Page 1

Stainless Series

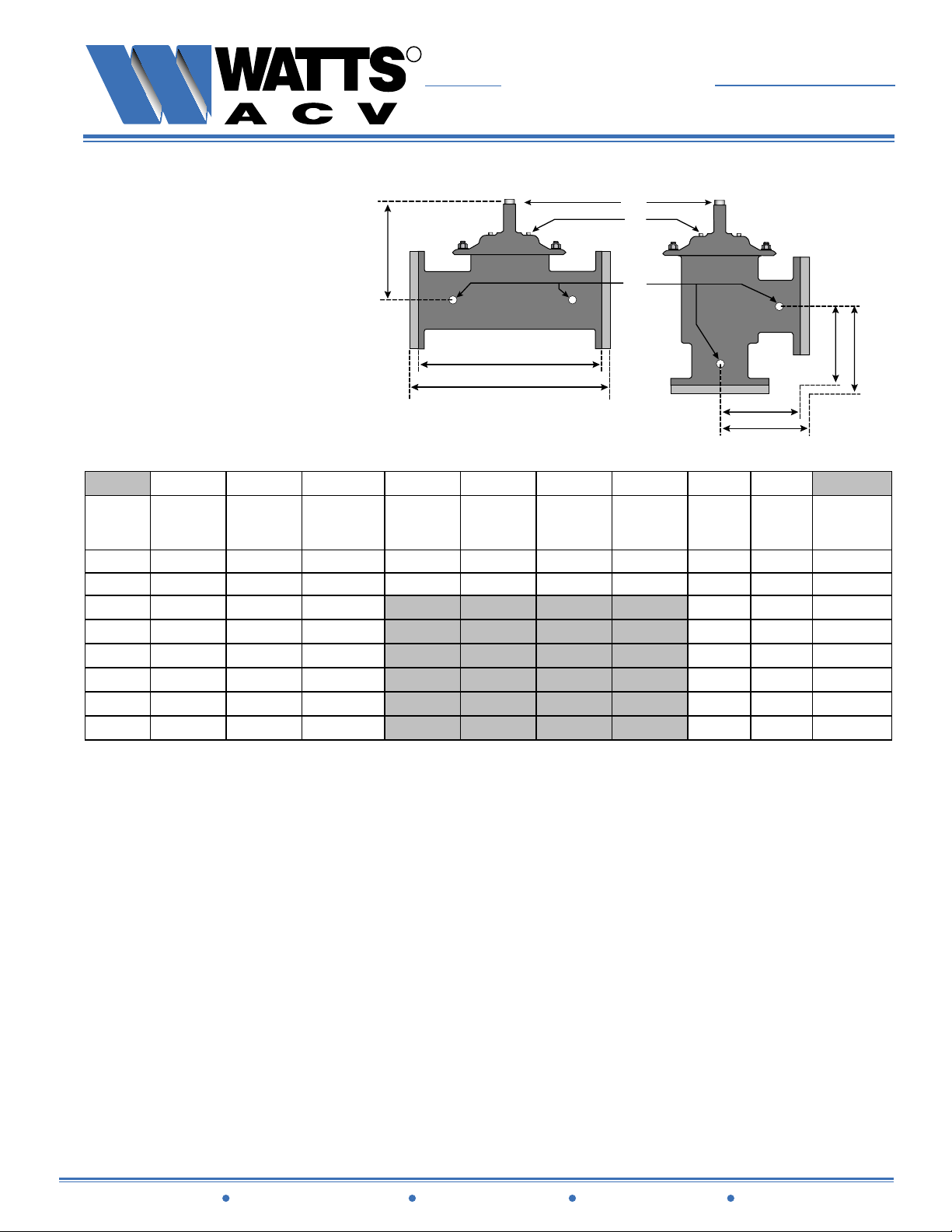

R

C

H

A

B

D

E

F

G

I

H

S6500 (Globe)

S61500 (Angle)

