Page 1

For Residential, Commercial and Industrial Applications

Job Name Contractor

Job Location Approval

Engineer Contractor’s P.O. No.

Approval Representative

Series HAV

Air Vent

Automatic Vent for

Hot Water

ES-HAV

Sizes:1⁄8" and 1⁄4"

(3 and 8mm)

The HAV Hot Water Vent is designed for automatic or

manual air release on baseboards, convectors, radiators, and high points in piping systems.

The HAV valve utilizes moisture retaining discs within

the body which vary in volume when they change

from a wet to a dry condition. As the discs dry, they

allow air to escape from the system and when wet,

provide a positive shut-off.

FEATURES

• Attractive chromed brass body

• Durable "Stainless Steel" check valve

• Automatic or manual operation

• Quick venting design

• Positive shut-off ball check

• Heat resistant handwheel

• Suitable for use with hot water and low pressure

steam systems

• Easily maintained–replacement cartridge can be

installed without system shut down

• Simple two piece construction

Ordering Code

No. No. Description

590712

590713

590714 HAV-RC Replacement Cartridge

1

⁄8 HAV HAV Air Vent

1

⁄4 HAV HAV Air Vent

Watts product specifications in U.S. customary units and metric

are approximate and are provided for reference only. For precise

measurements, please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without

incurring any obligation to make such changes and modifications

on Watts products previously or subsequently sold.

USA: 815 Chestnut Street, North Andover, MA 01845-6098

Canada: 5435 North Service Road, Burlington, Ontario L7L 5H7

Page 2

MATERIALS

The HAV Air Vent is manufactured in two parts (body

and disc cartridge).

• Chromed Brass - body

• Brass - disc bearing cover

• Stainless steel - check valve

• Copper - thermostat assembly

• Neoprene - O-ring

• Heat resistant ABS plastic material - handwheel

• Special cellulose fiber - disc

A periodic check of the condition of the discs will

establish the need for replacement. When the discs

are damaged, the valve can only operate manually;

to restore to automatic working, the cartridge must

be replaced.

To replace the cartridge, unscrew the handwheel,

clean the seat of the valve of any foreign matter and

then assemble a new disc cartridge. The body contains a check valve, preventing water leakage, therefore, this operation can be carried out without draining the water from the radiators.

PRESSURE-TEMPERATURE

Suitable for water only additives: Only inhibited glycol

based additives are permissible.

Maximum Working Pressure: 125 psi (8.6 bar)

Minimum Working Pressure: 1.45 psi (10 kPa)

Maximum Water Temperature: 240°F (116°C)

Minimum Water Temperature: 140°F (60°C)

Test Pressure: 130 psi (9 bar)

Maximum Steam Pressure: 10 psi (69 kPa)

CAPACITY

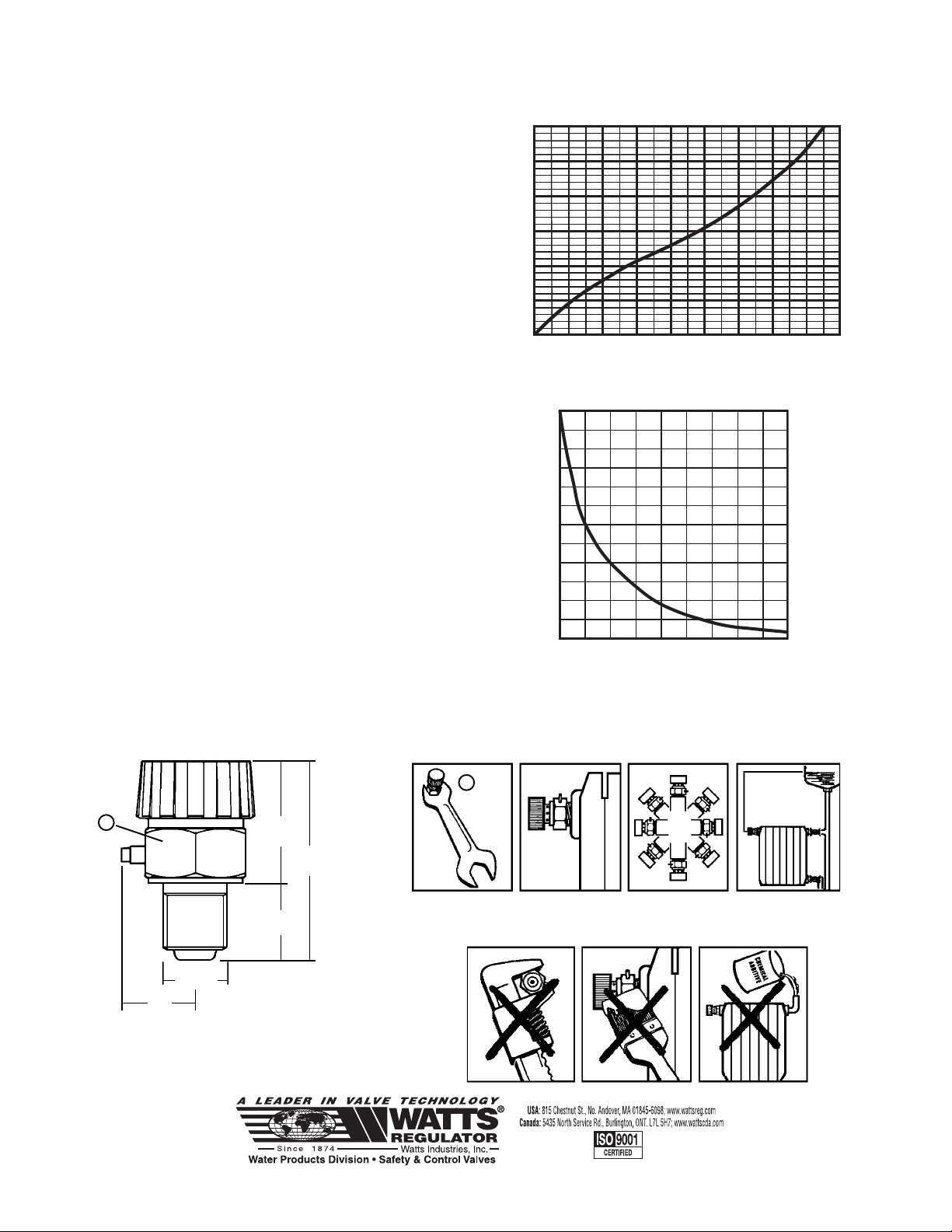

Diagram 1

Venting Capacity

2.12

1.77

1.41

1.06

SCFM

.71

.35

0

0 14.2 28.4 42.7 56.9 71.1 85.3 99.5 113.8 128 psi

0 .98 2.0 2.9 3.9 4.9 58.8 6.8 7.8 8.8 bars

Diagram 2

12

11

10

9

8

7

6

5

4

3

Drying Time in Hours

2

1

0

86 104 122 140 158 176 194 212 230 248 °F

30 40 50 60 70 80 90 100 110 120 °C

Water Temperature

BASIC CONSTRUCTION

15

1.14"

1.61"

.47"

1

⁄8" - 1⁄4"

.43"

Correct Installation/Maintenance

1

⁄8" - 1⁄4"

15

OK

Incorrect Installation/Maintenance

Min. 90"

ES-HAV 9844 © Watts Regulator Co., 1996 Printed in U.S.A.

Loading...

Loading...