Page 1

Instructions

Watts Vacuum

Series LF70A

Hot Water Extender Tempering Valves

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

!

WARNING

Watts Hot Water Master Tempering Valves cannot be used for

tempering water temperature at fixtures. Severe bodily injury (i.e.,

scalding or chilling) and/or death may result depending upon system

water pressure changes and/or supply water temperature changes.

ASSE standard 1016, 1069 or 1070 listed devices such as Watts

Series LFL111, LFMMV and LFUSG and valves should be used at fixtures to prevent possible injury.

The Watts Hot Water Tempering Valves are designed to be installed at

or near the boiler or water heater. They are not designed to compensate

for system pressure fluctuations and should not be used where ASSE

standard 1016, 1069 or 1070 devices are required. These Watts valves

should never be used to provide “anti-scald” or “anti-chill” service.

NOTICE

Inquire with governing authorities for local installation requirements

NOTICE

BE SURE TO REMOVE THERMOSTATIC ASSEMBLY from valve before

sweating connections, otherwise it will become damaged.

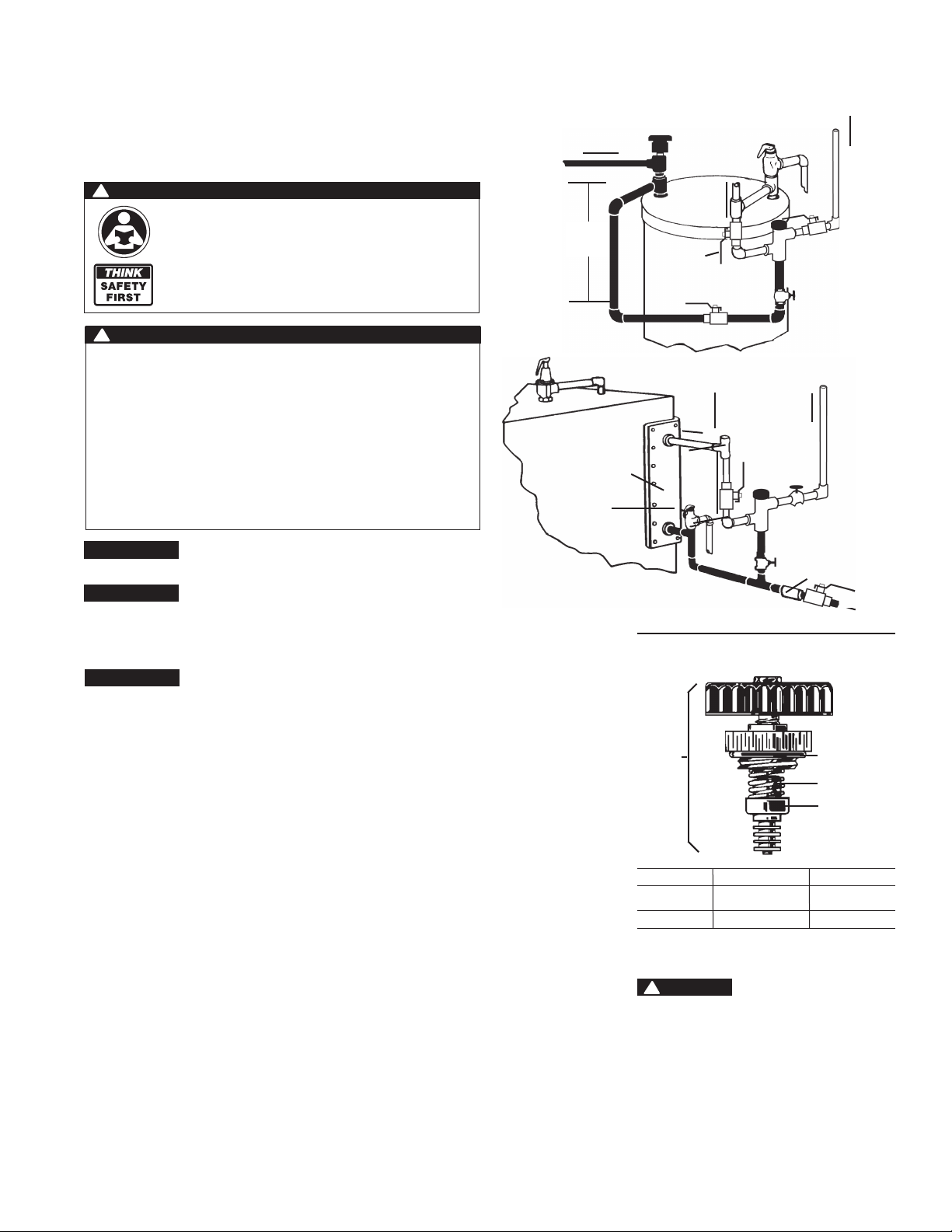

*A valve should be installed in cold water line to hot water extender tempering valve, as shown, to

help compensate for pressure drop through heater.

