Page 1

For Residential and Commercial Applications

ES-LFTP300

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

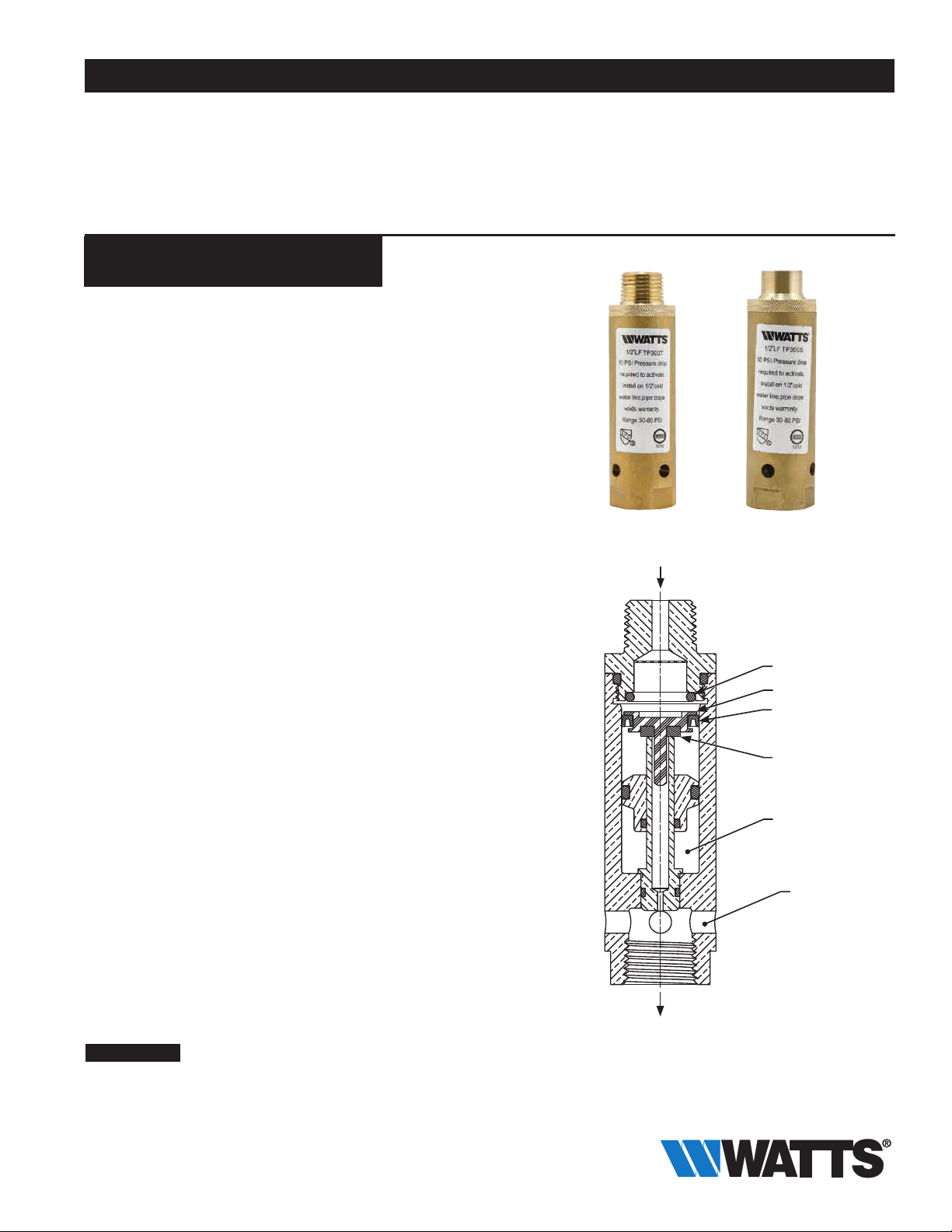

Series LFTP300

Trap Primer

Size: 1⁄2"

