Page 1

ENGLISH INSTRUCTIONS

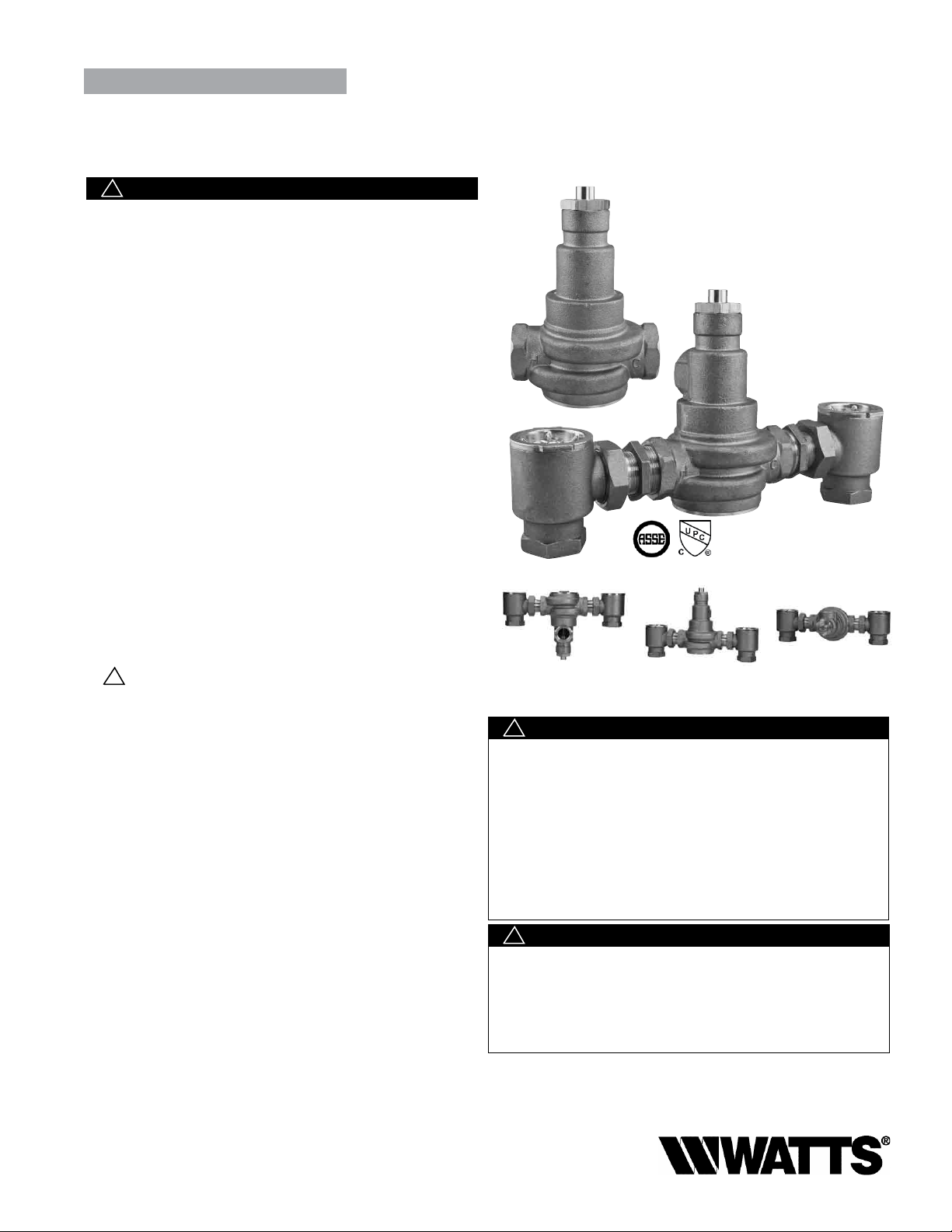

Series N170-M3 and LFN170-M3

Hot Water Master Tempering Valves

WARNING

!

You are required to thoroughly read all installation instructions and

product safety information before beginning the installation of this product. FAILURE TO COMPLY WITH PROPER INSTALLATION AND

MAINTENANCE INSTRUCTIONS COULD RESULT IN PRODUCT

FAILURE WHICH CAN CAUSE PROPERTY DAMAGE, PERSONAL

INJURY AND/OR DEATH. Watts is not responsible for damages result-

ing from improper installation and/or maintenance.

Local building or plumbing codes may require modifications to the

information provided. You are required to consult the local building and

plumbing codes prior to installation. If this information is not consistent

with local building or plumbing codes, the local codes should be followed.

Installation Instructions

Installation should be in accordance with acceptable plumbing practices. Flush all pipes thoroughly before installation. Installation and field

adjustment are responsibility of the installer and shall be carried out per

following installation instructions.

1. Valves are to be installed as close to building inlet supply as possible

to prevent/minimize pressure fluctuations.

2. Valve body can be installed in multiple positions, see below. Make

sure that the union nuts and tailpieces are tightened securely if you

are using checkstops.

3. Connect inlets and outlet and check for leaks.

!

4. CAUTION: When N170-M3 or LFN170-M3 supplies tempered

water to self-closing and/or solenoid valves, provide a shock absorber on the discharge line.

5. Before use, check discharge temperature. Reset if necessary

Temperature Adjustment

1. Turn off recirculation pump (if one is in the system).

2. Open enough fixtures to meet the minimum flow requirement of the

valve.

3. Loosen the lock nut. Turn temperature adjustment screw clockwise

to decrease or counterclockwise to increase outlet temperature.

NOTE: Please allow valve temperature to stabilize in before making

your next adjustment. Watts recommends that a temperature gauge is

installed on the tempered line and be checked at least monthly under

normal flow conditions. The gauge must be installed at least 6 ft. away

from the tempering valve.

4. When desired temperature is set, tighten the lock nut. Turn recirculation pump back on. Close open fixtures.

FRONT OUTLET

WARNING

!

Watts Hot Water Master Tempering Valves cannot be used for

tempering water temperature at fixtures. Severe bodily injury (i.e.,

scalding or chilling) and/or death may result depending upon system

water pressure changes and/or supply water temperature changes.

ASSE standard 1016, 1069 or 1070 listed devices such as Watts

Series MMV, LFMMV, USG, LFUSG, L111 or LFL111 valves should be

used at fixtures to prevent possible injury.

The Watts Hot Water Tempering Valves are designed to be installed at

or near the boiler or water heater. They are not designed to compensate

for system pressure fluctuations and should not be used where ASSE

standard 1016, 1069 or 1070 devices are required. These Watts valves

should never be used to provide “anti-scald” or “anti-chill” service.

WARNING

!

Need for Periodic Inspection: Periodic inspection by a licensed

contractor is recommended. Corrosive water conditions, temperatures over 210°F, unauthorized adjustments or repair could render

the valve ineffective for service intended. Regular checking and

cleaning of the valves internal components and checkstops helps

to assure maximum life and proper product function. Frequency of

cleaning depends upon local water conditions.

