Page 1

For Commercial Applications

ES-N170-M3

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

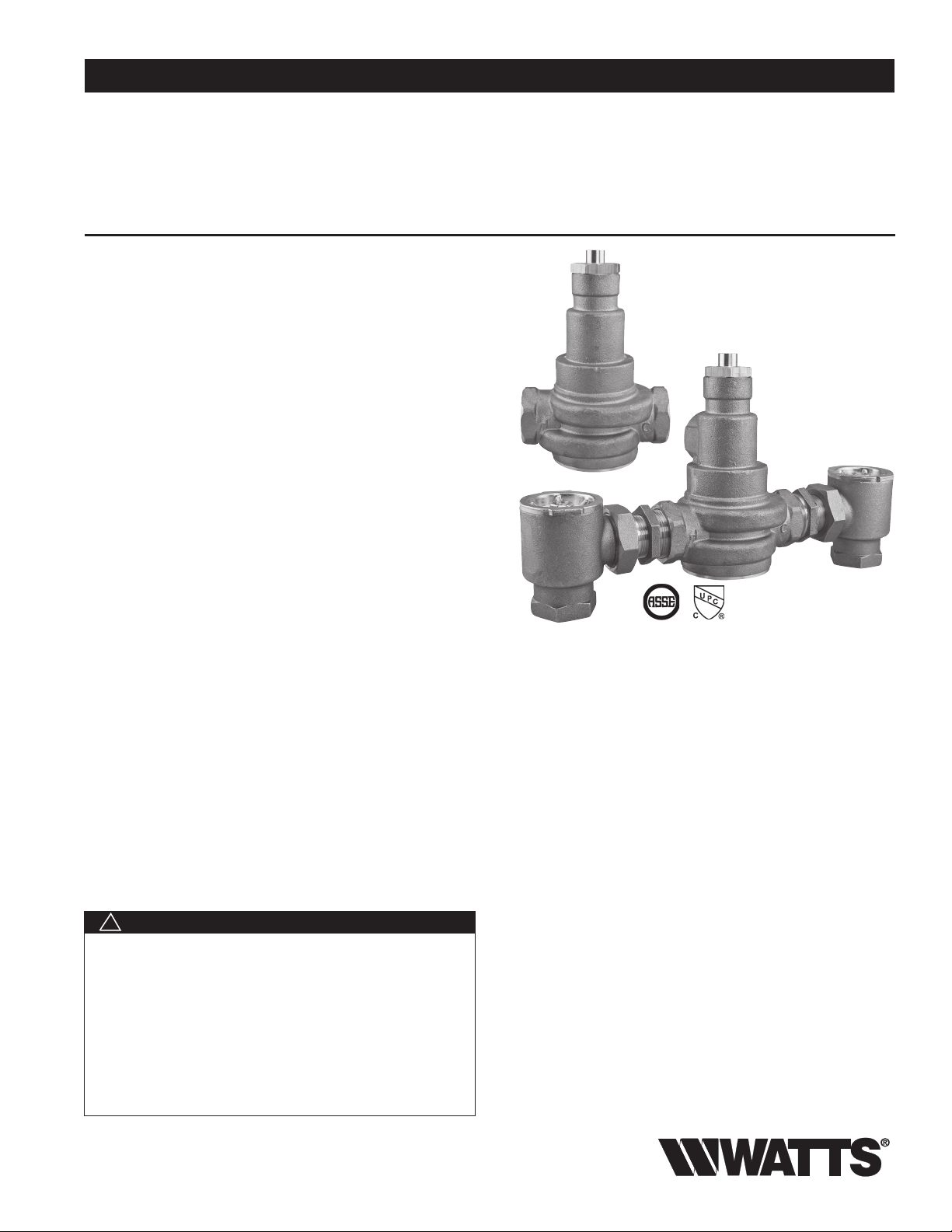

Series N170

Hot Water Master Tempering Valves

Watts Series N170 hot water master tempering valves are

especially designed for use on larger hot water supply systems

for mixing hot and cold water for a variety of applications to

extend the hot water supply. This series uses paraffin-based

thermostat to sense and adjust outlet temperature.

