a 1 T7400148 UV Chamber 2.5" OD 1 GPM 3/8" MNPT for B Series Controller

2b 1 T7400149 UV Chamber 2.5" OD 2 GPM 3/8" MNPT for B Series Controller

2c 1 T7400150 UV Chamber 2.5" OD 6 GPM 3/4" MNPT for B Series Controller

2d 1 T7400151 UV Chamber 2.5" OD 8 GPM 3/4" MNPT for B Series Controller

2e 1 T7400152 UV Chamber 3.5" OD 12 GPM 1" MNPT X 3/4" FNPT Combo for B Series Controller

2f 1 T7400153 UV Chamber 3.5" OD 12 GPM 1" MNPT X 3/4" FNPT Combo for C & D Series Controller

2g 1 T7400154 UV Chamber 3.5" OD 16 GPM 1" MNPT X 3/4" FNPT Combo for C & D Series Controller

2h 1 T7400155 UV Chamber 3.5" OD 20 GPM 1" MNPT X 3/4" FNPT Combo for C & D Series Controller

2i 1 T7400156 UV Chamber 4.0" OD 25 GPM 1 1/2" MNPT X 1" FNPT Combo for C & D Series Controller

2j 1 T7400157 UV Chamber 4.0" OD 40 GPM 1 1/2" MNPT X 1" FNPT Combo for C & D Series Controller

2k 1 T7400158 UV Chamber 4.0" OD 50 GPM 1 1/2" MNPT X 1" FNPT Combo for C & D Series Controller

3 1 T7401250 Flow Switch with Cable for All Systems

4a 1 T7401000 UV Sensor Accessory Kit with Cable for C & D Series Controllers

4b 1 T7402210 Plug for UV Sensor Port when Sensor is Not Used

5 1 T7400147 Spacer for Chamber

6a 1 T7401104 UV Quartz Sleeve for 1 GPM B Series 12.7" (324mm)

6b 1 T7401105 UV Quartz Sleeve for 2 GPM B Series 16.1" (409mm)

6c 1 T7401106 UV Quartz Sleeve for 6 GPM B Series 25.1" (639mm)

6d 1 T7401107 UV Quartz Sleeve for 8 & 12 GPM B Series 30.2" (769mm)

6e 1 T7401109 UV Quartz Sleeve for 12 GPM C & D Series 20.9" (531mm)

6f 1 T7401110 UV Quartz Sleeve for 16 GPM C & D Series 24.8" (631mm)

6g 1 T7401111 UV Quartz Sleeve for 20 & 25 GPM C & D Series 28.4" (722mm)

6h 1 T7401113 UV Quartz Sleeve for 40 GPM C & D Series 39.8" (1011mm)

6i 1 T7401114 UV Quartz Sleeve for 50 GPM C & D Series 46.9" (1192mm)

7 1 T7402102 UV Quartz Sleeve O-Ring

8a 1 T7401024 UV Lamp Assembly for 1 GPM B Series

8b 1 T7401025 UV Lamp Assembly for 2 GPM B Series

8c 1 T7401026 UV Lamp Assembly for 6 GPM B Series

8d 1 T7401027 UV Lamp Assembly for 8 & 12 GPM B Series

8e 1 T7401029 UV Lamp Assembly for 12 GPM C & D Series

8f 1 T7401030 UV Lamp Assembly for 16 GPM C & D Series

8g 1 T7401031 UV Lamp Assembly for 20 & 25 GPM C & D Series

8h 1 T7401033 UV Lamp Assembly for 40 GPM C & D Series

8i 1 T7401034 UV Lamp Assembly for 50 GPM C & D Series

9 1 T7400145 UV Quartz Sleeve Nut

10 1 T7400146 UV Ring Nut

11 1 T7402025 UV Antenna Housing

12 12 T7402056 Wire Bushing

13a 1 T7401205 B Series Controller with Audible Alarm

13b 1 T7401206 C Series Controller with Alarm & 4-20 Milliamp Output

13c 1 T7401207 D Series Controller with Touch Screen Graphic Display

14 1 T7402032 Pan Screw #8 X .375"

15 1 T7402222 Power Cord 6' 120V Standard USA Plug with Ground

16a 1 T7401001 Solenoid Valve Accessory Kit 1" FNPT for 12-20 GPM Systems with C & D Series Controller

16b 1 T7401002 Solenoid Valve Accessory Kit 1 1/2" FNPT for 25-50 GPM Systems with C & D Series Controller

13

Page 14

Troubleshooting

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Bacteria in outlet water Low or no UV transmittance into the water Replace lamp

Clean or replace quartz sleeve

Replace prefilter

Confirm the pretreatment is adequate

Confirm the feed water meets the feed water require-

ments within this manual

Biofilm in outlet plumbing System needs to be sterilized

System not on Confirm continuous power supply

Low power to lamp Replace controller

Low UV intensity Lamp over 1 year old Replace lamp

Fouled quartz sleeve Clean or replace quartz sleeve

Fouled prefilter Replace prefilter

High turbidity in feed water Confirm the pretreatment is adequate

Confirm the feed water meets the feed water requirements within this manual

UV sensor fouled or defective Clean or replace UV sensor

Low power to lamp Replace controller

Lamp intensity does not increase with water flow Confirm flow switch is functioning

White or milky colored water Air in water from new prefilter or quartz

sleeve replacement

Lamp out alarm ON Filaments broken in lamp Replace lamp

Glow cap not illuminated Lamp not rotated into position for normal

operation

Low pressure after system Clogged prefilter Replace prefilter

Quartz sleeve nut leaks Quartz sleeve nut loose Tighten quartz sleeve nut

O-ring is defective Replace o-ring

Flow water through the system until water runs clear

Rotate lamp glow cap so that electrical connections

align with cut out in bracket

NOTICE

All problem conditions called out within this troubleshooting chart require the disinfection procedure to be conducted after the

corrective action has been completed.