LFN170-M3

BACK OUTLET TOP OUTLET

IS-N170-M3

N170-M3 CSUT

Page 2

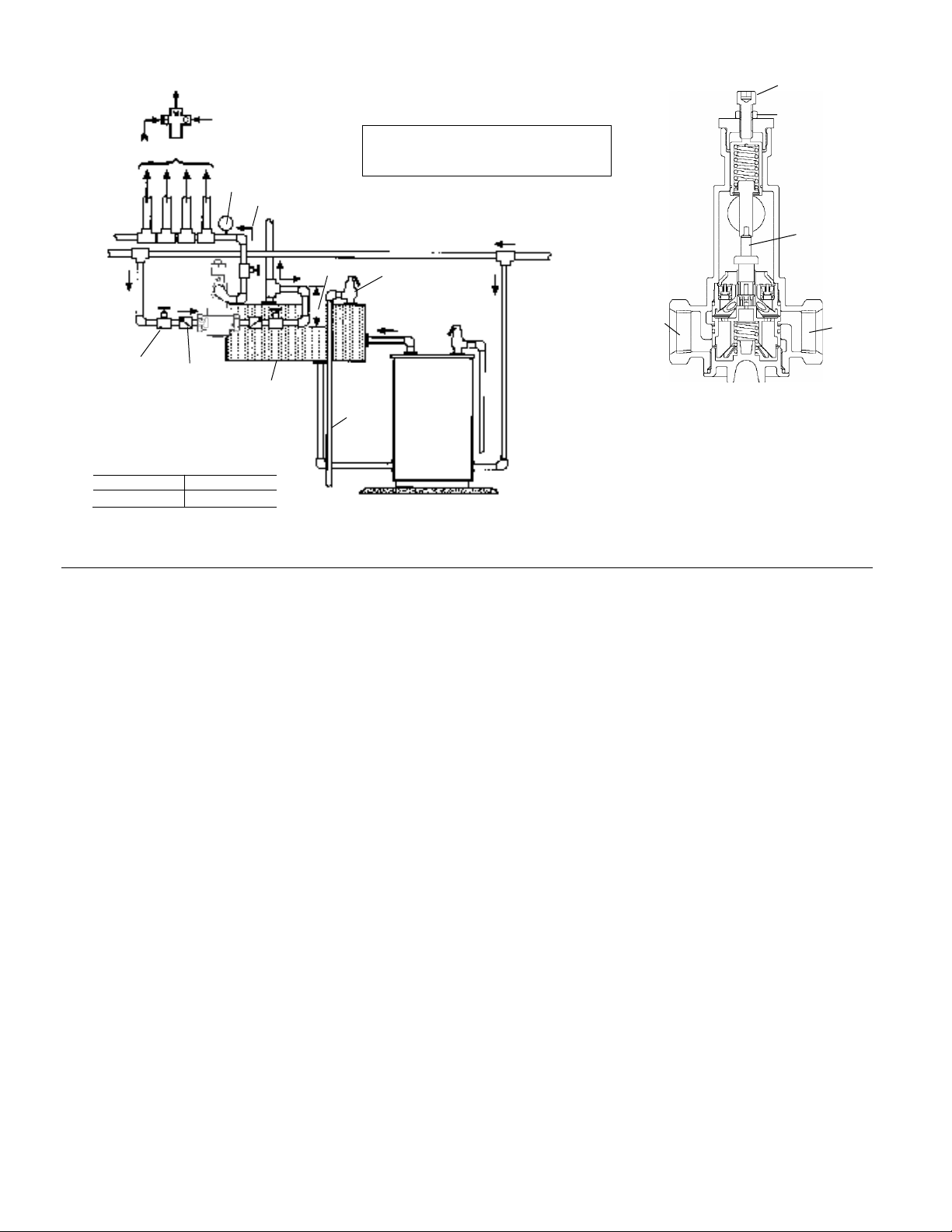

Basic Installation

To Fixture

To Model

L111, LFL111, MMV or LFMMV

From Cold Supply

Thermometer

Tempered 140°F *†

ATTENTION INSTALLER: After installation,

please leave this Instruction Sheet for

occupant’s information.

Temperature

Adjusting Screw

Lock Nut

Cold

† N170-M3

or LFN170-M3

Cold

Tempering

Valve

Shutoff Valves

(on both hot

and cold inlets)

Minimum Flow Requirements to

for N170-M3 or LFN170-M3 Series

Valve Size gpm

3

⁄4" thru 2" (20-50mm) 3 to 7 (11 to 26.5 lpm)

Check Valves

(on both hot and

cold inlets)

Maintain Set Temperature

Storage

Tank

180°F

8" to 12"

Drain

CSA/ASME T&P Valve

ASME Pressure

Relief Valve

Water Heater

or

Hot Water Boiler

Hot

Water

NOTE: Heat trap is recommended.

† Valves listed to ASSE Standard 1016, 1069

or 1070, such as the Watts L111, LFL111,

USG, LFUSG, MMV, or LFMMV should be

used at point of delivery.

Specifications

• Maximum Operating Pressure ............................. 125 psig (861 kPa)

• Maximum Hot Water Temperature .......................... 200°F (93°C)

• Minimum Hot Water Supply Temperature ..................... 5°F (3°C) Above Set-Point*

• Temperature Adjustment Range** ........................... 90 - 180°F (32 - 82°C)

• Hot Water Inlet Temperature Range ......................... 120 - 180°F (42 - 82°C)

• Cold Water Inlet Temperature Range ........................ 40 - 80°F (4 - 27°C)

• Listing ................................................ ASSE 1017, IAPMO CUPC

• Approval Standards ..................................... ASSE 1017, CSA B125.3

* With Equal Pressure

** Low limit can not be less than the cold water temperature. For best operation, hot water should be at least 5°F (3°C)

above desire set point.

Actuator

Cold

Water

2

Page 3

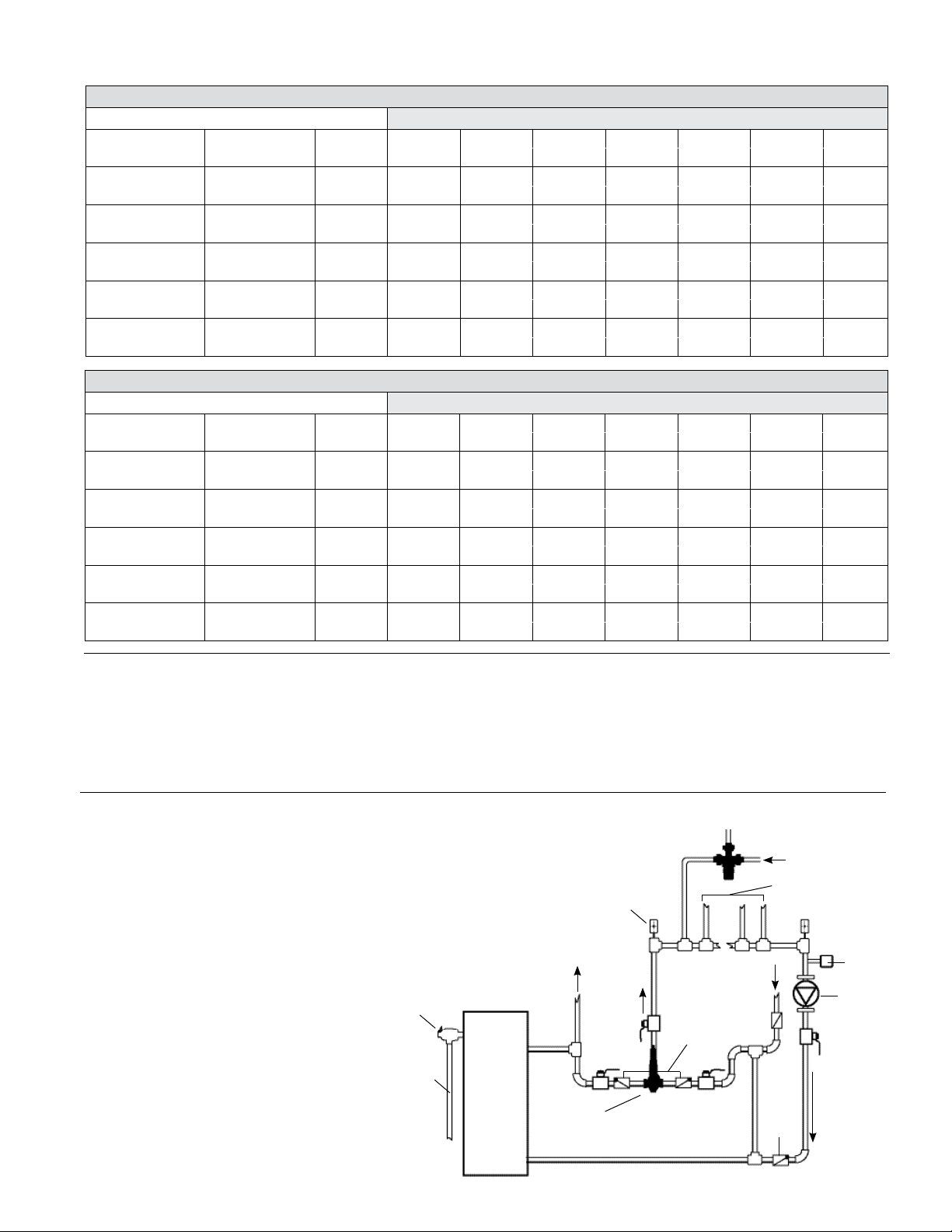

Capacity

Model Inlet / Outlet (NPT)

