Page 1

IOM-WQ-PWSRTA

PWSRTA Twin Alternating Series Softeners

Installation, Operation

and Maintenance Manual

Table of Contents

System Specification Table ................................ 2

Safety Information .......................................3

General Warnings ..................................... 3-4

Pre-Installation Considerations .................................4-5

General Installation Instructions ...................................5

PWSRTA System Programming ........................ 6-7

PWSRTA Quick Programming Guide .........................7

Regeneration and Error Screens ............................8

User Displays ..........................................9

Configuration Settings ................................ 10-13

OEM Softener System Setup........................... 14-16

Setting Option Table .................................... 17

OEM Filter System Setup.............................. 18-19

Installer Display Settings .................................20

Diagnostics ........................................ 21-22

PWSRTA Part List and Drawings ........................23

Front Cover and Drive Assembly ...........................23

PWSRTA Twin Alternating Softener

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can

result in death, serious personal injury, property damage, or

damage to the equipment.

Keep this Manual for future reference.

!

WARNING

You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual

is not consistent with local building or plumbing codes,

the local codes should be followed. Inquire with governing

authorities for additional local requirements.

!

WARNING

Need for Periodic Inspection/Maintenance: This product must

be tested periodically in compliance with local codes, but at least

once per year or more as service conditions warrant. All products must be retested once maintenance has been performed.

Corrosive water conditions, and/or unauthorized adjustments or

repair could render the product ineffective for the service intended.

Regular checking and cleaning of the product’s internal components helps assure maximum life and proper product function.

!

WARNING

Do not use with water that is microbiologically unsafe or of unknown quality adequate disinfection before and after the system.

Valve Body Compliance Table .............................24

PWSRTA with 1.050” Distributor Tube Opening Identification...... 24

Drive Cap Assembly, Downflow Piston, Upflow Piston,

Regenerant Piston and Spacer Stack Assembly ...............25

Twin Transfer ....................................... 26-27

Injector Cap, Injector Screen, Injector, Plug and O-Ring ..........28

Injector Order Information ................................29

Refill Flow Control Assembly and Refill Port Plug ...............30

Drain Line – 3/4” .......................................31

Drain Line - 1” .........................................32

V4017-01 T1 Interconnect Fitting Assembly...................33

D1400 1191 In/Out Head ................................34

PWSRTA Control Valve System Description ...............35

Drive Assembly ........................................35

Drive Cap Assembly, Main Piston and Regenerant Piston ........35

Spacer Stack Assembly..................................36

Injector Cap, Screen, Injector Plug and Injector . . . . . . . . . . . . . . . . 36

Refill Flow Control Assembly or Refill Port Plug ................36

Drain Line Flow Control and Fitting Assembly .................37

Troubleshooting ................................... 38-41

NOTES ..............................................42

NOTICE

Hydrocarbons such as Kerosene, Benzene, Gasoline,

etc., may damage products that contain O-rings or plastic

components. Exposure to such hydrocarbons may cause

the products to leak. Do not use the product(s) contained in

this document on water supplies that contain Hydrocarbons

such as Kerosene, Benzene, Gasoline, etc.

Page 2

Systems Specification Table

A. PWSRTA Series

MINERAL TANK BRINE TANK FLOW RATE & PRESSURE

TANK

SIZE

RESIN

FT

GRAVEL

3

(LBS.)

TANK

SIZE

SALT

FILL

SERVICE

(GPM)

DROP

(PSI)

BKW

(GPM)

SHIP WT.

(LBS.)

MODEL NO.

CAPACITY

(MAX.)

PIPE SIZE

(IN.)

PWSRTA130 30,000 1 9 x 48 1 15 18 x 40 400 13-19 15-25 2.2 230

PWSRTA145 45,000 1 10 x 54 1.5 20 18 x 40 400 14-21 15-25 2.7 290

PWSRTA160 60,000 1 12 x 52 2 30 18 x 40 400 15-21 15-25 3.2 420

2 PWSRTA Twin Alternating Series Softeners

Page 3

!

WARNING

General Installation Guidelines

This water conditioner’s control valve conforms to UL/

CE Standards. Generic valves were tested and certified for

compliance as verified by the agency listing. This water

conditioning system is to be used only for potable water.

Inspect the water conditioning system for carrier shortage or

shipping damage before beginning installation.

Operating Perameters:

• Operating ambient temperature: 40° to 110°F (5° to 43°C).

• Operating water temperature: 40° to 110°F (5° to 43°C).

• Operating water pressure range : 25 to 120 psi (1.7 to

8.27bar).

Installation Perameters: All plumbing should be done in

accordance with local plumbing codes.

• Do not use pipe dope or other sealants on threads. Use Teflon

tape on the threaded inlet, outlet and drain fittings. Teflon tape

is not necessary on the nut connection or caps because of

o-ring seals.

• All plastic connections should be hand tightened. Teflon® tape

may be used on connections that do not use an O-ring seal.

Do not use pipe dope type sealants on the valve body. Do not

use pliers or pipe wrenches.

• Observe drain line requirements.

• Keep the media tank in the upright position. Do not turn upside

down or drop. Turning the tank upside down or laying the tank

on its side can cause media to enter the valve.

• The pipe size for the drain line should be a minimum of ½”.

Backwash flow rates in excess of 7 gpm (26.5 lpm) or length in

excess of 20’ (6.1m) require ¾” drain line.

• Do not support the weight of the system on the control valve

fittings, plumbing, or the bypass.

Environmental:

• Use only regenerants designed for water conditioning. Do not

use ice melting salt, block salt or rock salt.

During cold weather it is recommended that the installer warm

the valve to room temperature before operating.

®

is a trademark of E.I. duPont de Nemours.

Teflon

• Do not use petroleum-based lubricants such as Vaseline, oils

or hydrocarbon-based lubricants. Use only 100% silicone

lubricants.

• Do not allow this water conditioning system to freeze. Damage

from freezing will void this water conditioning system’s

warranty.

• HYDROCARBONS SUCH AS KEROSENE, BENZENE,

GASOLINE, ETC., MAY DAMAGE PRODUCTS THAT

CONTAIN O-RINGS OR PLASTIC COMPONENTS.

EXPOSURE TO SUCH HYDROCARBONS MAY

CAUSE THE PRODUCTS TO LEAK. DO NOT USE THE

PRODUCT(S) CONTAINED IN THIS DOCUMENT ON

WATER SUPPLIES THAT CONTAIN HYDROCARBONS

SUCH AS KEROSENE, BENZENE, GASOLINE, ETC.

• THIS WATER METER SHOULD NOT BE USED AS THE

PRIMARY MONITORING DEVICE FOR CRITICAL OR

HEALTH EFFECT APPLICATIONS.

• Do not use Vaseline, oils, other hydrocarbon lubricants or spray

silicone anywhere. A silicone lubricant may be used on black

o-rings but is not necessary.

PWSRTA Twin Alternating Series Softeners 3

Electrical:

• Use only the power transformer supplied with this water

conditioning system.

• All electrical connections must be completed according to local

codes.

• The power outlet must be grounded.

• All electrical connections must be connected according to local

codes. (Be certain the outlet is uninterrupted.)

• Install grounding strap on metal pipes.

• The power adapter comes with a 15 foot power cord and is

designed for use with the control valve. The power adapter is for

dry location use only. The control valve remembers all settings

until the battery power is depleted if the power goes out.

• After the battery power is depleted, the only item that needs to

be reset is the time of day; other values are permanently stored

in the nonvolatile memory. The control valve battery is not

rechargeable but is replaceable.

• No user serviceable parts are on the PC board, the motor or

the power adapter. The means of disconnection from the main

power supply is by unplugging the power adapter from the

wall.

• Install an appropriate grounding strap across the inlet and

outlet piping of the water conditioning system to ensure that a

proper ground is maintained.

• To disconnect power, unplug the AC adapter from its power

source.

Soldering:

• Use only lead-free solder and flux, as required by federal and

state codes, when installing soldered copper plumbing.

• Use caution when installing soldered metal piping near the

water conditioning system. Heat can adversely affect the

plastic control valve and bypass valve.

• Solder joints near the drain must be done prior to connecting

the drain line flow control fitting. Leave at least 6” between the

drain line control fitting and solder joints when soldering pipes

that are connected on the drain line control fitting. Failure to do

this could cause interior damage to the drain line flow control

fitting.

• When assembling the installation fitting package (inlet and

outlet), connect the fitting to the plumbing system first and

then attach the nut, split ring and o-ring. Heat from soldering

or solvent cements may damage the nut, split ring or o-ring.

Solder joints should be cool and solvent cements should be

set before installing the nut, split ring and o-ring. Avoid getting

primer and solvent cement on any part of the o-rings, split

rings, bypass valve or control valve.

Control Valve:

• This glass filled Noryl1 (or equivalent) fully automatic control

valve is designed as the primary control center to direct and

regulate all cycles of a water softener or filter.

• The control valve, fittings and/or bypass are designed to

accommodate minor plumbing misalignments but are not

designed to support the weight of a system or the plumbing.

• The nuts and caps are designed to be unscrewed or tightened

by hand or with the special plastic wrench. If necessary a

pliers can be used to unscrew the nut or cap. Do not use a

pipe wrench to tighten or loosen nuts or caps. Do not place a

screwdriver in the slots on caps and/or tap with a hammer.

• After completing any valve maintenance involving the drive

assembly or the drive cap assembly and pistons unplug power

source jack from the printed circuit board (black wire) and plug

back in or press and hold NEXT and REGEN buttons for 3

Page 4

General Warnings (continued)

!

WARNING

Installation Guidelines:

seconds. This resets the electronics and establishes the

service piston position. The display should flash all wording,

then flash the software version and then reset the valve to the

service position.

• The control valve is compatible with a variety of regenerants

and resin cleaners. The control valve is capable of routing

the flow of water in the necessary paths to regenerate or

backwash water treatment systems. The injector regulates the

flow of brine or other regenerants. The control valve regulates

the flow rates for backwashing, rinsing, and the replenishing of

treated water into a regenerant tank, when applicable.

