Page 1

For Residential and Commercial Health Hazard Applications

ES-LFN9-CD

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

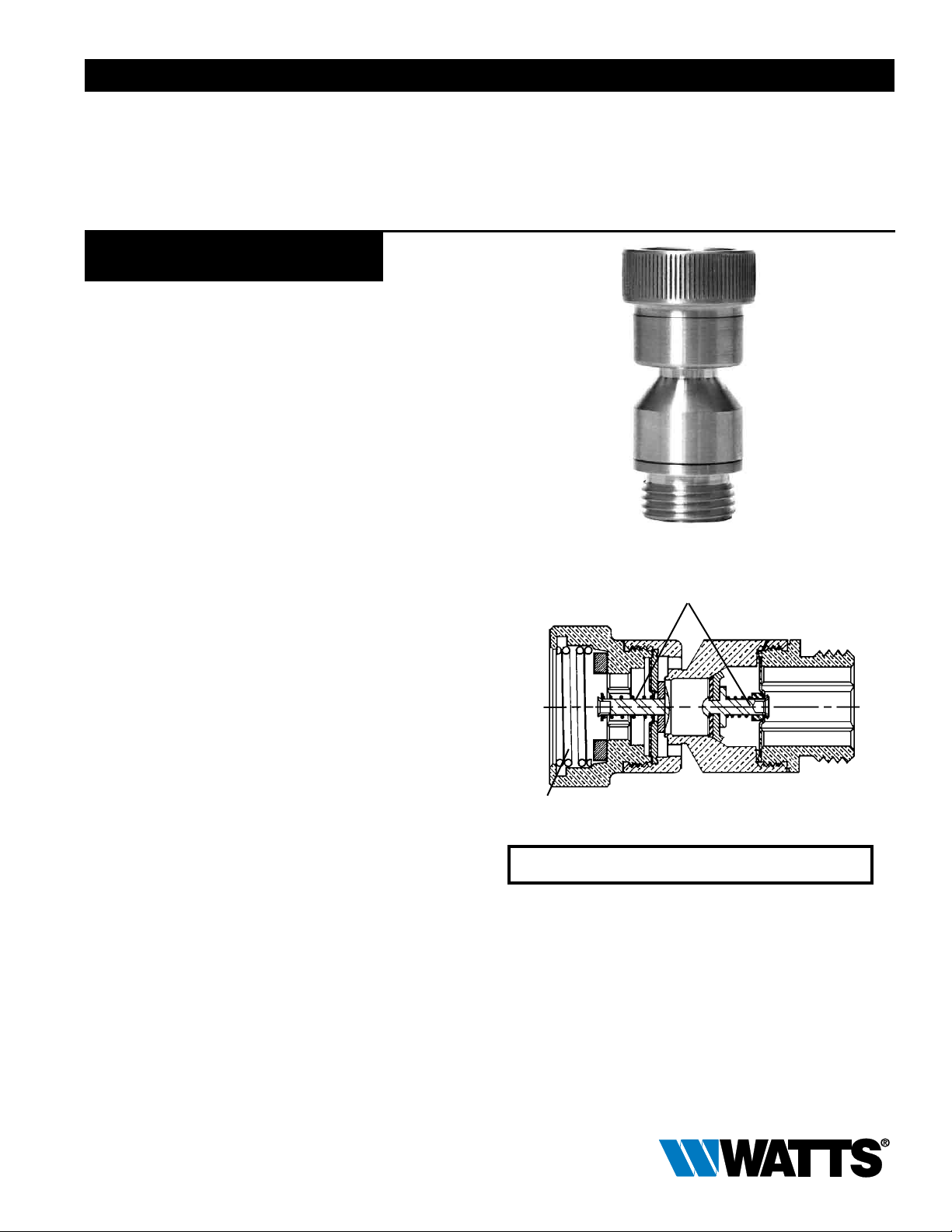

Series LFN9-CD

Field Testable Hose Connection

Backflow Preventer

Size: 3⁄4" (20mm) Hose thread

The LFN9-CD is designed to prevent high hazard backsiphonage backflow and low-head backpressure (10ft. or less) from

contaminating the potable water supply. The LFN9-CD is ideally

suited to prevent backflow associated with hose connections

and may be screwed directly to the sill cock, yard hydrant or

wall hydrant. Typical installations include service sinks, chemical

dispensers, sill cocks and frost proof hydrants.

Watts LFN9-CD features include two independently operating

rubber and stainless steel check valves with an atmospheric

vent located between the check valves. In the event of fouling

of the downstream check valve, leakage would be vented to

atmosphere, thereby, providing a visual indication of failure. The

integrity of the check valves can also be verified by performing

the field test procedure included with the LFN9-CD. The LFN9CD features Lead Free* construction to comply with the Lead

Free installation requirements.

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

3⁄4" (20mm) LFN9-CD

–––––––––––––––––––––––––––––––––––

Center Guided

Checks

Features

• Exclusive "Non-removable" design eliminates the need

for break-away set screw

• Center-guided check valves for repeatable seating

• In-line field testable - no special gauges required

• Manually drainable for freeze protection

• Durable brass body with stainless steel checks for

corrosion resistance

• Streamlined design for low pressure drop

• Can be installed vertically or horizontally

• Positive backsiphonage protection

Specifications

Maximum pressure: 125psi (8.6 bars).

Maximum temperature: 180°F (82°C).