3

/4" N170-M3

3

/4" LFN170-M3

1" N170-M3

1" LFN170-M3

"

1

1

/4

N170-M3

"

1

1

/4

LFN170-M3

"

1

1

/2

N170-M3

"

1

1

/2

LFN170-M3

2" N170-M3

2" LFN170-M3

Model Inlet / Outlet (NPT)

3

/4" N170-M3 CSUT

3

/4" LFN170-M3 CSUT

1" N170-M3 CSUT

1" LFN170-M3 CSUT

"

1

1

/4

N170-M3 CSUT

"

1

1

/4

LF170-M3 CSUT

"

1

1

/2

N170-M3 CSUT

"

1

1

/2

LFN170-M3 CSUT

2" N170-M3 CSUT

2" LFN170-M3 CSUT

3

/4 x 3/4"

1 x 1"

1

1-

/4 x 1-1/4"

1

1-

/2 x 1-1/2"

2 x 1-

3

/4 x 3/4"

3

/4 x 1"

1

1-

/4 x 1-1/4"

1

1-

/4 x 1-1/2"

1

1-

1

/2 x 2"

/4 x 2"

Flow Capacity at 50-50 mixed Less Checkstops

Pressure Drop Across Valve

Min. Flow

to ASSE 1017

3 gpm

11 lpm 57 lpm 79 lpm 114 lpm 140 lpm 170 lpm 197 lpm

4 gpm

15 lpm 87 lpm 121 lpm 170 lpm 212 lpm 257 lpm 299 lpm

4 gpm

15 lpm 121 lpm 170 lpm 238 lpm 288 lpm 360 lpm 416 lpm

5 gpm

19 lpm 134 lpm 185 lpm 265 lpm 326 lpm 397 lpm 458 lpm

7 gpm

26 lpm 159 lpm 223 lpm 314 lpm 386 lpm 473 lpm 545 lpm

C

V

6.70

10.13

14.16

15.65

18.63

5psi 10psi 20psi 30psi 45psi 60psi

(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa)

15 gpm 21 gpm 30 gpm 37 gpm 45 gpm 52 gpm

23 gpm 32 gpm 45 gpm 56 gpm 68 gpm 79 gpm

32 gpm 45 gpm 63 gpm 76 gpm 95 gpm 110 gpm

35 gpm 49 gpm 70 gpm 86 gpm 105 gpm 121 gpm

42 gpm 59 gpm 83 gpm 102 gpm 125 gpm 144 gpm

Flow Capacity at 50-50 mixed with Checkstops

Pressure Drop Across Valve

Min. Flow

to ASSE 1017

3 gpm

11 lpm 53 lpm 76 lpm 106 lpm 129 lpm 159 lpm 182 lpm

4 gpm

15 lpm 79 lpm 114 lpm 163 lpm 197 lpm 242 lpm 280 lpm

4 gpm

15 lpm 114 lpm 159 lpm 227 lpm 280 lpm 341 lpm 394 lpm

5 gpm

19 lpm 125 lpm 128 lpm 254 lpm 310 lpm 379 lpm 435 lpm

7 gpm

26 lpm 151 lpm 216 lpm 303 lpm 371 lpm 454 lpm 526 lpm

C

V

6.26

9.54

13.42

14.90

17.89

5psi 10psi 20psi 30psi 45psi 60psi

(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa)