14

Page 15

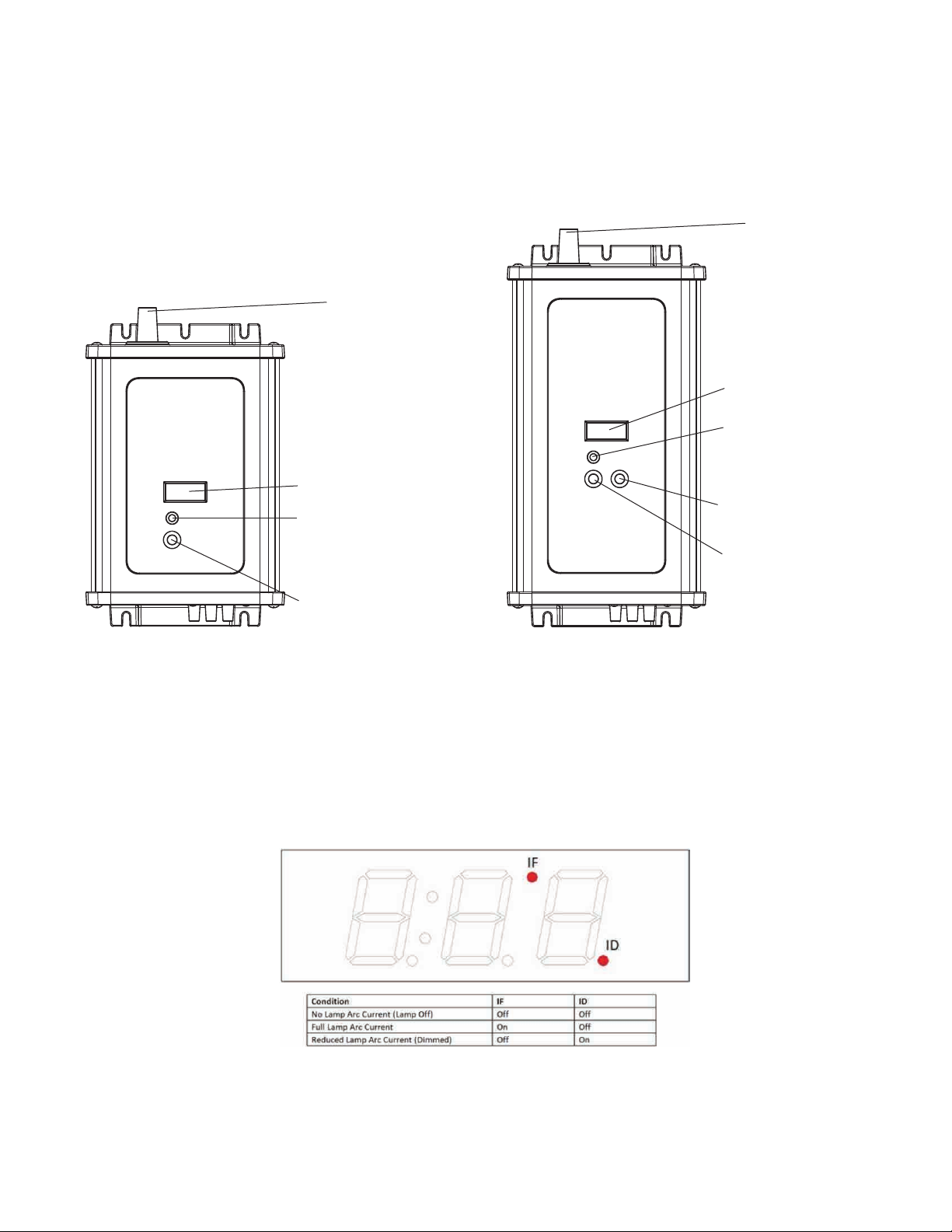

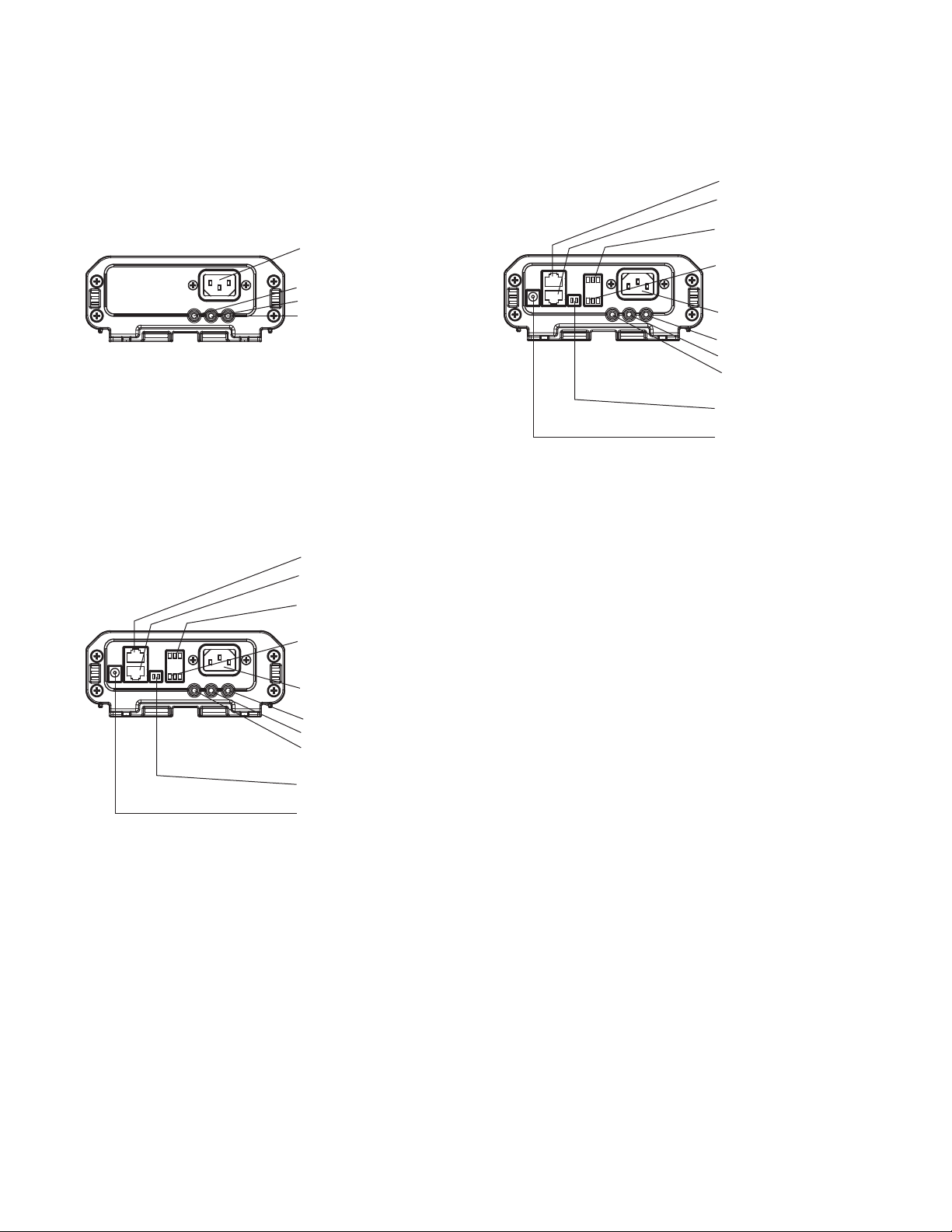

B and C Series Controller Screen and LED Identification

B Controller- Displays lamp life days remaining, Display dimming

light indicator, Button for silencing the alarm, LED

Status Indicator

C Controller- Displays lamp life days remaining, Display dim-

ming light indicator, Button for silencing the alarm,

Button for overriding the alarm relay, LED Status

Indicator

Lamp Cable

LED Display- Days remaining

and lamp dimming

System Status Indicator LED:

Green- operation normal

Red- lamp failure

Amber- Lamp life will expire

within 29 days

Audible Alarm Mute Button

(mutes alarm for 24 hours)

Lamp Cable

LED Display- Days remaining

and lamp dimming

System Status Indicator LED:

Green- operation normal

Red- lamp failure

Amber- Lamp life will expire

within 29 days

Alarm Relay Bypass Button

(bypasses as long as button

is held)

Audible Alarm Mute Button

(mutes alarm for 24 hours)

