Page 1

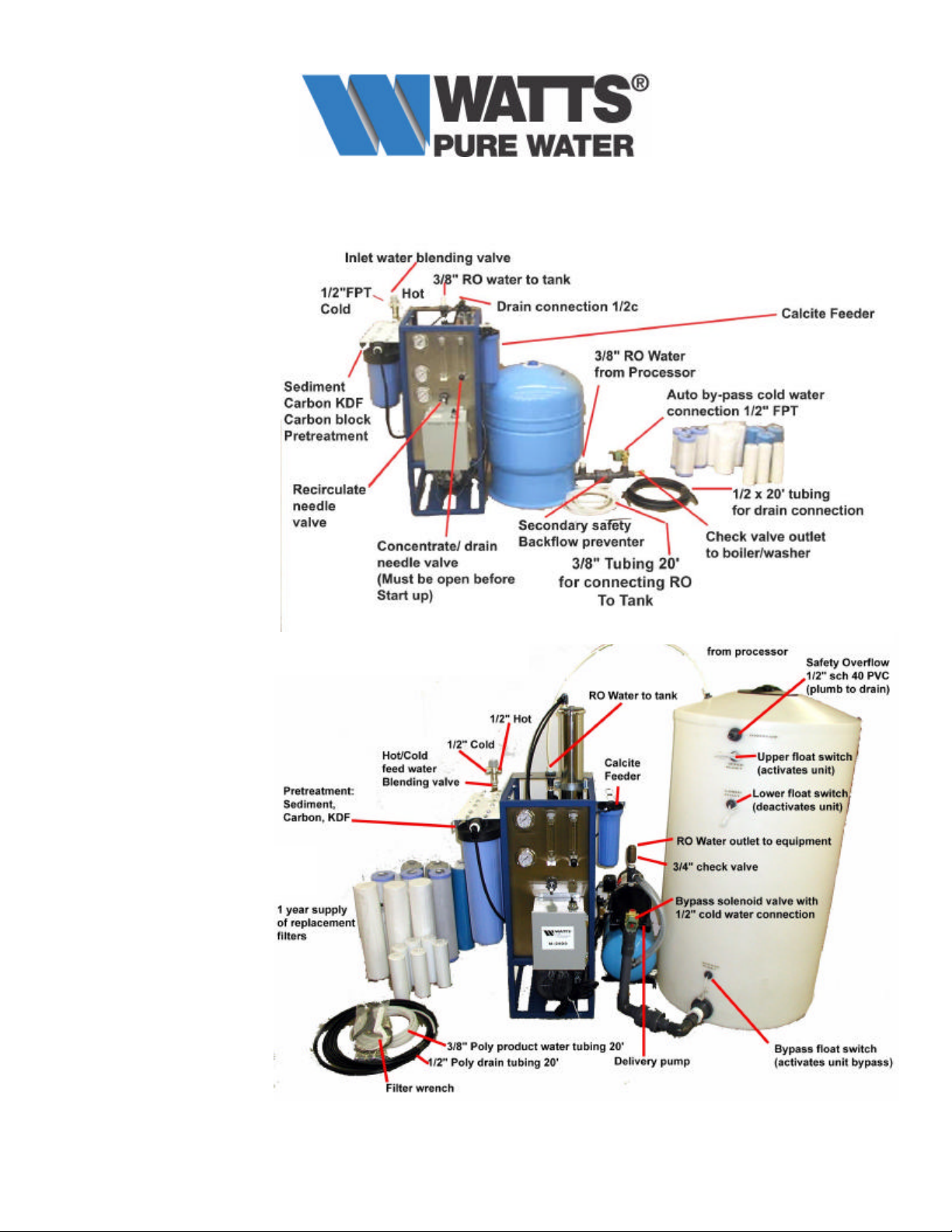

HS - Series Reverse Osmosis Processor

With Built-in Pre-treatment and Membrane Flush

HS-Series

Pressure Tank

Float Tank

Models

Installation, Operation

&

Maintenance Manual

Page 1 of 18

Page 2

Before installing and/or operating Watts HS-Series Reverse Osmosis system, read this manual