14 gpm 20 gpm 28 gpm 34 gpm 42 gpm 48 gpm

21 gpm 30 gpm 43 gpm 52 gpm 64 gpm 74 gpm

30 gpm 42 gpm 60 gpm 74 gpm 90 gpm 104 gpm

33 gpm 47 gpm 67 gpm 82 gpm 100 gpm 115 gpm

40 gpm 57 gpm 80 gpm 98 gpm 120 gpm 139 gpm

Series N170-M3 and LFN170-M3

Hot Water Master Tempering Valves

Installation Instructions for

A Two Temperature Recirculating Hot Water Supply System

Recirculation System 1

WATTS CSA/ASME

Temperature &

Pressure Relief Valve

Hot Water Supply

DrainTube

Water

Heater

or

Boiler

WATTS

Series N170-M3†

or LFN170-M3

Thermometer

WATTS

Ball

Valve

Series

MMV

WATTS

Check

Valves

Tempered Water Supply

To Fixture

Cold Water Supply

To MMV, USG-B, L111 or

LFL111 then to fixtures

Cold Water

Supply

WATTS

Check

Valves

Aquastat

Circulator

Recirculation Loop

3

Page 4

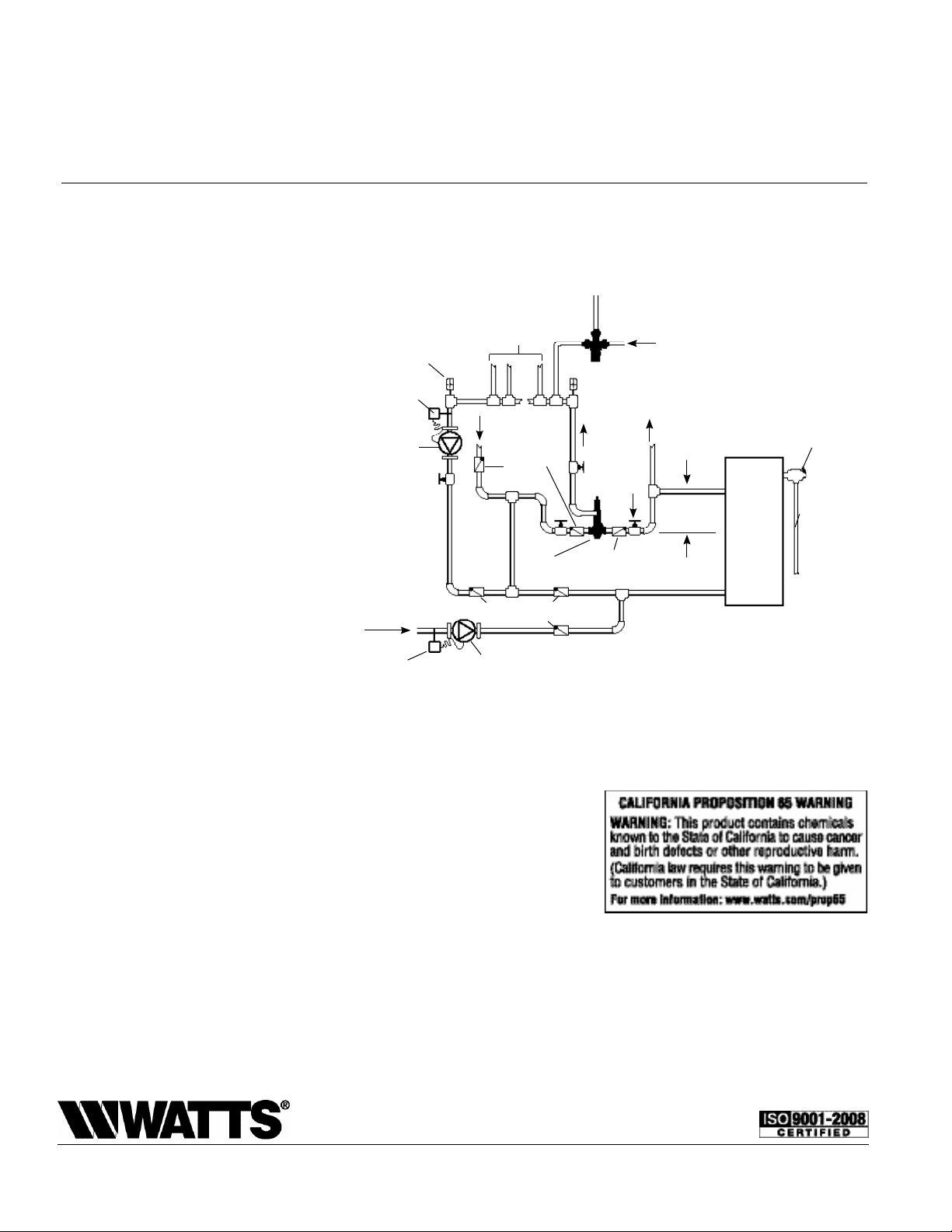

Series N170-M3 and LFN170-M3

Hot Water Master Tempering Valves Continued

Installation Instructions for

A Two Temperature Recirculating Hot Water Supply System

IMPORTANT: Valve must be installed

trapped as shown. (See reverse side for rec-

ommended minimum gpm flow requirements.)

The sketch illustrates a two-temperature (180°F

and 140°F) hot water supply system with

a Series N170-M3 and LFN170-M3 valve

and recirculating line for maintaining approxi-

mate fixture water temperatures in the mains.

Because very little hot water is required to maintain the low temperature in the mains (usually

140°F), a relatively small capacity recirculator

can generally be specified. The minimum flow

requirements must be maintained between 3-7

gpm. Providing the heat loss from the piping

is not too great (long runs of hot water piping

should be insulated) standard circulators are

usually adequate. However, each installation

should be evaluated for its own recirculation

requirements of gpm and pipe resistance.

NOTE: Recirculating control aquastat must

be set at least 5°F to 10°F lower than the

temperature setting of the Series N170-M3 or

LFN170-M3 valve, otherwise the recirculator will

run continually. Aquastat must be used to maintain water to fixtures at a desired temperature

and to eliminate temperature override during no

draw periods.

† Valves listed to ASSE Standard 1016, 1069 or

1070 such as the Watts L111, LFL111, USG,

LFUSG, MMV or LFMMV should be used at

point of delivery.

Recirculation System 2

Typical Two Temperature System with High

Temperature Hot Water Recirculation Line

To MMV, LFMMV,

USG, LFUSG, L111

or LFL111 then to

fixtures

Thermometer

Aquastat

WATTS

Circulator

Hot Water Return

Aquastat

Circulator

Check

Valves

Cold Water Supply

Watts

Series

N170-M3†

WATTS Check

Valve

To Fixture

Cold Water Supply

MMV

High

Temperature

Hot Water

Tempered Water 140°

Shut

Off

Valve

WATTS Series 600

Check Valves

Note: Water Heaters may be direct or indirect fired.

8”-12”

HeatTrap†

Water

Heater

or Boiler

WATTS CSA/ASME

Temperature &

Pressure Relief Valve

Drain Tube

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

IS-N170-M3 1209 EDP# 2915044 © 2012 Watts

Page 5

INSTRUCCIONES EN ESPAÑOL

Serie N170-M3 y LFN170-M3

Válvulas maestras de templado de agua caliente

ADVERTENCIA

!

Debe leer por completo todas las instrucciones de instalación y la

información de seguridad del producto antes de comenzar su instalación.

SI NO CUMPLE CON LAS INSTRUCCIONES CORRECTAS DE

INSTALACIÓN Y MANTENIMIENTO, PODRÍA PRODUCIRSE UNA

FALLA DEL PRODUCTO QUE PUEDE CAUSAR DAÑOS A LA

PROPIEDAD, LESIONES O LA MUERTE. Watts no se hace responsable

por daños derivados de una instalación o un mantenimiento incorrectos.

Es posible que los códigos locales de edificación y plomería exijan

modificaciones con respecto a la información provista. Deberá consultar

los códigos locales de edificación y plomería antes de instalar este

producto. Si la presente información no coincide con los códigos locales

de edificación o plomería, siga las pautas establecidas en dichos códigos.

Instrucciones de instalación

La instalación deberá hacerse de acuerdo con prácticas de plomería

aceptables. Enjuague bien todas las tuberías antes de la instalación. La

instalación y el ajuste del campo son responsabilidad del instalador y

deben realizarse según las siguientes instrucciones de instalación.

1. Las válvulas deben instalarse tan cerca del suministro de entrada del

edificio como sea posible para evitar/minimizar las fluctuaciones de

la presión.

2. El cuerpo de la válvula puede instalarse en muchas posiciones,

consulte a continuación. Asegúrese de que las tuercas de unión y

las alcachofas de aspiración estén ajustadas de forma segura si usa

tapones de retención.

3. Conecte las entradas y la salida y verifique que no haya fugas.

4. !PRECAUCIÓN: En los casos en que N170-M3 o LFN170-M3

les suministra agua templada a válvulas de cierre automático y/o a

válvulas solenoides, ubique un amortiguador en la línea de descarga.

5. Antes de usar, verifique la temperatura de descarga. Reajuste de ser

necesario.

Ajuste de temperatura

1. Cierre la bomba de recirculación (si en el sistema la hay).

2. Abra suficientes accesorios como para que pase el mínimo flujo

requerido para la válvula.

3. Afloje la contratuerca. Gire el tornillo de ajuste de la temperatura

hacia la derecha para disminuir la temperatura de salida o hacia la

izquierda para aumentarla.

NOTA: Permita que la temperatura de la válvula se estabilice antes de

realizar el siguiente ajuste. Watts recomienda que se instale un indicador de temperatura en la línea templada y que se verifique por lo menos

mensualmente bajo condiciones de flujo normales. El indicador debe

instalarse por lo menos a 1,83m (6 pies) de la válvula de templado.

4. Cuando llegue a la temperatura deseada, ajuste la contratuerca.

Vuelva a encender la bomba de recirculación. Cierre los accesorios

abiertos.

SALIDA FRONTAL

ADVERTENCIA

!

Las válvulas maestras de templado de agua caliente Watts no

se pueden utilizar para templar la temperatura del agua en los

accesorios. Pueden ocurrir graves lesiones corporales (es decir,

escaldaduras o congelamiento) y/o la muerte dependiendo de

los cambios de presión del agua del sistema y/o los cambios de

temperatura del suministro de agua. En los accesorios deben

utilizarse dispositivos bajo el estándar ASSE 1016, 1069 ó 1070,

como por ejemplo las válvulas Watts Serie MMV, LFMMV, USG,

LFUSG, L111 o LFL111, para evitar posibles lesiones.

Las válvulas de templado de agua caliente de Watts están diseñadas

para ser instaladas cerca de la caldera o del calentador de agua. No

están diseñadas para compensar las fluctuaciones de presión del

sistema y no se deben usar cuando se necesiten dispositivos bajo el

estándar ASSE 1016, 1069 ó 1070. Estas válvulas de Watts nunca

se deben usar para proporcionar un servicio que evite escaldaduras o

congelamiento.

ADVERTENCIA

!

Necesidad de inspección periódica: Se recomienda la inspección

periódica por parte de un contratista matriculado. Las condiciones

corrosivas del agua, las temperaturas de más de 99 ºC (210 ºF)

y los ajustes o las reparaciones no autorizados pueden hacer

que la válvula deje de ser efectiva para el servicio para el que fue

diseñada. La inspección y limpieza regular de los componentes

internos de las válvulas y tapones de retención ayudan a asegurar

la máxima vida útil y el funcionamiento correcto del producto. La

frecuencia de limpieza depende de las condiciones del agua local.

