Page 1

Installation, Operation, and

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

. . . . . . . . . . . . . . . . . . . .

Maintenance Manual

SentryPlus™ Alert

Universal Upgrade Kit

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

IOM-UPGRADEKIT-SentryPlusAlert

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Understanding Safety Information . . . . . . . . . . . . . . . . . . . . 2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

List of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Required Tools and Materials for Installation . . . . . . . . . . . . . . 2

Installation and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ISolenoid Operation

(For Existing LFF113RFP Installations Only) . . . . . . . . . . . . . 3

Installing the Flow Sensor (Backflow Upgrade Kit Only) . . . . 3

Wiring/Retrofitting the junction box . . . . . . . . . . . . . . . . . . . 4

Installing the Wireless Node . . . . . . . . . . . . . . . . . . . . . . . . . 6

Registering Your Device and Alert Configuration . . . . . . . . . . . 7

Start-up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page 2

Important Safety Information

Description

!

WARNING

To avoid death, serious personal injury, property damage,

or damage to the equipment:

• Learn how to properly and safely use the equipment

BEFORE installing, setting up, using, or servicing.

• Keep the manual available for easy access and future

reference.

• Replace missing, damaged, or illegible manual and

product labels.

• Read the manual and all product labels and follow all

safety and other information.

• Replacement manuals available at Watts.com.

Understanding Safety Information

This safety-alert symbol is

shown alone or used with

!

a signal word (DANGER,

WARNING, or CAUTION). A

pictorial and/or safety message to identify hazards and

alert you to the potential for

death or serious personal

injury.

• SentryPlus™ Alert Technology Universal Upgrade Kit detects

catastrophic discharge from the relief valve of an RPZ

(Reduced Pressure Zone) backflow preventer that can cause

flooding due to excessive discharge and/or a blocked/undersized floor drain

• Wirelessly issues multi-channel alerts (call, text, email)

• Can be installed without taking equipment offline

• Can be installed with any existing RPZ backflow preventer

• Can be used to upgrade an existing Watts LFF113RFP ACV to

support SentryPlus Alert Technology

List of Parts

There are two types of SentryPlus Alert Technology Universal

Upgrade Kits.

For existing 113RFP Flood Protection ACV upgrades, the kit

consists of following:

• Smart Electronics Junction Box (JB113)

• Wireless Node (WN113)

For existing Backflow RPZ upgrades, the kit consists of

following:

• Smart Electronics Junction Box (JB113)

• Wireless Node (WN113)

• Flow Sensor (FS99)

• 2" Tee (PVC) with NPTF threaded end connections to mount

FS99 Flow Sensor

DANGER

!

!

WARNING

!

CAUTION

NOTICE

2

Identifies hazards which, if not

avoided, will result in death or

serious injury.

Identifies hazards which, if not

avoided, could result in death

or serious injury.

Identifies hazards which, if not

avoided, could result in minor

or moderate injury.

Identifies practices, actions,

or failure to act which could

result in property damage or

damage to the equipment.

This pictorial alerts you to the

need to read the manual.

This pictorial alerts you to

electricity, electrocution, and

shock hazards.

Required Tools and

Materials for Installation

❏ Small Phillips head screwdriver

❏ Screws to mount Wireless Node; holes are 0.27" diameter.

Select screws based on your application conditions.

Page 3

Installation and Operation

Solenoid Operation

(For Existing LFF113RFP Installations Only)

The Solenoid is prewired to the existing Junction Box, and must

be rewired by a certified electrician. The solenoid is equipped

with a Solenoid Bypass valve (normally closed) which manually

closes the Main Valve when engaged.

Opening the Solenoid Bypass Valve pressurizes the Main Valve

cover as indicated by Pressure Gauge, closing the Main Valve.

Closing Solenoid Bypass Valve and opening the Manual Reset

Ball Valve returns the Main Valve to the full open position.

Pressure Gauge returns to zero when the Main Valve is fully

open.

NOTE: Manual Reset Ball Valve must be closed for normal

operation.