NOTICE

† Valves listed to ASSE Standard 1016, 1069 or 1070 such as Watts Series LFMMV or LFUSG-B

should be used at xture to prevent possible injury.

Minimum Flow Requirements to Maintain Set Temperature: 2 gpm for size 1⁄2" and 3⁄4"

Installation Instructions

Valve should be installed by a licensed contractor.

1. Close both the hot and cold water shutoff valves upstream of the valve.

2. Bleed pressure from the system.

3. Remove the thermostat and bonnet assembly (A), which is hand-tight, from body and

install valve body as illustrated in diagram. Valve must be trapped 8" to 12" as shown.

4. Reinsert Thermostat and Bonnet assembly in body and tighten knurled portion of bonnet

securely with pliers or channel locks.

5. START UP REQUIREMENTS: Open cold water then hot water shutoff valves. The cold

water supply line to Series LF70A valve should always be opened first to prevent possible

thermostat damage.

Adjustment

The Series LF70A features a new adjustment means which permits you to “dial” a temperature

quickly and conveniently. To increase or decrease the water temperature, simply turn the adjusting cap as indicated by the arrow. The adjustment temperature range is 120°F to 160°F and will

vary depending on system water pressure changes and water temperature fluctuations.

Model LFL70A: For lower tempered water or below 130°F, use low temperature Model LFL70A which provides a temperature range between 100°F-130°F.

NOTE: Model LFL70A (low temperature model) may be used in a radiant heat application.

Other models of this valve must not be used in radiant heat applications. When installing an

LFL70A valve in a radiant heat application, the components of the radiant heat system must be

of materials with a construction of withstanding the high limit output temperatures of the heating

boiler. If you are uncertain as to the products adaptability for your application, please consult an

authorized representative before installing or using the product.

Relief Valve

Cold

8"

to 12"

Watts LF174A

Hot Water

Boiler

Tankless

Watts Pressure

Relief Valve

Heater

IS-70A

Watts

T&P Relief Valve

▼

▼

Hot to

Appliances

Watts

Ball Valve

Water Heater

Hot

8"

to

12"