• Control valve installation is made easy because the distributor

tube can be cut ½” above to ½” below the top of tank thread.

The distributor tube is held in place by an o-ring seal and

the control valve also has a bayonet lock feature for upper

distributor baskets.

Pre-Installation Considerations

A. Water Pressure

A minimum of 25 pounds of water pressure is required for

regeneration valve to operate effectively.

B. Electrical Facilities

A continuous 115 volt, 60 Hertz current supply is required. Make

certain the current supply is always hot and cannot be turned off with

another switch.

C. Existing Plumbing

Condition of existing plumbing should be free from lime and iron

buildup. Piping that is built up heavily with lime and/or iron should

be replaced. If piping is clogged with iron, a separate iron filter unit

should be installed ahead of the water softener.

D. Location Of Softener And Drain

The softener should be located close to a drain.

E. Bypass Valves

Always provide for the installation of a bypass valve.

F. Valve to Tank Installation Instructions

1. Spin the valve onto the tank, ensuring the threads are not crossthreaded.

NOTICE

The main control valve and tank adaptor have right-hand threads, or

clockwise, to install

2. Rotate the valve freely without using force until it comes to a stop

(this position is considered zero).

3. Rotate the valve clockwise from zero, between ¼ turn and ½

turn to fully tighten. No tools are needed. Hand tight is enough.

Overtightening may cause valve or tank damage.

NOTICE

If lubricant is required, a silicone compound is strongly

recommended. Dow Corning

Watts), is recommended for best possible results. Dow Corning

Release Compound is used in the manufacture of this control valve.

The use of other types of lubricants may attack the control’s plastic

or rubber components. Petroleum-based lubricants can cause

swelling in rubber parts, including O-rings and seals.

®

Silicone Compound (available from

®

7

1

Noryl is a trademark of Sabic.

4 PWSRTA Twin Alternating Series Softeners

Page 5

Pre-Installation Considerations

(continued)

G. Pre Installation and Loading of Media

Systems that are 13” in diameter and larger are not loaded with

media. These systems must be loaded with media before placing

into service. To load a system follow the below steps.

1. Cap the top open end of the distributor tube with tape and

plastic sheeting to keep foreign debris from entering the

distributor tube. This cap must be secure and not come off

during media loading.

2. Place the distributor tube, screen end down, into the mineral

tank and center it in the bottom. The top of the distributor

tube should be flush with the top of the tank. If 4” x 2.5” tank

bushings are used, the distributor tube should be flush with the

top of the tank bushing.

3. Make sure the plastic and tape cap is secure to the top of the

distributor tube, place a funnel on the top of the tank and load

first the gravel (if different sizes of gravel are used load the largest

gravel first, then the smaller gravel) then the resin media into the

tank. The cap must not come off of the distributor tube during

the loading of the media.

4. Remove the plastic cap from the distributor tube. DO NOT

PULL UP ON THE DISTRIBUTOR TUBE when removing the

cap. The distributor tube top must remain flush with the top of

the tank.

5. Clean any media from the threads and top of the mineral tank.

6. Lubricate the O-rings on the bottom of the control valve

(distributor pilot O-ring and top of tank O-ring). Use nonpetroleum based silicone lubricant only.

7. Place the control valve on top of the tank. When doing this step,

seat the top of the distributor tube inside the centered O-ring

sealed port on the bottom of the valve first then press the valve

down until the tank threads come in contact with the valve

threads. This ensures that the distributor tube is properly seated

into the bottom of the control valve. Thread the valve on to the

tank clockwise. Be careful not to cross thread the valve or over

tighten it. A hand tight snug fit is appropriate for the control valve

torque. A wrench is not necessary. Do not use thread sealant or

PTFE tape on the valve base threads.

8. The system is now ready for installation. Follow the Installation

Section in the Installation, Operation and Maintenance Manual.

!

WARNING

Do not exceed water pressure of 120 psi (8.2 bar). Do not

exceed 110°F (43.3°C). Do not subject unit to freezing

conditions.

Installation Instructions

1. Turn off water heater(s).

2. Turn off the main water supply to the home and open an inside

faucet (cold and hot) to relieve any pressure within the plumbing

system.

3. Place the system in the desired installation location. Make sure

that the location is level and sturdy enough to support the weight

of the system once it is in operation.

4. Place the bypass valve in the bypass position.

5. Connect the cold water supply to the inlet of the water

conditioning system. While constructing the supply line, install a

master supply valve (user supplied) in the supply line and close it.

6. Connect the feed water line to the home to the outlet of the

system.

7. Plumb the drain line to an appropriate drain abiding by all local,

city, and state codes. Use a 3/4” drain line for backwash flow

rates of 7 gpm or for drain lines of 7 gpm and less that exceed

20’ in length. Use a 1” drain line for backwash flow rates of 10

gpm and 12 gpm.

8. Connect the brine tank to the water softener control valve brine

inlet port using the factory supplied fittings and tubing. Add

enough water to the brine tank so that water covers the top of

the air check. DO NOT ADD SALT AT THIS TIME.

9. Open the user supplied feed water valve. Check for leaks and

repair as needed.

10. Allow the inside hot and cold faucet to remain open until all air

has been purged from the plumbing system. Then close the

faucet.

11. Locate Manual Regeneration Options in this manual to see the

steps to initiate an Immediate Manual Regeneration. Once you

have read that section place the system in backwash and unplug

the system from its electrical outlet once it has cycled into the

backwash position. This will stall the unit in backwash so all air

can be purged from one of the tanks.

12. Adjust the user supplied feed water valve to 1/4 open and place

the bypass valve into the service position.

13. Air will come out of the drain line until the backwashing tank is

completely purged of air. Then water will flow to drain. Allow

water to flow to drain for 15 minutes or until the water to drain is

clear of resin color throw.

14. Plug the system back into the electrical outlet and manually cycle

it through the remaining regeneration steps until it arrives in the

service position.

15. Repeat installation steps 11, 12, 13, and 14 of the General

Installation Instructions to purge the air from the second tank.

16. Check for leaks and repair as needed.

17. Installation is now complete and the system is ready for

programming and one cycle of brine tank refill so that the correct

amount of water is in the brine tank for the first regeneration

cycle. The brine tank refill must be done after programming the

system.

PWSRTA Twin Alternating Series Softeners 5

Page 6

PWSRTA System Programming

PWSRTA Quick Programming Guide

A quick programming guide has been listed below for convenience specifically for the PWSRTA series water softening systems. For other

programming requirements not listed in the Quick Programming Guide, please see the detailed programming section of this manual.

NOTICE

The electronics in the PWSRTA control valve are used across a wide

variety of control valves and applications, including backwashing

filters. All programming for the electronics has been included in this

manual for reference however the valve must be programmed for

Twin Alternating Softening Applications when called for during valve

programming.

6 PWSRTA Twin Alternating Series Softeners

Page 7

NOTICE

The Water Softener Capacity of the system needs to be known prior to programming the system, to insure proper programming and

efficiency of system

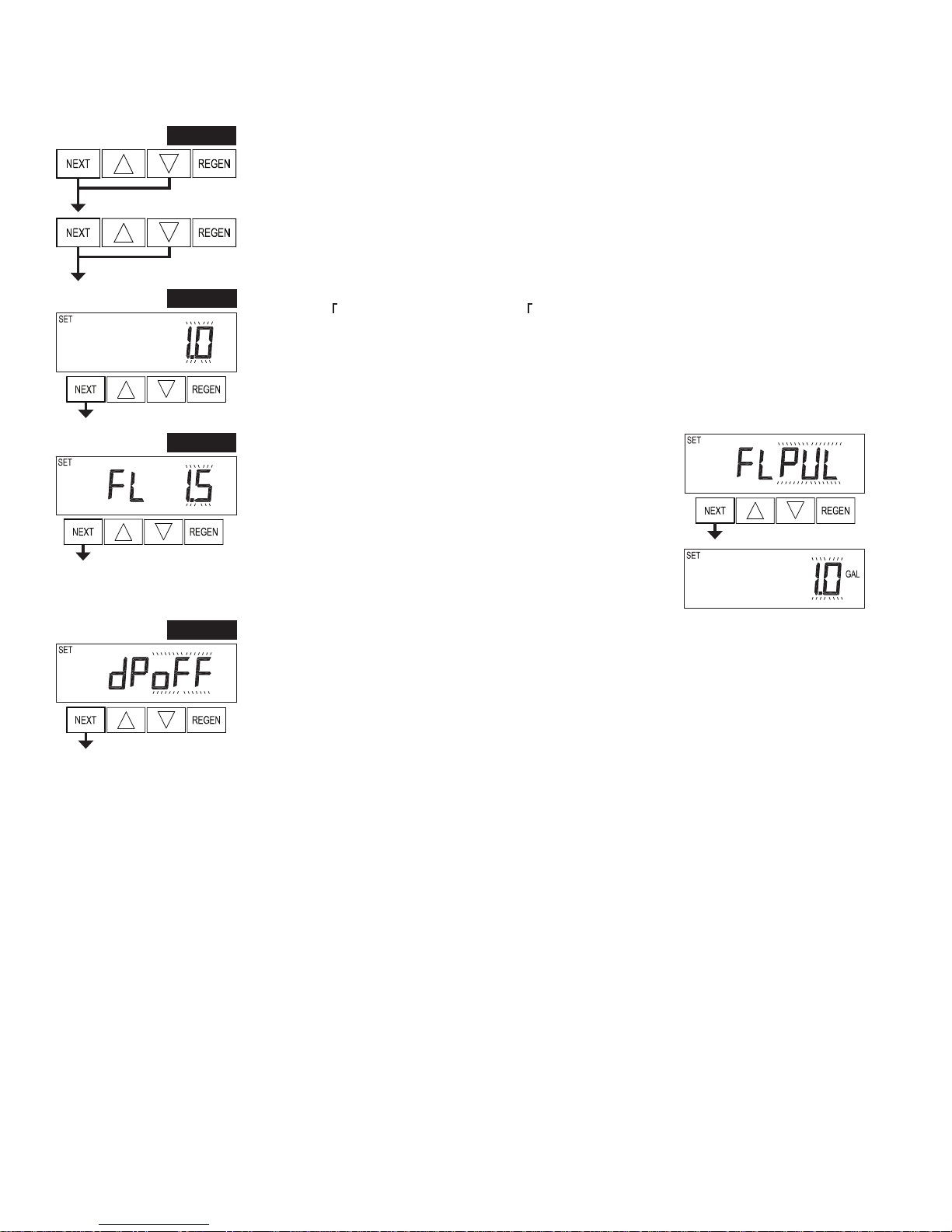

Chart 1: Setting Time of Day

Press the Set Clock button

Press the Next button to advance

to the minutes.