Features

• ASSE 1017 and IAPMO CUPC Listed

• N170-M3 uses paraffin-based thermostat to sense and

adjust outlet temperature

• Dirt and lime resistant poppet and seat design

• Virtual shutoff if supply pressure fails

• Vandal-resistant locking mechanism to secure temperature

setting

• Factory tested

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

N170-M3

N170-M3 CSUT

Specifications

Maximum Operating Pressure .............................. 125psig (861 kPa)

Maximum Hot Water Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 200°F (93°C)

Minimum Hot Water Supply Temperature . . . . . . . . . . . . . . . . . . . . . 5°F (3°C) Above Set Point*

Temperature Adjustment Range** ........................... 90 - 180°F (32 - 82°C)

Hot Water Inlet Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . 120 - 180°F (42 - 82°C)

Cold Water Inlet Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . 40 - 80°F (4 - 27°C)

Listing ................................................ ASSE 1017, IAPMO CUPC

Approval Standards ...................................... ASSE 1017, CSA B125.3

*With Equal Pressure

**Low Limit cannot be less than the cold water temperature. For best operation, hot water should be at least 5°F (3°C) above desired set point.

WARNING

!

Watts Hot Water Master Tempering Valves cannot be used for

tempering water temperature at fixtures. Severe bodily injury (i.e.,

scalding or chilling) and/or death may result depending upon system

water pressure changes and/or supply water temperature changes.

ASSE standard 1016, 1069 or 1070 listed devices such as Watts

Series MMV, USG, and L111 valves should be used at fixtures to

prevent possible injury.

The Watts Hot Water Tempering Valves are designed to be installed at

or near the boiler or water heater. They are not designed to compensate

for system pressure fluctuations and should not be used where ASSE

standard 1016, 1069 or 1070 devices are required. These Watts valves

should never be used to provide “anti-scald” or “anti-chill” service.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

