Watts Radiant WQC4 RO User Manual

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Please read carefully before proceeding with installation. Your failure to follow the instructions or

operating parameters may lead to the product’s failure and possible damage to property.

Warning

Save manual for future reference

SERIES

WQC4 RO

Refer to enclosed warranty and operating parameters to ensure proper use with your water supply.

DISTRIBUTED BY:

Page 1

Manual Edition: 4/12/07

NOTE: This manual is used for several variations of the same system. Your system may

vary slightly from the pictures or descriptions contained in this manual.

It is end users responsibility to ensure that this system is installed according to all

local codes and regulations.

Thank you for your purchase of a state of the art Watts Reverse Osmosis (RO) water treatment system. Water quality

concerns are becoming more of a focus for the public. This Watts water treatment system has been designed and tested to

provide you with high quality water for years to come. The following is a brief overview of the system.

Your Reverse Osmosis System:

Osmosis is the process of water passing through a semi permeable membrane in order to balance the concentration of

contaminants on each side of the membrane. A semi permeable membrane is a barrier that will pass some substances like

clean water, but not other substances such as salts and minerals.

Reverse osmosis uses a semi permeable membrane; however, by applying pressure across the membrane, it concentrates

contaminants on one side of the membrane, producing clean water on the other. This is why RO systems produce both clean

drinking water and waste water that is fl ushed from the system.

Your system is a Four Stage RO which is based upon four separate treatment segments within one complete water fi ltration

system. These stages are as follows:

Stage 1 – Sediment fi lter, recommended change 6 months.

The fi rst stage of your RO system is a fi ve micron sediment fi lter that traps sediment and other particulate matter

like dirt, silt and rust which affect the taste and appearance of your water.

Stage 2 – Pre-Carbon fi lter, recommended change 6 months.

The second stage contains a carbon block fi lter. This helps ensure that chlorine and other materials that cause bad

taste and odor are greatly reduced.

Stage 3- Membrane, recommended change 1-2 years.

Stage three is the heart of the reverse osmosis system, the RO membrane. This semi-permeable membrane will take

out salts, minerals, metals, bacteria, virsus, cysts, and much more. Because the process of extracting this high quality

drinking water takes time, your RO water treatment system is equipped with a storage tank.

Stage 4- Post Carbon Filter, recommend change 12 months.

The post carbon fi lter is a granular activated carbon (GAC) cartridge using coconut shell carbon. This fi lter

provides fi nal polishing and assures good tasting drinking water.

System Maintenance

Just because you can not taste it, does not mean that it is not there. Contaminants such as lead, chromium, VOC’s and arsenic

are undetectable to the taste. Additionally, over time if you do not replace the fi lter elements, other bad tastes and odors will

be apparent in your drinking water.

This is why it is important to change out your fi lter at the recommended intervals as indicated in this system manual. Should

you have any further questions please contact the dealer that you purchased the unit from.

Page 2

With proper installation and maintenance, this system will provide you with high quality water for years

to come. All of Watts water enhancement products are rigorously tested.

Operational Parameters ........................................................................................................................ 4

Table of Contents

Contents of Reverse Osmosis System .................................................................................................. 4

Tools Recommended For Installation .................................................................................................... 4

Drill a Hole for the Faucet in a Porcelain Sink ....................................................................................... 5

Punch a Hole for the Faucet in a Stainless Steel Sink ..........................................................................5

Faucet Installation ................................................................................................................................. 6

Adapta Valve Installation ...................................................................................................................... 7

Reverse Osmosis Module Mounting...................................................................................................... 7

Air Gap/Non Air Gap Installation............................................................................................................ 8

Drain Saddle Installation........................................................................................................................ 9

Tank Valve Installation ........................................................................................................................... 9

White Tube Connection ....................................................................................................................... 10

3/8” Black Tube Connection........................................................................................... ......................11

How to Use Quick Connect Fittings ......................................................................................................11

Red Tube Connection (From Faucet) .................................................................................................. 12

Blue Tube Connection (From Faucet) ................................................................................................. 12

Start Up Instructions ............................................................................................................................ 12

Cartridge Replacement........................................................................................................................ 13