Press the Next button to set time To Exit

Adjust hour with the UP and Down arrow buttons. There is an AM and PM indicator at the

top of the display

Adjust minutes with the Up and Down arrow buttons.

NOTICE

Once in the programming settings, simply use the UP and DOWN arrow buttons to change values

Chart 2: Master Programming

To enter the Master Programming

mode, press and hold the NEXT

and DOWN arrow buttons simultaneously for 3 – 5 seconds

Press NEXT Button This will take you into 1st Backwash setting and should be set at 8 minutes

Press NEXT Button This will take you into BRINE DRAW setting and should be set at 60 minutes

Press NEXT Button This will take you into 2nd Backwash setting and should be set at 8 minutes

Press NEXT Button This will take you into RAPID RINSE setting and should be set at 6 minutes

Press NEXT Button

Press NEXT Button This will complete Master Programming Steps

The display should read SOFT with an arrow next to the word SET. If FLTr is displayed on

the screen, hit the UP or DOWN arrow to display SOFT. This indicates you are now in the

Master Programming Mode

This will take you into BRINE TANK REFILL setting and should be set at following times

based on your water softener capacity

For 30K Water Softener - Fill (brine tank refill) is set at 6 minutes, which is most efficient

setting. This can be changed to maximum brining if needed, maximum brining would be set

at 10 minutes.

For 45K Water Softener - Fill (brine tank refill) is set at 8 minutes, which is most efficent

setting. This can be changed to maximum brining if needed, maximum brining would be set

at 15 minutes.

For 60K Water Softener - Fill (brine tank refill) is set at 12 minutes, which is most efficient setting. This can be changed to maximum brining if needed, maximum brining would

be set at 20 minutes.

NOTICE

Next you will need to set up Installer Programming, this MUST be done in addition to the Master Programming

Chart 3: Installer Programming

To enter Installation Display Setting

Programming mode, press and hold

the NEXT and UP arrow buttons

simultaneously for 3 - 5 seconds

Press Next Button

Press Next Button REGEN - Indicated when the system will regenerate, should be read 0”

Press Next Button

Volumetric capacity in gallons to regeneration (will soften 2500 gallons before a regeneration

is queued.

Day Override. Default should be set to 14 Days. Watts Pure Water water softeners regenerate based on water usage, but this day override setting will come into play if the softener sits

idle or has not regenerated and will automatic initiate regeneration on the 14

th

day.

Programming completed, Valve will return to normal mode and will be in service.

If you have additional questions regarding your water softener programming, please contact

Pure Water Technical Support at 1.800.224.1299, then press #2

PWSRTA Twin Alternating Series Softeners 7

Page 8

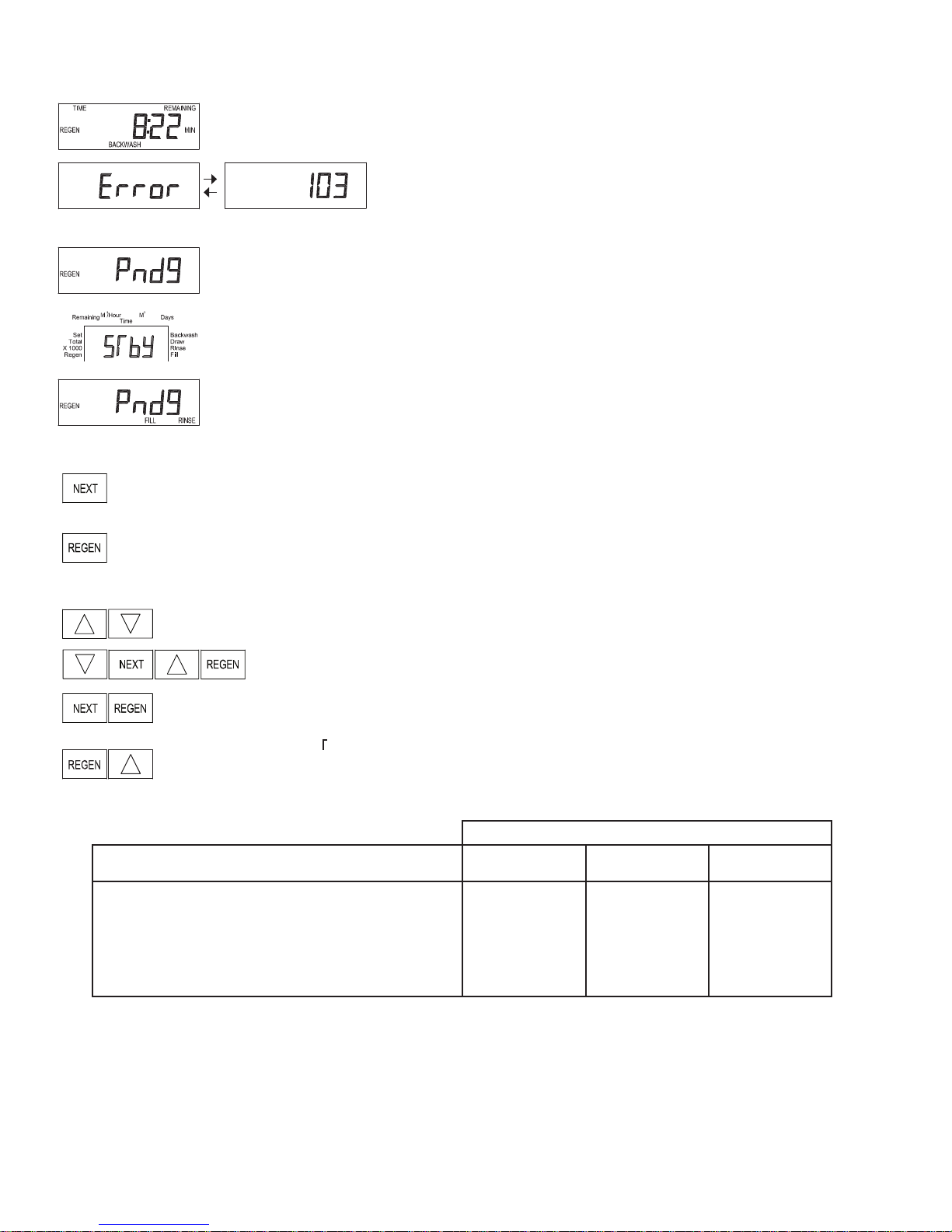

Regeneration and Error Screens

Regen Screen

Displays the time remaining in the current cycle. Pressing REGEN advances to the next cycle.

Error Screen

Alternated flashing Err and error code every 3 seconds. Clear by disconnecting

the power supply at the PC board and reconnecting, or press NEXT and REGEN

simultaneously for 3 seconds.

In Alternator Systems when a unit is waiting to initiate the first cycle step of regeneration, “REGEN

Pndg” is displayed.

“STbY” is displayed in Alternator Systems when a valve is in Standby state.

“REGEN Pndg RINSE FILL” is displayed whenever a zero-capacity tank has transferred to an off-line

state and is currently waiting to initiate the second portion of a regeneration cycle. Viewed only when

Delayed Rinse and Fill is set to ON.

Button Operation and Function

Scrolls to the next display.

Pressing once and releasing will schedule a regeneration at the preset delayed regeneration time.

Pressing again and releasing will cancel the regeneration.

Pressing and holding for 3 seconds will initiate an immediate regeneration

Pressing while in regeneration will advance to the next cycle.

Pressing in the program levels will go backwards to the previous screen

Changes variable being displayed.

Key sequence to lock and unlock program settings.

Holding for 3 seconds initiates a control reset. The software version is displayed and the piston returns

to the home/service position, resynchronizing the valve.

Used with valve type 1.0 , holding for at least 3 seconds causes a switch in the tank in Service without cycling the

regeneration valve. After tank switch, days remaining and capacity remaining status is retained for each tank until the

next regeneration.

Regeneration Cycles and Times

Range

Cycle Softening Filtering Regen

Backwash

Regenerant Draw/Slow Rinse (UP or DN)

Fast Rinse

Regenerant Rell

Regenerant Rell 2.0 or 1.5 set to MIN (softening only)

Service

If 1.5 or 2.0 is selected in Step 2CS, cycles can be set to “oFF”.

The user can initiate manual regeneration. The user has the option to request the manual regeneration at the delayed regeneration time or to

have the regeneration occur immediately:

1. Pressing and releasing the REGEN button. “

regeneration time. The user can cancel the request by pressing and releasing the REGEN button.

2. Pressing and holding the REGEN button for approximately 3 seconds will immediately start the regeneration. The user cannot cancel this

request, except by resetting the control by pressing NEXT and REGEN simultaneously for 3 seconds.

REGEN TODAY

” will flash on the display and the regeneration will occur at the delayed

1-120 minutes

1-180 minutes

1-120 minutes

0.1-200.0 lbs.

0.1-99.0 minutes

1-480 minutes

1-120 minutes

1-180 minutes

1-120 minutes

1-99.0 GAL

0.1-99.0 minutes

NA

Filtering

Backwash

1-120 min.

NA

1-120 min.

NA

NA

NA

8 PWSRTA Twin Alternating Series Softeners

Page 9

General Operation

User Displays

When the system is operating, one of five displays may be shown. Pressing NEXT will alternate

between the displays shown below.

User 1

Typical user display. Shows volume remaining to regeneration. This screen will not be viewed if the

control is set for time-clock operation.