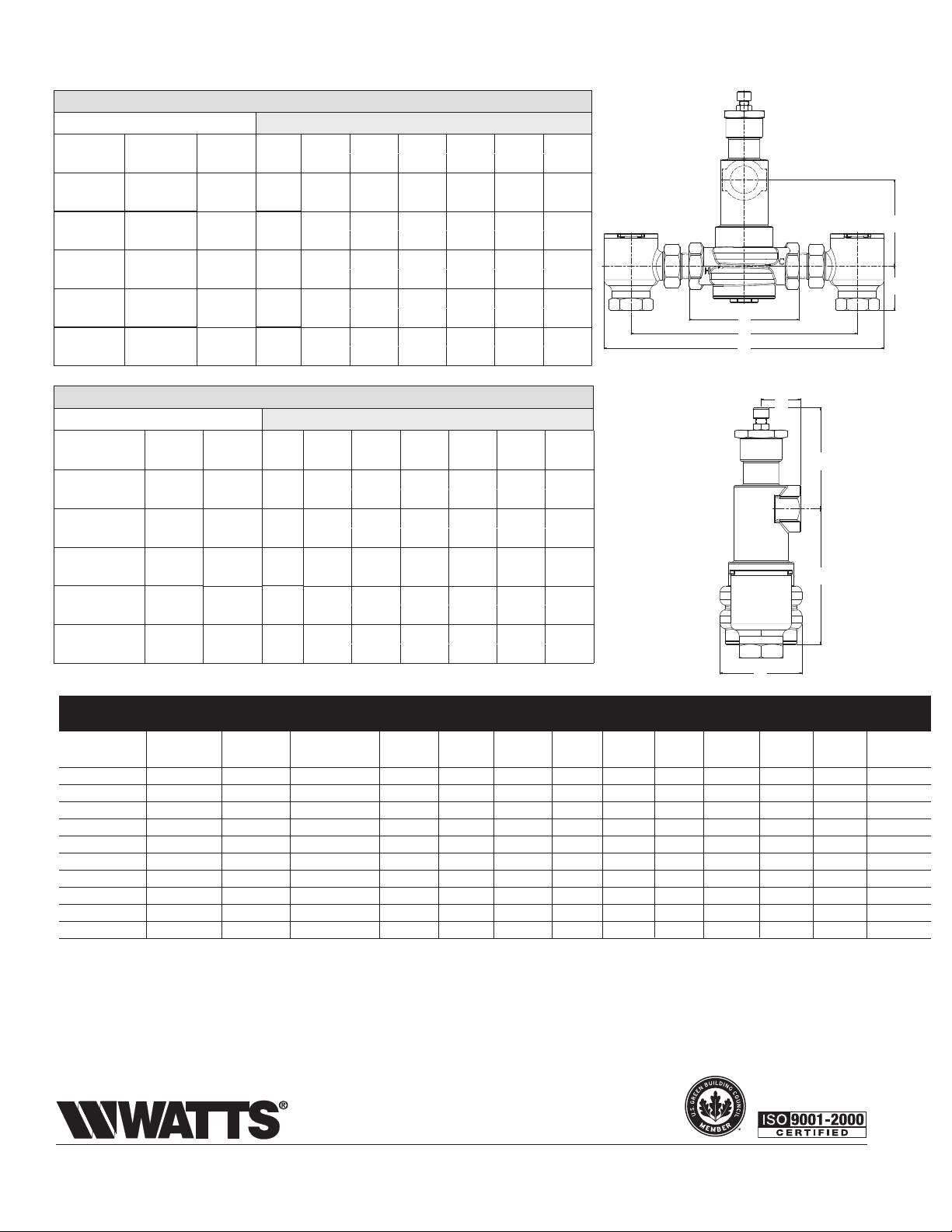

Capacity

H

G

F

J

H

G

F

J

A

B

C

D

E

Model

3

/4" N170-M33/4 x 3/4"

1" N170-M3 1 x 1"

1 1/4" N170-M3 1-1/4 x 1-1/4"

1 1/2" N170-M3 1-1/2 x 1-1/2"

2" N170-M3 2 x 1-1/2 x 2"

Inlet / Outlet

(NPT)

Flow Capacity at 50-50 mixed Less Checkstops

Pressure Drop Across Valve

Min. Flow

to ASSE 1017

3 gpm

11 lpm 57 lpm 79 lpm 114 lpm 140 lpm 170 lpm 197 lpm

4 gpm

15 lpm 87 lpm 121 lpm 170 lpm 212 lpm 257 lpm 299 lpm

4 gpm

15 lpm 121 lpm 170 lpm 238 lpm 288 lpm 360 lpm 416 lpm

5 gpm

19 lpm 134 lpm 185 lpm 265 lpm 326 lpm 397 lpm 458 lpm

7 gpm

26 lpm 159 lpm 223 lpm 314 lpm 386 lpm 473 lpm 545 lpm

6.70

10.13

14.16

15.65

18.63

5psi 10psi 20psi 30psi 45psi 60psi

C

V

(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa)

15 gpm 21 gpm 30 gpm 37 gpm 45 gpm 52 gpm

23 gpm 32 gpm 45 gpm 56 gpm 68 gpm 79 gpm

32 gpm 45 gpm 63 gpm 76 gpm 95 gpm 110 gpm

35 gpm 49 gpm 70 gpm 86 gpm 105 gpm 121 gpm

42 gpm 59 gpm 83 gpm 102 gpm 125 gpm 144 gpm

Dimensions

D

E

B

A

C

Flow Capacity at 50-50 mixed with Checkstops

F

Pressure Drop Across Valve

Model

3

/4" N170-M3 CSUT3/4 x 3/4"

Inlet / Outlet

(NPT)

1" N170-M3 CSUT3/4 x 1"

1 1/4" N170-M3

CSUT

1 1/2" N170-M3

CSUT

1-1/4 x 1-1/4"

1-1/4 x 1-1/2"

2" N170-M3 CSUT 1-1/4 x 2"

Min. Flow

to ASSE 1017

3 gpm

11 lpm 53 lpm 76 lpm 106 lpm 129 lpm 159 lpm 182 lpm

4 gpm

15 lpm 79 lpm 114 lpm 163 lpm 197 lpm 242 lpm 280 lpm

4 gpm

15 lpm 114 lpm 159 lpm 227 lpm 280 lpm 341 lpm 394 lpm

5 gpm

19 lpm 125 lpm 128 lpm 254 lpm 310 lpm 379 lpm 435 lpm

7 gpm

26 lpm 151 lpm 216 lpm 303 lpm 371 lpm 454 lpm 526 lpm

13.42

14.90

17.89

5psi 10psi 20psi 30psi 45psi 60psi

C

V

(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa)