Annual Maintenance ........................................................................................................................... 14

Procedure for Extended Non-Use ....................................................................................................... 15

Trouble Shooting ................................................................................................................................. 16

Service Record .................................................................................................................................... 17

Warranty Information ........................................................................................................................... 18

Unit Drawing ...................................................................................................................................... 19

Page 3

Operational Parameters

Operating Temperatures: Maximum 100°F (37.8°C) Minimum 40°F (4.4°C)

2

Operating Pressure: Maximum 85 psi (6.0 kg/cm

pH Parameters: Maximum 11 Minimum 2

Iron: Maximum 0.2 ppm

) Minimum 40 psi (2.80 kg/cm

2

)

TDS (Total Dissolved Solids) < 1800 ppm

Turbidity < 5 NTU

Hardness: Recommended hardness should not exceed 10 grains per gallon, or 170 ppm. System

will operate with hardness over 10 grains but the membrane life may be shortened. (Addition of a

water softener may lengthen the membrane life.)

Note: The operating pressure in your home should be tested over a 24 hour period to attain the

maximum pressure. If incoming pressure is above 85 psi a pressure regulator is recommended and

if over 100 psi then a pressure regulator is required.

Note: Reverse Osmosis water should not be run through copper tubing as the purity of the water

will leach copper and cause an objectionable taste in water and may cause damage to copper

tubing. Watts supplies specialty medias that can be used if copper tubing is down stream of

the RO. Be sure to follow any state or local regulations.

Contents of Reverse Osmosis (RO) System

1 Tank

1 RO System

1 Parts Bag

1 Faucet Bag

1 Manual and Warranty Card

If any of the items are missing please contact your

dealer.

Tools Recommended For Installation

1 1/4” Hole Saw Bit for Faucet opening and/ or

Round Knock out Punch for Stainless Sinks 1 1/4”