The Series LFTP300 operates by sensing the pressure drop in

the supply line from downstream fixtures or appliances. The pressure reduction above the Valve Disc (2) causes the disk to move

upward opening the Lower Disc Seal (4) and closing off the Upper

Disc Seal (1). With the Lower Disc Seal (4) open the stored air

pressure in the Air Chamber (5) pushes a portion of the contained

volume of water from the lower chamber out through the opening

beneath the Lower Disc Seal (4) to prime the trap. When there is

no longer a demand in the supply line and the full line pressure is

restored, the Valve Disc (2) lowers, opening the Upper Disc Seal,

allowing flow through the One Way Seal (3), seating the Lower

Disc Seal (4) and recharging the Air Chamber (5) for the next

pressure drop cycle. The Series LFTP300 incorporates a built in

vacuum breaker (6) which does not satisfy compliance to ASME

A112.1.2. The Series LFTP300 features Lead Free* construction to

comply with Lead Free* installation requirements.

This Engineering Sheet is not intended to replace the product

installation and safety information available or the experience of a

trained product installer. Please refer to the product installation

instructions for further information.

Models

• LFTP300T - Threaded Inlet and Outlet Connect

• LFTP300S - Solder Inlet and Threaded Outlet Connect

Features

• Built in Vacuum Breaker Ports (6)

Specifications

A trap primer shall be installed in plumbing systems to prevent

floor drain traps from losing their water seal by evaporation.

Maintaining the water seal will prevent the backflow of sewer gas

into the buildings or rooms where the traps are installed. Trap

primers are specified in various plumbing codes such as IAPMO,

Southern Standard Building Code, National Standard Plumbing

Code and many state and local plumbing codes in U.S.A.

and Canada. The device shall meet the requirements of ASSE

Standard 1018. Lead Free* Trap Primer Series LFTP300 shall be

constructed using Lead Free* materials. Lead Free Trap Primers

shall comply with state codes and standards, where applicable,

requiring reduced lead content. Watts Series LFTP300T

(threaded), or LFTP300S (solder).

NOTICE

Inquire with governing authorities for local installation requirements.

Contractor

Approval

Contractor’s P.O. No.

Representative

*The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

Model LFTP300T Model LFTP300S

Supply

To Trap

Upper Disc Seal (1)

Valve Disc (2)

One Way Seal (3)

Lower Disc Seal (4)

Air Chamber (5)

Vacuum Breaker

Ports (6)

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

Materials

1 1/4

[32 mm]

4 1/4

[107 mm]

Lead Free Adapter

Brass Body (Lead)

EPDM Seals

Pressure

Maximum supply pressure: 125psi.

Minimum supply pressure must exceed 25psi.

Operating Requirements

Activates with a 10psig pressure drop between 25-125psi. Must

be installed on a cold water line serving a frequently used fixture.

For proper trap priming, minimum flows must exceed those stated

in the flow chart.

Dimensions – Weights

Model LFTP300T Model LFTP300S

1 1/4

B

[32 mm]

1 1/4

[32 mm]

B

Standards

1018

Tested and approved in conformance with Standard

1018 of the American Society of Sanitary Engineers.

Listed by IAPMO and CSA.

B125.3

Flow Chart

INLET PRESSURE 25 50 75 100 125

*GPM

*LPM

*Minimum cold flow required for proper trap priming.

1.1 1.6 2.0 2.3 2.4

4.2 6.1 7.6 8.7 9.1

4 5/16

A

[110 mm]

MODEL SIZE DIMENSIONS WEIGHT

in.

LFTP300T

LFTP300S

1

⁄2 45⁄16 110 11⁄4 32 .97 .44

1

⁄2 41⁄4 107 11⁄4 32 .92 .42

4 1/4

A

[107 mm]

A B

in. mm in. mm lbs. kgs.

A Watts Water Technologies Company

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

ES-LFTP300 1339 © 2013 Watts

Loading...

Loading...