Page 1

Mustang Series Basic Valves

ES-ACV-M6500-M61500

Job Name

Job Location

Engineer

Approval

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

M6500 / M61500

Reduced Port Ductile Iron Dual

Chamber Basic Valve

The Watts ACV Models M6500 and M61500 are reduced port,

dual chamber basic valves that incorporate a one-piece disc

and diaphragm assembly. This assembly is the only moving part

within the valve allowing it to open, close, or modulate as commanded by the pilot control system. The reduced port design

offers improved low-flow performance as compared to the full

port valve on the same service.

When pressure is applied to the upper diaphragm chamber and

released from the lower diaphragm chamber, the valve travels

to a closed position. When pressure is applied to the lower

diaphragm chamber and released from the upper diaphragm

chamber the valve travels to a full open position. When pressure

is balanced between the upper and lower diaphragm chambers,

the valve will hold an intermediate position until commanded to

modulate open or closed by the pilot control system.

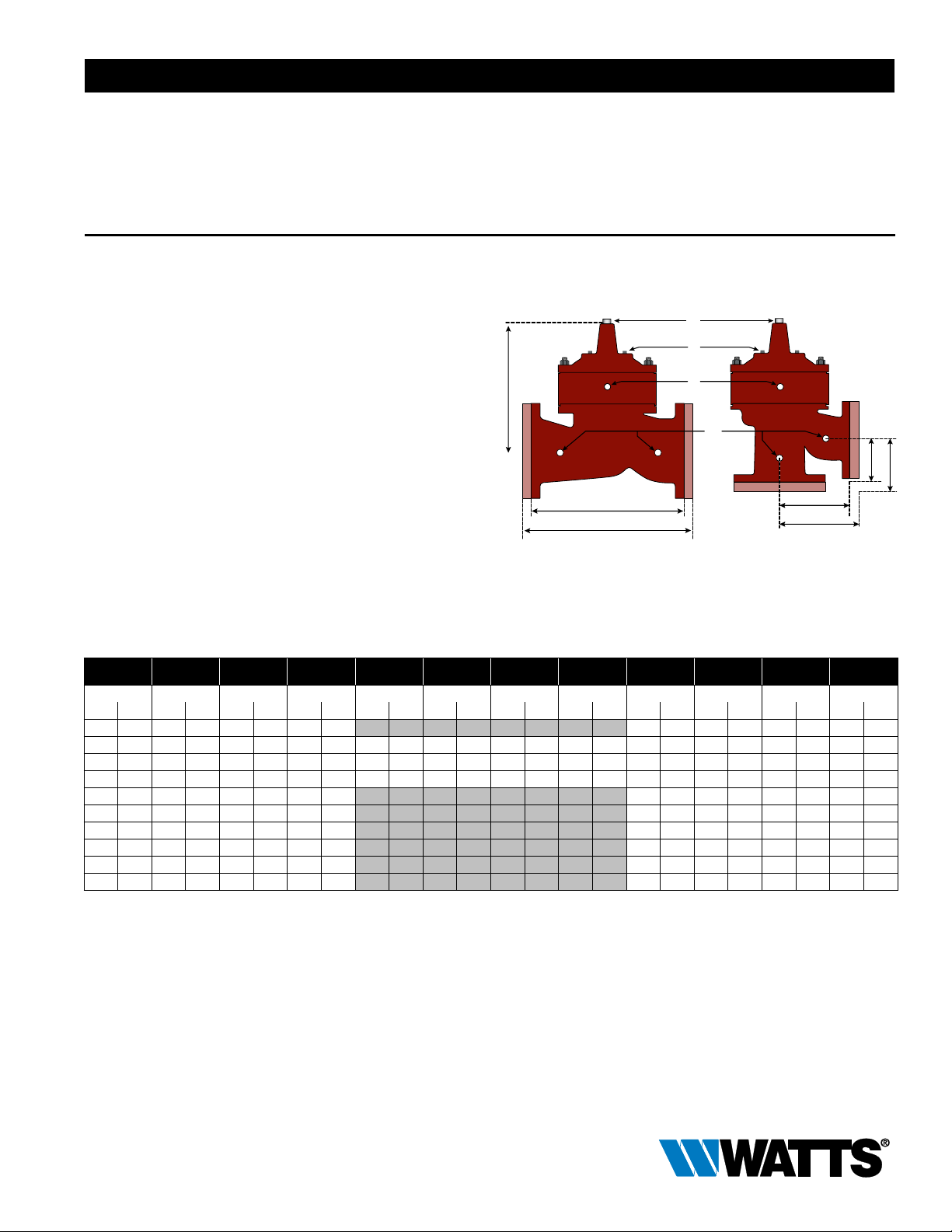

Model M6500: Globe Pattern Dual Chamber Basic Valve

Model M61500: Angle Pattern Dual Chamber Basic Valve

Contractor

Approval

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––

M6500 (Globe) M61500 (Angle)

