Page 1

RP/IS-909/909RPDA

Installation, Maintenance, & Repair

Series 909, LF909, 909RPDA, LF909RPDA

Reduced Pressure Zone Assemblies

Reduced Pressure Detector Assemblies

Sizes: 21⁄2" – 10" (65 – 250mm)

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information

can result in death, serious personal injury, property

damage, or damage to the equipment.

Keep this Manual for future reference.

Watts 909 OSY shown

Designed for inline servicing

Local building or plumbing codes may require modifications to

the information provided. You are required to consult the local

building and plumbing codes prior to installation. If this information is not consistent with local building or plumbing codes, the

local codes should be followed.

Need for Periodic Inspection/Maintenance: This product

must be tested periodically in compliance with local codes, but

at least once per year or more as service conditions warrant.

Corrosive water conditions, and/or unauthorized adjustments

or repair could render the product ineffective for the service intended. Regular checking and cleaning of the product’s internal

components helps assure maximum life and proper product

function.

IMPORTANT: Inquire with governing authorities for local installa-

tion requirements.

NOTICE

For Australia and New Zealand, line strainers should be installed

between the upstream shutoff valve and the inlet of the backflow preventer.

Its important that this device be tested periodically in compliance

with local codes, but at least once per year or more as service conditions warrant. If installed on a fire sprinkler system, all mechanical

checks, such as alarm checks and backflow preventers, should be

flow tested and inspected internally in accordance with NFPA 13

and NFPA 25.

Testing

For field testing procedure, send for IS-TK-DL,

IS-TK-9A, IS-TK-99E and IS-TK-99D.

For repair kits and service parts, reference PL-RP-BPD at

www.watts.com

For technical assistance, contact your local Watts

representative.

Basic Installation Instructions

NOTICE

The flange gasket bolts for the gate valves should be re tight ened

during in stal la tion as the bolts may have loos ened due to stor age

and ship ping.

High Capacity Relief Series:

Location and Installation Considerations

1. Backflow preventers must be installed in high-visibility locations

in order to allow for immediate notice of telltale discharge or

other malfunction. This location should also facilitate testing and

ser vic ing, and protect against freezing and vandalism.

2. Installing a backflow preventer in a pit or vault is not rec ommend ed. However, if this becomes necessary, Watts highly recom mends that a licensed journeyman tradesperson, who is recognized by the authority having jurisdiction, be consulted to

ensure that all local codes and required safety provisions are

met. An air gap below the relief port must be maintained so as

to avoid flooding and submersion of the assembly, which may

lead to a cross connection. *Please refer to Figure No. 1 for further information.

3. A strainer should be installed ahead of the backflow preventer to

protect all internal components from unnecessary fouling.

!

CAUTION

Do not install a strainer ahead of the backflow preventer on seldomused, emergency water lines (i.e. fire sprinkler lines). The strainer

mesh could potentially become clogged with debris present in the

water and cause water blockage during an emer gen cy.

4. Normal discharge and nuisance spitting are accommodated by

the use of a Watts air gap fitting and a fabricated indirect waste

line. Floor drains of the same size MUST be provided in case of

excessive discharge. *Please refer to Figure No. 1 and Figure

No. 2 for further in for ma tion.

5. When a 909/LF909 Series backflow preventer is installed for

dead-end service applications. (i.e. boiler feed lines, cooling

tower makeup or other equip ment with periodic flow requirements), discharge from the relief vent may occur due to water

supply pressure fluctuation during static no-flow con di tions. A

check valve may be required ahead of the backflow preventer.

*Please see “Troubleshooting”, Page 7, prior to installation.

Page 2

Basic Installation Instructions

Series 909/LF909

Sizes: 21⁄2" – 10" (65 – 250mm)

6. The relief valve module on 21⁄2" – 10" (65 – 250mm) 909/LF909

Series assemblies may be turned to discharge to the opposite

side. To do so, unbolt the relief valve and turn the relief valve discharge port to the opposite side. Mount the high pressure hose

on the op po site. This should be done by a licensed journeyman

tradesperson, who is rec og nized by the authority having jurisdiction and only when space is critical for testing or repair.

7. ASSEMBLY: If the backflow preventer is disassembled during

installation, it MUST be reassembled in its proper order. The gate

valve with the test cock is to be mounted on the inlet side of the

backflow preventer. The test cock must be on the inlet side of

the wedge. Please see above. Failure to reassemble correctly will

result in possible water damage due to excessive discharge from

the relief port/vent and possible malfunction of the backflow preventer.