completely. Keep this manual available for future reference. Further information is available by

contacting your local Watts distributor. Phone: (623)505-1512

Pressure Tank

Atmospheric Tank

Page 2 of 18

Page 3

TABLE OF CONTENTS

Specifications

Specifications Chart ……………………………… 4

Installation

Membrane installation ………………………………. 5

Inlet Connection ………………………………………. 6

Permeate Line Connection …………………..……. 7

Pressure Tank Connection ……………………..…. 8

Atmospheric Storage Tank ……………………… … 9

Plumb to Drain ………………………………………. 10

Operation

Start Up …………………………………………………..11

Alarms …………………………………………………….12

Maintenance

Quarterly Maintenance ………………………………13

Annual Maintenance ………………………………….14

Warranty

Warranty ………………………………………………….15

Glossary of Terms …………………………..………. 17

Page 3 of 18

Page 4

Specifications Complete System Packages

SPECIFICATIONS HS-450 HS-1000 HS-2400 HS-4800 HS-9600 HS-15000

DRY WEIGHT lbs. 300 310 350 650 750 950

WET WEIGHT lbs 550 1700 1750 4000 4100 4900

FEED WATER

COLD/Temp ½”/35°-70° ½”/35°-70° ½”/35°-70° ¾”/35°-70° ¾”/35°-70° 1”/35°-70°

HOT/ Temp ½”/70°-

140°

FLOW RATE 2 GPM 4 GPM 8 GPM 12 GPM 24 GP M 24 GPM

MAX.HARDNESS 17 Grains 17 Grains 17 Grains 17 Grains 17 Grains 17 Grains

MAX. TDS 2500 PPM 2500 PPM 2500 PPM 2500 PPM 2500 PPM 2500 PPM

MAX. IRON 0.1 MGL 0.1 MGL 0.1 MGL 0.1 MGL 0.1 MGL 0.1 MGL

MAX. PSIG 80 80 80 80 80 80

MIM. PSIG 25 25 25 25 25 25

DRAIN CONNECTION

FLOOR SINK MIM.

w/in 10 ft of

processor

ELECTRICAL

REQUIRMENTS

1/ ¼” 1/ ¼” 1/ ¼” 1/ ¼” 1/ ¼” 1/ ¼”