Adjustable Wrench

Sharp Knife

1/2”- 13/16” Open End Wrenches

Phillips Screw Driver

Needle Nose Pliers- Adjustable Pliers

Electric Drill

Page 4

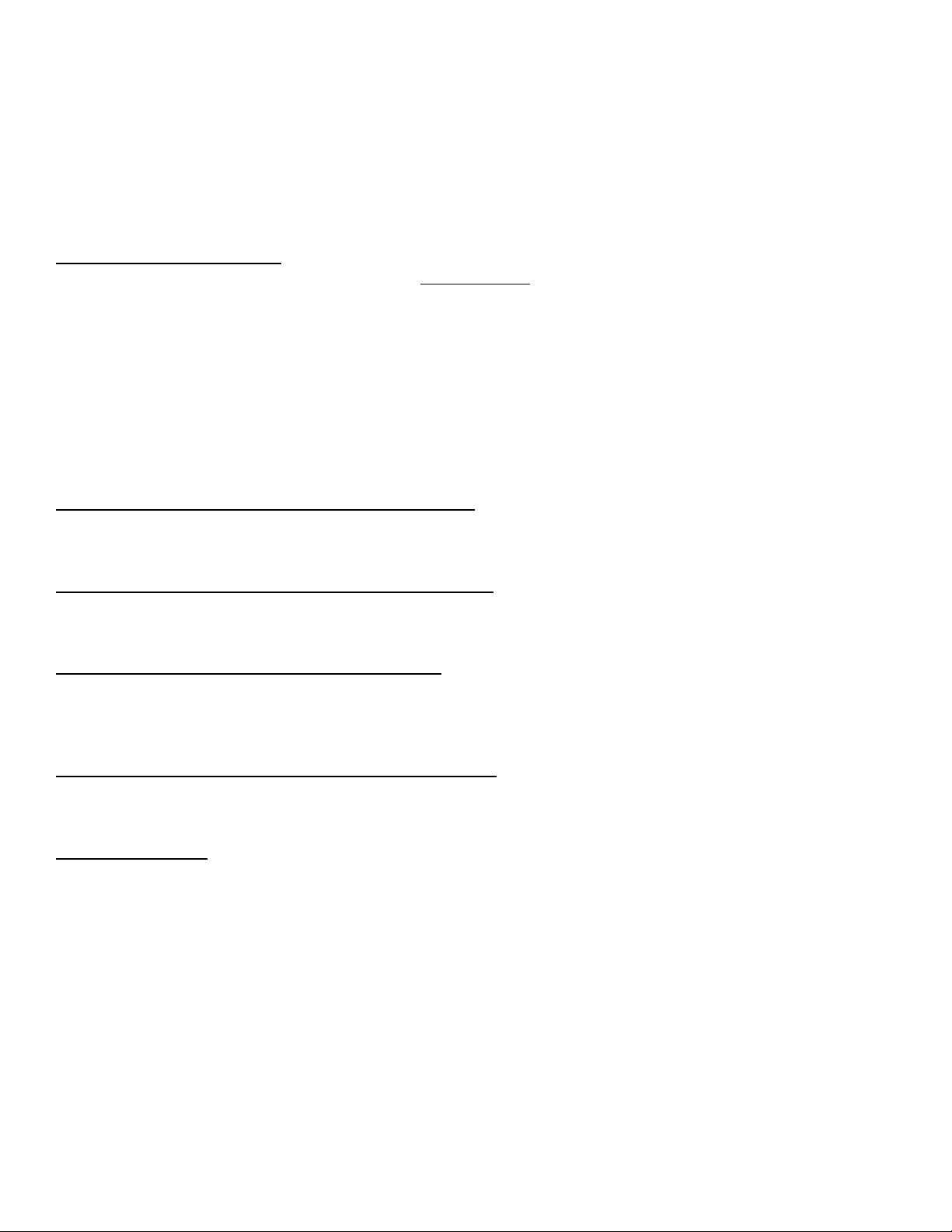

Drill a Hole for the Faucet in a Porcelain Sink

Note:

Some sinks are predrilled with 1 ½” or 1 ¼” diameter hole that you can use for your

RO faucet. (If you are already using it for a sprayer or soap dispenser, see step 1).

Porcelain sinks are extremely hard and can crack or chip easily. Use extreme caution

when drilling. Watts accepts no responsibility for damage resulting from the installation of

faucet.

Step 1

Determine desired location for the faucet on your sink and place a piece

of masking tape on location where the hole is to be drilled. Mark the

center of the hole on the tape.

Step 2

Using a variable speed drill on the slowest speed, drill a 1/8“ pilot hole

through both porcelain and metal casing of sink at the center of the

desired location. (If drill bit gets hot it may cause the porcelain to crack

or chip), use lubricating oil or liquid soap to keep cool.

Step 3

Using a 1 ¼” hole saw, proceed to drill the large hole. Keep drill speed

on the slowest speed and use lubricating oil or liquid soap to keep the

hole saw cool during cutting.

Step 4

Make sure the surroundings of the sink are cooled before mounting the

faucet to the sink after drilling. Remove all sharp edges.

Punch a Hole for the Faucet in a Stainless Steel Sink

Note:

Step 5

If mounting faucet to a Stainless Steel Sink you will need a 1 ¼” Hole

Punch. The faucet opening should be centered between the back

splash and the edge of the sink, ideally on the same side as the vertical

drain pipe.

Drill a ¼” pilot hole. Use a 1/2” Hole Punch and an adjustable wrench to

punch the hole in the sink. Change to the 1 ¼” Hole Punch to enlarge

the hole.

The faucet can now be installed.

