Page 1

For Health Hazard Applications

ES-LF957RPDA

Job Name

Job Location

Engineer

Approval

LEAD FREE

–––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

*

Series LF957RPDA,

LF957NRPDA,

LF957ZRPDA

Reduced Pressure Detector

Assemblies

Sizes: 21⁄2" – 10"

Series LF957RPDA, LF957NRPDA, LF957ZRPDA Reduced

Pressure Detector Assemblies provide protection to the potable

water system from contamination in accordance with national

plumbing codes. The LF957RPDA, LF957NRPDA, LF957ZRPDA are normally used in health hazard applications to protect

against backsiphonage and backpressure. The Watts LF957RPDA, LF957NRPDA, LF957ZRPDA are used to monitor unauthorized use of water from the fire protection system. They feature

Lead Free* construction to comply with Lead Free* installation

requirements.

Features

• Lead Free* construction

• Extremely compact design

• 70% lighter than traditional designs

• 304 (Schedule 40) stainless steel housing & sleeve

• Groove fittings allow integral pipeline adjustment

• Patented torsion spring check provides lowest pressure loss

• Unmatched ease of serviceability

• Replaceable check disc rubber

• Available with grooved butterfly valve shutoffs

• Bottom mounted cast stainless steel relief valve

• Metered bypass to detect leakage or theft of water from the

fire sprinkler system

Contractor

Approval

Contractor’s P.O. No.

Representative

––––––––––––––––––––––––––––––––––––––––––––

–––––––––––––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––

––––––––––––––––––––––––––––––––––––––––

LF957RPDA-OSY

Specifications

The Lead Free* Reduced Pressure Detector Assembly shall

consist of two independent torsion spring check modules, a

differential pressure relief valve located between and below the

two modules, two drip tight shutoff valves, and required torsion

spring check modules and relief valve shall be contained within a

sleeve accessible single housing constructed from 304 (Sch 40)

stainless steel pipe with groove end connections. Torsion spring

checks shall have reversible elastomer discs and in operation

produce drip tight closure against reverse flow caused by backpressure or backsiphonage. The Lead Free* Reduced Pressure

Detector Assemblies shall comply with state codes and standards, where applicable, requiring reduced lead content. The

bypass assembly consists of a meter registering either gallon or

cubic measurements, a double check assembly and required

test cocks. Assembly shall be Watts Series LF957RPDA, LF957NRPDA, LF957ZRPDA.