C

A

B

––––––––––––––––––––––––––––––––––

I

K

J

H

F G

D

E

Dimensions

Valve Size Globe 150# Globe 300# Cover To Center Angle 150# Angle 300# Angle 150# Angle 300# Port Size Port Size Port Size Shipping

A B C D E F G H I J

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

3 80 10

4 100 13

6 150 17

8 200 21

10 250 26 660 27

12 300 30 762 31

16 400 35 889 36

18 450 48 1219 49

20 500 48 1219 49

24 600 48 1219 49

Standard Materials

Body & Cover: Ductile Iron ASTM A536

Coating: NSF Listed Fusion Bonded Epoxy Lined

1

⁄4 260 11 279 91⁄16 230

7

⁄8 352 141⁄2 368 1111⁄16 297 615⁄16 176 71⁄4 184 51⁄2 140 513⁄16 1481⁄2 131⁄2 131⁄2 13 50 23

3

⁄4 451 185⁄8 473 151⁄4 387 87⁄8 225 93⁄8 238 63⁄4 171 71⁄4 1843⁄4 193⁄4 193⁄4 19 130 59

3

⁄8 543 223⁄8 568 201⁄8 511 1011⁄16 271 113⁄16 284 71⁄4 184 73⁄4 1973⁄4 193⁄4 193⁄4 19 210 95

3

⁄8 695 2311⁄16 602 1 25 1 25 1 25 363 165

1

⁄2 800 261⁄4 667 1 25 1 25 1 25 528 240

5

⁄8 930 341⁄8 867 1 25 11⁄4 32 1 25 826 375

5

⁄8 1260 41 1041 1 25 2 51 1 25 1365 620

5

⁄8 1260 41 1041 1 25 2 51 1 25 1390 630

3

⁄4 1260 41 1041 1 25 2 51 1 25 1485 674

3

⁄8 101⁄2 131⁄2 13 31 14

Operating Pressure

Threaded = 400psi (27.6 bar)

and Coated

150 Flanged = 250psi (17.2 bar)

300 Flanged = 400psi (27.6 bar)

Trim: 316 Stainless Steel

Elastomers: Buna-N (standard)

EPDM (optional)

Viton

®

(optional)

Stem, Nut &

Operating Temperature

Buna-N: 160°F (71°C) Maximum

EPDM: 300°F (140°C Maximum

®

Viton

: 250°F (121°C) Maximum

Spring: Stainless Steel

Weights*

*Estimated in lbs.

Viton® is a registered trademark of DuPont Dow Elastomers.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