Inlet Connection: 3⁄4" (20mm) standard female hose thread

Outlet Connection:

A hose connection backflow preventer shall be installed where

indicated on the plans to prevent the backsiphonage of potentially contaminated water. The device shall not be subjected

to continuous pressure (more than 12 hours) or backpressure

(more than 10 feet). The hose connection backflow preventer

shall consist of two independently operating check valves with

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

3

⁄4" (20mm) standard male hose thread

Non-removable

Interlocking Spring

Use only with approved hose bibbs or hose fittings having

four or more full American National Hose (NH) threads.

Specifications (cont.)

an intermediate atmospheric vent. The assembly shall be nonremovable via the use of an interlocking spring contained in the

backflow preventer. The use of break-away set screws as a

non-removable retention method is not allowed. The hose connection backflow preventer shall be in line field testable without

the use of special test gauges or instruments. The Lead Free*

Field Testable Hose Connection Backflow Preventer shall comply with state codes where applicable. The device shall meet the

requirements of ASSE Std. 1052 and shall be a Watts LFN9-CD.

*The wetted surface of this product contacted by consumable water

contains less than 0.25% of lead by weight.

Page 2

Standards

Tested and approved in conformance with Standard 1052 of the

American Society of Sanitary Engineers and by all principal cit-

ies, states, and areas having these requirements.

IMPORTANT: Inquire with governing authorities for local installation requirements.

These devices are not intended for installation where emergency

or temporary water discharge can cause water damage.

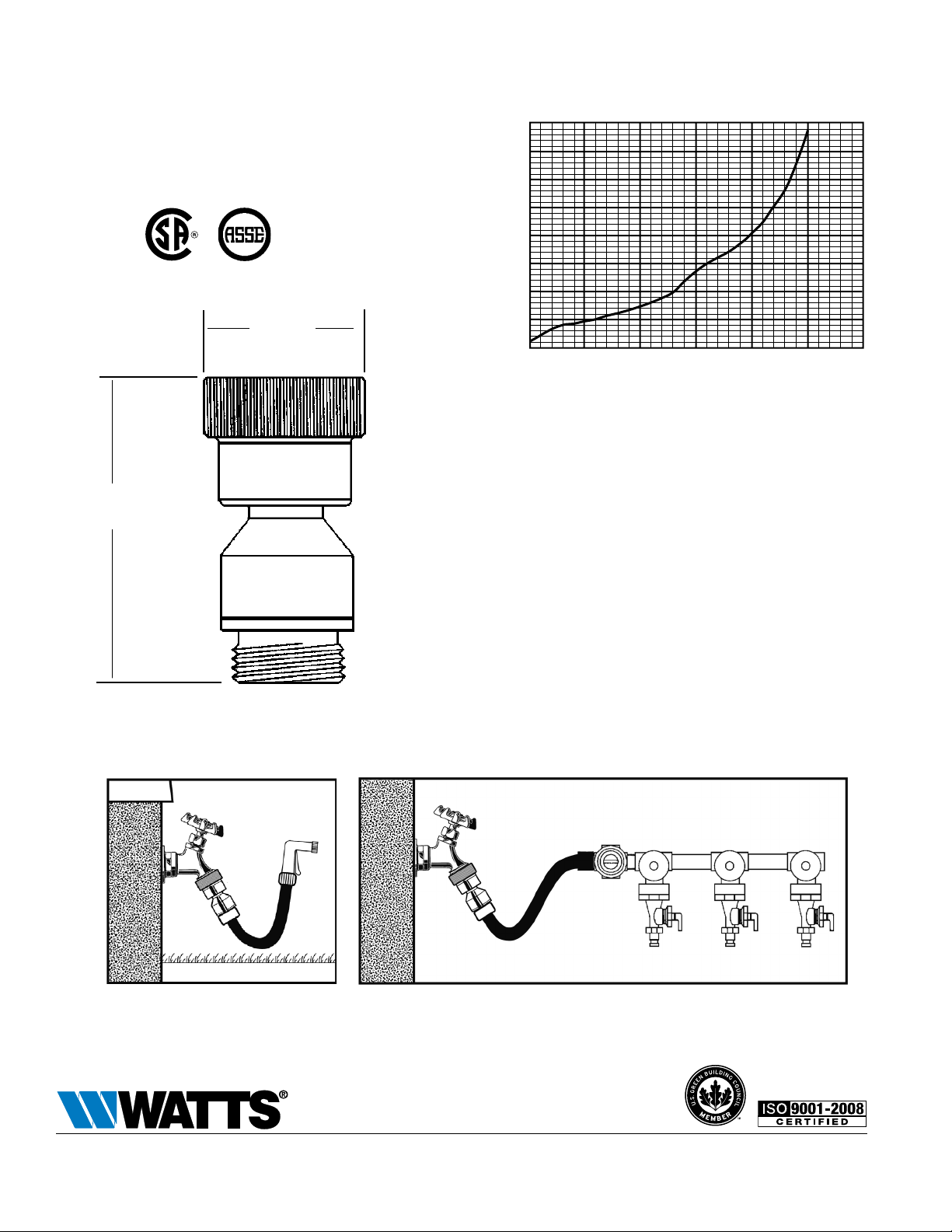

Dimensions - Weight

11⁄2"

(38mm)

Weight = .56 lbs.

(.25 kg.)

213⁄16"

(71mm)

Capacity

kPa psi

276 40

241 35

207 30

172 25

138 20

103 15

69 10

Pressure Loss

34 5

0 0

0 1 2 3 4 5 6 gpm

0 4 8 11 15 19 23 lpm

Flow Rate

Rated Flow: 4 gpm

Installations

Sillcock Installation

A Watts Water Technologies Company

ES-LFN9-CD 1305 © 2013 Watts

Chemical Dispenser Installation

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Loading...

Loading...