LFN170-M3

IS-N170-M3

N170-M3 CSUT

SALIDA POSTERIOR SALIDA SUPERIOR

Page 6

Instalación básica

Al accesorio

Al modelo L111, LFL111,

MMV o LFMMV

Desde el suministro

de agua fría

Termómetro

Templado 60 °C (140 °F) *†

ATENCIÓN INSTALADORES: Después de

la instalación, por favor deje esta hoja de

instrucciones para información de los ocupantes.

Tornillo de ajuste

de la temperatura

Contratuerca

20,3 cm a 30,5 cm

† Válvula de

templado

Fría

N170-M3 o

LFN170-M3

Válvulas de

cierre (en ambas

entradas, fría y

caliente)

Requisitos mínimos de flujo

para mantener la temperatura fija

para las series N170-M3 o LFN170-M3

Tamaño de la válvula lpm

20 a 50 mm (¾ a 2 pulg.) 11 a 26,5 lpm (3 a 7 gpm)

Válvulas de

retención (en ambas

entradas, fría y

caliente)

82,2 ºC

(180 ºF)

Tanque de

almacenamiento

(8 pulg. a 12 pulg.)

Válvula T&P CSA/ASME

Drenaje

Válvula de descarga

de presión ASME

Calentador de

agua o caldera

de agua caliente

Fría

Agua

caliente

NOTA: Se recomienda una trampa de calor.

† En el punto de entrega deben utilizarse válvulas

que cumplan con el estándar ASSE 1016, 1069

ó 1070, como las Watts L111, LFL111, USG,

LFUSG, MMV, o LFMMV.

Especificaciones

• Presión máxima de funcionamiento ......................... 861 kPa (125 psig)

• Temperatura máxima del agua caliente ....................... 93 °C (200 °F)

• Temperatura mínima del suministro de agua caliente ............ 3 °C (5 °F) por encima del punto fijado*

• Rango de ajuste de la temperatura** ........................ 32 a 82 °C (90 a 180 °F)

• Rango de temperatura de la entrada de agua caliente ........... 42 a 82 °C (120 a 180 °F)

• Rango de temperatura de la entrada de agua fría .............. 4 a 27 °C (40 a 80 °F)

• Conformidad .......................................... ASSE 1017, IAPMO cUPC

• Estándares de aprobación ................................ ASSE 1017, CSA B125.3

* Con igual presión

** El límite bajo no puede ser menor que la temperatura del agua fría. Para un mejor funcionamiento, el agua caliente debe

estar por lo menos 3 °C (5 °F) por encima del punto fijado deseado.

Accionador

Agua

fría

2

Page 7

Capacidad

Modelo

¾ pulg. N170-M3

¾ pulg. LFN170-M3

1 pulg. N170-M3

1 pulg. LFN170-M3

1¼ pulg. N170-M3

1¼ pulg. LFN170-M3

1½ pulg. N170-M3

1½ pulg. LFN170-M3

2 pulg. N170-M3

2 pulg. LFN170-M3

Modelo

¾ pulg. N170-M3 CSUT

¾ pulg. LFN170-M3 CSUT

1 pulg. N170-M3 CSUT

1 pulg. LFN170-M3 CSUT

1¼ pulg. N170-M3 CSUT

1¼ pulg. LFN170-M3 CSUT

1½ pulg. N170-M3 CSUT

1½ pulg. LFN170-M3 CSUT

2 pulg. N170-M3 CSUT

2 pulg. LFN170-M3 CSUT

Capacidad de flujo con mezcla 50-50 sin tapones de retención

Caída de presión en la válvula

Entrada/salida

(NPT)

¾ x ¾ pulg.

1 x 1 pulg.

1¼ x 1¼ pulg.

1½ x 1½ pulg.

2 x 1½ x 2 pulg.

Flujo mín. a

ASSE 1017

3 gpm

11 lpm 57 lpm 79 lpm 114 lpm 140 lpm 170 lpm 197 lpm

4 gpm

15 lpm 87 lpm 121 lpm 170 lpm 212 lpm 257 lpm 299 lpm

4 gpm

15 lpm 121 lpm 170 lpm 238 lpm 288 lpm 360 lpm 416 lpm

5 gpm

19 lpm 134 lpm 185 lpm 265 lpm 326 lpm 397 lpm 458 lpm

7 gpm

26 lpm 159 lpm 223 lpm 314 lpm 386 lpm 473 lpm 545 lpm

Válvula de

control

6,70

10,13

14,16

15,65

18,63

34 kPa 69 kPa 138 kPa 207 kPa 310 kPa 414 kPa

(5 psi) (10 psi) (20 psi) (30 psi) (45 psi) (60 psi)

15 gpm 21 gpm 30 gpm 37 gpm 45 gpm 52 gpm

23 gpm 32 gpm 45 gpm 56 gpm 68 gpm 79 gpm

32 gpm 45 gpm 63 gpm 76 gpm 95 gpm 110 gpm

35 gpm 49 gpm 70 gpm 86 gpm 105 gpm 121 gpm

42 gpm 59 gpm 83 gpm 102 gpm 125 gpm 144 gpm

Capacidad de flujo con mezcla 50-50 con tapones de retención

Caída de presión en la válvula

Entrada/salida

(NPT)

¾ x ¾ pulg.

¾ x 1 pulg.

1¼ x 1¼ pulg.

1¼ x 1½ pulg.

1¼ x 2 pulg.

Flujo mín. a

ASSE 1017

3 gpm

11 lpm 53 lpm 76 lpm 106 lpm 129 lpm 159 lpm 182 lpm

4 gpm

15 lpm 79 lpm 114 lpm 163 lpm 197 lpm 242 lpm 280 lpm

4 gpm

15 lpm 114 lpm 159 lpm 227 lpm 280 lpm 341 lpm 394 lpm

5 gpm

19 lpm 125 lpm 128 lpm 254 lpm 310 lpm 379 lpm 435 lpm

7 gpm

26 lpm 151 lpm 216 lpm 303 lpm 371 lpm 454 lpm 526 lpm

Válvula de

control

6,26

9,54

13,42

14,90

17,89

34 kPa 69 kPa 138 kPa 207 kPa 310 kPa 414 kPa

(5 psi) (10 psi) (20 psi) (30 psi) (45 psi) (60 psi)

14 gpm 20 gpm 28 gpm 34 gpm 42 gpm 48 gpm

21 gpm 30 gpm 43 gpm 52 gpm 64 gpm 74 gpm

30 gpm 42 gpm 60 gpm 74 gpm 90 gpm 104 gpm

33 gpm 47 gpm 67 gpm 82 gpm 100 gpm 115 gpm

40 gpm 57 gpm 80 gpm 98 gpm 120 gpm 139 gpm

Series N170-M3 y LFN170-M3

Válvulas maestras de templado de agua caliente

Instrucciones de instalación para

un sistema de suministro de agua caliente recirculante con dos temperaturas

Sistema de recirculación 1

Serie

MMV

Termómetro

WATTS CSA/ASME

Válvula de temperatura

y liberación de presión

Tubo de drenaje

Calentador

de agua o

caldera

Válvula

esférica

Suministro de agua caliente

WATTS

WATTS Series

N170-M3† o

LFN170-M3

Válvulas

de

retención

WATTS

Suministro de agua templada

Al accesorio

A MMV, USG-B, L111

o LFL111 , luego a los

de agua fría

Suministro

Válvulas

de

retención

WATTS

Suministro de agua fría

accesorios

Termostato

para el agua

Circulador

Bucle de recirculación

3

Page 8

Series N170-M3 y LFN170-M3

Válvulas maestras de templado de agua caliente, continuación

Instrucciones de instalación para

un sistema de suministro de agua caliente recirculante con dos temperaturas

IMPORTANTE: La válvula debe instalarse

colocada como se muestra. (Consulte al dorso

para obtener los requerimientos mínimos de flujo

de lpm/gpm).