8. Installation procedures must comply with all state and local

codes and must be completed by a licensed journeyman tradesperson who is recognized by the authority having ju ris dic tion.

9. Prior to installation, thoroughly flush all pipe lines to remove any

foreign matter.

10. START UP at Initial Installation and After Servicing: The downstream shutoff should be closed. Slowly open upstream shutoff

and allow the backflow preventer to fill slowly. Bleed air at each

test cock. When backflow preventer is filled, slowly open the

down stream shutoff and fill the water supply system. This is necessary to avoid dislodging O-rings or causing damage to internal

com po nents.

11. TEST: The 909/LF909 Series backflow preventer may be tested

by a certified tester at the time of installation in order to ascertain

that the assembly is in full working order and may be relied upon

to protect the safe drinking water as per applicable standard.

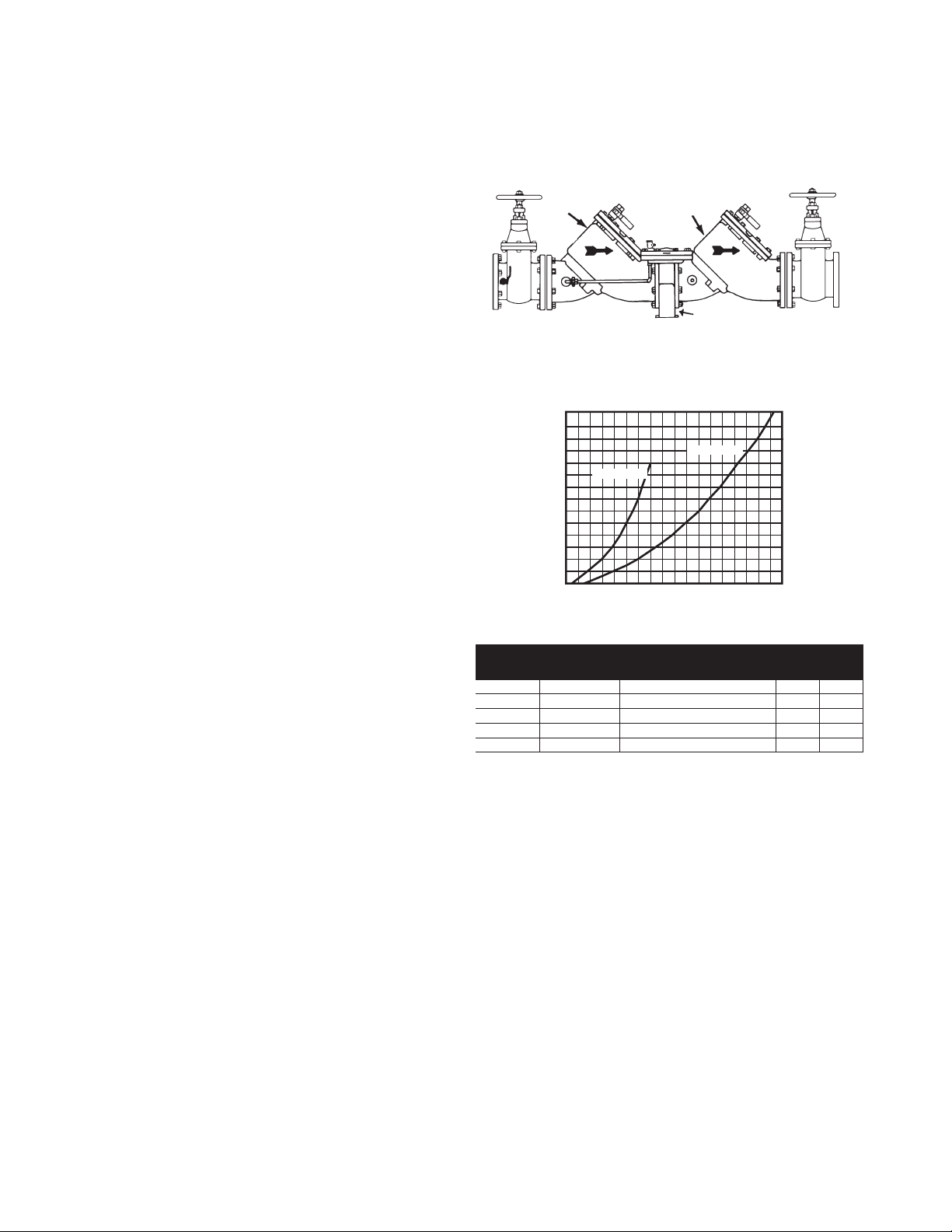

Watts No. 909/LF909

1

2

⁄2" – 10" (65 – 250mm)