14 gpm 20 gpm 28 gpm 34 gpm 42 gpm 48 gpm

6.26

21 gpm 30 gpm 43 gpm 52 gpm 64 gpm 74 gpm

9.54

30 gpm 42 gpm 60 gpm 74 gpm 90 gpm 104 gpm

33 gpm 47 gpm 67 gpm 82 gpm 100 gpm 115 gpm

40 gpm 57 gpm 80 gpm 98 gpm 120 gpm 139 gpm

G

H

J

MODEL BODY INLETS CHECKSTOP BODY OUTLET DIMENSIONS WEIGHT

NPT INLETS NPT NPT

A B C D E F G H J

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

3

⁄4 N170-M3

3

⁄4 N170-M3 CSUT N/A

1 N170-M3 1 N/A 1 N/A 49⁄16 116 N/A 31⁄2 89 N/A 17⁄16 36 35⁄8 92 47⁄8 124 215⁄16 75 4.8 2.2

1 N170-M3 CSUT N/A

11

⁄4 N170-M3 11⁄4 N/A 11⁄4 N/A 61⁄16 154 N/A 37⁄16 87 N/A 13⁄4 44 311⁄16 94 51⁄4 133 41⁄2 114 9.4 4.3

11

⁄4 N170-M3 CSUT N/A 11⁄4 1

11

⁄2 N170-M3 11⁄2 N/A 11⁄2 N/A 61⁄16 154 N/A 37⁄16 87 N/A 13⁄4 44 311⁄16 94 51⁄4 133 41⁄2 114 9.1 4.1

11

⁄2 N170-M3 CSUT N/A 11⁄4 1

2 N170-M3 2 (Hot) 11⁄2 (Cold) N/A 2 N/A 67⁄16 164 N/A 33⁄16 81 N/A 21⁄16 52 37⁄8 98 53⁄8 137 41⁄2 114 10.4 4.7

2 N170-M3 CSUT N/A 11⁄4 2 133⁄4 349 67⁄16 164 163⁄4 425 33⁄16 81 21⁄2 64 21⁄16 52 37⁄8 98 53⁄8 137 41⁄2 114 21.3 9.7

Typical Specification

Master mixing valve shall feature paraffin-based, thermal actuation technology for precise temperature control. Valve shall be listed to ASSE

1017 and cUPC and shall be approved to ASSE 1017 & CSA B125.3

standards. Master mixing valve shall have an approach temperature of

5°F (3°C). Valve shall have an outlet temperature range from 90 – 180°F

(32 to 82°C) with a lockable temperature-setting feature. Valve shall

be manufactured of corrosion resistant materials and feature a single-

3

⁄4 N/A

3

3

⁄4

3

⁄4 1 101⁄8 264 49⁄16 116 129⁄16 319 31⁄2 89 113⁄16 46 17⁄16 36 35⁄8 92 47⁄8 124 215⁄16 75 10.3 4.9

⁄4 N/A 41⁄2 114 N/A 31⁄2 89 N/A 17⁄16 36 35⁄8 92 47⁄8 124 215⁄16 75 4.8 2.2

3

⁄4 9

1

⁄4 121⁄16 306 61⁄16 154 151⁄16 383 37⁄16 87 21⁄2 64 13⁄4 44 311⁄16 94 51⁄4 133 41⁄2 114 19.3 8.8

1

⁄2 131⁄4 337 61⁄16 154 161⁄4 413 37⁄16 87 21⁄2 64 13⁄4 44 311⁄16 94 51⁄4 133 41⁄2 114 19.8 9.0

1

⁄4 235 41⁄2 114 117⁄16 291 31⁄2 89 113⁄16 46 17⁄16 36 35⁄8 92 47⁄8 124 215⁄16 75 9.8 4.5

seat design for positive shutoff. Minimum flows to ASSE 1017 shall be

3

/4 N170-M3 (3.0 gpm, 11 lpm), 1 N170-M3 (4.0 gpm, 15 lpm), 1-1/4

N170-M3 (4.0 gpm, 15 lpm), 1-1/2 N170-M3 (5.0 gpm, 19 lpm), 2

N170-M3 (7.0 gpm, 26 lpm).

Master mixing valves shall be of Watts Series N170-M3. Any alternate

must have a written approval prior to bidding.

A Watts Water Technologies Company

ES-N170-M3 0904 © 2009 Watts

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...