El bosquejo ilustra un sistema de suministro

de agua caliente de dos temperaturas (82 °C

y 60 °C [180 °F y 140 °F]) con una válvula

Series N170-M3 y LFN170-M3 y línea de

recirculación para mantener una temperatura

aproximada de los accesorios en la tubería

principal. Debido a que se requiere muy poca

agua caliente para mantener la temperatura

baja en la tubería principal (usualmente 60 °C

[140 °F]), por lo general se puede especificar

una capacidad relativamente pequeña del

recirculador. Los requerimientos mínimos de flujo

deben mantenerse entre 11 y 26,5 lpm (3 y 7

gpm). Por lo general, siempre que la pérdida de

calor de la tubería no sea demasiado grande (los

tramos largos de tubería de agua caliente deben

estar aislados) los circuladores estándar son

adecuados. Sin embargo, cada instalación debe

ser evaluada para los requisitos de recirculación

propios de lpm (o gpm) y resistencia de la

tubería.

NOTA: El termostato para el agua de control de

recirculación debe estar configurado por lo menos

entre 3 °C y 5,5 °C (5 °F a 10 °F) menos que la

temperatura configurada de la válvula de las series

N170-M3 o LFN170-M3, de lo contrario el recirculador funcionará en forma continua. El termostato

para el agua debe usarse para mantener el agua

en los accesorios a la temperatura deseada y para

eliminar el exceso de temperatura durante períodos sin flujo.

† En el punto de entrega deben utilizarse válvu-

las que cumplan con el estándar ASSE 1016,

1069 ó 1070, como las Watts L111, LFL111,

USG, LFUSG, MMV o LFMMV.

Sistema de recirculación 2

Sistema típico de dos temperaturas con línea de

recirculación de agua caliente de alta temperatura

A MMV, LFMMV, USG,

LFUSG, L111 o LFL111,

luego a los accesorios

Termómetro

Termostato

para el agua

Válvulas

Circulador

Regreso

de agua

caliente

Termostato

para el agua

Circulador

de

retención

WATTS

Suministro de agua fría

Watts

Serie

N170-M3†

Válvulas de retención

WATTS

Al accesorio

Suministro de agua fría

MMV

Agua caliente

de alta

temperatura

(140 °F)

Válvula

Agua templada, 60 °C

de

cierre

20,3 a 30,5 cm

(8 a 12 pulg.)†

Válvulas de retención

WATTS Serie 600

Nota: los calentadores de agua pueden ser encendidos

Trampa

de calor de

Calentador

de agua o

caldera

de forma directa o indirecta.

Válvula de temperatura

y liberación de presión

WATTS CSA/ASME

Tubo de

drenaje

Limitaciones: Watts Regulator Co. (la “Compañía”) garantiza cada producto contra defectos en el material y mano de obra bajo condiciones normales de uso por un periodo de un año a partir de la fecha del envío original.

En caso de que dichos defectos ocurran dentro del periodo de garantía, la Compañía, a su criterio, cambiará o reparará el producto sin costo alguno.

LA GARANTÍA AQUÍ ESTIPULADA SE OTORGA EN FORMA EXPRESA Y ES LA ÚNICA GARANTÍA OTORGADA POR LA COMPAÑÍA EN RELACIÓN CON EL PRODUCTO. LA COMPAÑÍA NO OTORGA NINGUNA OTRA

GARANTÍA, YA SEA EXPRESA O IMPLÍCITA. LA COMPAÑÍA POR LA PRESENTE RENUNCIA ESPECÍFICAMENTE A TODAS LAS DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS, INCLUYENDO PERO NO LIMITÁNDOSE A,

LAS GARANTÍAS IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN PARTICULAR.

El resarcimiento descrito en el primer párrafo de esta garantía constituirá el único y exclusivo resarcimiento por incumplimiento de garantía, y la Compañía no se hará responsable por daños fortuitos, especiales o derivados,

incluyendo sin limitación, la pérdida de ganancias o el costo de reparación o reemplazo de otra propiedad que resulte dañada por el mal funcionamiento de este producto, otros costos resultantes por mano de obra, retardos,

vandalismo, negligencia, contaminación ocasionada por materiales extraños, daños a causa de condiciones adversas del agua, sustancias químicas o cualquier otra circunstancia sobre la cual la Compañía no tenga control.

Esta garantía no tendrá validez en cualquier caso de abuso, uso indebido, aplicación incorrecta, instalación inadecuada o mantenimiento inadecuado o alteración del producto.

Algunos estados no permiten limitaciones en la duración de una garantía implícita y algunos estados no permiten la exclusión o limitación de daños fortuitos o derivados. Por lo tanto, es posible que las limitaciones anteriores

no sean aplicables en su caso. Esta garantía limitada le otorga derechos legales específicos. Usted podría tener también otros derechos que varían según el Estado en cuestión. Usted debe consultar las leyes estatales aplicables para determinar sus derechos. EN LA MEDIDA EN QUE SEA CONGRUENTE CON LAS LEYES ESTATALES APLICABLES, CUALQUIER GARANTÍA IMPLÍCITA QUE NO SEA RECHAZADA, INCLUYENDO LAS GARANTÍAS

IMPLÍCITAS DE APTITUD PARA LA COMERCIALIZACIÓN E IDONEIDAD PARA UN PROPÓSITO EN PARTICULAR, SE LIMITA EN SU DURACIÓN A UN AÑO A PARTIR DE LA FECHA DEL ENVÍO ORIGINAL.

Una compañía de Watts Water Technologies

EE.UU.: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

IS-N170-M3 1209 EDP# 2915044 © Watts, 2012

Page 9

INSTRUCTIONS EN FRANÇAIS

Série N170-M3 et LFN170-M3

Soupapes générales de mélange de l’eau chaude

AVERTISSEMENT

!

Vous êtes tenu de lire attentivement toutes les instructions d’installation

et tous les renseignements de sécurité du produit avant de commencer

l’installation de ce produit. LE NON-RESPECT DES INSTRUCTIONS

DE BONNE INSTALLATION ET D’ENTRETIEN APPROPRIÉES

PEUT PROVOQUER UN BRIS DU PRODUIT ET ENTRAÎNER DES

DOMMAGES AUX BIENS, DES BLESSURES OU LA MORT. Watts

décline toute responsabilité quant aux dommages pouvant résulter d’une

mauvaise installation ou d’une maintenance inadéquate.

Les codes du bâtiment ou de plomberie locaux peuvent commander

des modifications à l’information fournie. Vous êtes tenu de consulter les

codes du bâtiment ou de plomberie locaux avant l’installation. Si cette

information n’est pas compatible avec les codes du bâtiment ou de

plomberie locaux, les codes locaux doivent être suivis.

Installation

L’installation doit respecter les procédures acceptables de plomberie.

Purger à fond toutes les conduites avant l’installation. L’installateur est

responsable de l’installation et du réglage sur place, qui doivent être

faits en conformité avec les instructions d’installation.

1. Les soupapes doivent être posées aussi près que possible de l’arrivée d’eau du bâtiment, afin de prévenir/minimiser les fluctuations de

pression.

2. Le corps des soupapes peut être orienté dans divers sens (cf. cidessous). Si l’on utilise des valves d’arrêt anti-retour, veiller à bien

serrer les écrous union et les abouts.

3. Brancher les entrées et la sortie, puis vérifier qu’il n’y a pas de fuite.

4. !MISE EN GARDE : Prévoir un amortisseur de coups de bélier

sur la conduite de refoulement lorsque les soupapes N170-M3 ou

LFN170-M3 fournissent de l’eau mélangée à des robinets à fermeture

automatique ou à des robinets électromagnétiques.

