Page 1

For Steam Main Drip and Process Applications

ES-WTD

Job Name

––––––––––––––––––––––––––––––––––––––––––––

Contractor

––––––––––––––––––––––––––––––––––––––––––––

Job Location

––––––––––––––––––––––––––––––––––––––––––

Approval

––––––––––––––––––––––––––––––––––––––––––––––

Engineer

––––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

–––––––––––––––––––––––––––––––––––

Approval

–––––––––––––––––––––––––––––––––––––––––––––

Representative

–––––––––––––––––––––––––––––––––––––––––

Series WTD 600

Thermodynamic Steam Traps

Sizes 3⁄8

" – 1" (10 – 25mm)

For operating pressure up to 600psi (41 bars)

Series WTD 600 Thermodynamic Steam Traps are economical

and compact, designed to efficiently drain steam mains, steam

tracing lines, and small process equipment. The WTD 600

Steam Trap discharges condensate at near to steam temperatures, so the steam space remains free of condensate. Their

tight shut off feature ensures that valuable steam energy is not

wasted. The WTD 600's hardened disc is the only moving part,

assuring a long service life, easy low cost maintainability, and

improved steam system efficiency.

Features

• Inexpensive: low initial purchase price and lower maintenance

costs than traps requiring expensive repair kits

• Compact design: light weight and easy to install. Provides

longer service life with simple maintainability. The only moving

part is the hardened stainless steel disc

• Rugged all stainless steel: resistant to water hammer,

freezing, superheat and corrosion for extra long service life

• Audible discharge cycle: checking trap operation is simple

and does not require any special devices

• Blast discharge of condensate: eliminates dirt build up and

provides a tight shut off, saving valuable steam energy

Applications

• Steam main drainage

• Superheat steam applications

• Steam tracing lines

•Freeze protection for outside applications

• Small process equipment

Specifications

The thermodynamic steam trap shall be installed as indicated

on the plans. The steam trap shall have a maximum pressure of

600psi (41 bars) and a maximum temperature of 800°F (427°C).

The trap body shall be manufactured of ANSI 420 stainless

steel, the cap and disc shall be manufactured out of ANSI 416

stainless steel. The steam trap shall be a Watts Regulator

Company Series WTD 600.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

WTD 600

Page 2

ES-WTD 0323 © Watts Regulator Co., 2003 Printed in U.S.A.