Series B

Series C

B and C Series Controllers LED Screen Identification

15

Page 16

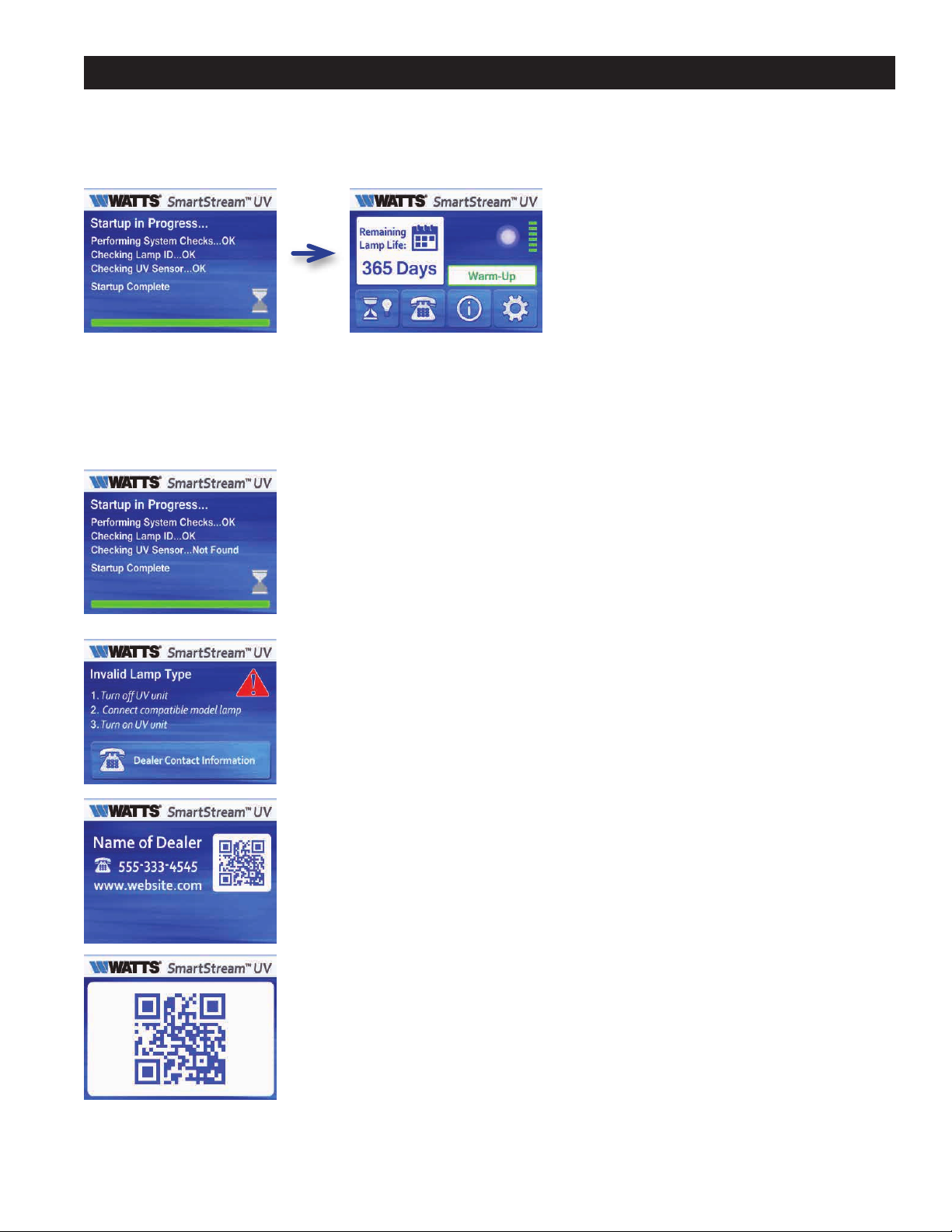

D Series Controller- Overview of Screens

Startup Screen-

When the system is first

powered up, this screen will

appear.

Lamp Warm Up Screen-

Once Startup Screen system

checks are complete, the lamp

warm up screen will appear, and

automatically complete the lamp

warm up sequence.

Home Screen-

Upon completion of the Lamp Warm Up Screen

the Home Screen will automatically appear.

This is the screen that the system will display

during normal operation. From the Home

Screen four sub-screens can be accessed by

touching the icons.

History Screen-

Displays the number of days

that the system and lamp have

been running. It also displays

the days remaining for the

current lamp.

Dealer Contact Screen-

Provides the contact information

for the service company that

installed the system.

Lamp & Sleeve

Replacement Screen-

Provides the lamp and sleeve

model numbers for the specific

system installed along with

QR codes for those items.

16

Set Up Screen-

Allows the user to select a

language as well as the bypassing and silencing of alarms.

Touching the house icon from

any of these sub-screens will

return the user to the Home

Screen.

Page 17

Start Up Screen

Normal Operation

Possible Alarms

System checks are automatically executed by

the controller in the Start Up Screen then

the system advances to the Lamp Warm Up

Screen. If an abnormal condition exists, a variety

of alarms can be displayed.

Upon start-up of the system, if the UV sensor is

not found, the user will be notified via this screen.

The system will continue to the Home Screen

when a UV sensor is not found and display the

warning message.

The lamp identifies its self via radio frequency. If

the wrong lamp is used in a system this message

will appear during start up.

Every 15 seconds the screen will change from

the Invalid Lamp Type message to the Name of

Dealer message. Touch on the QR Code to display the correct lamp QR code in full.

17

Page 18

Home Screen

Possible Alarms

The Home Screen is the normal operating

screen for the system. In this graphic the lamp

is operating at full power. If an alarm or warning

condition occurs, the system will notify the user

from this screen.

This graphic shows the lamp to be in a dimmed

condition to reduce water temperature and conserve energy.

If the system detects low UV intensity, a yellow

warning will appear. If the UV intensity is too low

for safe operation a red warning will appear. In

either condition the system should be checked

immediately for proper operation.

The system will reset an annual calendar upon

replacement of a new lamp. When 29 days

remain on any given lamp, a yellow warning will

appear. Upon zero days remaining on the lamp,

a red warning will appear. Replace lamp at this

time.

The user will be notified if a lamp failure occurs.

Upon a lamp failure condition, the alarm relay will

energize to close the outlet solenoid valve (optional) on the system and an audible alarm will sound.

Replace lamp if needed

The user will be notified if a UV sensor failure

occurs. Ensure proper wiring connections to the

controller. Clean or replace sensor if needed.