5. Avant l’utilisation, vérifier la température de refoulement. Régler à

nouveau au besoin.

Réglage de la température

1. Arrêter la pompe de recirculation, le cas échéant.

2. Ouvrir suffisamment de robinets pour satisfaire au débit minimum de

la soupape.

3. Desserrer le contre-écrou. Tourner la vis de réglage de température

dans le sens horaire pour baisser la température de l’eau mélangée

de la sortie, dans le sens anti-horaire pour l’augmenter.

REMARQUE : Attendre que la température de la soupape se stabilise

avant de faire le réglage suivant. Watts recommande de poser une

jauge de température sur la conduite de mélange et de vérifier la température au moins une fois par mois pour les conditions normales de

débit. Cette jauge doit être placée à

1,83 m au moins (6 pi) de la soupape de mélange.

4. Resserrer le contre-écrou lorsque la température a été réglée.

Remettre en marche la pompe de recirculation. Fermer les robinets

ouverts.

ORIFICE DE

SORTIE AVANT

AVERTISSEMENT

!

Les soupapes de mélange de l’eau chaude de Watts ne peuvent

pas être utilisées pour régler la température de l’eau au niveau des

robinets. Des changements de pression ou de température de l’eau

du circuit peuvent causer des blessures graves (brûlures ou hypothermie), voire la mort. Les pièces homologuées ASSE 1016, 1069

ou 1070, comme les soupapes Watts de série MMV, LFMMV, USG,

LFUSG, L111 ou LFL111, doivent être utilisées aux robinets pour

réduire les risques de blessure.

Les soupapes de mélange de l’eau chaude Watts sont conçues pour être

montées à proximité ou au niveau de la chaudière ou du chauffe-eau.

Elles ne sont pas conçues pour compenser les fluctuations de pression

du circuit et ne doivent pas remplacer des dispositifs conformes aux normes ASSE 1016, 1069 ou 1070, là où ils sont requis. Ne pas utiliser ces

soupapes Watts pour se prémunir contre les brûlures ou l’hypothermie.

AVERTISSEMENT

!

Inspection périodique : Une inspection périodique par un entrepreneur agréé est recommandée. Certaines conditions, comme de

l’eau corrosive, une température d’eau supérieure à 99 °C (210 °F)

ou encore des réglages ou des réparations non autorisés pourraient

rendre la soupape inefficace pour l’usage prévu. Une inspection et

un nettoyage réguliers des composants internes des soupapes et

des valves d’arrêt anti-retour favorisent une durée de vie utile maximum et un fonctionnement efficace des produits. La fréquence du

nettoyage dépend des propriétés de l’eau de la localité.

LFN170-M3

ORIFICE DE

SORTIE ARRIÈRE

IS-N170-M3

N170-M3 CSUT

ORIFICE DE

SORTIE SUPÉRIEUR

Page 10

Installation de base

Vers robinet

De l’arrivée d’eau froide

Vers Modèle L111,

LFL111, MMV ou LFMMV

Thermomètre

Mélange, 60 °C (140 °F) *†

ATTENTION INSTALLATEUR : Après

l’installation, veuillez laisser cette

feuille d’instructions à l’occupant.

Vis de réglage de

la température

Contre-écrou

20,3 cm à 30,5 cm

† Soupape

de mélange

N170-M3 ou

LFN170-M3

Eau froide

Robinets d’arrêt

(sur arrivées

d’eau chaude et

d’eau froide)

Diam. de la soupape gpm

20

à

Clapets de non-retour

(sur arrivées d’eau

chaude et d’eau

Débits minimum des soupapes

de Série N170-M3 ou LFN170-M3

pour maintenir la température réglée

50 mm (¾ po à 2 po)

Réservoir

froide)

11 à 26,5 lpm (3 à 7)

82 °C

(180 °F)

8 po à 12 po

Soupape de sûreté T&P CSA/ASME

Soupape de

décharge ASME

Tuyau

d’évacuation

Chauffe-eau

ou chaudière

Eau froide

Eau

chaude

REMARQUE : Piège à chaleur recommandé.

† Les soupapes homologuées ASSE, normes

1016, 1069 ou 1070, comme les Watts L111,

LFL111, USG, LFUSG, MMV ou LFMMV,

doivent être utilisées sur le lieu de livraison.

Caractéristiques techniques

• Pression de service maximum ..............................861 kPa (125 psig)

• Température maximum de l’eau chaude ......................93 °C (200 °F)

• Température minimum de l’alimentation en eau chaude ..........3 °C (5 °F) au-dessus du point de consigne*

• Plage de réglage de température** .......................... 32 à 82 °C (90 à 180 °F)

• Plage de température de l’entrée d’eau chaude ................42 à 82 °C (120 à 180 °F)

• Plage de température de l’entrée d’eau froide .................. 4 à 27 °C (40 à 80 °F)

• Homologation ..........................................ASSE 1017, IAPMO cUPC

• Normes approuvées .....................................ASSE 1017, CSA B125.3

* Avec pression égale

** La limite inférieure ne peut être en dessous de la température de l’eau froide. Pour un fonctionnement optimal, l’eau

chaude doit être au moins 3 °C (5 °F) au-dessus du point de consigne souhaité.

Actionneur

Eau

froide

2

Page 11

Écoulement

Modèle

¾ po N170-M3

¾ po LFN170-M3

1 po N170-M3

1 po LFN170-M3

1¼ po N170-M3

1¼ po LFN170-M3

1½ po N170-M3

1½ po LFN170-M3

2 po N170-M3

2 po LFN170-M3

Modèle

¾ po N170-M3 CSUT

¾ po LFN170-M3 CSUT

1 po N170-M3 CSUT

1 po LFN170-M3 CSUT

1¼ po N170-M3 CSUT

1¼ po LFN170-M3 CSUT

1½ po N170-M3 CSUT

1½ po LFN170-M3 CSUT

2 po N170-M3 CSUT

2 po LFN170-M3 CSUT

Pouvoir d’écoulement, mélange 50-50 moins valves d’arrêt anti-retour

Chute de pression dans la soupape

Entrée/Sortie

(NPT)

¾ x ¾ po

1 x 1 po

1¼ x 1¼ po

1½ x 1½ po

2 x 1½ x 2 po

Débit min. vers

ASSE 1017

3 gpm

11 lpm 57 lpm 79 lpm 114 lpm 140 lpm 170 lpm 197 lpm

4 gpm

15 lpm 87 lpm 121 lpm 170 lpm 212 lpm 257 lpm 299 lpm

4 gpm

15 lpm 121 lpm 170 lpm 238 lpm 288 lpm 360 lpm 416 lpm

5 gpm

19 lpm 134 lpm 185 lpm 265 lpm 326 lpm 397 lpm 458 lpm

7 gpm

26 lpm 159 lpm 223 lpm 314 lpm 386 lpm 473 lpm 545 lpm

Coefficient

Cv

6,70

10,13

14,16

15,65

18,63

5psi 10psi 20psi 30psi 45psi 60psi

(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa)

15 gpm 21 gpm 30 gpm 37 gpm 45 gpm 52 gpm

23 gpm 32 gpm 45 gpm 56 gpm 68 gpm 79 gpm

32 gpm 45 gpm 63 gpm 76 gpm 95 gpm 110 gpm

35 gpm 49 gpm 70 gpm 86 gpm 105 gpm 121 gpm

42 gpm 59 gpm 83 gpm 102 gpm 125 gpm 144 gpm

Pouvoir d’écoulement, mélange 50-50 avec valves d’arrêt anti-retour

Chute de pression dans la soupape

Entrée/Sortie

(NPT)