VOLTS/AMPS VOLTS/AMPS VOLTS/AMPS VOLTS/AMPS VOLTS/AMPS VOLTS/AMPS

½”/70°-140° ½”/70°-

140°

¾”/70°-140°

¾”/70°-

140°

1”/70°-140°

RO PROCESSOR 115/11.0 115/23

OPTIONAL 220V

DELIVERY PUMP N/A 115/8.8 115/12.4 115/12.4 115/12.4 115/12.4

KDF FILTER N/A N/A N/A 115/2 115/2 115/2

115/7.2 115/7.2

220/11.5 220/11.5

220/8.8 220/11.5

Page 4 of 18

Page 5

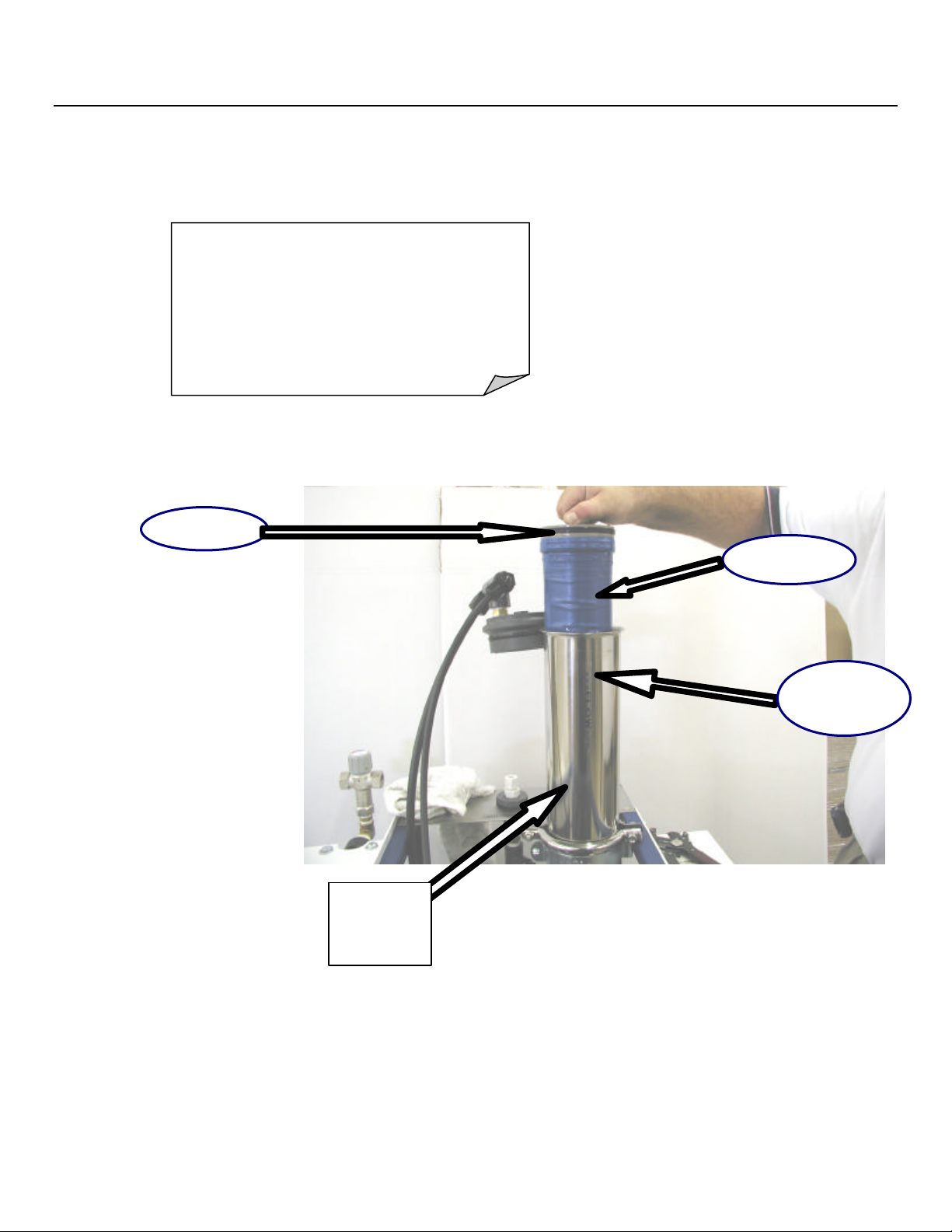

Membrane Installation

Note: All Membrane Vessels are

clearly marked with flow direction.

Membrane “Brine Seal” is always

facing the water entry to Vessel.

Brine Seal

Membrane

Flow

Direction

Marking

Membrane

Vessel

Page 5 of 18

Page 6

threaded pipe.

Inlet Connection

HOT and/or COLD FEED WATER

CONNECTION

Hard plumb Hot and/or Cold water

Connections into Blending Valve

Using (L) Copper Pipe. Refer to table

Below. Valve is marked with HOT

and Cold connections.

Recommend installing Ball Valves

just prior to the Blending Valve.

NOTE: Use only

Teflon tape on all

RO

HS-450 25/80 psig ½”

FEED WATER

MIN/MAX

PSIG

PIPE

SIZE

FLOW

RATE

2 GPM

HS-100 25/80 psig ½”

HS-2400

25/80 psig ½”

4 GPM

8 GPM

HS-4800 25/80 psig 1”

HS-9600 25/80 psig 1 ¼”

HS-

25/80 psig 1 ¼”

12 GPM

24 GPM

24 GPM

15,000

Page 6 of 18

Page 7

Permeate Line Connection

Required fittings for Bulkhead & Tank

HS450 ½” MPT x 3/8C .