User 2

Displays number of days to next regeneration.

User 3

Flow Rate.

Displays present flow rate.

Not viewed (along with SOFTENING or FILTERING Icon) if ALT A or ALT b is set in CONFIGURATION 4

and the valve is currently in Standby. When 1.0

the tank currently in Service (“A” or “b”) in the leftmost digit.

is set in CONFIGURATION 1, the display will indicate

User 4

Displays total volume in gallons since last reset. If a meter is not used this display will be shown but 0

will be displayed.

PRESS FOR 3 SECONDS TO RESET TO 0.

User 5

Shows current time.

Setting Time of Day

Push NEXT until time of day screen is displayed. Press and hold until SET TIME is displayed and the

hour flashes once. Press or until the correct hour is displayed.

Then press NEXT. The minutes will flash. Press or until the correct minute is displayed.

Press NEXT to return to the User Displays. Time of day should only need to be set after power outages

lasting more than 8 hours, if the battery has been depleted and a power outage occurs, or when

daylight saving time begins or ends. If a power outage lasting more than 8 hours occurs, the time of

day will flash on and off which indicates the time of day should be reset. If a power outage lasts less

than 8 hours and the time of day flashes on and off, the time of day should be reset and the battery

replaced.

PWSRTA Twin Alternating Series Softeners 9

Page 10

Step 1CS

Configuration Settings

Step 1CS – Press NEXT and simultaneously for 5 seconds and release. Press NEXT and simulta-

neously for 5 seconds and release. If the screen in Step 2CS does not appear, the lock on the valve is

activated. To unlock, press , NEXT, and REGEN in sequence, then press NEXT and simultaneously for 5 seconds and release. Press NEXT and simultaneously for 5 seconds and release.

Step 2CS

Step 3CS

Step 4CS

Step 2CS – Use or to select 1.0 for 1” valve, 1.25 for 1.25” valve, 1.5 for 1.5” valve, 2.0 for 2”

valve or 1.0

are selected, press NEXT to go to Step 3CS. Press REGEN to exit Configuration Settings.

for twin valve. If 1.0, 1.25 or 1.0 are selected, press NEXT to go to Step 4CS. If 1.5 or 2.0

Step 3CS – Use or to select meter size. Settings available

are 1.5, 2.0, 3.0, 1.0r (1.0 Remote Meter) or PUL (Variable Meter

Calibration.) Variable meter pulses of 0.1-150.0 PPG can be selected.

Press NEXT to go to Step 4CS. Press REGEN to return to previous

step.

Step 4CS – Selecting the use of an outside signal to initiate a regeneration: Selection only matters if a

connection is made to the two pin connector labeled DP SWITCH located on the printed circuit board.

Following is an explanation of the options:

oFF - feature not used

NOTE: In a twin alternating system each control must have a separate dP signal or dP switch. One dP

signal or one dP switch cannot be used for both controls.

on0 – If the dP switch is closed for an accumulative time of 2 minutes a regeneration will be signaled to

the unit. In a twin alternating system the MAV will transition first to switch units so that the signaled unit

can start regeneration. After the MAV has fully transitioned, the regeneration begins immediately. Note:

For PWSRTA control valves programmed for twin alternating: if the dP function “on0” is set, the Delayed

Rinse and Fill feature is not available.

dEL – If the dP switch is closed for an accumulative time of 2 minutes a regeneration will occur at the

scheduled delayed regeneration time. In a twin alternating system once the dP switch is triggered the PC

Board will display “REGEN TODAY” and when the delayed regen time comes the control will switch tanks

and the triggered unit will then go into regeneration. Note: For PWSRTA control valves programmed for

twin alternating: if the dP function “dEL” is set, the Delayed Rinse and Fill feature is not available.

HoLd – If the dP switch is closed a regeneration will be prevented from occurring while there is switch

closure. In a twin alternating system the regeneration of a unit can be prevented upon switch closure. If

the unit depletes the capacity down to zero, it will not be allowed to switch tanks to regenerate until the

switch is open. Note: For PWSRTA control valves programmed for twin alternating the Delayed Rinse and

Fill feature can be set.

Press NEXT to go to Step 5CS. Press REGEN to return to previous step.

10 PWSRTA Twin Alternating Series Softeners

Page 11

Step 5CS

Step 5CS –

2CS. Allows selection of one of the following using or :

• the Control Valve to have no hard water bypass;

• the Control Valve to act as an alternator;

• the Control Valve to have a separate source during the regeneration

cycle; or

• the Control Valve to operate with the System Controller.

Select OFF when none of these features are used.

Only use Watts No Hard Water Bypass Valves or Watts Motorized Alternating Valves (MAV) with these selections. Watts No Hard Water

Bypass Valves (1” or 1.25” V3070FF or V3070FM) are not designed to be used with the alternator or separate source functions.

Configuring the Control Valve for No Hard Water Bypass Operation:

Select nHbP for control operation. For no hard water bypass operation the three wire communication

cable is not used.

Selection requires that a connection to MAV or a No Hard Water Bypass Valve is made to the two pin

connector labeled MAV located on the printed circuit board. If using a MAV, the A port of the MAV must

be plugged and the valve outlet connected to the B port. When set to nHbP the MAV will be driven

closed before the first regeneration cycle that is not FILL or SOFTENING or FILTERING, and be driven

open after the last regeneration cycle that is not FILL.

This display will not appear if 1.0 was selected in Step

NOTICE

If the control valve enters into an error state during regeneration mode, the no hard water bypass valve

will return to the open Position, if not already there.

Configuring the Control Valve for Separate Source Operation:

Select SEPS for control operation. For separate source operation the three wire communication cable is

not used.

Selection requires that a connection to a Watts Motorized Alternator Valve (MAV) is made to the two pin

connector labeled MAV located on the printed circuit board. The C port of the MAV must be connected

to the valve inlet and the A port connected to the separate source used during regeneration. The B port

must be connected to the feed water supply.

When set to SEPS the MAV will be driven closed before the first regeneration cycle, and be driven open

after the last regeneration cycle.

NOTICE

If the control valve enters into an error state during regeneration mode, the MAV will return to the open

position, if not already there.

Selecting the Control Valve to act as an alternator:

519.0 and higher = Use 3-wire Interconnect Cables for all communication between units.

518.3 and lower = Use 2-wire Interconnect Cables for twin alternators with independent ow meters.

Prior to starting the programming steps, connect the communication cable to each control valve board’s three pin connector

labeled ‘COMM CABLE’. Also connect the meter cord to either control valve to the three pin connector labeled ‘METER’.

Softener Valve Programming Steps

Set to ALT A

Connect the outlet plumbing of ALT A

Configuration Settings Step 5CS

valve to the MAV’s A port and connect

the MAV’s two pin wire connector to

the two pin connector labeled “DRIVE”

Connect the outlet plumbing of ALT b valve to

the MAV’s B port. No electrical connections are

required between the ALT b valve and the MAV.

on the ALT A valve

Softener System Setup Step 10S Set System Capacity Set System Capacity

Softener System Setup Step 11S Set to ‘AUTO’ Set to ‘AUTO’

Softener System Setup Step 12S Set regeneration time option to ‘on 0’. Set regeneration time option to ‘on 0’.

Installer Display Settings Step 3I Set Day Override to “oFF” Set Day Override to “oFF”

If set up for a lter, in Step 5F set Volume Capacity in Gallons; in Step 6F select Regeneration Time Option “on 0”; and in Step 3I select

Day Override “oFF”.

NOTICE

If the control valve is in an error state during regeneration mode the MAV will close the B port and keep open the A port until the error is

corrected and reset.

PWSRTA Twin Alternating Series Softeners 11

Set to ALT b

Page 12

PWSRTA

For Watts alternator systems using PWSRTA valves there will be an option to delay the last two cycles of

regeneration (only “Rinse” and “Fill”). This feature splits the regeneration into two portions. The first portion

of the regeneration will start immediately and all programmed cycles before the “Rinse” and “Fill” cycles will

be performed. After all programmed cycles before “Rinse” and “Fill” are completed the control valve will

drive to the service position (displaying “Delayed Rinse + Fill Pending”). When the volume of the on-line

unit is depleted to 10% of its programmed capacity, the control valve will be triggered to finish the second

portion of the regeneration and complete the “Rinse” and “Fill” cycles and return to Service and be placed

into Standby mode, and wait to come on-line for service. Set to oFF to

deactivate this feature.

PWSRTA2

For Watts alternator systems using the PWSRTA2 valve, when NEXT is pressed after selecting ALT

A or ALT B, a display will allow the user to set the amount of pre-service rinse time for the stand by

tank just prior to returning to service. Set to oFF to deactivate this feature. With 1.0

display appears and is set in a similar manner.

set, the same

Retracted

Valve “A” in Service Position =

MAV piston rod Retracted

NOTICE

Watts Twin Alternator Operations

• Twin alternating systems can be programmed with a day override setting combined with the normal volume-based regeneration

programming. A twin alternating system in this conguration will then regenerate based on the volume used or the day override if there

is a period of low water usage.

• Twin alternating systems can be programmed as a time clock only based regenerating system. In this conguration, the days remaining

are counted only on the unit that is in service. The unit in Stand-by Mode only notes days in diagnostics, which results in time clock

only twin regeneration initiation.

• Twin alternating systems can be programmed for a delayed regeneration time. The system will allow an immediate transfer of the MAV

to switch tanks and place a fully regenerated unit in service once a unit becomes exhausted. The exhausted unit will then be placed into

Stand-by Mode and allowed to have a delayed regeneration at the pre-set time.

Extended

Valve “B” in Service Position =

MAV piston rod Extended

12 PWSRTA Twin Alternating Series Softeners

Page 13

Configuring the Control Valve for System Controller Operation:

Select “SYS” to link control valve to System Controller. For communication between control valve and

System Controller, a three-wire communication cable is required.

