Page 1

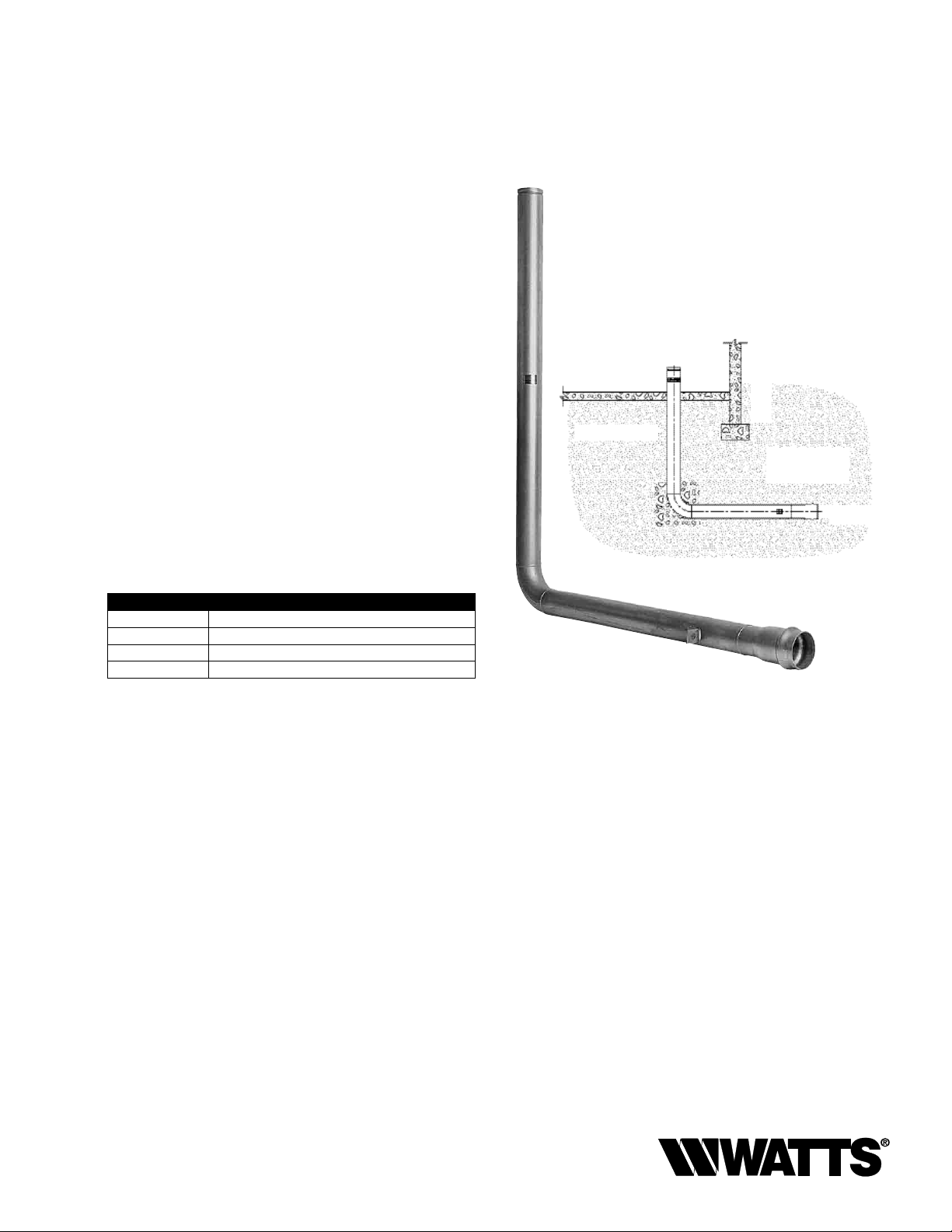

Watts SeriesTR

Transition Riser

Sizes: 4"- 10" (100 – 250mm)

Basic Installation Instructions

Watts Regulator Company Transition Risers are designed for

easy in stal la tion in stan dard con fig u ra tions as outlined using

stan dard con struc tion meth od.

The floor penetration detail of the transition riser shall be

re strained per direction outlined by site plans. Consult Uni-Bell

hand book of PVC pipe if instructions are not pro vid ed.

The below ground connection is a standard AWWA C900 gasketed coupler (either ductile iron or PVC). In stal la tion in accordance with the following information (from Uni-Bell handbook).