18

Page 19

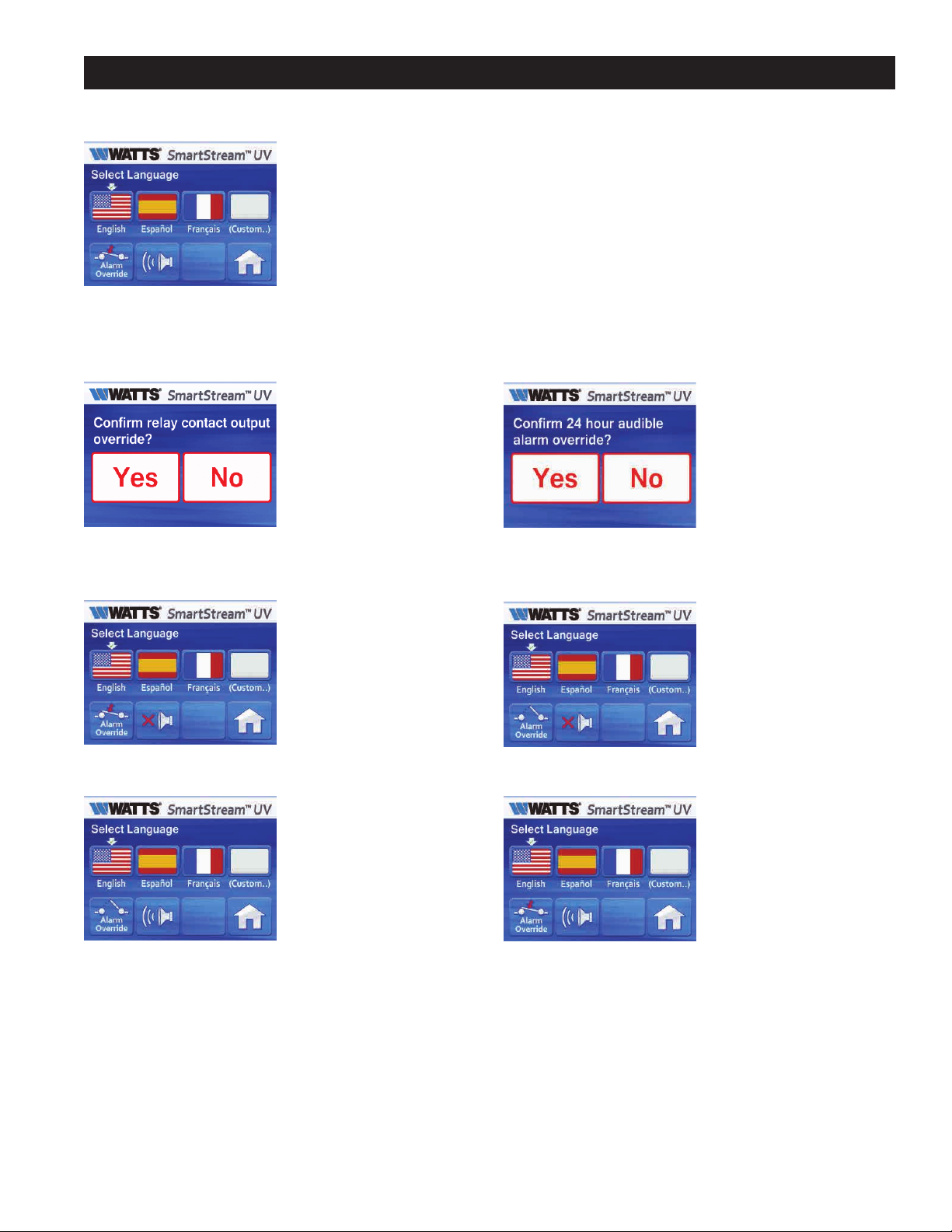

Set Up Screen

The Set Up Screen can be accessed by pressing

the gear icon on the Home Screen. This allows

the user to select a language, bypass the alarm

relay, and silence audible alarms. Touching the

house icon returns the user to the Home Screen.

Bypassing Alarms-Alarm Relay Output Bypassing Alarms-Audible Alarms

Touching the alarm override icon will bring up

a confirmation screen.

Touch Yes to return the

alarm relay to the normal operating position

and return to the Set

Up Screen. Touch No

to return to the set up

screen with the alarm

relay in the alarmed

condition.

Alarm relay output is

bypassed.

Alarm output relay is not

bypassed.

Touching the speaker

icon will bring up a confirmation screen. Touch

Yes to mute the audible

alarm for 24 hours and

return to the Set Up

Screen. Touch No to

return to the Set Up

Screen with the alarm

not muted.

Audible Alarm is muted.

Audible Alarm is not

muted.

19

Page 20

Lamp and Sleeve Replacement Screen

The Lamp and Sleeve Replacement Screen

can be accessed by touching the information

icon at the bottom of the Home Screen. This will

provide the system model number along with the

model number and QR codes for replacement

lamps and quartz sleeves.

Touching the QR Code icons on the Lamp and

Sleeve Replacement Screen will enlarge them.

If there are no buttons touched over a 30 seconds period the system will go back to the

Home Screen. To return from the full screen QR code, touch the screen.

20

Page 21

Series B, C and D Controller Wiring

Power Input AC 100-240

VAC 50/60HZ

Left- Antenna Wire

Center- Flow Switch

Right- Ground to Chassis

Series B

Series C

Top Cat 5- Future Accessories

Bottom Cat 5- UV Sensor

Alarm Relay A (Left to Right)

Normally Closed/Common/

Normally Open

Alarm Relay B (Left to Right)

Normally Closed/Common/

Normally Open

Power Input AC 100-240

VAC 50/60HZ

Right- Ground to Chassis

Center- Flow Switch

Left- Antenna Wire

4-20mA Transmitter (Left is

'Loop +', Right is 'Loop -')

Future Accessories

Series D

Top Cat 5- Future Accessories

Bottom Cat 5- UV Sensor

Alarm Relay A (Left to Right)

Normally Closed/Common/

Normally Open

Alarm Relay B (Left to Right)

Normally Closed/Common/

Normally Open

Power Input AC 100-240

VAC 50/60HZ

Right- Ground to Chassis

Center- Flow Switch

Left- Antenna Wire

4-20mA Transmitter (Left is

'Loop +', Right is 'Loop -')

Future Accessories

21

Page 22

Notes

22

Page 23

Notes

23

Page 24

Limited Warranty

Watts Regulator Co. (the “Company”) warrants its SmartStream™ ultraviolet disinfection product to be free from defects in material and

workmanship under normal usage for the following periods beginning on the date of original shipment:

• Stainless steel reactor chamber – 10 years

• Flow Switch – 3 years

• Electronics and ballast – 5 years prorated

• UV lamp, quartz sleeve, UV sensor and all other components - 1 year

In the event of such defects within the applicable warranty period, the Company will, at its option, repair or replace the product with-

out charge. Defective components are subject to inspection by the Company before any warranty remedy is provided. The Company

will cover the cost of shipping any repaired or replaced product to you in the event the original product was found by the Company

to be defective. The Company reserves the right to make changes or substitutions in defective parts or components with material of

equal quality or value.

A return authorization number, issued by the Company, is required before returning any product to the Company for warranty claim

evaluation. You must provide the product model number, serial number, and invoice number when making a warranty claim within

the applicable warranty period. The original serial number and model number labeling must be intact on any product at the time any

warranty claim is made in order for it to be eligible for a warranty remedy. You are responsible for the cost of shipping any defective

product to the Company for inspection. Damage caused by improper handling while the product is in transit is not covered by this

limited warranty. This limited warranty is provided by the Company to the original purchaser and is non-transferable.

Conditions

The SmartStream™ product must be installed in applications with water quality adhering to the Feed Water Quality Guidelines set forth

in the Company’s most recently published installation and operation manual or other published product specification sheet. The product must be installed and operated in compliance with the Company’s published installation and operation manual, product specification sheet, and local plumbing codes. This product must be installed in connection with an approved water supply. This product

must be operated at water pressures and temperatures that do not exceed the Company’s published specifications. This product

is limited to use within atmospheric environments indoors that are within ambient temperature limitations, free from external water

contact, where relative humidity is below 95% non-condensing, and that are noncorrosive to the product’s materials of construction,

including its electronic components.

