Page 1

Series LFB6800

Installation, Operation and Repair Manual

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

Installation

I. Threaded-end (LFB6800):

1. The above listed standard valves are bidirectional and as

such, can be installed for flow in either direction.

2. When installing threaded-end valves, be sure that the

threads on the mating pipe are free from excessive grit, dirt

or burrs. Take care to assure that any pipe sealants used

are not so excessively applied to the pipe threads that the

valve cavity becomes fouled.

II. Sweat-end (LFB6801): To protect seats and seals from high

temperatures encountered while soldering, these valves must

be disassembled prior to soldering.

LFB6801 Series

1. Remove body center section from adapters by removing

one body bolt and loosening others.

2. Solder end adapters onto copper tubing system, orienting

adapters to required valve position. One of the two adapter/

tubing assemblies must allow rotation to match alternate

adapter bolt pattern.

3. After soldering and cool-down, install body assembly using

new body seals provided and re-torque bolts as follows:

(Use sequence shown on back page).

Series LFB6800

Valve Size Body Bolt Torque (in.-lbs.)

1

⁄4", 3⁄8", 1⁄2" 30 ± 5

3

1" 200

11⁄4" 200

11⁄2" 300

2" 400

IS-B6800

TABLE 1

⁄4" 100

Valve Operation

1. All series Watts ball valves feature 1⁄4 turn operation. Turning

the valve handle 90° clockwise will fully close the valve while

a 90° counterclockwise rotation will fully open the valve. The

valve handle also serves as a ball orifice position indicator.

When the valve handle is parallel to the pipe, the valve is open,

when perpendicular to the pipe, the valve is closed.

2. All series Watts ball valves are designed to provide optimum

bubble-tight performance when properly selected in accordance with the valve’s pressure/temperature rating, unless

otherwise noted in seat material selection chart.

3. To provide the longest possible service-life, a hand-operated

ball valve should be operated in either it’s fully open or fully

closed position. If an intermediate operating position is to be

utilized, consult your Watts agent. Excessive pressure drops

could adversely affect service life of the valve.

4. All Watts valves are factory assembled using an F.D.A. approved lubricant. Valves can be ordered from the factory

without lubricant. The standard factory lubricant can be

removed, if objectionable, by disassembling the valve and

solvent washing.

5. The below listed torques are the normal expected maximum

break-away torques. These values represent the force required to begin to open the valve. Typically, this break-away

value is the maximum torque requirement of the valve during a

closed to open, opened to closed cycle. Bear in mind that these

values have been confirmed by laboratory testing of each valve

while pressurized with water to the valve’s maximum pressure

rating. Certain highly viscous or abrasive services could cause

an increase in torque requirements.

Maintenance

During it’s service life, the only maintenance that may be required

by your Watts ball valve should be periodic stem seal adjustment. If leakage at the stem is noted, simply tighten the valve

stem gland nut until leakage subsides. It is impractical to predict

frequency of stem adjustment as it is influenced by such factors

as frequency of cycling and service media.

IMPORTANT

As is the case with any valve on the market today, it is important

that stem leaks do not go unattended. Lack of maintenance of

stem leakage could cause a premature need to replace stem

seals.

NOTICE

If operating temperature of system is substantially lower or

higher than 80°F (27°C), initial stem packing adjustment may be

required to prevent leakage.

Page 2

Rebuilding

!

WARNING

Most standard bidirectional ball valves available on the market today, regardless of manufacturer, can trap fluids in the valve cavity

when closed. If your Watts ball valve has been used to conduct

hazardous media, the following steps should be taken prior to

removal from line and disassembly.

1. Relieve line pressure.

2. Place the valve in a half-open position and flush the line to

remove hazardous material from the cavity. The valve can now

be removed from the line.

NOTICE

Always advise maintenance personnel when they are maintaining

or rebuilding a valve that has been conducting hazardous material. Proper protective clothing and eye protection should always

be utilized.

3. To replace seats and seals:

a. For the LFB6800 series, remove 1 top bolt, loosen other 3

body bolts, slide body center section out.

b. Once the center section has been removed, close the valve

and remove the seats, ball and body seals.

NOTICE

If condition of the ball surface allows for its reuse, be careful

to handle and store the ball in such a manner so as to

prevent subsequent damage to the ball’s critical surfaces.

c. Remove valve handle nut, handle, gland packing nut and

remove the valve stem through the body cavity.

d. Remove the stem thrust-washer from the stem or the valve

body cavity, if the washer did not come free from the cavity

with the stem. Remove stem seal.

e. Examine all metallic sealing surfaces such as ball, stem

shank and pipe-ends for damage such as scratches or

nicks. In some cases, slight scratches across the sealing

surface of pipe ends can be removed using a light emery

cloth. If pipe end damage is excessive, the valve must be

replaced. If the ball or stem is excessively damaged, ball

and stem kits can be ordered. Consult your Watts agent.

f. Having assured that all critical surfaces have been inspected,

cleaned and/or replaced, reassembly can begin.

g. Place new thrust-washer on stem and install stem through

body cavity. Place new stem seal in position. Reinstall

gland nut and tighten to the torque listed on Table 2.

h. Lightly lubricate seats and body seals using a lubricant that

is compatible for the service media.

