Page 1

Gauge Glass Cut-offs

No. N89S

No. N89D

Instructions for Installing

No. N89S, N89D - Low water cut-off.

Note: Install carefully and line up so that the top of switch box is reason-

ably level.

1. Remove gauge glass and cocks from boiler.

2. Install the 1⁄2" tee, with long and short nipples, on the float chamber by

inserting the short nipple in the float chamber tapping, in the end opposite

the switch, and screwing up tight with the long nipple pointing in the correct direction, depending on the location of the boiler. Fig. 1 and 2.

3. Insert long nipple into lower gauge glass tapping in boiler. Swing the entire

float chamber until the nipple is made up tight. The cut-off must be level.

Fig. 3.

4. Screw the nipple which is in the tee carrying the tubing connector into the

upper gauge glass tipping and pull up tight. Install compression coupling in

top float chamber tapping. Fig. 4.

5. Hold tube bend in position, Fig. 5, and mark tube on level with top of hex

on compression coupling. Cut off tube at this mark.

6. Slide ring and nut over end of tube. Slide end of tube into compression cou-

pling in float chamber. Tighten both couplings.

7. Install drain valve in bottom float chamber tapping. Fig. 6.

8. Re-install gauge cocks in the end of the tees and replace the gauge glass.

Fig 6.

NOTE: Open the drain valve at least once every month or more often during boiler operation to flush out sediment from the float chamber. This must

be done to insure FULL boiler PROTECTION

Single Switch Assembly (See Page 4)

(Replaces former No. 89S and No. 89A)

"DUAL" (two) Switch Assembly (See Page 3)

(Replaces former No. 89D and No. DT89A)

Maximum Steam Pressure 15 lbs.

.

Fig. 1

IS-N89

Fig. 2

Fig. 3

Flared Connection

Compression

Coupling

Fig. 4

Cut tube on Level with

Top of Hex.

Standard switch entirely suitable for millivolt service on

self-energized control circuits of gas fired heating

installations.

Fig. 5

Top of Box

Must Be Level

Fig. 6

Page 2

Built-in Cut-offs

No. N93S, N193S, N101S

with Single Switch Assembly. (See Page 4)

No. N93D, N193, N101D

with "DUAL" (Two) Switch Assembly. (See Page 3)