Selection requires that a connection to a Watts No Hard Water Bypass (V3070FF or V3070FM) be

made to the two-pin connector labeled MAV located on the printed circuit board for PWSRTA control

valves. For valve types PWSRTA15 and PWSRTA2, a connection from a Watts No Hard Water Bypass

(V3097/ BSPT or V3098/ BSPT) to the two pin connector labeled MAV located on the printed circuit

board is required.

Press NEXT to go to Step 6CS. Press REGEN to return to previous step.

Step 6CS

EXIT TO DISPLAY SCREENS

Step 6CS – Fill Units: If set as a softener, if Step 2CS is set to 1.5, and FILL is part of the Regeneration

Cycle Sequence, FILL UNITS of MIN or LBS can be selected. Press

NEXT to exit OEM Configuration Setup. Press REGEN to return to previous step.

PWSRTA Twin Alternating Series Softeners 13

Page 14

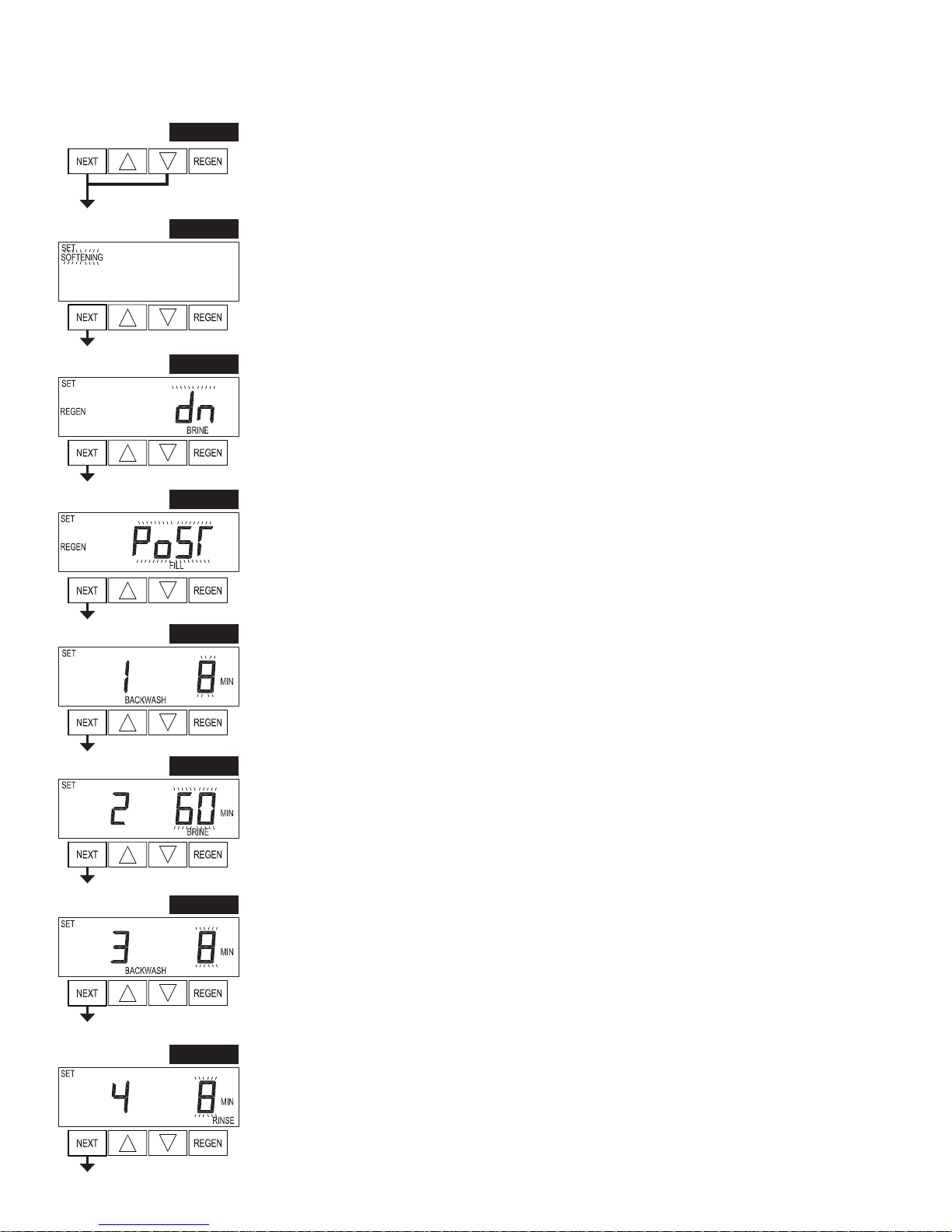

OEM Softener System Setup

Step 1S

Step 2S

Step 3S

Step 4S

Step 1S - Press NEXT and simultaneously for 5 seconds and release. If screen in Step 2S does not

appear, the lock on valve programming has been activated. To unlock press , NEXT, , REGEN in

sequence, then press NEXT and simultaneously for 5 seconds and release.

Step 2S – Choose SOFTENING using or . Press NEXT to go to Step 3S. Press REGEN to exit OEM

Softener System Setup.

Step 3S – Choose Brining Direction using or . This screen is not viewed when Step 2S is set to

Filtering. Press NEXT to go to Step 4S. Press REGEN to return to previous step.

Step 4S – Set Refill location using or :

• “PoST” to refill the brine tank after the final rinse; or

• “PrE” to refill the brine tank four hours before the regeneration time set.

This screen is not viewed when Step 2S is set to Filtering.

Press NEXT to go to Step 5S. Press REGEN to return to previous step.

Step 5S

Step 6S

Step 7S

Step 8S

Step 5S – Select the time for the first cycle using or . For valve types 1.5 and 2.0, “oFF” is also

available.

Press NEXT to go to Step 6S. Press REGEN to return to previous step.

Step 6S – Select the time for the second cycle using or . For valve types 1.5 and 2.0, “oFF” is also

available.

NOTE: The display will flash between cycle number and time, and brine direction (UP or dn).

Press NEXT to go to Step 7S. Press REGEN to return to previous step.

Step 7S – Select the time for the third cycle using or . For valve types 1.5 and 2.0, “oFF” is also

available.

Press NEXT to go to Step 8S. Press REGEN to return to previous step.

Step 8S – Select the time for the fourth cycle using or . For valve types 1.5 and 2.0, “oFF” is also

available.

Press NEXT to go to Step 9S. Press REGEN to return to previous step.

14 PWSRTA Twin Alternating Series Softeners

Page 15

Step 9S

Step 9S – Select the pounds for the fifth cycle using or . For valve types 1.5 and 2.0, “oFF” is also

available.

NOTE: if Step 2CS is set to 2.0 or Step 7CS is set to MIN, Fill will be in minutes.

Press NEXT to go to Step 10S. Press REGEN to return to previous step.

Step 10S

Step 11S

Step 12S

Step 10S – Set System Capacity using or . The System Capacity setting should be based on the

volume of resin and LBS of salt fill set in Step 9S. Press NEXT to go to Step 11S. Press REGEN to

return to previous step.

Step 11S – Set Volume Capacity using or . If value is set to:

• “AUTO” capacity will be automatically calculated and reserve capacity will be automatically estimated;

• “oFF” regeneration will be triggered solely by the day override setting (see Installer Display/Settings

Step 4I);

• a number, regeneration will be triggered by the value specified (in Gallons).

If “oFF” or a volume is used, the hardness display will not be allowed to be set in Installer Display

Settings Step 2I. See Setting Options Table for more detail. Press NEXT to go to Step 12S. Press

REGEN to return to previous step.

Step 12S – Set Regeneration Time Options using or . If value is set to:

• “NORMAL” means regeneration will occur at the preset time;

• “on 0” means regeneration will occur immediately when the volume capacity reaches 0 (zero); or

• “NORMAL + on 0” means regeneration will occur at one of the following:

— the preset time when the volume capacity falls below the reserve or the specified number of days

between regenerations is reached whichever comes first; or

— immediately after 10 minutes of no water usage when the volume capacity reaches 0 (zero).

“NORMAL” is the default if Step 5CS is set to ALT A or ALT B, and “NORMAL + on 0” is not

available.

“on 0” is the default if Step 2CS is set to 1.0

This step will not appear if Step 11S is set to oFF or Step 5CS is set to “SYS”.

See Setting Options Table for more detail. Press NEXT to go to Step 13S. Press REGEN to return to

previous step.

, and “NORMAL + on 0” is not available.

Step 13S

• Gallons Softening Regen on: Relay activates after a set number of gallons have been used while in

service, or during regeneration, and then deactivates after the meter stops registering flow and the set

time period has expired.

• ERROR: Relay closes whenever the valve enters error mode, and immediately deactivates when error

mode is exited. If set to ERROR, Steps 14S and 15S will not be shown.

• Off: If set to Off, Steps 14S and 15S will not be shown.

Press NEXT to go to Step 14S. Press REGEN to return to previous step.

Step 13S – Set Relay Operation using or . The choices are:

• Time on: Relay activates after a set time at the beginning of a regen-

• Gallons Softening on: Relay activates after a set number of gallons

PWSRTA Twin Alternating Series Softeners 15

eration and then deactivates after a set period of time. The start of

regeneration is defined as the first backwash cycle or Dn brine cycle,

whichever comes first.

have been used while in service and then deactivates after the meter

stops registering flow and the set time period has expired.

Page 16

Step 14S

Step 14S – Set Relay Actuation Time or Gallons using or . The choices are:

• Relay Actuation Time: After the start of a regeneration the amount of time that should pass prior to activating the relay. The start of regeneration is defined as the first backwash cycle, Dn brine cycle or UP brine

cycle whichever comes first. Ranges from 1 second to 200 minutes.

• Relay Actuation Gallons: Relay activates after a set number of gallons has passed through the meter.

Ranges from 1 to 200 gallons.

Press NEXT to go to Step 15S. Press REGEN to return to previous step.

Step 15S

Step 15S – Set Relay Deactivate Time using or .

• If Set Time on is selected in Step 13S the relay will deactivate after the time set has expired. Ranges from

1 second to 200 minutes.

• If Set Gallons Softening on or Set Gallons Softening Regen on is selected in Step 13S the relay will deactivate after the time set has expired or after the meter stops registering flow, whichever comes first. Ranges

from 1 second to 20 minutes.