Inlet

Shutoff

Valve

First

Check

Second

Check

Relief Valve

Second

Shutoff

Valve

Figure 1

Series 909/LF909

Relief Valve Dis charge Rates

175

150

125

21⁄2” – 3” 909

100

75

50

ZONE PRESSURE (PSIG)

25

0

0 100 200 300 400 500 600 700 800 900

FLOW RATE (GPM)

4” – 10” 909

Figure 2

VALVE SIZE TYPICAL FLOW RATES AS SIZED BY

FLOOR DRAIN MANUFACTURERS

in. mm in. mm

1

⁄2” 65 55 gpm 2 50

2

DRAIN SIZE

3” 80 112 gpm 3 65

4” 100 170 gpm 4 100

6”, 8”, 10” 150,200,250 350 gpm 5 125

2

Page 3

Installation

A. Series 909/LF909 should be installed in a horizontal and upright

position. This positions the relief valve below the first check

valve, enabling the zone to drain through the relief valve outlet.

The shutoff valve with the test cock is to be mounted on the inlet

side of the backflow preventer. The test cock is on the inlet side

of the shutoff valve.

B. The 909/LF909 should always be installed in an accessible loca-

tion to facilitate testing and servicing. Check the state and local

codes to insure that the backflow preventer is installed in compliance, such as the proper height above the ground.

C. Water discharge from the relief valve should be vented in accor-

dance with code requirements. The relief valve should never be

solidly piped into a drainage ditch, sewer or sump. The discharge should be funneled through a Watts air gap fitting piped

to a floor drain.

D. Watts recommends a strainer be installed ahead of Watts 909

Series assemblies to protect the discs from unnecessary fouling.

E. Backflow preventers should never be placed in pits unless abso-

lutely necessary and then only when and as approved by local

codes. Consult your local or state plumbing or health inspector.

Watts recommends installation indoors or above ground in an

insulated enclosure.

Start Up

F. The downstream shutoff should be closed. Open upstream

slowly, fill the valve and bleed the air through Test cock 2, 3 and

4. When valve is filled, open the downstream shutoff slowly and

fill the water supply system. This is necessary to avoid water

hammer or shock damage.

G. The installation of a Watts air gap with the drain line terminating

above a floor drain will handle any normal discharge or nuisance

spitting through the relief valve. However, floor drain size may

need to be designed to prevent water damage caused by a catastrophic failure condition. Do not reduce the size of the drain

line from the air gap fitting.