Page 5

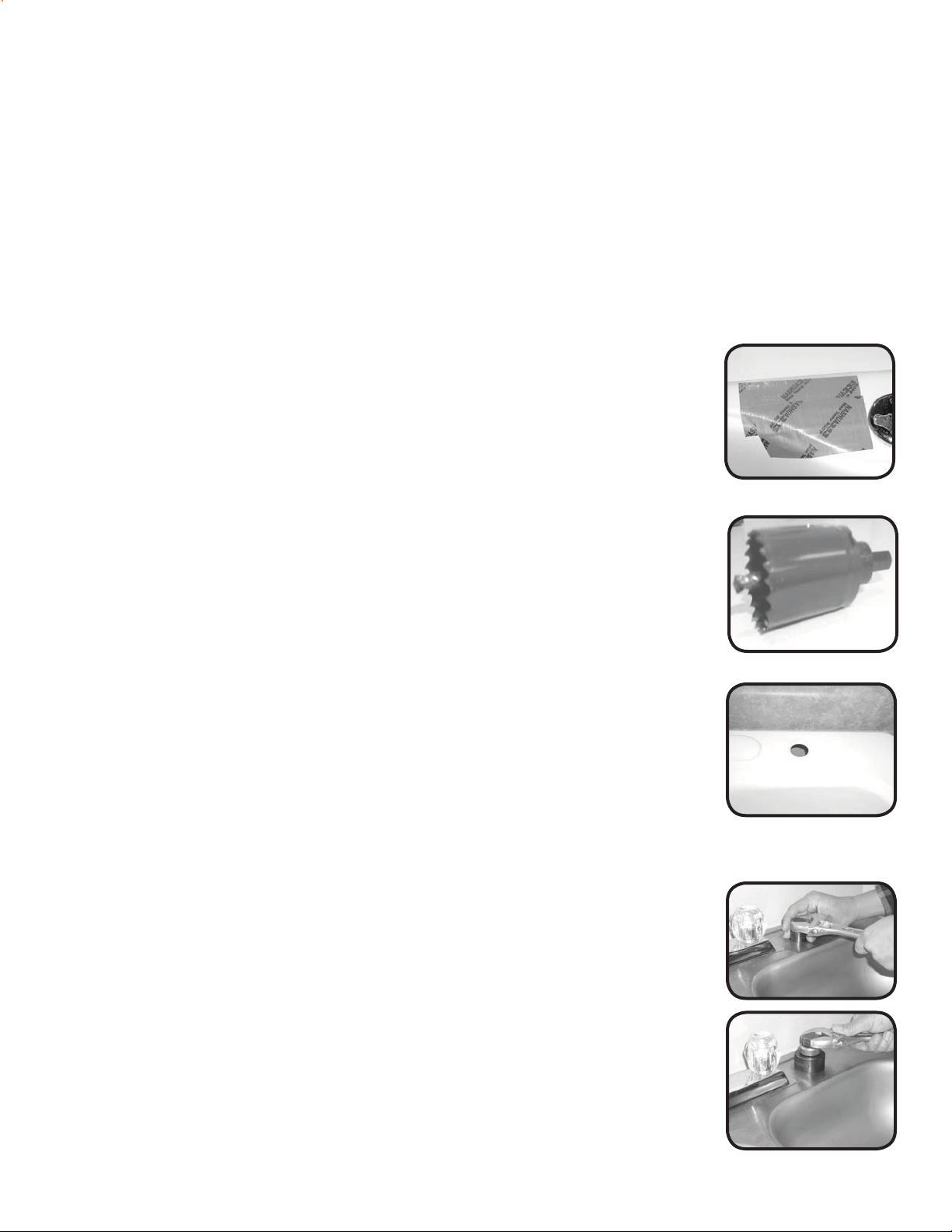

WATTS Chrome

(Top Mount) Faucet Installation

Watts Top Mount Faucet

Minimum Maximum

Mounting Hole Size 1.00” 1.25”

Torque on Toggle Bolt 5lb.in. (max)

Step 6

Step 7

Step 8

Gather and identify the faucet pieces.

Remove faucet base & faucet spout from their respective

plastic bags. From above the sink, feed the faucet tubing &

toggle bolt down through the 1¼” mounting hole in the sink.

Ensure that the soft rubber gasket is uniformly positioned in

between the base and the top of the sink.

Align the faucet base so that the handle is on the right side and

the base is sitting fl ush on the sink top. Turn the handle down

(towards you) to the “ON” position to reveal the tightening

screw (located where the spout will be inserted). Using a

phillips head screwdriver, turn the screw clockwise until the

toggle bolt secures the faucet base snug onto the sink top,

do not over torque toggle bolt (5lb. in. max)

Once the faucet base is securely fastened to the sink top,

insert the faucet spout into the faucet base until it is fully

seated. Turn the handle up (away from you) to the “OFF”

position.