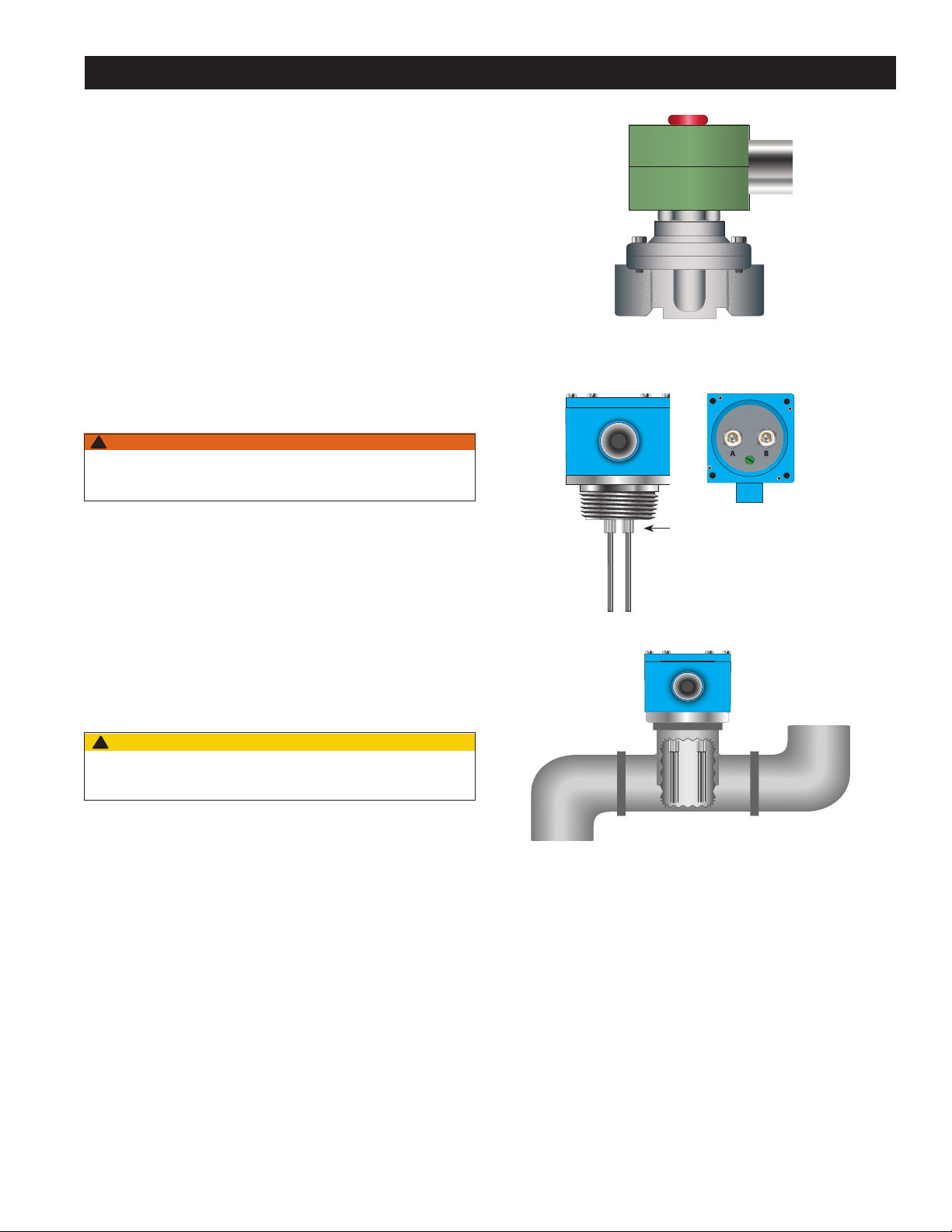

Installing the Flow Sensor

(Backfl ow Upgrade Kit Only)

!

WARNING

Certified electrician to connect main power and Flow Sensor to

Junction Box.

Front View

Top View with

Cover Removed

The Flow Sensor is installed in the discharge piping from the

RPZ relief valve. If the Flow Sensor senses water in the discharge piping, it will signal the Junction Box to close the valve.

Installation Notes

1. Install the supplied tee for the Flow Sensor in the RPZ discharge line in the HORIZONTAL position as shown below.

2. Cut Sensor Probes to length. The ends of the Sensor Probes

should be located between

eter from the pipe bottom. The probes MUST NOT BE less

than ¼" from the pipe wall.

3. Install Flow Sensor in tee, again ensuring that it is in the

HORIZONTAL position as shown below.

!

CAUTION

Ensure Sensor Probes do not contact pipe bottom or sides.

1

⁄3 and 1⁄2 of the pipe’s inner diam-

To Floor Drain

2" NPT

From RPZ Relief

Valve (with Air Gap)

Sensor Probes

Installed

3

Page 4

Installation and Operation

Wiring/Retrofi tting the junction box

Wireless Node

Cellular

Connection

to Internet

Wired to

Terminals

7 & 8

AC Power

Adapter

PROG

CN2

POWER

CELLULAR

loT

1

FLOOD

2

TESTRESET

FLOOD

FLOOD

GND

+12Vdc

Junction Box

Relay with Red

LED Indicator

11

N 65

L1

Incoming

Power

120V/1PH

1 2

Flow

Sensor

Probes

15

10 20

5 25

0 30

SEC

223344556677

3 4

Solenoid

Remote

Valve

Trip

Indication

Power

Remote

Trip

Indication

Wired to

Terminals

3 & 4

UP

88

87

Wired to

Terminals

1 & 2

120Vac

Power

BMS

The Junction Box is valve-mounted, but includes brackets for wall mounting.