Press NEXT to exit OEM Softener System Setup. Press REGEN to return to previous step.

EXIT OEM SOFTENER SYSTEM SETUP

16 PWSRTA Twin Alternating Series Softeners

Page 17

Filters should only use shaded options

Volume

Capacity

AUTO NORMAL oFF

AUTO NORMAL Any number

Any

number

oFF NORMAL Any number

Any

number

AUTO On 0 oFF

Any

number

Regeneration Time

Option

NORMAL oFF

NORMAL Any number

On 0 oFF

Day

Override

Setting Options Table

1

Result

Reserve capacity automatically estimated.

Regeneration occurs when volume capacity falls below the reserve capacity at the

next Regen Set Time.

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when volume capacity falls below

the reserve capacity or the specied number of days between regenerations is

reached.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when volume

capacity reaches 0.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when the specied number of

days between regenerations is reached.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when volume

capacity reaches 0 or the specied number of days between regenerations is

reached.

Reserve capacity NOT automatically estimated.

Regeneration occurs immediately when volume capacity reaches 0. Time of

regeneration will not be allowed to be set because regeneration will always occur

when volume capacity reaches 0.

Reserve capacity NOT automatically estimated.

Regeneration occurs immediately when volume capacity reaches 0. Time of

regeneration will not be allowed to be set because regeneration will always occur

when volume capacity reaches 0.

AUTO NORMAL on 0 oFF

AUTO NORMAL on 0 Any number

Any

number

NORMAL on 0 Any number

Reserve capacity automatically estimated.

Regeneration occurs when volume capacity falls below the reserve capacity at the

next Regen Set Time or regeneration occurs after 10 minutes of no water usage

when volume capacity reaches 0.

Reserve capacity automatically estimated.

Regeneration occurs at the next Regen Set Time when volume capacity falls below

the reserve capacity or the specied number of days between regenerations is

reached or regeneration occurs after 10 minutes of no water usage when volume

capacity reaches 0.

Reserve capacity not automatically estimated.

Regeneration occurs at the next Regen Set Time when the specied number of

days between regenerations is reached or regeneration occurs after 10 minutes of

no water usage when volume capacity reaches 0.

PWSRTA Twin Alternating Series Softeners 17

Page 18

OEM Filter System Setup

Cycle Sequence, Adjustable Default Times (minutes)

Type Backwash Draw Backwash Rinse Backwash* Fill

Filtering Backwash 8 4

Filtering Regen 8 60 8 8 0:30 .95 GAL

Filtering Regen (2.0”) 8 60 8 8 0:30 6

*Cycle is non-adjustable, not shown in cycle sequence programming.

Step 1F

Step 2F

Step 3F

Step 4F

Step 1F -

not appear, the lock on the valve is activated. To unlock press , NEXT, , REGEN in sequence, then

press NEXT and simultaneously for 5 seconds and release.

Press NEXT and simultaneously for 5 seconds and release. If screen in Step 2CS does

Step 2F – Choose FILTERING BACKWASH or FILTERING REGEN (see table) using or . Press NEXT

to go to Step 3F. Press REGEN to exit OEM Filter System Setup.

Step 3F – Select the time for the first cycle using or .

Press NEXT to go to Step 4F. Press REGEN to return to previous step.

Step 4F – Select the time for the second cycle using or .

If Step 2F is set to FILTERING REGEN, press NEXT to program the rest of the cycle times. If Step 2F is

set to FILTERING BACKWASH, press NEXT to go to Step 5F. Press REGEN to return to previous step.

Step 5F

Step 6F

Step 5F – Set Regeneration trigger using or . If value is set to:

• “oFF” regeneration will be triggered solely by the day override setting (see Installer Display/Settings Step

4I);

• a number, regeneration will be triggered by the value specified (in gallons).

See Setting Options Table for more detail.

Press NEXT to go to Step 6F. Press REGEN to return to previous step.

Step 6F – Set Regeneration Time Options using or . If value is set to:

• “NORMAL” means regeneration will occur at the preset time;

• “on 0” means regeneration will occur immediately when the volume capacity reaches 0 (zero); or

• “NORMAL + on 0” means regeneration will occur at one of the following:

— the preset time when the volume capacity falls below the reserve or the specified number of days

between regenerations is reached whichever comes first; or

— immediately after 10 minutes of no water usage when the volume capacity reaches 0 (zero).

“NORMAL” is the default if Step 5CS is set to ALT A or ALT B, and “NORMAL + on 0” is not

available.

“on 0” is the default if Step 2CS is set to 1.0

This step will not appear if Step 5F is set to off or Step 5CS is set to “SYS”.

See Setting Options Table for more detail. Press NEXT to go to Step 7F. Press REGEN to return to

previous step.

, and “NORMAL + on 0” is not available.

18 PWSRTA Twin Alternating Series Softeners

Page 19

Step 7F

Step 7F – Set Relay Operation using or . The choices are:

• Time on: Relay activates after a set time at the beginning of a

regeneration and then deactivates after a set period of time. The start

of regeneration is defined as the first backwash cycle or Dn brine

cycle, whichever comes first.

• Gallons Filtering on: Relay activates after a set number of gallons

have been used while in service and then deactivates after the meter

stops registering flow and the set time period has expired.

• Gallons Filtering Regen on: Relay activates after a set number of gallons have been used while in service, or during regeneration, and then deactivates after the meter stops registering flow and the set time

period has expired.

•ERROR: Relay closes whenever the valve enters error mode, and immediately deactivates when error

mode is exited. If set to ERROR, Steps 8F and 9F will not be shown.

• Off: If set to Off, Steps 8F and 9F will not be shown.

Press NEXT to go to Step 8F. Press REGEN to return to previous step.

Step 8F

Step 9F

Step 8F –

• Relay Actuation Time: After the start of a regeneration the amount of time that should pass prior to activating the relay. The start of regeneration is defined as the first backwash cycle or brine cycle, whichever

comes first. Ranges from 1 second to 200 minutes.

• Relay Actuation Gallons: Relay activates after a set number of gallons has passed through the meter.

Ranges from 1 to 200 gallons.

Press NEXT to go to Step 9F. Press REGEN to return to previous step.

Step 9F – Set Relay Deactivate Time using or .

• If Set Time on is selected in Step 7F the relay will deactivate after the time set has expired. Ranges

from 1 second to 200 minutes.

• If Set Gallons Filtering on or Set Gallons Filtering Regen on is selected in Step 7F the relay will deactivate after the time set has expired or after the meter stops registering flow, whichever comes first.

Ranges from 1 second to 20 minutes.

Press NEXT to exit OEM Filter System Setup. Press REGEN to return to previous step.

EXIT OEM FILTER SYSTEM SETUP

Set Relay Actuation Time or Gallons using or . The choices are:

PWSRTA Twin Alternating Series Softeners 19

Page 20

Installer Display Settings

Step 1I

Step 2I

Step 3I

Step 4I

Step 1I - To enter Installer Display press NEXT and simultaneously for about 5 seconds and

release.

Step 2I – Hardness: Set the amount of influent hardness using or . This display will not be viewed

if FILTERING BACKWASH or FILTERING REGEN is selected in Step 2F or if “oFF” or a number was

selected in Step 11S.

Press NEXT to go to step 3I. Press REGEN to exit Installer Display Settings.

Step 3I – Day Override: When volume capacity is set to “oFF”, sets the number of days between

regenerations. When volume capacity is set to AUTO or to a volume, sets the maximum number of days

between regenerations. If value set to “oFF”, regeneration initiation is triggered solely by volume used.

If value is set in days (allowable range from 1 to 28) regeneration initiation will be called for on that day

regardless of actual water usage. Set Day Override using or :

• number of days between regeneration (1 to 28); or

• “oFF”.

See Setting Options Table for more detail on setup.

Press NEXT to go to step 4I. Press REGEN to return to previous step.

Step 4I – Next Regeneration Time (hour): Set the hour of day for regeneration using or . The default

time is 2:00. This display will show “REGEN on 0 GAL” if “on 0” is selected in Set Regeneration Time

Option in OEM Softener System Setup or OEM Filter System Setup.

Press NEXT to go to step 5I. Press REGEN to return to previous step.

Step 5I

Step 5I – Next Regeneration Time (minutes): Set the minutes of day for regeneration using or . This

display will not be shown if “on 0” is selected in Set Regeneration Time Option in OEM Softener System

Setup or OEM Filter System Setup.

Press NEXT to exit Installer Display Settings. Press REGEN to return to previous step.

EXIT INSTALLER DISPLAY SETTINGS

20 PWSRTA Twin Alternating Series Softeners

Page 21

Diagnostics

Step 1D

Step 2D

Step 3D

Step 4D

Step 1D - Press and simultaneously for 5 seconds and release. If screen in Step 2D does not

appear the lock on the valve is activated. To unlock press , NEXT, , REGEN in sequence, then

press and simultaneously for 5 seconds and release.

Step 2D – Software Version. Press NEXT to go to Step 3D. Press REGEN to exit Diagnostics.

Step 3D – Volume, total used since start-up: This display shows the total gallons treated since startup.

This display will equal zero if a water meter is not installed. Press the NEXT button to go to Step 4D.

Press REGEN to return to previous step.

Step 4D – Days, total since start-up: This display shows the total days since startup. Press the NEXT

button to go to Step 5D. Press REGEN to return to previous step.

Step 5D

Step 6D

Step 7D

Step 8D

Step 5D – Regenerations, total number since start-up: This display shows the total number of regenera-

tions that have occurred since startup. Press the NEXT button to go to Step 6D. Press REGEN to return

to previous step.

Step 6D – Error Log: This display shows a history of the last 10 errors generated by the control

during operation. Press or to view each recorded error.

Press NEXT to go to Step 7D. Press REGEN to return to previous step.

Step 7D – Days, since last regeneration: This display shows the days since the last regeneration

occurred. Press NEXT to go to Step 8D. Press REGEN to return to previous step.

