Page 1

For Commercial Water Heater Applications

ES-40,140,240,340

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

Contractor

Approval

Contractor’s P.O. No.

Representative

Series 40, 140, 240 & 340

Automatic Re-seating T&P Relief Valves

The combined 2-in-1 Temperature & Pressure Relief Valve provides the

least expensive and proven means for protection against both excessive

temperature and pressure emergency conditions.

Fully automatic temperature and pressure relief protection for domestic

hot water supply tanks and heaters based on the latest ANSI Z21.22

Listing requirements for temperature discharge capacity.

40XL with test lever and extension thermostat for installation in hot

water outlet within the allowable distance from the top of the tank based

on latest ANSI Z21.22. Sizes

40L with test lever and short thermostat for installation directly in available tank tappings. Sizes

Series 140, N240 and 340 have the same basic body construction and

advanced design features as the Series 40 and are identical to the Series

40 except for discharge capacity and size of inlet and outlet connections.

For complete specifications (including specifications for the Series 40)

see other side. Sizes 1", 1

3

⁄4" and 1" (20 – 25mm).

3

⁄4" and 1" (20 – 25mm).

1

⁄4", 11⁄2" and 2" (25, 32, 40 and 50mm).

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

Series 40L and 40XL

Series 140X

Features

• Bronze body construction

• Non-mechanical seat-to-disc alignment

• Thermostat is accurate and proven. Exclusively designed and

manufactured by Watts

• Tamper-resistant bonnet screws

• Series 40 and 140 feature a unique thermostat with a special

thermo-bonded coating

• Series 140 sizes 1" (25mm) and above are standardly furnished with

stainless steel thermostat tube

Specifications

Temperature & Pressure Relief Valves

Each hot water storage heater shall be equipped with an automatic

temperature and pressure relief valve to protect the heater from excessive pressure and excessive temperature. The device shall be certified

as meeting the requirements of ASME low pressure heating boiler code

and ANSI Z21.22. The BTU discharge capacity of the device shall be in

excess of the BTU input rating of the heater. The T&P valve shall be a

Watts Regulator Company Series 40, 140, 240 or 340.

Standards

ASME Rated, ANSI Z21.22, Design certified and listed by CSA, National

Board of B&PVI to Section IV of the ASME B&PV code and meet current

FHA requirements and ANSI Z21.22 in addition to Military Spec. MIL-V136-12D, Type I.

Series N240X

Series 340

Pressure – Temperature

Temperature relief 210°F (99°C)

Pressure range 75 – 150psi (5.2 – 10.3 bar)

Standard setting 75, 100, 125 and 150psi

(5.2, 6.9, 8.6 and 10.3 bar)

Following installation, the valve lever MUST be operated AT LEAST

ONCE A YEAR by the water heater owner to ensure that the waterways are clear. Certain naturally occurring mineral deposits may

adhere to the valve, blocking waterways, rendering it inoperative. When

the lever is operated, Hot water will discharge if the waterways are

clear. Precautions must be taken to avoid personal injury from contact

with hot water and to avoid property damage.