*The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Page 2

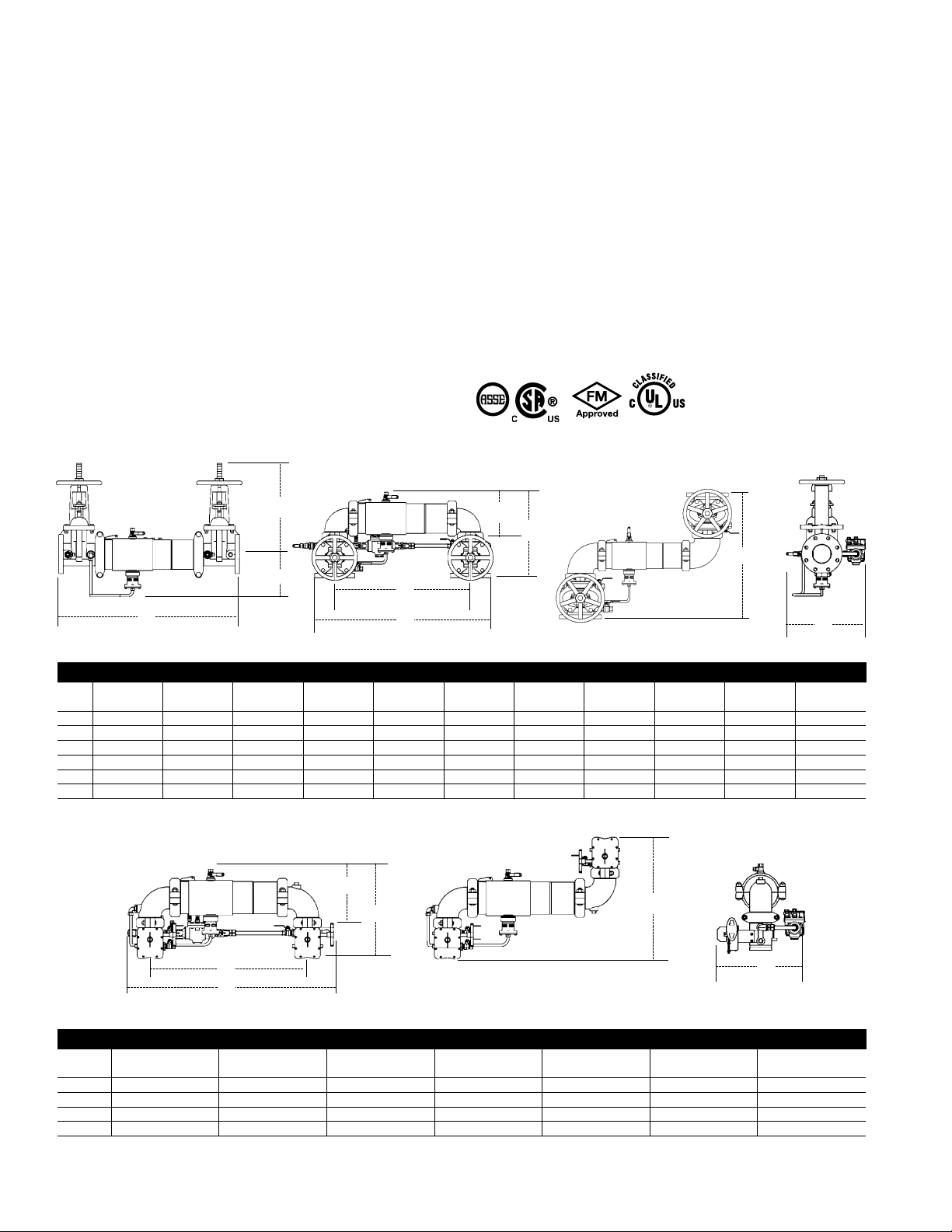

Available Models

Suffix:

OSY – UL/FM outside stem and yoke, resilient

seated gate valves

BFG – UL/FM grooved gear operated butterfly valves

with tamper switch

*OSY FxG – Flanged inlet gate connection and grooved outlet

gate connection

*OSY GxF – Grooved inlet gate connection and flanged outlet

gate connection

*OSY GxG – Grooved inlet gate connection and grooved outlet

gate connection

Available with grooved NRS gate valves - consult factory†

Post indicator plate and operating nut available - consult factory†

†Consult factory for dimensions

Materials

Housing & Sleeve: 304 (Schedule 40) Stainless Steel

Elastomers: EPDM, Silicone and Buna ‘N’

Torsion Spring Checks: Noryl

®

, Stainless Steel

Check Discs: Reversible Silicone or EPDM

Test Cocks: Lead Free Silicon Copper Alloy Body Nickel Plated

(Only Center TC)

Pins & Fasteners: 300 Series Stainless Steel

Springs: Stainless Steel

Pressure — Temperature

Temperature Range: 33°F – 110°F (0.5°C – 43°C)

Maximum Working Pressure: 175psi (12.1 bar)

Approvals

Dimensions — Weight

A

C (open)

D

H

G

1047 B64.4

J

I

(BFG & OSY only)

M

P

LF957RPDAOSY

SIZE DIMENSIONS WEIGHT

in. in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs. lbs. kgs.