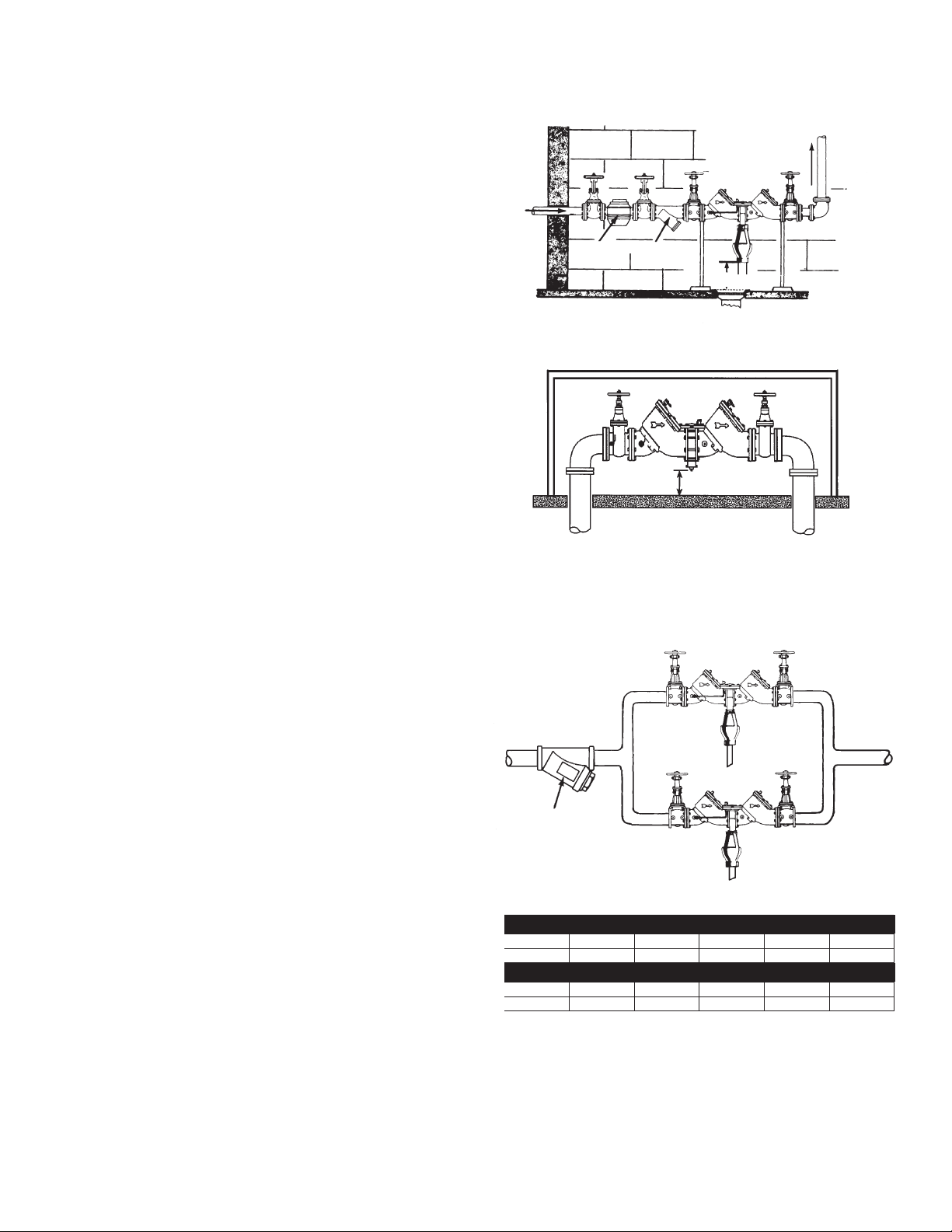

H. Two or more smaller size valves can be piped in parallel (when

approved) to serve a larger supply pipe main. This type of installation is employed where increased capacity is needed beyond

that provided by a single valve and permits testing or servicing of

an individual valve without shutting down the complete line.

The number of assemblies used in parallel should be determined by

the engineer’s judgement based on the operating conditions of a

specific installation.

Indoors

Watts 909S/LF909S FDA

1

2

⁄2” - 10” (65 - 250mm)

Main

Meter Strainer

Air

Gap

12” (300mm)

Above Ground

Min. 12” (300mm)

Now available, WattsBox Insulated Enclosures, for more information, send for ES-WB.

Parallel

Watts 909/LF909

21⁄2" – 10" (65 – 250mm)

Air Gap

support

Strainer

TABLE ONE - CAPACITY REQUIRED FOR SYSTEM

50 GPM 100 GPM 150 GPM 200 GPM 250 GPM 350 GPM

Two 3⁄4" Two 1" Two 11⁄4" Two 11⁄2" Two 11⁄2" Two 2"

Devices Devices Devices Devices Devices Devices

450 GPM 640 GPM 1000 GPM 2000 GPM 3000 GPM 5000 GPM

Two 21⁄2" Two 3" Two 4" Two 6" Two 8" Two 10"

Devices Devices Devices Devices Devices Devices

Table shows total capacity provided with dual valve installations of various sizes.

3

Page 4

Test Procedure for

Reduced Pressure Zone

Backflow Preventers

The following Test Procedure is one of several that is rec og nized

through out the Unit ed States for ver i fi ca tion of the func tion ing of

backflow pre ven ters.

The following procedure is not a specific rec om men da tion. The

Watts se ries of test kits are ca pa ble of per form ing any of the rec ognized backflow test procedures.

A. Open TC #4 and flush test cocks Nos. 1, 2, and 3 on BF

assembly, then close TC #4.

B. Turn tester on (before connecting hoses). Tester must read all

zeros. Close VA and VB.

Test No. 1 - Relief Valve

1. Install high side hose between TC #2 and tester connection A.

2. Install low side hose between TC #3 and tester connection B.

3. Open VB then TC #3. Now open VA then TC #2 slowly. Close

VA then VB.

