Page 1

APPLICATION

Today's ever-changing water quality issues demand that point-of

use water treatment systems become an essential component of

equipment applications. Because municipal water treatment

facilities are designed to reduce mainly biological contaminants,

they do not decrease contaminants that affect the performance of

water dependent equipment. The Watts HS-Series water treatment

systems are designed specifically for use on applications found

throughout the healthcare industry, such as point-at-use steam

generators. When used as suggested by the manufacturer, The

Watts HS-Series water treatment syst ems significantly reduce or

eliminate boiler scaling. This unit is intended for use with a single

sterilizer/electric boiler combination – with boilers in the range of

12 to 30 KW.

BENEFITS

• Extends equipment life

• No electrical service needed

• Reduces or eliminates boiler scale

• Increases boiler heating element life and efficiency

• Universal mounting system for quick, easy installation

• Small size (24”x16”x20”) permits installation virtually

anywhere

• Attractive stainless steel cabinet

EQUIPMENT FEATURES

• Complete pre-treatment

• Sediment filtration removes dirt, sand, and rust

• KDF media filter reduces iron

• Carbon filtration removes chlorine and other VOCs

• TFC reverse osmosis membrane reduces up to 99%

of TDS

• Complete post-treatment

• PH adjusted

• TDS balanced to ensure proper conductivity of water

• 1-year warranty

• Factory performance tested and sanitized

SYSTEM PERFORMANCE

When used as suggested by the manufacturer, the Watts HSSeries water treatment systems eliminate up to 99% of the

following contaminants:

• Total Dissolved Solids(TDS)

• Volatile Organic Chemicals

• Harness(CaCO3)

• Chlorine additives

Note Limitation

: Not intended for drinking water.

HS-200

Water Treatment System

# 61301605522

WARRANTY

Watts HS-Series water treatment systems

are warranted for One year. Labor for repairs

are provided for the first 90/days

following equipment installation and start up.

Warranty repairs are performed MondayFriday from 8:00a.m. - 5:00p.m.,

Excluding national holidays.

To order an HS-Series Water Treatment

System or for more information, please call:

Phone: 800-950-9912

Fax: 800-950-2570

Getinge USA Inc,

1777 East Henrietta Rd.

Rochester, NY 14623

Rev: 042704/570200

Page 2

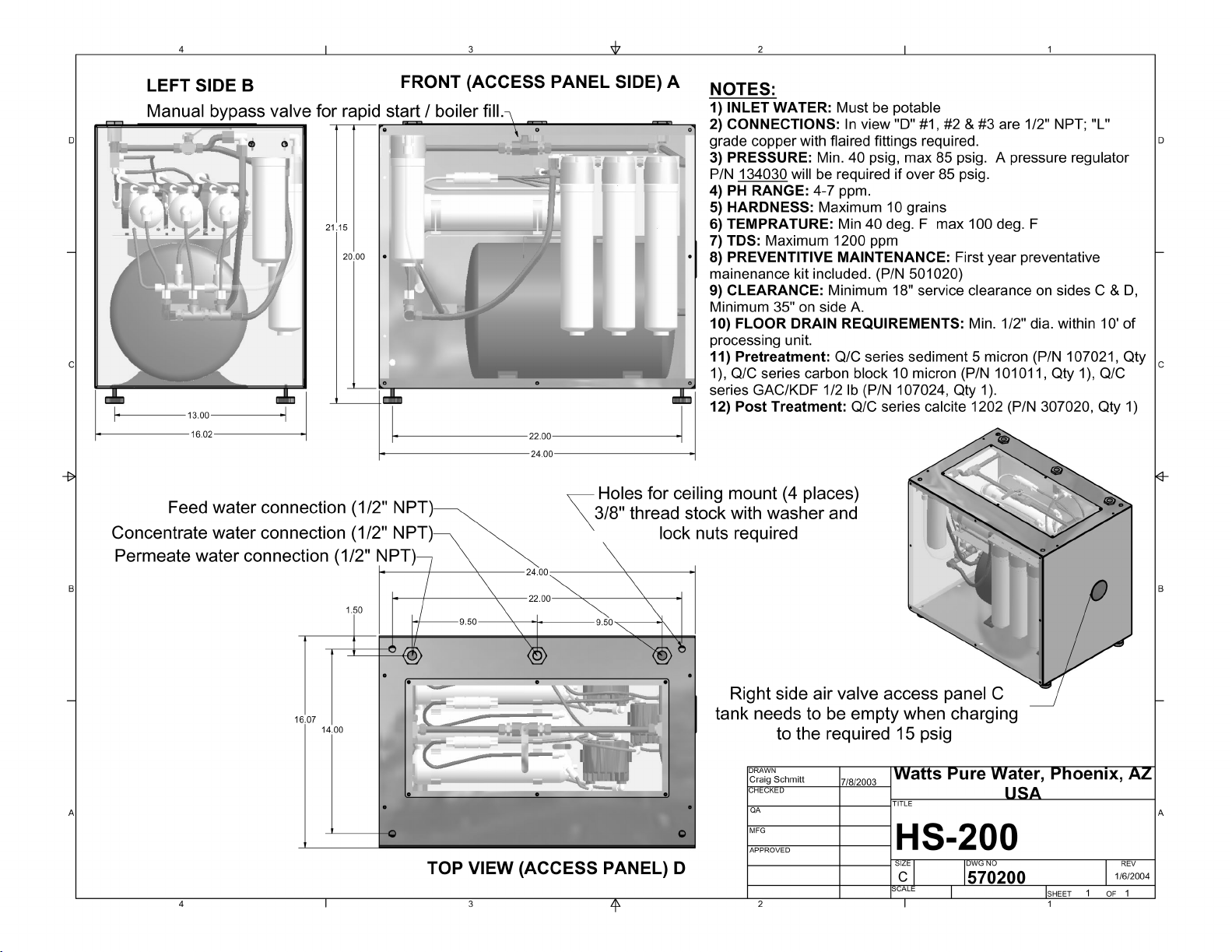

Page 3

1

Equipment

Outlet

A

Panel

Cover

18”

ACCESS

AREA

B

(Product Water)

16”

24”

NOTE:

Need access to front panel and

right side “Air Tank Access Cap” .

Recommended:

Front Panel Access - 18” clearance

Side Panel Access - 12” clearnace

Drain

Outlet

Air Tank

Access

Tapwater

Inlet

20-1/4”

ACCESS

AREA

Four Adjustable

Leveler Feet

2

12”

Nylon Lock Nut

34

Threaded Rod

Flat Washer

Threaded rods attached to ceiling

Rods run through

cabinet @ all four

corners.

Nylon lock nuts & flat washers

lock rods at top & bottom

of M-200 enclosure

18”

16”

A

B

C

D

E

California Code requires

four sizemic mounting holes

for floor attachment

1.09

1

D

14.00

2

D

2.063

20.25

9.50 9.50

A

1

E

2

E

24.00

22.00

Top View

17.876

Bottom panel

2.50

4

D

%%c.50

B

C

Rear panel

Mounting holes

for stud attachment

on 18” or 16” centers

Metal or wood stud

10.94 10.94 1.062

G

E1

1

C

E2

7.007.00

GG

2 3

G

3

D

E4

4

1.00

3.062

%%c2.50

Bottom View

E3

%%c.375

D

%%c.50

3

E

E

16.36

D

4

E

5

E

Rear View

1

7/18/02

7/18/02

7/18/02

7/18/02

7/18/02

DATE

DO NOT SCALE DRAWING

77 LBS

WEIGHT:

NAME

DRAWN

ENG.

PROD.

SALES

Q.A

NELSON A.

SCHMITT C.

HENSS M.

HANFORD J.

MANGIN P.