▼

▼

▼

▼

Hot to

Appliances

Watts

LF70A

†

Watts

▼

†

Drain

Tempered

▼

Tempered

LF70A

*

Watts Check Valve

▼

Cold

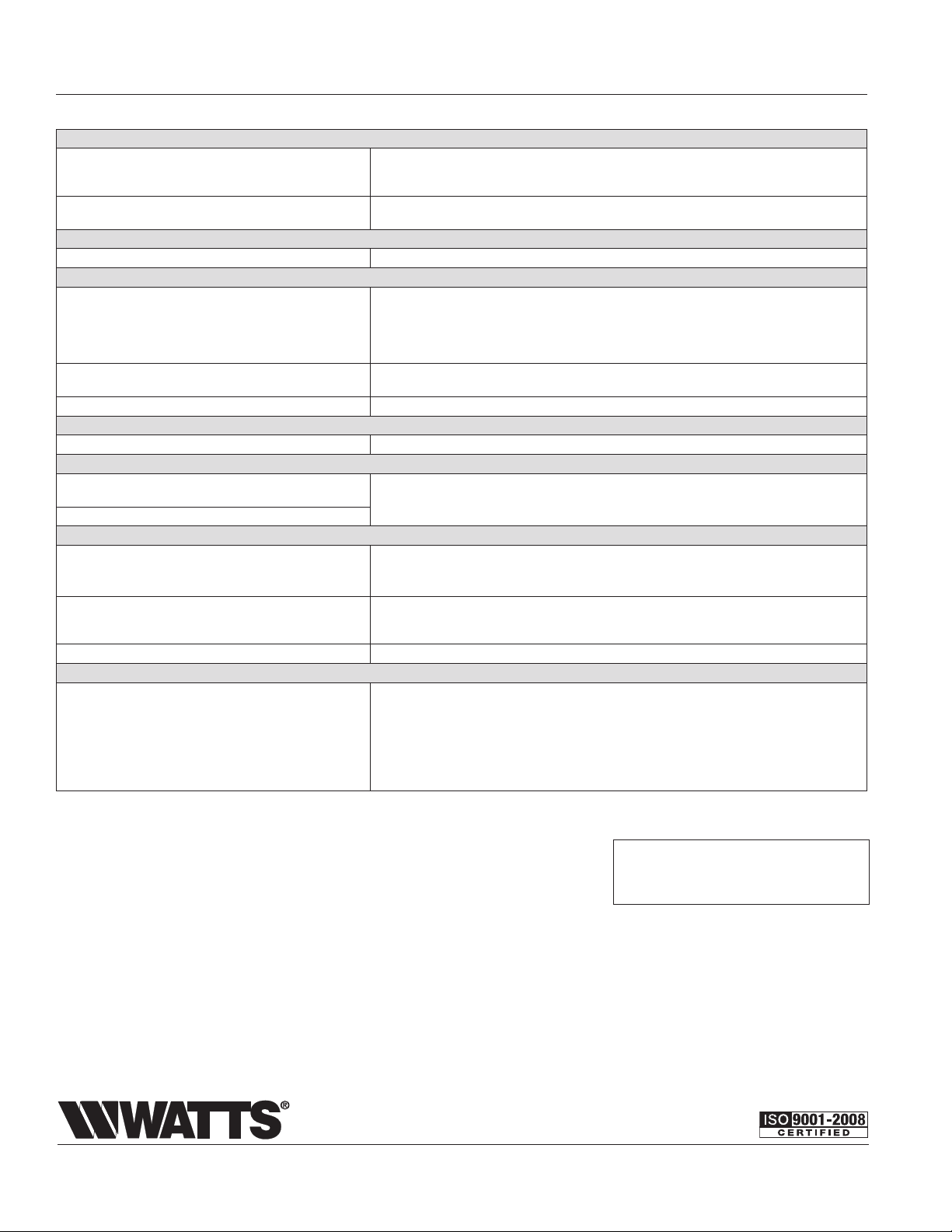

Thermostat and Bonnet Assembly

(A)

Repair Kit Model Ordering Code

LF70ARK ts LF70A, LF70AT 0869100

LFL70ARK LFL70A, LFL70AT 0869130

Includes O-ring and (B), Spring (C) and Thermostat

Assembly (D)

!

CAUTION

Need for Periodic Inspection

Periodic inspection by a licensed contractor is recommended. Corrosive water conditions, temperatures over 210°F, unauthorized adjustments or repair could render the

valve ineffective for service intended. Regular cleaning and checking of thermostat assembly (A) helps to assure maximum life and

proper product function. Frequency of cleaning depends upon local water conditions.

†See Warning.

(B)

(C)

(D)

Page 2

Series LF70A Troubleshooting Guide

Problem & Cause Answer

A. Fluctuating or erratic hot water temperature at xture.

A.1 Heavy draws of either cold or hot water elsewhere in

the system, such as clothes washer or dishwasher.

A.2 Unbalanced pressures. A.2 Install balancing or throttling valves (shutoff valves) in hot and cold legs to hot water

B. Hot water backing up into cold water line.

B. Hot water pressure overriding cold pressure. B. Install check valve in cold water leg to hot water temperature control valve.

C. Cannot adjust water temperature to desired temperature.

C.1 Unequal pressures. C.1 A balancing or throttling valve must be installed in the cold water leg to the hot water

C.2 Hot or cold temperature differential. C.2 Check water heater controls to verify that the water temperature is the same as the

C.3 Valve undersized. C.3 Check gpm ow required versus gpm ow capacity of valve.

D.

High pressure drop through hot water temperature control valve.

D. Valve undersized. D. Install larger hot water temperature control valve.

E. Insufcient hot water during peak demand

E.1 Valve undersized. E.1 Check gpm ow required during peak demand period and size hot water temperature

E.2 Heater or capacity insufcient for demand.

F. Frequent failure of thermostatic element.

F.1

Thermostatic element exposed to extremely high

temperature.

F.2

Corrosive water conditions. (Buildup of mineral

deposits)

F.3 Electrolysis (pitting deterioration, etc.) F.3 Electrically ground the piping system or install dielectric unions.

G. All hot or cold water ows at hot xture.

G.1 This problem will require considerable trouble-

shooting.

A.1 See warning on reverse side. Hot water temperature control valves cannot compensate

for this condition. Check valves in hot and cold legs to hot water temperature control valve

would help but not cure the problem.

extender tempering valve and adjust accordingly for demand.

temperature control valve to throttle or restrict the pressure. In most installations, the cold

water supply line feeds both the hot water temperature control valve and the water heater

or tankless heater. To compen

wa

ter to the hot water temperature control valve must be throttled or reduced.

sate for the pressure drop through the heater, the cold

heater thermostat setting.

control valve accordingly.

F.1 Check heater thermostat setting.

F.1a Hot water temperature control valve must be trapped at least 8” to 12” as per installa-

tion instructions. Install check valves as recommended.

F.2 Frequent cleaning of thermostat element and plunger would tend to prolong the life of

the element. A small coating of FDA approved silicone lubricant in the piston area of the

element would also help.

G.1 Verify that complete installation instructions were followed:

A. Is valve properly trapped?

2. Check to see if thermostatic element has failed.

3. Check to see if temperature control on water heater is set at desired

temperature.

4. Check to see if minimum ow requirements for valve size are met. Minimum ow

requirements for LF70A series valves is 2 gpm.

ATTENTION INSTALLER: After installation please leave this instruction sheet for

occupant’s information.

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

IS-70A 1325 EDP# 1910210 © 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information: www.watts.com/prop65

Loading...

Loading...