4. Close #2 shutoff valve.

5. Observe the apparent first check valve differential pressure (A B).

6. Install bypass hose between VA and VB. Open VB and bleed air

by loosening hose connection at VA. Tighten hose connection

and close VB.

Push - Print Head (wait) then Push - Start Test

7. Open VA, then slowly open VB (no more than 1⁄4 turn). When

relief valve drips, push the “hold” button for 2 seconds. Record

reading (must be 2 psid or more).

Push - Stop Test

8. Close VA and VB.

Test No. 2 - Test No. 2 Check Valve

9. Install bypass hose between VA and TC #4. Open VA, then

bleed air by loosening hose connection at TC #4. Tighten hose

connection. Close VA.

Push - Start Test

10. Open VB to reestablish pressure with in the “zone”. Close VB.

11. Open VA then TC #4. If relief valve does not drip, record second

check valve as “closed tight”.

Test No. 3 - Test No. 1 Check Valve

12. Open VB to reestablish first check valve differential pressure.

Close VB. Record pressure dif fer en tial.

Stop Test (Push Stop Test twice)

13. Close test cocks and remove tester, return assembly to normal

operating condition.

Watts TK-DP

RPZ

Test 1

RPZ

Test 2

RPZ

Test 3

VA

B VB

A

A

VA

B VB

A

VA

B VB

For complete testing information, send for IS-TK-9A or IS-TK-DP/DL.

4

For repair kits and parts, refer to Backflow

Prevention Products Repair Kits & Service Parts

price list PL-RP-BPD on www.watts.com

Page 5

Servicing First and Second Checks

Sizes: 21⁄2" – 10" (65-250mm)

1. Remove the hatch cover bolts. NOTE: The 909 is designed so

that when the bolts are backed off

re leased from the cover and retained by the check module.

!

CAUTION

Be sure to verify this before removing all the bolts.

2. Lift the check valve module straight out taking care not to hit

and damage the seating.

3. The seat ring may be removed and replaced by pulling out the

two wire retainers on sizes 4" – 10" (100 – 250) while on sizes

1

⁄2" – 3" (65 – 80mm), one quarter turn twist removes seat. The

2

wire retainers are 10” long. One is drawn out clockwise and the

other is drawn out counterclockwise.

4. With the retainer wires removed, the seat ring can be lifted

straight up and removed.

!

CAUTION

5. The check valve spring is in compression. The spring load is

captured by the two spring retainers and the stem. The spring

re tainers are not to be removed for servicing. If there is a need

to re place the spring, spring retainer or stem, an assembled

module must be obtained from the factory. These modules are

not interchangeable, be sure to replace the first check with a

first check mod ule and the second check with a second check

module.

6. To replace the disc on sizes 2

remove the re tain ing nut or for sizes 6” – 10” (150 – 250mm)

remove the allen head socket screws. Reverse this procedure to

install the new disc.

1

⁄2", all the spring load is

1

⁄2" – 4" (65 – 100mm) simply

No special tools

required to service

Series 909

909OSY/

LF909OSY

21⁄2" – 3" (65 – 80mm)

First and second checks

are not interchangeable

First

Check

Relief

Valve

*Disc & Spring

As sem bly

Seat

Seat O-ring

Cover O-ring

Second

Check

For further details contact your tech ni cal sales representative, see back page.

4" – 10" (100 – 250mm)

*Disc & Spring

As sem bly

Disc

Seat

Lower Stem

O-ring (6” only)

Retainer wire

Seat O-ring

Cover O-ring

!

WARNING

*Spring as sem bly is factory assembled. DO NOT DIS AS SEM BLE

5

Page 6

Servicing the Relief Valve

Sizes: 21⁄2" – 10" (65-250mm)

1. Remove the relief valve cover bolts. Note the 909/LF909 is

designed so that when the bolts are backed off

1

⁄2" all the relief

valve spring load is retained by the bottom plug spring module.

!

CAUTION

Be sure to verify this before removing all the bolts.

2. Remove the cover and diaphragm. The relief valve piston

assembly can be lifted straight up and out.

3. Replace the wiper seal and piston O-ring and apply grease to

the O-ring.

4. To replace the relief valve disc, hold the upper guide fin and

unscrew the diaphragm pressure plate. It may be necessary to

lightly tap the cast webs and the pressure plate to loosen.