1. Clean out inside of coupler making certain the beveled spigot

end and the gasket groove are free of dirt.

2. Apply lubricant to beveled spigot (male).

3. Insert gasket into coupling groove and seat firmly.

4. Push lubricated end past gasket into the bell housing. (Watts

Transition Risers are equipped with the lugs placed 180°

apart on either side of the unit which can be used to “pull”

the pipe into the bell using a “come-a-long” type equipment.

Also, the “bar and block” method described in the Uni-Bell

handbook can also be used for installation).

5. The maximum allowable pipe deflection angle between the

TR and underground pipe is as follows:

Grooved End

Building Floor

RP/IS-TR Riser

Flow➔

Building Perimeter

CIPS

Couplings

Flow

➔

TR Size Maximum Deflection

4" 1°

6" 1°

8" 1°

10" 1°

The above ground connection is an AWWA specification C606

groove. All underwriters Laboratory approved groove couplers

made to fit the AWWA C606 grooves can be used to join the

connection to the transition supply line.

1. Check gasket and lubricate it using groove coupler manufacturer’s recommended lubricant or approved equal.

2. Install gasket. Place gasket over pipe end being sure gasket

lip does not overhang pipe end.

3. Align and bring two pipe ends to geth er and slide gasket into

po si tion cen tered be tween grooves or each pipe (no por tion

of the gas ket should ex tend into the groove of ei ther pipe.)

4. Apply housings. Place housings over gasket, being sure the

housing keys engage into the grooves of the pipe. Insert

bolts and apply nuts finger tight.

5. Tighten nuts: Tighten nuts alternately and equally un til housing bolt pads are firmly together metal to metal: Uneven

tightening will cause gasket to pinch.

Materials

Because the Transition Riser is buried, the material of con struction has been chosen as Type 304L Stainless Steel. This ma te rial is gen er al ly recognized as a corrosion resistant ma te ri al which

is superior to Cast, Ductile Iron, or Coated Steel pipe for corro sion resistance, and which is superior to en gi neered plas tics

for strength and longevity. In general, the stain less steel is the

cath ode in joints of dis sim i lar metal, so that any corrosion which

may occur will not affect the stainless steel. In addition, an extra

pro tec tion is provided in that there is no ac tu al metal to metal

con tact at either joint due to the CIPS bell con nec tion de sign

and the groove coupler design.

IMPORTANT: Inquire with governing authorities for local installation requirements.

ATTN. INSTALLER: “After Installation, please leave this instruction

sheet for occupant's information.”

Page 2

Installation Practices

Good installation practice for all types of buried pipe of ten calls

for wrapping of the pipe to decrease corrosion due to soil conductivity. Although stainless steel is less sus cep ti ble to corrosion, local codes and general practices should still be followed.

Field Test Procedures

Normal field test procedures call for a hydrostatic pres sure

test of the system prior to final acceptance. Often, seg ments

of the system will be tested individually prior to the complete

system test. In order to hydrostatically test the transition riser as

installed, two methods are rec om mend ed.

1. Constrained Piping

If the piping installation is essentially complete, the pip ing

restraints may adequately take the thrust loads gen er at ed by

having a blind end on the pipe system. In these cases, no

special actions to restrain thrust or side loads are required,

and the fitting installed in the system may be ad e quate for

hydrostatic testing.

2. Free Piping

If just the riser or riser/main connection is to be tested, then

the thrust loads from the blind end cap on the riser may need

to be restrained. The riser design has been test ed in the

unrestrained state using a rigid coupler and end cap grooved

fitting. Flange adapters, expansion fit tings, or other styles

of end connectors may result in ex ces sive end thrust which

may cause a leak or fitting mal func tion. In addition, couplings

which are adequately rat ed for high pressure testing should

be used if thrust re straints are not feasible.

NOTE: It is important that all air is bled from the system

be fore pres sur iz ing any component.