I. Reinstall ball, seats and body seals.

j. Reinstall center section between pipe-ends and retighten

bolts in torquing sequence shown to the values listed on

Table 1.

k. Reinstall handle and secure with handle nut.

TABLE 2

Packing Nut Torques

Series LFB6800

Valve Size Torque (in.-lbs.)

1

⁄4", 3⁄8", 1⁄2" 25-60

1" 180-300

11⁄4" 200-300

2" 300-350

3

⁄4" 30-60

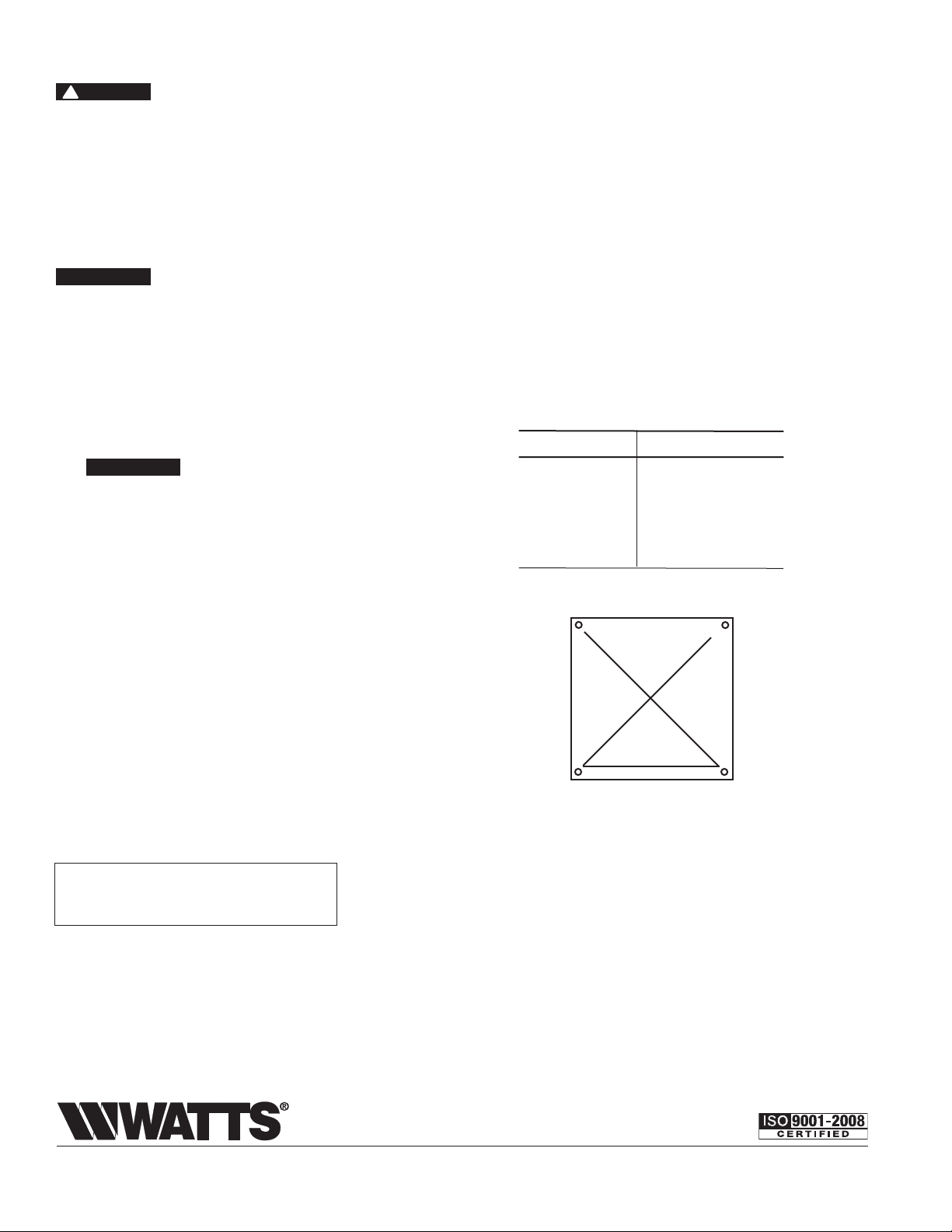

Torque Sequence

1

3

4

▼

2

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or other

reproductive harm.

For more information: www.watts.com/prop65

A Watts Water Technologies Company

IS-B6800 1323 EDP# 1910641 © 2013 Watts

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment. In the event of such defects within

the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH

RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY

HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of

warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without

limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from

adverse water conditions, chemical, or any other circumstances over which the Company has no control. This warranty shall

be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or

limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty

gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state

laws to determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES

THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.wattscanada.ca

Loading...

Loading...