01/05

Standard Materials

Globe

Angle

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion

Bonded Epoxy Lined

Standard Materials

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion

Bonded Epoxy Lined

and Coated

Trim: 316 Stainless Steel

Elastomers: Buna-N (standard)

EPDM (optional)

Viton (optional)

Dimensions

A B C D E F G H I

VALVE

SIZE

6 17-3/4 18-5/8 11-5/8 8-7/8 9-3/8 6-3/4 7-1/4 3/4 3/4 77

8 21-3/8 22-3/8 15 10-11/16 11-3/16 7-1/4 7-3/4 1 3/4 168

10 26 27-3/8 17-7/8 1 1 225

12 30 31-1/2 21 1 1-1/4 376

16 35 36-5/8 25-3/4 1 1-1/4 450

18 48 49-5/8 31 1 1-1/2 850

20 48 49-5/8 31 1 1-1/2 860

24 48 49-3/4 31 1 1-1/2 870

Description

The Watts ACV Models S6500 and S61500 are reduced port, dual chamber basic valves that incorporate a one-piece disc and

diaphragm assembly. This assembly is the only moving part within the valve, allowing it to open or close as commanded by the pilot

control system.

GLOBE

150#

GLOBE

300#

COVER TO

CENTER

ANGLE

150#

ANGLE

300#

ANGLE

150#

ANGLE

300#

PORT

SIZE

PORT

SIZE

SHIPPING

WEIGHTS*

*Estimated in lbs.

When pressure is applied to the upper diaphragm chamber and released from the lower diaphragm chamber, the valve travels to a

closed position. When pressure is applied to the lower diaphragm chamber and released from the upper diaphragm chamber the

valve travels to a full open position. When pressure is balanced between the upper and lower diaphragm chambers, the valve will

hold an intermediate position until commanded to modulate open or closed by the pilot control system.

The Stainless Steel design offers superior corrosion resistance, as well as a lightweight alternative to conventional heavy iron

valves. Stainless Steel construction provides extended, diaphragm life and reduces the frequency and labor costs associated with

traditional maintenance repairs.