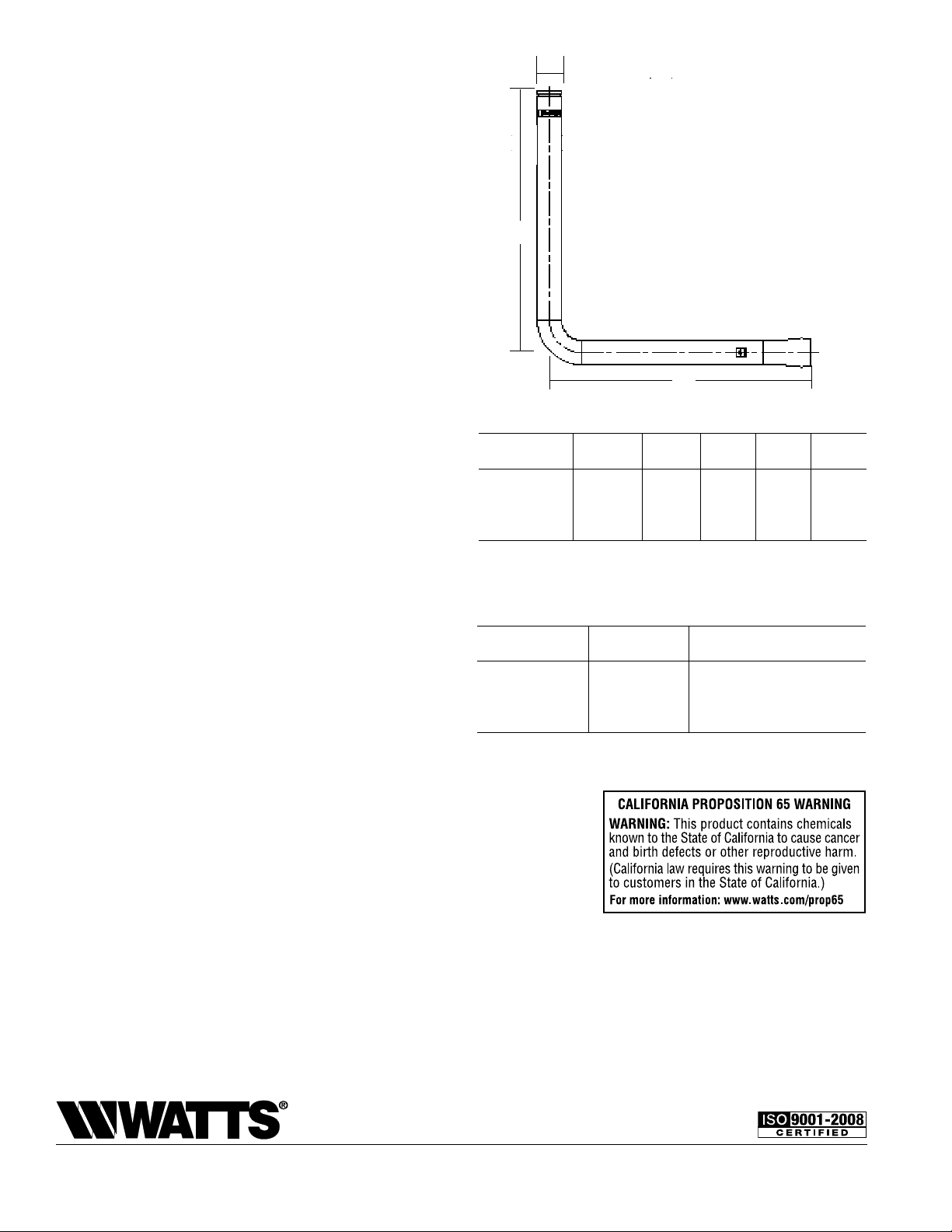

A

B

C

Dimensions — Weights

Size Ordering A B C Weight

in. mm Codes inches ft. ft. lbs.

1

4 100 0777500 4

⁄2 OD 6 6 71

6 150 0777501 65⁄8 OD 6 6 98

5

8 200 0777502 8

10 250 0777503 10

⁄8 OD 6 6 129

3

⁄4 OD 6 6 202

End Connections

Bell End: Mates with Ductile Iron Pipe and AWWA C900 Pipe

(PVC Pipe with Cast Iron Pipe Equivalent OD’s)

Size Mating Pipe OD Sealing Gasket (CIPS - C900)

in. mm

Spare Part Ordering Code

4 100 4.80 7014421

6 150 6.90 7014422

8 200 9.05 7014423

10 250 11.10 7014424

Utilizes Gasket conforming to UL 157 with “Lock in” gas ket configuration.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

RP/IS-TR-Riser 1235 EDP# 1915333 © 2012 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Loading...

Loading...