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscda.com

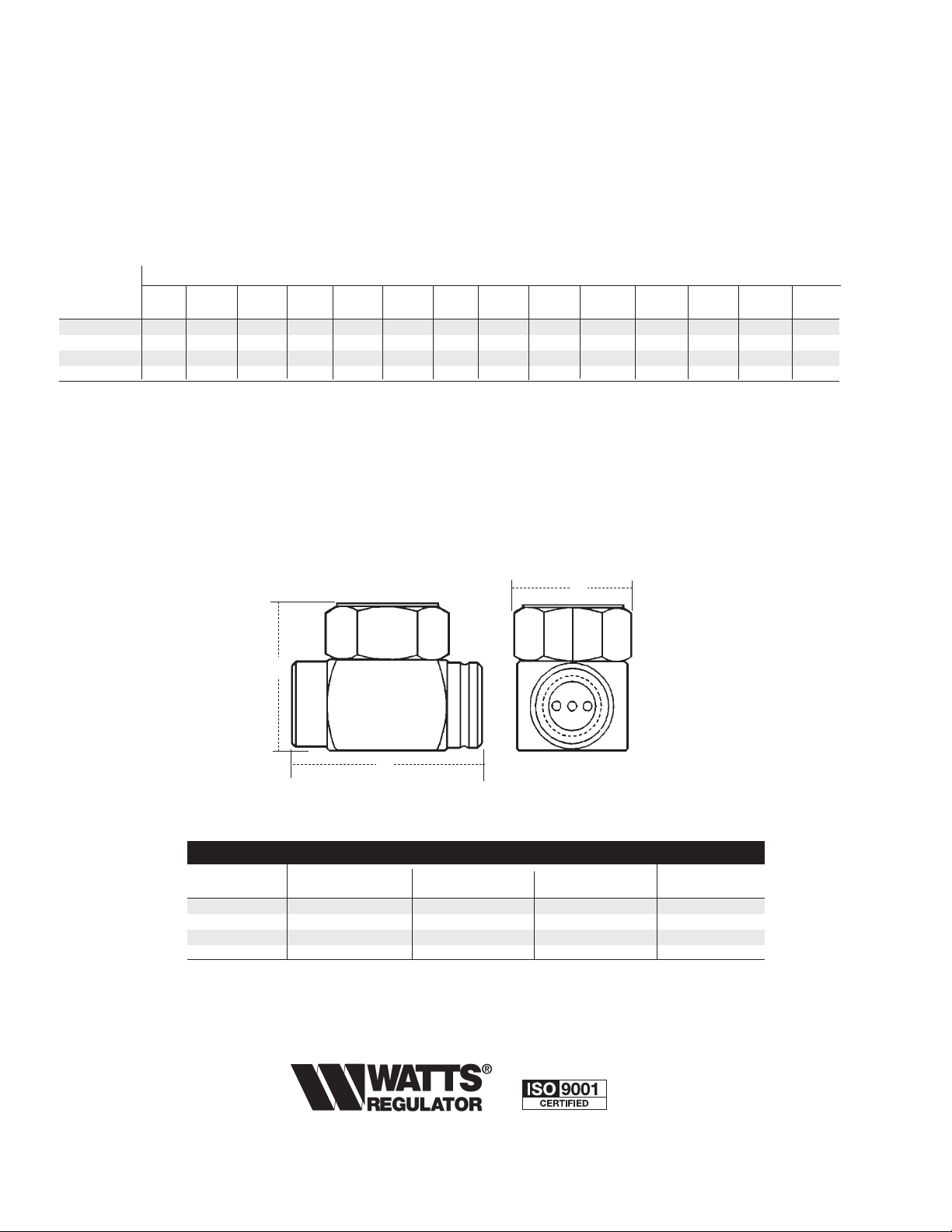

SIZE DN DIMENSIONS WEIGHT

ABC

in. mm in. mm in. mm in. mm lbs. kg.

3

⁄

8

102511

3

⁄

4

45 13⁄

4

45 .8 .36

1

⁄

2

15 211⁄

16

68 13⁄

4

45 2 51 1.2 .54

3

⁄

4

20 213⁄

16

71 25⁄

16

59 27⁄

16

62 1.8 .82

1253

5

⁄

16

84 21⁄

2

64 27⁄

8

73 3.1 1.41

C

A

B

Maximum Capacity - Lbs./Hr. at Saturation Steam Temperature

NPT psi (bar)

CONNECTION 3.5 5 10 20 30 50 75 100 150 200 300 400 500 600

in. mm (0.24) (0.34) (0.7) (1.4) (2.1) (3.4) (5.2) (6.9) (10.3) (13.8) (20.7) (27.6) (34.5) (41.8)

3

⁄8"10 180 185 190 200 215 245 305 370 500 610 790 960 1100 1250

1

⁄

2

"15 300 310 345 410 465 575 700 810 1000 1140 1410 1630 1830 2000

3

⁄4"20 405 420 470 550 640 810 1000 1160 1450 1670 2100 2430 2750 3050

1" 25 640 670 725 865 980 1200 1470 1750 2200 2600 3250 3780 4250 4700

For Kg./Hr. multiply by .454

Materials

Body: ANSI 420 F stainless steel

Cap: ANSI 416 stainless steel

Disc: ANSI 416 stainless steel

Dimensions – Weights

Pressure – Temperature

Maximum Operating Pressure: 600psi (42 bars)

Maximum Operating Temperature: 800°F (427°C)

Maximum Allowable Pressure: 600psi (42 bars)

Maximum Allowable Temperature: 800°F (427°C)

Loading...

Loading...