HS1000 ½” MPT x 3/8C

HS2400 ½” MPT x ½”C

HS4800 ¾” MPT x ¾” Female Slip Schedule 40 PVC

HS9600 1” MPT x 1” Female Slip Schedule 40 PVC

HS15,000 1” MPT x 1” Female slip schedule 40/80 PVC

Ball Valve used with Pressure Tank applications.

Note: Fittings are included with systems ordered as complete packages only!

HS-450 – HS2400 ½” Tubing or PVC pipe

HS4800 – HS15K 1” PVC Schedule 40 pipe

Permeate Line Connection

The HS Series permeate

connection is on the bulkhead

labeled “OUT TO TANK”

Page 7 of 18

Page 8

Pressure Tank Connection

Recommended tubing size

From bulkhead on unit to tank .

Note: Fittings are included with Systems ordered as complete packages only!

HS450 - HS2400

Flexible poly tubing acceptable.

HS4800 – HS15,000

Schedule 80 PVC required.

HS-450

3/8”

HS-1000

HS-2400

HS-4800 ¾”

HS-9600 ¾”

HS-15,000 1”

3/8”

3/8”

Note: Copper pipe is UNSUITABLE for any plumbing from RO Storage Tank!

Recommended materials include: Braided Stainless Steel Tubing, Hard Stainless.

Schedule 80 PVC or Poly Propylene is acceptable, if not being connected to boiler or

heating system.

Page 8 of 18

Page 9

Atmospheric Storage Tank

Bulkhead & Fitting Systems

HS-450 3/8”

HS-1000 3/8”

HS-2400 3/8”

HS-4800 3/4 “

HS-9600 3/4”

HS-15,000 1”

Storage tank!

Recommended materials include: Braided Stainless Steel Tubing, Hard Stainless.

Schedule 80 PVC or Poly Propylene , if not being connected to boiler or heating system.

Plumb Drain Connection located on Bulkhead of RO system to floor

drain, using table specifications below or appropriate air gap drain

with minimum drain size of 1 1/4”.

Note: Refer to local plumbing codes for requirements in your area.

Note: Copper pipe is UNSUITABLE for any plumbing from RO

Page 9 of 18

Page 10

If the HS-Series was ordered with the atmospheric storage tank, the three tank float switches

have been installed at the factory. Check to insure the tank floats have not been damaged.

1. Connect the gray electrical cable containing four (4) wires from the M-Series control box

to the corresponding electrical connection on the atmospheric tank.

2. Connect the gray electrical cable from Control Box, labeled “By-Pass Solenoid”

to the By-Pass Solenoid.

3. Connect the gray electrical cable from Control Box, labeled “By-Pass Float

Switch” the By-Pass Float Switch.

4. Using the table below connect the RO processor Bulkhead to the tank using

specified tubing or PVC pipe.

Plumb to Drain

HS-450 HS-1000 HS-2400 HS-4800

Bulkhead

Connection

Drain Size Min.

1/2” Poly 1/2” Poly 1/2” Poly ½” PVC 1” PVC

HS-9600HS15,000

1 ¼” 1 ¼” 1 ¼’ 1 ¼’ 1 ¼”

Drain Connection

Page 10 of 18

Page 11

psi, as this will damage membrane.

Start Up

ü Ensure power switch (located on top of control Box).

(#1) is in the OFF position.

3

ü Plug the unit into an appropriate power supply.

ü If installing a pressure Tank system, open the Ball

Valve (#2) on the Bulkhead.

6

ü Turn the Blending Valve to coldest setting [90°]. (#3)

ü Fully open the Concentrate Needle (#4) Valve by

turning it counter clockwise.

ü Fully close Recirculate Needle Valve (#5) by turning it

clockwise.

ü Turn the incoming water supply on the RO processor

to the “ON” position.

