Page 1

For Commercial Applications

ES-WQ-PWS10

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

Series PWS10

Commercial Water Softening

Systems

Connection Size: 1" (25 mm)

Flow Rates: Up to 25 gpm (94 lpm)

Watts Pure Water Series PWS10 water softening systems are

highly efficient conventional cation exchange type water softeners. They are suitable for commercial applications ranging from

30,000 to 120,000 grains of hardness removal and flow rates

up to 25 gallons per minute (94 lpm). Regeneration is meter

demand initiated. All cycles of regeneration are fully automatic

and do not require manual actuation.

Watts Pure Water Series PWS10 water softeners are designed

for point of use or point of entry applications where the benefits of softened water are required. These systems exchange

scale-forming calcium and magnesium ions with non scaleforming sodium ions to create soft water for a variety of applications. Steam boiler make up water, water heater pretreatment, reverse osmosis pretreatment, sterilizer make up water,

washing, and process water are all common applications for

the Watts Pure Water Series PWS10 water softeners.

Softened water provides a wide variety of benefits from not

introducing scale into pipes, valves, water heating equipment,

heat exchangers, and cooling towers to reducing mineral build

up in areas that see excessive splashing such as food preparation counters and sink areas. Softened water also conserves

soaps and cleaning agents by eliminating the formation of soap

curd, so your cleaners can work on cleaning – not reacting

with the hardness in your water.

Features

• WQA Certified fully automatic metered demand control valve

• Sophisticated digital electronic controls that store operating

history that can be accessed by the user

• Fully adjustable regeneration cycles

• Durable brass bodied control valve for years of service

• Dry contact lock out switch for remote interface is standard

• WQA Certified high capacity resin

• Highly corrosion resistant NSF Certified fiberglass tanks

• Durable polypropylene lower distribution system

Note: Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before or after

the system.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

PURE WATER

Series PWS10

Standards

Control Valve- WQA Certified to NSF/ANSI Std. 61

Ion Exchange Resin- WQA Certified to NSF/ANSI Std. 44

Mineral Tank- NSF Certified to ANSI Std. 44 or 61

Specifications

A Watts Pure Water Series PWS10 water softening system

shall be installed on the building’s main water line just after

it enters the building. The installation point shall be after any

backflow prevention or pressure regulating valves. Other instal-

lation options are to install a system just before the water

heater or other types of equipment needing the protection of

softened water. In installations where dedicated cold water

make up to a water heater is the installation point, a backflow

preventer and a thermal expansion tank must be installed as

well. The system shall be installed with a bypass valve to allow

for the shut down and removal of the unit without interrupting

the water supply to the building.

The water softener shall be a down flow regenerated, metered

demand, sodium cycle cation exchange type system with all

components necessary for proper operation. Electrical require-

ments are 120 volt 60 hertz. A local drain is required to accept

drain water from the system. The feed water pressure must not

fall below 25psi or exceed 125psi. Water temperature must not

fall below 34°F or exceed 110°F (1° - 43°C).

The system shall provide softened water measuring less than

one grain per gallon of hardness as Calcium Carbonate when

operated within the manufacturer’s operational specifications.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

Feed Water Guidelines

pH ....................... 6 to 10

Hardness (maximum) ......... Depends on customers acceptable

hardness leakage level.

Water Pressure ............. 25psi to 125psi (171 kPa to 8.5 bar)

Temperature ............... 34 - 110°F (1 - 43°C)

Free Chlorine (maximum) ...... 1mg/L

Iron (maximum) ............. 1mg/L

Oil and H2S ................ None Allowed

Turbidity Less than 5.0 NTU

For all other guideline information please contact your Watts

representative.