Step 9

Completion of faucet installation (tubing connections) will be

done later in this manual. Refer to the Black Tube Connection

(page 10), Red Tube Connection (page 11), and Blue Tube

Connection (page 11) sections of this manual.

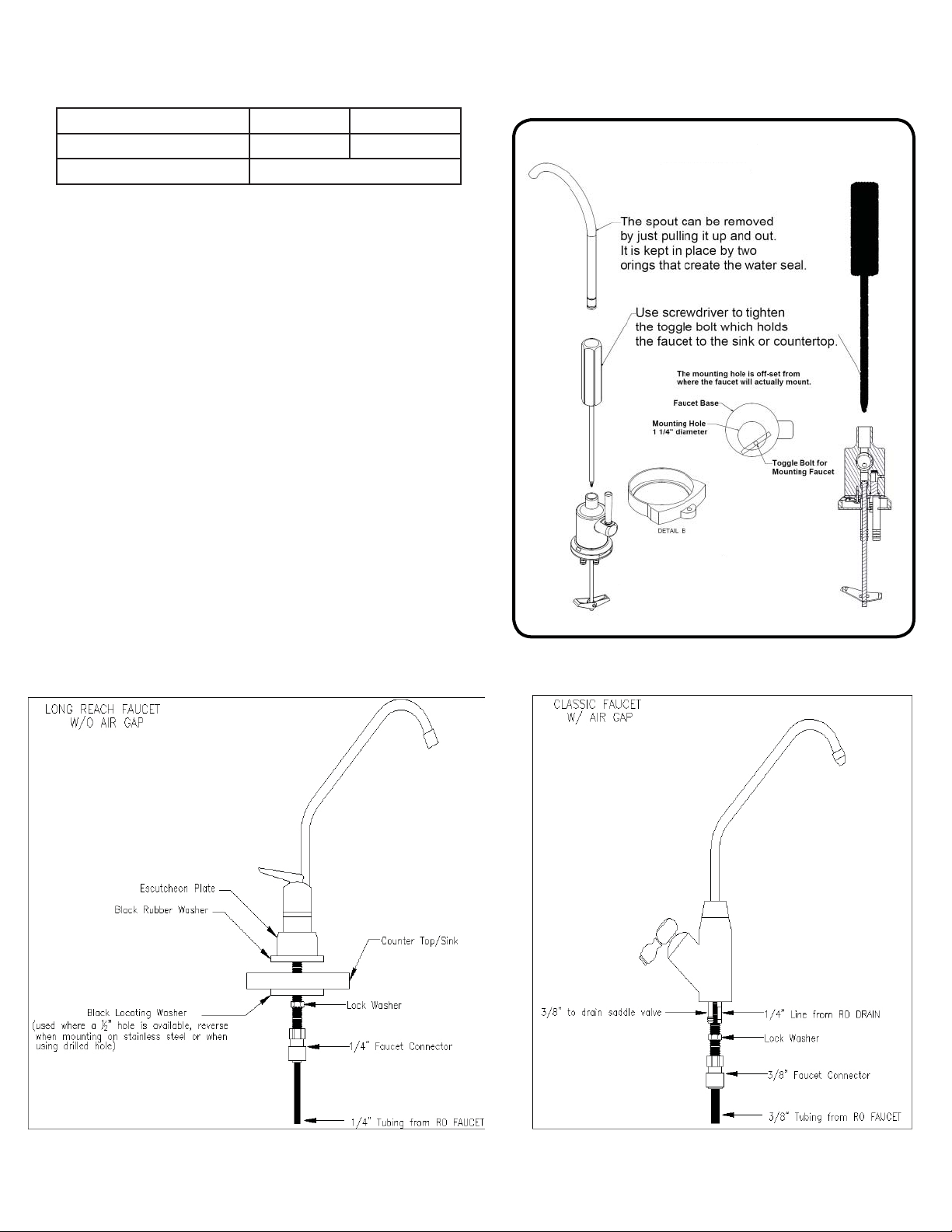

Other Faucet Style Installation

Page 6

Loading...

Loading...