ü Turn the Power Switch (#1) to “ON” position.

• The Water inlet solenoid valve will open.

• There will be a 5 second delay before the pump

starts.

• The system may cycle on and off automatically

during initial start up as air is purged from

system.

• Allow the unit to run for 5 minutes while excess

air is being purged from system.

ü Close the Concentrate Needle Valve (#4) until the

Feed Pressure Gauge(#6) reaches a max. of 150 psig.

ü Open the Recirculation Needle Valve (#5) until the

unit Feed Pressure Gauge (#6) drops to 140 psig.

ü Close the Concentrate Needle Valve (#4) until 150 psig is again achieved on the Pump Feed

Pressure Gauge (#6).

2

5

4

1

Repeat underlined sequence until both flow meters read equal flows and feed pressure gauge reads

150 psi. At this point the RO processor is operating at its maximum efficiency potential.

If using a Pressure Tank, system will continue to operate until Tank Pressure Gauge reads 60 psig or

Float Tank, upper float switch is triggered by the water level.

NOTE: At no time should the Concentrate

Valve ever be completely closed. RO system

must have some water running to the drain

during production or RO water.

NOTE: DO NOT operate over 150

The back pressure will read less

than 150 psi.

Page 11 of 18

Page 12

ALARMS

HS-Series processors are equipped with audible alarms.

1. The Constant Tone signals lack of incoming water pressure.

(-------------------------------------------------------- Constant Tone)

• Check incoming feed pressure to ensure a minimum of 20 psi.

• Water pressure below 20 psi will trigger alarm. Incoming feed water

pressure must be raised.

2. One second intermittent beeping signals systems is in Auto –Bypass.

(-- -- -- -- -- -- -- -- -- -- -- -- -- -- One second intermittent tone).

• During initial start up with empty tank, the system will automatically be in

Auto-Bypass until the tank has completely filled. The Auto by pass will only be

triggered if the tank pressure drops below 5 psi (Pressure tank systems). Float

switch controlled Atmospheric tank systems with float switches, remain on until

tank is full and processor has turned off automatically.

3. Two second intermittent beeping indicates possible wiring problem or

problem with installation of Float Switches.

(---- ---- ---- ---- ---- ---- Two second intermittent tone.)

Solution:

• Check to ensure labeled

electrical cables are connected

to corresponding float

switches.

• Check conductivity of wire to

ensure no broken wire cables

exist.

• Verify Float position per

drawing to the right.