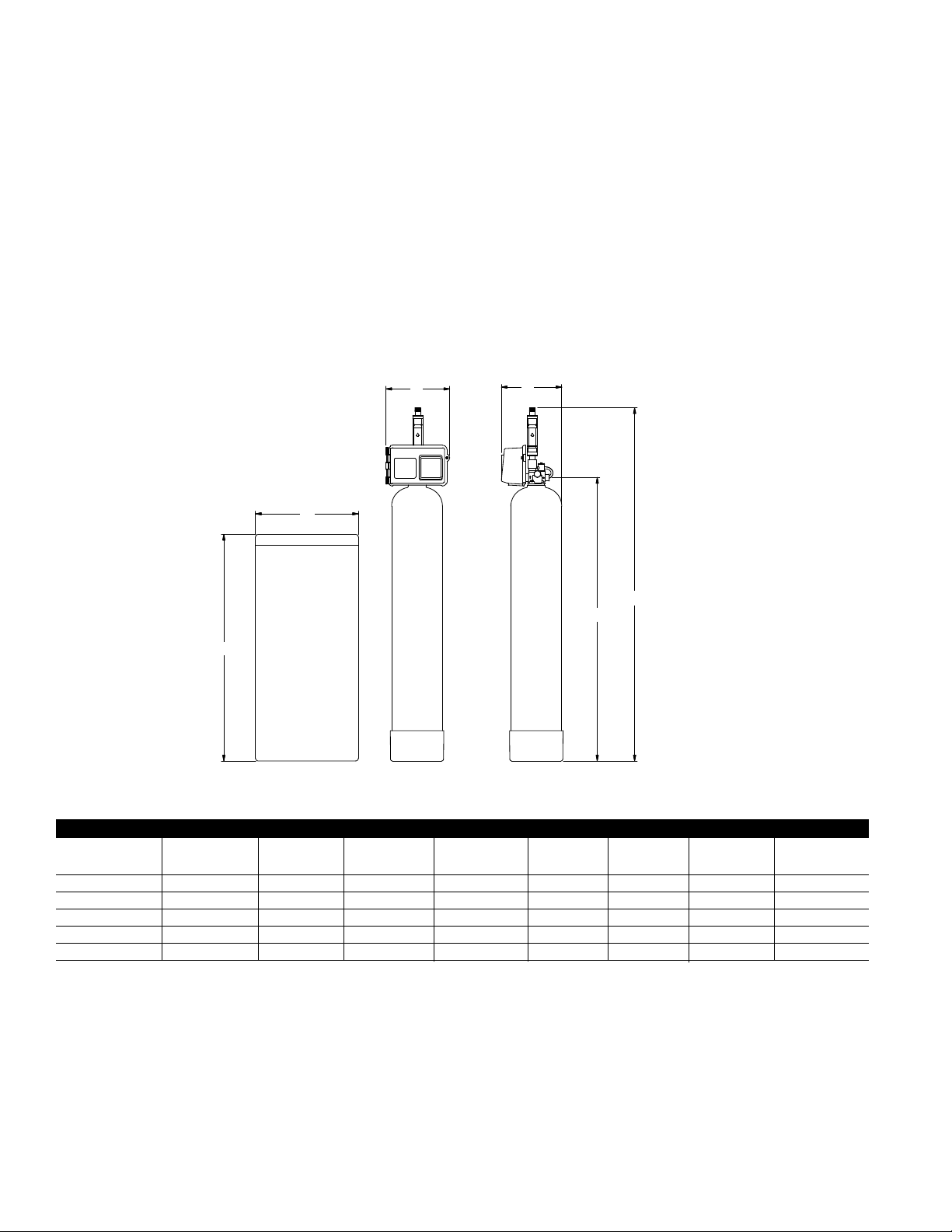

Dimensions - Weights

E

E

F

F

D

D

B & C

B & C

A

A

G

G

FRONT

FRONT SIDE

MODEL NO. DIMENSIONS WEIGHTS

A B C D E F G

in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs

SIDE

PWS10111A11 501/8 1273 64 1625 64 1625 111/2 292 123/4 324 18 457 40 1016 116 53

PWS10111B11 56

PWS10111C11 54

PWS10111D11 67

PWS10111E11 66

1

/4 1429 701/8 1781 701/8 1781 12 305 123/4 324 18 457 40 1016 136 62

5

/8 1387 687/16 1738 687/16 1738 13 330 123/4 324 18 457 40 1016 196 89

3

/8 1711 811/4 2064 811/4 2064 141/8 359 141/8 359 18 457 40 1016 240 109

3

/4 1695 801/2 2045 801/2 2045 161/8 409 161/8 409 18 457 40 1016 320 145

Page 3

Specifications

MINERAL TANK BRINE TANK SOFTENING LBS. SALT PER FLOW RATE & PRESSURE

TANK RESIN GRAVEL TANK SALT CAPACITY REGENERATION SERV DROP BKW

MODEL NO. SIZE Ft

3

SIZE FILL MAX MIN MAX MIN GPM PSI GPM

PWS10111A11 9" x 48" 1.0 10 lbs. 18" x 40" 400 30 K 20 K 15 6 9/15 15/25 2.0

PWS10111B11 10" x 54" 1.5 10 lbs. 18" x 40" 400 45 K 30 K 22.5 9 10/15 15/25 2.4

PWS10111C11 12" x 52" 2.0 30 lbs. 18" x 40" 400 60 K 40 K 30 12 15/20 15/25 3.5

PWS10111D11 14" x 65" 3.0 60 lbs. 18" x 40" 400 90 K 60 K 45 18 18/23 15/25 5.0

PWS10111E11 16" x 65" 4.0 80 lbs. 18" x 40" 400 120 K 80 K 60 24 19/25 15/25 7.0

Ordering Information

SPACE

MODEL NO. DESCRIPTION PIPE SIZE REQUIRED WEIGHT

W x D x H LBS KGS

PWS10111A11 1 Cubic Foot Simplex Softener with Flow Meter 1" 18" x 32" x 59" 116 53

PWS10111B11 1.5 Cubic Foot Simplex Softener with Flow Meter 1" 18" x 33" x 65" 136 62

PWS10111C11 2 Cubic Foot Simplex Softener with Flow Meter 1" 18" x 35" x 63" 196 89

PWS10111D11 3 Cubic Foot Simplex Softener with Flow Meter 1" 18" x 40" x 76" 240 109

PWS10111E11 4 Cubic Foot Simplex Softener with Flow Meter 1" 18" x 40" x 76" 320 145

Notes: Capacities are based on resin manufacturer’s data and are dependent upon influent water TDS, temperature, bed depth, and

flow rates. Feed water must be free of oil and color. Pipe size, tank size, and space requirements are in inches. Flow rates listed at 25

psi drops are for intermittent peak flow rates and are not to be used as continuous flows.

Note: This information is not intended to replace the product

installation and safety information available or the experience of

a trained product installer. Please refer to the product installation and safety instructions for further information.

A Watts Water Technologies Company

ES-WQ-PWS10 1136 © 2011 Watts

USA: North Andover, MA • Tel. (800) 224-1299 • www.watts.com

Canada: Burlington, ON • Tel. (888) 208-8927 • www.wattscanada.ca

Loading...

Loading...