F

6

E

1.95

2

Side View

3

5.94

TITLE: M-200 BoilerMate

M-200-1

DWG NO.

MATERIAL:

304 Stainless Steel

REVISION

7/15/02

6.3

4

A2

Page 4

1

2

34

A

TAPWATER

INLET

GREEN TUBING

A

EQUIPMENT

OUTLET

9

10

X

4 4 4

BLACK TUBING

DRAIN

OUTLET

BLACK

PERM

BLUE

BLUE

B

BLACK

BRINE

IN

IN

BRINE

PERM

OUT

OUT

BLACK TUBING

C

D

B

BLACK TUBING

BLACK TUBING

7

1

2

BLACK TUBING

C

ITEMITEM

1

2

3

4

5

6

D

7

8

9

1010

PART NUMBER

107021

107024

101011

210000

222019

152002

219002

307020

234010

134028

3

8

5 MICRON SEDIMENT FILTER

GAC/KDF

10 MICRON CARBON BLOCK

MEMBRANE TFM 100 GPD

750 ML FLOW RESTRICTOR

PERMEATE PUMP WITH CLIP

PRESSURE TANK

ALL CALCITE

1/2” BRASS CHECK VALVE

1/2” BY PASS VALVE

BLUE

BLACK > BLACK >

PERMINPERM

BRINE

IN

IN

BLUE

6 6 6

BLACK

PERM

OUT

BRINE

OUT

DESCRIPTION

BLUE

5 5 5

BRINE

PERM

IN

IN

BLUE

PERM

OUT

BRINE

OUT

ON UNIT CONNECTION SIZE APPROVED MATERIAL

A

PERMEATE WATER TO BOILER

B

DRAIN WATER CONNECTION

C

INLET “COLD” WATER CONNECTION

D

E

AIR TANK ACCESS

MOUNTING LOCATION

D1-D4

CEILING MOUNT ( TOP PANEL )

E1-E4

CEILING MOUNT ( BOTTOM PANEL )

H1-H6

WALL MOUNT

G1-G4

FLOOR MOUNT

G1-G4

FLOOR MOUNT FOR SEISMIC STATES

1/2” FPT

1/2” FPT

1/2” FPT

2 1/2” OPENING

SIZE

3/8”

3/8”

3/8”

3/8”

3/8”

1/2” L COPPER ( SWEAT OR FLAIR )

1/2” L COPPER/PVC/POLY PROPYLENE

1/2” L COPPER/PVC/POLY PROPYLENE

TIRE PRESSURE GAUGE 0-50 PSI RANGE

APPROVED MATERIAL

THREADED STOCK

THREADED STOCK

5/16” X 2 1/2”

LEG GUIDE ( PROVIDED )/HILTI

HILTI ANCHORS (3/8” X 3 1/2” )

E

1

7/18/02

7/18/02

7/18/02

7/18/02

7/18/02

DATE

DO NOT SCALE DRAWING

WEIGHT:

77 LBS

NAME

DRAWN

ENG.

PROD.

SALES

Q.A

NELSON A.

SCHMITT C.

HENSS M.

HANFORD J.

MANGIN P.

F

2

TITLE: M-200 BoilerMate

DWG NO.

MATERIAL:

REVISION

3

M-200-1

304 Stainless Steel

7/15/02

4

A1

Page 5

Model HS-200 Boiler Mate # 570200 Replacement Parts

t

Item # Item Description Qty per uni

61301605453 Permeate Pump 3

61301605455 Membrane Filter 3

61301605473 Flow Restrictor 750 ml 3

61301605471 5 Gal Storage tank 1

61301605449 Filter Sediment 5 micron 1

61301605447 Filter Carbon Block 5 micron 1

61301605450 Filter GAC/KDF 1

61301605516 Filter Calcite 1

61301605476 Valve Check 1/2" Brass 2

61301605474 Valve Ball 1/2" Brass 1

61301605518 HS-200 Unit PM Kit 1

Loading...

Loading...