Page 12 of 18

Page 13

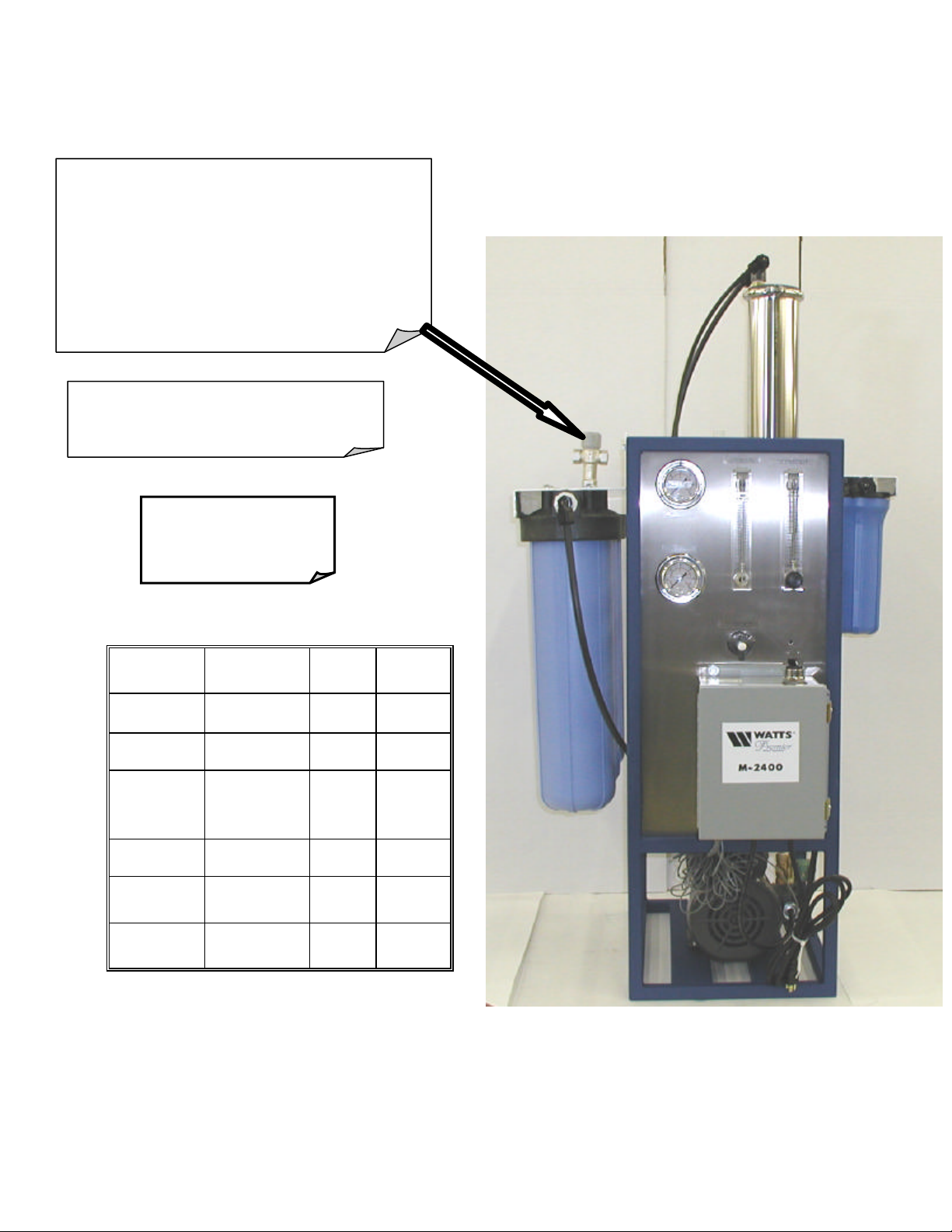

Maintenance

Quarterly Preventive Maintenance for Systems with complete Pre and Post

treatment.

The M-Series RO processor requires quarterly preventive maintenance

consisting of replacing (3) pre-filters and post

Filters if supplied.

1. Pre-filters are located on left side of RO

processor.

2. Post filters located on right side of RO

processor unit.

Quarterly preventive maintenance procedure.

1. Turn incoming feed water off while unit is

running.

2. System will automatically turn off due to lack of

feed water pressure.

3. Turn Power Switch to the OFF position.

4. Close Ball Valve on Permeate Line Connection on

Bulkhead (Pressure Tank Systems).

5. Unplug unit from Power Supply.

6. Place bucket under pre-filters to catch the water

from the filter housings.

7. Using supplied filter wrench, loosen filter housing

starting on the left.

8. Replace with new 5 micron Sediment Filter and replace filter

housing using wrench to tighten securely.

(O-rings and Bowls need to be lubricated with a water

soluble lubricant such as KY Jelly).

9. Follow the above sequence with remaining filters.

and Post Filters if supplied.

10. Replace Calcite Feeder located on right hand side of unit using

supplied filter housing wrench.

(Calcite feeder is only needed on units feeding boilers).

Follow “START UP” procedures on page 11

Page 13 of 18

Page 14

Pull membrane from vessel using pliers i

Annual Preventive Maintenance

Perform quarterly preventive maintenance.

Include replacement of O-Rings.

Replace RO membrane by

loosen retaining clamp at top

of stainless steel membrane

vessel.

necessary and discard. Take note of

location of black BRINE SEAL located

approx. 1/2” from one end of membrane,

so the new membrane will be installed in

the proper direction.