The use of any unauthorized or inappropriate replacement parts will void this limited warranty.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH

RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY

HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described above in this Limited Warranty shall constitute the sole and exclusive remedy for breach of warranty, and the

Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the

cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from labor

charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any

other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication,

improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation

of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty gives you specific

legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to determine your

rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED,

INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN

DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

Contact:

Watts

13700 US Hwy 90 West

San Antonio, TX 78245

Phone: 210-677-8400

Fax: 210-677-8402

Watts.com

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information: www.watts.com/prop65

A Watts Water Technologies Company

Latin America: Tel: (52) 81-1001-8600 • Fax: (52) 81-8000-7091 • Watts.com

IOM-WQ-SmartStream-BCD 1550 EDP#2915188 © 2015 Watts

USA: Tel: (800) 659-8400 • Fax: (800) 659-8402 • Watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • Watts.ca

Page 25

Manuel d'installation,

d'utilisation et d'entretien

Systèmes de désinfection par

ultraviolets germicides de

254nanomètres

Modèles

WB001 WB002 WB006 WB008 WB012 WC012 WC016

WC020 WC025 WC040 WC050 WD012 WD016 WD020

WD025 WD040 WD050

Désinfection de l'eau sans agents

chimiques par ultraviolets SmartStream

™

IOM-WQ-SmartStream-BCD_FR

Traduction des

instructions d’origine

!

AVERTISSEMENT

Lisez ce manuel AVANT d’utiliser

cet équipement. Le non-respect

de cette instruction ou des rensei-

gnements relatifs à la sécurité et à

l'utilisation risque de provoquer des blessures

graves, voire mortelles, des dégâts matériels et

des dommages à l'équipement. Conservez ce

manuel pour référence ultérieure.

Cet appareil est conforme à la section15 du règlement de la FCC.

L'utilisation est assujettie aux deux conditions suivantes: (1) cet

appareil est susceptible de causer des interférences nuisibles, et (2)

cet appareil doit accepter toute interférence reçue, y compris des

interférences causant un fonctionnement indésirable.

Cet appareil est conforme aux normes CNR exemptes de permis

d'IndustrieCanada. L'utilisation est assujettie aux deux conditions

suivantes: (1) cet appareil est susceptible de causer des interférences, et (2) cet appareil doit accepter toute interférence, y compris des

interférences causant un fonctionnement indésirable de l'appareil.

Cet appareil est conforme aux normes CNR applicables aux appareils radio exempts de permis d'Industrie Canada. L'utilisation est

assujettie aux deux conditions suivantes : (1) l'appareil ne doit pas

produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter

tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Toute transformation ou modification de ce produit non autorisée par

le fabricant pourrait annuler le droit de l'utilisateur d'utiliser le matériel.

Cet appareil est conforme aux limites de la norme CNR-102

d'Industrie Canada sur l'exposition aux radiations établies pour

un environnement non-contrôlé. Cet appareil doit être installé et

utilisé avec une distance minimale de 20cm entre le radiateur et

votre corps.

Conformément à la réglementation d'Industrie Canada, le présent

émetteur radio peut uniquement fonctionner avec une antenne d'un

type et d'un gain maximal (ou inférieur) approuvé pour l'émetteur

par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l’intention des autres utilisateurs, il faut choisir

le type d’antenne et son gain de sorte que la puissance isotrope

rayonnée équivalente (p.i.r.e.) ne dépasse pas l’intensité nécessaire à

l’établissement d’une communication satisfaisante.

!

AVERTISSEMENT

Cet appareil contient un émetteur UV-C

(lampe UV). Un usage abusif de l'appareil ou

un dommage au porte-filtre peut entraîner

la libération de rayons UV-C dangereux. Les

rayons UV-C peuvent, à petites doses, causer

des problèmes dermatologiques et oculaires. Tout appareil clairement endommagé ne

doit pas être utilisé. N'utilisez pas l'émetteur

UV-C lorsqu'il est sorti du boîtier de l'appareil.

L'appareil doit être débranché de la source de

courant avant de remplacer l'émetteur UV-C.

NE REGARDEZ PAS directement la lumière

provenant de l'émetteur UV-C quand il est

allumé. Vous risquez de subir de graves dommages permanents aux yeux.

Table des matières

Précautions d'installation..................................3

Caractéristiques du système ............................. 4-7

Table des caractéristiques du produit....................... 5-7

Dimensions ............................................8

Exigences concernant l'eau d'alimentation ....................9

Procédure d'installation ................................ 9-10

Entretien .............................................11

Remplacement de la lampe et du manchon en quartz ........... 11

Procédure de désinfection................................11

Liste des pièces..................................... 12-13

Dépannage ...........................................14

Identification du contrôleur................................15

Aperçu des écrans .................................. 16-20

Câblage du contrôleur ...................................21

Garantie et conditions ...................................24

Page 26

AVIS

L'installation et l'entretien de ce système doivent être effectués seulement par un professionnel qualifié. Respectez tous les codes du

bâtiment ou de plomberie nationaux, provinciaux et locaux lors de l'installation du système.

Introduction

La gamme de systèmes de désinfection par ultraviolets Watts

SmartStream™ assure une protection contre la contamination

microbiologique dans l'eau pour les applications résidentielles

et commerciales.

La désinfection de l'eau avec le SmartStream™ est un procédé

physique simple et rapide. Quand l'eau contaminée est exposée

à la lumière ultraviolette de 254nanomètres du SmartStream™,

celle-ci pénètre dans les parois cellulaires des micro-organismes

et bouleverse leur matériel génétique (acide désoxyribonucléique

ou ADN). S'ensuit une inactivation rapide des micro-organismes

par la destruction de leur capacité à se reproduire et à infecter.

AVIS

Les systèmes par ultraviolets Watts SmartStream™

sont conçus avec des composants de première

qualité. Si, à un moment quelconque, un composant doit être remplacé, n'utilisez que des pièces

recommandées et fournies par Watts. N'ajoutez

PAS des composants au système et n'en retirez

pas non plus.

La lampe par ultraviolets peut être utilisée pendant 9000heures dans des conditions normales

de fonctionnement, et doit être remplacée tous

les ans pour maintenir l'intensité des UV au

rendement maximal. Les manchons en quartz

doivent être nettoyés au besoin ou remplacés si

nécessaire pour garantir un degré maximum de

transmittance UV dans l'eau.

N'utilisez que des lampes par ultraviolets et des

manchons en quartz fournis par Watts pour votre

modèle précis. Le non-respect de cette consigne pourrait entraîner une panne du système et

annulera toutes les garanties.

N'utilisez PAS ce système d'une manière

non prévue. Ce purificateur ne doit être utilisé que dans les applications d'eau où l'eau

d'alimentation, l'environnement d'installation et la

méthode d'installation respectent les exigences

décrites dans le présent manuel.

Le système doit être correctement dimensionné.

Ne dépassez PAS la capacité de débit nominal

du système. Des contrôleurs de débit disponibles

chez Watts permettent de s'assurer que le débit

nominal du système n'est pas dépassé.

Suivez toutes les consignes que contiennent les

étiquettes sur la sécurité des produits.

• Empêchez le gel du système. Le système

pourrait s'endommager.

• Installez le système sur une surface plane

et horizontale.