IMPORTANT: INQUIRE WITH GOVERNING AUTHORITIES

FOR LOCAL INSTALLATION REQUIREMENTS

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

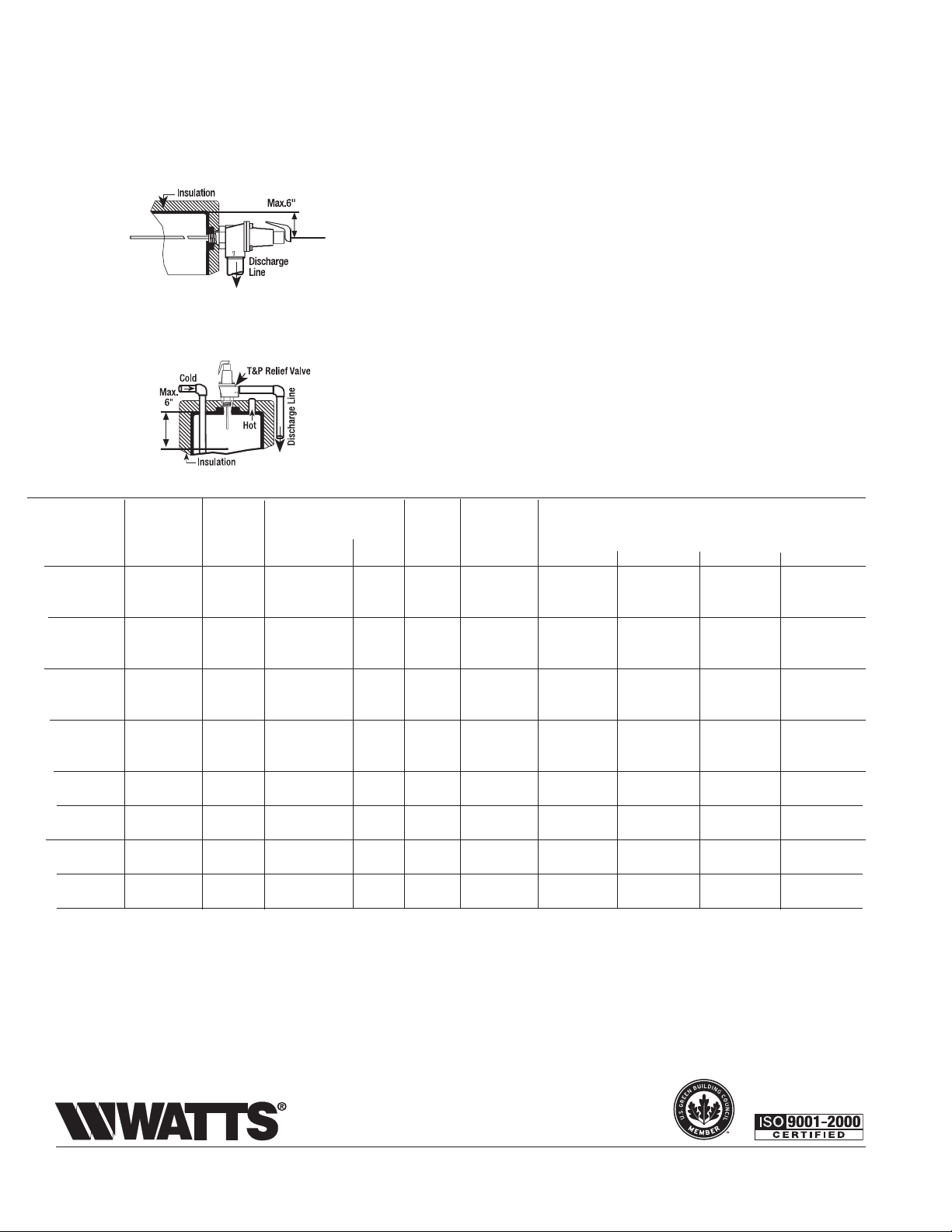

Direct Side Tapping

FOR EXTERNAL FLUE HEATERS

Use extra length extension thermostat to extend into water storage tank.

General Recommendations

For gas, electric or oil-fired storage water heaters between 180,000 to

205,000 BTU/Hr. rating: Use

3

⁄4" (20mm) Series 40, 140 tested under

†

ANSI Z21.22 with ratings as certified and listed by CSA.

FOR INTERNAL FLUE HEATERS

Use short or standard length thermostat. Vertical discharge line must be

installed with its direction downward.

For gas or oil-fired storage water heaters between 205,000 and 730,000

BTU/Hr. rating and for compliance with applicable water heater labeling

requirements: Use 1" (25mm) 40, 140, N240 Series tested under ANSI

Z21.22 with ratings as certified and listed by CSA.

Max. 6"

(152mm)

For installations of gas or oil-fired hot water supply boilers over 730,000

BTU/Hr. output heating domestic water and for steam coil storage water

heaters: Use Series 340, 342 tested under ANSI Z21.22 with rating as

certified and listed by CSA.

1

⁄2" (40mm) size only. Pressure setting

For Heaters with Direct Top Tapping

SPECIAL MODEL: No. 340X-8 M4Z 1

175psi (5.2 bar). Temp. 210°F (99°C). Certified by CSA only.

Use standard or extra length extension thermostat.

Thermostat

Inlet X Length (in.) Dimensions (in.) CSA

Outlet (Below Inlet Height Weight Temp. Steam **ASME PRESSURE STEAM RATING BTU/HR

Model (in.) thread) (Less Thermostat) Width Lbs. Rating BTU/HR @75psi set pres. @100psi set pres. @125psi set pres. @150psi set pres.