21⁄2 31 787 163⁄8 416 61⁄2 165 291⁄16 738 22 559 151⁄2 393 813⁄16 223 219⁄16 548 133⁄16 335 142 64 150 68

3 31

4 33

6 43

8 50 1270 37

10 57

A C (OSY) D G H I J M P 957RPDA 957NRPDA

11

⁄16 805 187⁄8 479 611⁄16 170 301⁄4 768 223⁄4 578 171⁄8 435 93⁄16 233 231⁄8 587 141⁄2 368 162 73 175 79

11

⁄16 856 223⁄4 578 7 178 33 838 24 610 181⁄2 470 915⁄16 252 261⁄2 673 153⁄16 386 178 81 201 91

1

⁄2 1105 301⁄8 765 81⁄2 216 443⁄4 1137 333⁄4 857 233⁄16 589 131⁄16 332 323⁄4 832 19 483 312 142 353 160

1

⁄2 1460 453⁄4 1162 113⁄16 285 66 1676 50 1270 321⁄2 826 175⁄16 440 463⁄8 1178 24 610 797 362 964 437

3

⁄4 959 911⁄16 246 541⁄8 1375 405⁄8 1032 277⁄16 697 1511⁄16 399 371⁄8 943 213⁄16 538 497 225 572 259

J

I

H

G

M

P

LF957RPDABFG

SIZE DIMENSIONS WEIGHT

in. in. mm in. mm in. mm in. mm in. mm in. mm lbs. kgs.

21⁄2 321⁄2 826 231⁄2 597 151⁄2 394 91⁄2 241 2113⁄16 555 1513⁄16 402 81 37

3 34 864 24

4 35

6 46

Noryl® is a registered trademark of SABIC Innovative Plastics™.

G H I J M P 957RPDABFG

1

5

⁄8 905 26 660 173⁄16 437 1015⁄16 279 2415⁄16 634 165⁄8 422 101 46

1

⁄2 1181 3512⁄16 908 201⁄2 521 131⁄2 343 281⁄4 718 19 483 174 79

⁄2 622 165⁄16 414 101⁄16 256 231⁄8 587 161⁄8 410 84 38

Page 3

Capacity

Series LF957RPDA, LF957NRPDA, LF957ZRPDA flow curves as tested by Underwriters Laboratory per UL 1469, 1996.

Flow characteristics collected using butterfly shutoff valves

** = Rated flow *** = UL Rated flow

Horizontal N-Pattern Z-Pattern

kPa psi

124 18

110 16

96 14

83 12

69 10

55 8

41 6

0 50 100 150 200 250 300 350 gpm

0 190 380 570 760 950 1140 1330 lpm

15 fps

4.6 mps

kPa psi

110 16

96 14

83 12

69 10

55 8

41 6

0 100 200 300 400 500 gpm

0 380 760 1140 1520 1900 lpm

15 fps

4.6 mps

21⁄2"

*

3"

*

**

**

kPa psi

Z

N

H

N

Z

H

124 18

110 16

96 14

83 12

69 10

55 8

41 6

kPa psi

124 18

110 16

96 14

83 12

69 10

55 8

41 6

0 300 600 900 1200 1500 gpm

0 1140 2280 3420 4560 5700 lpm

15 fps

4.6 mps

0 500 1000 1500 2000 2500 gpm

0 1900 3800 5700 7600 9500 lpm

15 fps

4.6 mps

6"

8"

*

*

**

**

Z

N

H

Z

N

H

kPa psi

179 26

152 22

124 18

96 14

69 10

41 6

0 100 200 300 400 500 600 700 800 gpm

0 380 760 1140 1520 1900 2280 2660 3040 lpm

15 fps

4.6 mps

4"

*

**

kPa psi

Z

N

H

110 16

96 14

83 12

69 10

55 8

41 6

28 4

0 500 1000 1500 2000 2500 3000 3500 gpm

0 1900 3800 5700 7600 9500

fps

mps

10"

*

**

11400 13300

Z

N

H

lpm

NOTICE

Inquire with governing authorities for local installation

requirements

A Watts Water Technologies Company

ES-LF957RPDA 1334 © 2013 Watts

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

Loading...

Loading...