!

CAUTION

When retrofitting an existing Model 113RFP Flood Protection ACV,

disconnect the electrical power before retrofitting the old Junction

Box to the new one.

NOTICE

During the retrofitting process on the 113RFP, the system

will not be monitoring for flood detection or protection..

Wiring the Junction Box

!

WARNING

Ensure that all power supply to the Junction Box is turned

off before making any connections to the Junction Box.

Failure to do so may result in electrocution, personal

injury, and /or death.

For Existing LFF113RFP Installations Only

• After removal of power from the circuit, disengage the

wiring from:

o Main terminals inside Junction Box

o Terminals 1 and 2 (Flow Sensor)

o Terminals 3 and 4 (Solenoid)

o Terminals 5 and 6 (remote trip indicator, if wired)

• Remove the Junction Box from the ACV or wall mount

• Replace the Junction Box with the new, upgraded Junction

Box. The physical dimensions of the new Junction Box are

identical to older units and can be mounted at the same

location.

• The solenoid valve must be rewired into the new junction box

using terminals 3 and 4. If needed, the connection can be

extended by using similar gauge extension wire and a terminal

box. The solenoid must be rewired by a certified electrician.

4

For All Installations

• Connect the Flow Sensor to the Junction Box using terminals

1 and 2.

• Connect to a Building Management System or alarm for

remote indications of a continuous water discharge using terminals 5 and 6.

• Connect to the Wireless Node using terminals 7 and 8.

NOTICE

• The terminal block accepts 10-22 AWG.

• Terminals 5 and 6 have 120V, 10A maximum.

• The Junction Box voltage is 120V.

• The Sensor Probe voltage is 120VAC, 1.5mA.

• The terminal block has a less than 1 amp draw.

Page 5

Installation and Operation

Adjusting the Time Delay

• Adjust the time delay to avoid alert / valve closure due to intermittent or nuisance relief valve discharge. The delay is adjustable from 0 seconds to over 1 hour.

• Adjust the time delay by using the delay adjustment dial in the

Junction Box.

• Use a small Phillips head screwdriver to adjust either the range

selector (0-6, 0-12, 0-30, 0-60) on the left side or the unit

selector (0.1 sec, sec, min, hr) on the right side.

• Increase the time delay by adjusting the dial clockwise;

decrease the time delay by adjusting the time delay counterclockwise.

• Recommended adjustment delay is 30-60 seconds. However,

the ideal set point can vary widely depending on the product

application, including drain size, location, backflow preventer,

water pressure, and tolerance for discharge.

Range selector

(0-6, 0-12, 0-30, 0-60)

RANGE SELECTION UNIT SELECTION

0.1 sec Sec Min Hrs

0-6 0.05-0.6s 0.5-6s 0.5-6min 0.5-6hr

0-12 0.1-1.2s 1-12s 1-12min 1-12hr

0-30 0.25-3s 2.5-30s 2.5-30min 2.5-30hr

0-60 0.5-6s 5-60s 5-60min 5-60hr

Unit selector

(0.1s, sec, min, hrs)

5

Page 6

Installation and Operation

Installing the Wireless Node

!

WARNING

Ensure all power supply to the Wireless Node is turned

off before making any connections to the Wireless Node.

Failure to do so may result in electrocution, personal

injury, and/or death.

1. Identify preferred location for mounting Wireless Node. The

Wireless Node must be located away from large metal components and structures that may block the cellular signal. In

addition, the cellular antenna is located on the inner sidewall

of the enclosure (11). When mounting, ensure that this side

of the device is away from any walls, wires, pipes, or other

obstructions, especially anything metallic.

2. Before mounting, plug in the Wireless Node to ensure that

a connection can be made in the preferred location. Once

plugged in, the device will automatically go through a startup process. A cellular connection has been made if, after the

start-up process, the Cellular LED (8) is a steady blue. If it is

blinking, there is a poor connection, and if it is off, there is

no connection. If there is a poor or no connection, identify a

new location for mounting.

3. Unplug the Wireless Node from the power supply.

4. Mount the Wireless Node in the identified location using the

four 0.27" diameter mounting holes (13). Screws are not

included.

5. Route wires from terminals 7 and 8 of the Junction Box

through the wiring gland (12) and connect to the Wireless

Node at the "Flood" screw terminal (2). Polarity does not

matter. Six feet of wire is supplied with the unit, but the

Wireless Node can be located up to 100 feet away from

the Junction Box. If additional wire is used. it must meet the

required rating for the Junction Box (300V, 16-24 AWG).