M6500 / M61500 — Reduced Port Ductile Iron Dual Chamber

Basic Valve

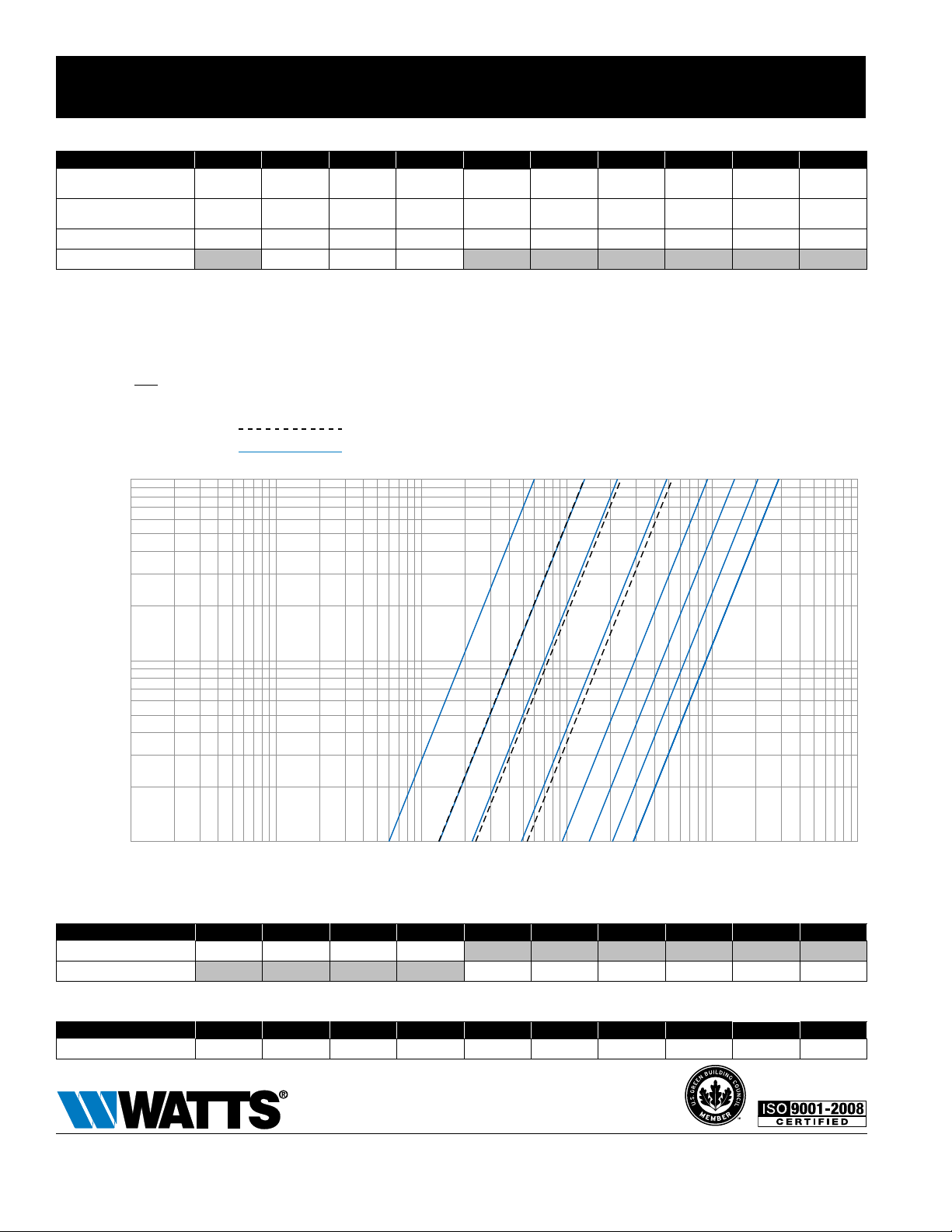

Flow Data - ACV M6500 (Globe) / M61500 (Angle)

Valve Size - Inches 3 4 6 8 10 12 16 18 20 24

Maximum Continuous

Flow Rate Gpm (Water)

Maximum Intermittent

Flow Rate Gpm (Water)

CV Factor GPM (Globe) 60 133 224 489 932 1428 2067 2881 2881 2881

CV Factor GPM (Angle) 132 237 534

Maximum continuous flow based on velocity of 20 ft. per second.

Maximum intermittent flow based on velocity of 25 ft. per second.

The Cv Factor of a value is the flow rate in US GPM at 60°F that will cause a 1psi drop in pressure.

The factors stated are based upon a fully open valve.

Cv factor can be used in the following equations to determine Flow (Q) and Pressure Drop (∆P):

Q (Flow) = Cv√∆P ∆P (Pressure Drop) = (Q/Cv)

210 485 800 1850 3100 5000 7000 11100 11100 11100

265 590 1000 2300 4000 6250 8900 14100 14100 14100

2

Estimated

Headloss

100

80

60

40

30

20

10

8

6

4

Pressure Drop (psi)

3

2

Angle

4

Globe

3

2 4 6 8 10 20 40 60 80 100 200 500 1000 2000 5000 10000 20000

6

4

6

8

8

10

12

18 / 20 / 24

16

Flow Rate - Gallons per minute (Water)

Valve Cover Chamber Capacity

Valve Size - Inches 3 4 6 8 10 12 16 18 20 24

fluid oz. 4 10 22 70

U.S. Gal 1-1/4 2-1/2 4 9-1/2 9-1/2 9-1/2

Valve Travel

Valve Size - Inches 3 4 6 8 10 12 16 18 20 24

Travel - Inches 1/2 3/4 1 1-1/2 2 2-1/2 3 4 4 4

A Watts Water Technologies Company

ES-ACV-M6500-M61500 1219 © 2012 Watts

USA: Tel. (713) 943-0688 • (713) 944-9445 • www.watts.com

Loading...

Loading...