Step 8D – Volume, since last regeneration: This display shows the volume of water that has been

treated since the last regeneration. This display will equal zero when a water meter is not installed. Press

NEXT to go to Step 9D. Press REGEN to return to previous step.

PWSRTA Twin Alternating Series Softeners 21

Page 22

Step 9D

Step 9D – Volume, reserve capacity used for last 7 days: If the valve

is set up as a softener, a meter is installed, and Set Volume Capacity

is set to “Auto,” this display shows day 0 (for today) and flashes the

reserve capacity. Pressing will show day 1 (which would be yesterday) and flashes the reserve capacity used. Pressing again will

show day 2 (the day before yesterday) and the reserve capacity. Keep

pressed to move backwards in the day series. This display does not appear if 1.0

pressing to show the capacity for days 3, 4, 5 and 6. can be

if ALT A or ALT B are selected in Step 5CS, or anytime the reserve capacity is not determined by the

control.

Press NEXT at any time to go to Step 10D. Press REGEN to return to previous step.

is set in Step 2CS,

Step 10D

Step 11D

Step 12D

Step 10D – Volume, 63-day usage history: This display shows day

0 (for today) and flashes the volume of water treated today. Pressing

will show day 1 (which would be yesterday) and flashes the volume

of water treated on that day. Continue to press to show the maximum volume of water treated for the last 63 days. If a regeneration

occurred on the day the word “REGEN” will also be displayed. This

Press NEXT at any time to go to Step 11D. Press REGEN to return to previous step.

display will show dashes if a water meter is not installed.

Step 11D – Twin Tank Valve transfer history: only displays when

was selected in Step 2CS. Use or to scroll through the last

1.0

10 tank transfers. The first position in the display ranges from 0 to 9

with the lowest number being the most recent transfer. The second

position in the display will be either “A” or “b”. If “A” then the tank with

the valve on it was in service, if “b” the tank with the in/out head on

ago that the transfer occurred. The display alternates with the volume that was treated before the tank

transferred. Press NEXT at any time to go to Step 12D. Press REGEN to return to previous step.

it was in service. The next three digits represent the number of hours

Step 12D – MAV Drive History in the direction of retracted piston rod

position. Display will only be shown if 1.0

or OFF is not selected in Step 5CS. Up to a four digit number will

appear after the “L” which stands for latest and “A” which stands for

average. Drive time is measured in 1/100 of a second; i.e., a 17.10

second move is displayed as “1710”. Press NEXT at any time to go

to Step 13D. Press REGEN to return to previous step.

is selected in Step 2CS,

Press and hold and buttons for 3 seconds while in Step 12D to

reset the MAV drive history in both the retracted and extended piston

rod position. To view the old MAV drive history data for retracted

and extended rod position press and hold REGEN and while in

Step 12D. Press NEXT to advance display to the old MAV drive history.

Step 13D

the extended and retracted piston rod position. To view the old MAV drive history data see Step 12D.

Press NEXT at any time exit Diagnostics. Press REGEN to return to previous step.

EXIT DIAGNOSTICS

22 PWSRTA Twin Alternating Series Softeners

Step 13D – MAV Drive History in the direction of extended piston

rod position. Display will only be shown if 1.0

2CS, or OFF is not selected in Step 4CS. Up to a four digit number

will appear after the “L” which stands for latest and “A” which stands

for average. Drive time is measured in 1/100 of a second; i.e., a

17.15 second move is displayed as “1715”. Press and hold and

for 3 seconds while in Step 13D to reset the MAV drive history in both

is selected in Step

Page 23

PWSRTA Part List and Drawings

Front Cover and Drive Assembly

Drawing No. Order No. Description Quantity

1 V3175EE-01 PWSRTA Front Cover Assembly 1

2 V3107-01 PWSRTA Motor 1

3 V3106-01 PWSRTA Drive Bracket & Spring Clip 1

4 V3408EE-03BOARD PWSRTA THRU 2L/2 EEPCBRD MAV/ALT REPL 1

5 V3110 PWSRTA Drive Gear 12x36 3

6 V3109 PWSRTA Drive Gear Cover 1

Not Shown

Not Shown V3178 PWSRTA Drive Back Plate 1

Refer to Control Valve Service Manual for other drawings and part numbers.

V3186 PWSRTA AC ADAPTER 120V-12V

V3186-01 PWSRTA AC ADAPTER CORD ONLY

AC Adapter U.S. International

Supply Voltage 120 V AC 230V AC

Supply Frequency 60 Hz 50 Hz

Output Voltage 12 V AC 12 V AC

Output Current 500 mA 500 mA

1

When replacing the battery, align

positives and push down to fully seat.

Battery Fully Seated

Correct

Battery

Orientation

Battery replacement is 3 volt

lithium coin cell type 2032.

4

1

PC Board Relay

Terminal Block

5

6

PWSRTA Twin Alternating Series Softeners 23

3

2

Page 24

Valve Body Compliance Table

Application Injector and/or Plug(s) Main Piston

1” Downflow Softener or

Regenerating Filter

1” Backwash Only Filter

1” Upflow Softener

Injector in “DN” hole, Plug

in “UP” hole

Plug in “DN” and “UP”

holes, Install Refill Port Plug

Injector in “UP” hole, Plug

in unlabeled hole

V3011 V3174 V3005 V3031

V3011 None V3005 V3031

V3011-01 V3174 V3005 V3031

Regenerant

Piston

Stack Body*

PWSRTA with 1.050" Distributor Tube Opening Identification

Spacer Color:

Grey

1.25"

1.25"

NOTICE

The downflow piston is a solid amber color. The upflow piston is black and amber.

24 PWSRTA Twin Alternating Series Softeners

Page 25

Drive Cap Assembly, Downfl ow Piston, Upfl ow Piston, Regenerant

Piston and Spacer Stack Assembly

Drawing No. Order No. Description Quantity

1 V3005 PWSRTA Spacer Stack Assembly 1

2 V3004 Drive Cap ASY 1

3a V3011* PWSRTA Piston Downfl ow ASY

3b V3011-01* PWSRTA Piston Upfl ow ASY

4 V3174 PWSRTA Regenerant Piston 1

5 V3135 O-ring 228 1

*V3011 is labeled with DN and V3011-01 is labeled with UP. Upfl ow option is not applicable to

EA, EE or EI control valves.

NOTICE

The regenerant piston is not used in backwash only applications.

Refer to programming and Cover Drawing Manual

1

1

3b

2

4

3a

5

PWSRTA Twin Alternating Series Softeners 25

Page 26

22

21

17

20

19

18

15

16

1

2

7

12

Twin Transfer

13

4

14

5

6

10

11

10

7

9

8

6

5

4

3

2

1

26 PWSRTA Twin Alternating Series Softeners

Page 27

Twin Transfer (continued)

Drawing No. Order No. Description Quantity

1 V3470 SCREW BHC 1/4-20 X 1 SS 12

2 V3724 WASHER FLAT SS 1/4 12

3 V4005-01 T1 TRANSFER CAP ASY 1

4 V4029 O-RING 236 2

5 V4015 T1 TRANSFER SPRING 2

6 V4014 T1 TRANSFER SPRING SUPPORT 2

7 V4036 T1 ROTOR DISK ASY 2

8 V3105 O-RING 215 (DISTRIBUTOR TUBE) 1

9 V3180 O-RING 337 1

10 V4016 T1 TRANSFER SEAL 6

11 V3031 T1 BODY SFT WTR REGEN 1

12 V4023 T1 TRANSFER DRIVE SHAFT ASY 1

13 V3287 O-RING 110 2

14 V4006-01 T1 TRANSFER DRIVE CAP ASY 1

15 V4011-01 T1 TRANSFER DRIVE GEAR ASY 1

16 V4012 T1 TRANSFER DRIVE GEAR AXLE 1

17 V4013 T1 TRANSFER REDUCTION GEAR 1

18 V3264 CWS200 BYPASS REDUCTION GEARAXLE 3

19 V3110 PWSRTA DRIVE REDUCING GEAR 12X36 3

20 V3262-01 1.5” & 2” ALT/2BY REDUCGEARCVRASY 1

21 V3592 SCREW #8-1 PHPN T-25 SS 3

22 V4049 T1 COVER ASSEMBLY 1

NOT SHOWN V4043 T1 TRANSFER MOTOR ASY 1

NOT SHOWN V3151 PWSRTA NUT 1 QC 1

NOT SHOWN V4055* TWIN TANK METER ASY 1

NOT SHOWN V4017-01 T1 INTERCONNECT FITTING ASY 1

NOT SHOWN D1400 1191 IN/OUT HEAD 1

!

WARNING

*THIS WATER METER SHOULD NOT BE USED

AS THE PRIMARY MONITORING DEVICE FOR

CRITICAL OR HEALTH EFFECT APPLICATIONS.

PWSRTA Twin Alternating Series Softeners 27

Page 28

Injector Cap, Injector Screen, Injector, Plug and O-Ring

Drawing No. Order No. Description Quantity

1 V3176 INJECTOR CAP 1

2 V3152 O-RING 135 1

3 V3177-01 INJECTOR SCREEN CAGE 1

4 V3010-1Z PWSRTA INJECTOR ASY Z PLUG 1

V3010-1A PWSRTA INJECTOR ASY A BLACK

V3010-1B PWSRTA INJECTOR ASY B BROWN

V3010-1C PWSRTA INJECTOR ASY C VIOLET

V3010-1D PWSRTA INJECTOR ASY D RED

V3010-1E PWSRTA INJECTOR ASY E WHITE

5

Not Shown

Not Shown

* The injector plug and the injector each contain one 011 (lower) and 013 (upper) o-ring.

NOTICE

For upflow position, injector is located in the up hole and injector plug is in the other hole.

Upflow option is not applicable to EA, EE or EI control valves.

For a filter that only backwashes, injector plugs are located in both holes.