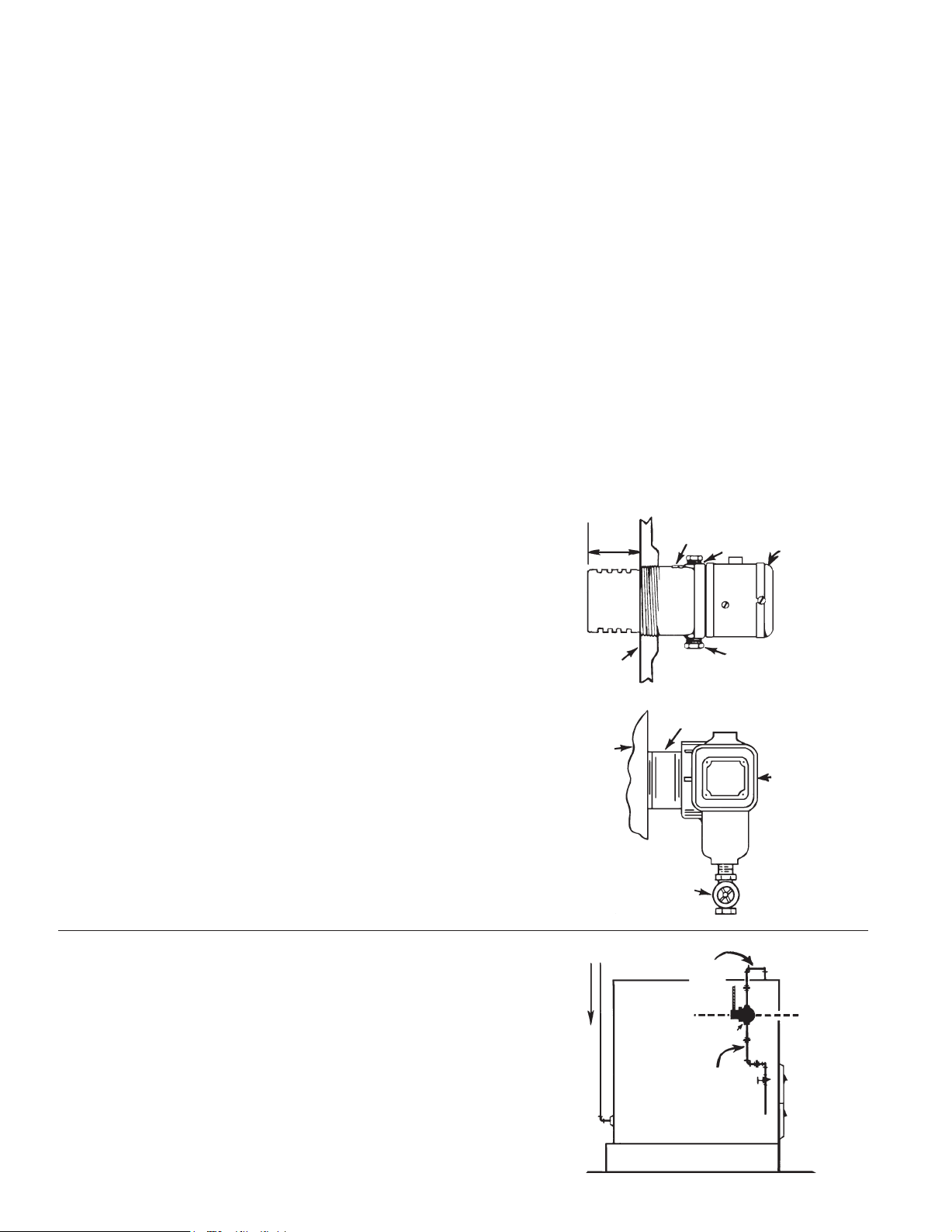

This line of cut-offs was designed for boilers where a 21⁄2" pipe tapping is provided for the low water cut-off

and where space is limited by the boiler jacket. For boilers that do not have this tapping, use WATTS No.

N89S, N89D which is made for gauge glass connection.

Special Notice

Before leaving the job, it is recommended that the installation of the cut-off be checked under actual working conditions;

this will reveal any installation irregularities.

To check, turn on switch to burner and if water in boiler is at or above

the water line, the cut-off will allow the burner to start. Now lower the water line by draining off water from

the boiler; if the cut-off is wired and installed correctly, the burner will shut off when the water level drops to

approximately

3

⁄8" below the normal water line.

Float chamber should be flushed at least once every month or more often to remove any accumulated sediment by

opening drain valve where installed or removing drain plug.

Instructions for Installing

No. N93S, N193S, N93D, N193D

Attach cut-off to the boiler by screwing into the 21⁄2" tapping provided,

make up tight with the "TOP" marking uppermost and the adjacent flat

edge of the square flange is exactly level. Before installing No. N93S,

N93D, be sure that there is a minimum distance of 2

1

⁄4" between the

inside of the boiler shell and any wall or other protrusion inside the boiler. (See Figure 1.) Maximum Steam Pressure 15 lbs.

Fig.1

Insertion

Length

1

2

⁄4"

N93

Only

Marked Top

Level

N93

N193

No. N101S, N101D

Attach cut-off to boiler as in Fig. 2 using a 21⁄2" close or space nipple

to suit installation requirements. Make up tight with float chamber levelled in position shown. Attach drain valve. Maximum Steam Pressure

15 lbs.

No. N50S, N50D, N501S, N501D

Watts Series N50 and N501 are designed with a heavier float and bellows construction for protection of hot water space heating boilers

against emergency low water conditions. Float chamber has 1" female

top and bottom connections, for equalizing pipe connection. (See

Figure 3). Maximum Boiler Pressure 50 lbs. @ 250°F.

For installation of N501, see Figure 2.

Inside Boiler Shell

Boiler

Fig. 2

Supply

Fig. 3

Drain Valve

Cut-off Line

1

2

⁄2" Nipple

Equalizing

No. N50

Drain Plug

N101

N501

Pipe

Equalizing

Pipe

Page 3

Wiring Diagrams For

Low Water Cut-offs

No. N89D, N101D, N93D, N193D, N50D, N501D

with "Dual" (Two) Switch Assembly

For independent line voltage burner service and for low (or high) voltage alarm, feed

valve or pump starter service. Alarm, feed valve or pump starter switch actuates just

bbeeffoorree

the burner switch cuts the firing.