• La qualité de l'eau à traiter doit respecter les indices

pour l'eau d'alimentation contenus dans le présent

manuel. Le défaut d'assurer un prétraitement

approprié entraîne une désinfection inadéquate.

!

AVERTISSEMENT

NE VOUS fiez pas uniquement à ce système

pour rendre l'eau potable. Les systèmes de

désinfection par ultraviolets SmartStream™

sont destinés à être utilisés comme partie d'un

système de traitement d'eau conçu avec soin.

Une eau qui contient des contaminants

microbiologiques doit être testée régulièrement

pour garantir sa qualité et sa salubrité au

point d'utilisation.

AVIS

L'utilisation de cet appareil est réservée aux

personnes de plus de 18ans et aux personnes

ayant des capacités physiques, mentales

ou sensorielles ou manquant d'expérience à

condition que ces personnes aient reçu une

supervision ou des instructions concernant

l'utilisation sûre de l'appareil et en comprennent

les dangers. Les enfants ne sont pas autorisés à jouer avec l'appareil. Le nettoyage et

l'entretien ne peuvent en aucun cas être réalisés par des enfants.

2

Page 27

!

AVERTISSEMENT

Utilisation du SmartStream™ avec un autre

équipement de traitement d'eau.

Les appareils par ultraviolets SmartStream™

peuvent être installés comme une méthode de

désinfection finale dans un système de traitement

d'eau, ou comme un dispositif de prétraitement

pour protéger les composants sensibles, telles que

les membranes d'osmose inverse, des biofilms.

L'injection de produits chimiques dans l'eau doit

se faire à la sortie du système SmartStream™

pour s'assurer de la dégradation du produit

chimique par les UV et qu'il n'y a pas de turbidité

dans le flux d'UV.

Un filtre à particules de 5microns doit toujours

être installé immédiatement avant le système

SmartStream™.

Veiller à ce que l'eau d'alimentation respecte tous

les critères décrits dans la section Indications

pour l'eau d'alimentation du présent manuel.

!

AVERTISSEMENT

Directives d'installation

• NE PAS laisser ce système allumé sans eau à

l'intérieur pendant de longues périodes.

• NE PAS installer le système à proximité d'une

source de chaleur. En outre, ne PAS installer

le système à proximité d'un appareil ou d'une

zone de dégagement qui pourrait être affecté(e)

par l'eau.

• NE PAS installer ce système à une hauteur de plus

de 10000pieds au-dessus du niveau de la mer.

• NE PAS installer le système à l'envers avec la con-

duite d'alimentation d'eau connectée à la sortie.

• NE PAS installer le système à un endroit où il

pourrait entrer en contact avec des produits

chimiques, ou à un endroit où il pourrait être

heurté par un équipement en mouvement, un

chariot, un balai, ou tout autre élément pouvant

l'endommager.

• NE PAS installer le système à l'extérieur.

Protéger le système de l'humidité, la pluie et la

lumière directe du soleil. La température de l'air

ambiant doit rester en dessous de 122°F et

l'humidité relative doit rester inférieure à 95%.

• EMPÊCHER le gel du système.

• Le système DOIT être monté sur une surface

avec un matériel de montage assez robuste

pour supporter le poids du système sous eau.

• Le système DOIT être raccordé à une unité

d'alimentation permanente qui est conforme à sa

puissance nominale requise. En ce qui concerne

les installations européennes, l'appareil doit être

fourni avec un dispositif différentiel résiduel (DDR)

avec un courant de fonctionnement résiduel nominal ne dépassant pas 30milliampères.

• Le système DOIT être installé conformément

à tous les codes nationaux, provinciaux et

locaux applicables.

• Un préfiltre avec une réduction de taille de

particules de 5microns minimum doit être

installé sur la conduite d'entrée du système.

Un prétraitement supplémentaire peut être

nécessaire afin que l'eau d'alimentation soit

conforme à la section Indications pour l'eau

d'alimentation de la page8.

• Le matériel de plomberie sensible à la lumière

UV, généralement les matières plastiques, ne

doit pas être raccordé directement au système.

Pour empêcher la dégradation par les UV sur

les points de raccord de plomberie du système,

utilisez un matériel de plomberie en cuivre ou en

inox d'un pied minimum pour raccorder l'entrée

et la sortie du système.

• Si un coup de bélier est apparent, installer des

antibéliers en amont du système.

• Sécuriser toujours les vannes et les adaptateurs

à l'aide d'une clé lors de l'installation de la plomberie pour réduire les contraintes inutiles sur le

système et sa plomberie.

Placer le système à un emplacement adéquat.

S'assurer qu'il y a assez d'espace entre l'extrémité

de la chambre UV et toute obstruction, pour permettre le démontage de la lampe et du manchon

en quartz.

Les systèmes de désinfection par ultraviolets

SmartStream™ doivent être installés aussi près

que possible du point d'utilisation de l'eau traitée.

3

Page 28

Caractéristiques du Système

Clé d'identification de la référence du système par ultraviolets SmartStream™

Préfixe «W» «Série du contrôleur» «G/M» «Type de raccord» «Taille de tuyau» «Bouchon» «Accessoires»

Watts Type de Contrôleur

Contrôleur B

ContrôleurC

ContrôleurD

Caractéristiques du contrôleur

Trois différents contrôleurs sont disponibles sur les différents

systèmes par ultraviolets SmartStream™. Les contrôleurs sont

identifiés sous la série «B», «C» ou «D». Chaque contrôleur

possède des caractéristiques uniques qui sont présentées

comme suit:

ModèleB ModèleC ModèleD

G/M du Système

(3chiffres)

Types d'orifices de

raccordement:

A: NPT

B: Conique BSP

Taille du tuyau B:

3/8po C: 1/2po D:

3/4po E: 1"

F: Raccord combiné

femelle 3/4po X 1po

mâle Raccord combiné femelle 1po X 1

1/2po mâle

A: Nord-américain

Européen

Britannique R.U.

Australien

Accessoires:

Pas d'accessoires

(accessoires disponibles uniquement

pour les systèmes

utilisant des

contrôleurs de type

C et D.) Capteur

d'UV

B- Contrôleur de base avec fonction de gradation de l'éclairage,

capteur de débit, alarme sonore d'extinction de lampe, indicateur d'état du système de LED multicolores, témoin luminescent,

minuterie de durée de vie de lampe avec écran LED 3chiffres,

communication par radiofréquence vers la lampe pour vérifier si

c'est la bonne lampe et la durée de vie restante de la lampe. La

minuterie de durée de vie de la lampe se réinitialise quand une

nouvelle lampe est introduite.

Les contrôleurs sérieB sont certifiés par la Federal Communications Commission (FCC) sous le numéro d'identification

FCC ID: 2AFJT-SMARTSTREAM-B et par Industrie Canada (IC)

sous le numéro d'identification d'IC: 20623-SMARTSTRMB.

C- Toutes les caractéristiques du contrôleur B plus la sortie

d'alarme pour l'électrovanne, l'entrée du capteur d'UV, la sortie

4-20milliampères pour l'intensité des UV (lorsque le capteur

d'UV est utilisé).

Les contrôleurs sérieC sont certifiés par la Federal Communications Commission (FCC) sous le numéro d'identification

FCC ID: 2AFJT-SMARTSTREAM et par Industrie Canada (IC)

sous le numéro d'identification d'IC: 20623-SMARTSTREAM.

