Page 1

Series M9400 Valves

Brass Bypass Valve

"" DD II VV EE RR TT AA FF LL OO ""

IS-M9400

For use on

Autotrol Control Valves

SPECIAL FEATURES OF M9400 VALVES

• Rugged/durable brass bypass valve.

• Streamlined/compact/good looking.

• Dependable/very easy to operate/easy to service.

• Eliminates the need for a grounding strap.

• Maximum flow/great performance.

• Simplest valve available.

• Each valve has flow arrows plus "in" and "out" and "drain"

markings cast into the body.

• Same performance as our regular Divertaflo valve series - push

rods are interchangeable.

• Available in three valve models (

NPT and 1" (25mm) sweat piping).

3

⁄4" (20mm) sweat, 3⁄4" (20mm)

Parts List

Item Description P/N Qty. Per Valve

1" copper sweat shown (P/N M9401)

3

Also available

• All valves offer a 1⁄2" (15mm) F.I.P. threaded drain port.

• All valves offered in the Custom Label series.

• Phillips pan head screws normally furnished with each valve.

• Screw mounting hole pattern is wider than on current fiber

glass valves. This makes screw installation much easier.

• Plenty of finger room to install/tighten the regular brass mounting screws. Unlike present fiberglass valves, there is no necessity to furnish special carriage mounting bolts.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from labor charges,

delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control. This warranty shall be

invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to determine your

rights.

SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

⁄4" (20mm) copper sweat (P/N M9400)

3

{

⁄4" (20mm) F.I.P. thread (P/N M9402)

End cap, rod 44442 1

Push rod 44441 1

O-rings, valve 34443 2

Valve body, brass (see styles below) 1

3

⁄4" sweat M400 —

1" sweat M401 —

3

⁄4" F.I.P. M402 —

Nut, brass mtg. hex 65700-2 4

Screw, brass mtg. 3⁄4" (20mm) 65700-4 4

O-ring, large manifold 65831 2

O-ring, small manifold 65830 1

Hardware Kit (complete package for one valve - P/N 60034)

* A complete valve push nut including four lubricated rings is

available (P/N 4444)

Page 2

Installation Instructions

CAUTION:

When solder connections are being made, keep all heat

away from all rubber, fiberglass or plastic parts. Carefully

study all instructions on this sheet prior to starting the

bypass valve installation. Follow the sequence here as you

proceed with the installation.

a) Remove the bypass valve push rod prior to making

sweat connections to the bypass valve. Install pushrod

and tighten screw on cap after the valve installation is

complete and the valve is cool to the touch.

b) Always use the small wooden spacer blocks provided

to avoid exposing the control valve to any excess heat

during any sweating (soldering) operations.

C) Wooden spacer blocks, instructions and all necessary

mounting hardware and packed in a single clear plastic

bag and furnished with each valve. (Ref. our P/N 60034)