HI or LO

LINE

()

Voltage

HI or LO

Voltage

Service Switch

Closed Circuit

Burner Switch

Closed Circuit

When Used For

When Used For PILOT DUTY

BURNER SWITCH and

ACCESSORY CIRCUITS

HI or LO

LINE

Burner

Load

Alarm Feed

Valve or Pump

Starter

CommonCommon

Norm

Norm

TOP

Open

Norm

Open

Norm

Closed

Closed

For loads in excess of ratings or when a 3-phase burner motor is used, use either switch

as pilot to operate a relay or magnetic starter as shown under "Pilot Duty" above for

burner switch.

Incoming leads must be suitable for temperature rise of 90°C (194°F).

LINE

()

Voltage

HI or LO

Voltage

Service Switch

Closed Circuit

Burner Switch

Closed Circuit

Alarm Feed

Valve or

Pump Starter

CommonCommon

Norm

Norm

TOP

Open

Norm

Open

Norm

Closed

Closed

Relay

LINE

Line

(Burner)

1

AC

⁄2 H.P. 1 Phase 110-120 volts

1 H.P. 1 Phase 220-240 volts

Pilot Duty

AC 15 Amps. 120, 240 volts

DC1⁄2 Amps. 120 volts

Motor Duty

1

⁄2 H.P. 1 Phase 100-120 volts

AC

1 H.P. 1 Phase 220-240 volts

472 V.A. 120 volts

AC

768 V.A. 240 volts

Motor Duty

Pilot Duty

Alarm Circuit

AC 15 Amps. 120, 240 volts

DC1⁄2 Amps. 120 volts

WARNING: DO NOT CONNECT TO AN ELECTRICAL LOAD IN EXCESS OF THE RATED

Switch cuts off burner or stoker when water line drops approximately 3⁄8" below center line. Switch alarm

circuit when used is closed just before burner cuts off.

CAUTION:"This switch mechanism is factory set for optimum performance, alteration may cause the

valve to malfunction and will invalidate the warranty.

CAPACITY OF THE SWITCH.

ALWAYS CHECK THE CUT-OFF LEVEL BEFORE LEAVING THE JOB.

Page 4

Wiring Diagrams

No. N89S, N101S, N93S, N193S, N50S, N501S with Single Switch

Assembly For Burner Service with Single Pole, Single Throw Switch

When Used For BURNER SWITCH When Used For PILOT DUTY

LINE

TOP

Line

(Burner)

Burner Switch

Closed Circuit

Common

For loads in excess of ratings or when a 3-phase burner motor is used, use switch as pilot to

operate a relay or magnetic starter as shown under "Pilot Duty" above for burner switch. Incoming

leads must be suitable for a temperature rise of 90°C (194°F).

1

AC

⁄2 H.P. 1 Phase 110-120 volts

1 H.P. 1 Phase 220-240 volts

Float and Switch Assemblies

Interchangeable in Low Water Cut-offs

Open

Norm

Motor Duty

Norm

Closed

Burner Switch

Closed Circuit

AC

AC

LINE

TOP

Open

Norm

Common

1

⁄2 H.P. 1 Phase 110-120 volts

1 H.P. 1 Phase 220-240 volts

472 V.A. 120 volts

768 V.A. 240 volts

Norm

Closed

Motor Duty

Pilot Duty

Line

(Burner)

Watts float and switch assemblies are furnished to provide a complete new low water cut-off, less the

float

chamber, and are recommended for field servicing of such units. They can be quickly installed without changing existing piping and eliminate the possibility of disturbing factory adjustments. The complete

one piece unit not only facilitates installation but also assures the user of receiving latest, up to date construction.

SAN89D - Complete assembly facilitates maintenance and inventory, by being

interchangeable in all previous Series 89, 101, 93 and 193. Maximum Steam

Pressure 15 lbs.

SAN89S - Same as above, but furnished with single switch assembly.

SAN50D - Complete assembly facilitates servicing by being interchangeable in all

previous Series 50 and 501. Maximum Boiler Pressure 50 lbs.

SAN50S - Same as above, but furnished with single switch assembly. Standardly

furnished with "Dual" switch assembly unless single switch assembly type number is specified.

When required for manual reset models, specify SAN50SM.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from

labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control.

This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights.

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

SAN89D or

SAN89S

SAN50D or

SAN50S

Water Safety & Flow Control Products

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

IS-N89 0829 EDP# 1910095 © Watts, 2008

Loading...

Loading...