D- Toutes les caractéristiques du contrôleur C. L'afficheur passe

d'un écran LED à 3chiffres à un écran tactile graphique. Le

nombre total d'heures du système apparaît avec les principales

données opérationnelles.

Les contrôleurs sérieD sont certifiés par la Federal Communications Commission (FCC) sous le numéro d'identification

FCC ID: 2AFJT-SMARTSTREAM et par Industrie Canada (IC)

sous IC: 20623-SMARTSTREAM.

4

Page 29

Caractéristiques du système

Contrôleur sérieB avec fonction de gradation de l'éclairage

FCC ID: 2AFJT-SMARTSTREAM-B Débit en g/m 1 2 6 8 12

IC: 20623-SMARTSTRMB

Bloc d'alimentation à entrée universelle

Chambre en inox 316

Alarme sonore

Indicateur de lampe allumée

Témoin luminescent

Minuterie de durée de vie de lampe avec écran 3chiffres

Extinction automatique de la lampe lorsqu'elle est retirée de la

chambre (sans fil)

Gradation de l'éclairage

Support de montage intégré

Relais de contact d'alarme (pour

l'électrovanne)

Entrée du capteur d'UV

Sortie 4 à 20mA

Puissance de 12V pour le ventilateur de refroidissement de la chambre

Écran graphique

Indicateur du nombre total d'heures du système

Modèle

du système n°

WB001 WB002 WB006 WB008 WB012

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4 4 4

4 4 4

Table des caractéristiques du produit

MODÈLE WB001

DÉBIT à 16mJ

(95%UVio en fin de vie)

(peut être limité hydrauliquement)

DÉBIT à 40mJ

(95%UVio en fin de vie)

DÉBIT à 40mJ

(95%UVio en fin de vie)

ORIFICES D'ENTRÉE/SORTIE NPT STANDARD 3/8"NPT-M 3/4"NPT-M

ORIFICES D'ENTRÉE/SORTIE BSP-T EN OPTION 3/8"BSP-M 3/4"BSP-M

MATÉRIAU DE CHAMBRE INOX 316L

MONTAGE DU CONTRÔLEUR Éloigné de la chambre

TENSION D'ENTRÉE 100 à 240V c,a, 50/60Hz

PUISSANCE D'ENTRÉE NOMINALE MAX DU SYSTÈME (Watt) 11 15 26 34 34

PUISSANCE ÉLECTRIQUE NOMINALE MAX DE LA LAMPE (Watt) 10 14 25 32 32

TECHNOLOGIE DE LAMPE

CLÉ DE LAMPE SANS FIL Standard

GRADATION DE L'ÉCLAIRAGE/CAPTEUR DE DÉBIT Standard

VENTILATEUR DE REFROIDISSEMENT DE LA CHAMBRE Sans objet

TYPE D'ÉCRAN DU SYSTÈME LED trois chiffres à sept segments

MONITEUR DE DURÉE DE VIE DE LAMPE Écran LED 3chiffres, réinitialisation auto avec nouvelle lampe

CAPTEUR D'UV Sans objet

SORTIE 4 à 20mA Sans objet

ALARME VISUELLE LED d'état multicolore

ALARME SONORE Yes (Oui)

MISE EN SOURDINE ALARME SONORE Yes (Oui)

CONTACTS RELAIS D'ALARME/SOLÉNOÏDE Sans objet

NEUTRALISATION MANUELLE DU RELAIS D'ALARME Sans objet

TEMPÉRATURE D'AIR AMBIANTE/HUMIDITÉ MAXIMALE 50°C (122°F) / 95 % HR (sans condensation)

GAMME DES TEMPÉRATURES POUR L'ENTRÉE D'EAU 1°C (34°F) à 45°C (113°F)

PRESSION D'EAU MAX 861kPa (125psi)

POIDS À L'EXPÉDITION 11LB (5KG) 11LB (5KG) 17LB (8KG) 18LB (8KG) 19LB (9KG)

usgpm

litres/min

usgpm

litres/min

usgpm

litres/min

2,8 gpm

10,6 lpm

1,5 gpm

5,7 lpm

2g/m

(7,6l/m)

Lampe basse pression en verre de quartz / ne produit pas d'ozone /

WB002 WB006 WB008 WB012

4,7 gpm

17,8 lpm

2g/m

(7,6l/m)

2g/m

(7,6l/m)

démarrage véritable par préchauffage / témoin luminescent

11,4 gpm

43,1 lpm

6,1 gpm

23,1 lpm

4,6 gpm

17,4 lpm

15,0 gpm

56,8 lpm

8,0 gpm

30,3 lpm

6,0 gpm

22,7 lpm

Sur le support de la chambre

ou éloigné de la chambre

23,4 gpm

88,6 lpm

12,5 gpm

47,3 lpm

35,6 lpm

Orifices combinés 1po

NPT-M / 3/4po NPT-F

Orifices combinés

1po BSP-M / 3/4po BSP-F

9,4 gpm

5

Page 30

Caractéristiques du système

Contrôleur sérieC avec fonction de gradation de l'éclairage

FCC ID: 2AFJT-SMARTSTREAM Débit en g/m 12 16 20 25 40 50

IC: 20623-SMARTSTREAM Modèle

du système n°

Bloc d'alimentation à entrée universelle

Chambre en inox 316

Alarme sonore

Indicateur de lampe allumée

Témoin luminescent

Minuterie de durée de vie de lampe avec écran 3chiffres

Extinction automatique de la lampe lorsqu'elle est retirée de la

chambre (sans fil)

Gradation de l'éclairage

Support de montage intégré

Relais de contact d'alarme (pour l'électrovanne)

Entrée du capteur d'UV

Sortie 4 à 20mA (si le capteur d'UV est utilisé)

Puissance de 12V pour le ventilateur de refroidissement de la chambre

Écran graphique

Indicateur du nombre total d'heures du système

WC012 WC016 WC020 WC025 WC040 WC050

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

Table des caractéristiques du produit

MODÈLE WC012

DÉBIT à 16mJ

(95%UVio en fin de vie)

(peut être limité hydrauliquement)

DÉBIT à 40mJ

(95%UVio en fin de vie)

DÉBIT à 40mJ

(95%UVio en fin de vie)

ORIFICES D'ENTRÉE/SORTIE NPT STANDARD

ORIFICES D'ENTRÉE/SORTIE BSP-T EN OPTION

MATÉRIAU DE CHAMBRE INOX 316L

MONTAGE DU CONTRÔLEUR Sur le support de la chambre ou éloigné de la chambre

TENSION D'ENTRÉE 100 à 240V c.a. 50/60Hz

PUISSANCE D'ENTRÉE NOMINALE MAX DU SYS-

TÈME (Watt)

PUISSANCE ÉLECTRIQUE NOMINALE MAX DE LA

LAMPE (Watt)

TECHNOLOGIE DE LAMPE

CLÉ DE LAMPE SANS FIL Standard

GRADATION DE L'ÉCLAIRAGE/CAPTEUR DE DÉBIT Standard

VENTILATEUR DE REFROIDISSEMENT DE LA CHAMBRE Applicable en option

TYPE D'ÉCRAN DU SYSTÈME LED trois chiffres à sept segments

MONITEUR DE DURÉE DE VIE DE LAMPE Écran LED 3chiffres, réinitialisation auto avec nouvelle lampe