Replace with a new disc holder assembly and O-ring. Note: the

disc rubber is molded into the disc holder and is supplied as a

disc holder assembly.

5. Removal of the bottom plug and spring assembly. During normal field service there is no need to remove the bottom plug

spring assembly other than inspection. It can be removed by

simply unscrewing with a large pipe wrench.

!

CAUTION

The spring as retained on the bottom plug is highly loaded. NO

attempt should be made in the field to remove the spring. For

replacement, a complete bottom plug assembly must be obtained

from the factory.

For further details contact your technical sales representative, see

back page.

Relief Module

CLEARANCE REQUIRED FOR SERVICING

in. mm A B

1

⁄2 – 3 65-80 10" 11"

2

4 100 15" 14"

B

6 150 15" 16"

8 200 23" 21"

10 250 25" 21"

Adapter O-ring

Diaphragm

Relief Valve Disc

Relief Valve Piston

Assembly

Piston O-Ring

Sizes

1

2

⁄2" – 3"

(65 – 80mm)

O-ring

Seat

Adapter O-ring

Diaphragm

Relief Valve Piston

Assembly

Piston seal

Seat

O-ring

Sizes 4", 6"

(100, 150mm)

8"M1, 10"M1

Plug &

Spring Piston

Assembly

Adapter o-ring

Diaphragm

Relief Valve Assembly

Seat

O-ring

Sizes 8", 10"

(200, 250mm)

Plug & Spring

Assembly

6

Page 7

Troubleshooting Guide - Backflow Preventers

Problem Cause Solution

A. Valve spits periodically

from the vent

B. Valve drips continually

from the vent

C. Valve exhibits high

pressure drop.

D. No water flows down-

stream of valve.

E. Valve does not test

properly

F. Valve quickly and

repeatedly fouls following servicing.

G. Winterization of back-

flow preventers.

A.1 Fluctuating supply pressure. A.1 Install a soft seated check valve immediately upstream

A.2 Fluctuating downstream pressure A.2 Install a soft seated check valve downstream of the

B.1 Fouled first check B.1 Flush valve. If flushing does not resolve problem, dis-

B.2 Damage or fouled relief valve seat. B.2 Clean or replace the relief valve seat.

B.3 Relief valve piston O-ring not free to

move due to pipe scale, dirt or build

up of mineral deposits.

B.4 Excessive back pressure, freezing, or

water hammer has distorted the second check.

B.5 Electrolysis or relief valve seat or first

check seats.

B.6 Valve improperly reassembled. B.6 If valve is dis as sem bled during installation, caution

C.1 Fouled strainer. C.1 Clean strainer element or replace.

C.2 Valve too small for flows encountered. C.2 Install proper size device based upon

D. Valve installed backwards. D. Install valve in accordance with flow direction arrow.

E.1 Follow manufacturer’s test procedure E.1, E.2 Clean or replace gate valve with full port ball

E.2 Leaky downstream gate valve.

F. Debris in pipe line is too fine to be

trapped by strainer.

of the de vice.

device close as possible to the shutoff valve.

assemble valve and clean or re place the first check.

B.3 Clean, grease or replace the piston O-ring.

B.4 Elim i nate source of excessive backpressure or water

hammer in the system downstream of the device. Use

Watts No. 15 to eliminate water hammer. Replace

defective second check assembly.

In case of freezing; thaw, dis as sem ble and inspect

internal components.

Replace as necessary.

B.5 Replace relief valve seat or inlet cover.

Electrically ground the piping system and/or electrically isolate the device with plastic pipe immediately

upstream and down stream of the device.

must be exercised to install check springs in their

proper location.

flow requirements.

valves or resilient wedge shutoff valves.

F. Install finer mesh strainer element in the strainer.

G. Electric heat-tape wrap closely together around valve

body. Build a small shelter around the valve

with a large light bulb installed and left on at all times.

If supply line is not used during the winter, removal

of the com plete body is the best. This would create

an air gap to eliminate any possible backflow.

7

Page 8

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

Limited Warranty: Watts Regulator Co. (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of

original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting

from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no

control. This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the above

limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

A Watts Water Technologies Company

USA: Tel: (978) 688-1811 • Fax: (978) 794-1848 • www.watts.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • www.watts.ca

RP-IS-909-909RPDA 1319 EDP# 1915172 © 2013 Watts

Loading...

Loading...