6. Route wires for included 12VDC power supply through the

wiring gland (12) and connect to the Wireless Node at the

appropriate screw terminal (1). Polarity must be correct or

the Wireless Node will not operate.

7

8

9

10

11

6

5

4

3

2

1

13

13

12

!

CAUTION

Use only the provided power supply as other power supplies may not

meet the rating and specifications for this device.

7. Tighten the wiring gland (12) to prevent water or dust from

entering the Wireless Node.

8. Connect the power supply to the Wireless Node and

Junction Box.

6

Page 7

Installation and Operation

Wireless Node Operation

1. Start-Up – Upon start-up, the Power LED (7) will light up

a steady green to indicate power is supplied. The Wireless

Node will automatically go into its start-up sequence. During

the start-up sequence, the light over the Program button

(5) will begin as solid white and then change to a blinking

green, indicating the Wireless Node is searching for a cellular connection. Once a cellular connection is established, the

Program button light will start blinking cyan, indicating that

the Wireless Node is connecting to the Cloud. Once a Cloud

connection is established, the Program button light will blink

rapidly for a few seconds, and then shut off. The Cellular

LED (8) and IoT LED (9) should both be a solid blue.

2. Cellular Connection – Once the start-up sequence is

completed, the Cellular LED will be a steady blue if there is

a good connection. It will blink if there is a poor connection.

There will be no color if there is no connection.

3. IoT Connection – If there is a Cloud connection, the IoT

LED will be a steady blue. There will be no color if it is off.

NOTICE

If there is no Cloud connection, then notifications will not be

sent to the user via Syncta.

4. Flood LED – If a flood event occurs, the Flood LED (10)

will be a steady orange. It will remain on so long as there

is a flood condition.

5. Test Button – When Cellular and Cloud connections

have been made, a test message can be sent through the

Syncta app by pressing the Test Button (3).

6. Reset Button – You can reset the Wireless Node and

restart the start-up sequence by pressing the Reset button (4). This will cause all on-going operations to cease.

7. Program Button – The Program button (5) should not be

pressed and is for factory use only.

Registering Your Device and Alert Confi guration

1. Using a smart phone or tablet,

scan the QR code on the side

on the Wireless Node, or go to

https://connected.syncta.com.

2. When prompted, enter the

Device ID. The Device ID is a

15-digit number found beneath

the QR code on the side of the

Wireless Node.

3. Follow onscreen prompts to

create a Syncta account, or

if you are an existing Syncta

user, log in to your account.

The device can be registered

to multiple accounts.

4. Once the device is registered to your account, follow

prompts to add notifications.

To manage alerts, login to your

account on Syncta.com.

7

Page 8

Start-up Instructions

1. Open Junction Box. Apply power and observe the Electric

Relay Control.

2. Pour adequate amount of water into RPZ Relief Valve Air

Gap until the red LED indicator light on the Electrical Relay

illuminates / flashes. This indicates the Flow Sensor is properly installed and is sensing water in the discharge piping.

3. Trap water in discharge piping and observe red LED on

Electrical Relay. A message will be sent via Syncta when

the duration of the time delay elapses, observe Flood LED

(10) to ensure activation after the time delay. Adjust time

delay to customer/project specifications. When connected to a LFF113RFP ACV, solenoid will energize and valve

will go closed after time delay elapses. To manually reset

valve, refer to step four in the Start-Up Instructions of the

LFF113FP Installation, Operation, and Maintenance Manual,

available on watts.com

4. For final test simulate actual RPZ Relief Valve discharge

and observe floor drain for excessive pooling or flooding.

Re-adjust time delay and Adjustable Closing Speed (when

used with a LFF113RFP ACV) control as needed to achieve

desired alert/valve closure time.

Valve Travel

VALVE SIZE - INCHES 1 1/4 1 1/2 2 2 1/2 3 4 6 8 10

Travel - Inches

3

⁄8

3

⁄8

3

⁄8

5

⁄8

3

⁄4 1 11⁄2 2 21⁄2

Valve Cover Chamber Capacity

VALVE SIZE - INCHES 1 1/4 1 1/2 2 2 1/2 3 4 6 8 10

fl.oz. 4 4 4 10 10 22 70

U.S. Gal 1

Limited Warranty: Watts (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment.

In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

1

⁄4 21⁄2

USA: T: (978) 689-6066 • F: (978) 975-8350 • Watts.com

Canada: T: (905) 332-4090 • F: (905) 332-7068 • Watts.ca

Latin America: T: (52) 81-1001-8600 • Watts.com

IOM-UPGRADEKIT-SentryPlusAlert 1905 EDP# 1915433 © 2019 Watts

Loading...

Loading...