CAPTEUR D'UV Disponible en option

SORTIE 4 à 20mA Avec capteur d'UV en option

ALARME VISUELLE LED d'état multicolore

ALARME SONORE Yes (Oui)

MISE EN SOURDINE ALARME SONORE Yes (Oui)

CONTACTS RELAIS D'ALARME/SOLÉNOÏDE Oui - 24V, 5A maximum

NEUTRALISATION MANUELLE DU RELAIS D'ALARME Yes (Oui)

TEMPÉRATURE D'AIR AMBIANTE/HUMIDITÉ MAXIMALE 50°C (122°F) / 95 % HR (sans condensation)

GAMME DES TEMPÉRATURES POUR L'ENTRÉE D'EAU 1°C (34°F) à 45°C (113°F)

PRESSION D'EAU MAX 861kPa (125psi)

POIDS À L'EXPÉDITION

usgpm

litres/min

usgpm

litres/min

usgpm

litres/min

24,0 gpm

90,8 lpm

12,8 gpm

48,4 lpm

9,6 gpm

36,3 lpm

Orifices combinés 1po NPT-M /

Orifices combinés 1po BSP-M /

47 58 67 67 100 118

45 55 64 64 95 112

Lampe basse pression en verre de quartz / ne produit pas d'ozone / démarrage véritable

19LB (9KG) 19LB (9KG) 20LB (9KG) 25LB (11KG) 27LB (12KG) 29LB (13KG)

WC016 WC020 WC025 WC040 WC050

31,5 gpm

119,2 lpm

16,8 gpm

63,6 lpm

12,6 gpm

47,7 lpm

3/4po NPT-F

3/4po BSP-F

39,0 gpm

147,6 lpm

20,8 gpm

78,7 lpm

15,6 gpm

59,0 lpm

par préchauffage / témoin luminescent

46,9 gpm

177,5 lpm

25,0 gpm

94,6 lpm

18,8 gpm

71,2 lpm

Orifices combinés 1,5po NPT-M /

Orifices combinés 1,5po BSP-M /

1po BSP-F

75,0 gpm

283,9 lpm

40,0 gpm

151,4 lpm

30,0 gpm

113,6 lpm

1po NPT-F

6

93,8 gpm

355,0 lpm

50,0 gpm

189,3 lpm

37,5 gpm

141,9 lpm

Page 31

Caractéristiques du système

Contrôleur sérieD avec fonction de gradation de l'éclairage et

FCC ID: 2AFJT-SMARTSTREAM Débit en g/m 12 16 20 25 40 50

IC: 20623-SMARTSTREAM Modèle

du système n°

Bloc d'alimentation à entrée universelle

Chambre en inox 316

Alarme sonore

Indicateur de lampe allumée

Témoin luminescent

Minuterie de durée de vie de lampe avec écran 3chiffres

Extinction automatique de la lampe lorsqu'elle est retirée de

la chambre (sans fil)

Gradation de l'éclairage

Support de montage intégré

Relais de contact d'alarme (pour l'électrovanne)

Entrée du capteur d'UV

Sortie 4 à 20mA (si le capteur d'UV est utilisé)

Puissance de 12V pour le ventilateur de refroidissement de la chambre

Écran graphique

Indicateur du nombre total d'heures du système

WD012 WD016 WD020 WD025 WD040 WD050

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

4 4 4 4 4 4

écran graphique

Table des caractéristiques du produit

MODÈLE WD012

DÉBIT à 16mJ

(95%UVio en fin de vie)

(peut être limité hydrauliquement)

DÉBIT à 40mJ

(95%UVio en fin de vie)

DÉBIT à 40mJ

(95%UVio en fin de vie)

ORIFICES D'ENTRÉE/SORTIE NPT STANDARD

ORIFICES D'ENTRÉE/SORTIE BSP-T EN OPTION

MATÉRIAU DE CHAMBRE INOX 316L

MONTAGE DU CONTRÔLEUR Sur le support de la chambre ou éloigné de la chambre

TENSION D'ENTRÉE 100 à 240V c.a. 50/60Hz

PUISSANCE D'ENTRÉE NOMINALE MAX DU SYSTÈME (Watt) 47 58 67 67 100 118

PUISSANCE ÉLECTRIQUE NOMINALE MAX DE LA LAMPE (Watt) 45 55 64 64 95 112

TECHNOLOGIE DE LAMPE

CLÉ DE LAMPE SANS FIL Standard

GRADATION DE L'ÉCLAIRAGE/CAPTEUR DE DÉBIT Standard

VENTILATEUR DE REFROIDISSEMENT DE LA CHAMBRE Disponible en option

TYPE D'ÉCRAN DU SYSTÈME Écran tactile couleur, plusieurs langues disponibles, navigation intuitive de

MONITEUR DE DURÉE DE VIE DE LAMPE Afficheur de l'écran graphique tactile, réinitialisation auto avec nouvelle lampe

CAPTEUR D'UV Disponible en option

SORTIE 4 à 20mA Avec capteur d'UV en option

ALARME VISUELLE Icônes animées et messages textuels sur l'écran graphique

ALARME SONORE Yes (Oui)

MISE EN SOURDINE ALARME SONORE Yes (Oui)

CONTACTS RELAIS D'ALARME/SOLÉNOÏDE Oui - 24V, 5A maximum

NEUTRALISATION MANUELLE DU RELAIS D'ALARME Yes (Oui)

TEMPÉRATURE D'AIR AMBIANTE/HUMIDITÉ MAXIMALE 50°C (122°F) / 95 % HR (sans condensation)

GAMME DES TEMPÉRATURES POUR L'ENTRÉE D'EAU 1°C (34°F) à 45°C (113°F)

PRESSION D'EAU MAX 861kPa (125psi)

POIDS À L'EXPÉDITION

usgpm

litres/min

usgpm

litres/min

usgpm

litres/min

24.0 gpm

90.8 lpm

12.8 gpm

48.4 lpm

9.6 gpm

36.3 lpm

Orifices combinés 1po NPT-M /

Orifices combinés 1po BSP-M /

l'écran, messages détaillés d'état du système, entretien/diagnostic, program-

19LB (9KG) 19LB (9KG) 20LB (9KG) 25LB (11KG) 27LB (12KG) 29LB (13KG)

WD016 WD020 WD025 WD040 WD050

31.5 gpm

119.2 lpm

16.8 gpm

63.6 lpm

12.6 gpm

47.7 lpm

3/4po NPT-F

3/4po BSP-F

Lampe basse pression en verre de quartz / ne produit pas d'ozone /

démarrage véritable par préchauffage / témoin luminescent

mable par le distributeur avec site Web/coordonnées/Codes QR

39.0 gpm

147.6 lpm

20.8 gpm

78.7 lpm

15.6 gpm

59.0 lpm

46.9 gpm

177.5 lpm

25.0 gpm

94.6 lpm

18.8 gpm

71.2 lpm

Orifices combinés 1,5po NPT-M /

Orifices combinés 1,5po BSP-M /

75.0 gpm

283.9 lpm

40.0 gpm

151.4 lpm

30.0 gpm

113.6 lpm

1po NPT-F

1po BSP-F