Note: If using pliers to remove NEW membrane for any reason, protect end of membrane with

cloth, to prevent teeth marks which could result in leaks.

Carefully pry loose PVC end

cap from stainless steel

vessel.

Page 14 of 18

Page 15

Annual Preventive Maintenance

Lubricate O-Rings on both ends of

the Membrane and PVC Vessel Cap

with K-Y Jelly or other water soluble

lubricant.

*Vaseline or other petroleum based

lubricants will damage rubber o-ring

and cause leaks.

Insert new membrane into vessel with

the Brine Seal on same position as the

old one just removed.

Replace PVC end cap

and tighten clamp

evenly.

Page 15 of 18

Page 16

WARRANTY

WHAT YOUR WARRANTY COVERS:

If any part of your Watts Pure Water Treatment Device is defective in workmanship (excluding replacement filter elements), return the

unit within 1 year of date of original purchase. Watts will repair or, at WATTS option, replace it at no charge.

HOW TO OBTAIN WARRANTY SERVICE:

Contact WATTS customer service department (1-888-774-7405) to obtain a Return Goods Authorization Number (RGA#). Model and

Serial Number are required for obtaining an RGA #. For warranty service, ship your water treatment device with the RGA # printed on

the Shipping Label to Watts , freight and insurance prepaid, with proof of original purchase date. Watts will repair or replace the water

treatment device and ship it back to you prepaid.

WHAT YOUR WARRANTY DOES NOT COVER:

This warranty does not cover defects resulting from improper installation, customer abuse, misuse, misapplication, improper

maintenance, neglect, alteration, accidents, casualties, fire, flood, freezing, heat, environmental factors or acts of nature.

This warranty will be voided if defects occur due to failure to observe the following conditions:

1. The water treatment device must be hooked up to a potable municipal water supply.

2. The pH of incom ing water must not be lower than 6.0 or higher than 8.5.

3. The incoming water pressure must be between 25 psi and 80 psi. If water pressure exceeds 80 psi a pressure regulator

must be installed.

4. Incoming water temperature cannot exceed 100° F (40° C).

This warranty does not cover any equipment that has been relocated from the site of its original installation.

This warranty does not cover equipment that is installed outside North America.

LIMITATIONS AND EXCLUSIONS:

Watts WILL NOT BE RESPONSIBLE FOR ANY IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

WATTS WILL NOT BE RESPONSIBLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING TRAVEL EXPENSES,

TELEPHONE CHARGES, LOSS OF REVENUE, LOSS OF TIME, INCONVENIENCE, LOSS OF USE OF THE EQUIPMENT, AND DAMAGES

CAUSED BY THE EQUIPMENT AND ITS FAILURE TO FUCTION PROPERLY.

THIS WARRANTY SETS FORTH ALL OF WATTS’S RESPONSIBILITIES REGARDING THIS EQUIPMENT.

OTHER CONDITIONS: IF Watts chooses to replace the equipment, Watts may replace it with reconditioned equipment. Parts used in

repairing or replacing the equipment will be warranted for 90 days from the date the equipment is returned to you or for the remainder

of the original warranty period, whichever is longer. This warranty is not assignable or transferable.

YOUR RIGHTS UNDER STATE LAW:

Some states do not allow limitations on how long an implied warranty lasts and some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific

legal rights. You may have other legal rights, which vary from state to state.

Page 16 of 18

Page 17

GLOSSARY OF TERMS

Atmospheric tank: A storage container requiring additional delivery system to distribute stored water.

Typically constructed of polyurethane or stainless steel. Used in situations where greater storage

capacity is needed than offered by conventional pressure tanks.

Auto By -Pass: A feature that allows tap water to be delivered to downstream demands in the event the RO

processor is unable to meet demand.

Brine Seal: A black “O-ring type seal located on one end of membrane that seals the membrane to the vessel

preventing cross contamination of process water and feed-water.