40L-3

40XL-5

40XL-8

140S-3

140X-5

140X-8

3

⁄4 M x 3⁄4 F 3 55⁄8 2

3

⁄4 M x 3⁄4 F 5 55⁄8 2

3

⁄4 M x 3⁄4 F 8 55⁄8 2

3

⁄4 F x 3⁄4 F 3 55⁄8 2

3

⁄4 F x 3⁄4 F 5 55⁄8 2

3

⁄4 F x 3⁄4 F 8 55⁄8 2

40L-2 1M x 1F 2 6

40XL-4 1M x 1F 4 6

40XL-7 1M x 1F 7 6

*140S-3 1F x 1F 3 5

*140X-6 1F x 1F 6 5

*140X-9 1F x 1F 9 5

*N240X-6 1F x 1F 6 6

*N240X-9 1F x 1F 9 6

*N241X-5 1

*N241X-8 1

*340-3 1

*340X-8 1

*342-3 2 M 1

*342X-8 2 M x 1

1

⁄4 M x 1F 5 65⁄8 3

1

⁄4 M x 1F 8 65⁄8 3

1

⁄2 F x 11⁄2 F 3 93⁄4 4

1

⁄2 F x 11⁄2 F 8 93⁄4 4

1

⁄2 F 3 93⁄4 4

1

⁄2 F 8 93⁄4 4

1

⁄4 2

1

⁄4 2

1

⁄4 2

1

⁄2 3 21⁄4 570,000 1,670,000 2,140,000 2,610,000 3,085,000

1

⁄2 3 21⁄4 670,000 1,670,000 2,140,000 2,610,000 3,085,000

1

⁄2 3 21⁄4 670,000 1,670,000 2,140,000 2,610,000 3,085,000

5

⁄8 3

5

⁄8 3

5

⁄8 1

5

⁄8 1

5

⁄8 1

5

⁄8 1

5

⁄8 1

5

⁄8 1

3

⁄4 2

3

⁄4 2

3

⁄4 2

3

⁄8 2

3

⁄8 2

3

⁄8 2

3

⁄8 2

1

⁄2 7 1,150,000 3,450,000 4,426,000 5,403,000 6,379,000

1

⁄2 8 1,150,000 3,450,000 4,426,000 5,403,000 6,379,000

1

⁄2 7 1,150,000 3,450,000 4,426,000 5,403,000 6,379,000

1

⁄2 8 1,150,000 3,450,000 4,426,000 5,403,000 6,379,000

3

⁄4 180,000 777,600 997,600 1,217,600 1,437,600

3

⁄4 205,000 777,600 997,600 1,217,600 1,437,600

3

⁄4 205,000 777,600 997,600 1,217,600 1,437,600

3

⁄4 180,000 777,600 997,600 1,217,600 1,437,600

3

⁄4 205,000 777,600 997,600 1,217,600 1,437,600

3

⁄4 205,000 777,600 997,600 1,217,600 1,437,600

1

⁄4 450,000 1,155,000 1,481,000 1,808,000 2,134,000

1

⁄4 500,000 1,155,000 1,481,000 1,808,000 2,134,000

1

⁄4 500,000 1,155,000 1,481,000 1,808,000 2,134,000

3

⁄4 730,000 2,195,000 2,817,000 3,438,000 4,059,000

3

⁄4 730,000 2,195,000 2,817,000 3,438,000 4,059,000

3

⁄4 730,000 2,195,000 2,817,000 3,438,000 4,059,000

3

⁄4 730,000 2,195,000 2,817,000 3,438,000 4,059,000

*Standardly furnished with stainless steel thermostat tube. M = Male F = Female

**ASME capacities are steam pressure ratings and do not reflect the CSA temperature relieving capacity of the valves for selection purposes.

†LL40XL and LLL40XL valves with extended inlet shanks should be used for water heaters that have extra thick insulation, Ask for ES-LL/LLL-40XL.

Temperature and Pressure Relief Valves should be inspected AT LEAST ONCE EVERY THREE YEARS, and replaced, if necessary, by a licensed

plumbing contractor or qualified service technician, to ensure that the product has not been affected by corrosive water conditions and to ensure that the

valve and discharge line have not been altered or tampered with illegally. Certain naturally occurring conditions may corrode the valve or its components

over time, rendering the valve inoperative. Such conditions can only be detected if the valve and its components are physically removed and inspected.

Do not attempt to conduct an inspection on your own. Contact your plumbing contractor for a reinspection to assure continuing safety.

A Watts Water Technologies Company

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

ES-40,140,240,340 0927 © 2009 Watts

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...