V3010-1F PWSRTA INJECTOR ASY F BLUE

V3010-1G PWSRTA INJECTOR ASY G YELLOW

V3010-1H PWSRTA INJECTOR ASY H GREEN

V3010-1I PWSRTA INJECTOR ASY I ORANGE

V3010-1J PWSRTA INJECTOR ASY J LIGHT BLUE

V3010-1K PWSRTA INJECTOR ASY K LIGHT GREEN

V3170 O-RING 011

V3171 O-RING 013

1

*

*

1

2

4

3

5

28 PWSRTA Twin Alternating Series Softeners

Page 29

Injector Order Information

Injector Order Number Injector Color

V3010-1A Black 6" 8"

V3010-1B Brown 7" 9"

V3010-1C Violet 8" 10"

V3010-1D Red 9" 12"

V3010-1E White 10" 13"

V3010-1F Blue 12" 14"

V3010-1G Yellow 13" 16"

V3010-1H Green 14" 18"

V3010-1I Orange 16" 21"

V3010-1J Light Blue 18"

V3010-1K Light Green 21"

Actual tank size used may vary depending on the design and application of the system. Tank diameter is an approximation for the following:

1. Downflow softener using standard mesh synthetic cation exchange media regenerating with sodium chloride.

2. Upflow softener using standard mesh synthetic cation exchange media regenerating with sodium chloride, an inlet water pressure of 30

to 50 psi (2.1 to 3.4 bar) and water temperature of 60°F (15.6°C) water or warmer. Higher pressures or lower temperatures would need

smaller injectors to avoid lifting the bed.

Typical Tank Diameter

Down Up*

*Not applicable for EA, EE or EI control valves.

PWSRTA Twin Alternating Series Softeners 29

Page 30

Refill Flow Control Assembly and Refill Port Plug

Drawing No. Order No. Description Quantity

1 V3195-01 PWSRTA Refill Port Plug Asy

2 H4615 Elbow Locking Clip 1

3 JCP-P-6 Polytube insert 3/8” 1

4 JCPG-6PBLK Nut 3/8” 1

5 H4613 Elbow Cap 3/8” 1

6 V3163 0-ring 019 1

7 V3165-01* PWSRTA RFC Retainer Asy (0.5 gpm) 1

8 V3182 PWSRTA RFC 1

9 V3330-01 PWSRTA Brine Elbow Asy w/RFC 3/8" 1

Not Shown V3552 PWSRTA Brine Elbow Asy w/RFC 1/2" Option

Not Shown H4650 Elbow ½” with nut and insert Option

*Assembly includes V3182 PWSRTA (0.5 gpm) RFC.

This part is required for backwash only

systems

4

5

3

1

6

7

8

9

Water

Flow

Proper RFC orientation

directs rell water ow

towards the washer face

with rounded edge and text.

2

30 PWSRTA Twin Alternating Series Softeners

Page 31

Drain Line – 3/4”

Drawing No. Order No. Description Quantity

1 H4615 Elbow Locking Clip 1

2 PKP10TS8-BULK Polytube insert 5/8 Option

3 V3192 PWSRTA Nut ¾ Drain Elbow Option

4* V3158-01 PWSRTA Drain Elbow ¾ Male 1

5 V3163 O-ring 019 1

6* V3159-01 PWSRTA DLFC Retainer ASY 1

V3162-007 PWSRTA DLFC 0.7 gpm for ¾

V3162-010 PWSRTA DLFC 1.0 gpm for ¾

V3162-013 PWSRTA DLFC 1.3 gpm for ¾

V3162-017 PWSRTA DLFC 1.7 gpm for ¾

V3162-022 PWSRTA DLFC 2.2 gpm for ¾

V3162-027 PWSRTA DLFC 2.7 gpm for ¾

7

*4 and 6 can be ordered as a complete assembly - V3331 PWSRTA Drain Elbow and Retainer Asy

Valves are shipped without drain line flow control (DLFC) - install DLFC before using. Valves are shipped without ¾ nut for drain elbow (polytube

installation only) and 5/8" polytube insert (polytube installation only).

V3162-032 PWSRTA DLFC 3.2 gpm for ¾

V3162-042 PWSRTA DLFC 4.2 gpm for ¾

V3162-053 PWSRTA DLFC 5.3 gpm for ¾

V3162-065 PWSRTA DLFC 6.5 gpm for ¾

V3162-075 PWSRTA DLFC 7.5 gpm for ¾

V3162-090 PWSRTA DLFC 9.0 gpm for ¾

V3162-100 PWSRTA DLFC 10.0 gpm for ¾

One DLFC must

be used if ¾

fitting is used

Water

Flow

Proper DLFC orientation

directs water ow towards

the washer face with

rounded edge.

2

3

5

4

6

7

1

PWSRTA Twin Alternating Series Softeners 31

Page 32

Drain Line - 1”

Drawing No. Order No. Description Quantity

1 H4615 Elbow Locking Clip 1

2 V3008-02 PWSRTA Drain FTG 1 Straight 1

3* V3166 PWSRTA Drain FTG Body 1 1

4* V3167 PWSRTA Drain FTG Adapter 1 1

5* V3163 0-ring 019 1

6* V3150 PWSRTA Split Ring 1

7* V3151 PWSRTA Nut 1” QC 1

8* V3105 O-ring 215 1

V3190-090 PWSRTA DLFC 9.0 gpm for 1

V3190-100 PWSRTA DLFC 10.0 gpm for 1

V3190-110 PWSRTA DLFC 11.0 gpm for 1

9

* Can be ordered as a set. Order number V3008-02, description: PWSRTA Drain FTG 1 Straight.

V3190-130 PWSRTA DLFC 13.0 gpm for 1

V3190-150 PWSRTA DLFC 15.0 gpm for 1

V3190-170 PWSRTA DLFC 17.0 gpm for 1

V3190-200 PWSRTA DLFC 20.0 gpm for 1

V3190-250 PWSRTA DLFC 25.0 gpm for 1

One DLFC must

be used if 1” fitting

is used

Water

Flow

Proper DLFC orientation

directs water ow towards

the washer face with

rounded edge.

3

9

8

2

6

7

4

5

1

32 PWSRTA Twin Alternating Series Softeners

Page 33

V4017-01 T1 Interconnect Fitting Assembly

4

1

2

3

Drawing No. Order No. Description Quantity

1 V3151 PWSRTA Nut 1" Quick Connect 4

2 V3150 PWSRTA Split Ring 4

3 V3105 O-Ring 215 4

4 V4017 T1 Interconnect Fitting 2

A. Fitting Installation Instructions:

• Installation fittings are designed to accommodate minor plumbing misalignments, but are not designed to support the weight of a system

or the plumbing.

• Slide nut on first, then the split ring and o-ring.

• Hand tighten the nut only.

The V4017-01 can be used on tanks up to 10” in diameter.

If using 12” diameter tanks or larger V4052 PIPE PVC SCH 80 1-1/4X 20

(36 pieces per box) may be purchased and combined with two V3007-07 W100T FTG 1.25&1.5 PVC SLVNT ASY. The V4052 PIPE

PVC SCH 80 1-1/4X 20 can be cut to the desired length.

PWSRTA Twin Alternating Series Softeners 33

Page 34

D1400 1191 In/Out Head

1

2

Drawing No. Order No. Description Quantity

1 V3180 O-Ring 337 1

2 V3105 O-Ring 215 (Distributor Tube) 1

34 PWSRTA Twin Alternating Series Softeners

Page 35

PWSRTA Control Valve System Description

The PWSRTA control valves consist of the following components:

1. Drive Assembly

2. Drive Cap Assembly, Main Piston and Regenerant Piston

3. Spacer Stack Assembly

4. Injector Cap, Screen, Injector Plug and Injector

Drive Assembly

The drive assembly consists of the following parts:

• Drive Bracket

• Printed Circuit (PC) Board

• Motor

• Drive Gears

• Drive Gear Cover

The drive bracket holds the PC board, the motor, the drive gears and the drive gear cover in place.

The PC board receives and retains information, displays the information, determines when to regenerate and initiates regeneration. The display

shows different types of information in the initial system set up (for softeners or filters), installer display settings, diagnostics, valve history or

user display settings.

The PC board powers the motor. The PC board’s two-prong jack connects wires to the direct current (DC) motor. The motor is held in place on

the drive bracket by a spring-loaded clip and a small bulge in the plastic, which fits in one of the slots on the motor housing. The motor turns

drive gears that drive the piston to cycle positions for backwashing, regeneration, rinsing, refill or service. The motor is fully reversible (turns

both ways) and changes direction of rotation to change the direction of piston motion. The motor is easily replaced if necessary.

5. Refill Flow Control Assembly or Refill Port Plug

6. Drain Line Flow Control and Fitting Assembly

7. Water Meter

8. Twin Transfer Valve

There are three drive gears held in place by the drive gear cover. All three drive gears are the same size. A reflective coating is applied to the

gears. As the center drive gear turns a light shines on the coating and a light sensing diode determines if a light pulse was returned. The PC

board counts the pulses and determines when to stop driving the motor.

Drive Cap Assembly, Main Piston and Regenerant Piston

The drive gears turn the main gear of the drive cap assembly, which moves the piston. The screw-driven, horizontally moving piston stops at

specific positions to direct the flow of water to backwash, regenerate, rinse or refill. The PC board determines the position of the piston by

counting pulses produced when the piston is moved. An optical sensor looking at one of the reduction drive gears generates these pulses.

Each cycle position is defined by a number of pulses. The counter is zeroed each time the valve goes to the service position. The PC board

finds the service position by noting the increase in current delivered to the motor when the mechanical stop at the service position is reached.

This method of controlling piston position allows for greater flexibility and requires no switches or cams (U.S. Patent 6444127).

One of two main pistons is always used:

1. A 1.25" diameter downflow piston is used when the PWSRTA control valve is used as a downflow softener, regenerating filter or nonregenerating filter.

2. A 1.25" diameter upflow piston is used when the PWSRTA control valve is used as an upflow softener. Upflow option not applicable for EA,

EE or EI control valves.

If the control valve is used as a softener or a regenerating filter, a regenerant piston must be attached to the main piston. If the control valve is

to be used on a system that does not require a regenerant to be added, the regenerant piston must be removed.