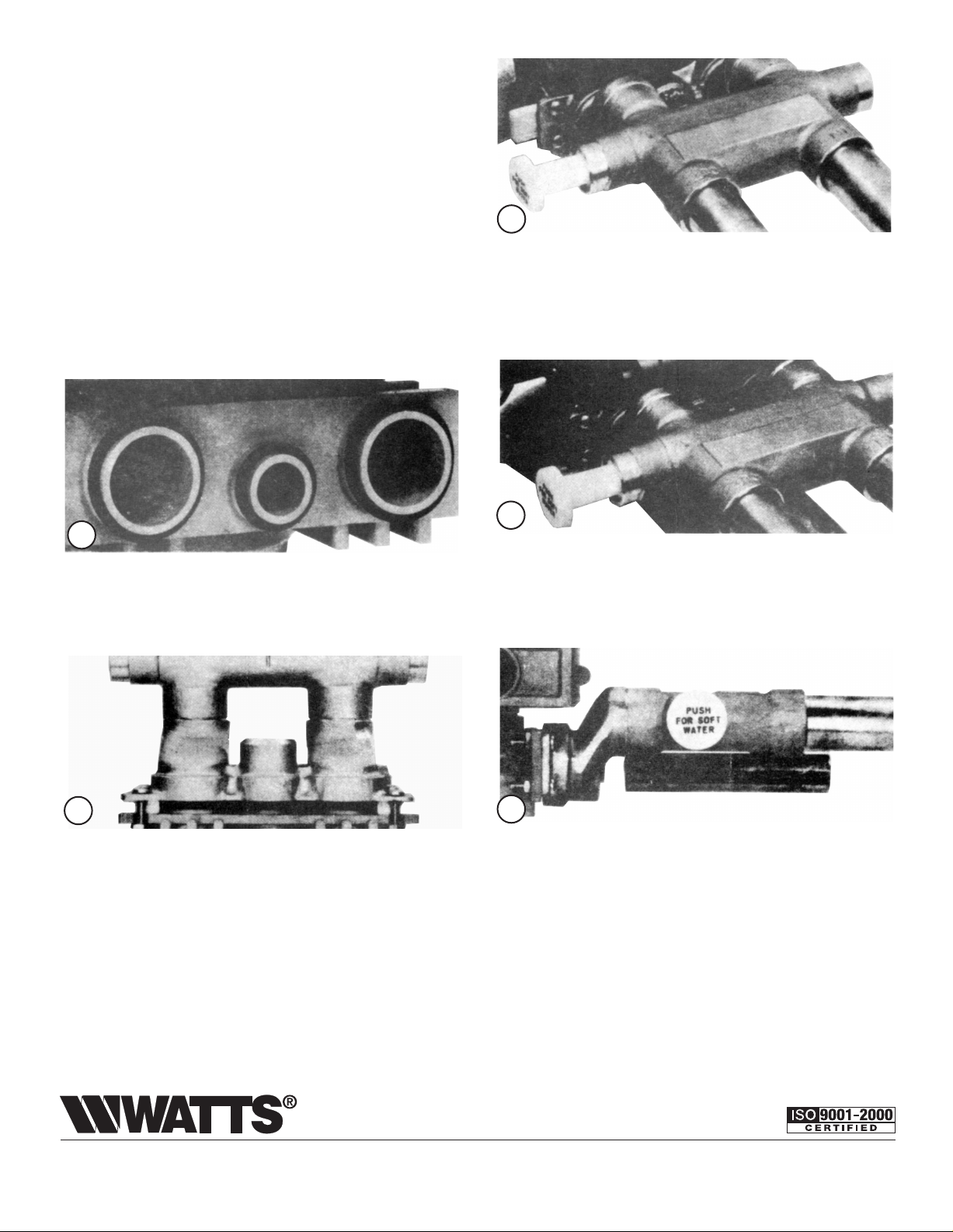

1

• Apply O-rings (3 req'd) to tank adapter.

• Always lubricate O-rings prior to installing bypass valve. Silicone

spray, O-lube or vaseline may be used.

• Fully insert each O-ring so it is resting against molded ledge of the

control valve as pictured in Figure 2.

3

• Once the wooden blocks are fully inserted then snug mounting

screws, being careful to maintain approximate equal torque to each.

Do not overtighten mounting screws at any time.

• After blocks are in place, then valve may be heated for sweating

copper pipes. After valve cools, push rod can be re-inserted as

shown.

• This figure shows 1" (25mm) copper piping installed.

4

• After valve cools to the touch, the wooden blocks may be removed.

For easy removal it may be helpful to loosen screws slightly.

• Tighten each screw snugly but don't overtighten.

• The push rod may be installed from either side of valve body. Either

way the valve will function properly.

• A complete installation would look like Figure 4 above or like Figure 5.

2

• When installed properly O-rings should be as pictured here.

• Install four brass mounting screws and nuts and tighten about as

shown in the figure.

• Insert wooden spacer blocks by sliding between screws.

• If you prefer, spacer blocks may be turned to a vertical position

placed just on the outside of the four mounting screws.

5

• This particular figure shows a complete installation using 1" copper

"in" and "out" piping. Models available also for

piping

• The drain connection on each valve is 1⁄2" (15mm) F.I.P. thread for

easy installation.

• The figure above shows 1⁄2" (15mm) iron pipe for the drainline. (Use

Teflon tape on all threaded connections.)

3

⁄4" (20mm) supply

General Notes

• If making sweat connection, always keep heat away from plastic items. Apply heat only in the immediate area of the brass as needed for soldering

and try to minimize the time the valve is heated consistent with achieving a good solder joint.

• If no heating of the bypass valve is necessary, then there is no need to remove valve pushrod. Also the wooden blocks are not needed and

may be discarded. For example certain valve models are intended expressly for threaded piping connections.

• When making the installation, be certain to leave slack in the inlet and outlet plumbing line connections to the by-pass valve. The softeners

must not be supported by the plumbing connectors. Also, any stress created by piping connections may damage the fiberglass control valve.

• For bypass valve maintenance or service instructions, see "regular Divertaflo valve" service and installation instruction sheet.

Water Safety & Flow Control Products

Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca

IS-M9400 0904 EDP#1910858 © Watts, 2008

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com

Loading...

Loading...