Model S6500: Globe Pattern Dual Chamber Basic Valve

Model S61500: Angle Pattern Dual Chamber Basic Valve

Operating Pressure

150 Flanged = 250 psi / 300 Flanged = 400 psi

Operating Temperature

Buna-N: 160°F Maximum

EPDM: 300°F Maximum

Viton: 250°F Maximum

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.wattsacv.com

Page 2

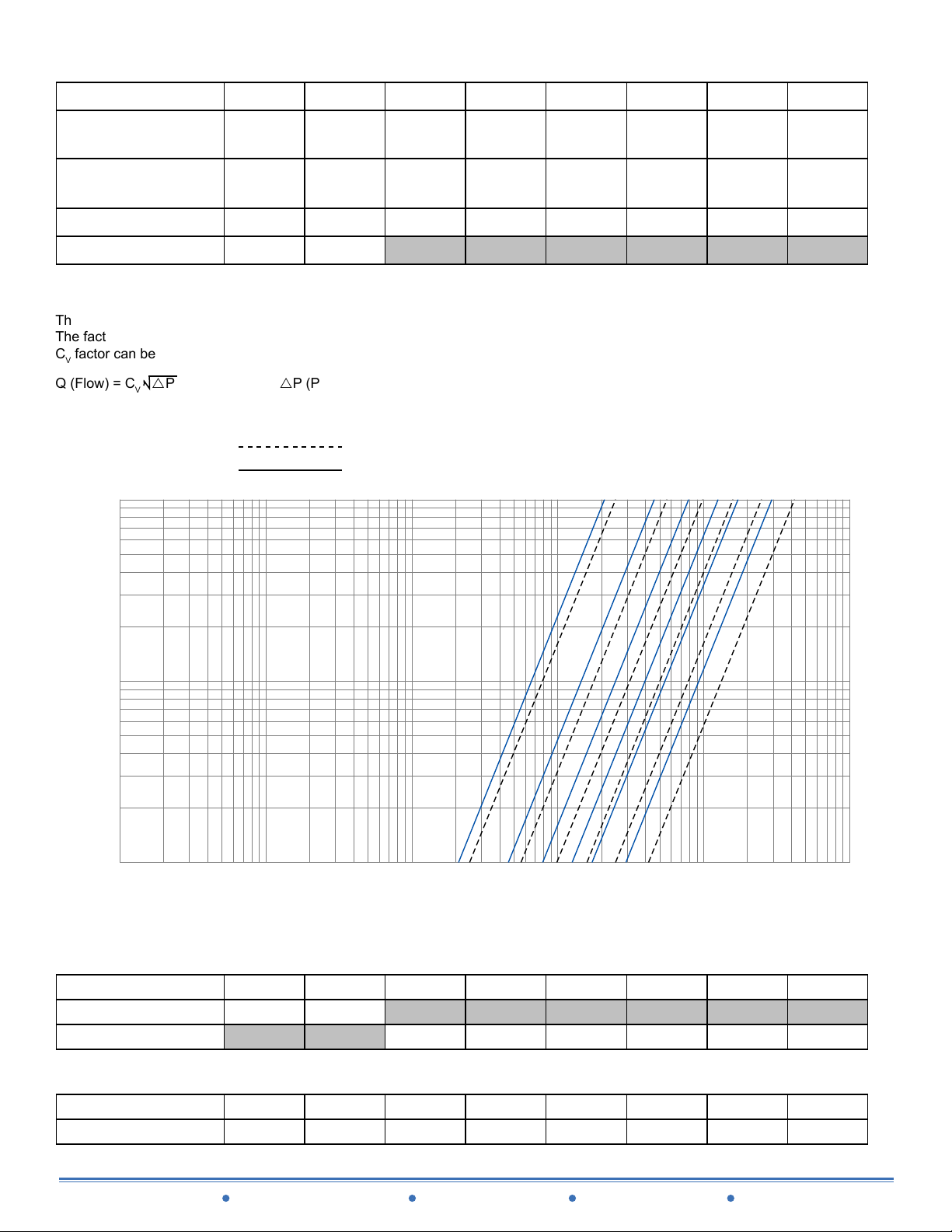

Maximum continuous flow based on velocity of 20 ft. per second.

Maximum intermittent flow based on velocity of 25 ft. per second.

The CV factor of a valve is the flow rate in US GPM at 60° F that will cause a 1 psi drop in pressure.

The factors stated are based upon a fully open valve.

CV factor can be used in the following equations to determine Flow (Q) and Pressure Drop (r P):

Q (Flow) = CV r P rP (Pressure Drop) = (Q/CV)

2

Flow Data

Flow Data - ACV S6500 (Globe) / S61500(Angle)

Valve Size - Inches 6 8 10 12 16 18 20 24

Maximum Continuous

Flow Rate Gpm (Water)

Maximum Intermittent

Flow Rate Gpm (Water)

800 1850 3100 5000 7000 11100 11100 11100

1000 2300 4000 6250 8900 14100 14100 14100

CV Factor GPM (Globe) 224 489 932 1428 2067 2881 2881 2881

CV Factor GPM (Angle) 237 534

Headloss

Angle

8

8

10

12

16

18 / 20 / 24

100

80

60

40

30

Globe

6

6

20

10

8

6

Pressure Drop (p.s.i.)

4

3

2

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000

100,000

Valve Cover Chamber Capacity

Valve Cover Cham-

Valve Size (in) 6 8 10 12 16 18 20 24

fl.oz. 22 70

U.S. Gal 1-1/4 2-1/2 4 9-1/2 9-1/2 9-1/2

Flow Rate - Gallons per minute (Water)

Valve Travel

Valve Travel

Valve Size (in) 6 8 10 12 16 18 20 24

(in) 1 1-1/2 2 2-1/2 3 4 4 4

8550 Hansen Road • Houston, Texas 77075 • (Ph) 713.943.0688 • (Fx) 713.944.9445 • www.wattsacv.com

Loading...

Loading...