Calcite Feeder: Calcite is a naturally occurring mineral used to raise the Total Dissolved Solids (TDS) in the

water to promote conductivity in the final product water. Used in situations where conductivity is

needed for proper equipment function i.e. conductivity probes.

Carbon Block: Acid washed carbon is used to absorb VOC’s (Volatile Organic Chemicals) such as herbicides,

pesticides and chlorine, which will damage RO membranes.

Concentrate needle valve: A needle valve located on the right side flow meter that controls the concentrate

(drain water) water flow to the drain.

Concentrate: Water being rinsed to drain after it has been rejected by the membrane.

Concentrate Line : Tubing or pipe used to transport concentrated waste water to a suitable drain.

Feed pressure: Referring to the water pressure being supplied to the RO processor before it has entered the

pre-filter. Raw water.

Feed pressure gauge: The upper most gauge on the control panel that indicates the water pressure the

membrane is receiving.

Flow meter: A meter that reads water flow in gallons/liters per minute

GPM: Gallons per minute

GPD: Gallons per day

Hardness: Total quantity of CaCO3 (Calcium/magnesium) present in water.

1 gr. = 17.1 TDS in ppm per U. S. gallon

Iron: A naturally occurring mineral that has detrimental effects on a membranes ability to produce water.

Reduced by ion exchange (water softening) or KDF media.

KDF Media Filter: A proprietary blend of metals and other substances that help reduce Iron and CaC03

(hardness). Used as pretreatment on some models of high production RO systems.

L Copper pipe: A high grade of copper pipe that will withstand water temperatures up to 160 degrees

Fahrenheit.

Membrane: A thin sheet or surface film, either natural or man-made, of microporus structure that performs as

an efficient filter of particles down to the size rang of chemical molecules and ions. Such membranes

are termed “semi-permeable” because some substances will pass through but others will not. Usually

small ions, water, solvents, gases, and other very small molecules can pass through a membrane, but

other ions and macromolecules such as proteins and colloids are barred form passage. Membranes are

used in reverse osmosis.

Page 17 of 18

Page 18

GLOSSARY OF TE RMS (Continued)

Permeate: That portion of the feed water which passes through the membrane to become product water.

Permeate Line : Tubing or pipe used to transport purified (RO processed) water from processor to the storage

tank.

Pressure tank: A water storage device using a pressurized bladder that provides delivery pressure to down

stream uses.

Purge: The act of flushing out. A term to describe the purging of entrained air in a system

Recirculation Valve: A needle control valve used to blend concentrate water past the membrane again to

scavenge water molecules.

Recirculation Ratio : The ratio in which concentrate water is reticulated past the membrane in order to

osmoisize more water molecules and reduce the wasted ratio of water. Typical recirculation ratio is 1:1

(1 gallon permeate: 1 gallon concentrate

Reverse Osmosis : A water treatment process that removes undesirable material from water by using

pressure to force the water molecules through a semi-permeable membrane. This process is called

“reverse” osmosis because the pressure forces the water to flow in the reveres direction (from the

concentrated solution to the dilute solution) to the flow direction (from the dilute to the concentrated)

in the process of natural osmosis. RO removes ionized salts, colloids, and organic molecules down to a

molecular weigh of 100. May be called hyper-filtration.

RO: Reverse Osmosis

RO Processor: The system main stand, that consists of the main frame, pump, electrical controls, flow meters

and pressure gauges. A term used to signify a specific piece of the overall system.

Sediment Filter: A filter used to trap and reduce rust, dirt and sand. Typically made from spun poly.

TDS: Total Dissolved Solids, the total weight of dissolved matter present in water that does not constitute pure

water molecules. Measured in the form of resistively and or conductivity equated into TDS in ppm

(parts per million per 1 U.S. gallon)

VOC: Volatile Organic Chemicals, synthetic organic chemicals that turn into vapor at relatively

Zero Soft Water: Water produced by Reverse Osmosis measuring less than 1/0 grain per U.S. gallon (17.1

ppm or 17.1 mg/L) as calcium carbonate.

Page 18 of 18

Loading...

Loading...