¾ x ¾ po

¾ x 1 po

1¼ x 1¼ po

1¼ x 1½ po

1¼ x 2 po

Débit min. vers

ASSE 1017

3 gpm

11 lpm 53 lpm 76 lpm 106 lpm 129 lpm 159 lpm 182 lpm

4 gpm

15 lpm 79 lpm 114 lpm 163 lpm 197 lpm 242 lpm 280 lpm

4 gpm

15 lpm 114 lpm 159 lpm 227 lpm 280 lpm 341 lpm 394 lpm

5 gpm

19 lpm 125 lpm 128 lpm 254 lpm 310 lpm 379 lpm 435 lpm

7 gpm

26 lpm 151 lpm 216 lpm 303 lpm 371 lpm 454 lpm 526 lpm

Coefficient

Cv

6,26

9,54

13,42

14,90

17,89

5psi 10psi 20psi 30psi 45psi 60psi

(34 kPa) (69 kPa) (138 kPa) (207 kPa) (310 kPa) (414 kPa)

14 gpm 20 gpm 28 gpm 34 gpm 42 gpm 48 gpm

21 gpm 30 gpm 43 gpm 52 gpm 64 gpm 74 gpm

30 gpm 42 gpm 60 gpm 74 gpm 90 gpm 104 gpm

33 gpm 47 gpm 67 gpm 82 gpm 100 gpm 115 gpm

40 gpm 57 gpm 80 gpm 98 gpm 120 gpm 139 gpm

Série N170-M3 et LFN170-M3

Soupapes générales de mélange de l’eau chaude

Instructions d’installation pour

un circuit d’eau chaude à deux températures avec recirculation

Circuit de recirculation 1

Thermomètre

CSA/ASME de WATTS

Soupape de sûreté

Température et Pression

Tuyau

d’évacuation

Chauffe-eau

ou chaudière

Robinet

à tournant

sphéri-

Alimentation d’eau chaude

que de

WATTS

Série N170-M3†

ou LFN170-M3 de

WATTS

Alimentation d’eau mélangée

Série

MMV

Clapets

de non-

retour de

Watts

Vers robinet

Alimentation

d’eau froide

Vers MMV, USG-B, L111

ou LFL111, puis vers

Alimentation

d’eau froide

Clapets

de nonretour de

Watts

robinets

Aquastat

Pompe de

recirculation

Boucle de recirculation

3

Page 12

Série N170-M3 et LFN170-M3

Soupapes générales de mélange de l’eau chaude, Suite

Instructions d’installation pour

un circuit d’eau chaude à deux températures avec recirculation

IMPORTANT : La soupape doit être fixée

comme sur l’illustration. (Voir au verso pour

connaître le débit gpm minimum recommandé.)

Le schéma montre un circuit d’eau chaude

à deux températures (82 et 60 °C [180°F

et 140 °F]), équipé d’une soupape de séries

N170-M3 et LFN170-M3 et d’une conduite de

recirculation pour maintenir des températures de

robinets approximatives dans les canalisations.

Parce qu’il suffit de très peu d’eau chaude

pour maintenir la basse température dans les

canalisations (en général, 60 °C [140 °F]), une

pompe de recirculation d’assez faible capacité est

normalement prescrite. Le débit minimum doit être

maintenu entre 3 et 7 gpm (11 et 26,5 lpm). Dans

la mesure où la perte de chaleur de la tuyauterie

n’est pas trop élevée (les longs tuyaux d’eau

chaude doivent être isolés), les pompes standard

de recirculation répondent d’ordinaire aux besoins.

Néanmoins, chaque installation doit être évaluée

quant à ses propres besoins (recirculation [débit

gpm] et résistance des tuyaux).

REMARQUE : L’aquastat de recirculation doit

être réglé au moins 3 à 5,5 °C (5 à 10°F) plus

bas que le réglage de température de la soupape

de Série N170-M3 ou LFN170-M3. Sinon, la

pompe fonctionnera en permanence. L’aquastat

doit être utilisé pour maintenir l’eau aux robinets

à la température souhaitée et pour contrôler

celle-ci lorsque la soupape reste en repos.

† Les soupapes homologuées ASSE, normes

1016, 1069 ou 1070, comme les soupapes

Watts L111, LFL111, USG, LFUSG, MMV ou

LFMMV, doivent être utilisées sur le lieu de

livraison

Circuit de recirculation 2

Circuit typique à deux températures, avec conduite

de recirculation d’eau chaude à haute température

Vers MMV, LFMMV, USG,

LFUSG, L111 ou LFL111,

puis vers robinets

Thermomètre

Aquastat

Pompe de

recirculation

Conduite

de retour

de l’eau

chaude

Aquastat

Pompe de

recirculation

Clapets de

non-retour

de Watts

Alimentation d’eau froide

Série

N170-M3

de Watts†

Clapets de non-retour

de Watts

Vers robinets

Alimentation d’eau froide

MMV

Eau chaude à

température

élevée

(140 ºF)

Eau mélangée, 60 °C

Robinet

d’arrêt

Piège à chaleur

8 po – 12 po†

Clapets de non-retour

Watts de série 600

Remarque : L’allumage des chauffe-eau

Soupape de sûreté

Température et Pression

CSA/ASME de Watts

Chauffe-eau

ou chaudière

peut être direct ou indirect.

d’évacuation

Tuyau

Garantie limitée : Watts Regulator Co. (la « Société ») garantit chaque produit contre tout défaut de matériau et de fabrication lors d’une utilisation normale, et ce pour une période de un (1) an à

partir de la date de l’expédition d’origine. Si une telle défaillance devait se produire au cours de la période sous garantie, la Société aura à sa discrétion l’alternative suivante : le remplacement ou

bien la remise en état du produit, sans frais pour le demandeur.

LA PRÉSENTE GARANTIE EXPRESSE EST LA SEULE ET UNIQUE GARANTIE, RELATIVE AU PRODUIT, FOURNIE PAR LA SOCIÉTÉ. LA SOCIÉTÉ NE FORMULE AUCUNE AUTRE GARANTIE, EXPRESSE OU

IMPLICITE. LA SOCIÉTÉ REJETTE AUSSI FORMELLEMENT PAR LA PRÉSENTE TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, Y COMPRIS (SANS S’Y LIMITER) LES GARANTIES IMPLICITES DE

QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE PARTICULIER.

Le dédommagement précisé dans le premier paragraphe de cette garantie constitue la seule et unique alternative en cas de service demandé sous cette garantie. La Société ne pourra être tenue responsable de dommages spéciaux ou indirects, incluant, sans s’y limiter : pertes de profit, coûts de réparation ou de remplacement des autres biens ayant été endommagés si ce produit ne fonctionne pas

correctement, autres coûts afférents aux frais de main d’œuvre, de retards, de vandalisme, de négligence, d’engorgement causés par des corps étrangers, dommages causés par des propriétés de l’eau

défavorables, des produits chimiques, ou toute autre circonstance indépendante de la volonté de la Société. Cette garantie est nulle et non avenue en cas de mésusage du produit, d’une installation ou

d’un entretien inappropriés, ou de modification du produit.

Certaines juridictions ne permettent pas les limitations de durée de la garantie implicite, tandis que d’autres ne permettent pas l’exclusion ou la limitation des dommages indirects. En conséquence,

ces limitations pourraient ne pas s’appliquer à votre cas. Cette garantie limitée vous confère des droits spécifiques, reconnus par la loi ; vous pourriez également avoir d’autres droits, lesquels varient

selon la loi en vigueur. Vous devez donc prendre connaissance des lois applicables pour votre cas particulier. LA DURÉE DE TOUTE GARANTIE IMPLICITE PRÉVUE PAR LA LOI EN APPLICATION ET

DEVANT DONC ÊTRE ASSUMÉE, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE PARTICULIER, SERA LIMITÉE À UN AN À PARTIR DE LA

DATE DE L’EXPÉDITION D’ORIGINE.

Une entreprise de Watts Water Technologies

É.-U. : Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada : Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

IS-N170-M3 1209 EDP# 2915044 © Watts, 2012

Loading...

Loading...